Page 1

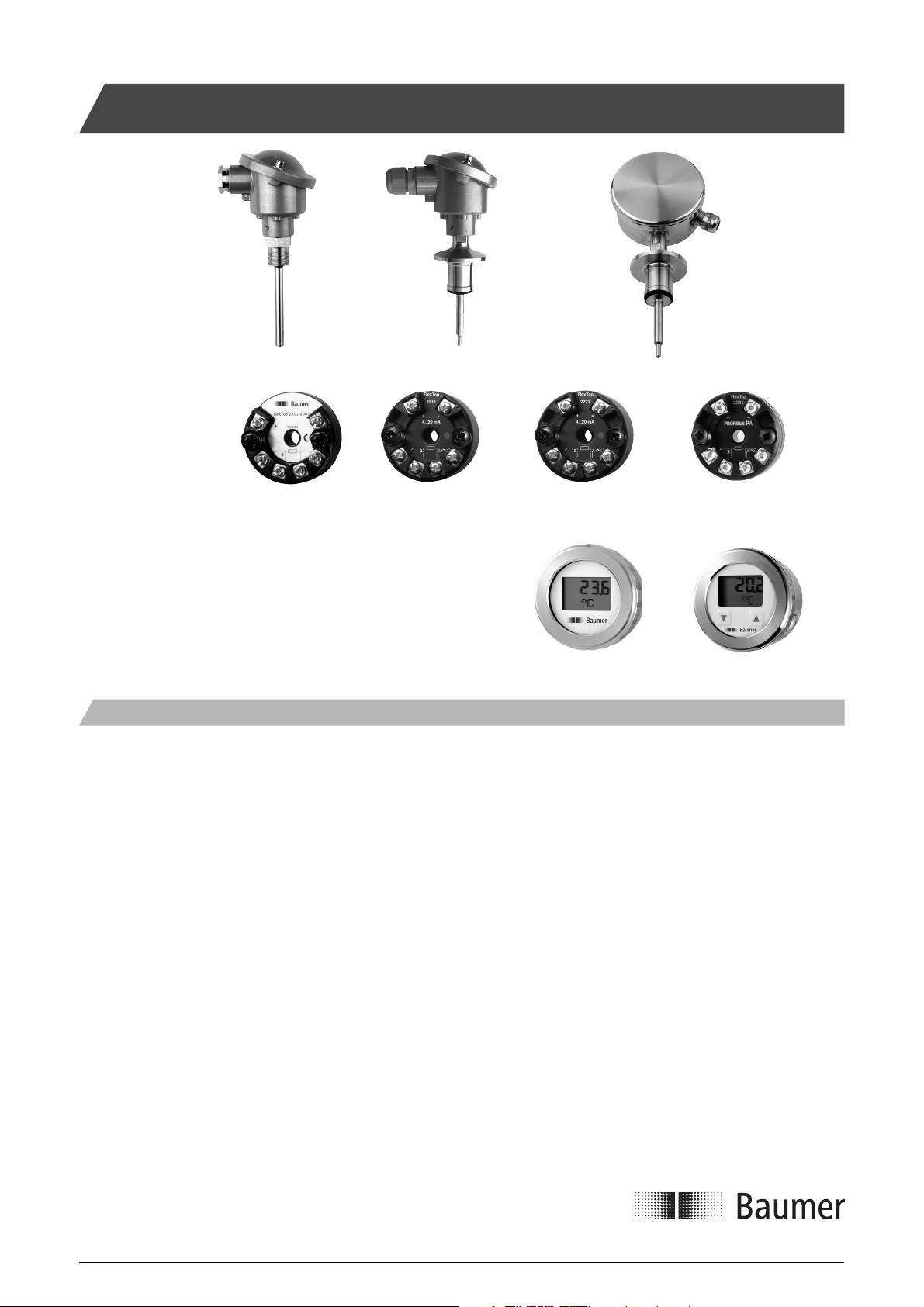

CombiTemp Temperature Measuring System

Housing

DIN-B

Standard or

Ex ia safety

Transmitters

FlexTop 2201 FlexTop 2211 FlexTop 2221 FlexTop 2231

Displays

The process connections shown

are examples.

Description

DIN-B

Ex n safety

Ø80 mm

stainless steel

FlexView BattTemp

CombiTemp comprises a series of basic elements which can be

combined to various temperature sensors and transmitters. Being a

building block system CombiTemp offers a great fl exibility in respect to

modifi cation, service and maintenance.

The basic components in the system are:

Housing: DIN-formB or Ø80mm stainless steel

Process connection: Refer to the data sheet

FlexTop transmitters: 2201, 2211, 2221, 2231

FlexView 4...20 mA LC-display

BattTemp, Battery operated Pt100 LC-display

The parts can be assembled by the user or delivered assembled and

calibrated, if relevant. However, an Ex ia or Ex n approved product will

always be assembled at the factory.

All documentation can be found at www.baumerprocess.com

This Ex-approved product is manufactured by:

Baumer A/S

Jacob Knudsens Vej 14

DK-8230 Aabyhoej

Denmark

Please refer to the relevant data sheets and installation manuals for

each product:

Product Data Sheet Manual

CombiTemp 2000-1 This manual

FlexTop2201 2201-1 2201-8906

FlexTop2211 2211-1 2211-8900

FlexTop2221 2221-1 2221-8900

FlexTop2231 2231-1 2231-8900

FlexView 9401-1 9401-8904

BattTemp 2400-1 2400-8900

Installation Manual 5850-008www.baumerprocess.com

Page 1 Design and specifi cations subject to change without notice

Page 2

Technical Data, General

Environmental conditions

Media temperature, std. -50...400°C

Surface sensor -40...150°C

Ambient temperature -40...160°C

(or max. temperature range for display/transmitter)

Humidity < 100% RH, condensing

(or max. humidity for display/transmitter)

Protection class DIN housing IP 65

ø80 mm housing IP 65 + IP 66

Vibrations GL, test 2

(sensor tubes < 200 mm only)

Disposal of product and packing

According to national laws or by returning to Baumer

Sensor tube and connection

Material Acid-proof, stainless steel

(AISI 316L/W.1.4404)

Media pressure Max. 16 bar

Time constant t

Mechanical tolerances ISO 2768-m

See table below

0.5

Sensor element

Sensor type Pt100, Class A or B

Pt1000, Class B

Accuracy DIN/EN/IEC 60751

1/1 DIN B: ±(0.3 + 0.005 x t) °C

1/3 DIN B: +1/3 x (0.3 + 0.005 x t) °C

1/6 DIN B: +1/6 x (0.3 + 0.005 x t) °C

1/1 DIN A: +(0.15 + 0.002 x t) °C

Safety Instructions Ex-Application - Confi guration

This instrument is built and tested ac cord ing to the current EU-directives and packed in technically safe con di tion. In order to main tain this

condition and to ensure safe op er a tion, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed.

Ignoring the warnings may lead to severe per son al injury or substantial

damage to property.

The product must be op er at ed by trained staff. Correct and safe

operation of this equipment is de pend ent on proper transport, storage,

installation and op er a tion.

All electrical wiring must conform to local stand ards. In order to prevent

stray elec tri cal radiation, we rec om mend twisted and shielded input

cables, as also to keep power sup ply cables separated from the input

cables. The con nec tion must be made ac cord ing to the connecting

di a grams.

Before switching on the power supply take care that other equip ment

is not af fect ed. Ensure that the supply voltage and the conditions in the

environment comply with the spec i fi ca tion of the de vice.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

WARNING

For electrical installation and com mis sion ing of explosion protected

devices, the data given in the con form i ty cer tifi cate as also the local

reg u la tions for installation of elec tri cal apparatus within explosion pro tect ed areas must be considered. The intrinsically safe versions can be

mounted in the explosion hazarded area according to its spec i fi ca tion

only con nect ed to a certifi ed intrinsically safe supply loop with the cor re spond ing electrical values.

Valid for FlexTop 2201 / 2211 / 2221 and FlexView:

None of the two types of FlexProgrammer confi guring unit must be

connected to the FlexView within the hazardous area.

Confi guring procedure:

a) Disconnect mains from the 4...20 mA loop circuit.

b) Disconnect the product from the circuitry within

the hazardous area.

c) Bring the product to the safe area.

d) Connect the FlexProgrammer and perform the

confi guring session.

e) Re-install the product in the hazardous area.

f) Connect the power supply to the circuit.

Valid for FlexTop 2221 only:

Confi guration of the FlexTop2221 can be made within the hazardous

area by means of a handheld HART confi gurator, providing the

precautions and guidelines described in the product´s manual are

observed.

Valid for FlexTop 2231 only:

Confi guration of the FlexTop2231 can be made within the hazardous

area by means of a Profi bus PA confi gurator, providing the precautions

and guidelines described in the product´s manual are observed.

WARNING

This product contains no replaceable parts.

In case of malfunction the product must be shipped to Baumer for

repair.

WARNING

Products with painted and/or plastic surfaces (e.g. display) imply a risk

of electrostatic charging.

To prevent electrostatic hazard - do only clean with a moist cloth.

After mounting the device - do check that the housing has a ground

potential.

Installation Manual 5850-008www.baumerprocess.com

Page 2 Design and specifi cations subject to change without notice

Page 3

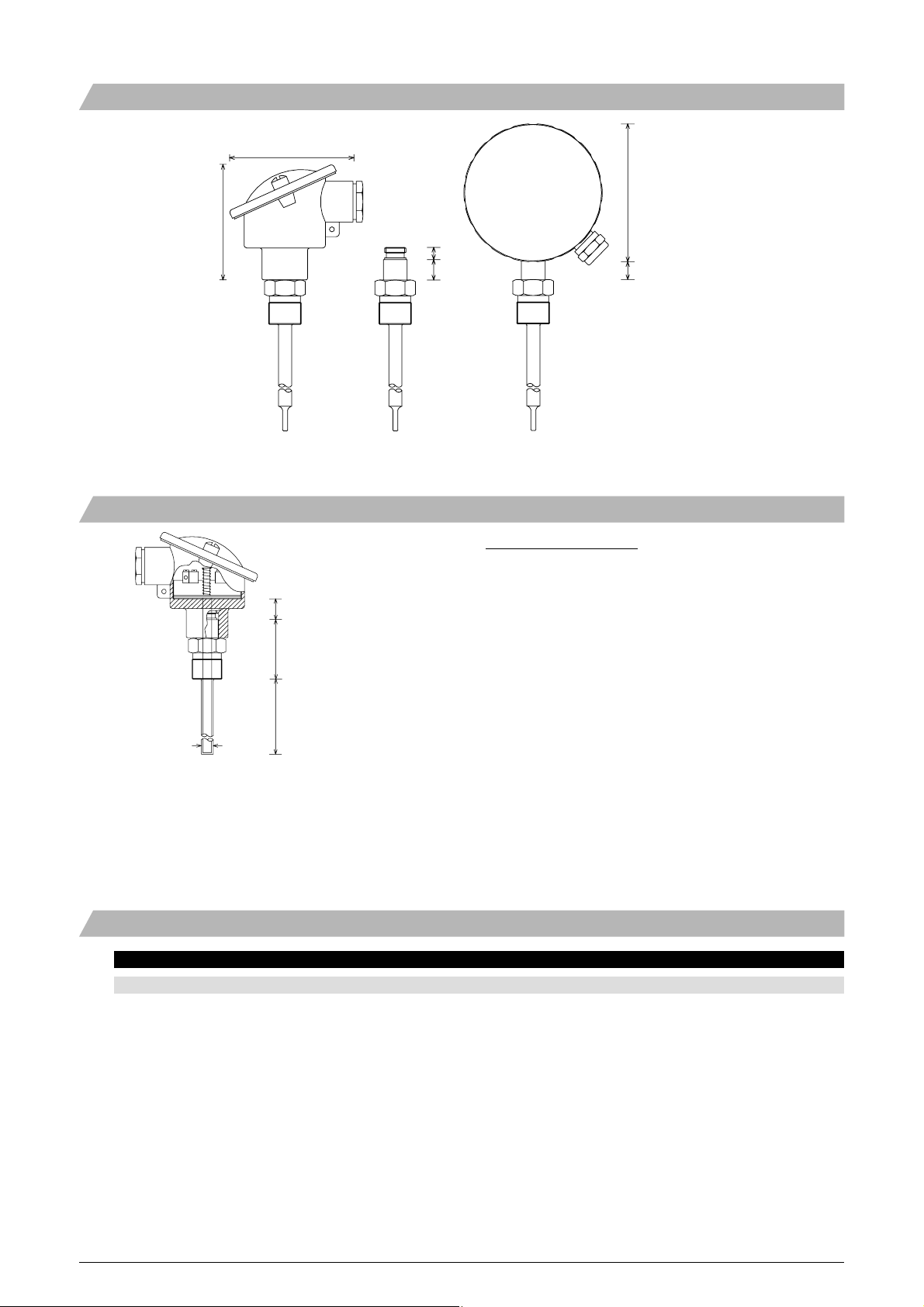

Dimensional Drawings - Mounting Details

[mm]

76

71

7.5

12.5

Male Nipple G1/2A Male Nipple G1/2A Male Nipple G1/2A

mounted on DIN B housing mounted on ø80 mm housing

Sensor inserts

Calculation of insert length:

When ordering an insert the length must be calculated from the

formula:

85

11

Housing shaft {8}

Total body length

Sensor length (L)

DIN housing with G1/2A male nipple connection

and sensor insert

Note {8}

Housing shaft DIN housing: 11.5 mm

ø80 housing: 6.5 mm

Time Constant τ

0.5

Insert length = Sensor length + total body length + housing shaft

(Total body length can be calculated from the dimensional drawings on

pages 6 and 7)

Example.

Insert for a G1/2A male nipple sensor in a DIN housing, 100 mm

sensor tube, normal response sensor tip:

Housing shaft = 11.5 mm

Total body length = 27.5 + 12.5 = 40 mm (see page 6)

Sensor length = 100 mm

This insert must be ordered with a 151.5 mm sensor tube.

Sensor type Liquids Air

Dimension Response Insert 0.4 m/sec. 3 m/sec. 0 m/sec.

ø6 mm tube fast < 1.5 sec. < 21.4 sec. < 135.6 sec.

ø8 mm tube fast < 1.5 sec. < 33.6 sec. < 181.0 sec.

ø10 mm tube fast < 1.5 sec. < 46.8 sec. < 238.9 sec.

ø12 mm tube fast < 1.5 sec. < 59.9 sec. < 311.4 sec.

ø6 mm tube normal < 6.1 sec. < 27.2 sec. < 137.8 sec.

ø8 mm tube normal < 7.6 sec. < 47.7 sec. < 200.9 sec.

ø10 mm tube normal < 11.1 sec. < 57.8 sec. < 270.6 sec.

ø12 mm tube normal < 16.2 sec. < 70.8 sec. < 319.8 sec.

ø8 mm tube normal 5.6 mm < 13.6 sec. < 51.1 sec. < 253.1 sec.

ø10 mm tube normal 5.6 mm < 28.1 sec. < 67.0 sec. < 271.1 sec.

ø12 mm tube normal 5.6 mm < 31.3 sec. < 82.3 sec. < 289.3 sec.

Surface sensor, fl ush mounted < 1.0 sec.

Installation Manual 5850-008www.baumerprocess.com

Page 3 Design and specifi cations subject to change without notice

Page 4

Technical Data, Ex ia IIC T4/T5, ATEX II 1G Approval

Product Identifi cation

The label at the product will show the type no. like this:

814x xxxx xxxx xx4 xxxx + xxxx xxxx + xx xx-xxx

CombiTemp no. + FlexTop no. + FlexView/BattTemp no.

The complete confi guration will be referred to as CombiTemp.

A CombiTemp with a type no. with the upmentioned structure is

Ex ia IIC T4/T5, ATEX II 1G approved in accordance with the current

EU-directives.

Ex- data for the below listed confi gurations

Ø80 housing: FlexTop 2201 / 2211 / 2221 / FlexView

DIN-B housing: FlexTop 2201 / 2211 / 2221

Internal inductivity L

Internal capacity C

Barrier data U < 28 Vdc ; I < 0.1 A ; P

Temperature class T4: -20 < T

T5: -20 < T

< 11 µH

i

< 36 nF

i

< 70°C

amb

< 60°C

amb

< 0.7 W

The CombiTemp must be installed in accordance with prevailing

guidelines for zone 0 or 1, and a certifi ed, intrinsically safe zener

barrier or isolation barrier with the listed maximum values must be

used.

Ex- data for the below listed confi gurations

Ø80 housing: FlexTop 2231

DIN-B housing: FlexTop 2231

Internal inductivity L

Internal capacity C

Coupler/link FISCO standard;

Zener barrier U < 20 Vdc ; I < 0.1 A ; P

Temperature class T4: -30 < T

T5: -30 < T

The CombiTemp must be installed in accordance with prevailing

guidelines for zone 0 or 1, and a certifi ed, intrinsically safe zener

barrier or isolation barrier with the listed maximum values must be

used.

< 10 µH

i

< 2 nF

i

U < 17.5 Vdc ; I < 215 mA ; P

< 0.75 W

< 85°C

amb

< 60°C

amb

< 2 W

Ex- data for the below listed confi guration

Ø80 housing: BattTemp

Temperature class

Battery: Energizer Lithium FR6 L91 AA

T4: -10 < T

T5: -10 < T

< 70 °C

amb

< 50 °C

amb

Battery: Duracell Alkaline MN1500 LR6 AA

T3: -10 < T

T4: -10 < T

< 70 °C

amb

< 60 °C

amb

The CombiTemp must be installed in accordance with prevailing

guidelines for zone 0 or 1. However, being a battery operated

instrument the installation does not involve a barrier.

CAUTION: Replacement of the battery must be done

outside hazardous areas.

The BattTemp is battery supplied and must not be connected to any

external power supply, nor to a 4...20 mA loop circuit.

When the BattTemp is installed in a hazardous area the battery clip

must be mounted. Observe the polarity of the battery.

BattTemp contains no repairable parts and must be replaced as a unit

in case of malfunction. It has no need for preventive maintenance,

except replacement of the battery.

Confi guring by the push buttons is allowed within the hazardous area.

Battery

Battery clip

+

Terminals

for Pt100 sensor

Ex-Application Example

230 Vac

RTD

Zone 0/1 Safe area

- +

2 - + 1

FlexTop 2211 FlexView Isolation Barrier Power Supply

CombiTemp

3 4

1 2

+ -

24 VDC 4...20 mA

Installation Manual 5850-008www.baumerprocess.com

Page 4 Design and specifi cations subject to change without notice

Page 5

Technical Data, Ex nA II T4/T5, ATEX II 3G Approval

Product Identifi cation

The label at the product will show the type no. like this:

814x xxxx xxxx xx5 xxxx + xxxx xxxx + xx xx-xxx

CombiTemp no. + FlexTop no. + FlexView/BattTemp no.

The complete confi guration will be referred to as CombiTemp.

A CombiTemp with a type no. with the upmentioned structure is

Ex nA II T4/T5, ATEX II 3G approved in accordance with the current

EU-directives.

Ex- data for the below listed confi gurations

Ø80 housing: FlexTop 2201 / 2211 / 2221 / 2231/FlexView

DIN-B housing: FlexTop 2201 / 2211 / 2221 / 2231

Temperature class T4: -20 < T

T5: -20 < T

The CombiTemp must be installed in accordance with prevailing

guidelines for zone 2 without a barrier.

WARNING: Do not open when energised.

< 70°C

amb

< 60°C

amb

Ex- data for the below listed confi gurations

Ø80 housing: BattTemp

Temperature class

Battery: Energizer Lithium FR6 L91 AA

T4: -10 < T

T5: -10 < T

< 70 °C

amb

< 50 °C

amb

Battery: Duracell Alkaline MN1500 LR6 AA

T3: -10 < T

T4: -10 < T

< 70 °C

amb

< 60 °C

amb

Warning: Observe battery ambient temperature !!!

The CombiTemp must be installed in accordance with prevailing

guidelines for zone 2.

CAUTION: Replacement of the battery must be done

outside hazardous areas.

The BattTemp is battery supplied and must not be connected to any

external power supply, nor to a 4...20 mA loop circuit.

When the BattTemp is installed in a hazardous area the battery clip

must be mounted. Observe the polarity of the battery.

BattTemp contains no repairable parts and must be replaced as a unit

in case of malfunction. It has no need for preventive maintenance,

except replacement of the battery.

Confi guring by the push buttons is allowed within the hazardous area.

Battery

Battery clip

Terminals

for Pt100 sensor

Electrical Connection Application

CombiTemp Gland Cable diameter Gland torque

mm Nm

Ø80 mm housing M16 3...9 8

DIN-B housing M20 8...13 6

Warning: If the CombiTemp is to be installed in ambient

temperature exceeding 70°C a proper cable should be installed.

CombiTemp

- +

4...20 mA

we

6

2 1

Zone 2 Safe area

RTD

5

4

3

- +

24 VDC

230 Vac

3 4

1 2

+ -

FlexView FlexTop 2211 Power supply

Installation Manual 5850-008www.baumerprocess.com

Page 5 Design and specifi cations subject to change without notice

Page 6

Mounting the ø80 mm Housing

35 Nm

2 Nm

Installation Manual 5850-008www.baumerprocess.com

Page 6 Design and specifi cations subject to change without notice

Page 7

Mounting the DIN-B Housing

2mm 2 Nm

35 Nm

Installation Manual 5850-008www.baumerprocess.com

Page 7 Design and specifi cations subject to change without notice

Page 8

4-wire Sensors Double Elements

White White Red Red White White Red Red

Warning:

One of the wires may not be

connected in case of a 3-wire

connection to the temperature

transmitter

Application Photos

ø80 mm housing with FlexView Cut through DIN - B housing ø80 mm housing with 2 glands

Gland (blind plug at the rear) FlexTop 2201 temperature transmitter Cover not mounted

Clamp connection G1/2A male nipple connection 3A connection at the rear

Fast response sensor Normal response sensor Fast response sensor

5850-008-UK/2008-04-25/Rev. A1 This data sheet may only be reproduced in full.

Installation Manual 5850-008www.baumerprocess.com

Page 8 Design and specifi cations subject to change without notice

Loading...

Loading...