Page 1

Operating Instructions

Interface Description

N 155 Target Display

Program 01

From version 2.10

Content Page

1. General information 2

1.1 Safety precautions 2

1.2 Description 3

2. Pin assignment 3

3. Interface 4

3.1 Interface data 4

3.2 Protocol 4

3.3 Check sum 5

3.4 Special features in data transfer 5

3.5 Broadcast commands 5

4. Description of commands 6

4.1 General information 6

4.2 Operating commands 6

4.3 Parameter commands and their significance 10

4.4 Identifier commands 13

4.5 Specific commands 14

5. Error signals 16

5.1 CRC error 16

5.2 Format error 16

6. Overview of commands 16

7. Technical data 17

Baumer IVO GmbH & Co. KG 03.10

Dauchinger Strasse 58-62 • DE-78056 Villingen-Schwenningen Subject to modification

Phone +49 (0)7720 942-0

www.baumer.com

• info.de@baumerivo.com

• Fax +49 (0)7720 942-900 in technic and design.

• 171.02.294/4

Page 2

N 155

1. General information

1.1 Safety precautions

General remarks

The equipment is designed and assembled according to the prevailing regulations of technology. The equipment

left the manufacturer in perfect working order and in line with all safety-relevant conditions. To maintain this

status of the equipment, it is imperative to stick to the following when installing and using the device:

- use only according to the intended purpose,

- observation of any precautions regarding safety and hazards,

- observe the present manual and especially the relevant safety precautions!

Make sure that the operating manual and especially the chapter describing the safety precautions is read and

well understood by the staff in charge. Supplementary to the operating instructions, ad other generally or legally

relevant regulations regarding accident prevention and environmental care are to be considered and observed.

This manual is a supplement to already existing documentation (data sheet, mounting instructions, catalogues).

Intended purpose of the equipment

Intended purpose of the equipment is industrial process monitoring and control in metal, wood, plastic, paper,

glass and textile etc. industry.

It is imperative that the equipment is applied only

- in properly installed condition and

- in line with the relevant technical data!

Any operation outside the technical specifications/parameters is improper use and in conjunction

with the equipment/processes/machines to be monitored/controlled might lead to

- fatal injuries

- serious damage to health,

- damage to property or corporate equipment or

- damage to the device!

Any overvoltage the device might be exposed to at its connecting terminals has to be limited to the values

stipulated in overvoltage category II (see technical data).

The device must not be operated

- in hazardous areas where is danger of explosion,

- as medical equipment or in medical areas,

- or in any applications expressly named in EN 61010!

If the device is utilized for control/monitoring of machines or processes where as the result of a

failure/malfunction or incorrect operation of the device might occur

- any threats to life,

- risks of damage to health or

- any risk of damage to property or environment

the corresponding appropriate safety precautions must be taken!

Do not open the housing of the device or proceed any modifications! Any modifications of the device can affect

operating safety and result in danger!

Do not proceed any repairs but return defective devices to the manufacturer!

Installation/commissioning

In case of any extraordinary incidents (including in the operating behaviour) that impair safety switch off the device immediately.

Installation must be carried out by suitably trained experts only. After proper mounting and installation the device

is ready for operation

Maintenance/repairs

Always disconnect the power supply of all appliances involved. Maintenance and repair work must only be carried out by suitably trained experts.

If troubleshooting is unsuccessful, do not continue using the device but contact the manufacturer.

.

www.baumer.com 2

Page 3

N 155

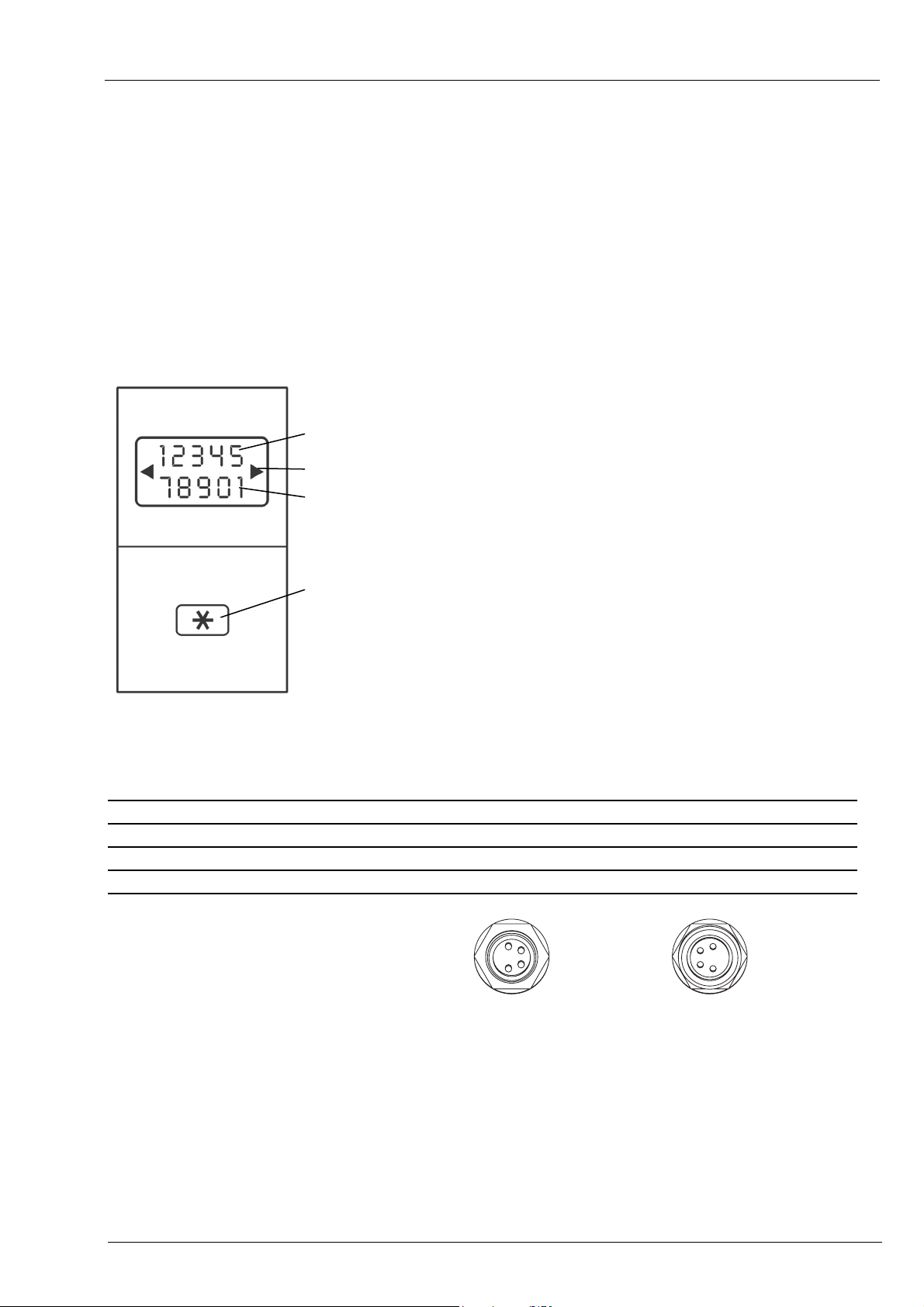

1.2 Description

Mounting the target display is by using the attached mounting plate that is fixed at the machine by using two

screws. The target display can be hooked onto the brackets provided at the mounting plate.

The position data will not get lost even in case of power failure (min. 10 years).

The current position value is indicated as running value in the two-line LCD display with backlight (2 x 5 digits,

numeric). Optionally the target received by the control unit (master) can be indicated simultaneously in the same

display. Two arrows show the editing engineer the turning direction in order to align current value with target. As

soon as the current value is in coincidence with the target and within the tolerance window, the target will disappear. Programming the relevant parameters at the master enables the display to be turned by 180° to allow vertical installation of the target display. Connecting the target display is by the help of an M8 connector. Power

supply of all target displays connected is by the same cable directly by master. Programming of target display by

master only.

target display

arrows indicating the direction

display „current value“

enter key

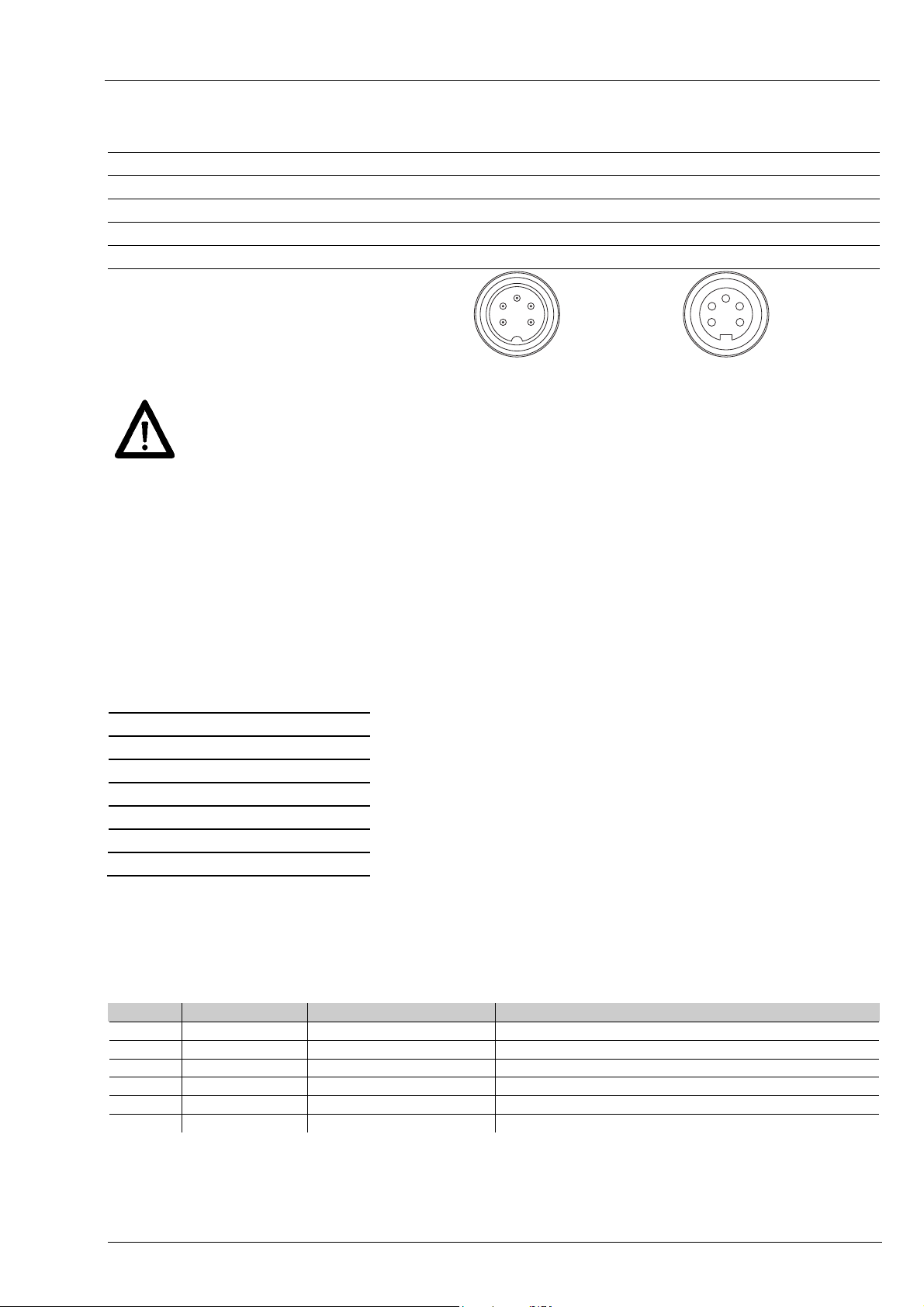

2. Pin assignment

Terminal Assignment Wire color DIN47100

Pin 1 Tx/Rx-, RS485 white orange

Pin 2 Tx/Rx+, RS485 brown brown

Pin 3 sensor supply +24 V yellow red

Pin 4 sensor supply 0 V green black

1

2

3

4

connector M8

IEC757

2

4

1

3

mating

connector M8

www.baumer.com 3

Page 4

N 155

Terminal Assignment Wire color DIN47100

IEC757

Pin 1 sensor supply +24 V yellow red

Pin 2 sensor supply 0 V green black

Pin 3 -- -- --

Pin 4 Tx/Rx+, RS485 brown brown

Pin 5 Tx/Rx-, RS485 white orange

3

4

2

1

5

2

1

connector M16

Connect power supply that is free from interference emission. The supply must not be used as

parallel supply of drives, shields, magnetic valves, etc.

Apply DC according to terminal assignment power supply: 24 VDC ±10 %

Shield

Use shielded cables only. The cable shield must be grounded at the machine

(two examples each depending on the cable, see drawings).

3

4

5

mating

connector M16

3. Interface

3.1 Interface data

Type: RS485

Baud rate: 19200

Parity: No

Data bits: 8

Stop bits: 1

Handshake: No

Check sum: Yes (CRC)

Lag time response*: 1...16 ms

3.2 Protocol

The target display operates with ASCII protocol (clear text protocol). Depending on the command, the volume of

the protocol varies between 5 and 17 bytes.

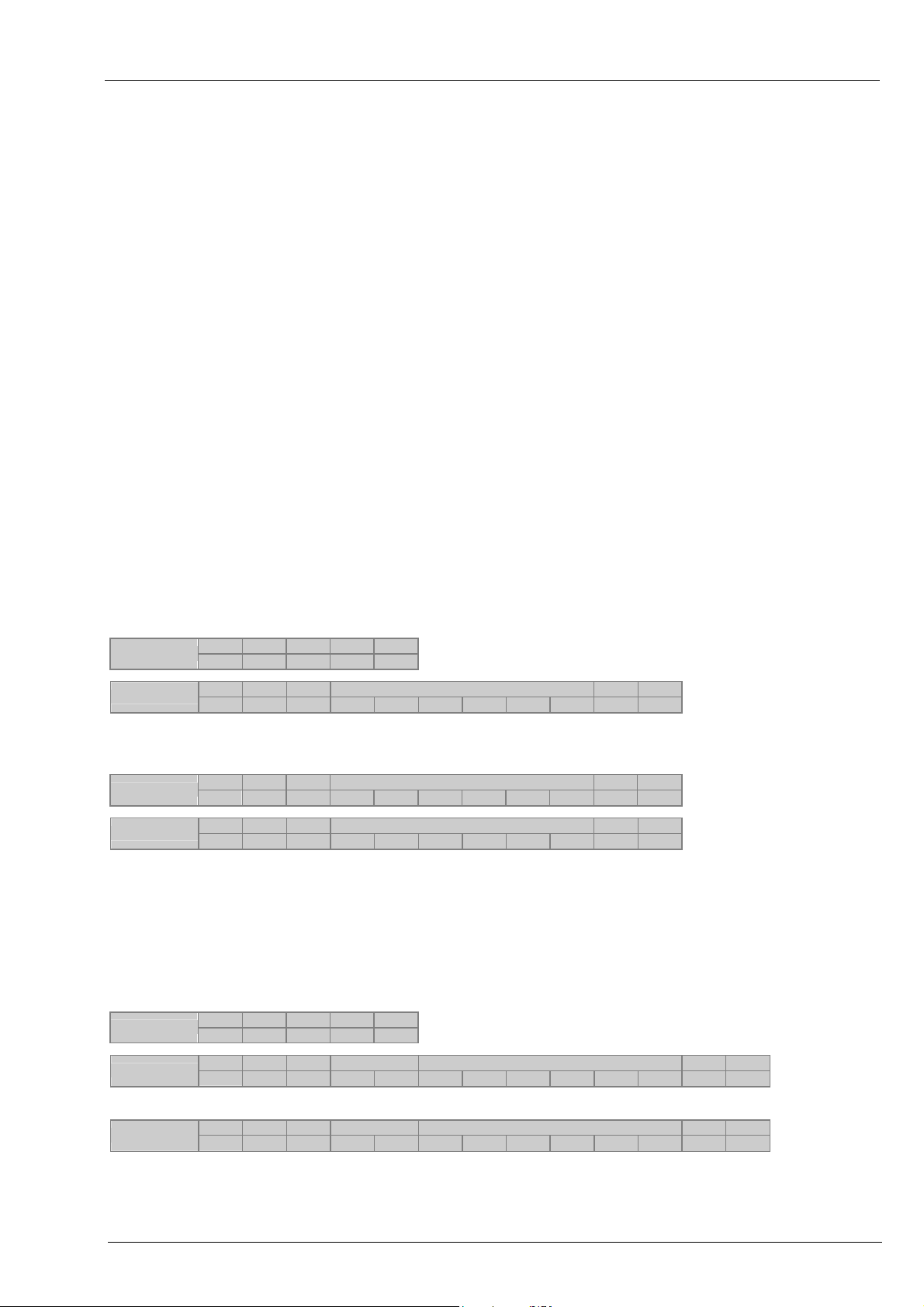

Byte Hex-Code Significance Value range

1 01H SOH = header token fix on 01h

2 XXh Adr = address 00...31dez + 20h Offset (address 00 = 20h)

3 XXh Cmd = command code defined commands

4-n [XXh..XXh] [Data] = data 20h-7Fh

n+1 04h EOT = footer token fix on 04h

n+2 XXh CRC = check sum 00h...FFh

* To avoid Bus collisions, a minimum time lag in responding of 1 ms

is imperative, i.e. the time elapsed between the last bit of the query

and sending the 1st bit of the N 155 response.

Important: Please consider that due to the abovementioned

minimum time lag of 1 ms in responding the Bus switching time

after having sent the last bit must not exceed 1 ms.

www.baumer.com 4

Page 5

N 155

3.3 Check sum

To support an error-free data transmission, a check sum byte CRC is added after the footer token (EOT) to the

string to be transferred. Upon reception of a command the CRC byte received is crosschecked with the selfcalculated CRC byte.

Algorithm:

1) Reset check sum byte.

2) Rotate check sum byte by 1 bit to the left.

3) Link result to first data byte XOR.

4) Rotate result by 1 bit to the left.

5) Link result to the second data byte XOR.

:

x) Rotate result by 1 bit to the left.

y) Link result to the last data byte (always 04H) XOR.

z) Add result as CRC after the footer token (04H) to the sending string.

Note:

1101 0000 RL 1010 0001 Important: Bit 7 is being shifted into bit 0 during rotation

Example:

Transmission string w/o CRC = 01h 20h 43h 04h

CRC-Byte = 0Ah

0000 0000 RL 0000 0000 XOR 0000 0001 (01h) = 0000 0001

0000 0001 RL 0000 0010 XOR 0010 0000 (20h) = 0010 0010

0010 0010 RL 0100 0100 XOR 0100 0011 (43h) = 0000 0111

0000 0111 RL 0000 1110 XOR 0000 0100 (04h) =

Legend: RL = rotate left; XOR = non-equivalence link

0000 1010

= CRC

3.4 Special features in data transfer

For reasons of compatibility and independent from the number of digits provided in the display, the complete

multicon system features the same data volume (refer to chart „overview of commands). For example, command “R” (read current value) comprises 6 bytes as data volume to be transferred whilst it is a 5-digit display

only.

3.5 Broadcast commands

Some specific commands are defined as so-called broadcast commands. As soon as such a command is sent

by master to identifier 99, the command will be accepted by each N 155 in the network. Each individual target

display will accomplish the respective function but will not return any confirmation to the master.

www.baumer.com 5

Page 6

N 155

4. Description of commands

4.1 General information

The following is describing the individual interface commands broken down into the four groups below:

- operating commands [ commands required during operation ]

- parameter commands [ commands serving for parameterization ]

- identifier commands [ commands for indication or alteration of the device identifier (address)]

- specific commands [ commands for specific functions as device reset or read version number]

The following abbreviations will be applied:

SOH = Start of header (header token)

EOT = End of transmission (footer token)

Adr = device identifier including offset 20h

Cmd = Command

data = data being sent or received

4.2 Operating commands

4.2.1 Read current value „R“ (52h)

This command is for reading the 5-digit current value (lower display line). Data volume is always 6 bytes. In case

of a negative value, the negative “-“ sign (2Dh) together with 5 data bytes will be returned. Positive values are

depicted by 6 data bytes without sign. Values of less than 5 (4) digits will come with preceding zeroes. Please

note that the current value is always of 5 digits (refer also to chapter “Special features in data transfer”).

Example 1: Read current value (current value = -32.50

Send

Response

Example 2 Programming the current value (new current value = 75.50)

Send

Response

4.2.2. Read / write target (profile) „S“ (53h)

This command is for reading the presently active target or for programming respectively reading a specific target. The data are composed of profile number (2 bytes) and target (6 bytes). Important: Negative targets are

transferred as 5 digit numbers (see example no. 3). Please consider that the targets are always of 5 digits only.

Example 1: Read active target (current profile number = 12; target = 12.50)

Send

Response

Response upon clearing all targets:

Response

SOH Adr Cmd EOT CRC

01h 20h 52h 04h 40h

SOH Adr Cmd current value = -32.50 EOT CRC

01h 20h 52h

SOH Adr Cmd current value = 75.50 EOT CRC

01h 20h 52h

SOH Adr Cmd current value = 75.50 EOT CRC

01h 20h 52h

SOH Adr Cmd EOT CRC

01h 20h 53h 04h 2Ah

SOH Adr Cmd Profil-Nr. = 12 target = 12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Profil-Nr. = FFh target = FFFFFFh EOT CRC

01h 20h 53h

2Dh 30h 33h 32h 35h 30h

30h 30h 37h 35h 35h 30h

30h 30h 37h 35h 35h 30h

31h 32 30h 30h 31h 32h 35h 30h

3Fh 3Fh 3Fh 3Fh 3Fh 3Fh 3Fh 3Fh

04h 54h

04h C9h

04h C9h

04h 3E

04h 2Ah

www.baumer.com 6

Page 7

N 155

Example 2: Read target of a specific profile (profile number = 17; target = 12.50)

Send

Response

SOH Adr Cmd Profil-Nr. = 17 EOT CRC

01h 20h 53h

31h 37h

04h 16h

SOH Adr Cmd Profil-Nr. = 17 target = 12.50 EOT CRC

01h 20h 53h

31h 37h 30h 30h 31h 32h 35h 30h

04h BCh

Example 3: Write target of specific profile (profile number = 17; target = -12.50)

s

Send

Response

SOH Adr Cmd Profil-Nr. = 17 target = -12.50 EOT CRC

01h 20h 53h

31h 37h 2Dh 30h 31h 32h 35h 30h

04h FBh

SOH Adr Cmd Profil-Nr. = 17 target = -12.50 EOT CRC

01h 20h 53h

31h 37h 2Dh 30h 31h 32h 35h 30h

04h FBh

4.2.3 Read / write profile number „V“ (56h)

This command is for reading the number of the presently active profile respectively for altering the profile.

Example 1: Read active profile (active profile number = 38)

Send

Response

Response after reset upon clearing all profiles:

Response

SOH Adr Cmd EOT CRC

01h 20h 56h 04h 20h

SOH Adr Cmd Profile no. = 38 EOT CRC

01h 20h 56h

33h 38h

04h 28h

SOH Adr Cmd Profile no. = FF EOT CRC

01h 20h 56h

3Fh 3Fh

04h 16h

Example 2: Send new profile (New profile number = 17)

Send

Response

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 20h 56h

31h 37h

04h 3E

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 20h 56h

31h 37h

04h 3E

Example 3: Send new profile by broadcast command to each N 155 (Adr = 99 (83h); new profile number = 17)

Send

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 83h 56h

31h 37h

04h 04

Response No confirmation

To check whether the new profile has been entered by all N 155 in the network, check command „C“ (43h) can

be applied.

4.2.4 Check position „C“ (43h)

This command is providing the alignment status of target versus current value. If current value is in coincidence

with target the response will be „o“ (6Fh) for OK together with the current profile number. If the running value is

beyond the target, „x“ (78H) followed by the current profile number will be replied.

Example: (active profile number = 05)

Send

Response if current value = target:

Response

Response if current value ≠ target:

Response

SOH Adr Cmd EOT CRC

01h 20h 43h 04h 0Ah

SOH Adr Cmd Status Profile no. = 05 EOT CRC

01h 20h 43h

6Fh 30h 35h

04h A5h

SOH Adr Cmd Status Profile no. = 05 EOT CRC

01h 20h 43h

78h 30h 35h

04h 1D

www.baumer.com 7

Page 8

N 155

The following state-related values are available:

State Significance

o (6Fh) current value=target

x (78h) current value≠ arget

Extended command Check Position „CX“

Besides the state value of the target/current value comparison, the extended command „Check Position“ reads

out the current value. The profile number is not transmitted. Regarding available state-related values please see

above.

Example:

transmission

Response

SOH Adr Cmd

01h 20h 43h 58h 04h A8h

SOH Adr Cmd

01h 20h 43h

4.2.5 Read / write offset „U“ (55h)

This command is for reading or writing the offset to be added to the actual current value. This function however

has to be activated first in the command bit parameter ‚a’ (61h).

Example 1: Read offset

Send

Example 2: Write offset

Send

Response in both examples:

Response

SOH Adr Cmd EOT CRC

01h 20h 55h 04h 26h

SOH Adr Cmd data (offset = –20.00) EOT CRC

01h 20h 55h

SOH Adr Cmd data (offset = –20.00) EOT CRC

01h 20h 55h

4.2.6. Write a number sequence in upper line of the display „t“ (74h)

The command is for writing a 5-digit number sequence in the upper display line. The sequence is depicted without dot respectively comma. Preceding zeroes as well as both arrows for direction are hidden. The bottom line is

still showing the current value.

The number sequence will remain until any command except „t“, „u“ or „R“ is received by interface.

Example: (number sequence = 054321)

Send

Response

SOH Adr Cmd Number sequence = 054321 EOT CRC

01h 20h 74h

SOH Adr Cmd Number sequence = 054321 EOT CRC

01h 20h 74h

SCmd

EOT CRC

state

reserved reserved Current value = -12.50 EOT CRC

6Fh 80h 80h 80h 80h 2Dh 30h 31h 32h 35h 30h

2Dh 30h 32h 30h 30h 30h

2Dh 30h 32h 30h 30h 30h

30h 35h 34h 33h 32h 31h

30h 35h 34h 33h 32h 31h

04h C3h

04h C3h

04h C6h

04h C6h

04h B7h

www.baumer.com 8

Page 9

N 155

4.2.7 Write a number sequence in the lower line of the display „u“ (75h)

The command is for writing a 5-digit number sequence in the lower display line. The sequence is depicted without dot respectively comma. Preceding zeroes as well as both direction arrows are hidden. The upper line is still

showing the current target or number sequence.

The number sequence will remain until any command except „t“, „u“ or „R“ is received by the interface.

Example: (number sequence = 012345)

send

response

SOH Adr Cmd Number sequence = 012345 EOT CRC

01h 20h 75h

SOH Adr Cmd Number sequence = 012345 EOT CRC

01h 20h 75h

30h 31h 32h 33h 34h 35h

30h 31h 32h 33h 34h 35h

04h B6h

04h B6h

Important:

Combining the commands „t“ and „u“ enables a 10-digit number in the display.

Both number sequences are not saved by EEPROM.

www.baumer.com 9

Page 10

N 155

4.3 Parameter commands and their significance

4.3.1 Read / write bit parameters „a“ (61h)

To exploit the maximum storage capacity, several parameters are put together and transferred as “pack”.

Parameter codes as follows:

Data1: 1 0 X X 0 0 0 0

┬ ──┬── ───┬───

│ │ └───── reserved

│ └──────────── arrows 0/1/2/3 (UP/DOWN/UNI/OFF)

└──────────────── 1

Data2: 1 0 0 X 0 X 0 0

┬ ┬ ─┬─ ─┬─ ─┬─

│ │ │ │ └─── reserved

│ │ │ └─────── turn display 0/1 (OFF/ON)

│ │ └─────────── offset 0/1 (OFF/ON)

│ └────────────── reserved

└──────────────── 1

Data3: 1 0 X X X 0 X X

┬ ┬ ──┬── ┬ ─┬─

│ │ │ │ └─── hide target 0/1/2 (ON/OFF/EVER)

│ │ │ └────── resolution 0/1 (1/100 or 1/10)

│ │ └────────── decimal point 0/1/2/3/4/5 (AUTO/OFF/0.0/0.00

│ │ 0.000/0.0000)

│ └────────────── reserved

└──────────────── 1

Data4/5: 0 0 1 1 X X X X

───┬───

└───── reserved

Important: Only bits marked ‘X’ may be altered. The fix values „1“ and „0“ must not be altered since thereby a

control token (tokens < 20h) might be created what is not allowed in ASCII protocol.

Example 1: Read bit-parameters (Data1 to Data3 = 80h; Data4 to Data5 = 30h)

Send

Response

Example 2: Write bit parameters (positioning direction = Down; turn display = On)

Send

Response

Parameter significance

Arrows

This parameter is for displaying arrows intended as support for the editing engineer. They indicate the direction for

the new setting (clockwise or counter clockwise, up or down). The following settings are possible

00 = Up If current value < target: arrow at the right; current value > target: arrow at the left

01 = Down Similar to „Up“, but direction of the arrows the other way round

10 = Uni If current value ≠ target: always indicate both arrows

11 = Off Arrows always hidden

SOH Adr Cmd EOT CRC

01h 20h 61h 04h 4E

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

80h 80h 80h 30h 30h

81h 84h 80h 30h 30h

81h 84h 80h 30h 30h

04h F1

04h 91h

04h 91h

Bit parameter default

www.baumer.com 10

Page 11

N 155

Turn display

This parameter is for turning the display by 180°.

0 = Off Display with standard mounting, i.e. display on top, key below

1 = On Display with inverted mounting, i.e. display below, key on top

Offset

The „U“ command is for programming the offset to be added to current value and relevant target. This parameter

is for defining whether the offset is to be considered in the calculation.

0 = Off Offset not active. Any transferred offset is not added to current value nor target.

1 = On Offset active. The offset is added to current value and target.

Hide target

This parameter is for defining when to indicate the target in the upper line of the display.

0 = On Always show target if target ≠ current value.

1 = Off Always show target, even if target = current value. Indicate in addition arrows if target ≠ current

value.

2 = Ever Always hide both target and arrows.

Resolution

This parameter defines the resolution related to the current value. Switching to another resolution will relocate the

decimal point accordingly by one digit to the right or left, both for current value and target. The targets however are

not calculated anew but only the decimal point is relocated. Make sure that during the machine editing procedure

the resolution is defined first and the target values are transmitted to the SPAs afterwards when having selected

the resolution. When switching from mm to inch, the decimal point is displaced by one digit to the left. Both current

value and target are converted into inches. See also command “I” for mm/inch-conversion.

Note: This function is only enabled if parameter decimal point= auto.

0 Resolution 1/100 of a mm resp. 1/1000 of an inch Displayed: 000.00 mm resp.

00.000 inch

1 Resolution 1/10 of a mm resp. 1/100 of an inch Displayed: 0000.0 mm resp.

000.00 inch

Decimal point

This parameter is for setting the decimal point.

000 = Auto The resolution function (see above) is active, this means the decimal point is automatically placed

according to the resolution parameter.

001 = Off No decimal point is indicated, neither when switching from mm to inch.

010 = 0.0 Fix decimal point for current value and target. No automatic setting of decimal point when switch-

ing from mm to inch. The decimal point remains at the defined digit.

011 = 0.00 Same as with 0.0

100 = 0.000 Same as with 0.0

101 = 0.0000 Same as with 0.0

4.3.2. Read / write measuring unit „i“ (69h)

This command is for reading or programming the measuring unit in mm or inches.

Data = 0 (30h) = mm

Data = 1 (31h) = inch

Example 1: Read parameters (setting = mm)

Send

Response

SOH Adr Cmd EOT CRC

01h 20h 69h 04h 5E

SOH Adr Cmd Data EOT CRC

01h 20h 69h

30h

04h D0h

www.baumer.com 11

Page 12

N 155

Example 2: Changing the measuring unit into inch

Send

Response

Example 3: Programming mm as measuring unit with all target displays by broadcast command (Adr=99)

Send

Response No confirmation

SOH Adr Cmd Data EOT CRC

01h 20h 69h

31h

04h D2

SOH Adr Cmd Data EOT CRC

01h 20h 69h

31h

04h D2

SOH Adr Cmd Data EOT CRC

01h 83h 69h

30h

04h CDh

Important: Parameter programming is in mm. The target display will convert the mm into inches when displaying the position values.

www.baumer.com 12

Page 13

N 155

4.4 Identifier commands

4.4.1. Placing a device-specific identifier within the network „A“ (41h)

This command is for creating an automated process for defining successively the device identifier of each individual N 155 upon commissioning of the equipment. The first device identifier to be placed is given by broadcast

command to all networked N 155 as follows:

send

All N 155 will now show the identifier to be set which has just been sent in the upper line of the display. The

lower line will indicate the device-specific identifier. Push key provided at N 155 to enter the new identifier. The

identifier is entered and indicated in the lower line of the display (as new device identifier). Both identifiers are

now identical. After 3 seconds N 155 will send the following confirmation „B“ (42h) to the master:

Send to

Master

The Master now is able to give command „A“ with the next identifier to be placed as previously described.

This way, all N 155 in the network are automatically given the specific identifier (in successive order).

Important: The confirmation command „B“ sent by N 155 to the master will be repeated after 3 seconds in case

the master is not giving the „A“ command again.

Show identifier in the display „A“ (41h)

This command as broadcast command (Adr = 99) without any parameters will make each N 155 in the network

indicating the device-specific identifier in the bottom line of the display. The upper line is blind.

This command is a designated broadcast command.

Send

Response no confirmation

N 155 remains in this mode until being switched off and on again or receiving another command except „A“, „R“,

„t“ or „u“.

If this command without any parameters is sent to a valid device identifier (except 99), the target display will

return to standard operation mode. The presently valid device identifier will be replied.

Send

Response

Extended identifier command „AX“ (41h,58h)

This command is for placing the individual N 155 device identifiers in a way as previously described.

The identifier to be given is sent to all N 155 in the network by the following broadcast command:

Send

Similar to the standard command, the upper line of the N 155 display will show the identifier to be placed that

has just been sent. Also entering the identifier will be the same.

However, in this case NO identifier confirmation command „B“ is returned. W hether the identifier has been entered or not has to be checked by master, for example by “R” command (read current value). The “R” command

is sent to the N 155 with corresponding identifier. If the identifier is entered, the target display will reply and the

master can pass on to the next identifier. Regarding other commands the N 155 display will switch to standard

operation.

SOH Adr Cmd address = 01 EOT CRC

01h 83h 41h

SOH Adr Cmd address = 01 EOT CRC

01h 21h 42h

SOH Adr Cmd EOT CRC

01h 83h 41h 04h 80h

SOH Adr Cmd EOT CRC

01h 21h 41h 04h 0Ah

SOH Adr Cmd Adr=01 EOT CRC

01h 21h 41h

SOH Adr Cmd Cmd2 address = 01 EOT CRC

01h 83h 41h 58h

30h 31h

30h 31h

30h 31h

04h B4h

04h 86h

04h 9Eh

30h 31h

04h 40h

www.baumer.com 13

Page 14

N 155

4.5 Specific commands

4.5.1. Read version, device type or serial number „X“ (58h)

This command is for reading off version number, device type or serial number. The following sub-commands are

available:

Data = V (56h) = read off version number

Data = T (54h) = read off device type

Data = S (53h) = read off serial number

Example 1: Read version number

Send

Response

Example 2: Read device type (device type = N 155; software no. = 01)

Send

Response

Structure of the transferred device type code:

1 0 0 1 0 1 0 1 1 0 0 0 0 0 0 1 = 95 81 hex

┬ ──────┬────── ┬ ───────┬─────

│ │ │ └─────── software no. 01h = software 01

│ │ └──────────────── fix on 1

│ └────────────────────────── device type 15h = N 155

└────────────────────────────────── fix on 1

Example 3: Read serial number

Send

Response

Structure of the serial number code transferred:

The Low-Nibble (lower 4 bits of a byte) of the 8 data bytes received equal together a 4-byte value including the

serial number.

The serial number itself is generated by production date and time. Since also the seconds are coded and only

one number is created per second the serial number is unique.

Example: serial number for production date and time 01.06.2005 16:58:36 = 15 83 0E A4 hex

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X Bit position

J J J J J J M M M M T T T T T h h h h h m m m m m m s s s s s s content

0 0 0 1 0 1 0 1 1 0 0 0 0 0 1 1 0 0 0 0 1 1 1 0 1 0 1 0 0 1 0 0 example = 15 83 0E A4 hex

─────┬───── ────┬──── ────┬──── ─────┬───── ──────┬────── ─────┬─────

│ │ │ │ │ └─────── seconds 10

│ │ │ │ └──────────────────── minutes 11

│ │ │ └───────────────────────────────── hours 1

│ │ └──────────────────────────────────────────── day 0

│ └────────────────────────────────────────────────────── month

└───────────────────────────────────────────────────────────────── year 00

│

01.06.05 16:58:36 <──────┘

SOH Adr Cmd Data EOT CRC

01h 20h 58h

56h

04h D8h

SOH Adr Cmd Data Version number = 2.00 EOT CRC

01h 20h 58h 56h

20h 32h 30h 30h

04h FAh

SOH Adr Cmd Data EOT CRC

01h 20h 58h

54h

04h DCh

SOH Adr Cmd Data type EOT CRC

01h 20h 58h 54h

95h 81h

04h 32h

SOH Adr Cmd Data EOT CRC

01h 20h 58h

53h

04h D2h

SOH Adr Cmd Data Serial number code = 07090EA4 EOT CRC

01h 20h 58h 53h

30h 37h 30h 39h 30h 3Eh 3Ah 34h

04h 20h

0100 = 24h = 36d

1010 = 3Ah = 58d

0000 = 10h = 16d

0001 = 01h = 01d

0110 = 06h = 06d

0101 = 05h = 05d

www.baumer.com 14

Page 15

4.5.2. N 155 reset to default „Q“ (51h)

This command is for resetting several parameters to default, either by individual or collective reset.

Data = q (71h) = reset parameters to default

Data = t (74h) = reset device identifier to 98.

Data = x (78h) = reset current value (lower line of display) to 0

Data = ∆ (7Fh) = all above functions except „r“ (72h) are accomplished.

Note: No profile reset. Profile reset by command „R“.

Example 1: Reset N 155 to default

Send

Response

SOH Adr Cmd Data EOT CRC

01h 20h 51h

7Fh

04h AEh

SOH Adr Data EOT CRC

01h 20h

04h 52h N 155 replies by standard response ‚o’ (6Fh) = OK

6Fh

Example 2: Reset all N 155 to default by broadcast command (Adr=99)

Send

SOH Adr Cmd Data EOT CRC

01h 83h 51h

7Fh

04h B3

Response no confirmation

4.5.3. Profile reset of the target display „K“ (4Bh)

This command is clearing all prior profiles.

Example 1: Profile reset in a specific N 155

Send

Response

SOH Adr Cmd Data EOT CRC

01h 20h 4Bh

7Fh

04h C6h

SOH Adr Data EOT CRC

01h 20h

04h 52h N 155 standard reply ‚o’ (6Fh) = OK

6Fh

Example 2: Profile reset with all N 155 by broadcast command (Adr=99)

Send

SOH Adr Cmd Data EOT CRC

01h 83h 4Bh

7Fh

04h DBh

Response No confirmation

Important: After profile reset all profile data are set to auf FFFFFFhex respectively FFhex (current profile

number). The display will show 5 dashes instead of the target.

N 155

www.baumer.com 15

Page 16

N 155

5. Error signals

5.1 CRC error

If the target display recognises a CRC error in a command transferred, the following signal will be replied:

Response

SOH Adr Error EOT CRC

01h 20h 65h 04h 46h Error = „e“ (65h) = CRC error

5.2 Format error

If the target display recognises a format error i.e. volume of protocol incorrect or invalid command (Cmd); the following signal will be replied:

Response

SOH Adr Error EOT CRC

01h 20h 66h 04h 40h Error = „f“ (66h) = Format error

6. Overview of commands

The following chart is showing in alphabetical order all possible commands (Cmd) as well as options regarding

read and write (programming) etc.

Command

code

a (61h) 5 X X - Read/write general parameters

i (69h) 1 X X X Parameter: mm / inch

t (74h) 6 - X - Send tool number

u (75h) 6 - X - Send any number sequence

A (41h) 2 X X X Place or indicate device identifier

C (43h) 3 X - - Check current value = target

K (4Bh) - - X X Profile reset

Q (51h) 1 - X X Specific command: reset N 155

R (52h) 6 X X - Read/write current value

S (53h) 8 X X - Read/write target

U (55h) 6 X X - Offset

V (56h) 2 X X X Read/write profile number

X (58h) 4 X - - Specific command: read version number

Data volume

in bytes

Read Write Broadcast Significance

www.baumer.com 16

Page 17

7. Technical data

Technical data - electrical ratings

Supply voltage 24 VDC ±10 %

Current consumption ≤30 mA

Display LCD, 7-segment display, 2-lines, backlit

Display range -9999...+99999

Interface RS485 (ASCII protocol)

Data memory >10 years in EEPROM

Programmable parameters Measuring unit mm/inch

Direction arrows

Decimal point

Standard DIN EN 61010-1 Overvoltage category II

Protection class II

Pollution degree 2

Emitted interference DIN EN 61000-6-3

Interference immunity DIN EN 61000-6-2

Approval UL/cUL

Technical data - mechanical design

Protection DIN EN 60529 IP 65

Operating temperature -10...+50 °C

Storing temperature -20...+70 °C

Relative humidity 80 % non-condensing

E-connection - Male/female connector M8, 4-pins

- Cable output (30/15 cm) with male/female connector M8, 4-pins

- Cable output (30/15 cm) with male/female connector M16, 5-pins

Operation / keypad Membrane with one softkey (handshake)

Housing type Surface mount housing with mounting plate

Dimensions W x H x L 37 x 75 x 29 mm

Mounting Mount onto plate

Weight approx. 60 g

Material Polyamide black, UL 94V-0

N 155

www.baumer.com 17

Loading...

Loading...