Page 1

Operating Instructions

Electronic preselection counter

NE215 preliminary testing by PTB

Contents Page

1 Safety indications 2

2 Getting to know the counter 4

2.1 Block diagram 5

3 Counter connection 6

3.1 Supply voltage connection 6

3.2 Assignment of signal outputs „relays contact“ 7

3.3 Assignment of signal inputs 8

3.4 Encoder supply connection 9

3.5 Interface connection 9

3.6 Executing the test routine 10

4 Operator mode 11

5 Programming mode 14

5.1 Operating modes 20

5.2 Counting modes for main and totalizing counter 21

5.3 Output responses (output modes) 21

6 Technical Data 22

6.1 Dimensions and cutout size 23

6.2 Default settings 23

6.3 Error messages 23

7 Open interface description 24

8 Supplementary manual open and closed

interface 34

9 Supplementary operation manual

scaling factor 36

10 Suitable encoder 37

11 Order designation 39

Baumer IVO GmbH & Co. KG

P.O. Box 3360 • D-78022 Villingen-Schwenningen

Phone +49 (0)7720 942-0 • Fax +49 (0)7720 942-900

www.baumer.com • e-mail: info.de@baumerivo.com

Subject to modifcation in technic & design.

06.12 • 171.02.109/4

Page 2

Explanation of symbols

Italics

NE215General Information/Safety Instructions

General Information

In the following you will find the explanations of the symbols used

in this operating manual.

This symbol indicates activities to be carried out.

● This symbol indicates supplementary technical information.

This symbol is located before texts to which particular

attention is to be paid to ensure proper use of the

NE215.

This symbol is located before texts that provide important

additional information.

Important terms in the left text column are printed in italics

to help you find information more quickly.

1 Safety Instructions

1.1 General information

The products has been developed and built in accordance with the

recognized rules of technology. The units have left the

manufacturing plant ready to operate and in safe condition.

To keep the units in this condition, it is necessary that the

units be installed and operated

– properly,

– in a safety and hazard-conscious manner,

– under observance of this operating manual and in particular of

these safety precautions!

Make sure that the personnel has read and understood the

operating manual, and in particular the "Safety Instructions" chapter.

In addition to the operating manual, the generally applicable legal

and other binding regulations for accident prevention and

environmental protection must be observed and ensured.

1.2 Proper use

The application of the units consists of controlling and monitoring

industrial processes in the metal, wood, plastics, paper, glass and

textile industry etc.

The units may only be operated

– in the properly installed state and

– in accordance with the specifications of the technical data!

Operation not covered by the specified

descriptions/parameters is improper and can lead to

– fatal injuries,

– serious damage to health,

– property damage or

– damage to the units

in conjunction with the systems/machines/processes

to be controlled/monitored!

2

Page 3

NE215Safety Instructions

The overvoltages to which the units are subjected at the connection

terminals must be limited to the value of the overvoltage category II

(see Technical Data)!

The units may not be operated

– in hazardous areas,

– as medical units,

– in applications expressly named in EN 61010!

If the units are used to control/monitor machines or processes with

which, as the result of a failure/malfunction or incorrect operation

of the units

– a life-threatening danger,

– health risks or

– a danger of property or environmental damage

could result, then appropriate safety precautions

must be taken!

Do not open the housing of the units or make any

changes to it!

Tampering with the units can have a negative affect on their

operating safety, resulting in dangers!

Do not make repairs on the units! Return defective units to the

manufacturer!

1.3 Installation/commissioning

In case of changes (including in the operating behavior) that

impair safety, shut-down the units immediately.

Installation may only be carried out in accordance with the

procedure described in Chapter 3 "Connecting".

During installation work on the units, the power supply must

always be disconnected. Installation work may only be carried out

by appropriately trained experts.

Max. voltage 250 V terminal - terminal, ground - terminal.

Following proper assembly and installation, the units are ready for

operation. Following commissioning, familiarize yourself with the

use of the units in Chapter 4 "Operator Level".

1.4 Maintenance/repairs

Always disconnect the power supply of all units involved.

Maintenance and repair work may only be carried out by

appropriately trained experts.

If troubleshooting is unsuccessful, do not continue to use the units.

Please contact the manufacturer in this case.

3

Page 4

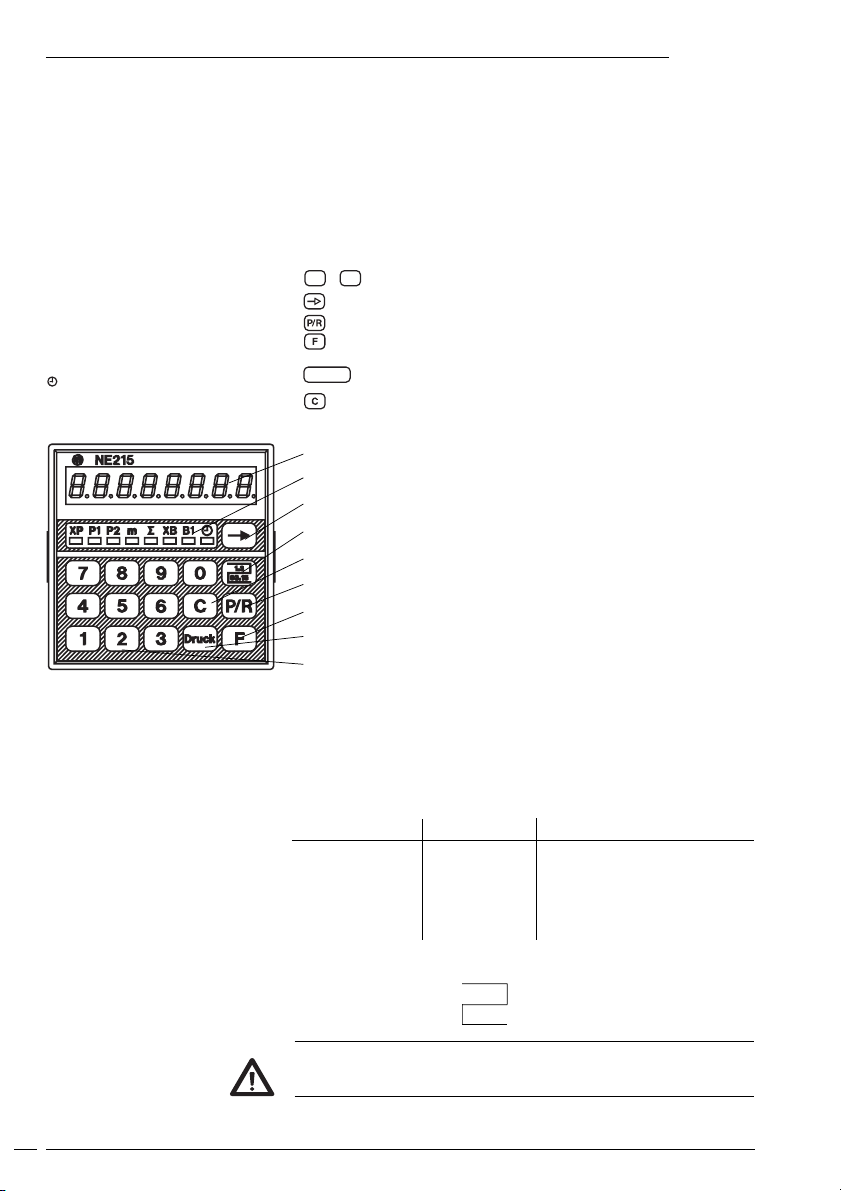

NE215Getting to know the counter

2 Getting to know the counter

The counter comprises the following:

– Presetting the counter with 2 preset value, (preliminary testing by PTB)

– Secondary counter with preset value and multiplier,

– Totalizing counter, (preliminary testing by PTB)

– Time meter

Components / LED-display

XP Counter status, main counter

P1 Preset value 1, main counter

P2 Preset value 2, main counter

m Meter display

Σ Totalizing counter

B1 Preset value, sec. counter

Current value, time meter

Control panel

0

...9Numerical keypad

Selector key for function display

Selector key for programming/operating mode

Function key

Druck

The counter is a micro-processor controlled electronic device with

serial interface for counting, controlling and monitoring. The device is

approved by the German Physical Technical Authorities (PTB) as

calibrated for the use as: “measured value transfer device for

application in calibrated machines for length measurement”.

Key for printing

Reset key

Function display

LEDs- Symbol display

Selector key/Function display

PTB-Number

Reset key C

Selector key for programming/operating mode

Function key

Key for printing

Numerical keypad

Address for printer:

DATAMEGA Mikrodatent. GmbH

Landsberger Str. 318-320

80687 München

Tel.: +49 (0)89 56017-300

4

Registration From Reference number

NE215 23.12.1993 1.62-3251.11 / IVO-040293

1. addendum 16.03.1995 1.62-3251.11 / IVO-040293

2. addendum 28.09.1997 1.62-3251.11 / IVO-040293

3. addendum 24.06.1999 5.23-99037480

4. addendum 29.03.2001 5.21-01028291

PTB-Approval:

The counter is only PTB approved in combination with an encoder.

The PTB- approved system for example provides a chart printer

model STAR SP298.

1. 3

93.15

Page 5

Getting to know the counter

Example for print

NE215

Main counter systems: (PTB-approved)

1 up/down preset counter with totalizer.

Batch counter systems: 1 preset counter, adding.

A key provided at the counter enables switching the display to the

respective counters of the main respectively batch counting

system.

Counter function

Applications

The counter is administrating the inputs of both counting systems

and will react by the programmed output action upon achieving the

set presets respectively limit values.

Thanks to various programming options the device is capable of

many machine monitoring and controlling tasks. Running values and

the set parameters remain even after power failure.

The serial interface allows printout of counter values.

● Interior use for monitoring and control of production machines

and systems.

● In any branches of industry where length measurement is

subject to calibration.

The device must not be used in: explosive areas, medical appliances

as well as in applications explicitly mentioned in the standards of

VDE 0411 part 100.

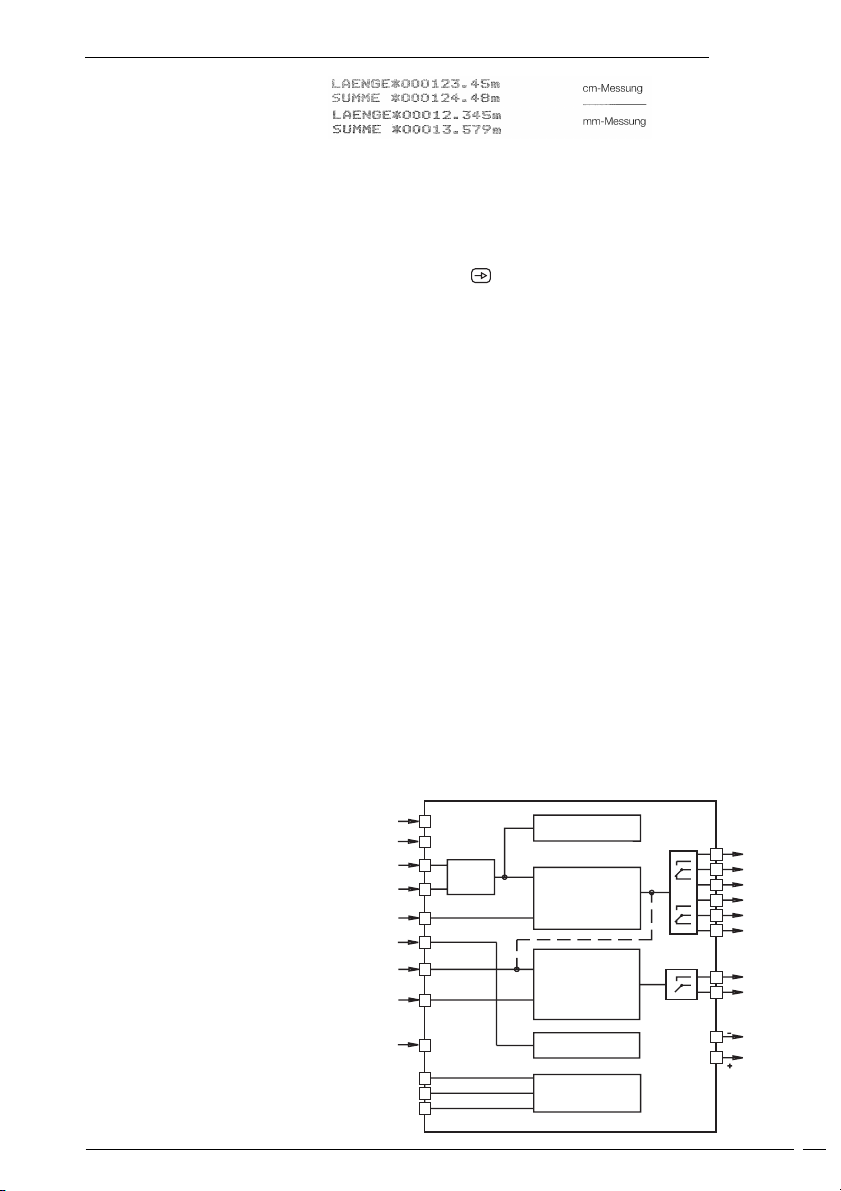

2.1 Block diagram

The block diagram shows the components together with its contacts

and connections.

Supply

voltage

count

XP-Reset

h counter

B1 counter

B1 reset

2

3

12

A

B

A 90° B

13

14

15

16

17

Totalizer

Main counter

Batch counter

or

Tachometer

4

5

P1

6

7

8

P2

9

10

B1

11

Coding

Interface

19

18

T

23

R

25

GND

26

Time Meter

Interface

RS232

Sensor

supply

20

5

Page 6

Counter connect

NE215

3 Counter connect

This chapter will explain how the contacts are assigned.

Under chapters 3.1 to 3.5 you will find actual tips and technical data

for the various connections.

The electrical inputs and outputs are assigned to two 12-pole plug-in

screw terminals, coded to prevent reversed polarity.

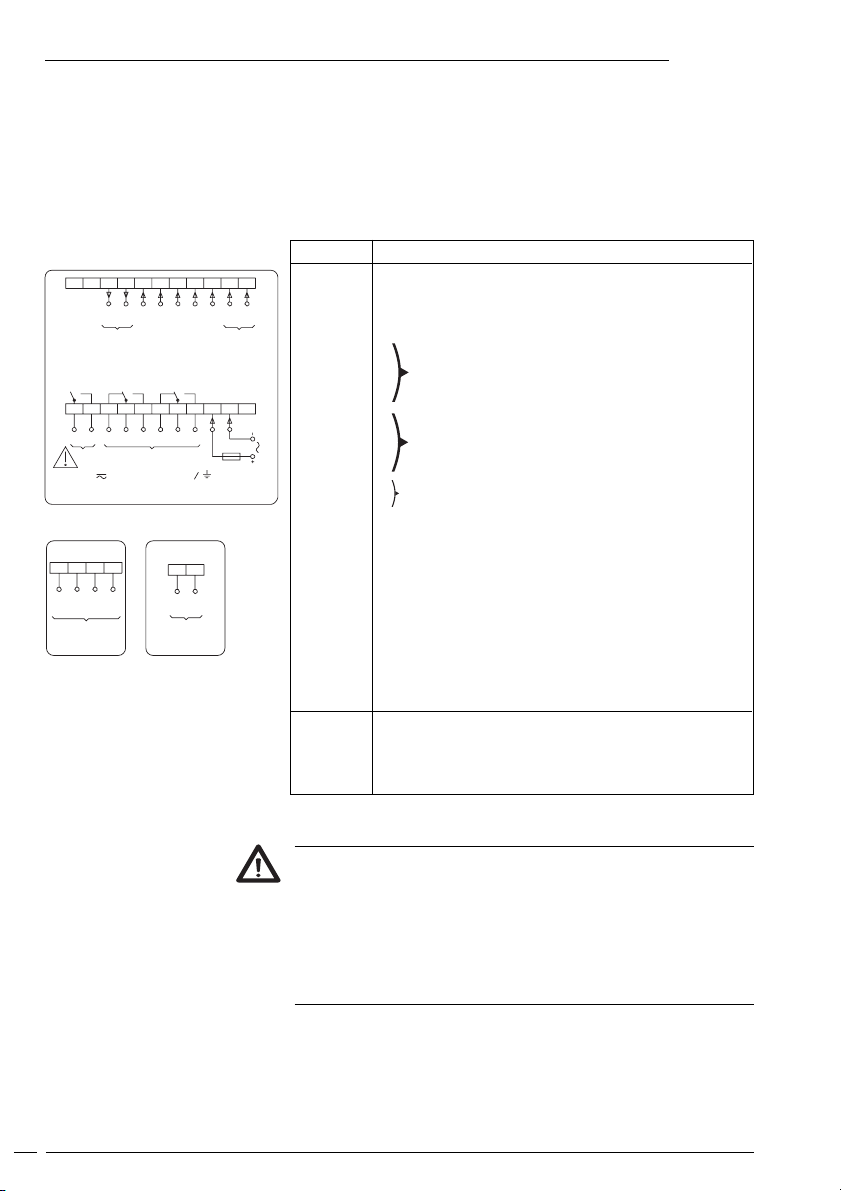

Assignment

22 2 1 20 19 18 17 16 15 14 13 12

+24V 0V

Sensor

supply

NPN Br. 18-20

PNP Br. 18-19

B1 reset

11 10 9 8 7 6 5 4 3 2 1

B1 P2 P1

Output

max. 250 V Terminal - Terminal - Terminal

* Models with scaling

26 25 24 23

RxD

TxD

GND

RS232

B1 counter

22 21

T, R +

RS485

(Scaling on)*

XP reset

h counter

T, R -

BA

Count

Contact Function

1 Not assigned

2 Supply voltage

3 Supply voltage

4

5

6

1 Relay contact output P1

7

Supply

8

9

10

11

1 Relay contact output P2

1 Relay contact output B1

12 Signal input, track A

13 Signal input, track B

14 Reset XP

15 Time meter

16 Signal input, track B1

17 Reset B1

18 Coding input for input logic

19 Encoder supply 0 Volt

20 Encoder supply +24 Volt

21 Option RS485 T,R22 Option RS485 T,R+

23 Option RS232 TXD

24 25 Option RS232 RXD

26 Option RS232 GND

Litz contact only by means of connector sleeves with insulating

enclosures for reasons of shock protection according to VDE 0411

part 100. Do not otherwise assign contacts that have been left

unassigned ex factory. We recommend to screen all encoder

terminal leads and to ground the shield on one side. Shields on

both sides are recommended in case of RF interference or in case

of equipotential bonding over long distances. The encoder leads

should not be in the same phase winding as the MAINS supply and

the output contact leads.

6

Page 7

Counter connect

115 VAC 230 VAC

6 5 47 8 9

NE215

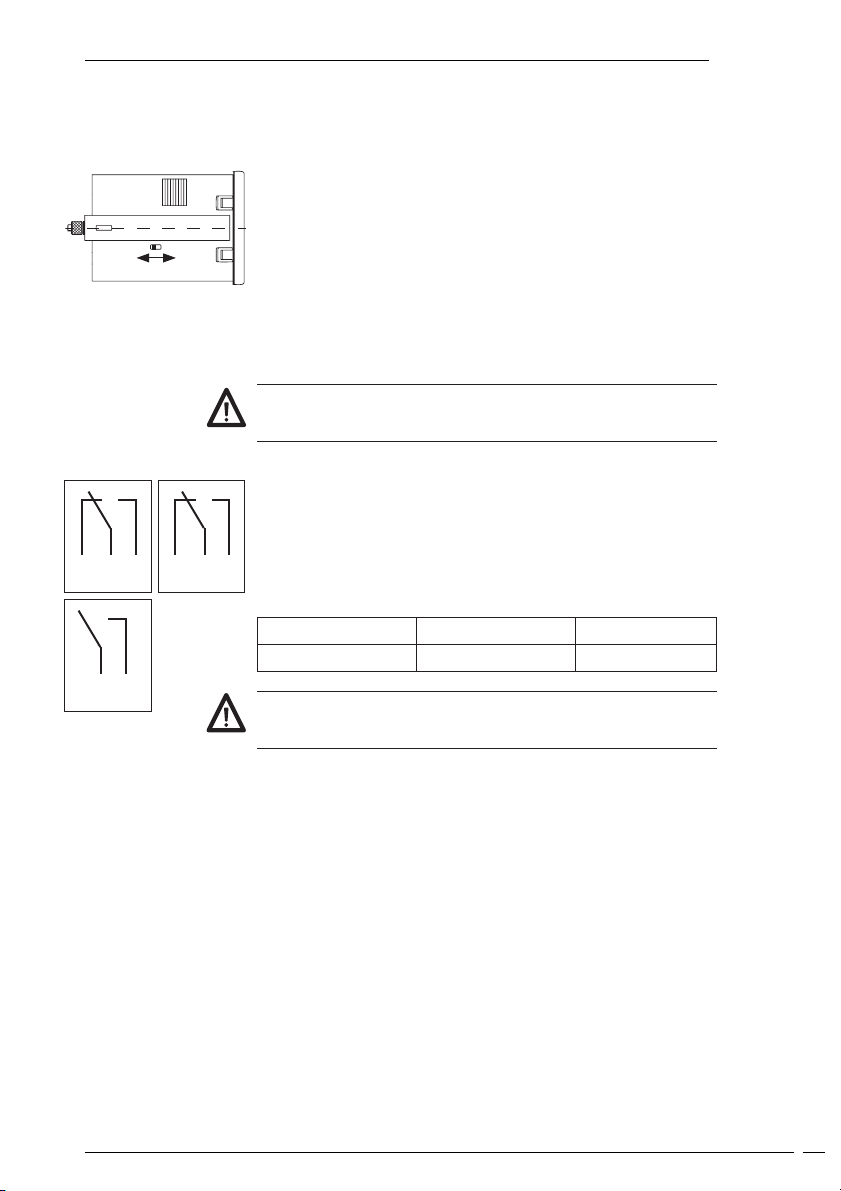

3.1 Connecting the power supply

For power supply following voltage ranges are available:

AC 115/230 VAC (50/60 Hz)

DC 24 VDC ±10%

Voltage supply Recommended external fuse

115/230 VAC M 125 mA

24 VDC M 400 mA

➜ Assign voltage supply to terminals 2 and 3 according to

diagramm.

DC-voltage 24 VDC:

Connect voltage supply that is free from any interference. Do not utilize the voltage supply for parallel supply of drives, shields, magnetic

valves, etc. Supplying lines must be separated from lines providing

load current.

Fire protection: Operate the instrument using the recommended

external fusing indicated in the terminal diagram. EN 61010 specifies

that 8 A/150 VA (W) must never be exceeded in the event of a fault.

3.2 Assignment signal output „relay contact“

Terminals 4, 5, 6 and 7, 8, 9 are no-potential changeover contacts.

Terminals 10 and 11 are configured as NC or NO contacts in accordance with the purchase order specification. The signal outputs

can be assigned in accordance with the adjoining wiring diagram.

Implementation as a pulse or continuous signal, together with the

pulse time, is effected in the programming mode (lines 31, 32, 33).

11 10

Max. rating Max. voltage Max. current

150 VA/30 W 265 V 1 A

The user is responsible for ensuring that a switching load of 8 A/150

VA (W) is not exceeded in the event of a fault. Internal spark suppression by means of two zinc oxide varistors (275 V).

➜ Assign terminals 4, 5, 6; 7, 8, 9; and 10, 11 (relay contactoutputs)

accordingly.

7

Page 8

Counter connect

20 19 18 17 16 15 14 13 12

18 and 20

NE215

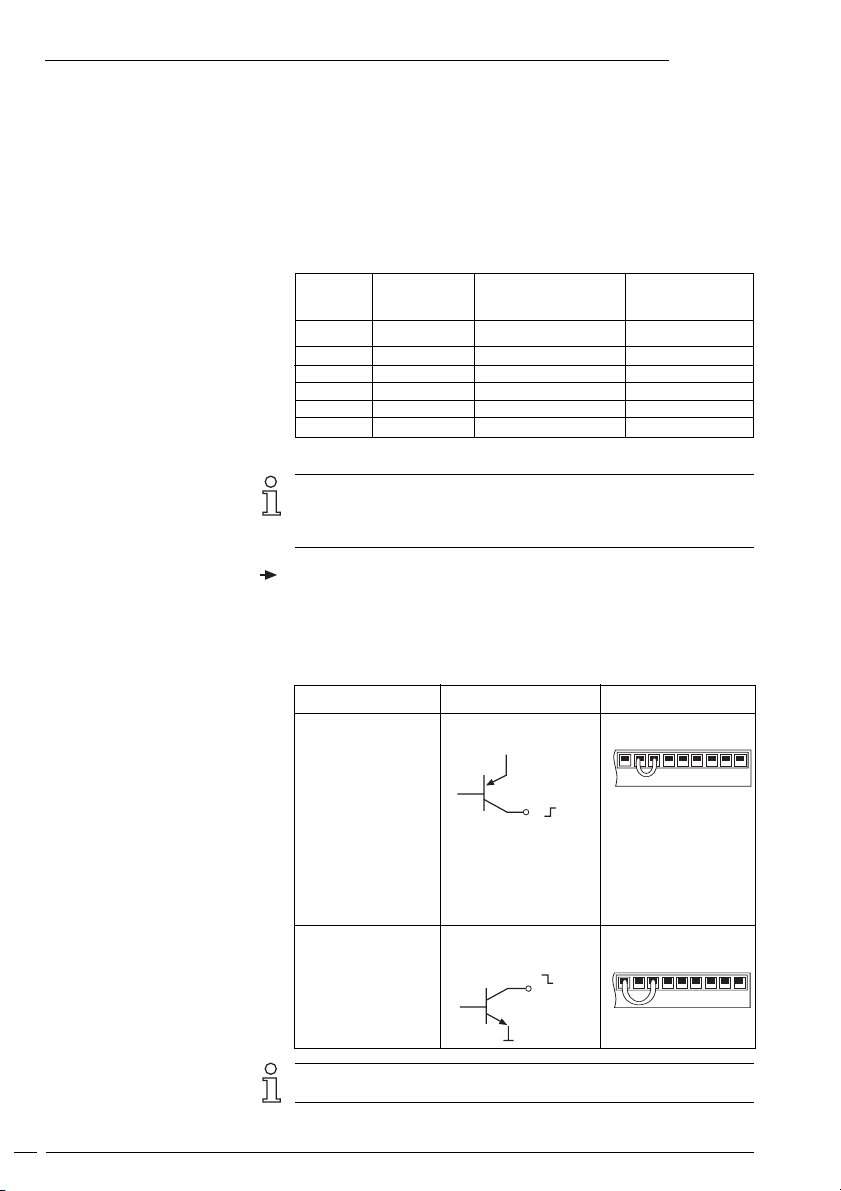

3.3 Assignment the signal inputs

Terminals 12 to 17 are AC optocoupler inputs. Terminals 12 (track A)

and 13 (track B) are pulse inputs for the main counter (XP) counting

function.

Terminal 14 is an external reset input for the main counter.

Depending on what is set in the programming mode (line 40),

terminal 15 serves as a starting input for the operating hours counter.

Terminal 16 (track B1) is the pulse input for the secondary counter

(XB). Terminal 17 is the input for resetting the secodary counter.

Programming input logic

Terminal Input Starting current Abschaltstrom

resistance

12 1,65 Kohm > 9 mA, < 16 mA < 0,5 mA

13 1,65 Kohm > 9 mA, < 16 mA < 0,5 mA

14 3,3 Kohm > 5 mA, < 8 mA < 0,5 mA

15 3,3 Kohm > 5 mA, < 8 mA < 0,5 mA

16 1,65 Kohm > 9 mA, < 16 mA < 0,5 mA

17 3,3 Kohm > 5 mA, < 8 mA < 0,5 mA

The main counter (XP) is reset by pplying an external signal (signal

width ≥ 30 ms) at terminal 14; the secondary counter (XP) at terminal

17. While an external signal is present, no counter take place. The

method of resetting is set in the programming mode (lines 29, 30).

Assign terminals 12 to 17 accordingly. The maximum counter

frequency is selected in the programming mode (line 26).

The signal input logic can be programmed by means of a bridge between terminals 18, 19 and 20, in accordance with the table below.

Apply

- if encoder supply

is not provided by

the counter.

- if the encoder is

featuring push-pull

or PNP output

- if several counters

are triggered in a

parallel way by one

encoder

Encoder signals

PNP, triggered by

positive signals.

E

B

K

Pin assignment

18 and 19

18 and 19

20 19 18 17 16 15 14 13 12

8

- if the encoder is

featuring a NPN

output.

NPN, triggered by

negative signal.

B

K

E

18 and 20

Electrical isolation is provided for instruments with an AC power

supply and a relay output without interface.

Page 9

Counter connect

NE215

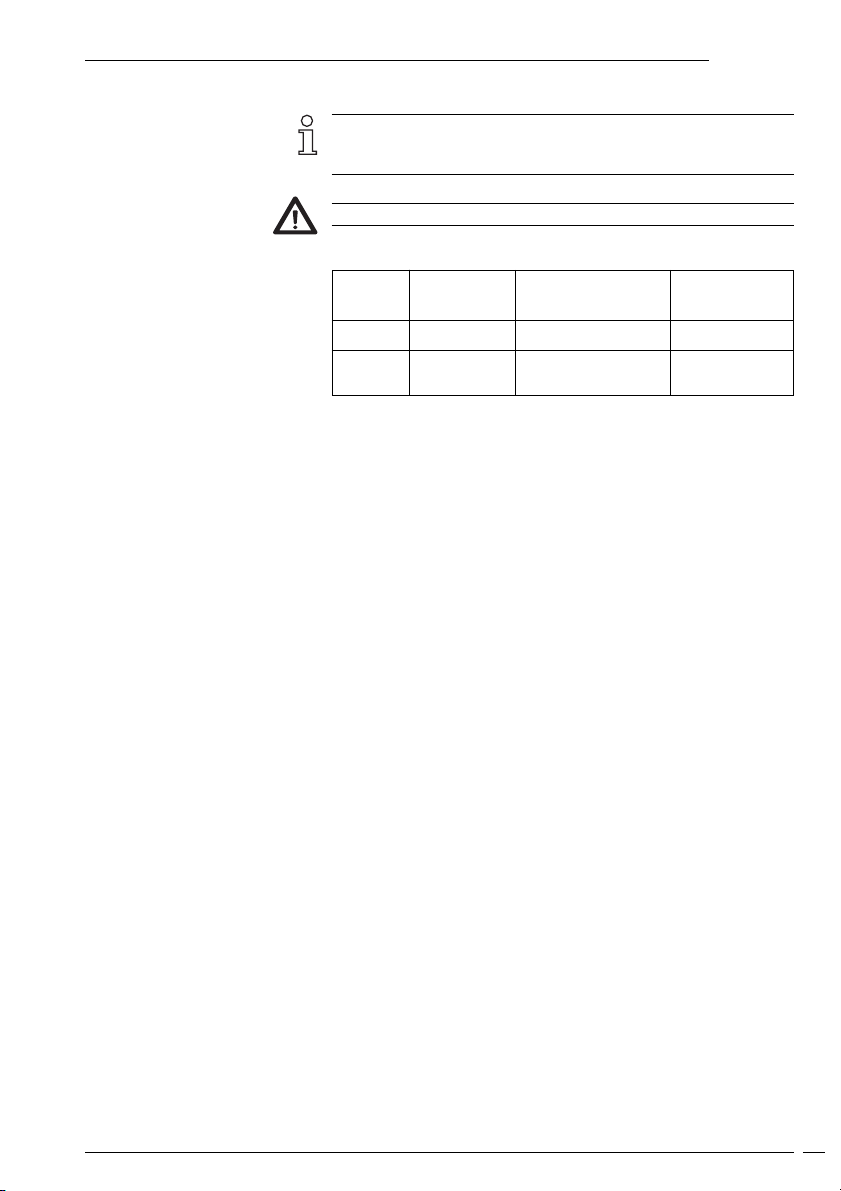

3.4 Connecting the encoder supply

Connect the encoder supply at terminals 19 and 20.

Do not use the encoder supply to supply non-earthed inductive or

capacitive loads.

The encoder power supply is not short-circuit proof.

Terminal Voltage Max. Max. permissible

19 0V ––

20 +24 VDC Depending on load 80 mA

3.5 Interface connect

The serial interface is capable of executing the following functions:

– Data printout

Interface parameter are as follows:

– Data transmission rate (baud rate),

– Parity bit,

– Number of stop bits,

The interface parameters can be set in the programming

(lines 43, 44, 45 and 46).

The following interfaces can be connected to the counter:

– RS232

Interface characteristics

RS232

Transmission with the following characterisics:

– Asymmetric

– Two leads

– Point-to-Point connection - 1 transmitter and 1 receiver

– Max. data transmission distance: 30 m

+10 %/-50 %

residual ripple current

9

Page 10

To start test

NE215Counter connecting and operating

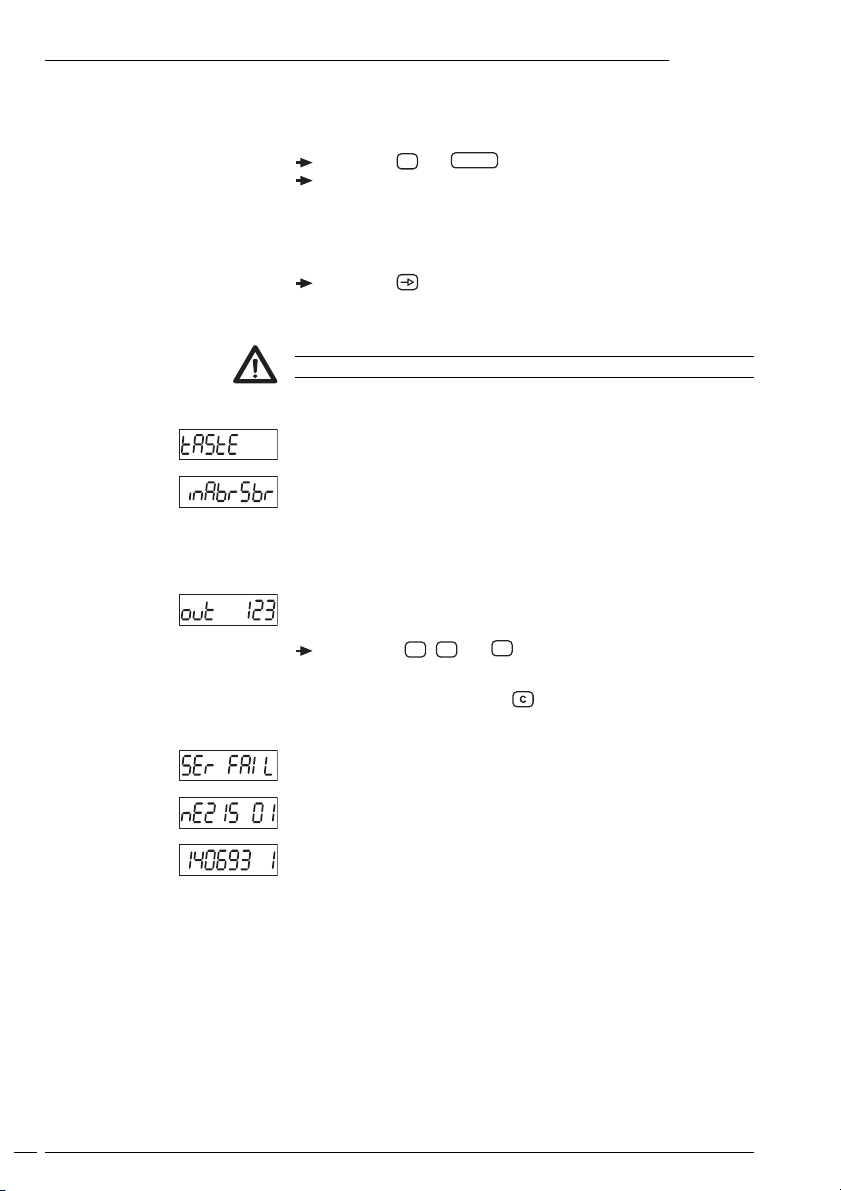

3.6 Executing the test routine

The test routine is described below.

Press the 2 and

Switch the counter on.

● All the display segments will be displayes automatically in

sequence and are therby tested for functional capability.

Druck

key simultaneously.

Test extension

Using the key, test the keyboard, the inputs, outputs and

interface in sequence.

No machine fuctions may connected when the outputs are tested.

Keyboard test

Input test

● Inputs can be triggered simultaneously or individually. A display

is only provided when a signal is applied.

Output test

Press keys 1, 2 and 3 .

The outputs are now activated.

Reset the outputs with the key.

Interface test

Display: Model and program number

Display: Program date and version

10

End of test

The test routine is terminated, the counter is now in the operating

mode.

Page 11

Operating mode

Operating mode

To read

Reset

To read

NE215

4 Operating mode

The operation and use of the counter are described in this section.

● As soon as the power supply has been switched on, the

counter is automatically set to the operating mode.

In the operating mode:

– the current main counter status can be read and reset;

– the preset values for the main and secondary counters can be

read;

– the current total can be read and reset;

– the current status of the secondary counter can be read and reset;

– the operating hours counter can be read.

All the parameters can be disabled in the programming mode.

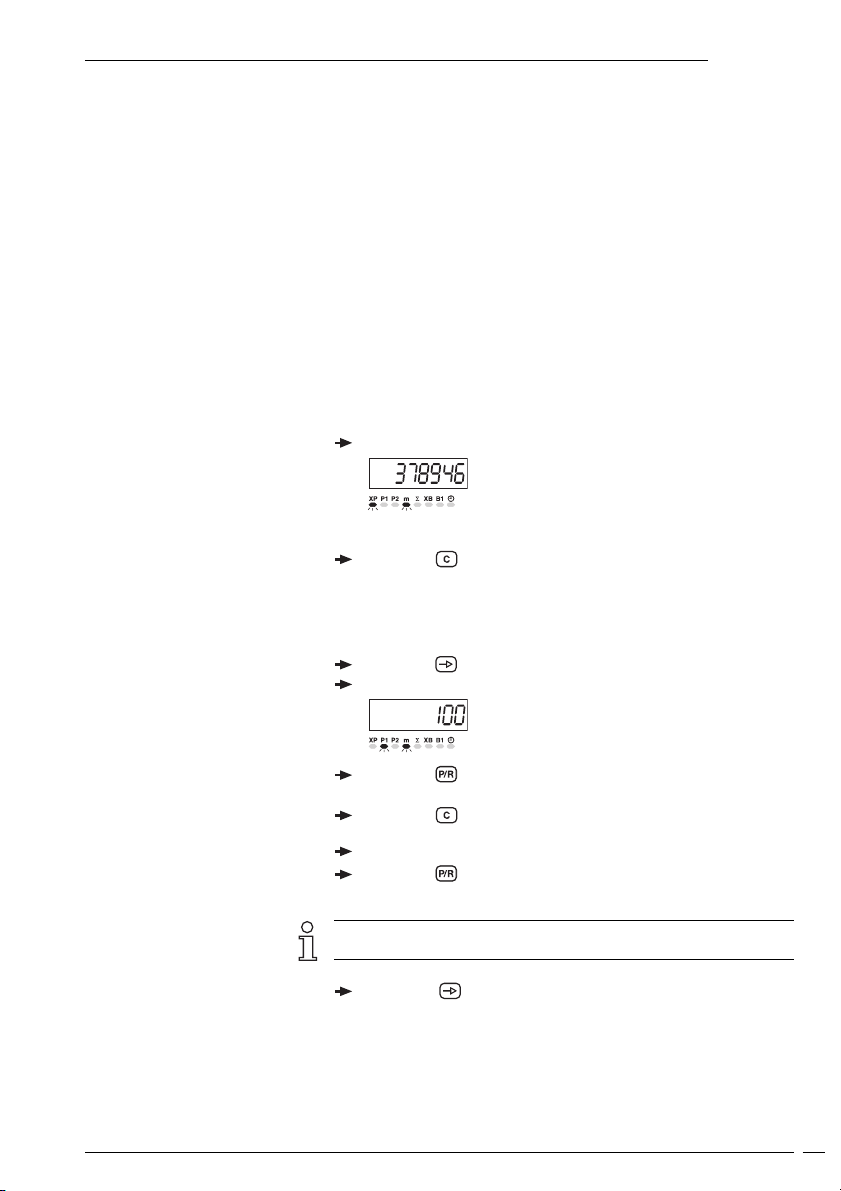

Main counter status

The current counter status is displayed in the operating mode;

no keying is necessary.

Readout running counter value.

Resetting must be enabled in the programming mode.

Press the key.

Main counter preset value

Resetting must be enabled in the programming mode

Press the key.

Read preset value P1.

To change

Other changes

Press the key.

● LED P1 flashes.

Press the key.

● Preset 1 is being deleted.

Input the preset value P1 via the numerical keypad.

Press the key.

● The change is completed.

If a key is not operated within 15 seconds, the preset value will

automatically be re-displayed in the operating mode.

Press the key.

● The following values can also be changed.

11

Page 12

Operating mode

NE215

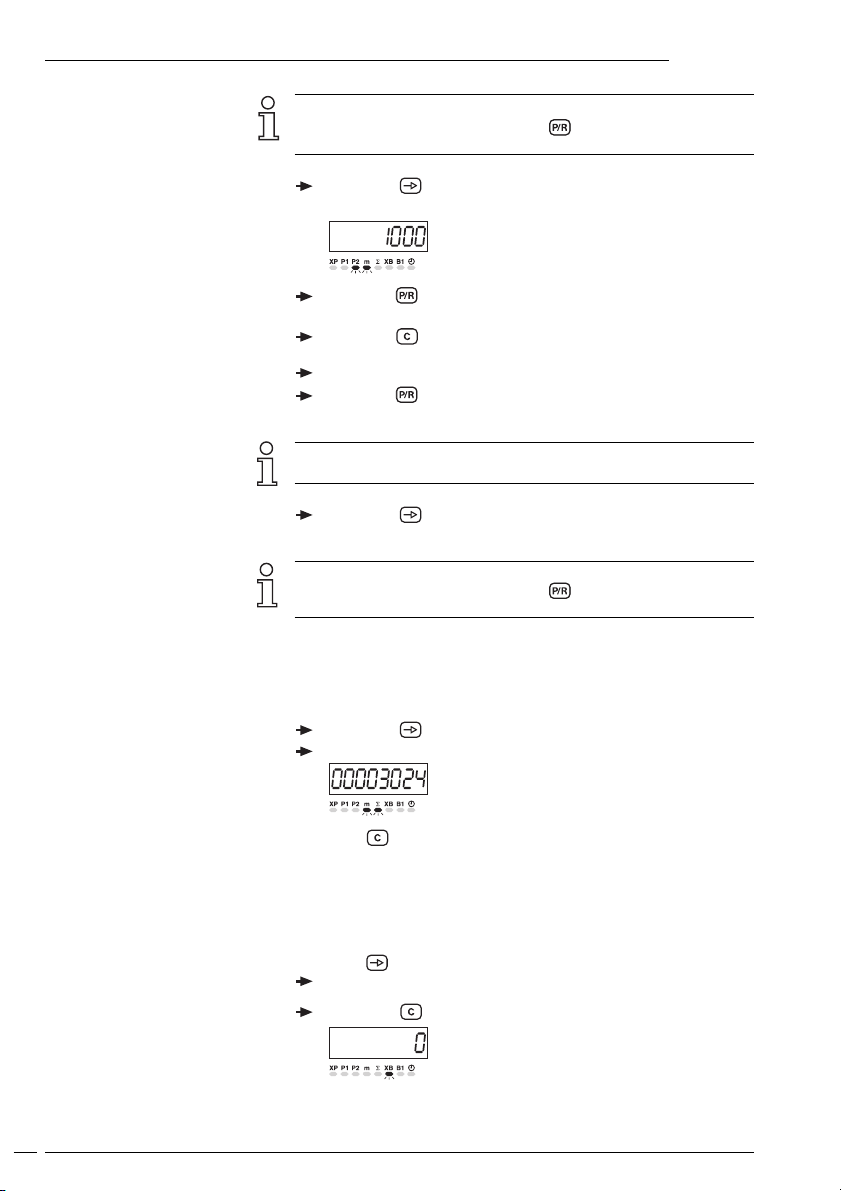

If other values are changed, the value at witch the operating level

was left can be re-displayed with the key after the

programming mode has been left.

Other changes

To change

Other changes

To read

Press the key.

● Read preset value P2

Press the key.

● LED P2 flashes.

Press the key.

● Preset 2 is being deleted.

Input the preset value P2 via the numerical keypad.

Press the key.

● The change is completed.

If a key is not operated within 15 seconds, the preset value will

automatically be re-displayed in the operating mode.

Press the key.

● The following values can also be changed.

If other values are changed, the value at witch the operating level

was left can be re-displayed with the key after the

programming mode has been left.

Totalizing counter

The totalizing counter can be disabled in the programming mode.

Press the key.

Read the totalizing counter.

12

Reset

To read

Reset

Press the key.

Secondary counter status

The secondary counter can be disabled in the programming mode.

Press the key.

Read off the current limit value secondary counter status

Press the key.

Page 13

Operating mode

To read

NE215

Secondary counter preset status

Press the key.

Read the secondary preset value.

To change

Other changes

To change

Press the key

● LED B1 flashes.

Press the key.

● Preset value of the batch counter is being deleted.

Input the new secondary counter preset value via the numerical

keypad.

Press the key.

● To change is completed.

If a key is not operated within 15 seconds, the preset value will

automatically be re-displayed in the operating mode.

Press the key.

● The following values can also be changed.

If other values are changed, the value at witch the operating level

was left can be re-displayed with the key after the

programming mode has been left.

Time meter

The time meter can be disbled in the programming mode.

Press the key.

Read the time meter

Press the key.

13

Page 14

Programming mode

Programming segment 1

Programming segment 2

Programming segment 3

Programming segment 4

To access programming

NE215Programming mode

5 Programming mode

This section describes the procedure for programming the counter.

Operating parameters are set in the programming mode, which is

subdivided into four programming segments.

In the first programming segment, all the operating parameters

can be accessed and changed. The operating parameters which are

disabled in the operating mode are also displayed here. The first

programming segment consists of 8 lines.

In the second programming segment, the individual operating

parameters for access to the operating mode can be disabled and

enabled. In the first programming segment, access is possible to

these disabled operating parameters.

In the third programming segment, all the machine-related

functions and values can be programmed.

In the fourth programming segment, the interface parameters can

be programmed.

Keying

The same key assignments apply to the individual programming segments. Since key functions may vary in the operating and programming modes, however, all the functions are described in full below.

Function in operating and

programming modes

Function in operating and

programming modes

Function in operating and

programming modes

Function in the operating mode

Function in the programming mode

Function in the operating mode

Function in the programming mode

14

Key

Transfer to the next operating parameters in the operating and

programming modes. For a fast run-through, hold the key down.

Key

Transfer from programming to operating mode and vice versa.

Keys 0...

Change of values via the numerical keypad.

Key

Deletes the display. Reset of possible programmed operating

continuous contacts.

Deletes the display. Reset of possible programmed operating

continuous contacts. Selection of output signals on continuous

signal (latch).

Key

Transfer from any display to a parameter corresponding the selection

in line 35.

In conjunction with the key, transfer to programming mode.

9

Page 15

NE215Programming mode

Function in the operating mode

Function in operating and

programming modes

In correct code

Correcter code unkown

Key for printing

The simultaneous operation of the Key for printing an the 2 key

starts the test routine; the power supply must be switched on at the

same time.

Printout release of the main counter.

The method of accessing the programming mode is described

below, together with the four programming segments in the order in

which they are used.

To access programming

Press the key.

● The system transfers from the operating to the programming

mode.

Press the key.

● is displayed. The code applies to programming

segments 1 - 4.

Input code.

Press the key.

No code is entered before delivery.

If an incorrect code has been input:

● appears in the display when the key is pressed.

● The counter reverts to the operating mode.

Press the key.

Press the key.

Input the correct code.

If the correct code is not known:

Return the counter to the factory.

When the correct code has been input, press the key.

● Now the programming lines are being called off one after the

other.

Druck

15

Page 16

Programming mode

NE215

Programming segment 1

Information on the displays and changing individual values is also

given in Part 4.

Press the key again.

● The operating parameters are now called up. The respective

LED flashes.

To changing operating parameters

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

Input the new values via the numerical keypad.

XP - Current counter status

P1 - Preset value 1

P2 - Preset value 2

Σ - Totalizer

XB - Secondary counter status

B1 - Secondary counter preset value

The LED display below

the meter symbol “m” is

always active with

length measurement

parameters.

16

Line 7

- Time meter

● At the conclusion of the first programming segment, a broken

line appears in the display.

Page 17

To change status

NE215Programming mode

Programming segment 2

In the second programming segment, the message STAT appears in

the display, signifying status selection.

● appears in the display. The LED for the corresponding

operating parameter flashes.

Significance of status numbers

0 Full access for operator (read and alter parameters).

1 Restricted access for operator (read parameters only).

2 None access for operator (No altering, no reading of parameters).

Input the appropriate status number.

● The changed status will automatically be stored when the next

programming line is selected.

Press the key again.

● The status of each individual operating parameter is called up in

sequence.

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

Line 7

XP - Main counter status

P1 - Preset value 1

P2 - Preset value 2

∑ - Totalizer

XB - Secondary counter status

B1 - Secondary counter preset value

- Time meter

● At the conclusion of the first programming segment, a broken

line appears in the display.

The default operating parameter status is zero.

17

Page 18

Programming mode

NE215

Programming segment 3

Programming segment 3 begins with programming line 21.

14 programming lines are displayed in sequence in these segments.

Default settings are always printed with * .

Line 21

Line 23

Line 26

Line 30

Line 31

Line 32

Operating modes

0 * Step preset

1

P1 Self-adjusting preset

Multiplier, secondary counter

1 * 1

2

2-99

Frequency, secondary counter XB

0 * 10 kHz

1

25 Hz

2

15 Hz

Reset secondary counter

0 * Autom. reset and external static

1

Autom. reset and external differential

2

External static

3

External differential

Output time P1

00.00 * Data in Sec. (Tol. -0.01 s, range 00.02 -99.99 s)

00.25 0.25

99.99

Maximum puls time

LAtch

Latch= continuous signal

Output time P2

00.00 * Data in Sec. (Tol. -0.01 s, range 00.02 -99.99 s)

00.25 0.25

99.99

Maximum puls time

LAtch

Latch= continuous signal

18

Line 33

Line 34

Line 35

Output time B1

00.00 * Data in Sec. (Tol. -0.01 s, range 00.02 -99.99 s)

00.25 0.25

99.99 Maximum puls time

LAtch Latch= continuous signal

Accept presets P1, P2 and B1

0 * On reset

1

Effective immediately

Adresses for function key

0 * No function

1 Any parameter selection

:

8

Page 19

NE215Programming mode

Line 36

Line 37

Line 38

Examples

Secondary counter functions XB

0 * External

1

Internal

2

Tachometer

Pulses per unit of measurement, as tachometer

1.0 0 * 1, 00

0,01 - 9999.99

Input of time measurement in seconds (s)

0 * Time base 1 s

1

Time base 2 s

2

Time base 3 s

3

Time base 6 s

4

Time base 10 s

5

Time base 20 s

6

Time base 30 s

7

Time base 60 s

The time base must be selected in accordance with the pulse

rate.

Pulses per rev. Time base in seconde

≥ 60 pulses/rev 1 s

< 60 ≥ 30 pulses/rev 2 s

1 pulses/rev 60 s

to to

Line 40

Line 41

Function input time meter

0 *

Operating hours with supply

1 Operating hours on/off

Code setting

0 *No code

1 -9999

● At the conclusion of these programming lines, a broken line will

appear in the display, signifying the competion of the third

programming segment.

on/off

19

Page 20

Programming mode

NE215

Programming field 4

Line 43

Line 44

Line 45

Line 46

To leave programming mode

Baud rate

0 * 4800 baud

1 2400 baud

2 1200 baud

3 600 baud

Parity

0 * Even parity

1 Odd parity

2 No parity

Address

* 0

1-9 9

Stop bits

0 * 1 Stop bit

1 2 Stop bits

● At the conclusion of these programming lines, a broken line will

appear in the display, signifying the competion of the fourth

programming segment.

Press the key.

● Counter now reverts to the operating mode.

20

Reprogramming the counter

to the defaults settings

Step preset

P1- Self-adjusting preset

Switch on the instrument and press the key simultaneously.

● All the programmed values will now revert to their defaults

settings.

5.1 Operating modes

The operating modes are described below.

On reaching a preset value, the counter continues to count to the

next preset value. Preset values are always processed in the

sequence: preset value 1, preset value 2. Any values can be chosen.

External or manual resetting can be carried out at any time.

Preset value P1 serves as a preliminary signal and functions as a

self-adjusting preset. The preliminary signal always switches to the

input value before the final signals is given. Any second preset value

can be chosen.

Page 21

Track A

Track B

RESET

VW (P2)

VW (P1)

O (SC)

OUT P1

OUT P2

NE215Programming mode

5.2 Counting modes for the main and totalizing counter

Up/down counting with two counting signals, phase-offset by

90 degrees

The counting direction is automatically identified from the leading/

lagging 90o phase offset.

The internal phase discriminator performs the necessary evaluation.

5.3 Output responses (Output Modes)

Signal output response is determined by the following:

– Programming of the preset value, output time, output logic and

output function;

– external resetting;

– external counting direction control.

The diagrams belows show the output signal responses.

Adding operating mode

Step preset with continuous signal, without automatic reset

RESET

SC

VW (P1)

VW (P2)

OUT P1

OUT P2

RESET

VW (P2)

O

(SC)

OUT 1

OUT 2

VW (P1)

Adding operating mode

Step preset with pulse signal, without automatic reset

Adding operating mode

Self-adjusting preset with pulse signal, without automatic reset

Input of the preset value P1 corresponds to the interval between the

preliminary signal and the final signal. This means that, if the final

signal (i.e. preset value P2) is changed, the preliminary signal is

automatically readjusted.

Tw

Tw

21

Page 22

Technical data

NE215

6 Technical data

Display 7-segment-LED display

Digit height 7,6 mm

Power supply As per purchase order

Power consumption 7 VA, 6 W

Encoder power supply 12...26 VDC, max. 80 mA

Optocoupler inputs NPN, PNP

Max. counting frequency 15 Hz, 25 Hz for XB

Data storage > 10 years

Mounting With clamping frame

Dimensions DIN-housing 72 x 72 mm, housing for front panel mounting

Mounting depth 100 mm

Core cross-section max 1,5 mm

Housing material Polycarbonate black, UL 94V-0

Weight AC version: approx. 450 g

Ambient temperature 0...+50 oC

Storage temperature -20...+70 oC

Relative humidity Max. relative humidity 80%, at 25 °C, not-condensing

General rating EN 61010 part 1

Interference immunity EN 50082-2

Emitted interference EN 50081-1

Max. speed Measuring in mm 600 m/min

Max. speed Measuring in cm 6000 m/min

8-digit, red

with minus sign

10 kHz für XP

2

DC version: approx. 320 g

- Protection class II

- Overvoltage protection category II

- Contamination factor 2

22

Page 23

72

6.1 Dimensions and cutout size

Sealing screw

NE215Technical data

105

100

10

Packing

72

75 min.

75 min.

68 +0,7

67.7

1-6

7

68 +0,7

Cutout

68 + 0.7 x 68 + 0.7 mm

6.2 Default settings

The following parameters are programmed into the counter by the

factory prior to delivery:

Preset value, main counter P1 100

Preset value, main counter P2 1000

Preset value, secondary counter B1 10

Secondary counter multiplier 1

Display Depending on the model with

either 2 or 3 DP

Pulse signal time

main/secondary counters 0.25s

Counting mode 1 (step preset)

Preset change the new preset becomes

active after reset.

Input function, secondary counter External triggering

Counting frequency,

secondary counter 10 kHz

Error messages

6.3 Error messages

and : Fault must be rectified by the factory.

: Excessively fast sequences, i.e.

inadequate intervals between presets

at high counting frequency.

● Error messages and can be cleared with the

key.

23

Page 24

NE215Open interface description

7 Open interface description

7.1 General information

The open interface is of the RS485 type. It is possible to send the

commands documented in the „Description of the Open Interface“

for remote control to the counter. The interface allows to call up data

and to change the programming of parameters not relevant for the

values to be calibrated.

In general, the counter is operated via the serial interface on a

personal computer – that is why the external device will be called PC

for short in the following. However, it is also possible to use another

device with similar features.

7.2 Transmission protocol

Transmission is effected character by character in ASCII code. Each

character consists of 8 bits. The 8th bit is the parity bit; in case of „no

parity“, the 8th bit will always be transmitted as a zero. The counter

responds to every request of the PC via the serial interface – if data

have been transmitted correctly.

The transmission of characters is introduced by the start-of-text character

<STX> and closed by the end-of-text character <ETX>. In addition, the

tachometer also sends a <CR> (carriage return) after the character

<ETX>. This allows the input (in high-level languages such as BASIC) of a

complete record of data with only one command. The character <STX> is

followed by an address allotted to the counter. This allows a target

approach of the counter in a serial network. The address is followed by

the indication of the line (position) that is to be read out or programmed.

In case of a programming instruction, the line indication is followed by a

„P“ (program) and the data (parameters).

24

The protocol is split into three groups, as described in the following:

a) Reading of storage locations (READ instruction):

<STX> Address Line <ETX> [<CR>]

b) Programming of storage locations (WRITE instruction):

<STX> Address Line P [VZ] Data <ETX> [<CR>]

c) Special commands:

<STX> Address Parameter <ETX> [<CR>]

<STX> Start of Text (02Hex)

Address 00..99 (device address)

Line 01..XX (please refer to operating plan)

P Programming command

D Print command

VZ Plus/Minus sign, only indicated if value

is negativ

Data Programming data

Parameter Special commands

<ETX> End of Text (03Hex)

<CR> 0DHex (Control character „carriage return“).

„CR“ needs not be indicated (optional),

will however, always be returned by

counter.

Page 25

NE215Open interface description

Important

The blanks between the particular characters of the commands

only serve the purpose of better legibility. The input at the PC must

be effected without blanks. Control characters (less than 20Hex) are

set in „pointed“ brackets. If a false protocol has been sent by the

PC, the counter will return an error message. Please read the

paragraph regarding error messages on page 29 under 7.7.

7.3 Reading of storage location

All storage locations that are indexed with a line number in the

programming scheme (except the separating lines that are indexed

dashes) can be read out. The protocol: <STX> Address line <ETX>

[<CR>] can be used for each line. The return answer of the counter

may vary in the protocol length from one line to the other. This

depends on the data length of the individual storage locations.

The counter can also be read out if operated in the RUN mode as

well as in the PGM mode. The only difference is that the return

answer of the counter will contain an „R“ or a „P“ in the mode

parameter, as described in the following.

Answer to a Read instruction (general):

<STX> Address Line Mode VZ Data <ETX> <CR>

Mode P = Counter is in Programming mode

R = Counter is in RUN mode

VZ Plus/Minus sign, only indicated if value is negative

Data Max. number of digits, with leading zeros w/o

decimal point.

7.3.1 Examples for the reading of storage locations

The following statement applies for the subsequent examples:

Counter address = 35; Counter mode = R (RUN mode)

Readout of preselection counter XP (Line=01, Count=-15.00)

Polling: <STX>3501<ETX>

Answer: <STX>3501R-00001500<ETX><CR>

Readout of operating mode (Line=21, Setting=Pos. 1)

Polling: <STX>3521<ETX>

Answer: <STX>3521R1<ETX><CR> (1 corresponds to P1 trailing preselection)

Readout of output time P1 (Line=31, Setting=0,25s)

Polling: <STX>3531<ETX>

Answer: <STX>3531R0025<ETX><CR>

Readout of address (Line=45, Address=35)

Polling: <STX>3545<ETX>

Answer: <STX>3545R35<ETX><CR>

7.4 Programming of storage locations

All storage locations that are indexed with a line number according

to the programming plan, except for the separating lines (that are

indexed by dashes) and the lines 1, 5, 6 and 8, may be programmed.

25

Page 26

The protocol: <STX> Address line P [VZ] data <ETX> [<CR>]

can be used for each line. The answer of the counter that is returned

after every programming step is the same as for the readout of the

line.

All storage locations may, principally, be programmed during the

RUN mode in the programming mode.

Please refer to page 27 (under 7.5.2) to find out how to switch to the

PGM mode.

Programming command (general):

<STX> Address Line P [VZ] Data <ETX> [<CR>]

7.4.1. Examples for the programming of storage locations

The following statement applies for the subsequent examples:

Counter address = 35; Counter mode = R (RUN mode)

Programming of preselection P1 (Line=02, Preselection P1=12.50)

Command: <STX>3502P00001250<ETX>

Answer: <STX>3502R00001250<ETX><CR>

Programming of preselection P2 (Line=03, Preselection P2=50.00)

Command: <STX>3503P00005000<ETX>

Answer: <STX>3503R00005000<ETX><CR>

Programming of output time P3 (Line=33, Time=0.30s)

Command: <STX>3533P0030<ETX>

Answer: <STX>3533R0030<ETX><CR>

7.5 Special commands

In the case of special commands, we are talking about instructions

that do not refer to any line number, with the exception of the

commands „Clear count“ and „Output to printer“.

NE215Open interface description

26

7.5.1 Clear counts

The counts XP (line 1), totalizer (line 5), batch counter (line 6), and

operating time meter (line 8) can be cleared via this special

command. It concerns all lines that cannot be programmed. All other

lines, such as preselections, are cleared by programming the value

ZERO (as described under item 4).

The instruction to clear corresponds to a reset via the C key and/or to

an external reset if a reset input is available.

The response (answer) of the counter when clearing is the same as

when reading the corresponding line.

General: <STX> Address Line <DEL> <ETX>

Example: Clearing of preselection counter XP

Address=35, Line=01, Status=RUN mode

Command: <STX>3501<DEL><ETX> <DEL> = 7FHex

Answer: <STX>3501R00000000<ETX><CR>

Page 27

NE215Open interface description

7.5.2 Switch counter to PGM mode or RUN mode

This command allows you to switch the counter upon every call

between the PGM mode and the RUN mode.

The current line, as with the reading command on this line, will be

returned as an answer.

General: <STX> Address <DC1> <ETX>

Example: Address=35, Status=RUN mode, Current line = 1, Count=0.15

Command: <STX>35<DC1><ETX> <DC1> = 11Hex

Answer: <STX>3501P00000015<ETX><CR>

If the instruction is repeated, the program switches back to the RUN

mode.

Command: <STX>35<DC1><ETX>

Answer: <STX>3501R00000015<ETX><CR>

7.5.3 Read out counter identification

It is only possible to read the identification data. Two parameters

follow the address: the command parameter „I“ (for identification)

and the selection parameter „T“ (Type and programming number) or

„D“ (date and version) for the different identification data.

Readout device type and programming number:

Command: <STX>35IT<ETX>

Answer: <STX>35NE215 03<ETX><CR>

Command: <STX>35ID<ETX>

Answer: <STX>35160295 1<ETX><CR>

Address=35, Type=NE215, Programming number=03

Readout date and version number:

Address=35, Date=16.02.95, Versions number=01

7.5.4 Readout of counter identification

It is only possible to read the identification data.

Two parameters follow the address: the command parameter „I“ (for

identification) and the selection parameter „T“ (Type and program-

ming number) or „D“ (date and version) for the different

identification data.

General: <STX> Address E <ETX>

Example:

Command: <STX>35E<ETX>

Answer: <STX>35Error 7<ETX><CR>

Address=35, Status=Error mode, Error=7

7.5.5 Clearing the error message

This command allows to clear error messages appearing on the

counter display. It is only possible to clear the error message that

can be cleared via the C key on the device itself (e.g.: not Error 1 or

2). The contents of the current line will be returned as an answer.

Address=35, Status=Error mode, Error=7, Line=01, Count=25.00

Command: <STX>35<ACK><ETX> <ACK> = 06H

Answer: <STX>3501R00002500<ETX><CR>

27

Page 28

Open interface description

Example: 29.08.94 10:30:45

<Daten>:

<Data>: Up to 11 data at choice may additionally be sent to the counter,

Example: Data_Time=29.08.94 10:32:20

Printout: 29.08.94 10:32:20

Answer: <STX>3501D00022368<ETX><CR>

NE215

7.6 Output to the printer

The command parameter „D“ allows the initiation of the output of

the lines 01, 02, 03 and 05 to the printer.

7.6.1 Appearance of the printout

The printout comprises

- date and time that need to be sent along by the PC upon a print

command

- optionally further data, which the PC may send along

- the length measurement needing to be calibrated, indexed by the

sign * .

LENGTH*000123.45m

7.6.2 Printout of the XP values

The protocol addressed to the counter is as follows:

Counter address=35, Line=01, Count XP=000223.68

PC Command: <STX>3501D<Date_Time> <Data><ETX>

<Date_Time> must be given in the following format:

<TT.MM.JJ hh:mm:ss>

TT: Tag MM: Monat JJ: Jahr

hh: Stunden mm: Minuten ss: Sekunden

TT:Day MM: Month JJ: Year

hh: Hour mm: Minutes ss: Seconds

All values must be 2-digit values and the punctuation must be

observed. (The characters < bzw. > / < and/or > only serve the

purpose of indexing and should not be transmitted.)

which will then also be printed. The sign * should not occur,

otherwise it will be ignored by the counter, i.e. it will not be sent to

the printer.

Date and time serve the purpose of clearly allocating the printed

length measurement to the data of the PC. After printing, the

counter will automatically trigger a carriage return so that the length

indication will always stand on a separate line.

PC Command: <STX>3501D29.08.94 10:32:20<ETX>

LENGTH*000223.68m

The counter will only respond to the PC when all characters have

been sent to the printer. The protocol then returned will contain the

value emitted to the printer:

28

7.6.3 Error message

If the PC does not send the date and the time as described above,

i.e. date/time are not complete or the punctuation is wrong, there

will be no printout and the counter sends an error message to the

PC.

Page 29

Open interface description

Answer: <STX>3501D<CAN>4<ETX><CR>

NE215

7.6.4 Printout of the lines 02, 03: preselections P1 and P2

As these are not length measurements that need to be calibrated,

the value of the preselections P1 and P2 is not printed with the sign

*, and it is also not necessary that the PC sends Date/Time along.

Example: Counter address=35, Line=02, P1=1.00

Printout: 29.08.94 10:33:18

Answer: <STX>3502D00000100<ETX><CR>

Printout: 29.08.94 10:33:29

Answer: <STX>3503D00001000<ETX><CR>

Example: Counter address=35, Line=05,

Printout: 29.08.94 10:34:52

Answer: <STX>3505D00122368<ETX><CR>

Further data=29.08.94 10:33:18

PC Command: <STX>3502D29.08.94 10:33:18<ETX>

P1 1.00

Counter address=35, Line=03, P2=10.00

Further data=29.08.94 10:33:29

PC Command: <STX>3503D29.08.94 10:33:29<ETX

P2 10.00m

7.6.5 Printout of Line 05: totalizer Σ

The value of the totalizer is printed with the sign *. Similarly Date/

Time will have to be sent along as with the XP value, otherwise the

same error message will be returned.

Totalizer count Σ=001223.68,

Data_Time=29.08.94 10:34:52

PC Command: <STX>3505D29.08.94 10:34:52<ETX>

SUM *001223.68m

7.6.6 Printing via key [Print] / [Druck]

If you press the key [Druck] during operation and if the value of the

preselection counter XP, the preselection P1, the preselection P2 or

the totalizer Σ are displayed, then the value will be indexed with the

sign * as with the PC command for the counter XP (line 01) and for

the totalizer (line 05). There is no printout of any additional data.

7.7 Error messages during data transfer

If the PC sends a wrong data protocol to the counter (e.g.: line that

does not exist or letter instead of digit), then the counter will return a

corresponding error message to the counter. In order to still receive

an error message after an error, the control character <STX> and the

address must at least be correct. If this is not the case, the data

block received by the counter will not be considered, and the

counter will not respond to the PC. If the PC does not receive a

response after a request has been sent, i.e. not even an error

message, then a fatal error has occurred. This may be the case if the

control character <STX> or the address are missing and if the

interface parameter of PC and counter are not congruent. Should

these be correct, however, then it can only be a matter of a failure of

the hardware or of the data line.

29

Page 30

Open interface description

Example: Address=35, Line=09 (invalid line),

Error 1: Format error (<ETX> not at the right place). This

Error 2: Line (position) not available or separating line

Error 3: Parameter error (inadmissible values in the

Error 4: This error message occurs if the PC requests the

NE215

General structure of the error messages:

<STX> Address Line Status <CAN> Error number <ETX> <CR>

Error number=2 <STX>3509R<CAN>2<ETX><CR>

The two positions „Line“ and „Status“ will not occur with the

special commands.

Error description in particular:

error might happen, for example, if the data format

was not observed when programming (e.g.: when

programming the limit value, only 5 instead of 6

data positions are transmitted.)

protocol). This means, for example, that the limit

value consists not only of digits but also of other

inadmissible characters, or that a value given lies

outside the admissible range.

counter to print in the programming mode, if the

printout of any line except the lines 01-03 and 05

is to be initiated, or if the PC does not send Date/

Time or sends them in a wrong format. The counter

will not allow the value to be sent to the printer

and responds with an error mistake to the PC.

Example for a returned error message:

Address=35, Line=01, Error number=4

<STX>3501D<CAN>4<ETX><CR>

30

7.8 List of the control characters used

Control character Hex Decimal

<STX> 02 02

<ETX> 03 03

<ACK> 06 06

<LF> 0A 10

<CR> 0D 13

<DC1> 11 17

<CAN> 18 24

<DEL> 7F 127

Page 31

Open interface description

7.9 Operating Plan

Line Display Short description

01 Preselection counter XP

02 Preselection 1

03 Preselection 2

Not applicable

05 Totalizer

06 Batch counter

07 Preselection batch counter

08 Time meter

10 Separating line

11 Status of preselection counter XP

12 Status of preselection 1

13 Status of preselection 2

14 Not applicable

15 Status of totalizer

16 Status of batch counter

17 Status of batch counter preselection

18 Status of time meter

20 Separating line

21 Operating mode main counter

22 Not applicable

23 Scaling factor batch counter

24 Not applicable

25 Not applicable

26 Frequency batch counter counting input

27 Not applicable

28 Not applicable

29 Not applicable

30 Reset batch counter

31 Output time P1

32 Output time P2

33 Output time P3

34 Take-over of preselections P1, P2, P3

35 Address of function key

36 Function of batch counter

37 Impulses per unit of tachometer

38 Selection of time base for the tachometer functions

39 Not applicable

40 Operating time counter input

41 Code setting

42 Separating line

43 Baud rate

44 Parity

45 Address

46 Stop bits

47 Separating line

NE215

31

Page 32

Open interface description

7.10 Programming plan

Lines in

italic*

= Factory setting

NE215

Line 11-18 Status for line 11-18

0 * Parameter can be changed

1 Clearing and/or input disabled

2 Parameter is skipped

Line 21 Operating mode principal count system

0 * Progressive preselections

1 P1 Trailing preselection

Line 22 Not applicable

Line 23 Scaling factor batch counter

00 Minimum value

1 * Default value

99 Maximum

Line 24 Not applicable

Line 25 Not applicable

Line 26 Frequency batch counter counting

0 * 10 kHz

1 25 Hz

2 15 Hz

Line 27 Not applicable

Line 28 Not applicable

Line 29 Not applicable

Line 30 Reset batch counter

0 * Autom. reset and external static

1 Autom. reset and external differential

2 External static

3 External differential

Line 31 Output time P1, (P2), (P3), B1

00.00 Maintained contact (LAtcH displayed)

0.25 * Default value

99.99 Maximal value

Line 32 Output time P1, (P2), (P3), B1

00.00 Maintained contact (LAtcH displayed)

0.25 * Default value

99.99 Maximal value

Line 33 Output time P1, (P2), (P3), B1

00.00 Maintained contact (LAtcH displayed)

0.25 * Default value

99.99 Maximal value

Line 34 Take-over of preselection P1, P2, B1

0 * In case of reset

1 After input

Line 35 Address for function key

0 * Function key not connected

:

8 Maximum value

32

Page 33

Open interface description

NE215

Line 36 Function of batch counter

Line 37 Impulses per unit at tachometer

Line 38 Time basis for tachometer function

Line 39 Not applicable

Line 40 Function of time meter

Line 41 Code setting

Line 43 Baud rate

Line 44 Parity

Line 45 Device address

Line 46 Stop bit

0 * external

1 internal

2 Tachometer

00.00 Minimum value

1.00 * Default value

9999.99 Maximum value

0 * 1 secound

1 2 secounds

2 3 secounds

3 6 secounds

4 10 secounds

5 20 secounds

6 30 secounds

7 60 secounds

0 * Time meter is running

1 Time meter on / off

0000 * Code not active

:

9999

0 * 4800 Baud

1 2400 Baud

2 1200 Baud

3 600 Baud

0 * Even Parity

1 Odd Parity

2 No Parity

00 * Minimum value

:

99 Maximum value

0 * 1 Stop Bit

1 2 Stop Bit

33

Page 34

Supplement

NE215

8. Supplementary operation manual for

open and closed interface

(February 1994, Erg. 31.8.1994)

The addendum describes the interfaces and documents the

modifications of the Operating Instructions for the Counter regarding

the additional open interface. Corresponding to the 1st. addendum

to file number: 1.62-3251.11 IVO-040293 dated 16.03.1995.

8.1 The closed interface

The closed interface is of the RS232 type. It allows to send data that

can be calibrated to the printer. The interface parameters cannot be

modified and are to be set at the printer as follows: Parity off, 7 data

bits, 1stop bit, Baud rate: 4800 Baud. Configuration of the interface

data at the printer: DIL-switch 7 and 8 „ON“.

Features of the RS232 interface:

– asymmetric

– 3 lines

– Point-to-point connection: 1 emitter and 1 receiver

– Data transmission distance: max. 30 m

8.2 The open interface

The open interface is of the RS485 type. It is possible to send the

commands documented in the „Description of the open interface“

for remote control to the counter. The interface allows to call up data

and to change the programming of parameters not relevant for the

values to be calibrated.

Features of the RS485 interface:

– symmetric

– 2 lines

– Multipoint connection: Emitter and receiver (max. 32 devices)

– Data transmission distance: max. 1500 m

34

8.3 Modifications of the operating instructions

8.4 Modifications in Chapter 2: „Get to know your counter“

All indications regarding interfaces refer to the closed interface.

8.5 Modifications in Chapter 3: „Counter connection“

All indications regarding interfaces refer to the closed interface.

8.6 Modifications in Chapter 3.5: „Interface connection“

The closed interface:

Set the interface parameters as indicated under Chapter 1.1.

The contacts 23-26 are assigned to the closed RS232-type interface.

The open interface:

It is possible to choose the interface parameters as described in the

Operating Instructions under lines 43 - 46.

Interface parameters are:

- the speed of transmission (Baud rate)

- the parity bit

Page 35

Supplement

NE215

- the number of stop bit

The contacts 21(-T,R) and 22(+T,R) are assigned to the open RS485-type

interface.

9. Supplement to the scaling factor manual

(May 1999)

This supplementary manual is describing the modification of the

counter’s operation manual regarding application of the scaling factor

and the alibi printer SP 298 of the company Star. It is according to the

third addendum of licence No. 1.62-3251.11 file number 5.23-99037480

dated 24.06.1999.

Address for printer: DATAMEGA Mikrodatentechnik GmbH

Landsberger Str. 318-320

80687 München

Tel.: 089/56017-300

9.1 Modifications in Chapter 2: „Get to know the counter“

The counter consist of

- preset counter with 2 presets (PTB-approved) and scaling factor

- batch counter with preset and multiplier

- totalizer, (PTB-approved) with scaling factor

- hour counter

The device is approved by the German Physical-Technical Authorities

(PTB) for calibration. The PTB-approved register system provides a

printer model Star SP298 with serial interface RS232.

Printer DIP switch settings (for counters with closed interface):

Schalter 1 2 3 4 5 6 7

Off On Off Off Off Off On

Baudrate: 7 Datenbits gerade Parität Xon/Xoff 2K Puffer

4800 Bit/s

The settings correspond to the counter default parameters in programming lines 43 and 44. Upon any modifications the DIP switch

settings have to be adapted correspondingly.

Printer DIP switch settings (for counters with closed and open

interface):

Schalter 1 2 3 4 5 6 7

Off On Off On Off Off On

Baudrate: 7 Datenbits keine Parität Xon/Xoff 2K Puffer

4800 Bit/s

These settings are always valed since they cannot be altered in any

way at the counter.

35

Page 36

Supplement to the operation manual with scaling factor

9.2 Modifications in Chapter 3: „Counter connection“

New pin assignment for pin 15: scaling on.

9.2.1Modifications in Chapter 3.3: „Assignment of signal inputs“

Pin 15 is for activating the setting of the scaling factor (line 22

programming level). Prior to sealing the pins the setting of the

scaling factor is activated by the signal trigger “scaling on” (pin 15).

Activation is realized by connecting pins 15 and 20, by a bridge from

18 to 19 or by 15 to 19, if 18 has to be connected to 20 (refer also to

page 8 “programming of input logic” in the operation manual).

After having set the scaling factor, the connection to pin 15 has to be

removed. Once being sealed, this pin is no longer accessible and the

scaling factor is indicated in the programming level without allowing

any alteration.

9.3 Modifications in Chapter 5: „programming the counter“

The scaling factor of the main counter is shown in programming line

22. Any modification is only possible if pin 15 is being activated (see

above).

Programming line 22:

Line 22 Scaling factor main counter

1.0000 Default

0.0001 Scaling range 0,0001

99.9999 up to 99,9999

Programming line 40 “function of the hour counter input” is

obsolete. The hour counter is always active after “on”.

2 2 1.0 0 0 0

NE215

Scaling factor main counter

36

Page 37

Suitable encoder PTB-version

NE215

10. Suitable encoder

Technical Data

Model Incremental Encoder

RPM value 10.000 min

Supply Voltage 10...30 VDC, with reverse voltage protection

Input signals Push-pull, outp., short-circuit-protect.

Signal output Kanal A, B, N

Resolution Up to 500 Impuls

Current consumption Max. 60 mA (w/o load) for 24 VDC

Ambient temperature -20...+70 °C

Storage temperature -20...+100 °C

Protection to

Shaft w/o seal IP 54

Shaft with seal IP 65

Relative humidity Max. 95 %, not condensing

Endurance

Vibration IEC 68 part 2-6 ≤100 m/s2 / 16-2000 Hz

Schock IEC 68 part 2-27 ≤1000 m/s2 4 ms

Starting torque

w/o seal (IP54) ≤0,010 Nm

with seal (IP65) ≤0,015 Nm

Interference immunity EN 50082-2

EN 61000-4 - 2 to 4 Serverity grade 3

Emitted interference EN 50081-2

Shaft loading Axial < 20 N, radial < 40 N

Inertia torque 1,45 x 10-6 kgm

Housing material Aluminium

Weight Ca. 250 g

-1

2

Order designation

GPI0W.

Order Flange / Shaft

0 Clamping flange / 10 mm, mounting M3

1 Clamping flange / 10 mm, mounting M4

5 Servo flange / 6 mm, mounting M4

Voltage / Signals

10 10...30 VDC push-pull output A 90° B +0

Connection

12 Cable 2 m axial, Pg9

14 Cable 5 m axial, Pg9

16 Cable 10 m axial, Pg9

22 Cable 2 m radial, Pg9

24 Cable 5 m radial, Pg9

26 Cable 10 m radial, Pg9

Impuls

39 50 Imp./rev.

15 500 Imp./rev.

37

Page 38

Suitable encoder PTB-version

35

10 20

15

9.

ø 10h8

13

Level High > UB -3 V (with I = -20 mA)

Level Low < 1,5 V (with I = 20 mA)

Load High < 40 mA

Load Low < 40 mA

M3 / 5 deep

(M4 / 5 deep)

120°

NE215

Pin assignment

Assignment Cable color

A blue

B beige

0 green

UB brown

0V black

Output signals

Signals with clockwise sense or rotation when looking at the flange.

Track A

Track B

Zero pulse

Push-pull output (10...30 VDC)

Dimensions

GPI0W Clamping flange

16 3 5 10 20

15

38

9.

15

36f8

48 ±0.1

58

ø 10h8

GPI0W Servo flange

M4 / 7 deep

120°

42 ±0.1

50h7

58

16

15

10

4

41

9.

ø 6f8

5.5

3

3

16

13

10

4

41

9.

ø 6f8

5,5

3

3

Page 39

Models/order designation

Part number

NE215. 1 AX0

5 In cm, 9999.99

Display

50 pulses/rev.

w/o interface/RS232

6 In mm, 999.999

500 pulses/rev.

w/o interface/RS232

7 In cm, 9999.99

50 pulses/rev.

at RS232/RS485

8 In mm, 999.999

500 pulses/rev.

Voltage supply

2 115/230 VAC

3 24 VDC

at RS232/RS485

Outputs

1 Relay outputs, B1 normally closed

Interface

0 Without interface

1 RS232

2 RS232/RS485

39

Page 40

Loading...

Loading...