Page 1

EN

INSTALLATION INSTRUCTIONS MODBUS TEDM - ETTNM

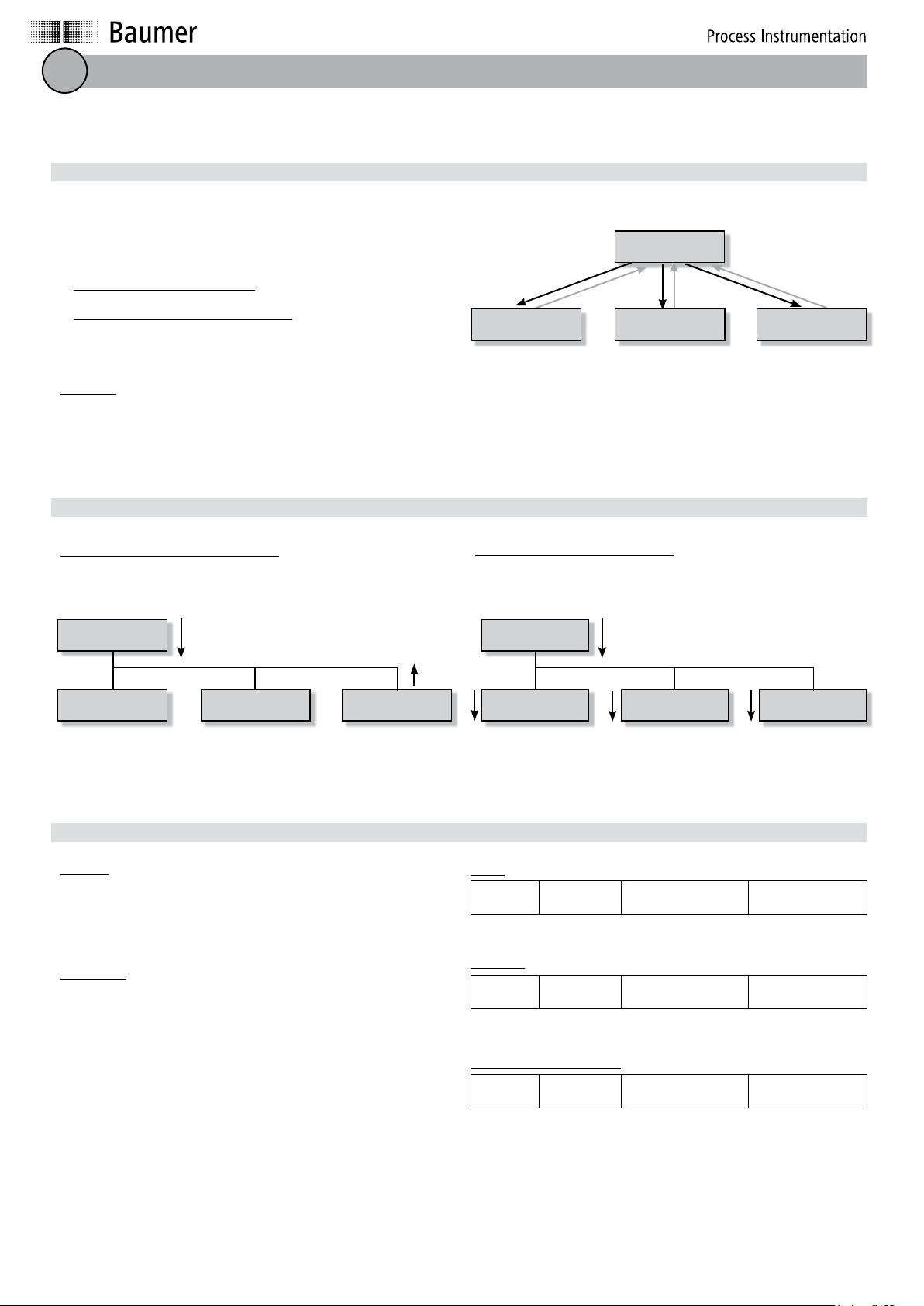

Modbus Communication - Overview

The TEDM pressostat and the ETTNM thermostat have a serial RS485 port and use

the Modbus RTU communication protocol.

The Modbus protocol is a dialog protocol based on a hierarchical structure consisting

of a master and several slave devices. It supports reading the pressure level (TEDM)

or the temperature (ETTNM), as well as the status of each coil (open or closed).

Communication from master to 1 slave: the master sends a query and waits for a

response.

Communication from master to all slave devices: the master sends a message to all

slaves currently on the network, they execute the command in the message without

sending a reply.

Two slave devices cannot talk to each other.

Addressing

The devices on the bus are identified by addresses assigned by the user. The address

of each subscriber is not related to its physical location.

Modbus communication - Principles

Master

Slave device A Slave device B Slave device C

E.g.: slave device = TEDM / ETTNM ...

These addresses range from 1 to 247 and do not have to be assigned sequentially.

There cannot be two slave devices with the same address.

Factory default address TEDM / ETTNM: 246.

Communication from master to a single slave

The master queries the slave over the network and waits for a response from that

slave.

Master

Slave device A Slave device B Slave device C

Query

Response

Frame for query/response

The query

It contains a function code telling the slave being queried what type of action is

required.

The data contains any additional information the slave may need to execute the function.

The checksum allows the slave to check the integrity of the query content.

The response

If an error occurs, the function code is changed to indicate that the reply is an exception response (MSB*=0: no error; MSB=1: error).

The data then includes a code (exception code) indicating the type of error.

Exception code:

01 Illegal function (function code error)

02 Error in the register address or coil address

08 Transmission error (after checking the CRC or the synchronization)

*MSB : Most Significant Bit

Communication from master to all slaves

Communication from the master to all slave devices: the master sends a message

to all slaves currently on the network, they execute the command in the message

without sending a reply.

Master

Slave device A Slave device B Slave device C

Command

Query:

Device #

of slave

1 byte 1 byte n bytes 2 bytes

Function code

+ error bit

Specific information

about the command

Checksum

Response:

Device #

of slave

1 byte 1 byte n bytes 2 bytes

Function code

+ error bit

Transmitted data Checksum

Response in case of an error:

Device #

of slave

1 byte 1 byte 1 byte 2 bytes

Function code

+ error bit

Exception code Checksum

Baumer Bourdon-Haenni S.A.S. · 125, rue de la Marre · B.P. 70214 · 41103 Vendôme Cedex · France

Tel. +33 (0)2 54 73 74 75 · Fax France +33 (0)2 54 73 74 74 · Fax Export +33 (0)2 54 73 74 73

sales.fr@baumerprocess.com · www.baumer.com

320124 ind a 11/2012

Page 2

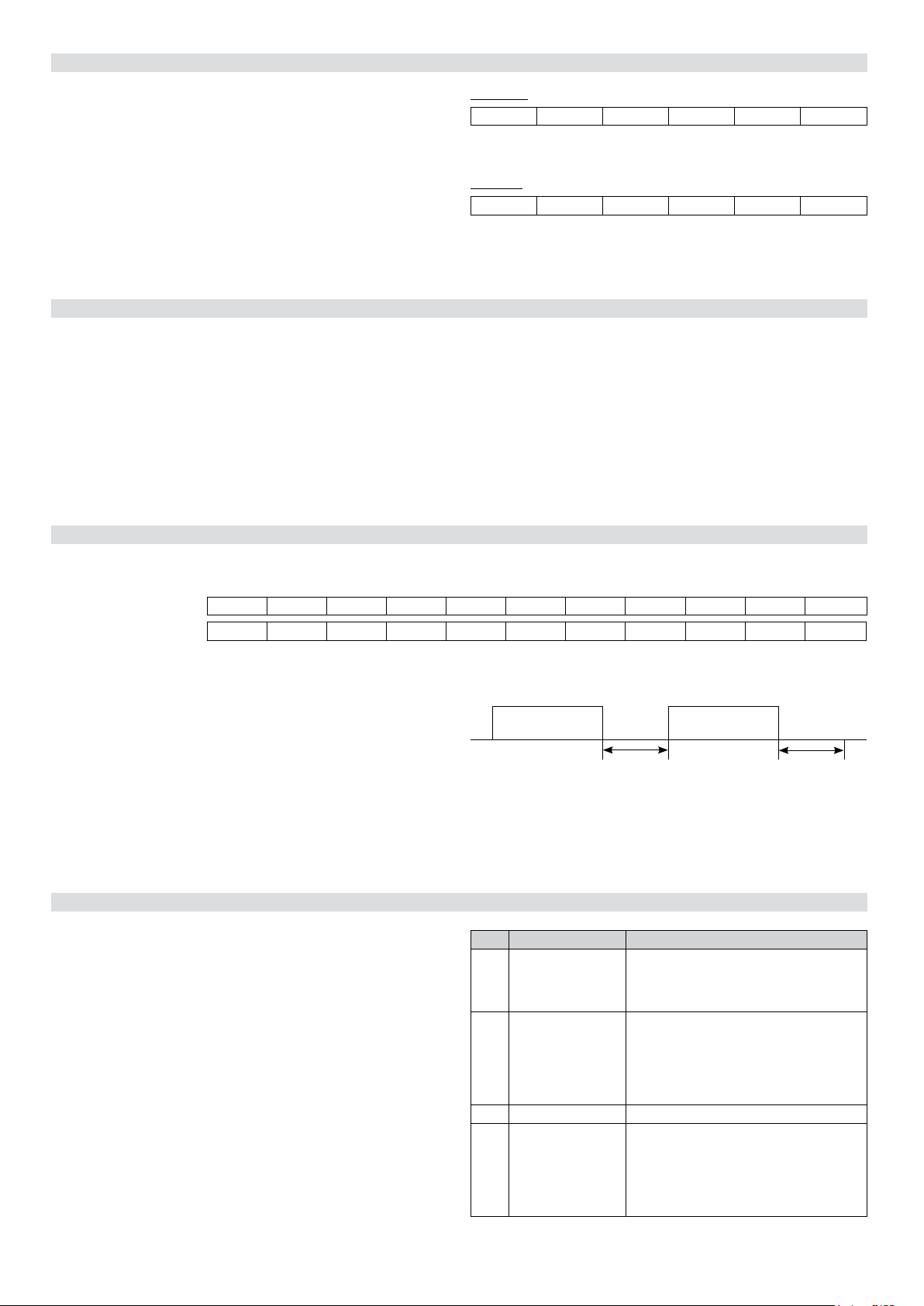

General format of a frame

Two types of encoding may be used to communicate over a Modbus network:

ASCII - each byte making up the frame consists of 2 ASCII characters

RTU (Remote terminal unit) - each byte making up the frame consists of 2 hexa-

decimal characters (2 x 4 bits).

ASCII mode allows having gaps of more than one second between the different characters without causing errors, while the RTU mode allows more data to be passed at

the same transmission speed.

The TEDM and ETTNM use RTU coding to communicate over the Modbus network.

ASCII frame:

START Address Function Data LRC END

1 chara 2 charas 2 charas n charas 2 charas 2 charas

RTU frame:

START Address Function Data CRC 16 END

1 byte 1 byte 1 byte n bytes 2 bytes Silence

RTU Type

The maximum data size is 256 bytes. All the information contained in the message is written as hexadecimal.

The master instructs a slave. The function code tells the slave what type of action to

carry out. For example: read the register, function code 03 hex.

The data field is coded for n words in hexadecimal from 00 to FF, or for n bytes.

Depending on the function code, the data field may hold different additional information allowing the slave to interpret the message.

If RTU coding is used, the checksum CRC (Cyclical Redundancy Check) allows

the integrity of the received data to be checked. The CRC contains a value which is

encoded as 16 bits..

The slave sends its response; it places its own address in the address field so that

the master can identify it.

For a normal response, the slave uses the same function code as the one in the

message sent by the master.

The checksum field contains a value which is encoded as 16 bits. This value is the

result of a CRC calculation using the message.

Data carrier

Each byte making up a message is transmitted as follows in RTU mode:

No parity check START Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 STOP STOP

With parity check START Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Parity STOP

In the TEDM and ETTNM configuration menu it is possible to opt for parity

checking or not.

Before and after each message (frame), there must be a silence lasting a minimum

of 3.5 times the time needed to transmit a byte.

The whole message must be sent continuously. The maximum time between 2 bytes

must be less than 1.5 times the time required to transmit a byte.

Otherwise there is a transmission error.

The MODBUS protocol only defines the message structures and their exchange

mechanism.

If a parity check is used, you need to confirm the reference status: ‘even’ or ‘odd’.

Message from the

master

Minimum delay of 3.5 times the

time needed to transmit a byte

You can use any transmission interface, RS 232, RS 422 or RS 485, but the RS485

connector is the most widely used because it supports multipoints.

TEDM-ETTNM:

Data transmission speed: 9600 baud. Interface: RS485.

Message from the

slave

Minimum delay of 3.5 times the

time needed to transmit a byte

TEDM/ETTNM - Function codes

The TEDM and ETTNM use 4 function codes.

These function codes allow collection of:

- the value of the pressure reading (TEDM) or the temperature (ETTNM)

- the status of each coil (open or closed),

and writing of

- the status and setting of the coils

- the access code

- the address for the slave

Code Function Action

01 Read Coils Status Read the status of coils 1 and 2: open or closed

03 Read Holding Register Read the measured value. Pressure (TEDM) or

05 Write Single Coil

06 Write Single Register

Read the coil setting: Normally Open (NO) or

Normally Closed (NC)

Read the position of the decimal point (display)

Temperature (ETTNM)

Read the access code

Read the value of the high and low switching points

for each coil

Read the value of the timer for each coil

Write the coil’s configuration: NO or NC

Write the access code

Write the value of the high and low switching points

for each coil

Write the value of the timer for each coil

Write the slave’s address (TEDM or ETTNM)

320124 ind a 11/2012

Page 3

Transmission samples

Read Coil Status - function code 01

The master queries the TEDM/ETTNM about the coils’ status.

The start address for reading the coils is fixed and the number of coils is always 16. Coils are always addressed starting from zero: so

coils 1-16 are addressed as 0-15.

Sample command to read coils 16-01 of slave 59:

Field name Example

Slave Address 3B hex

Function 01 hex

Starting Address Hi 00 hex

Starting Address Lo 00 hex

Query

No. of Points Hi 00 hex

No. of Points Lo 10 hex

Error Check (CRC) —

Read Holding Register - function code 03

The master queries the TEDM/ETTNM on the value of the reading, the code, the setting of the high and low switching points of the timers for the coils.

The query indicates the register address to be read. Registers are always addressed starting from zero: so registers 1-11 are addressed as 0-10.

Sample response to the query:

Field name Example

Slave Address 3B hex

Function 01 hex

Byte Count 02 hex

Data (Coils 08-01) 21 hex

Response

Data (Coils 16-09) 00 hex

Error Check (CRC) —

The status of the coils (08-01) results in the byte value 21

hex, or 0010 0001 in binary, so coil 1 is active.

Coil 1 configured as NO and Coil 2 configured as NC.

Bit = 0: NC configuration. Bit = 1: NO configuration.

Addr.

Action

Coil

00 Status Coil 1

01 Status Coil 2

02

03

04 NO-NC 1

05 NO-NC 2

06

07

08 Position

09 of

10 decimal

11 point

12

13

14

15

Sample request to read register 1 (measured value) of slave 59:

Field name Example

Slave Address 3B hex

Function 03 hex

Starting Address Hi 00 hex

Starting Address Lo 00 hex

Query

No. of Points Hi 00 hex

No. of Points Lo 01 hex

Error Check (CRC) —

Write Single Coil - function code 05

This function code is used to remotely configure coils as NO or NC. The coils involved are 05 (NO) and 06 (NC) with addresses adr 04

and adr 05 respectively.

To configure a coil as NO, the value FF 00 hex is sent to the slave.

To configure a coil as NC, the value 00 00 hex is sent to the slave.

Sample request to set coil 05 of slave 59 to 1.

The master transmits the value FF 00:

Field name Example

Slave Address 3B hex

Function 05 hex

Starting Address Hi 00 hex

Starting Address Lo 04 hex

Query

No. of Points Hi FF hex

No. of Points Lo 00 hex

Error Check (CRC) —

Write Single Register - function code 06

This function code is used to remotely configure the access code*, the high and low switching points for the coils, the timer for the coils, the

address of the TEDM or ETTNM.

The query indicates the register address involved. The registers are always addressed starting from 1: registers 2-11 are addressed as 1-10.

Please note: the switching values, the access code and the slave address are inserted in the respective registers in hexadecimal.

Sample request to write the set point for slave 59:

Field name Example

Slave Address 3B hex

Function 06 hex

Starting Address Hi 00 hex

Starting Address Lo 02 hex

Query

No. of Points Hi 00 hex

No. of Points Lo 6E hex

Error Check (CRC) —

* access code for configuration from the front of the TEDM or ETTNM.

Sample response to the query:

Field name Example

Slave Address 3B hex

Function 03 hex

Byte Count 02 hex

Data Hi (Register 1) 0A hex

Response

Data Lo (Register 1) 2B hex

Error Check (CRC) —

For register 1: The content results in the value of two bytes

0A 2B hex or 2603 decimal.

The slave confirms the write action by sending back the

same message.

Sample response to the query:

Field name Example

Slave Address 3B hex

Function 05 hex

Starting Address Hi 00 hex

Starting Address Lo 04 hex

Response

No. of Points Hi FF hex

No. of Points Lo 00 hex

Error Check (CRC) —

Coil 1 is configured as NO.

Sample response to the query:

Field name Example

Slave Address 3B hex

Function 05 hex

Starting Address Hi 00 hex

Starting Address Lo 02 hex

Response

No. of Points Hi 00 hex

No. of Points Lo 6E hex

Error Check (CRC) —

The set point for coil 1 is set to 00 6E hex or 110 decimal.

Addr.

Action

Reg

00

Value measured

01 Code

02 Value HSP1

03 Value LSP1

04 Value HSP2

05 Value LSP2

06

07 Value TS1

08 Value TH1

09 Value TS2

10 Value TH2

Addr.

Action

Coil

00

01

02

03

04 NO-NC 1

05 NO-NC 2

06

07

08

09

10

11

12

13

14

15

Adr.

Action

Reg

00

01 Code

02 Value HSP1

03 Value LSP1

04 Value HSP2

05 Value LSP2

06 Slave addr.

07 Value TS1

08 Value TH1

09 Value TS2

10 Value TH2

For more information about the Modbus protocol go to: http://www.modbus.org/

320124 ind a 11/2012

Page 4

Baumer Bourdon-Haenni S.A.S. · 125, rue de la Marre · B.P. 70214 · 41103 Vendôme Cedex · France

Tel. +33 (0)2 54 73 74 75 · Fax France +33 (0)2 54 73 74 74 · Fax Export +33 (0)2 54 73 74 73

sales.fr@baumerprocess.com · www.baumer.com

320124 ind a 11/2012

Loading...

Loading...