Page 1

Operating instructions

Interface description

N 153 spindle position display (SPA)

Firmware 01 version 1.11 and up

Contents Page

1. General information 2

1.1. Safety precautions 2

1.2. SPA description and explanation 3

1.3. Betriebsarten 3

2. Terminal assignment 4

3. Interface 4

3.1. Interface data 4

3.2. Protocol 5

3.3. Checksum (Cyclic Redundancy Check) 5

3.4. Data transmission properties 5

3.5. Broadcast commands 5

3.6. Data saving 6

3.7. Transmitting and reading negative values 6

3.8. Transmitting and reading position values (decimal point) 6

4. Command explanations 7

4.1. General information 7

4.2. Operating commands 7

4.3. Parameter commands 13

4.4. Identifier (address) commands 21

4.5. Specific commands 23

5. Error warnings 25

5.1. CRC error 25

5.2. Format error 25

5.3. Display error indication 25

6. Overview on commands 26

7. Technical data 27

7.1. Dimensions 28

8. Part number 28

Baumer IVO GmbH & Co. KG 12.10

Dauchinger Strasse 58-62 • DE-78056 Villingen-Schwenningen Subject to modification

Phone +49 (0)7720 942-0 • Fax +49 (0)7720 942-900 in technic and design.

www.baumer.com • info.de@baumerivo.com

• 171.02.314/5

Page 2

N 153

1. General information

1.1. Safety precautions

General remarks

The equipment is designed and assembled according to the prevailing regulations of technology. The equipment left the manufacturer in perfect working order and in line with all safety-relevant conditions. To maintain

this status of the equipment, it is imperative to stick to the following when installing and using the device:

- use only according to the intended purpose,

- observation of any precautions regarding safety and hazards,

- observe the present manual and especially the relevant safety precautions!

Make sure that the operating manual and especially the chapter describing the safety precautions is read and

well understood by the staff in charge. Supplementary to the operating instructions, ad other generally or legally

relevant regulations regarding accident prevention and environmental care are to be considered and observed.

This manual is a supplement to already existing documentation (datasheet, mounting instructions, catalogues).

Intended purpose of the equipment

Intended purpose of the equipment is industrial process monitoring and control in metal, wood, plastic, paper,

glass and textile etc. industry.

It is imperative that the equipment is applied only

- in properly installed condition and

- in line with the relevant technical data!

Any operation outside the technical specifications/parameters is improper use and in conjunction

with the equipment/processes/machines to be monitored/controlled might lead to

- fatal injuries

- serious damage to health,

- damage to property or corporate equipment or

- damage to the device!

Any overvoltage the device might be exposed to at its connecting terminals has to be limited to the values

stipulated in overvoltage category II (see technical data).

The device must not be operated

- in hazardous areas where is danger of explosion,

- as medical equipment or in medical areas,

- or in any applications expressly named in EN 61010!

If the device is utilized for control/monitoring of machines or processes where as the result of a

failure/malfunction or incorrect operation of the device might occur

- any threats to life,

- risks of damage to health or

- any risk of damage to property or environment

the corresponding appropriate safety precautions must be taken!

Do not open the housing of the device or proceed any modifications! Any modifications of the device can affect

operating safety and result in danger!

Do not proceed any repairs but return defective devices to the manufacturer!

Installation/commissioning

In case of any extraordinary incidents (including in the operating behaviour) that impair safety switch off the device immediately.

Installation must be carried out by suitably trained experts only. After proper mounting and installation the device is ready for operation

Maintenance/repairs

Always disconnect the power supply of all appliances involved. Maintenance and repair work must only be carried out by suitably trained experts.

If troubleshooting is unsuccessful, do not continue using the device but contact the manufacturer.

.

www.baumer.com 2

Page 3

N 153

1.2. SPA description and explanation

Mounting the spindle position display (SPA) is by docking hollow shaft onto spindle shaft (max.14 mm in diameter).The hollow shaft is fixed to the spindle shaft by hexagon screw and secured by power grip.

This way, the SPA is mounted in an overhung position and secured against torsion by torque support provided

at rear of the housing. The SPA features an absolute multiturn sensing system capable of detecting the position

after several spindle turns even in powerless state. Position data will be retained even in case of power failure

(min. 10 years).

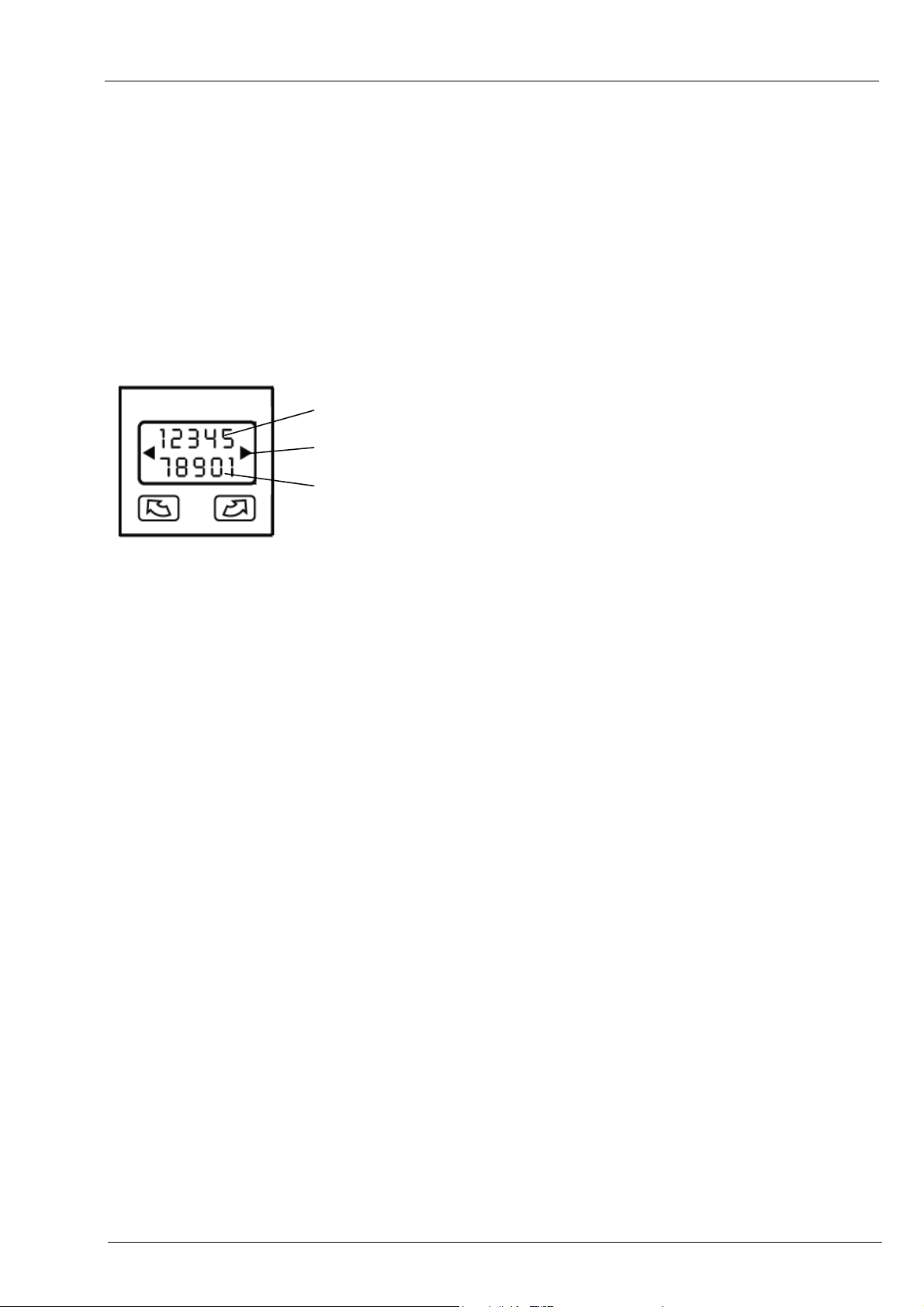

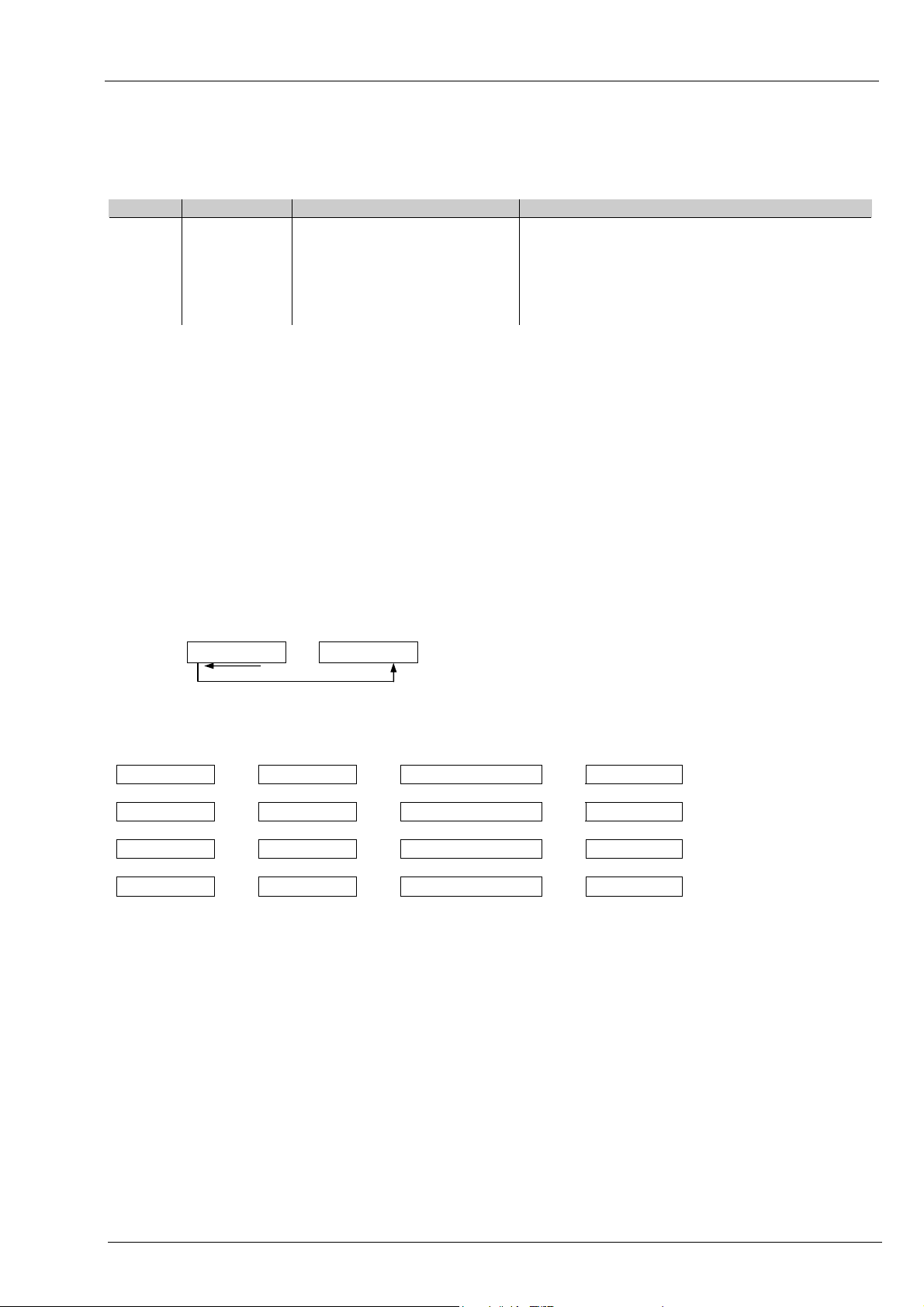

The current position value is indicated in the two-line backlit LCD display (2x 5 digits, numeric), optionally together with the target transmitted by the control (master). Two arrows indicate the editing engineer the direction

the spindle must be turned to for aligning actual value with target. As soon as actual value is in alignment with

target and within the permitted tolerances, the target will disappear. By corresponding master parameterization

the display can be turned by 180° enabling vertical respectively horizontal installation. SPAs are networked by

M8 connector, power supply is by the same cable directly by master. SPA parameterization by master only.

indication „target“

arrows indicating the required direction for target/actual value alignment

indication „actual value“

1.3. Betriebsarten

Two operating modes are available to define the order of SPA alignment within the network.

Direct mode: The master will enable the SPAs in successive order for the positioning operation.

Interactive mode: The master will enable all SPAs respectively all SPAs in one group. The processing order

a) Direct mode:

In „direct mode“ the master will transmit the motor start signal (command „D“) to a specific SPA which is first to

be aligned by power tool. The red status LED is flashing fast (at approx. 2 Hz) while the relevant IR positioning

data are being transmitted to the power tool. After the positioning operation the LED switches to green continuous what is recognized by the master when reading out the status flag (command „CX“ or „F“). Now the master

will transmit the motor start signal to the next SPA. This procedure will repeat until all SPAs have been aligned.

The order allows for individual alteration upon every profile change.

b) Interactive mode:

In „interactive mode“, the operator defines the order of SPA alignment.

Instead of transmitting the motor start signal (command „D“) to a specific SPA, the master will address all SPAs

in one group by broadcast command (address 99). The red status LEDs of all addressed SPAs is flashing slowly (at approx. 1 Hz). Now the SPAs are enabled for alignment but so far no positioning data have been transmitted to the power tool via the IR interface. The operator chooses one of the slowly flashing SPAs and pushes

one of its buttons. The red LED is now flashing rapidly (at approx 2 Hz) while this SPA is transmitting the IR

data. Once the aligning operation has been completed, the LED switches to green continuous. The operator

turns to the next SPA with a slowly flashing LED and will repeat the procedure until all SPAs have been aligned.

An already activated SPA (LED flashing fast) is set back to stand-by when pressing the button anew. The LED

is flashing slowly again and IR data transmission is aborted.

In group alignment operations, both modes can be combined. Example:

Firstly all Multicon AccuDrive devices are enabled for positioning by broadcast command, the order of alignment

is up to the operator .As soon as each SPA of group 1 is „in position“, the master will proceed with the next

group in direct mode.

in the alignment operation must be defined by the operator.

www.baumer.com 3

Page 4

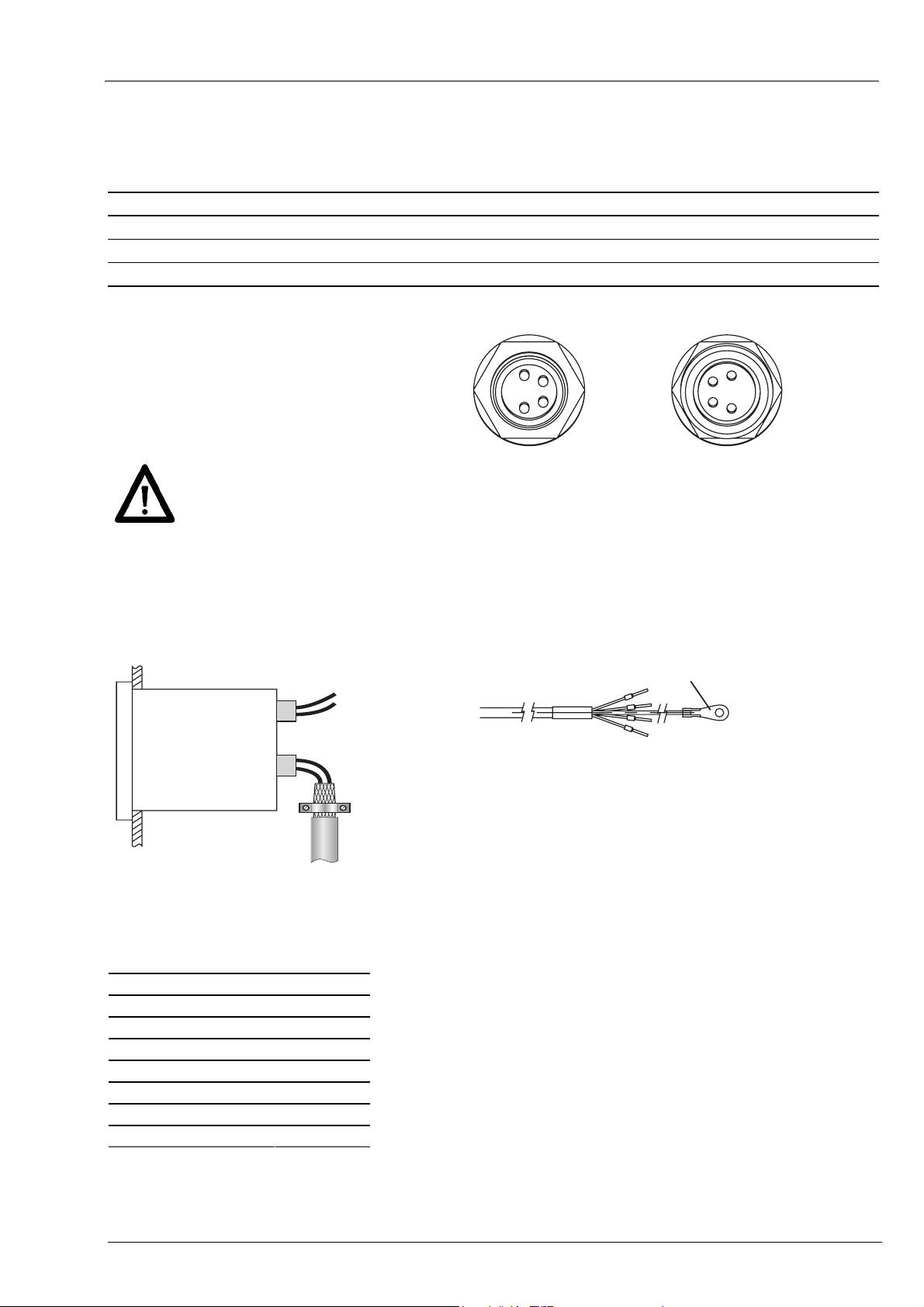

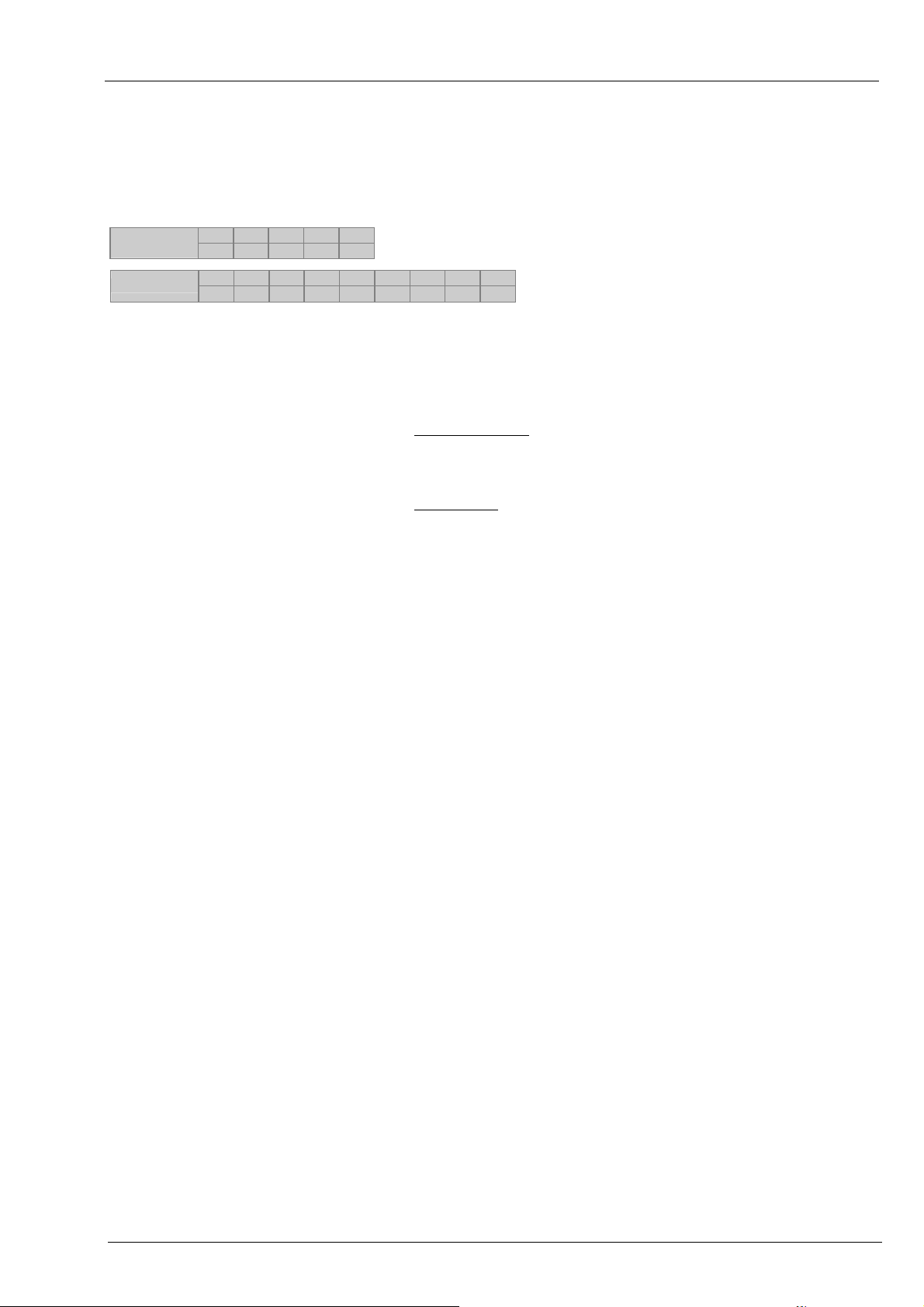

2. Terminal assignment

Pin Assignment Core colour DIN47100

Pin 1 Tx/Rx-, RS485 white orange

Pin 2 Tx/Rx+, RS485 brown brown

Pin 3 Sensor supply +24 V yellow red

Pin 4 Sensor supply 0 V green blackk

male connector M8 female connector M8

IEC757

N 153

1

2

3

4

1

2

3

4

Connect power supply that is free from interference emission. The supply must not be used as parallel supply of drives, shields, magnetic valves, etc.

Apply DC according to the terminal assignment

Power supply: 24 VDC ±20 %

Shield

Use shielded cables only. Ground of the shield must be provided at the machine (two examples corresponding

to the cable applied, see drawings).

Abschirmungsanschluss

3. Interface

3.1. Interface data

Type: RS485

Baudrate: 19200

Parity: No

Data bits: 8

Stop bits: 1

Handshake: No

Checksum: Yes (CRC)

Timeout reply*: 0,1...60 ms

BUS switching time**: <0,1 ms

www.baumer.com 4

* To avoid bus collisions a minimum timeout reply of 1 ms (default parameter)

is to be kept, i.e. the time elapsed between transmitting the last bit of the

query until start transmitting the 1st bit of the SPA response.

The operator should see that due to the minimized timeout reply of 1 ms

the bus switching time after having transmitted the last bit must not exceed

1 ms.

The default parameter of 1 ms can optionally be altered by serial interface

in steps of 0,1 ms within the range of 0,1 ... 60 ms. Refer to command „x“

(78h).

** The BUS switching time is the time the SPA requires to be ready again for

transmission receipt after having replied to host.

Page 5

N 153

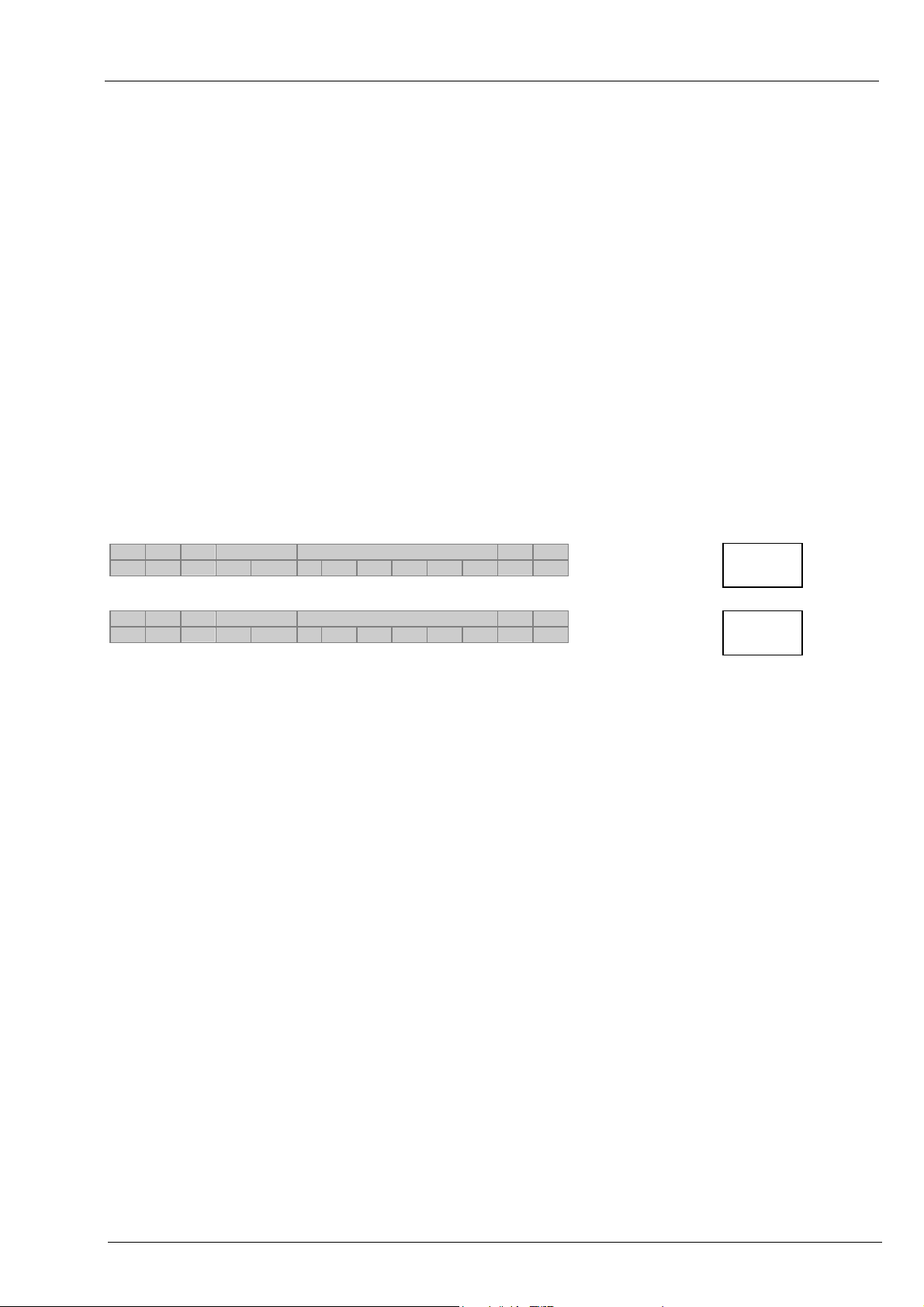

3.2. Protocol

The spindle position display operates with ASCII protocol (clear text protocol). Depending on the command, the

protocol data package varies between 5 and 17 bytes.

Byte Hex code Significance Values

1 01H SOH = start of heading permanent 01h

2 XXh Adr = identifier 00...31dez + 20h offset (identifier 00 = 20h)

3 XXh Cmd = command code specific commands

4-n [XXh..XXh] [Data] = data 20h-7Fh

n+1 04h EOT = end of transmission permanent 04h

n+2 XXh CRC = checksum 00h...FFh

3.3. Checksum (Cyclic Redundancy Check)

For optimized error-free data transmission the CRC byte is added after the footer token (EOT, end of transmission) to the string to be transmitted. Upon receiving a command the CRC byte transmitted is crosschecked with

the auto-calculated CRC byte.

Algorithm:

1) Reset CRC byte.

2) Rotate CRC byte by 1 bit to the left.

3) Link result to first data byte XOR.

4) Rotate result by 1 bit to the left.

5) Link result to the second data byte XOR.

:

x) Rotate result by 1 bit to the left.

y) Link result to the last data byte (ever 04H) XOR.

z) Add result as CRC after the footer token (04H) to the string transmitted.

Note:

1101 0000 RL 1010 0001 Important: Bit 7 is shifted in bit 0 during rotation

Example:

Transmitted string less CRC = 01h 20h 43h 04h

CRC-Byte = 0Ah

0000 0000 RL 0000 0000 XOR 0000 0001 (01h) = 0000 0001

0000 0001 RL 0000 0010 XOR 0010 0000 (20h) = 0010 0010

0010 0010 RL 0100 0100 XOR 0100 0011 (43h) = 0000 0111

0000 0111 RL 0000 1110 XOR 0000 0100 (04h) =

Legend: RL = rotate left; XOR = antivalence link

0000 1010

= CRC

3.4. Data transmission properties

For reasons of compatibility, within the complete multicon system the amount of data is always the same (see

table in chapter 6), no matter how many digits are in the display. For example, command “R” (read actual value)

comprises a transmitted data amount of 6 bytes, but only 5 digits are indicated in the display. If it is a negative

value, digit 6 respectively digit 5 is always 0 (30h).

3.5. Broadcast commands

Some specific commands are designated so-called broadcast commands. As soon as the master broadcasts a

command to identifier 99, the command is addressed to every multicon device in the network. Each individual

SPA will accomplish the respective command but will not respond any confirmation to master.

www.baumer.com 5

Page 6

N 153

3.6. Data saving

Specific parameters are saved in EEPROM (1.000.000 writing cycles). Data saving is via interface upon every

parameter transmission to SPA.

Important:

There should not be a cyclic transmission of these parameters to SPA but only if necessary, for example in

case of parameter alteration. The relevant parameters saved in EEPROM are listed in the charts in chapter

“Comand explanations” or “Overview on commands”.

3.7. Transmitting and reading negative values

The minus sign (2DHex) is always transmitted by digit 6 of the data field.

Example: Taking for granted a negative target of –1.5 and a programmed resolution of 1/10, the transmitted

value is –00015.

3.8. Transmitting and reading position values (decimal point)

Position values as for example target (command „S“), offset (command „U“) or end positions (command “g”) are

generally transmitted and read without decimal point. Visualization in the display corresponds to the format in

the data field of the interface command.

Thus, the transmission format depends on the resolution (see command „a“).

Example 1: resolution = 1/100; target = 278.50; actual value = 1.00 Display

SOH Adr Cmd Profile no=17

01h 20h 53h 31h 37h

Example 2: resolution = 1/10; target = 278.5; actual value = 1.0

SOH Adr Cmd Profile no=17

01h 20h 53h 31h 37h

30h 32h 37h 38h 35h 30h

30h 30h 32h 37h 38h 35h

Target = 278.50

Target = 278.5

EOT CRC

04h 29h

EOT CRC

04h 29h

2 7 8.5 0

1.0 0

2 7 8.5

1.0

www.baumer.com 6

Page 7

N 153

4. Command explanations

4.1. General information

The following is describing the individual interface commands broken down into the four groups below:

- operating commands [ commands required during operation ]

- parameter commands [ commands for SPA parameterization ]

- identifier commands [ commands to indicate or alter the device identifier (address)]

- specific commands [ commands for specific functions as device reset or version number readout]

The following abbreviations are applied:

SOH = start of heading (header token)

EOT = end of transmission (footer token)

Adr = device identifier, including offset 20h

Cmd = command

Sub = sub-Command

Data = data transmitted or received

CRC = checksum (cyclic redundancy check)

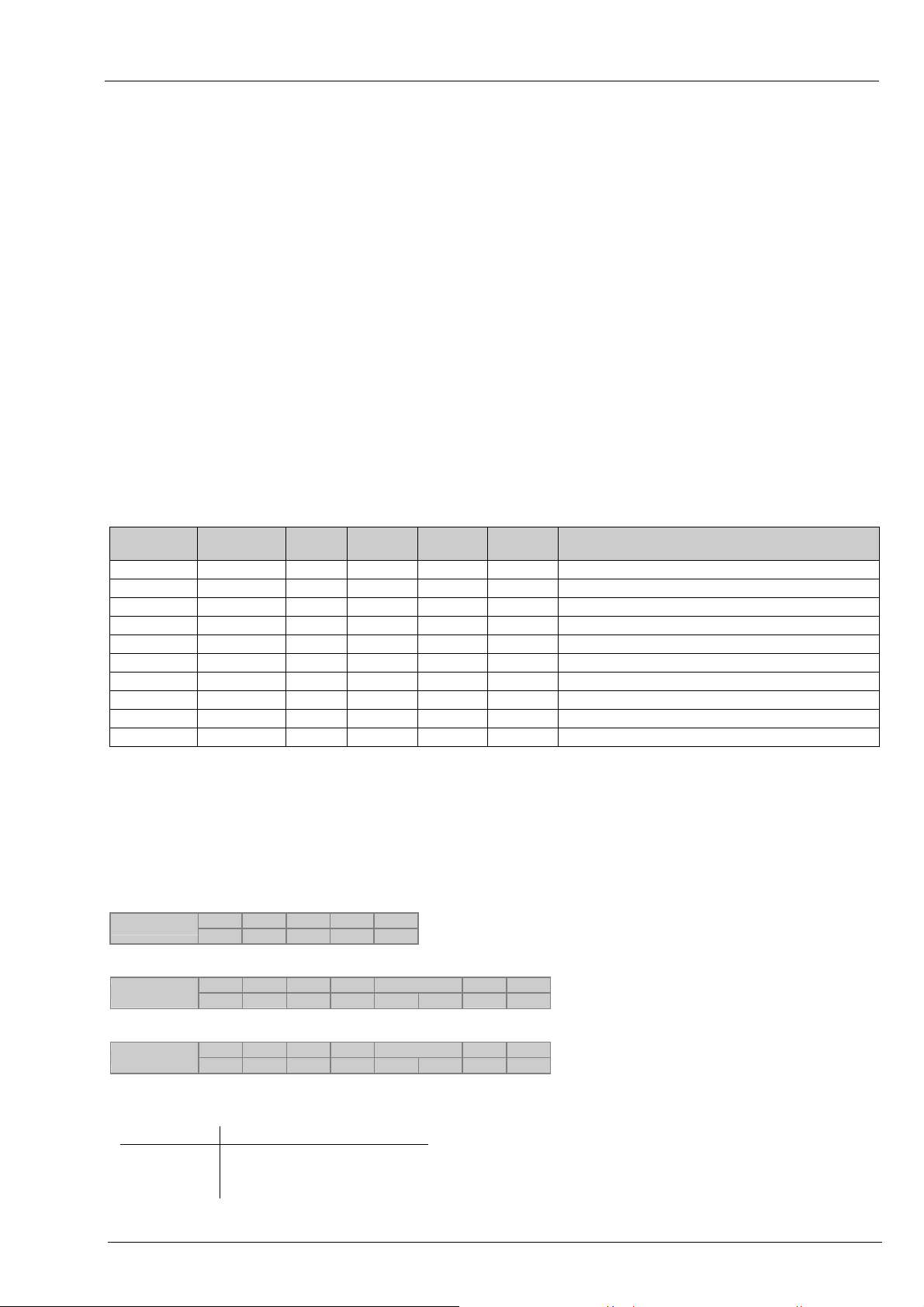

4.2. Operating commands

Command

code

C (43h) 3 / 11 X - - - Check if actual value = target

D (44h) 1 X X X - Start motor

F (46h) 4 X - - - Read device status and error

R (52h) 6 X - - - Read actual value

S (53h) 8 X X - X Read / write target

U (55h) 6 X X - - Offset

V (56h) 2 X X X X Read / write profile number

Z (5Ah) 6 X X X X Set preset

t (74h) 6 - X - - Transmit tool number

u (75h) 6 - X - - Transmit optional column of figures

4.2.1. Check Position „C“ (43h)

This command provides the alignment status of target versus actual value. If the actual value is within the target

tolerance window, the response will be „o“ (6Fh) for OK together with the current profile number. If the actual

value is outside the tolerances, „x“ (78H) followed by the current profile number will be replied. In case of any

SPA error occurred, the response will be “e” together with the active profile number.

Example: (active profile number = 05)

Transmission

Response if actual value within the tolerances:

Response

Response if actual value is outside the tolerances:

Response

Following values relating to status are possible:

Status Significance

o (6Fh) Actual value = target

x (78h) Actual value ≠ target

e (65h) SPA error

Data amount

in bytes

SOH Adr Cmd EOT CRC

01h 20h 43h 04h 0Ah

SOH Adr Cmd Status Profile no. = 05 EOT CRC

01h 20h 43h

SOH Adr Cmd Status Profile no. = 05 EOT CRC

01h 20h 43h

read write Broad-

cast

6Fh 30h 35h

78h 30h 35h

Saved in

EEPROM

04h A5h

04h 1D

Significance

www.baumer.com 7

Page 8

N 153

Command extension Check Position „CX“

Command extension „Check Position CX “provides besides the alignment status target versus current value

also the contents of the status and error register as well as the current value. The profile number is not transmitted. For the relevant status parameters (status) refer to the table above, the significance of the individual bits in

the status and error register is explained under command readout device status „F“.

Example:

Transmission

Response

SOH Adr Cmd

01h 20h 43h 58h 04h A8h

SOH Adr Cmd

01h 20h 43h

SCmd

EOT CRC

Status

Status-Reg Error-Reg Actual value = -12.50 EOT CRC

78h 80h 80h 80h 80h 2Dh 30h 31h 32h 35h 30h

04h 0Fh

4.2.2. Motor start enable „D“ (44h)

This command is utilized to read the actual SPA enable status or to set respectively clear motor start enable.

The following modes are available:

Status Significance

0 (30h) abort motor start enable, motor stops

1 (31h) start enable SPAs of group 1

2 (32h) start enable SPAs of group 2

3 (33h) start enable SPAs of group 3

There are two separate options regarding start enable. First, every SPA can be started individually. The order is

determined by host and might also relate to SPAs of other groups. Start command “D” is transmitted to the respective device identifier including group number. The status LED is flashing rapidly, indicating that the SPA is

transmitting motor control data (see also examples 1 and 2).

Second, all SPAs of one group can be started at the same time by broadcast command (ID = 99). In this case,

the status LEDs of the SPAs belonging to the respective group are flashing at the frequency of 1 Hz, but the

SPAs have not yet been transmitting any motor control data. By key actuation the operator starts control data

transmission and now the status LED is flashing rapidly (see example 3). Upon another key actuation the control data transmission is deactivated what is visualized by the status LED flashing slowly.

Example 1: Read actual motor start enable status (status = 0 = disable)

Transmission

Example 2: enable motor start in group 1

Transmission

Example 3: start enable for all motors by broadcast command (identifier=99) in group 2

Transmission

Example 4: abort start enable for all motors by broadcast command (identifier=99) (stop command)

Transmission

: : :

SOH Adr Cmd EOT CRC

01h 20h 44h 04h 04h

Response

Response

Response not confirmed

Response not confirmed

SOH Adr Cmd Stat. EOT CRC

01h 20h 44h

SOH Adr Cmd Stat. EOT CRC

01h 20h 44h

SOH Adr Cmd Stat. EOT CRC

01h 20h 44h

SOH Adr Cmd Stat. EOT CRC

01h 83h 44h

SOH Adr Cmd Stat. EOT CRC

01h 83h 44h

30h

31h

31h

32h

30h

04h 64h

04h 66h

04h 66h

04h 7Dh

04h 79h

www.baumer.com 8

Page 9

N 153

4.2.3. Read device status „F“ (46h)

This command provides the device statii Stat1 and Stat2 together with error flags Err1, Err2. In case of error

check command “C” will come with an “e” in reply.

Example:

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 46h 04h 00h

SOH Adr Cmd Stat1 Stat2 Err1 Err2 EOT CRC

01h 20h 46h

80h 80h 80h 80h

04h 4Bh

Stat1: 1 0 0 0 0 0 0 X

┬ ─────┬───── ┬

│ │ └── Motor on standby for transmission

│ │ 0 = No motor start signal. SPA does not transmit any IR data

│ │ 1 = Motor start signal.

│ │ Interactive mode

(motor start by broadcast command):

│ │ SPA is enabled for alignment by power tool, however so far there

│ │ has not been any IR data transmission. LED is flashing slowly.

│ │ Motor start is enabled using the key.

│ │ Direct mode

(motor start signal via device address):

│ │ SPA is enabled for alignment by power tool, IR data are being

│ │ transmitted. LED is flashing.

│ └───────── reserved

└──────────────── ever 1

Stat2: 1 0 0 0 0 0 0 X

┬ ─────┬───── ┬

│ │ └── 1 = Motor is running (Moving Bit). The bit is set during motor start

│ │ enable. LED is flashing rapidly.

│ └───────── reserved

└──────────────── ever 1

Err1: 1 0 0 0 0 0 X X

┬ ──┬── ┬ ┬ ┬ ┬

│ │ │ │ │ └── 1 = Err 8 - target > MAX limit position (motor does not start)

│ │ │ │ └──── 1 = Err 9 - target < MIN limit position (motor does not start)

│

│ │ └────── reserved

│ │ └──────── reserved

│ └──────────── reserved

└──────────────── ever 1

Err2: 1 0 0 X 0 0 X X

┬ ┬ ┬ ┬ ┬ ┬ ┬ ┬

│ │ │ │ │ │ │ └── 1 = Err 1 - hurt MAX limit position

│ │ │ │ │ │ └──── 1 = Err 2 - hurt MIN limit position

│ │ │ │ │ └────── reserved

│ │ │ │ └──────── reserved

│ │ │ └────────── 1 = Err 5 – target not achieved

│ │ └──────────── reserved

│ └──────────────

reserved

└──────────────── ever 1

www.baumer.com 9

Page 10

N 153

4.2.4. Read actual value „R“ (52h)

This command is for reading the 5-digit actual value (bottom display). Data amount is always 6 bytes. In case of

a negative value, the minus sign (2Dh) together with 5 data bytes is replied. Positive values are represented by

6 data bytes without sign. Values inferior to 5(4) digits will come with preceding zeroes. Please note that N 153

provides a 5-digit actual value.

Example: Actual value = -32.50

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 52h 04h 40h

SOH Adr Cmd Actual value = –32.50 EOT CRC

01h 20h 52h

2Dh 30h 33h 32h 35h 30h

04h 54h

4.2.5. Read / write target (profile) „S“ (53h)

This command is utilized to read the presently active target (profile value) respectively to read or write a specific

target. Data are composed by profile number (2 bytes) and target (6 bytes). Note: Negative targets are transmitted as 5-digit number (see example 3). Please consider that SPA targets comprise 5 digits only.

Example 1: Read active target (profile number = 12; target = 12.50)

Transmission

Response

Response upon clearing all targets:

Response

Example 2: Read specific target (profile number = 17; target = 12.50)

Transmission

Response

Example 3: Write specific target (profile number = 17; target = -12.50)

s

Transmission

Response

Note: Instead of command „S“ also command „SP“ may be utilized. The function is fully identical to command

“S”. In case command SD is utilized it might be easier to apply command SP due to their identical protocol

length. Please consider that with anterior or other multicon devices command „SP“ maybe is not available.

Example 4: As in example 3 but utilizing command „SP“

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 53h 04h 2A

SOH Adr Cmd Profile no. = 12 Target = 12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Profile no= FFh Target = FFFFFFh EOT CRC

01h 20h 53h

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 20h 53h

SOH Adr Cmd Profile no. = 17 Target = 12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Profile no. = 17 Target = -12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Profile no. = 17 Target = -12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Sub Profile no.=17 Target = -12.50 EOT CRC

01h 20h 53h

SOH Adr Cmd Sub Profile no.=17 Target = -12.50 EOT CRC

01h 20h 53h

31h 32 30h 30h 31h 32h 35h 30h

3Fh 3F 3Fh 3Fh 3Fh 3Fh 3Fh 3Fh

31h 37h

31h 37h 30h 30h 31h 32h 35h 30h

31h 37h 2Dh 30h 31h 32h 35h 30h

31h 37h 2Dh 30h 31h 32h 35h 30h

31h 37h 2Dh 30h 31h 32h 35h 30h 04h 29h

50h

31h 37h 2Dh 30h 31h 32h 35h 30h 04h 29h

50h

04h 16h

04h 3E

04h 2Ah

04h BCh

04h FBh

04h FBh

www.baumer.com 10

Page 11

N 153

Direct positioning „SD“

This command may be utilized for direct positioning operations. Only the target less any profile number is transmitted to SPA. The profile number after the command “S” is replaced by sub command “D” ( = dimension). Motor start enable requires transmitting in addtion motor start command “D”.

Example 4: Write position value for direct positioning operation (less profile)

Transmission

Response

SOH Adr Cmd Sub Position value = 278.25 EOT CRC

01h 20h 53h

44h 30h 32h 37h 38h 32h 35h

04h 6Bh

SOH Adr Cmd Sub Position value = 278.25 EOT CRC

01h 20h 53h

44h 30h 32h 37h 38h 32h 35h

04h 6Bh

Note: The position value is saved in the non-volatile memory and will be retained in case of power failure. In this

case the previously selected profile is utilized again.

Transmitting targets with simultaneous motor start signal

Specific applications require autonomous re-alignment of shafts to the new target when it is received without

prior enable signal by command „D“. For this intention the following commands are available:

SPF transmits to SPA profile number together with motor start signal for automated positioning operations

SDF transmits to SPA position value together with motor start signal for automated positioning operations

The addressed SPA is enabled by adding sub-command „F“ to the respective basic command. Since it is a pure

individual positioning operation, defined groups are not affected. Collision prevention is up to the operator.

Example: Write specific target utilizing command „SPF“ (profile number = 17; target = -12.50)

Transmission

Response

SOH Adr Cmd Sub1 Sub2 Profile=17 Target = -12.50 EOT CRC

01h 20h

53h 50h 46h

31h 37h 2Dh 30h 31h 32h 35h 30h 04h A0h

SOH Adr Cmd Sub1 Sub2 Profile=17 Target = -12.50 EOT CRC

01h 20h

53h 50h 46h

31h 37h 2Dh 30h 31h 32h 35h 30h 04h A0h

4.2.6. Read / write offset „U“ (55h)

This command is utilized to read or write the offset that is added to the true actual value. First however the function must be enabled in command bit parameter ‚a’ (61h).

Example 1: Read offset

Transmission

Example 2: Write offset

Transmission

Response in both examples:

Response

SOH Adr Cmd EOT CRC

01h 20h 55h 04h 26h

SOH Adr Cmd Data (offset = –20.00) EOT CRC

01h 20h 55h

2Dh 30h 32h 30h 30h 30h

04h C3h

SOH Adr Cmd Data (offset = –20.00) EOT CRC

01h 20h 55h

2Dh 30h 32h 30h 30h 30h

04h C3h

4.2.7. Read / write profile number „V“ (56h)

This command is utilized to read the number of the presently active profile respectively for profile alteration.

Example 1: Read active profile (active profile number = 38)

Transmission

Response

Response after reset upon having cleared all profiles:

Response

SOH Adr Cmd EOT CRC

01h 20h 56h 04h 20h

SOH Adr Cmd Profile no. = 38 EOT CRC

01h 20h 56h

33h 38h

04h 28h

SOH Adr Cmd Profile no. = FF EOT CRC

01h 20h 56h

3Fh 3Fh

04h 16h

www.baumer.com 11

Page 12

N 153

Example 2: Transmit new profile (new profile number = 17)

Transmission

Response

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 20h 56h

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 20h 56h

31h 37h

31h 37h

04h 3E

04h 3E

Example 3: New profile by broadcast command to all SPAs (identifier = 99 (83h); new profile number = 17)

Transmission

Response Not confirmed

SOH Adr Cmd Profile no. = 17 EOT CRC

01h 83h 56h

31h 37h

04h 04

To check whether the new profile has been adopted by all SPAs utilize check command „C“ (43h).

4.2.8. Set actual value as preset „Z“ (5Ah)

Command “Z” is utilized to set the actual value at any optional value. The required position value is transmitted

to the SPA. The SPA will calculate a so-called “preset offset” value relating to the true absolute encoder position. When calculating the preset offset, any programmed offset transmitted by command “U” will be considered,

so that after having accomplished command “Z” the current value always equals the preset.

Note: If the resolution is altered (see command “a”) from 1/100 to 1/10 or vice-versa, the previously programmed preset has to be set anew. The auto-calculated offset is provided in the previously selected resolution.

The actual value displayed is composed as follows:

actual value

Immediately after having accomplished command „Z“ applies preset value = current valuet-

displ

Current value

Current value

actual value indicated in the display and read out by interface

displ

internal absolute actual value (not corresponding to the transmitted preset value).

abs

Preset offset offset generated by command „Z“.

Offset Additional offset enabled by command „U“. This function must be enabled first in command

bit parameter ‚a’ (61h), otherwise the offset is 0.

Example 1: Read out presently active preset value

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 5Ah 04h 38h

SOH Adr Cmd Preset value = 2.50 EOT CRC

01h 20h 5Ah

30h 30h 30h 32h 35h 30h

Example 2: Set actual value as preset value (preset value = 17.25)

Transmission

Response

SOH Adr Cmd Preset value = 17.25 EOT CRC

01h 20h 5Ah

SOH Adr Cmd Preset value = 17.25 EOT CRC

01h 20h 5Ah

30h 30h 31h 37h 32h 35h

30h 30h 31h 37h 32h 35h

Example 3: Set actual value as preset at all SPAs by broadcast command

Transmission

Response Not confirmed

SOH Adr Cmd Preset value = 17.25 EOT CRC

01h 83h 5Ah

30h 30h 31h 37h 32h 35h

= actual value

displz

+ preset offset + Offset

abs

04h 27h

04h 09h

04h 09h

04h AAh

www.baumer.com 12

Page 13

N 153

4.2.1. Indicate optional column of figures in upper line „t“ (74h)

This command is utilized to indicate a 5-digit number in the upper line of the display. The numerical column is

indicated less dot respectively comma. Preceding zeroes as well as both arrows are suppressed. The bottom

line still indicates the actual value.

The numerals are indicated in the display until any command except „t“, „u“ or „R“ is received. The number will

be retained after power failure.

Example: (Column of figures = 054321)

Transmission

Response

SOH Adr Cmd Column of figures = 054321 EOT CRC

01h 20h 74h

SOH Adr Cmd Column of figures = 054321 EOT CRC

01h 20h 74h

30h 35h 34h 33h 32h 31h

30h 35h 34h 33h 32h 31h

04h C6h

04h C6h

4.2.2. Indicate optional column of figures in bottom line „u“ (75h)

The command utilized to indicate a 5-digit column of figures in the bottom line of the display. The number is indicated less dot respectively comma. Preceding zeroes as well as both arrows are suppressed. The upper line

still indicates actual target or the column of figures.

The column is indicated until any optional command except „t“, „u“ or „R“ is received by the interface. The number will be retained after power failure.

Example: (Column of figures = 012345)

Transmission

Response

SOH Adr Cmd Column of figures = 012345 EOT CRC

01h 20h 75h

SOH Adr Cmd Column of figures = 012345 EOT CRC

01h 20h 75h

30h 31h 32h 33h 34h 35h

30h 31h 32h 33h 34h 35h

04h B6h

04h B6h

Note:

Command “t” in conjunction with command “u” enables indication of a 10-digit number.

Both columns are not saved in EEPROM.

4.3. Parameter commands

Command

clode

a (61h) 5 X X - X Read / wriete parameters

b (62h) 8 X X - X Parameter: tolerance compensation, window

c (63h) 8 X X - X Parameter: scaling factor of spindle pitch

g (67h) 12 X X - X Parameter: limit positions MIN, MAX

h (68h) 12 X X - X Parameter: Motor speed switching points

i (69h) 1 X X X X Parameter: mm / inch

j (69h) 3 X X X X Parameter: timeout window bus error

k (6Bh) 9 X X - X Parameter: motor system times

m (6Dh) 5 X X - X Read / write general parameters

Data amount

in bytes

read write Broad-

cast

Saved in

EEPROM

Significance

www.baumer.com 13

Page 14

N 153

4.3.1. Read / write bit parameters „a“ (61h)

To exploit maximum memory capacity, several parameters are put together and transferred as “data pack” under the following parameter codes:

Data1: 1 0 X X 0 X 0 X

┬ ──┬── ─┬─ ─┬─

│ │ │ └─── positioning direction 0/1 (UP/DOWN)

│ │ └─────── counting direction 0/1 (UP/DOWN)

│ └──────────── arrows 0/1/2/3 (UP/DOWN/UNI/OFF)

└──────────────── 1

Data2: 1 0 0 X X X 0 X

┬ ┬ ─┬─ ┬ ┬ ─┬─

│ │ │ │ │ └─── round actual value 0/1 (OFF/ON)

│ │ │ │ └────── turn display 0/1 (OFF/ON)

│ │ │ └──────── dimension 0/1 (OFF/ON)

│ │ └─────────── offset 0/1 (OFF/ON)

│ └────────────── reserved

└──────────────── 1

Data3: 1 0 0 0 0 X X X

┬ ───┬─── ┬ ─┬─

│ │ │ └─── hide target 0/1/2 (ON/OFF/EVER)

│ │ └────── resolution 0/1 (1/100;1/10)

│ └─────────── reserved

└──────────────── 1

Data4/5: 0 0 1 1 0 0 0 0

───┬───

└───── reserved

Important: Only bits marked ‘X’ may be altered. The permanent parameters „1“ and „0“ must not be altered

since this might create a control token ( tokens <20h) what is not permitted in ASCII protocol.

Example 1: read bit parameter (data1 to data3 = 80h; data4 to data5 = 30h)

Transmission

Response

Example 2: write bit parameter (positioning direction = down; turn display = On)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 61h 04h 4E

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 61h

80h 80h 80h 30h 30h

81h 84h 80h 30h 30h

81h 84h 80h 30h 30h

04h F1

04h 91h

04h 91h

bit parameter default

www.baumer.com 14

Page 15

N 153

Significance of parameter „a“

Positioning direction

This parameter defines the direction the target is aimed for. Tolerances that occur for example at cogwheels,

joints, shafts etc during a precise positioning operation requires a tolerance compensation. The tolerance compensation is proceeded by aiming for the target position always from the same direction utilizing so-called loops.

Loops mean that the target position is first crossed by a defined distance and then aimed for again from the opposite direction. The parameter for the crossing distance is programmed by command “b”. Whether a loop is required or not is indicated by the arrows in the display. A flashing arrow means tolerance compensation required.

Upon reaching the turning point the direction changes and the arrow stops flashing. Targets allowing direct positioning are marked by a non-flashing arrow. Upon achieving the target within the programmed tolerances (see

command “b”) the arrows will not disappear until the required tolerance compensation has been completed.

00 = Up 00 = Up

01 = Down 01 = Down

Counting mode

This parameter assigns either „ascending“ or „descending” counted values in relation to the shaft’s direction of

rotation. Following parameters are available:

00 = Up Clockwise rotation, ascending counted values

01 = Down Clockwise rotation, descending counted values

Arrows

This parameter relates to the arrows in the display that indicate the operator the direction (to the right or to the

left, up/down) of the new positioning operation. Following parameters are available:

00 = Up If actual value < target = arrow to the right; actual value > target = arrow to the left

01 = Down As „Up“, but inverted arrows direction

10 = Uni If actual value ≠ target arrows ever indicated

11 = Off Arrows ever hidden

Note: A loop operation (as backlash compensation) is only performed with settings Up and Down. Uni and Off

always implicate a direct movement to the target without backlash compensation.

Rounding the actual value

This means that the actual value being within the tolerances but still differing from the target is rounded up or

down to the target value as soon as the shaft remains idle for approx. 3 seconds. The rounding operation is only

visual, the true internal actual value remains unchanged. For actual value readout by serial interface (command

“R”) the true, not rounded actual position value is provided. The true actual value will immediately reappear on

the display upon actuating a key. If the position is still within the tolerance window the rounding operation will be

repeated after 3 seconds.

Note: In operating mode „Suppress target = Ever“ the target is deactivated and the SPA serves as pure actual

value display with disabled rounding function. The following parameters are available:

0 = Off Round actual value disable

1 = On Round actual value enable

Turn display

This parameter is utilized to turn the display by 180°.

0 = Off Display readout with standard mounting, i.e. display above keypad

1 = On Display readout with inverted mounting, i.e. display below keypad

Dimension

Only in conjunction with N 242 master. By this parameter the master enables indication of actual value and direct positioning (so-called dimension). Refer also to N 242 user manual.

Utilized with other controls (PLC or PC) this parameter may be assigned to general identifications.

0 = Off Device not indicated in N 242 master

1 = On Device indicated in N 242 master. Direct target input possible

www.baumer.com 15

Page 16

N 153

Offset

Command „U“ is utilized for programming the offset that is added to actual value and actual target. This parameter defines whether the offset is considered in the calculation.

0 = Off Offset disabled. Any offset previously transmitted is NOT added neither to actual value nor

taget.

1 = On Offset enabled. Offset is added to actual value and actual target.

Suppress target

This parameter defines when to indicate the target in the upper line of the display.

0 = On Target indicated if target ≠ current value.

1 = Off Target ever indicated, also if target = current value. Indicate arrows too if target ≠ current value.

2 = Ever Target and arrows ever suppressed.

Resolution

This parameter defines the resolution of the actual value. Upon altering the resolution the decimal point is

shifted correspondingly by one digit to the right or left, same applies also to actual value and target. The target

values however are not converted correspondingly but only the decimal point is shifted. When editing the machine please pay attention to defining the resolution first so that the target values are transmitted to the SPAs

with the corresponding resolution.

0 Resolution 1/100 mm resp. 1/1000 inch visualized in display: 000.00 mm resp. 00.000 inch

1 Resolution 1/10 mm resp. 1/100 inch visualized in display: 0000.0 mm resp. 000.00 inch

www.baumer.com 16

Page 17

N 153

4.3.2. Read / write bit parameter motor „m“ (6Dh)

To exploit maximum memory capacity, several parameters are put together and transferred as “data pack” under the following parameter codes:

Data1: 1 0 0 0 0 X 0 X

┬ ──┬── ─┬─ ─┬─

│ │ │ └─── TASTE key assignment 0/1 (UP/DOWN)

│ │ └─────── RICHTG motor direction 0/1 (UP/DOWN)

│ └──────────── reserved

└──────────────── 1

Data2: 1 0 X X 0 0 0 0

┬ ──┬── ┬ ──┬──

│ │ │ └──── reserved

│ │ └──────── reserved

│ └──────────── shaft type 0/1 (R/A)

└──────────────── 1

Data3: 1 0 0 0 0 X X X

┬ ┬ ─┬─ ┬ ──┬──

│ │ │ │ └──── GROUP 0 – 7 (group1/group2/…/group8)

│ │ │ └──────── reserved

│ │ └─────────── reserved

│ └────────────── reserved

└──────────────── 1

Data4/5: 0 0 1 1 X X X X 0 0 1 1 X X X X

───────┬─────── ───────┬───────

│ └──────── reserved

└─────────────────────────── reserved

Important: Only bits marked ‘X’ may be altered. The permanent values „1“ and „0“ must not be altered since

thereby a control token ( tokens < 20h) might be created what is not permitted in ASCII.

Example 1: read bit parameter (data 1 to data 3 = 80h; data 4 to data 5 = 30h)

Transmission

Response

Example 2: write bit parameter (key assignment = down; motor direction = Down)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 6Dh 04h 56h

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 6Dh

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 6Dh

SOH Adr Cmd Data1 Data2 Data3 Data4 Data5 EOT CRC

01h 20h 6Dh

80h 80h 80h 30h 30h

81h 84h 80h 30h 30h

81h 84h 80h 30h 30h

04h F2h

04h 92h

04h 92h

Bit parameter default

www.baumer.com 17

Page 18

N 153

Significance of parameter „m“

Key assignment

This parameter assigns a specified direction of rotation to a certain key. For the mounting option “keypad below

display” and the remaining default parameters applies the following:

0 = Up left/right key actuation = shaft rotation ccw/cw, counting mode UP/DOWN

1 = Down left/right key actuation = shaft rotation cw/ccw, counting mode UP/DOWN

Motor direction of rotation

The parameter “motor direction of rotation” enables inversion of the two output signals for motor ccw (pin B) and

motor cw (pin C) provided at the motor cable.

0 = Up Standard direction of rotation

1 = Down Inverted direction of rotation

Shaft type

The shaft type parameter assigns the shaft type.

Some applications may call for different treatment of radially and axially operated shafts what is already taken

into consideration when utilizing the IVO master. For example, only certain shafts shall be displayed in DIM

mode. Other controls (for example PLC or PC) may utilize this parameter for general assignments.

0 = R Shaft type R

1 = A Shaft type A

Groups

Parameter for division in groups. Individual SPAs can be bundled to 8 different groups to be started in successive order group by group (command „D“) in order to prevent collisions.

0 = group 1

Start command „D“ must comprise the designated group number to start the respective group.

1 = group 2

: :

7 = group 8

4.3.3. Read / write spindle tolerance compensation and window „b“ (62h)

This command is utilized to read or write the parameters tolerance compensation and tolerance window.

Example 1: Read parameter (tolerance compensation = 0.50; tolerance window = 0.25)

Transmission

Response

Example 2: Write parameter (tolerance compensation = 1.30; tolerance window = 0.75)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 62h 04h 48h

SOH Adr Cmd tolerance compensation=0.5 tolerance window =0.25 EOT CRC

01h 20h 62h

SOH Adr Cmd tolerance compensation =1.30 tolerance window =0.75 EOT CRC

01h 20h 62h

SOH Adr Cmd tolerance compensation =1.30 tolerance window =0.75 EOT CRC

01h 20h 62h

30h 30h 35h 30h 30h 30h 32h 35h

30h 31h 33h 30h 30h 30h 37h 35h

30h 31h 33h 30h 30h 30h 37h 35h

04h 0Bh

04h 1Eh

04h 1Eh

www.baumer.com 18

Page 19

N 153

4.3.4. Read / write spindle pitc (scaling factor) „c“ (63h)

This command is utilized to read or write the scaling factor relating to the spindle pitch within the range from

0,0000001...9,9999999. The decimal point is not transmitted.

Resolution per turn is 1440 steps. A scaling factor of 1.000000 will increase respectively decrease the indicated

value by 14.4 mm.

How to calculate the scaling factor:

Resolution per turn: 14.40 mm (corresponding to length with scaling factor 1.0000000)

Spindle pitch: 4.00 mm

Spindle pitch 4.00

scaling = ───────────────── = ───── = 0.2777777

resolution per revolution 14.40

Example 1: Read scaling (scaling factor = 1.000000)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 63h 04h 4Ah

SOH Adr Cmd Scaling factor = 1.0000000 EOT CRC

01h 20h 63h

31h 30h 30h 30h 30h 30h 30h 30h

04h 4B

Example 2: Write scaling (scaling factor = 0.2777777)

Transmission

Response

SOH Adr Cmd Scaling factor = 0.2777777 EOT CRC

01h 20h 63h

30h 32h 37h 37h 37h 37h 37h 37h

04h 30h

SOH Adr Cmd Scaling factor = 0.2777777 EOT CRC

01h 20h 63h

30h 32h 37h 37h 37h 37h 37h 37h

04h 30h

4.3.5. Read / write limit positions „g“ (67h)

This command is utilized to read or write the MIN and MAX limit positions within the range from -999.99 to

9999.99. The decimal point is not transmitted.

Example 1: Read limit positions (MIN = 15.00; MAX = 850.25)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 67h 04h 42h

SOH Adr Cmd MIN limit position = 0015.00 MAX limit position = 0850.25 EOT CRC

01h 20h 67h

30h 30h 31h 35h 30h 30h 30h 38h 35h 30h 32h 35h

04h 1Fh

Example 2: Write limit positions (MIN = -33.22; MAX = 1234.56)

Transmission

Response

SOH Adr Cmd MIN limit position = -033.22 MAX limit position = 1234.56 EOT CRC

01h 20h 67h

2Dh 30h 33h 33h 32h 32h 31h 32h 33h 34h 35h 36h

04h 92h

SOH Adr Cmd MIN limit position = -033.22 MAX limit position = 1234.56 EOT CRC

01h 20h 67h

2Dh 30h 33h 33h 32h 32h 31h 32h 33h 34h 35h 36h

04h 92h

4.3.6. Read / write motor speed switching points „h“ (68h)

This command is utilized to read or write the motor speed switching points. Prior to reaching the target the motor speed can be slowed down for high-precise target positioning. Furthermore it is possible to set the motor

switch-off point at a designated value relating to the target. The following two parameters are defined:

The individual switching points are indicated in relation to the target.

Example 1: Read parameter (precision speed = 0.70; switchoff point = 0.02)

Transmission

Precision speed: point where SPA changes from high speed to precision speed.

Switch off point: Position where motor is stopped by SPA .

SOH Adr Cmd EOT CRC

01h 20h 68h 04h 5Ch

Response

SOH Adr Cmd reserved Precision speed =0.70 Switchoff point =0.02 EOT CRC

01h 20h 68h

30h 30h 30h 30h 30h 30h 37h 30h 30h 30h 30h 32h

04h 66h

www.baumer.com 19

Page 20

N 153

Example 2: Write parameter (precision speed = 0.50; switch off point = 0.01)

Transmission

00

Response

SOH Adr Cmd reserved Precision speed =0.50 Switchoff point =0.01 EOT CRC

01h 20h 68h

30h 30h 30h 30h 30h 30h 35h 30h 30h 30h 30h 31h

04h E0h

SOH Adr Cmd reserved Precision speed =0.50 Switchoff point =0.01 EOT CRC

01h 20h 68h

30h 30h 30h 30h 30h 30h 35h 30h 30h 30h 30h 31h

04h E0h

4.3.7. Read / write measuring unit „i“ (69h)

The command is utilized to read or write the measuring unit in mm or inches.

Data = 0 (30h) = mm

Data = 1 (31h) = inch

Example 1: Read parameter (setting = mm)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 69h 04h 5E

SOH Adr Cmd Data EOT CRC

01h 20h 69h

30h

04h D0h

Example 2: Change measuring unit into inches

Transmisison

Response

SOH Adr Cmd Data EOT CRC

01h 20h 69h

31h

04h D2

SOH Adr Cmd Data EOT CRC

01h 20h 69h

31h

04h D2

Example 3: Write measuring unit mm in all SPAs by broadcast command (identifier=99)

Transmission

SOH Adr Cmd Data EOT CRC

01h 83h 69h

30h

04h CDh

Response not confirmed

Important: Parameters are programmed in mm and auto-converted by SPA into inches upon displaying the position values.

4.3.8. Read / write timeout at bus error RS485 „j“ (6Ah)

This command is utilized to read or write the system time: timeout at bus error. Value range is within 00,1 s to

99,9 s. Tolerance: ±7% at minimum time; < 1‰ at maximum time, approx. 1% at 1.

Function: RS485 bus monitoring during motive shaft positioning operations. If there is no interface activity within

the programmed timeout the motor will stop (EMERGENCY OFF) upon occurring a bus error or in case of an

inactive control. A motor restart requires transmitting the profile (command „S“ or „V“) together with the start

signal (command „D“). Setting 0.00 s means function disabled.

Example 1: Read parameter (time= 2.5 s)

Transmission

Response

Example 2: Write parameter (time = 13.5 s)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 6Ah 04h 58h

SOH Adr Cmd Time =2.5 s EOT CRC

01h 20h 6Ah

30h 32h 35h

04h C5h

SOH Adr Cmd Loop =13.5 s EOT CRC

01h 20h 6Ah

31h 33h 35h

04h C9h

SOH Adr Cmd Loop =13.5 s EOT CRC

01h 20h 6Ah

31h 33h 35h

04h C9h

www.baumer.com 20

Page 21

N 153

4.3.9. Read / write motor system times „k“ (6Bh)

This command is utilized to read or write the individual motor system times within the range of 0,1 s to 99,9 s.

Tolerance: ±7% at minimum time; < 1‰ at maximum time, approx. 1% at 1 s.

The following parameter is available:

Loop: Waiting time at turning point during loop operation

Example 1: Read parameter (loop = 1.0s)

Transmission

Response

SOH Adr Cmd EOT CRC

01h 20h 6Bh 04h 5Ah

SOH Adr Cmd Loop=1.0 s reserved reserved EOT CRC

01h 20h 6Bh

30h 31h 30h 30h 30h 30h 30h 30h 30h

04h D9h

Example 2: Write parameter (loop = 2.0s)

Transmission

Response

SOH Adr Cmd Loop=2. s reserved reserved EOT CRC

01h 20h 6Bh

SOH Adr Cmd Loop=2.0 s reserved reserved EOT CRC

01h 20h 6Bh

30h 32h 30h 30h 30h 30h 30h 30h 30h

30h 32h 30h 30h 30h 30h 30h 30h 30h

04h DAh

04h DAh

4.3.10. Read / write specific parameter „x“ (78h)

The specific parameter „x“ comprises several sub-parameters enabling alteration of originally permanent parameters to adapt them to new circumstances. Presently the following sub-parameter is available:

D (44h) = delaytime for minimized timeout reply of serial interface

Sub-Parameter: Delaytime „D“ (44h)

This parameter defines the minimum delay time (break) between the last bit received and the first bit of the response transmitted. Delay time is programmable in steps of 0,1 ms from 00.0 ... 60.0 ms, default is 1.0 ms.

Example 1: Read actual delaytime

Transmission

Response

SOH Adr Cmd Sub EOT CRC

01h 20h 78h 44h 04h 7Ch

SOH Adr Cmd Sub Delaytime = 4.5 EOT CRC

01h 20h 78h 44h

30h 30h 34h 35h

04h BBh

Example 2: Write new delaytime

Transmission

Response

SOH Adr Cmd Sub Delaytime = 15.0 EOT CRC

01h 20h 78h 44h

SOH Adr Cmd Sub Delaytime = 15.0 EOT CRC

01h 20h 78h 44h

30h 31h 35h 30h

30h 31h 35h 30h

04h BDh

04h BDh

Please not that the true delaytime might be prolonged. It depends on the required processing time as well as on

internal software cycles. Tolerance is approx. 8 ms.

4.4. Identifier (address) commands

Command

code

A (41h) 2 X X X X Assign or indicate device identifier

B (42h) 2 - - - - SPA feedback in addressing mode

Data amount

in bytes

read write Broad-

cast

Saved in

EEPROM

Significance

www.baumer.com 21

Page 22

N 153

4.4.1. Assigning device identifiers in the network „A“ (41h)

This command is creating an automated process assigning the device identifier in successive order to every

single SPA upon commissioning of the system. The first identifier to be assigned is broadcasted to all networked SPAs as follows:

Transmission

All SPAs now show the identifier just transmitted and that is to be assigned in the upper display. The bottom line

indicates the device-specific identifier.To make the SPA adopt the new identifier, the shaft must be turned by

half at least (direction does not matter). The identifier is now adopted and indicated in the bottom line of the display (as new device-specific identifier). Both identifiers are now identical. As soon as the shaft is in idle position

again and after having elapsed 3 seconds, the SPA will transmit the following command „B“ (42h) as confirmation to master:

Transmission

to master

The Master can now transmit command „A“ with the next identifier to be assigned as previously described.

This way, the different (successive) identifiers are automatically assigned to all networked SPAs, one after the

other.

Important: Confirmatory command „B“ transmitted by SPA to master will be repeated after 3 seconds provided

the master has not previously transmitted another „A“ command.

Indicate identifier in the display „A“ (41h)

This command less parameters as a broadcast command (address/Identifier=99) will make every networked

SPA indicate the device-specific identifier in the bottom line of the display. The upper line is blind.

This command is a designated broadcast command.

Transmission

Response Not confirmed

SPA remains in this mode until being switched off and on again or until transmission of another command except „A“, „R“, „t“ or „u“.

If this command is transmitted to a valid device identifier (except 99) without any parameters, the respective

SPA will return to standard operating mode and reply the actual device identifier.

Transmission

Response

Extended identifier command „AX“ (41h, 58h)

This extended command is utilized to address individual SPAs in the bus network in a similar way as described

above. By broadcast command the identifier to be assigned is transmitted to all networked SPAs as follows:

Transmission

Similar to the standard command all SPAs now indicate the identifier just transmitted which is to be assigned in

the upper display. Adopting the identifier is in the same way. However, contrary to the above there is not any

acknowledgement „B“ in reply. Checking whether the new identifier has been adopted is up to master, for example utilizing command “R” (read actual value). The R-command with the corresponding identifier is transmitted to the SPA. If the addressed SPA confirms that the assignment was successful, the master can proceed

with next identifier. Regarding other commands the display of the respective SPA switches to standard operation.

SOH Adr Cmd identifier = 01 EOT CRC

01h 83h 41h

SOH Adr Cmd identifier = 01 EOT CRC

01h 21h 42h

SOH Adr Cmd EOT CRC

01h 83h 41h 04h 80h

SOH Adr Cmd EOT CRC

01h 21h 41h 04h 0Ah

SOH Adr Cmd Identifier =01 EOT CRC

01h 21h 41h

SOH Adr Cmd Cmd2 Identifier = 01 EOT CRC

01h 83h 41h 58h

30h 31h

30h 31h

30h 31h

04h B4h

04h 86h

04h 9Eh

30h 31h

04h 40h

www.baumer.com 22

Page 23

N 153

4.5. Specific commands

Command

code

K (4Bh) - - X X X Specific command: profile reset (clear)

Q (51h) 1 - X X X Specific command: SPA reset

X (58h) 2 / 4 / 8 X - - - Specific commands

4.5.1. SPA profile reset „K“ (4Bh)

This command is clearing all previously programmed profiles.

Example 1: profile reset of a specific SPA

Transmission

Response

Example 2: profile reset in all SPAs by broadcast command (identifier=99)

Transmission

Response Not confirmed

Important: After profile reset all profile data are set to FFFFFFhex, the current profile number to FFhex.

The SPA display now is indicating 5 hyphens instead of target.

4.5.2. SPA restore default „Q“ (51h)

This command restores default either of individual or collective parameters.

Data = q (71h) = Restore default parameters

Data = t (74h) = Device identifier = 98

Data = x (78h) = Multiturn counter reset to 0. No singleturn reset possible.

Data = ∆ (7Fh) = All above functions are accomplished.

Note: No profile reset. Profile reset by command „R“.

Example 1: Restore default in specific SPA

Transmission

Response

Example 2: Restore default in all SPAs by broadcast command (identifier=99)

Transmisison

Response Not confirmed

4.5.3. Read version, type or serial number „X“ (58h)

This command is utilized to read version number, device type or serial number. The following sub-commands

are available:

Data = V (56h) = read version

Data = T (54h) = read device type

Data = S (53h) = read serial number

Data amount

in bytes

SOH Adr Cmd Data EOT CRC

01h 20h 4Bh

SOH Adr Data EOT CRC

01h 20h

SOH Adr Cmd Data EOT CRC

01h 83h 4Bh

SOH Adr Cmd Data EOT CRC

01h 20h 51h

SOH Adr Data EOT CRC

01h 20h

SOH Adr Cmd Data EOT CRC

01h 83h 51h

read write Broad-

cast

04h C6h

7Fh

04h 52h SPA replies by standard response ‚o’ (6Fh) = OK

6Fh

04h DBh

7Fh

04h AEh

7Fh

04h 52h SPA replies by standard response ‚o’ (6Fh) = OK

6Fh

04h B3

7Fh

Saved in

EEPROM

significance

www.baumer.com 23

Page 24

N 153

Example 1 : Read version number

Transmission

Response

SOH Adr Cmd Data EOT CRC

01h 20h 58h

56h

04h D8h

SOH Adr Cmd Data Version number = 2.00 EOT CRC

01h 20h 58h 56h

20h 32h 30h 30h

04h FAh

Beispiel 2: Read device type (device type = N 153; firmware = 01)

Transmission

Response

Code configuration of the transmitted device type:

1 0 0 1 0 0 1 1 1 0 0 0 0 0 0 1 = 93 81 hex

SOH Adr Cmd Data EOT CRC

01h 20h 58h

54h

04h DCh

SOH Adr Cmd Data Type EOT CRC

01h 20h 58h 54h

93h 81h

04h 26h

┬ ──────┬────── ┬ ───────┬─────

│ │ │ └─────── software no. 01h = firmware 01

│ │ └──────────────── permanent 1

│ └────────────────────────── device type 13h = N 153

└────────────────────────────────── permanent 1

Example 3: Read serial number

Transmission

Response

SOH Adr Cmd Data EOT CRC

01h 20h 58h

53h

04h D2h

SOH Adr Cmd Data Coded serial number = 07090EA4 EOT CRC

01h 20h 58h 53h

30h 37h 30h 39h 30h 3Eh 3Ah 34h

04h 20h

Code configuration of the transmitted serial number:

The Low-Nibble (lower 4 bits of a byte) of the 8 data bits received equal together a 4 byte value comprising the

serial number.

The serial number is composed by date and time of production. Since also the seconds are coded and by assigning only one number per second the serial number is unique.

Example: Serial number for 01.06.2005 16:58:36 = 15 83 0E A4 hex

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X bit position

J J J J J J M M M M T T T T T h h h h h m m m m m m s s s s s s content

0 0 0 1 0 1 0 1 1 0 0 0 0 0 1 1 0 0 0 0 1 1 1 0 1 0 1 0 0 1 0 0 Example = 15 83 0E A4 hex

─────┬───── ────┬──── ────┬──── ─────┬───── ──────┬────── ─────┬─────

│ │ │ │ │ └─────── seconds 10

│ │ │ │ └──────────────────── minutes 11

│ │ │ └───────────────────────────────── hours 1

│ │ └──────────────────────────────────────────── day 0

│ └────────────────────────────────────────────────────── month

└───────────────────────────────────────────────────────────────── year 00

│

0100 = 24h = 36d

1010 = 3Ah = 58d

0000 = 10h = 16d

0001 = 01h = 01d

0110 = 06h = 06d

0101 = 05h = 05d

01.06.05 16:58:36 <──────┘

www.baumer.com 24

Page 25

N 153

5. Error warnings

5.1. CRC error

Upon recognizing a CRC error in a transmitted command the SPA will respond as follows:

Response

5.2. Format error

Upon recognizing a format error (incorrect length of protocol or void command (Cmd) in a command transmitted

the SPA will respond as follows:

Response

5.3. Display error indication

Error warnings are visualized by a flashing upper display, indicating alternately both error signal and current

value (usually target).

SOH Adr Error EOT CRC

01h 20h 65h 04h 46h Error = „e“ (65h) = CRC error

SOH Adr Error EOT CRC

01h 20h 66h 04h 40h Error = „f“ (66h) = format error

MAX limit of SPA hurt by manual positioning operation (utilizing key)

Troubleshooting: Set SPA to the admissible positioning range.

MIN limit of SPA hurt by manual positioning operation (utilizing key)

Troubleshooting: Set SPA to the admissible positioning range.

SPA did not reach target window.

Troubleshooting: Extend the tolerance window. Set switchover to precision speed at an earlier poit.

Select a stop value that is inferior to the tolerance window.

The target transmitted resp. DIM value is exceeding the MAX limit.

Note: Take loops into consideration.

Troubleshooting: Transmit new admissible position value.

Target transmitted respectively DIM parameter is below the MIN limit.

Note: Take loops into consideration..

Troubleshooting: Transmit new admissible position value.

www.baumer.com 25

Page 26

N 153

6. Overview on commands

The following chart shows in alphabetical order all available commands (Cmd) as well as options regarding read

and write (parameterization).

Command

code

a (61h) 5 X X - X Read / write general parameters

b (62h) 8 X X - X Parameter: tolerance compensation, window

c (63h) 8 X X - X Parameter: Scaling factor spindle pitch

g (67h) 12 X X - X Parameter: limit positions MIN, MAX

h (68h) 12 X X - X Parameter: motor speed switching points.

i (69h) 1 X X X X Parameter: mm / inch

j (69h) 3 X X X X Parameter: timeout bus error

k (6Bh) 9 X X - X Parameter: motor system times

m (6Dh) 5 X X - X Read / write general parameters

t (74h) 6 - X - - Transmit tool number

u (75h) 6 - X - - Transmit optional column of figures

x (78h) 5 X X - X Read / write specific parameters

A (41h) 2 X X X X Assign or display device identifier

B (42h) 2 - - - - SPA response in addressing mode

C (43h) 3 X - - - Check if current value = target

D (44h) 1 X X X - Motor start enable

F (46h) 4 X - - - Readout device status and error

K (4Bh) - - X X X Specific command: Profile reset (clear)

Q (51h) 1 - X X X Specific command: SPA reset

R (52h) 6 X - - - Read current value

S (53h) 8 X X - X Read / write target

U (55h) 6 X X - - Offset

V (56h) 2 X X X X Read / write profile number

X (58h) 4 X - - - Specific command: read version number

Z (5Ah) 6 X X X X Set preset

Data amount

in bytes

read write Broadcast

Saved in

EEPROM

Function

www.baumer.com 26

Page 27

7. Technical data

Technical data – electrical ratings

Supply voltage 24 VDC ±10%

Power consumption <40 mA

Display LCD, 7 segment, 2 lines, backlit

Sensing principle Absolute multiturn sensing

Sensing range -99.99...+999.99 mm

-9.999...+99.999 inch

Number of steps/revolution 1440

Number of revolitions 4096 / 12 bit

Spindle pitch ≤14 mm

Interface RS485 (ASCI protocol)

Data saving Parameter buffer: EEPROM

Actual value buffer: >10 years by integrated 3 V Lithium battery

Programmable parameter Display position horizontal / vertical

Measuring unit mm/inch

Counting direction

Spindle pitch

Spindle tolerances

Positioning direction

Arrows

Tolerance window

Rounding function

Motive positioning Two softkeys with jog operation for format alignment

connected to power tool by infrared interface

Standard DIN EN 61010-1 Protection class II

Overvoltage category II

Pollution degree 2

Interference emission DIN EN 61000-6-3

Interference immunity DIN EN 61000-6-2

Approval UL/cUL

Technical data – mechanical design

Hollow shaft ø14 mm

Operating speed ≤600 rpm (short-term)

Protection DIN EN 60529 IP 65

Operating temperature -10...+50 °C

Storage temperature -20...+70 °C

Relative humidity 80 % not condensing

Torque support Torque pin provided at housing

E-connection - male/female 4-pin M8 connector

- cable output (30/ 5 cm) with male/female 4-pin M8 connector

User surface / keypad Keypad with two softkey

Housing With hollow shaft for direct shaft mount

Dimensions W x H x L 37 x 75 x 45 mm

Mounting Hollow shaft mount

Weight approx. 120 g

Material Polyamide black, UL 94V-0

N 153

www.baumer.com 27

Page 28

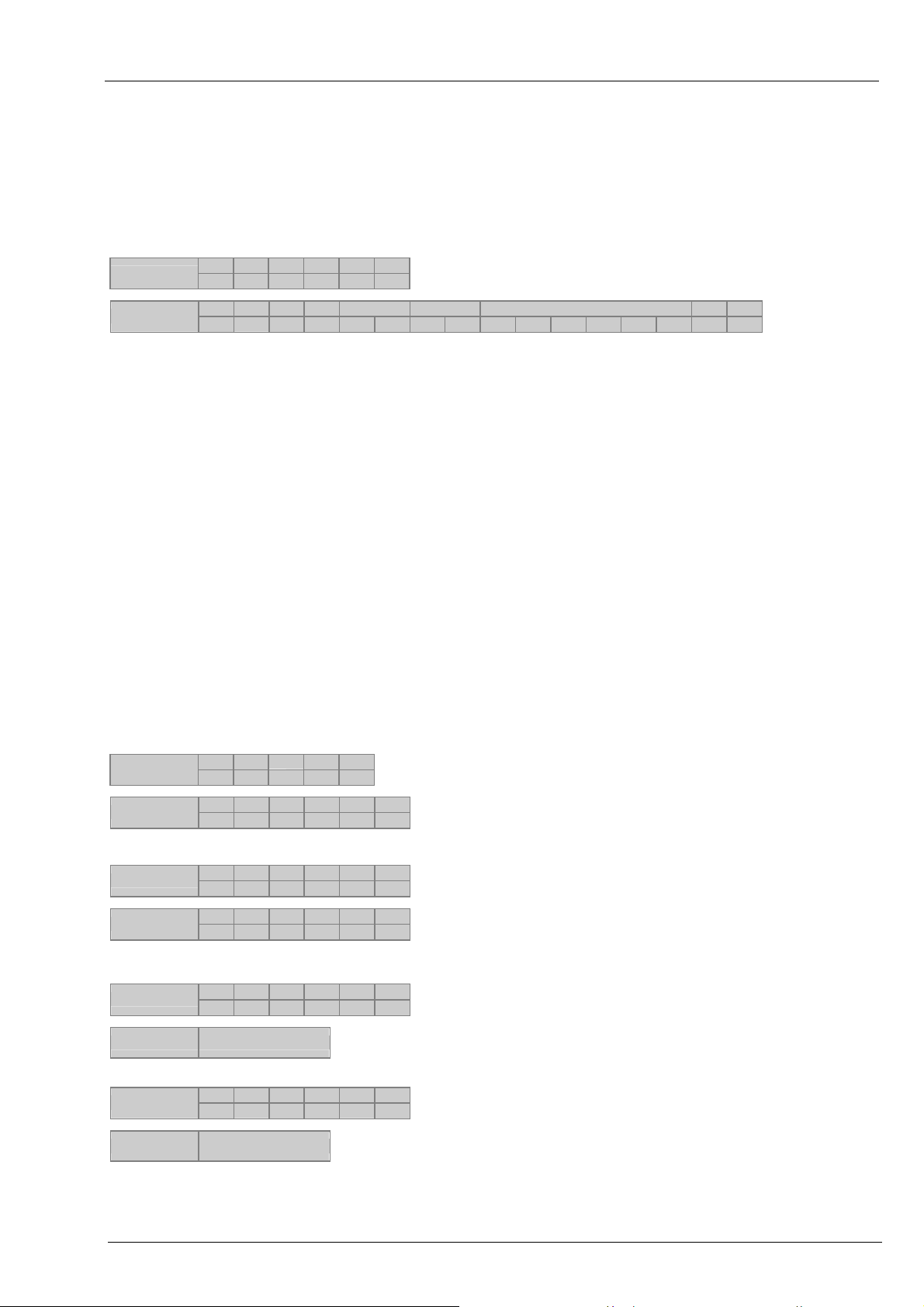

7.1. Dimensions

75°

4.8

Torque pin

N 153

Cable outputConnect or output

6

0.5x 45°

10

75

22

20.5

16

30.15

13

26

37

31.8

Pin M4

12.5

Connector

ø20

6.5

ø14H7

45

28

Seal

14

1

Female connector

2:1

IR-Diode

ø6h9

13

52

ø12

StatusLED

A

A

60

ø12

8. Part number

Reference Interface

1 RS485

E-connection

0 Connector output

1 Cable output 4-pin M8 connector

Supply voltage

3 24 VDC

Display

A At slope

Hollow shaft

A ø14 mm

N 153.1 3 A A01

150

300

M8

female

connector

M8

connector

www.baumer.com 28

Loading...

Loading...