Page 1

LSK Conductive Level Sensor

LSK320

LSK420 LSK350

Safety Instructions

This instrument is built and tested according to the current EU-direc-

tives and packed in technically safe condition. In order to maintain this

condition and to ensure safe operation, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed.

Ignoring the warnings may lead to severe personal injury or substantial

damage to property.

The product must be operated by trained staff. Correct and safe

operation of this equipment is dependent on proper transport, storage,

installation and operation.

All electrical wiring must conform to local standards. In order to prevent

stray electrical radiation, we recommend twisted and shielded input

cables, as also to keep power supply cables separated from the input

cables. The connection must be made according to the connecting

diagrams.

Before switching on the power supply take care that other equipment

is not affected. Ensure that the supply voltage and the conditions in the

environment comply with the specification of the device.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

LKP100

Ver. 1

LKP100

Ver. 2

DNGA230100

WARNING

This product contains no replaceable parts.

In case of malfunction the product must be shipped to Baumer for

repair.

Installation Manualwww.baumer.com

Page 1 Design and specifications subject to change without notice

Page 2

Mechanical Installation

Welding part

Please refer to “Accessories” data sheet. The welding part has an

engraved mark or hole. When the product has been mounted and

correctly tightened the gland or M12 plug will align with this mark.

Make sure that the gland/plug is pointing downwards to prevent fluids

from penetrating into the instrument.

Cautions

Use only the authorised special designed accessories.

The product warranty is void when installed with other adapters.

The sensor can be shortened.

Coated rods: Remove approx. 10 mm of the coating from the rod tip to

ensure a proper contact to the media.

Do not use teflon, paper or other gaskets.

The process connection must have electrical contact with the tank.

if not, a separate grounding cable must be installed.

If the tank is non-conductive an additional ground electrode must be

installed. This should have electrical connection to the LSK process

connection.

Make sure that the rod can not touch the tank wall even with the highest movement of the media.

When installed <100 mm from the tank wall the rod must be parallel

with the tank wall. For larger distances non-parallelity can be allowed.

After carefully insertion of the sensor into the welding part tighten the

union with a torque of:

LSKx2x: 10...20 Nm.

LSKx5x: 20...30 Nm.

After Installation and Configuration

Check the leak tightness of the sleeve.

Check the tightness of glands or M12 plugs.

Check the tightness of the cover.

Check that the rod is not touching the tank wall.

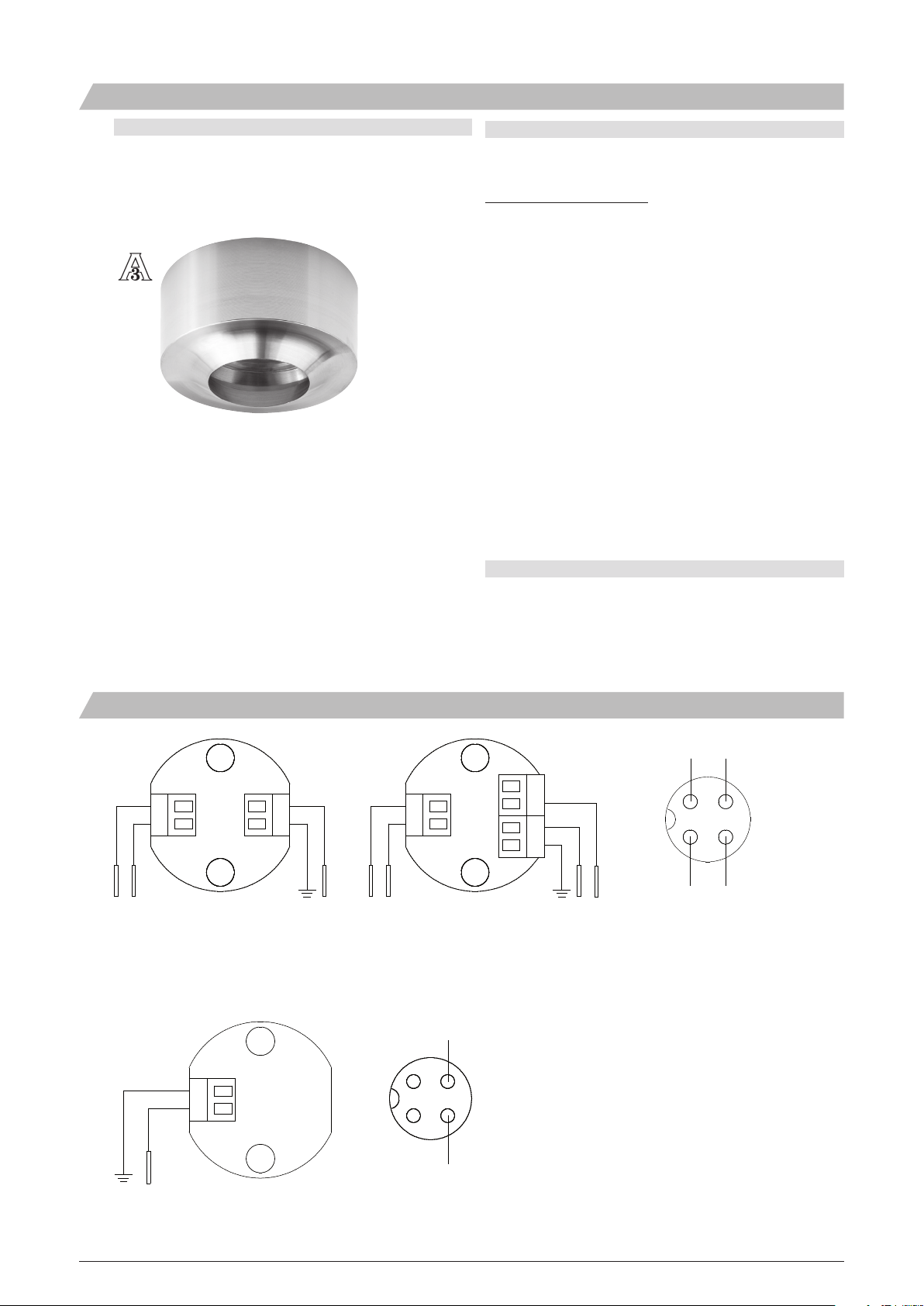

Electrical Installation

E3

E1

3

2

1

E2 E1 Gnd E3 E2 E1 Gnd E4 E3

2 or 3 rods 4 rods M12 plug

3

4

2

1

Connection terminal M12 Plug

E

2

1

Gnd

Input

1 4

2

3

4

5

6

WARNING:

Do not connect the LSK to a high DC potential, which could damage

the sensor. The most suitable evaluation module is a type with a

sensing frequency > 200 Hz and input voltage < 5Vrms.

1

2

E2

4

3

Gnd

1: Brown

2: White

3: Blue

4: Black

Gnd E

Gnd

1 rod

Installation Manualwww.baumer.com

Page 2 Design and specifications subject to change without notice

Page 3

Electrical Installation - LKP100 Amplifier for In-head Mounting

M12 Plug

Input

5

6

Gnd

Output load

max. 50 mA

Input

5

6

Gnd

Output load

max. 50 mA

0 mA

50 mA

50 mA

0 mA

LED

LED

+

4

1

2

3

S

-

+

4

1

2

3

S

-

+

18...36 Vdc

-

+

18...36 Vdc

-

4

3

S

2

1

4

3

S

2

1

Sensibility Connection Typical application

20 KOhm

Terminal S connected to + (plus) Water

2 KOhm Terminal S not connected Beer, juice, youghurt

200 Ohm

Note: Terminal S is for local or remote setting of the sensibility.

Terminal S connected to - (minus) Acid, Alkalis

Electrical Installation - DNGA 230100

1: Brown

2: White

3: Blue

4: Black

ø7

33

ø44

Refer to Installation manual 5511-507.

DNGA230100

Installation Manualwww.baumer.com

Page 3 Design and specifications subject to change without notice

Page 4

Mounting of 3A Approved Products

Max. ± 85°

1)

2)

3)

Installation of 3A approved products:

1) Use only

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Weldings should be grinded to Ra= 0.8

a 3A approved counter part.

4)

5)

Max. ± 175°

Refer to the data sheet “Accessories” for O-rings, gaskets and other

accessories.

The LSK32x, LSK42x, LSK52x, LSK 35x and LSK 45x are approved

by 3A providing it is mounted in a 3A approved counter part and

installed according to the guidelines given in the installation manual.

The 3A approved products fulfill the FDA demands and follow the

EHEDG guidelines regarding design, materials and finishing.

Refer to the 3A marked counter parts in the data sheet “Accessories”.

5850-003_UK/2009-12-02/Rev. B1 This data sheet may only be reproduced in full.

Installation Manualwww.baumer.com

Page 4 Design and specifications subject to change without notice

Loading...

Loading...