Page 1

LSP 05X Potentiometric Level Transmitter

Safety instructions

This instrument is built and tested ac cord ing to the current EU-directives and packed in technically safe con di tion. In order to main tain this

condition and to ensure safe op er a tion, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed.

Ignoring the warnings may lead to severe per son al injury or substantial

damage to property.

The product must be op er at ed by trained staff. Correct and safe

operation of this equipment is de pend ent on proper transport, storage,

installation and op er a tion.

All electrical wiring must conform to local stand ards. In order to prevent

stray elec tri cal radiation, we rec om mend twisted and shielded input

cables, as also to keep power sup ply cables separated from the input

cables. The con nec tion must be made ac cord ing to the connecting

di a grams.

Before switching on the power supply take care that other equip ment

is not af fect ed. Ensure that the supply voltage and the conditions in the

environment comply with the spec i fi ca tion of the de vice.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

LSP051

Description

The level measuring device LSP05X utilises the potentiometric meas-

urement principle and can be used in all medias that have a minimum

conductivity of 50 µS/cm.

From the low resistive measuring rod a high frequent current is fed

through the media to the tank wall. The voltage between the tip of the

rod and the tank wall is measured. This output voltage is proportional

to the tank fi lling level.

The measurement is unaffected by temperature and adhesive media.

The instrument is ideal for measurements in small wessels with tough,

pasty or strong adhesive media, such as ketchup, honey, and tooth-

paste. The integrated electronics provide a 4...20 mA output.

WARNING

This product contains no replaceable parts.

In case of malfunction the product must be shipped to Baumer for

repair.

The LSP has automatic recognition of top/buttom mounting position.

Even angled installation is possible. In a non-conductive tank such as

a plastic tank a reference rod must be installed.

Please observe that a non-linear conductivity in the media will affect

the accuracy of the measurement.

A version with separate rod sensor and electronics is available for

applications where the ambient temperature at the measuring point

exceeds 60°C. Due to the high temperature limit the LSP050 is well

suitable for CIP and SIP processes.

The hygienic installation is guaranteed by using one of the hygienic

weld-in sleeves. (Please refer to the separate data sheet).

Installation Manualwww.baumerprocess.com

Page 1 Design and specifi cations subject to change without notice

Page 2

Mechanical Installation

Welding part

Please refer to “Accessories” data sheet. The welding part has an

engraved mark or hole. When the product has been mounted and

correctly tightened the gland or M12 plug will align with this mark.

Make sure that the gland/plug is pointing downwards to prevent fl uids

from penetrating into the instrument.

Cautions

Use only the authorised special designed accessories.

The product warranty is void when installed with other adapters.

The sensor can not be shortened.

Please be aware of the active measuring zone on the rod

(see drawing)

Do not use tefl on, paper or other gaskets.

The process connection must have electrical contact with the tank.

if not, a separate grounding cable must be installed.

If the tank is non-conductive an additional ground electrode must be

installed. This should have electrical connection to the LSP process

connection.

Make sure that the rod can not touch the tank wall even with the highest movement of the media.

When installed <100 mm from the tank wall the rod must be parallel

with the tank wall. For larger distances non-parallelity can be allowed.

After carefully insertion of the sensor into the welding part tighten the

union with a torque of 20...30 Nm.

After Installation and Confi guration

Check the leak tightness of the sleeve.

Check the tightness of glands or M12 plugs.

Check the tightness of the cover.

Check that the rod is not touching the tank wall.

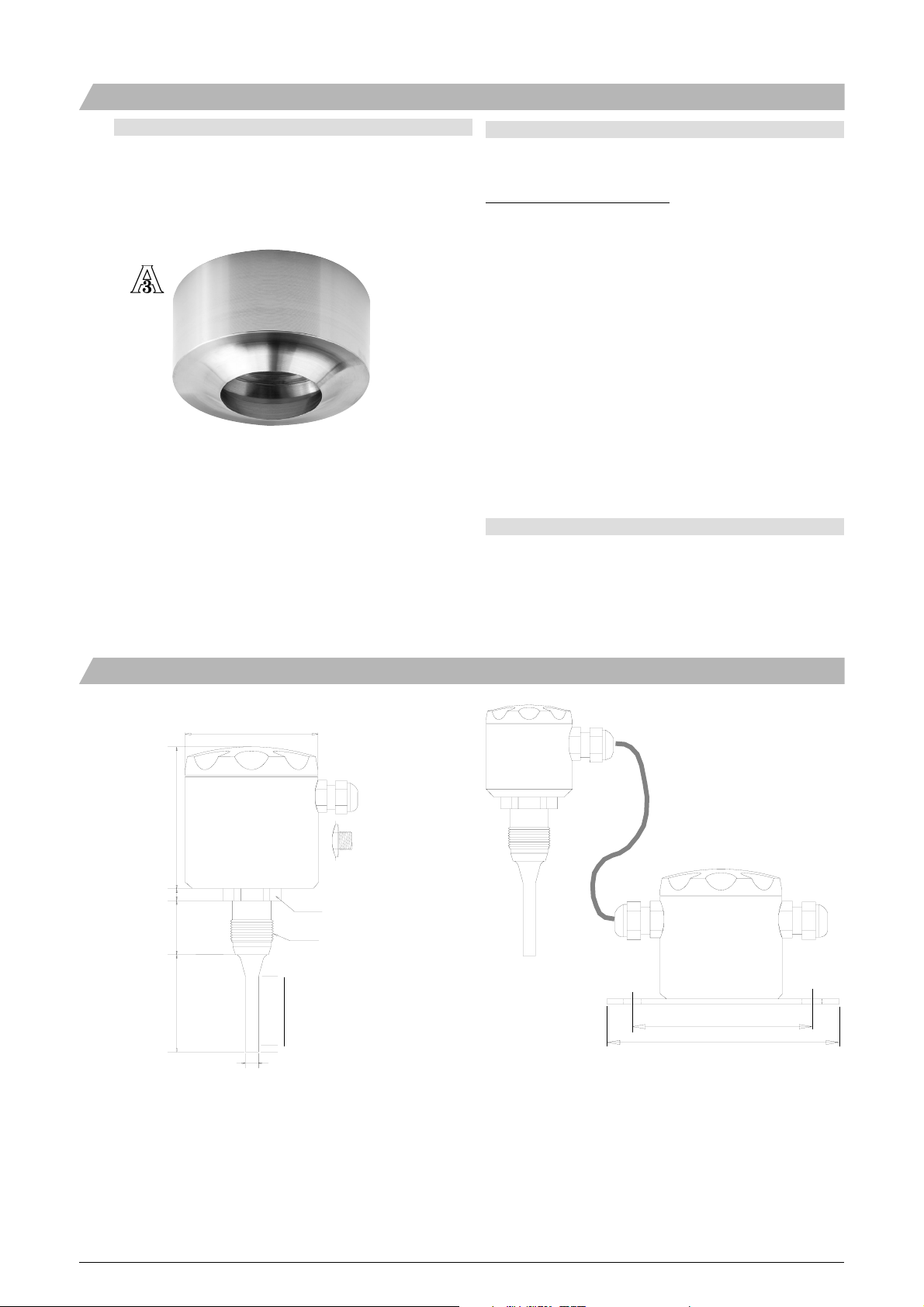

Dimensional Drawings

[mm]

ø89

Gland

92

M12 plug

8

33

L

ø10

LSP050/LSP051 - integrated electronics LSP055/LSP056 - separate electronics

AF36

G1

Active zone

5 mm

ø55 housing

Interconnection cable.

Specify length.

ø89 housing

ø8ø8

125

145

Installation Manualwww.baumerprocess.com

Page 2 Design and specifi cations subject to change without notice

Page 3

Electrical Installation

Push buttons >3 sec.

1 2 3 4

+-

18...36 Vdc

Connector LED Buttons M12 plug

+-

4...20 mA

to set 0% and 100%

Push both > 3 sec.

to reset.

Setpoint

100%; 20 mA

Setpoint

0%; 4 mA

18...36 Vdc (+) (+) 4...20 mA

1

2

4...20 mA (-)

(-)18...36 Vdc

4

3

1: Brown

2: White

3: Blue

4: Black

Operator Control

The green LED indicates that a supply voltage > 18 V with the correct

polarity is present.

The two red LEDs show different fl ashing rates according to the control

of the 4...20 mA output.

The sensor can be installed in the top or the buttom of the tank.

The sensor is calibrated for installation from the top. Then 4 mA output

corresponds to the tip of the rod, and 20 mA to the thread end.

When installed from the buttom of the tank an output excessive of 4

mA is obtained.

The sensor can be calibrated by pressing one of the two setpoint keys

for more than 3 seconds. The relevant LED will show a steady light.

With these two buttons any empty/full level can be confi gured on the

entire length of the rod.

The factory setting will be valid again by pressing both keys for more

than 3 seconds.

The “dry” signal level is adjusted together with the low level setting.

The “dry” indication is 2.4 mA output current.

Measuring Principle

Uout

to amplifi er

Ugen

100%

Caution

If different medias are used the low level adjustment should be made

with the media having the lowest conductivity.

Caution

The minus pole of the power supply is connected to the housing via a

protective diode.

However, the 4...20 mA output is galvanically isolated from the power

supply.

Theory

The liquid is stored in a ground connected tank.

The immersed level probe is a low resistance rod where the ends

are powered by an AC generator operating in the lower kiloherz

frequency range.

Between the rod and the tank wall is an endless amount of high level

resistances. Since they connect to the same potential (the tank wall)

they can be shown as two equivalent resistances, R1 and R2 con-

nected to an imaginary center point.

A high resistance input amplifi er is connected between the generator

and the tank wall.

0%

X%

R1

Since the generator is supplying a high range current it will create a

signifi cant voltage drop across the low resistance rod.

The resistances R1 and R2 form a voltage divider in range of the

immersed part of the rod. Output from this divider will indicate half

the level of the liquid. The amplifi er then calculate the actual level of

liquid from 0 to 100%.

The formula is:

Uout= 1/2 x media level (%) x Ugen

Media level (%) = Uout/Ugen x 2

R2

The level measurement is insensitive to adhesion.

Caution

It is very essential that the media conductivity is homogenious.

Otherwise R1 will not be equal to R2 and the output voltage will be

infl uenced.

Installation Manualwww.baumerprocess.com

Page 3 Design and specifi cations subject to change without notice

Page 4

Mounting of 3A Approved Products

Max. ± 85°

1)

2)

3)

Installation of 3A approved products:

1) Use only a 3A approved counter part.

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Weldings should be grinded to Ra= 0.8

4)

5)

Max. ± 175°

Refer to the data sheet “Accessories” for O-rings, gaskets and other

accessories.

The LSP 051 and LSP 056 are approved by 3A providing it is mounted

in a 3A approved counter part and installed according to the guidelines

given in the installation manual.

The 3A approved products fulfi ll the FDA demands and follow the

EHEDG guidelines regarding design, materials and fi nishing.

Refer to the 3A marked counter parts in the data sheet “Accessories”.

Example of Application

LSP Output

21.6 mA

21.6...20 mA

Set point 100% = 20 mA

5850-004_UK/2009-03-20/Rev. B1 This data sheet may only be reproduced in full.

20...4 mA

Set point 0% = 4 mA

4...2.4 mA

2.4 mA

Installation Manualwww.baumerprocess.com

Page 4 Design and specifi cations subject to change without notice

Loading...

Loading...