Page 1

Operators instructions

CleverLevel switch, LFFS

CleverLevel switch, type LFFS is an universal level switch, which

can be used for all applications in liquids and solids with a DK-value

above 1,5

Safety instructions

This instrument is constructed and tested according to the current EUdirectives and packed in technically safe condition. In order to maintain

this condition and to ensure safe operation, the user must follow the

instructions and warnings given in this instruction.

During the installation local standards have to be observed. Ignoring the

warnings may lead to severe personal injury or substantial damage to

property.

The product must be operated by trained staff. Correct and safe operation of this equipment is dependent on proper transport, storage, installation and operation.

All electrical wiring must conform to local standards and the connection

must be made according to the connecting diagrams.

Before switching on the power supply take care that other equipment is

not affected. Ensure that the supply voltage and the conditions in the

environment comply with the specification of the device.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

To obtain the specified protection degree, the LFFS must be mounted

with a compliant cable.

Description

The Level Switch LFFS designed to detect levels in tanks, media separation and provide empty-pipe detection or dry-run protection

for pumps.

A high frequency sweep signal is radiated from the sensor tip into the tank. The media will act as a virtual capacitor, which together

with a coil in the sensor head, will form a circuit creating the switch point signal. This virtual capacity will depend of the di-electric

value (DK-value) of the media.

By means of the FlexProgrammer 9701 the output can be configured to either NPN, PNP or digital output signal. A damping of the

output signal can be activated in case of a fluctuating media level, e.g. during tank filling.

The measurement is precise and unaffected by the mounting position in the tank. In the Flex-software a compensation for foam,

bubbles and condensate as well as viscous media can be set.

The Flex-software also features an adjustment facility making the user able to adjust the sensor to a specific media.

The Level Switch LFFS measures liquids such as water and beer as well as viscous, sticky fluids, such as honey, yoghurt, toothpaste and ketchup. Even dry medias can be measured, e.g. sugar or flour.

The Level Switch LFFS is resistant against CIP and SIP agents.

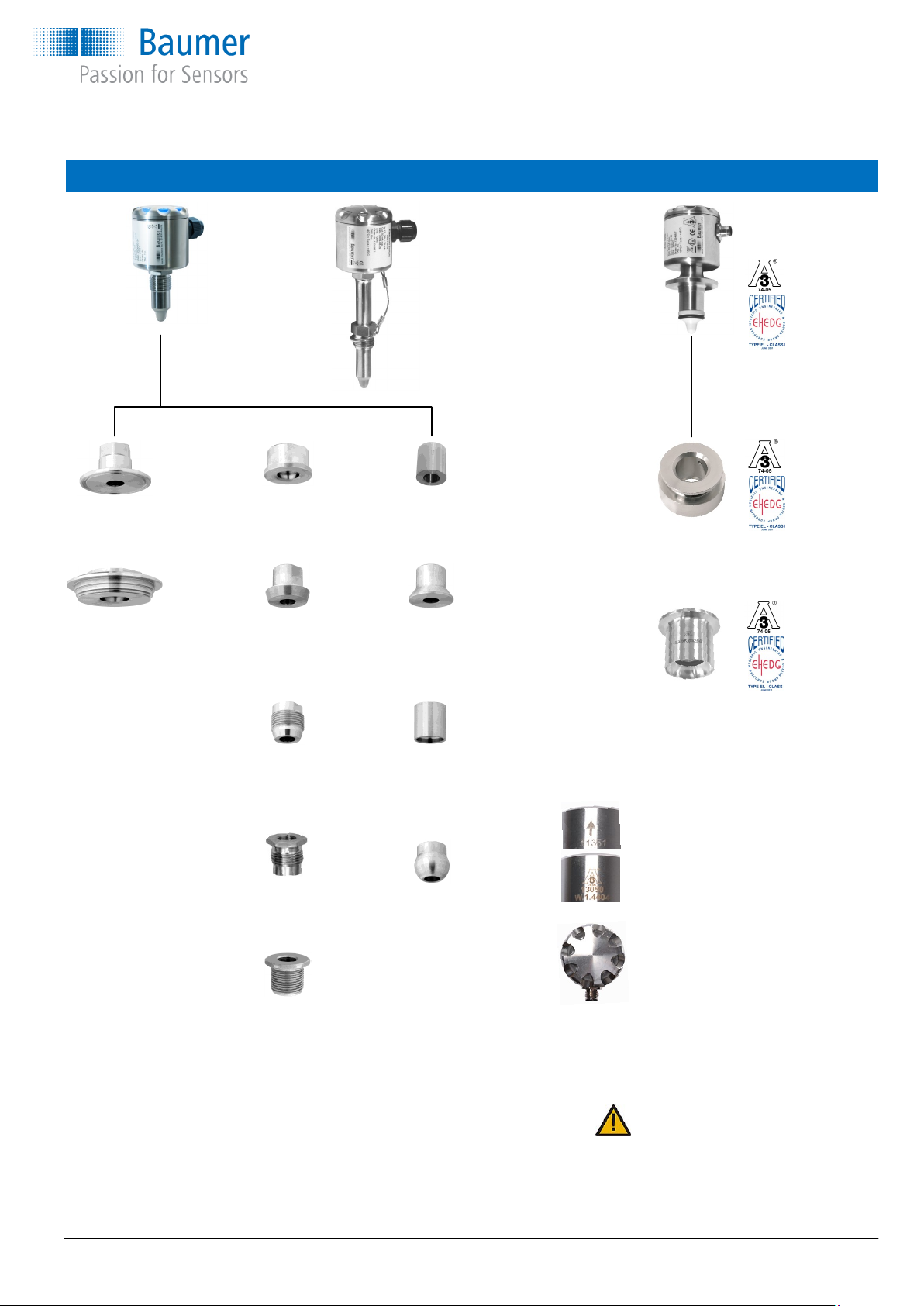

Hygienic installation is also possible with the comprehensive range of accessories, see the overview at page 6.

WARNING

When the top cover is removed, do not look directly at the blue LED with unshielded eyes or damage to retina may occur !

This product contains no replaceable parts. In case of malfunction the product must be shipped to Baumer for repair.

www.baumer.com

Operators instructions: 11109132 02 EN Page 1 / 12

2013-08-23 Design and specifications subject to change without notice

Page 2

Operators instructions

CleverLevel switch, LFFS

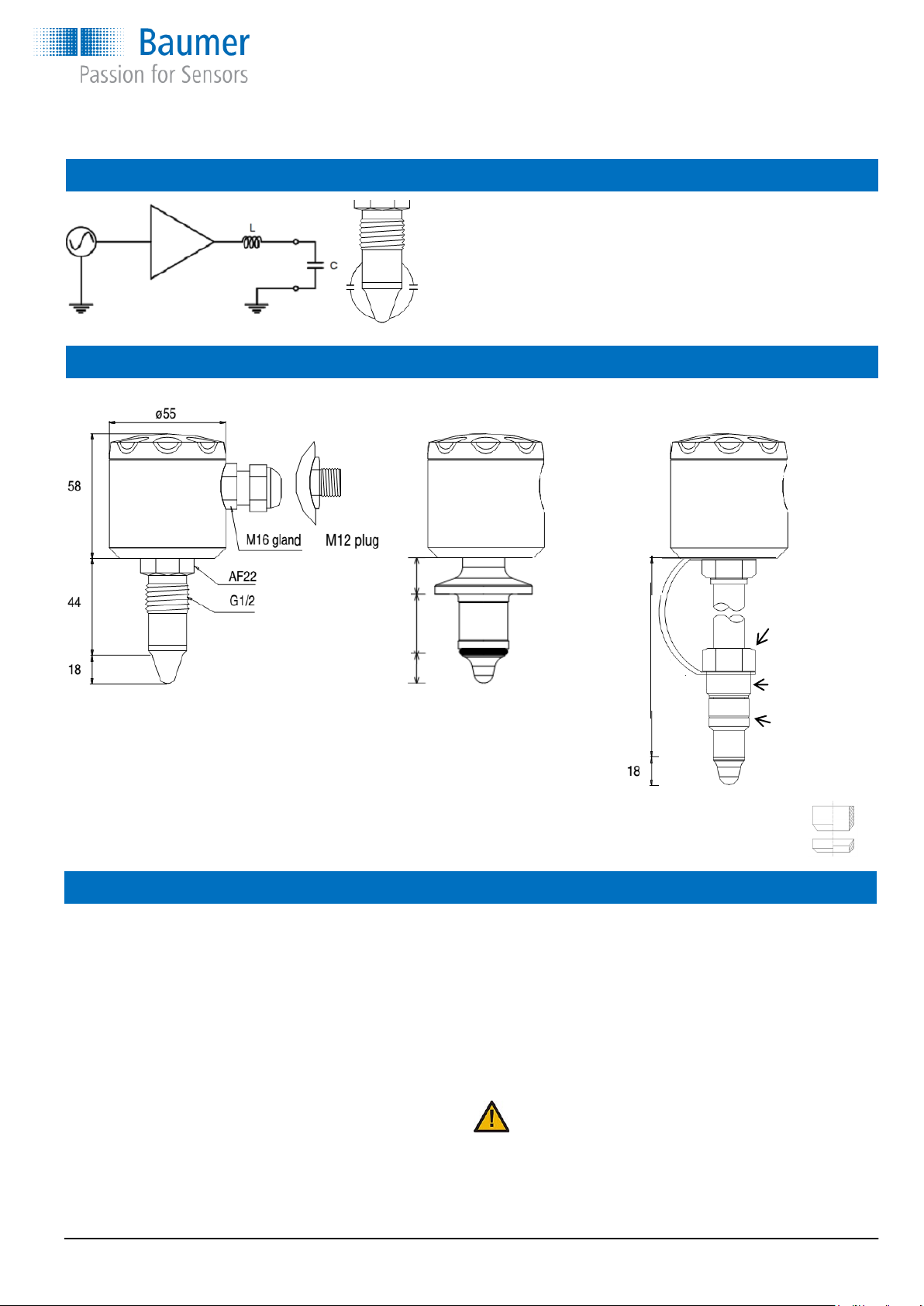

Measuring principle

The capacity (C) of the media is directly proportional to the dielectric

value of the media.

A frequency between 100 and 180MHz is swept into the media.

When the coil (L) and the capacitor (C) reach a resonance frequency,

it will be detected by the electrical circuit.

Dimensions

G½ hygienic 3A DN38 hygienic G½ hygienic sliding connection

19,0

31,5

14,5

Mounting

Please refer to “Accessories” data sheet. The welding part has

an engraved mark or a leak hole. When the product has been

mounted and correctly tightened the gland or M12 plug will

align with this mark.

Make sure that the gland/plug is pointing downwards to prevent fluids from penetrating into the instrument.

Use only the authorised special designed accessories. The

product warranty is void when installed with other adapters.

Do not use PTFE, fibre or other gaskets. The PEEK tip against

the stainless steel welding part will perform a hygienic tightening provided that the guidelines have been followed.

Due to the measuring principle it is essential that the sensor tip

can “see” an ample amount of the metal shaft or welding part.

Safety

wire

100

or

250

Mounting instructions for sliding connection:

1) Clean the sliding shaft.

2) Mount the smallest ring against the media as indicated.

3) Tighten the G1/2 Hygienic sliding nipple at 25...30 Nm.

4) Replace the Washer ring kit when one or both parts are

permanently deformed or stick to the shaft of the sliding

connection.

WARNING

The Level Switch LFFS with sliding connection can be mounted

in installations with a static pressure up to 16 bar.

To prevent personal injuries or property damage it is essential

that the safety wire is mounted correctly and is undamaged.

Sliding

connection

G½

2 × PEEK

sealing

washers

Spare part set:

4401.8001

www.baumer.com Operators instructions: 11109132 02 EN Page 2 / 12

Page 3

Mounting

Operators instructions

CleverLevel switch, LFFS

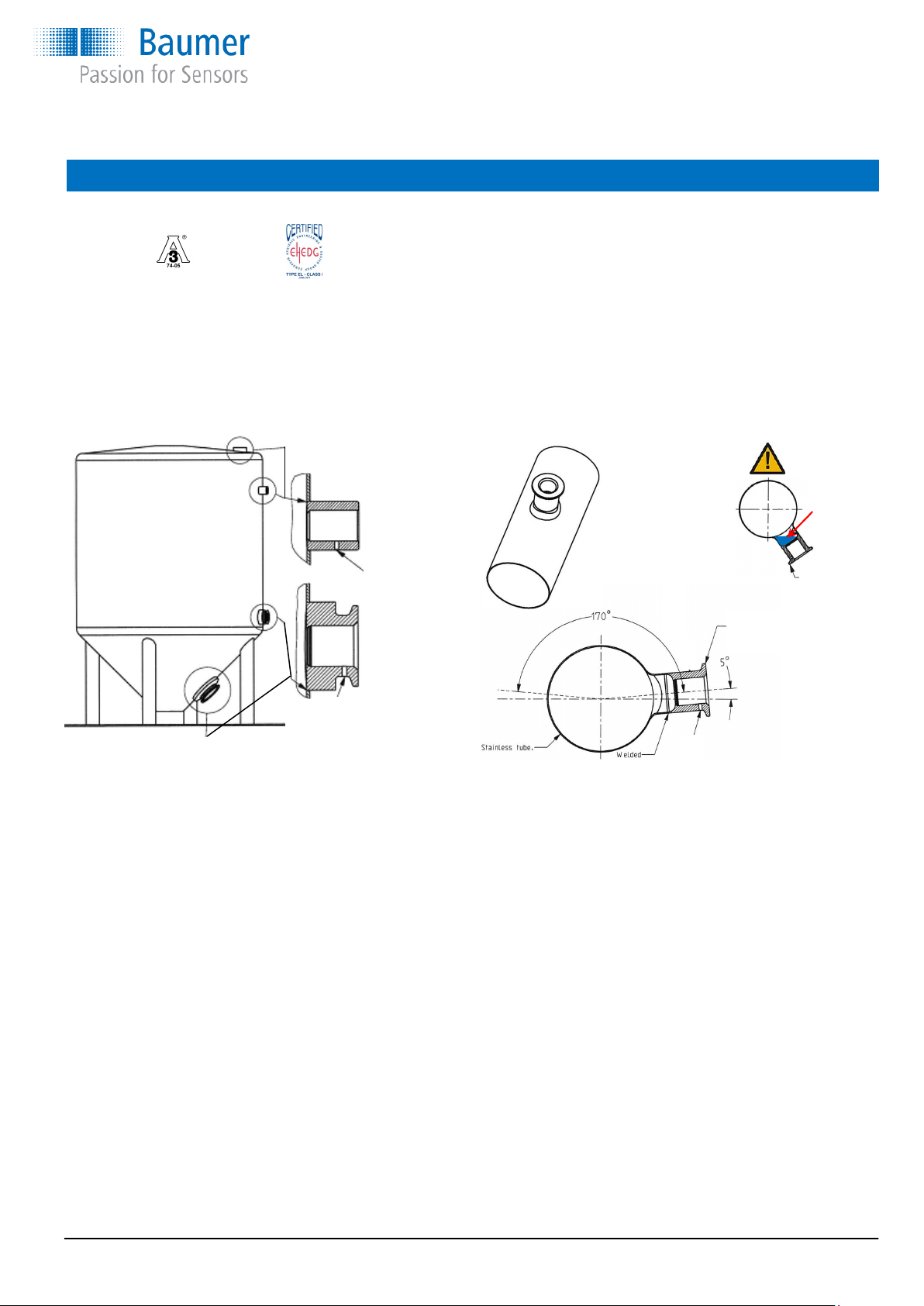

Installation of 3A approved and EHEDG certified products:

1) Use only a 3A approved counter part.

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Welding's should be grinded to Ra= 0.8

Example

with PM023

Tighten the union with a torque of:

Std. version 20...25 Nm.

Sliding connection 25...30 Nm.

WARNING

Cannot be

drained

Fitted

incorrect

Example

with 8126-928

Example

with 8126-916

After installation and configuration

Check the leak tightness of the sleeve.

Check the tightness of glands or M12 plugs.

Check the tightness of the cover

Leakage indication hole

must be places downwards

www.baumer.com Operators instructions: 11109132 02 EN Page 3 / 12

Page 4

Operators instructions

CleverLevel switch, LFFS

Mounting connections

ISO2852 SMS 1145 Welding

DN38: CAM023.505 DN51: SAM020.051.1 for tank

DN51: CAM023.640 PM023

Variline, type N DIN 11851 Welding

VAM023 DN25: MAM020.025 for tank

DN40: MAM020.040 PM021

DN50: MAM020.050

Adapter Welding

G½ → G1 to pipe end

RAM020.1 DN25...50: PM022.1

DN65...100: PM022.2

Adapter Welding Ø35

1” level switch for tank/tube

LAM020.3 PM025

Adapter, industrial

G½ → G1

RAM020.2

Welding

for tank

8126916

Welding

for pipe end

8126928

On a welding adapter there is an

arrow or a 3A logo.

This must be placed upwards when

welding the adapter into a tank

(horizontal position).

This assures that the electrical connection will be pointing downwards

(opposite of the arrow; 3A logo)

Refer to data sheet ”Accessories Universal” for further

information

NOTE:

The LFFS must be mounted in a Baumer mounting

connection. If not, Baumer do not guarantee correct

function or tightness.

www.baumer.com Operators instructions: 11109132 02 EN Page 4 / 12

Page 5

Operators instructions

CleverLevel switch, LFFS

Media temperature and external length for sliding connection

LFFS-xx1.x / LFFS-xx2.x LFFS-xx3.x and LFFS-xx4.x

Media temperature °C

120

115

110

105

100

95

90

85

80

75

50 55 60 65 70 75 80 85 90

Ambient temperature °C

For CIP/SIP Media temperature, max. 140°C

Ambient temperature, max. 60°C

Duration, max. 1 hour

External length

Media temperature °C

See example

External length of sliding connection

It is essential that the max. ambience temperature for the electronics

is never exceeded (85°C). For ATEX approved products please refer

ATEX data.

Example, how to read External length curve:

Example: Media temperature / Ambient temperature / External length

160°C 60°C 120 mm

A 250 mm sliding connection is mounted in a tank with a total in-

The drawing shows how the sliding connection can be

used for at least 4 applications:

1) Mounted at the top of a tank to adjust to a

maximum level.

2) Serving as a cooling neck in high media

temperature applications.

3) Adjusted to place the sensor tip deeper

inside the tank.

4) To reach in through insulation material.

sert length of 130 mm. Hence the external length of the sliding

connection will be 250 – 130 = 120 mm.

The media temperature will be max. 160 °C.

Read the x-axis at 120 mm an the y-axis at 160°C and find that

the ambient temperature must be kept below 60°C.

In case the radiated heat from the tank will cause a higher ambient

temperature at the housing efficient insulation of the tank must be

established.

When re-ordering a CleverLevel switch

If a new CleverLevel switch is installed in an existing application, it is normally a “plug-n’-play” operation.

If the settings of the level switch was changed from standard factory settings, it is necessary to re-adjust the new switch to same

as the “old” switch. It is possible to save the settings of the “old” switch on the PC and download those again to the new level

switch.

The factory setting of the sensitivity of the media may vary up to ±5%. This means that if an very exact set point is required, a new

teach-in or adjustment by the FlexProgram must be performed.

www.baumer.com Operators instructions: 11109132 02 EN Page 5 / 12

Page 6

Operators instructions

CleverLevel switch, LFFS

Teach-In using the FlexProgram and FlexProgrammer 9701

Sophisticated settings for Teach-In as well as output type, diagnostics, data logging, tag no. and damping can be configured using

the FlexProgrammer 9701. Integrated HELP-menus will give full instruction.

Using the FlexProgrammer 9701 alone and Teach-In

FlexProgrammer 9701 stand alone menu

Press

Turn on FlexProgrammer if in sleep mode

Empty configuration

Search for product

LFFS/LBFS configuration

Product LFFS / LBFS

TAG number xxxxxxxxxxxxxxx

Range min. x.x%

Range max. xx.x%

Damping x,x sec

Output config. Xxxxxxx

Trigger level xx,x%

Range hyst. x,xx%

Trigger hyst. x.xx%

Press or to browse the menus

to access current menu point

to return to previous menu

and simultaneously to reset FlexProgrammer

and go in sleep mode

Teach-In

Press

and simultaneously

Select Menu “Teach-In”

Search for product

= Product LFS/LBFS

At empty tank setting 0%

At full tank setting 100%

Manually Teach-In

Make sure that power is on before Teach-In.

For best Teach-In it is important the product is fixed in the final application.

During Teach-In mode the light intensity of the LED will decrease, please protect your eyes.

Step To do LED Result

Connect terminal ”Teach-In” to

1

- VDC (T1 or T2) for 3,5 second

With no media present connect

2

”Teach-In” to - VDC shortly

With media present connect

3

”Teach-In” to - VDC shortly

NOTE:

If the media is sticky, foamy, powdery or in other ways leaving parts of the media at the sensor tip this situation has to be established also during the Teach-In process. Otherwise a faulty calibration can be the result.

If Teach-In for some reason do not succeed, the CleverLevel Switch LFFS will enter “Error State” and automatically reload factory

settings . The factory settings can always be reloaded by connecting the terminal “Teach-In” to -VDC for more than 6.5 seconds.

A reloaded factory settings will be confirmed by pulsing light intensity 3 times.

Error state description LED Result

Flash 1 time per second

Light on for 2 second and then flash

Light on for 2 seconds

Ready for Teach-in

Register ”empty” state. Pls. See note

Register ”full” state, stores the value and returns to

Normal operation with new setting

Error state Blinking, 3 × short and 1 × long Can normally be fixed by powering off and on and remake the Teach-In.

Alternatively remake the Teach-In configuration by use of the FlexProgram and the FlexProgrammer 9701

www.baumer.com Operators instructions: 11109132 02 EN Page 6 / 12

Page 7

Electrical connection

Electrical specifications:

Power supply 12,5...36 VDC, 35 mA max.

Output PNP, NPN or Digital

Max. 50 mA, short-circuit and high

temperature protected

Active “Low” NPN and Digital output

(-VDC +2,5V) ±0,5V, R

Active “High” PNP and Digital output

(+VDC -2,5V) ±0,5V, R

load

load

1 kΩ

1 kΩ

Operators instructions

CleverLevel switch, LFFS

M12 plug: 1 Brown

2 White*

3 Blue

4 Black

* To avoid unintended Teach-In, be aware not to

connect the Teach-In pin or expose it to any

electrical noise during normal operation.

Normally open - NO

Normally closed - NC

5

1

2

5

1

2

5

1

2

5

1

2

5

1

2

5

1

2

www.baumer.com Operators instructions: 11109132 02 EN Page 7 / 12

Page 8

ATEX

Operators instructions

CleverLevel switch, LFFS

Conditions for Ex certification

Connection type Ambient temperature Media temperature

G½ hygienic -40 … +85 °C +85 °C

3A DN38

100 mm -40 … +85 °C +85 °C

Sliding connection

250 mm -40 … +85 °C +85 °C

Sliding connection

ATEX Gas ia

Ex ia IIC T5, ATEX II 1G - Installation

A Level Switch LFFS-1xx.x is Ex ia IIC T5, ATEX II 1G approved for application in hazardous areas in accordance with

the current EU directives. The product must be installed in

accordance with prevailing guidelines for zone 0 with a barrier

Ex-data

Supply range 24...30 VDC

Temperature class T1...T5 Pls. see above table

Internal inductivity Li <10 µH

Internal capacity Ci <33 nF

Barrier data U <30 VDC

I <0.1 A

P <0.75 W

Note:

There is an electrical connection between intrinsic safe circuit

and housing due to the measurement principle

Note

(max. allowed)

-40 … +60 °C +95 °C 1)

-40 … +40 °C +115 °C 1)

-40 … +60 °C +155 °C 1)

-40 … +40 °C +175 °C 1)

-40 … +60 °C +195 °C 1)

-40 … +40 °C +200 °C 1)

LFFS-1xx.x

with NPN output

NPN out

LFFS-1xx.x

with PNP output

Note:

For NPN output only!

A standard barrier may be used

Standard barrier

Note:

For PNP output the barrier module

PFOFSI3-B25100-ALG-LS

is required for functional purposes.

1) Provided that

the sensor tip

at the instru ment is the

only part in

contact with

the media

Two-channel

ZENER barrier

Safe area

+ 22...120 VDC

PFOFSI3-B25100-ALG-LS

www.baumer.com Operators instructions: 11109132 02 EN Page 8 / 12

or

- 90...253 VAC

Page 9

Operators instructions

CleverLevel switch, LFFS

ATEX Dust tD

A Level Switch LFFS-2xx.x is Ex tD A20 IP67 T100°C, ATEX II 1D

approved for application in hazardous areas in accordance with the

current EU-directives. The product must be installed in accordance

with prevailing guidelines for zone 20 without a barrier.

Ex-data

Supply range VDC 12,5...30

Load I <0.1 A

Temperature class T1...T5 Pls. see table top page 8

ATEX Gas nA

A Level Switch LFFS-3xx.x is Ex nA II T5, ATEX II 3G approved for

application in hazardous areas in accordance with the current EU

directives. The product must be installed in accordance with prevailing

guidelines for zone 2 without a barrier.

Ex-data

Supply range VDC 12,5...30

Load I <0.1 A

Temperature class T1...T5 Pls. see table top page 8

5

1

2

12,5...30 VDC

5

1

2

12,5...30 VDC

Ex-Configuring

The FlexProgrammer 9701 configuring unit must not be connected to the CleverLevel

Switch LFFS within the hazardous area.

Configuring procedure:

a) Disconnect mains from the 4...20 mA loop circuit.

b) Disconnect the Level Switch from the circuitry within the hazardous area.

c) Uninstall and bring the Level Switch to the safe area.

d) Connect the FlexProgrammer 9701 and perform the configuring session.

e) Re-install the Level Switch in the hazardous area.

f) Connect the power supply to the circuit.

Outside hazardous area

Links

Operation instructions in other languages and certificates can be found on Baumer home page

Operation instructions www.baumer.com → downloads → certificates-approvals → product main group

Certificates ATEX / DNV www.baumer.com → downloads → certificates-approvals → certificate / approval

WHG certificate/instruction leakage www.baumer.com/LxFS-WHG-Leak

WHG certificate/instruction overfill www.baumer.com/LxFS-WHG-Overfill

www.baumer.com Operators instructions: 11109132 02 EN Page 9 / 12

Page 10

WHG leakage approval

Operators instructions

CleverLevel switch, LFFS

www.baumer.com Operators instructions: 11109132 02 EN Page 10 / 12

Page 11

WHG overfill protection approval

Operators instructions

CleverLevel switch, LFFS

www.baumer.com Operators instructions: 11109132 02 EN Page 11 / 12

Page 12

Operators instructions

CleverLevel switch, LFFS

WHG leakage and overfill protection approval

www.baumer.com Operators instructions: 11109132 02 EN Page 12 / 12

Loading...

Loading...