Page 1

Cleaning and maintenance

There is no need cleaning the pressure transmitter. However, in order to avoid any damage,

please do not direct high pressure cleaning “jets

of water” directly at the diaphragm. In particular,

never clean the diaphragm with tools or other

mechanical objects. Do not insert hard objects

into the pressure gauge opening.

Operation / procedure in case of

malfunction

The admissible range acc. to technical datasheet must be respected in any case.

In case of malfunction, please check the following points :

– Check the data on the label plate and compare

with the installed confi guration.

– Check wiring.

– Check the power supply and load.

– Check if the diaphragm is ok or damage.

– Check the possibilities of EMC infl uences.

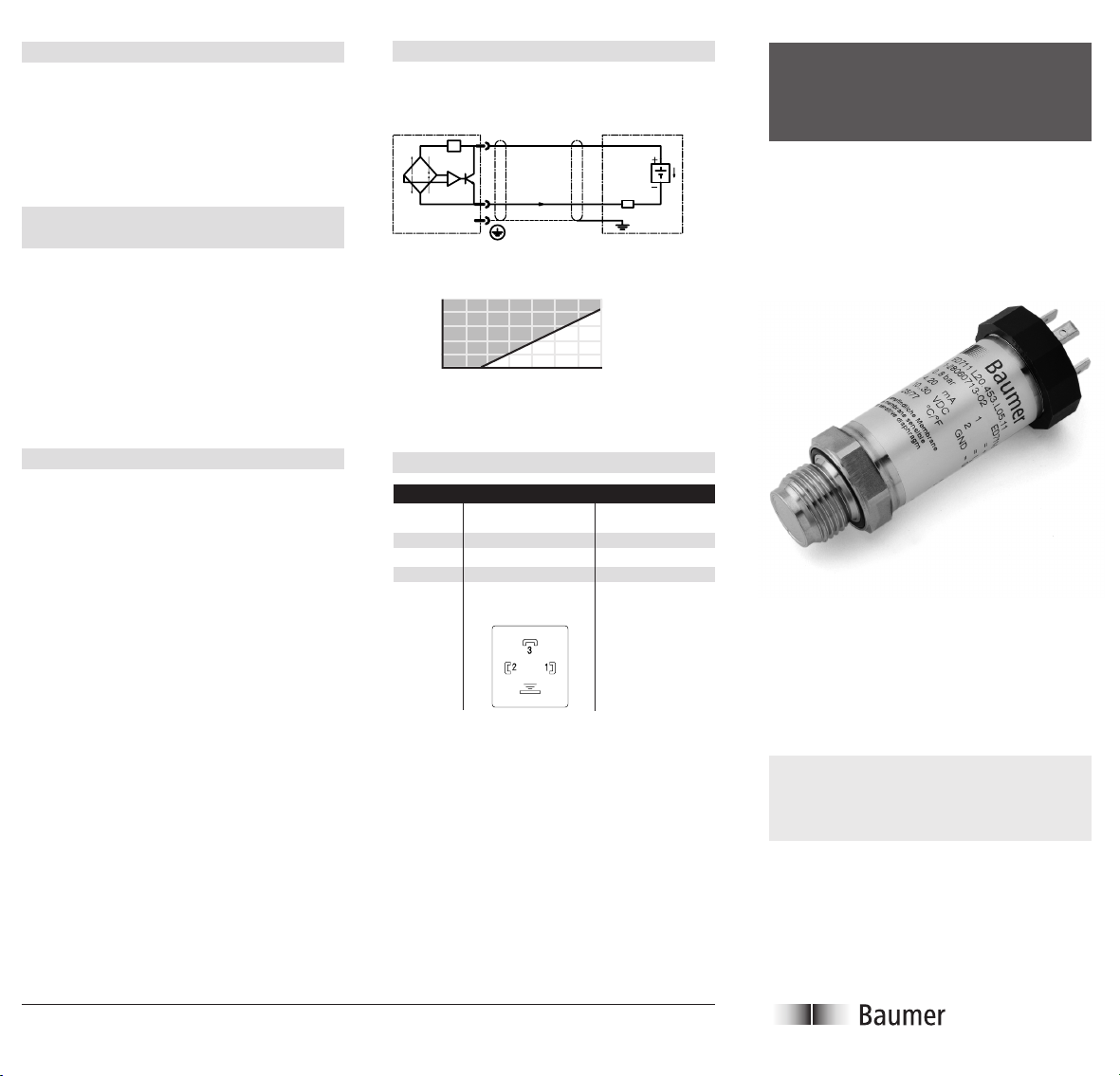

Connecting diagram

Electrical connection

For 4 … 20 mA current loop

a

b

I

A

d

Load RL + R

1500

Line

1200

900

+R

L

600

300

Load R

:

Line

Prohibited

zone

0

0 5 10 15 20 25 30 35

Supply voltage

Pressure Transmitter

ED 711

U

B

R

L

Repair

Please send the pressure transmitter (if possible with the original packing) to the nearest

representation.

Detailed information regarding the malfunction

helps us in obtaining a faster anal y sis.

www.baumerprocess.com Application Manual G45214.1

Design and specifi cations subject to change without notice

Pin assignment

Contact DIN 43650 plug

4…20 mA

a 1

b 2

c –

d GND

View

soldering

side

cable

socket

Installation and

Operating Instructions

E-2004-05-01

Page 2

Thank you for having chosen our product. These

instructions should allow you an easy installation. Please study this documentation carefully

and retain for further reference. Information

about the materials used and general technical

data can be obtained from the relevant technical

data sheet.

1. General points

This pressure transmitter is a precision measuring device. The highly sensitive diaphragm is

protected with a cap which should only be removed just prior to the installation. Take special

care to avoid abrasive media, solid bodies and

other mechanical damage (thumb-mark).

Please follow these instructions carefully so

that the pressure transmitter works perfectly.

The admissible storage temperature is –10 °C ...

+100 °C (dry air).

The pressure transmitter corresponds – under

the condition that the installation has been

properly effected – to the EMC standards EN

50081-1 and 2, as well as EN 50082-2 and EN

61326.

2. Installation / Removal

2.1 Pressure transmitter with thread

Screw the pressure transmitter in the corresponding threaded hole and tighten with the

following torque :

Pressure range (bar) Torque (Nm)

0,1 – 10 30

It is advisable to grease the threads lightly

with a molybdenum disulfi de grease such as

Molykote or Molymagus. In food applications,

use Vaseline.

2.2

Do not install the pressure transmitter close to

any fast closing valves or pumps (for example in

hydraulic systems), however the sensitive sensor is protected against pressure peaks.

Before removals, make sure that the tube carrying the medium is completely de pres su rized.

Attention: Serious injury can result if the line is

still pressurized!

After removal, the diaphragm resp. the pressure

connection, must be protected with the original

cap immediately.

3. Electrical connection

We recommend a shielded cable in order to

obtain the best possible EMC pro tec tion. The

shield has to be connected to the GND of the

plug. In addition, we rec om mend not to install

the cable in a chan nel where al ready cables

of controlling pumps, motors, etc. have been

in stalled. The cable shield has to be earthed at

the side “Power supply/con trol”.

3.1 Plug version

Fix the socket on the corresponding wires of the

cable. Assignement of contacts – please refer to

the labelling plate or to the corresponding list.

Fix the cable shield to the socket in such a way

that there will be a good contact between shield

and housing. Plug in and fi x the cable socket

connector.

3.2

For pin assignment, cable colors, electrical diagrams and load, please refer to the reverse page

of this manual.

The pressure transmitter is protected against

reverse polarity of the suply volt age, as well as

against over voltage.

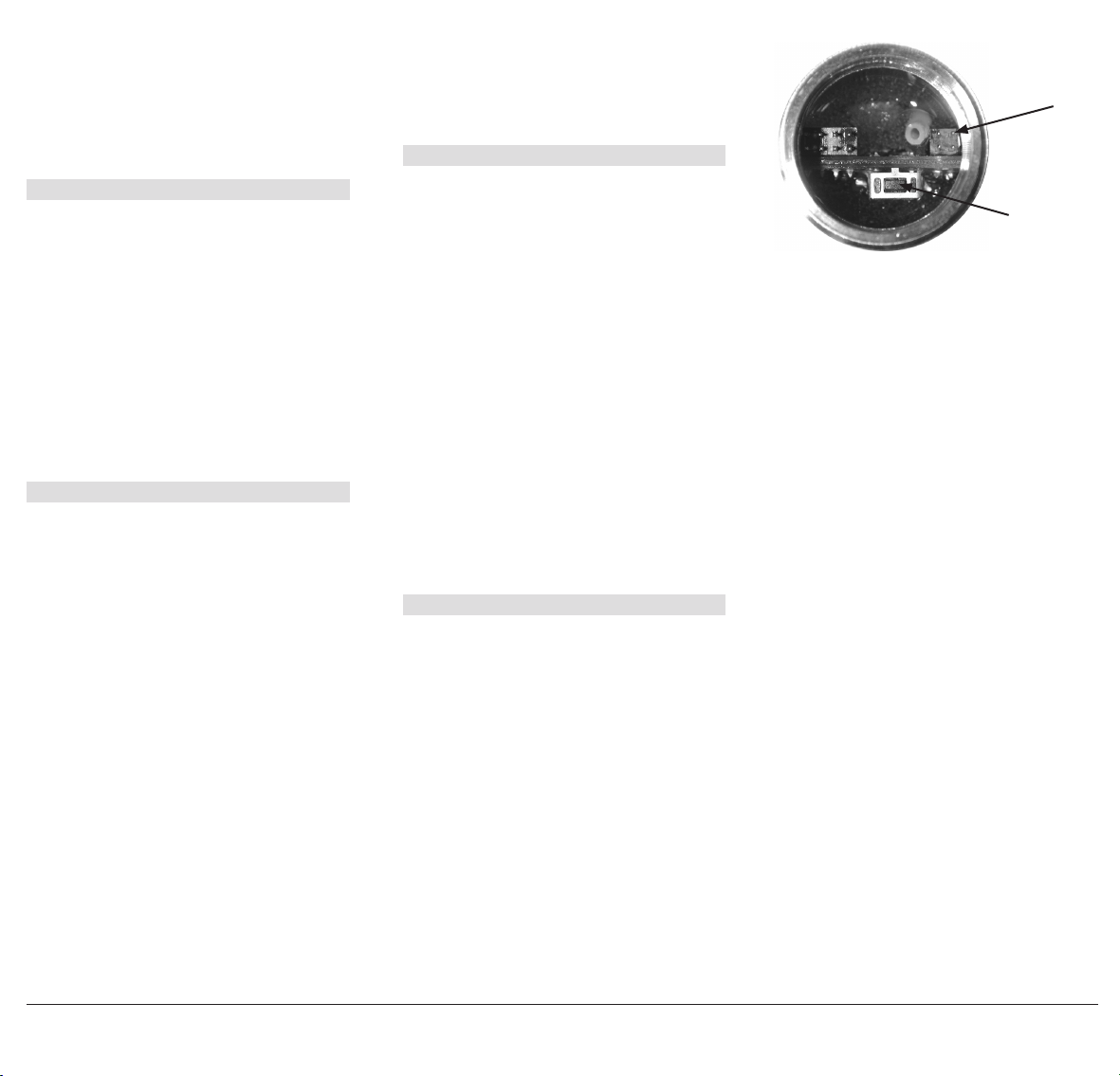

4. New – Calibration of the Zero point

The function for the new calibration of the Zero

point is accessible on the device. This function

allows you to make a correction of the output

signal drift, for example caused by the installation. Any long term drifts can be corrected likewise. Caution: Usually, the pressure transmitter

must be free of any pressure, when adjusting

the Zero point. An exception, if for example you

want to adjust a level transmitter and you want

to set a new Zero point. If you need to set the

pressure transmitter with a negative range (-1 …

X bar ) or with an absolute range, it can only be

achieved if the defi ned pressure is applied on the

pressure transmitter. This can be done by means

of using a calibrator.

white wire

Zero point

push button

So the Zero point can be found, the device must

be connected to a power supply. The New-Calibration of the Zero point is achieved with a single

push on the push button.

The Zero point switch can be reached in different

way depending on the model:

The model with the plug unit connector: Unplug

the device plug, then loosen the plug unit from

the pressure transmitter, turn it anticlockwise.

Caution: The plug unit is connected with the

electronic system. Try to avoid to pull out the

cable to much, because you can possible pull

out the plug. Although using all your caution and

you unplug the connection, you take the white

wire and plug it in the right top hand corner (see

picture). Now you can apply the power supply

by plugging in the plug of the device. Press the

Zero point switch. Detach the plug of the device.

To assemble the plug unit, turning it clockwise

onto the device. Caution: Watch out and take the

necessary caution not to have the wires twisted

between the plug unit and the electronic, before

assembling. Fasten the plug unit on the device.

Your pressure transmitter is now reset with a

new Zero point and is ready to be used.

www.baumerprocess.com Application Manual G45214.1

Design and specifi cations subject to change without notice

Loading...

Loading...