Baumer CleverLevel LFFS-1, CleverLevel LFFS-4, CleverLevel LFFS-3, CleverLevel LFFS-2 Operating Instructions Manual

Page 1

www.baumer.com Operating instructions: 11109132 09 EN Page 1 / 20

Safety instructions

2019-03-20 Design and specifications subject to change without notice

This instrument is constructed and tested according to the current EUdirectives and packed in technically safe condition. In order to maintain

this condition and to ensure safe operation, the user must follow the

instructions and warnings given in this instruction.

During the installation local standards have to be observed. Ignoring the

warnings may lead to severe personal injury or substantial damage to

property.

The product must be operated by trained staff. Correct and safe operation of this equipment is dependent on proper transport, storage, installation and operation.

All electrical wiring must conform to local standards and the connection

must be made according to the connecting diagrams.

Before switching on the power supply take care that other equipment is

not affected. Ensure that the supply voltage and the conditions in the

environment comply with the specification of the device.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

To obtain the specified protection degree, the LFFS must be mounted

with a compliant cable.

Description

The Level Switch LFFS designed to detect levels in tanks, media separation and provide empty-pipe detection or dry-run protection

for pumps.

By means of the FlexProgrammer 9701 the output can be configured to either NPN, PNP or digital output signal. A damping of the

output signal can be activated in case of a fluctuating media level, e.g. during tank filling.

The measurement is precise and unaffected by the mounting position in the tank. In the Flex-software a compensation for foam,

bubbles and condensate as well as viscous media can be set.

The Flex-software also features an adjustment facility making the user able to adjust the sensor to a specific media.

The Level Switch LFFS measures liquids such as water and beer as well as viscous, sticky fluids, such as honey, yoghurt, toothpaste and ketchup. Even dry medias can be measured, e.g. sugar or flour.

The Level Switch LFFS is resistant against CIP and SIP agents.

Hygienic installation is also possible with the comprehensive range of accessories, see the overview at page 6.

WARNING

When the top cover is removed, do not look directly at the blue LED with unshielded eyes or damage to retina may occur!

This product contains no replaceable parts. In case of malfunction the product must be shipped to Baumer for repair.

Operating instructions

CleverLevel switch, LFFS

CleverLevel switch, type LFFS is an universal level switch, which

can be used for all applications in liquids and solids with a DCvalue above 1.5

Page 2

www.baumer.com Operating instructions: 11109132 09 EN Page 2 / 20

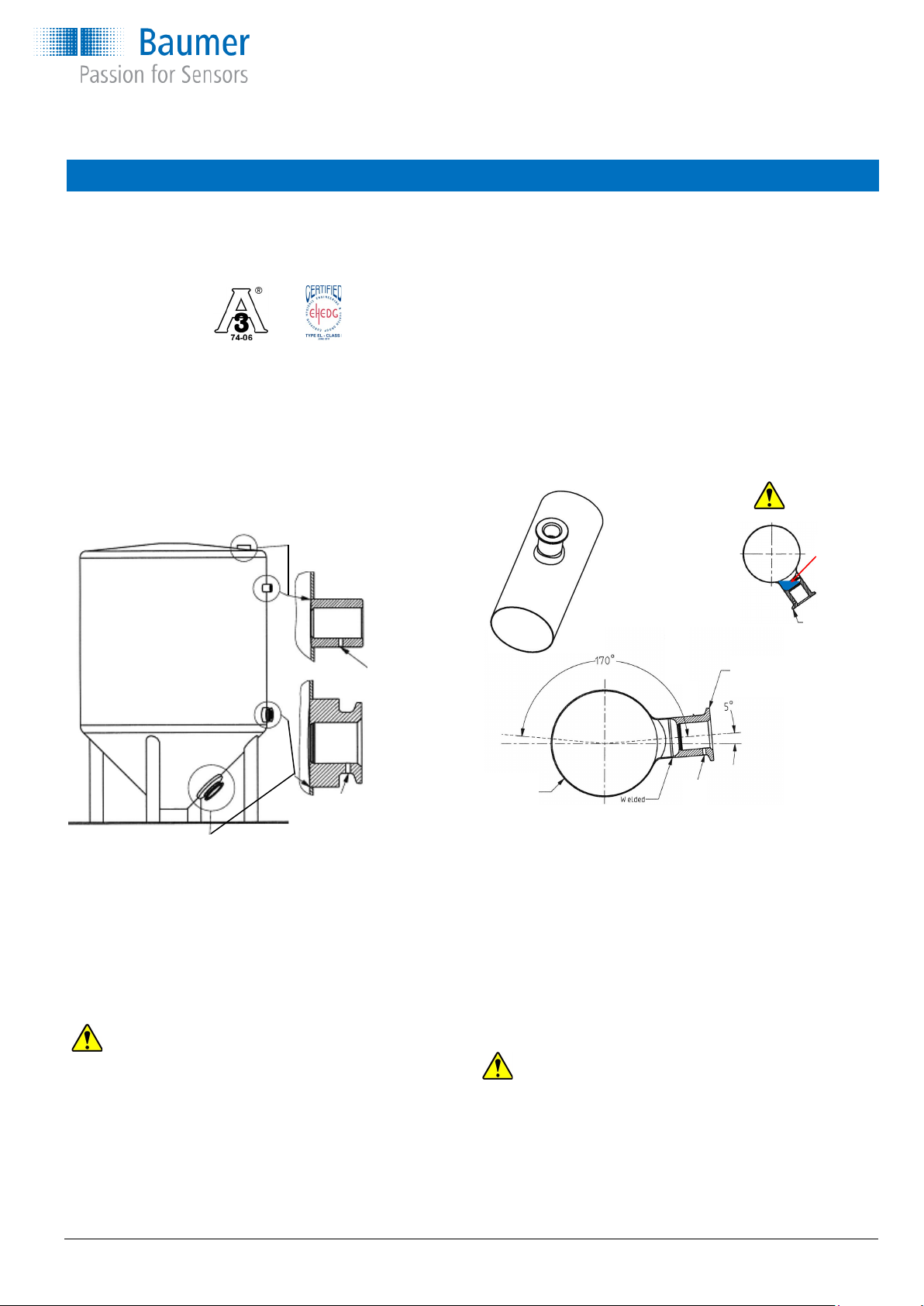

Mounting

Operating instructions

CleverLevel switch, LFFS

Please refer to “Accessories” data sheet. The welding part has

an engraved mark or a leak hole. When the product has been

mounted and correctly tightened the gland or M12 plug will

align with this mark.

Make sure that the gland/plug is pointing downwards to prevent fluids from penetrating into the instrument.

Use only the authorised special designed accessories. The

product warranty is void when installed with other adapters.

Do not use PTFE, fibre or other gaskets. The PEEK tip against

the stainless steel welding part will perform a hygienic tightening provided that the guidelines have been followed.

Due to the measuring principle it is essential that the sensor tip

can “see” an ample amount of the metal shaft or welding part.

Dimensions

Mounting instructions for sliding connection:

1) Clean the sliding shaft.

2) Mount the smallest ring against the media as indicated.

3) Tighten the G1/2 Hygienic sliding nipple at 25...30 Nm.

4) Replace the Washer ring kit when one or both parts are

permanently deformed or stick to the shaft of the sliding

connection.

The Level Switch LFFS with sliding connection can be mounted

in installations with a static pressure up to 16 bar.

To prevent personal injuries or property damage it is essential

that the safety wire is mounted correctly and is undamaged.

WARNING

Compression ring kit

ZPX1-006 for sliding

version

G 1/2 A hygienic sliding connection BHC 3A DN38 hygienic G 1/2 A hygienic

Measuring principle

An electrode inside the sensor tip builds a capacitor together with the surroundings. The medium with its dielectric constant (DC value) is defining

the capacitance value. A resonance circuit is created in combination with a

coil in the sensor head. Switching signal tripping is according to the measured resonance frequency and the programmed trigger thresholds.

Page 3

Operating instructions

CleverLevel switch, LFFS

Mounting

www.baumer.com Operating instructions: 11109132 09 EN Page 3 / 20

NOTE

The M12 cable rotating nut must be tightened by hand force only.

Max. torque is 0.6 Nm. Do not use any tool.

Refer to www.baumer.com for O-rings, gaskets and other accessories.

If the PEEK sealing rings for sliding connection is damaged or seriously scratched, the instrument or sealing rings should be replaced

(type ZPX1-006).

1) Use only a 3-A approved counterpart.

2) The leak detection port should be visible and drained.

3) Mount the adapter in a self-draining position/angle.

4) Level the inner surface of the pipe with the counterpart.

After installation:

Check the leak tightness of the sleeve.

Check the tightness of cable glands or M12 plug.

Example

with ZPW2-626

Example with

ZPW3-321

Example with

ZPW2-621

Leak detection port

must be placed at the

lowest possible position.

Fitted

incorrectly

Cannot be

drained

WARNING

5) The 3-A mark or the arrow shall be placed upwards.

6) Welding should be grinded to Ra ≤ 0.8.

7) Tighten the instrument in the adapter with a torque of 15...20 Nm.

If the seal is leaking and the media appears in the leak detection

port, the seal is to be changed immediately.

Before reassembly, clean the hole and inside of the connection with

detergent and sanitising liquid. Use a small brush. Verify that all of

the inside area is completely clean.

Reassemble and verify that the connection is tight.

Do not use Teflon, elastomer or other types of gaskets for the hygienic process connection featuring a conical seal.

The industrial versions with thread must be sealed e. g. by gasket or

Teflon® tape and tightened into the counterpart.

Installation of hygienic 3-A approved and EHEDG certified products,

please refer to below:

The switch provides IP67 protection in cable version or if installed

with IP67-compliant M12 cable. Switch installation using an IP69K

cable ensures IP69K conformity.

Stainless

steel tube

NOTE

The CleverLevel switch is to be mounted in a closed metal pipe, tank

or container.

Page 4

Refer to adaptor instruction manual for further information

NOTE:

The LFFS must be mounted in a Baumer mounting

connection.

If not, Baumer do not guarantee correct function or

tightness.

Operating instructions

CleverLevel switch, LFFS

Mounting connections

ISO2852 SMS 1145 Welding

DN38: ZPH3-3213 DN51: ZPH1-3236 for tank

DN51: ZPH3-3216 ZPW3-321

Varivent®, type N DIN 11851 Welding

ZPH3-324E DN25: ZPH3-3221 for tank

Varivent®, type F DN40: ZPH3-3224 ZPW3-322

ZPH3-344F DN50: ZPH3-3225

DIN 11864-1-A Welding Ø35

DN 40: ZPH3-3254 for tank/tube

DN 50: ZPH3-3255 ZPW2-324

Adapter Welding

EH FTL to pipe extrusion

G¾A: ZPH1-32BA DN 25...DN50: ZPW2-326

G1A: ZPH1-32CB DN 65...DN150: ZPW2-327

VS

G¾A: ZPH1-32BC

G1A: ZPH1-32CD

Adapter Adapter, industrial Adapter, industrial

G½ → G1 G½ → G1: ZPI1-32B Sliding connection

ZPH1-32C0 G½ → G1½: ZPI1-32D G½ → G½ DIN 3852-E

G½ → G2: ZPI1-32E ZPI1-32A

Welding

for tank

ZPW2-621

Welding

for pipe end

ZPW2-626

www.baumer.com Operating instructions: 11109132 09 EN Page 4 / 20

On a welding adapter there is an

arrow or a 3A logo.

This must be placed upwards when

welding the adapter into a tank

(horizontal position).

This assures that the electrical connection will be pointing downwards

(opposite of the arrow; 3A logo)

Page 5

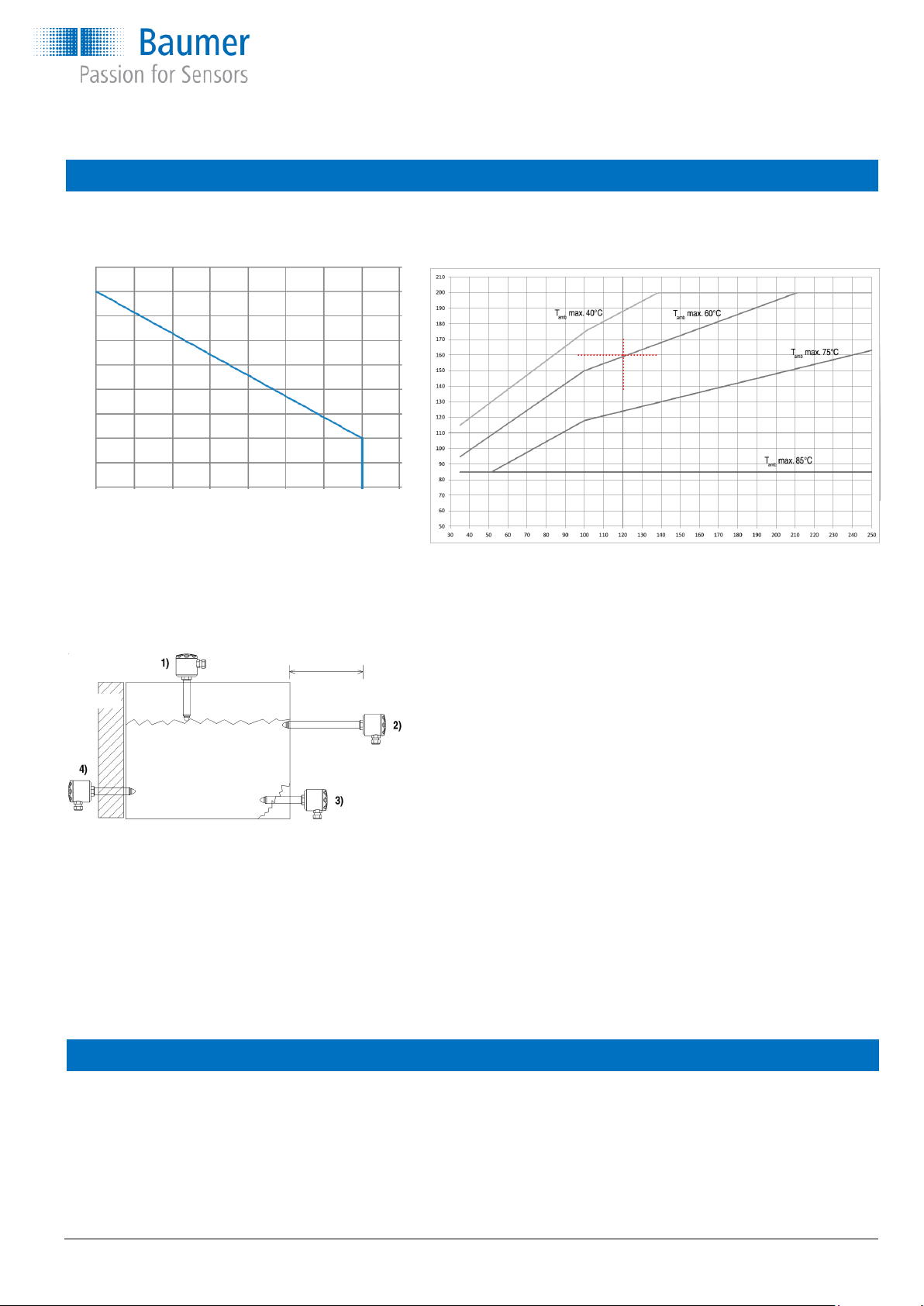

Media temperature and external length for sliding connection

Operating instructions

CleverLevel switch, LFFS

Media temperature °C

120

115

110

105

100

95

90

85

80

75

50 55 60 65 70 75 80 85 90

Ambient temperature °C

LFFS-xx1.x / LFFS-xx2.x LFFS-xx3.x and LFFS-xx4.x

External length of sliding connection

Media temperature °C

External length

See example

The drawing shows how the sliding connection can be

used for at least 4 applications:

1) Mounted at the top of a tank to adjust to a

maximum level.

2) Serving as a cooling neck in high media

temperature applications.

3) Adjusted to place the sensor tip deeper

inside the tank.

4) To reach in through insulation material.

It is essential that the max. ambient temperature for the electronics is

never exceeded (85°C). For ATEX approved products please refer

ATEX data.

Example, how to read External length curve:

Example: Media temperature / Ambient temperature / External length

160°C 60°C 120 mm

A 250 mm sliding connection is mounted in a tank with a total in-

sertion length of 130 mm. Hence the external length of the sliding

connection will be 250 – 130 = 120 mm.

The media temperature will be max. 160 °C.

Read the x-axis at 120 mm and the y-axis at 160°C and find that

the ambient temperature must be kept below 60°C.

In case the radiated heat from the tank will cause a higher ambient

temperature at the housing efficient insulation of the tank must be

established.

www.baumer.com Operating instructions: 11109132 09 EN Page 5 / 20

For CIP/SIP Media temperature, max. 140°C

Ambient temperature, max. 60°C

Duration, max. 1 hour

When re-ordering a CleverLevel switch

If a new CleverLevel switch is installed in an existing application, it is normally a “plug-n’-play” operation.

If the settings of the level switch was changed from standard factory settings, it is necessary to re-adjust the new switch to same

as the “old” switch. It is possible to save the settings of the “old” switch on the PC and download those again to the new level

switch.

The factory setting of the sensitivity of the media may vary up to ±5%. This means that if an very exact set point is required, a new

teach-in or adjustment by the FlexProgram must be performed.

Page 6

Operating instructions

CleverLevel switch, LFFS

Teach-In using the FlexProgram and FlexProgrammer 9701

Sophisticated settings for Teach-In as well as output type, diagnostics, data logging, tag no. and damping can be configured using

the FlexProgrammer 9701. Integrated HELP-menus will give full instruction.

Press or to browse the menus

to access current menu point

to return to previous menu

and simultaneously to reset FlexProgrammer

and go in sleep mode

Teach-In

Press

and simultaneously

Select Menu “Teach-In”

Search for product

= Product LFFS/LBFS

At empty tank setting 0%

At full tank setting 100%

Manually Teach-In

Make sure that power is on before Teach-In.

For best Teach-In it is important the product is fixed in the final application.

During Teach-In mode the light intensity of the LED will decrease, please protect your eyes.

Step To do LED Result

1

Connect terminal ”Teach-In” to

- VDC (T1 or T2) for 3,5 second

Flash 1 time per second

Ready for Teach-in

2

With no media present connect

”Teach-In” to - VDC shortly

Light on for 2 second and then flash

Register ”empty” state. Pls. See note

3

With media present connect

”Teach-In” to - VDC shortly

Light on for 2 seconds

Register ”full” state, stores the value and returns to

Normal operation with new setting

NOTE:

If the media is sticky, foamy, powdery or in other ways leaving parts of the media at the sensor tip this situation has to be established also during the Teach-In process. Otherwise a faulty calibration can be the result.

If Teach-In for some reason do not succeed, the CleverLevel Switch LFFS will enter “Error State” and automatically reload factory

settings . The factory settings can always be reloaded by connecting the terminal “Teach-In” to -VDC for more than 6.5 seconds.

A reloaded factory settings will be confirmed by pulsing light intensity 3 times.

Error state description LED Result

Error state Blinking, 3 × short and 1 × long Can normally be fixed by powering off and on and remake the Teach-In.

Alternatively remake the Teach-In configuration by use of the FlexProgram and the FlexProgrammer 9701

Using the FlexProgrammer 9701 alone and Teach-In

FlexProgrammer 9701 stand alone menu

Press

Turn on FlexProgrammer if in sleep mode

Empty configuration

Search for product

LFFS/LBFS configuration

Product LFFS / LBFS

TAG number xxxxxxxxxxxxxxx

Range min. x.x%

Range max. xx.x%

Damping x,x sec

Output config. Xxxxxxx

Trigger level xx,x%

Range hyst. x,xx%

Trigger hyst. x.xx%

www.baumer.com Operating instructions: 11109132 09 EN Page 6 / 20

Page 7

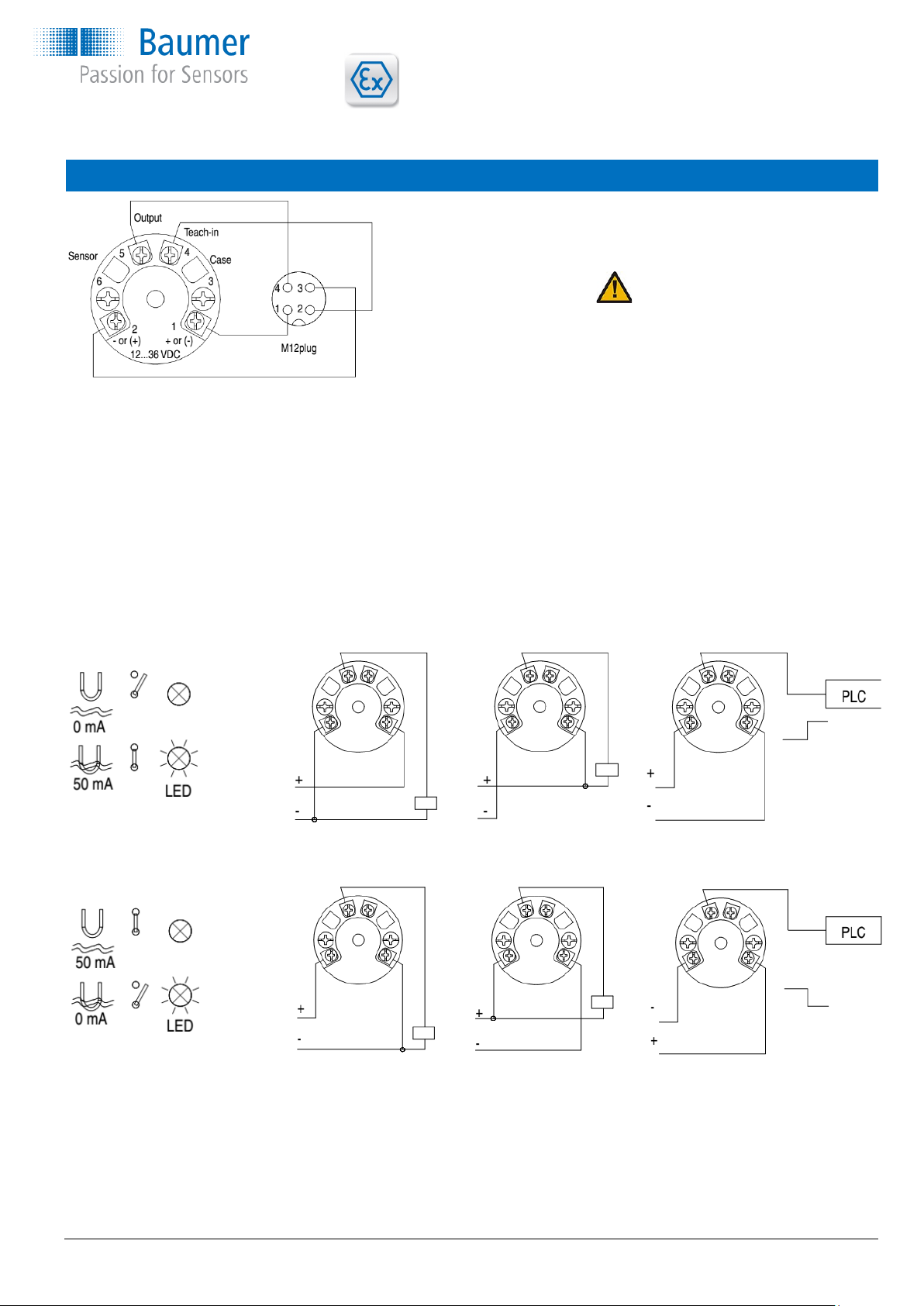

Electrical connection

Operating instructions

CleverLevel switch, LFFS

M12 plug: 1 Brown

2 White*

3 Blue

4 Black

WARNING

* To avoid unintended Teach-In, be aware

not to connect the Teach-In pin or expose it

to any electrical noise during normal operation.

Normally open - NO

Normally closed - NC

Electrical specifications:

Power supply 12,5...36 VDC, 35 mA max.

Output PNP, NPN or Digital

Max. 50 mA, short-circuit and high

temperature protected

1

2

5

1

2

5

1

2

5

1

2

5

1

2

5

1

2

5

www.baumer.com Operating instructions: 11109132 09 EN Page 7 / 20

Active “Low” NPN and Digital output

(-VDC +2,5V) ±0,5V, R

load

= 1 kΩ

Active “High” PNP and Digital output

(+VDC -2,5V) ±0,5V, R

load

= 1 kΩ

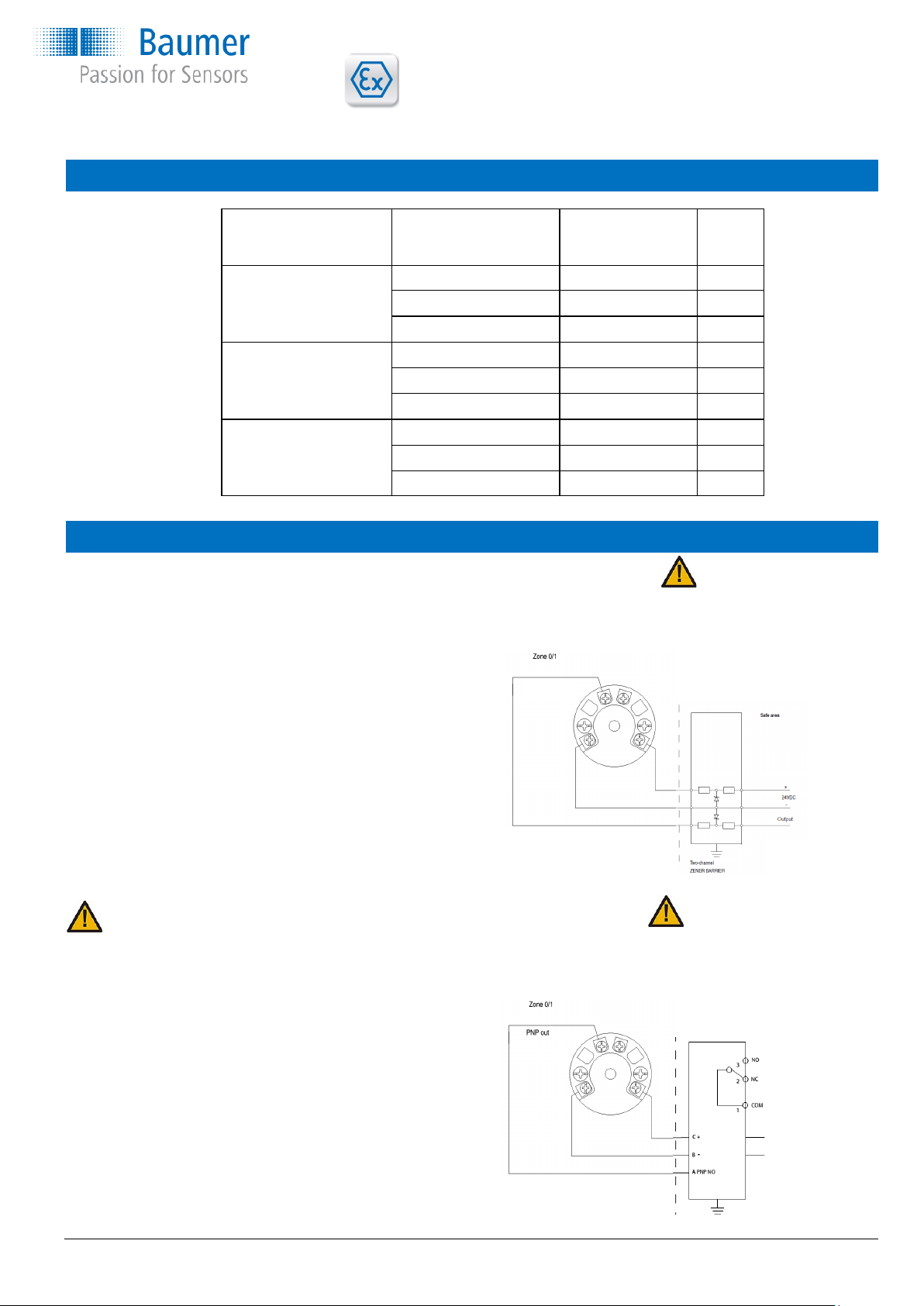

ATEX

Connection type Ambient temperature Media temperature

(max. allowed)

Note

G½ hygienic -40 … +85 °C +85 °C

3A DN38

-40 … +60 °C +95 °C 1)

-40 … +40 °C +115 °C 1)

100 mm -40 … +85 °C +85 °C

Sliding connection

-40 … +60 °C +155 °C 1)

-40 … +40 °C +175 °C 1)

250 mm -40 … +85 °C +85 °C

Sliding connection

-40 … +60 °C +195 °C 1)

-40 … +40 °C +200 °C 1)

Conditions for Ex certification

1) Provided that

the sensor tip

at the instru ment is the

only part in

contact with

the media

Page 8

Operating instructions

CleverLevel switch, LFFS

Ex ia IIC T5, ATEX II 1G - Installation

A Level Switch LFFS-1xx.x is Ex ia IIC T5, ATEX II 1G approved for application in hazardous areas in accordance with

the current EU directives. The product must be installed in

accordance with prevailing guidelines for zone 0 with a barrier

ATEX Gas ia

LFFS-1xx.x

with PNP output

Safe area

+ 22...120 VDC

or

- 90...253 VAC

Note:

For PNP output the barrier module

PFOFSI3-B25100-ALG-LS

is required for functional purposes.

PFOFSI3-B25100-ALG-LS

NPN out

LFFS-1xx.x

with NPN output

Note:

For NPN output only!

A standard barrier may be used

Standard barrier

Two-channel

ZENER barrier

www.baumer.com Operating instructions: 11109132 09 EN Page 8 / 20

Note:

There is an electrical connection between intrinsic safe

circuit and housing due to the measurement principle

ATEX Dust tD

A Level Switch LFFS-2xx.x is Ex tD A20 IP67 T100°C, ATEX II 1D

approved for application in hazardous areas in accordance with the

current EU-directives. The product must be installed in accordance

with prevailing guidelines for zone 20 without a barrier.

Ex-data

Supply range VDC 12,5...30

Load I <0.1 A

Temperature class T1...T5 Pls. see table top page 7

12,5...30

1

2

5

ATEX Gas nA

A Level Switch LFFS-3xx.x is Ex nA II T5, ATEX II 3G approved for

application in hazardous areas in accordance with the current EU

directives. The product must be installed in accordance with prevailing

guidelines for zone 2 without a barrier.

Ex-data

Supply range VDC 12,5...30

Load I <0.1 A

Temperature class T1...T5 Pls. see table top page 7

12,5...30

1

2

5

Ex-data

Supply range 24...30 VDC

Temperature class T1...T5 Pls. see above table

Internal inductivity Li <10 µH

Internal capacity Ci <3 nF

Barrier data U <30 VDC

I <0.1 A

P <0.75 W

Ex-Configuring

The FlexProgrammer 9701 configuring unit must not be connected to the CleverLevel Switch LFFS within the hazardous area.

Configuring procedure:

a) Disconnect mains from the 4...20 mA loop circuit.

b) Disconnect the Level Switch from the circuitry within the hazardous area.

c) Uninstall and bring the Level Switch to the safe area.

d) Connect the FlexProgrammer 9701 and perform the configuring session.

e) Re-install the Level Switch in the hazardous area.

Page 9

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 9 / 20

Sicherheitshinweise

Dieses Gerät wurde gemäss den geltenden EU-Richtlinien gebaut und

geprüft und unter technisch sicheren Bedingungen verpackt. Um diesen

Zustand zu erhalten und einen sicheren Betrieb zu gewährleisten, muss

der Anwender die in dieser Anleitung gegebenen Anweisungen und

Warnhinweise befolgen.

Bei der Installation sind die vor Ort geltenden Vorschriften zu beachten.

Die Nichtbeachtung der Warnhinweise kann zu erheblichen Personenund Sachschäden führen.

Das Produkt darf nur von geschultem Personal bedient werden. Sachgemässer Transport sowie eine sachgemässe Lagerung, Installation

und Bedienung sind entscheidend für einen korrekten und sicheren

Betrieb dieses Gerätes.

Die gesamte elektrische Verkabelung muss den örtlichen Standards

entsprechen und die Anschlüsse müssen gemäss den Anschlussschemata ausgeführt werden.

Vor dem Einschalten der Spannungsversorgung ist darauf zu achten,

dass keine anderen Geräte beeinflusst werden. Es ist sicherzustellen,

dass die Versorgungsspannung und die Umgebungsbedingungen den

Spezifikationen für dieses Gerät entsprechen.

Vor dem Abschalten der Versorgungsspannung sind mögliche Auswirkungen auf andere Geräte und das gesamte System zu prüfen.

Um die spezifizierte Schutzklasse zu erreichen, müssen die entsprechenden Kabel verwendet werden.

Beschreibung

Der Füllstandsschalter LFFS eignet sich hervorragend für die Füllstandserkennung in Behältern, die Medientrennung sowie die

Erkennung leerer Rohre und den Trockenlaufschutz von Pumpen.

Mithilfe des FlexProgrammer 9701 kann der Ausgang als NPN-, PNP- oder ein digitales Ausgangssignal konfiguriert werden. Im

Falle eines veränderlichen Medienfüllstandes (z. B. während der Befüllung des Behälters) kann eine Dämpfung des Ausgangssignals aktiviert werden.

Die Messung erfolgt präzise und wird nicht von der Montageposition im Behälter beeinflusst. In der Flex-Software kann eine Kompensierung für Schaum, Blasen, Kondensat und viskose Medien eingestellt werden.

Die Flex-Software umfasst auch eine Einstellfunktion, die es dem Benutzer ermöglicht, den Sensor an ein bestimmtes Medium

anzupassen.

Der Füllstandsschalter LFFS misst Flüssigkeiten wie Wasser und Bier sowie viskose, klebrige Flüssigkeiten wie Honig, Joghurt,

Zahnpasta und Ketchup. Auch trockene Medien, wie z. B. Zucker oder Mehl, können gemessen werden.

Der Füllstandsschalter LFFS ist gegen CIP- und SIP-Mittel beständig.

Das umfangreiche Zubehörsortiment ermöglicht eine hygienegerechte Installation, siehe Übersicht auf Seite 6.

WARNUNG

Bei entferntem Deckel nicht mit ungeschützten Augen direkt in die blaue LED schauen, da die Netzhaut Schaden nehmen kann!

Dieses Produkt enthält keine austauschbaren Teile. Bei Fehlfunktion ist das Produkt zur Reparatur an Baumer einzusenden.

Betriebsanleitung

CleverLevel switch, LFFS

Der CleverLevel Switch LFFS ist ein vielseitiger Füllstandsschalter,

der für alle Anwendungen mit Flüssigkeiten und Feststoffen mit

einem DK-Wert über 1,5 eingesetzt werden kann.

Page 10

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 10 / 20

Das Messprinzip

Montage

Betriebsanleitung

CleverLevel switch, LFFS

Eine Elektrode im Innern der Sensorspitze bildet zusammen mit der

Umgebung einen Kondensator. Das Medium mit der Dielektrizitätskonstante (DK-Wert) definiert den Kapazitätswert. In Kombination mit

einer Spule im Sensorkopf wird eine Resonanzschaltung gebildet.

Das Auslösen von Schaltsignalen erfolgt entsprechend der gemessenen Resonanzfrequenz und den programmierten Schwellenwerten für

die Auslösung.

Siehe Datenblatt „Zubehör”. Die Einschweissmuffe hat eine

eingravierte Markierung oder ein Bohrloch. Wenn das Produkt

montiert und richtig angezogen ist, stimmen Verschraubung

oder M12-Stecker mit dieser Markierung überein.

Bitte darauf achten, dass die Verschraubung bzw. der Stecker

nach unten zeigt, damit keine Flüssigkeit in das Gerät eindringen kann.

Ausschliesslich das zugelassene speziell angefertigte Zubehör

verwenden. Die Produktgarantie erlischt, wenn andere Adapter

installiert werden.

Bitte keine Dichtungen aus PTFE, Fasern oder sonstige Dichtungen verwenden. Wenn sich die aus PEEK bestehende Spitze gegen die Einschweissmuffe aus Edelstahl drückt, bildet

dies eine hygienegerechte Dichtung, vorausgesetzt die Richtlinien wurden befolgt.

Aufgrund des Messprinzips ist es wichtig, dass für die Sensorspitze ein ausreichend grosses Stück von Metallachse oder

Einschweissmuffe „sichtbar“ ist.

Dimensions

Montageanleitung für den verschiebbaren Anschluss:

1) Gleitachse reinigen.

2) Den kleinsten Ring in Richtung Medium anbringen.

3) Den hygienegerechten verschiebbaren Anschluss G1/2 mit

25...30 Nm festziehen.

4) Wenn eine oder beide Teile des Unterlegscheibensatzes

deformiert sind oder an der Achse des verschiebbar

Anschlusses anhaften, ist der Unterlegscheibensatz zu

ersetzen.

Der Füllstandsschalter LFFS mit verschiebbarem Anschluss eignet sich zum Einbau in Anlagen mit einem statischen Druck von

maximal 16 bar.

Um Personen- und Sachschäden zu vermeiden, ist es wichtig,

dass die Sicherheitskette richtig angebracht und unbeschädigt ist.

WARNUNG

Klemm-Ring-Kit

ZPX1-006 für verschiebbarem Anschluss

G 1/2 A hygienegerecht verschiebbarer Anschluss BHC 3A DN38 hygienegerecht G 1/2 A hygienegerecht

Page 11

Betriebsanleitung

CleverLevel switch, LFFS

Montage

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 11 / 20

ANMERKUNG

Die M12-Kabel-Drehmutter darf nur von Hand angezogen werden.

Max. Drehmoment 0,6 Nm. Kein Werkzeug verwenden.

O-Ringe, Dichtungen und weiteres Zubehör sind im

www.baumer.com zu finden.

Falls die PEEK-Dichtringe des verschiebbaren Anschlusses beschädigt oder stark verkratzt sind, sollten das Gerät oder die Dichtringe

ausgetauscht werden (Typ ZPX1-006).

1) Nur Montageteile mit 3-A-Standard verwenden.

2) Die Kontrollbohrung muss sichtbar und selbstentleerend angeordnet sein.

3) Den Adapter so in einer Position bzw. einem Winkel montieren,

dass er von selbst abtropfen kann.

4) Die innere Oberfläche des Rohres mit dem Montageteil frontbündig abschliessen lassen.

Nach der Installation:

Dichtigkeit der Muffe überprüfen.

Dichtigkeit der Kabelverschraubungen oder M12-Stecker über-

prüfen

Beispiel mit

ZPW2-626

Beispiel mit

ZPW3-321

Beispiel mit

ZPW2-621

Die Kontrollbohrung

muss an der tiefstmöglichen

Position angeordnet werden

Nicht korrekt

eingesetzt

Kann nicht

abtropfen

WARNING

5) Die 3A-Markierung bzw. der Pfeil sollte nach oben zeigen.

6) Schweissnähte sollten so abgeschliffen werden, dass sie einen

Wert von Ra ≤ 0,8 aufweisen.

7) Gerät im Adapter mit einem Drehmoment von 15 ... 20 Nm festziehen.

Wenn die Dichtung undicht ist und die Medien in der Kontrollbohrung

sichtbar werden, muss die Dichtung sofort ausgetauscht werden.

Vor dem erneuten Zusammenbau die Bohrung und das Innere des

Anschlusses mit Reinigungsmittel und desinfizierender Flüssigkeit

reinigen. Eine kleine Bürste verwenden. Sicherstellen, dass die gesamte Innenfläche vollständig sauber ist.

Wieder zusammenbauen und überprüfen, ob der Anschluss dicht ist.

Keine Dichtungen aus Teflon, Elastomer oder andere Arten mit konischer Abdichtung für den hygienegerechten Prozessanschluss verwenden.

Die industriellen Versionen mit Gewinde müssen z. B. durch eine

Dichtung oder durch Teflon®-Band abgedichtet werden.

Für die Montage der hygienegerechten Produkte mit 3-A-Standard

und EHEDG-Zulassung siehe unten:

Der Schalter bietet IP67-Schutz in Kabelausführung oder bei Installation mit IP67-konformem M12-Kabel. Bei Installation des Schalters

mit einem IP69K-Kabel wird die IP69K-Konformität sichergestellt.

Edelstahlrohr

ANMERKUNG

Der CleverLevel Switch muss in einem geschlossenen Metallrohr,

Tank oder Behälter montiert werden.

Page 12

Weitere Informationen siehe Betriebsanleitung für

Anschlüsse

ANMERKUNG:

Der LFFS muss mit einem Montageanschluss von

Baumer montiert werden. Andernfalls übernimmt Baumer keine Garantie für korrekte Funktion oder Dichtigkeit.

Betriebsanleitung

CleverLevel switch, LFFS

Montageanschlüsse

ISO2852 SMS 1145 Einschweissmuffe

DN38: ZPH3-3213 DN51: ZPH1-3236 für Behälter

DN51: ZPH3-3216 ZPW3-321

Varivent®, Typ N DIN 11851 Einschweissmuffe

ZPH3-324E DN25: ZPH3-3221 für Behälter

Varivent®, Typ F DN40: ZPH3-3224 ZPW3-322

ZPH3-344F DN50: ZPH3-3225

DIN 11864-1-A Einschweissmuffe Ø35

DN 40: ZPH3-3254 für Behälter/Rohr

DN 50: ZPH3-3255 ZPW2-324

Adapter Einschweissmuffe

EH FTL für Rohr mit Auszug

G¾A: ZPH1-32BA DN 25...DN50: ZPW2-326

G1A: ZPH1-32CB DN 65...DN150: ZPW2-327

VS

G¾A: ZPH1-32BC

G1A: ZPH1-32CD

Adapter Adapter, Industriell Adapter, Industriell

G½ → G1 G½ → G1: ZPI1-32B verschiebbarer Anschl.

ZPH1-32C0 G½ → G1½: ZPI1-32D G½ → G½ DIN 3852-E

G½ → G2: ZPI1-32E ZPI1-32A

Einschweissmuffe für Behälter

ZPW2-621

Einschweissmuffe für Rohrende

ZPW2-626

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 12 / 20

Auf dem Einschweissadapter befindet sich ein Pfeil oder ein 3A-Logo.

Diese müssen nach oben weisen,

wenn der Adapter in einen Behälter

eingeschweisst wird (horizontale

Position).

Dadurch ist gewährleistet, dass der

elektrische Anschluss nach unten

zeigt (dem Pfeil bzw. dem 3A-Logo

entgegengesetzt).

Page 13

Medientemperatur und externe Länge des verschiebbaren Anschlusses

Betriebsanleitung

CleverLevel switch, LFFS

Medientemperatur °C

120

115

110

105

100

95

90

85

80

75

50 55 60 65 70 75 80 85 90

Umgebungstemperatur °C

LFFS-xx1.x / LFFS-xx2.x LFFS-xx3.x und LFFS-xx4.x

Externe Länge des verschiebbaren Anschlusses

Medientemperatur °C

äußere Länge

siehe Beispiel

Die Skizze zeigt beispielhaft 4 verschiedene Anwendungsmöglichkeiten für den verschiebbaren Anschluss:

1) Von oben in den Behälter hineinragend zur

Einstellung des maximalen Füllstands

2) Als Kühlstrecke bei Anwendungen mit hoher

Medientemperatur

3) So eingestellt, dass die Sensorspitze tiefer in den

Behälter hineinragt

4) Durch Isoliermaterial hindurch in den Behälter

ragend

Es ist wichtig, dass die für die Elektronik gültige maximale Umgebungstemperatur (85 °C) nie überschritten wird. Bezüglich ATEXzugelassener Produkte siehe ATEX-Daten.

Beispiel: So ist die Kurve für die externe Länge abzulesen:

Beispiel: Medientemperatur / Umgebungstemperatur / Externe Länge

160°C 60°C 120 mm

Ein Schiebeanschluss von 250 mm Länge ist mit seiner gesamten

Einschublänge von 130 mm in einen Tank montiert. Seine externe

Länge beträgt daher 250 – 130 = 120 mm

Die Medientemperatur beträgt max. 160°C

Liest man den Schnittpunkt aus 120 mm auf der X-Achse und

160°C auf der Y-Achse ab, so ergibt sich, dass die Umgebungstemperatur unter 60°C gehalten werden muss.

Falls die Abstrahlwärme vom Behälter zu einer höheren Umgebungstemperatur am Gehäuse führt, muss für eine wirksame Isolierung des

Behälters gesorgt werden.

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 13 / 20

Für CIP/SIP Medientemperatur max. 140 °C

Umgebungstemperatur max. 60 °C

Dauer max. 1 Stunde

Nachbestellung eines CleverLevel Switch

Wenn ein neuer CleverLevel Switch in einer bestehenden Anwendung installiert wird, geschieht dies in der Regel als „Plug-n'Play“.

Wurden die Standard-Werkseinstellungen des Füllstandsschalters verändert, muss der neue Schalter an die Einstellungen des

„alten“ Schalters angepasst werden. Die Einstellungen des „alten“ -Schalters lassen sich auf dem PC speichern und anschliessend in den neuen Füllstandsschalter herunterladen.

Die Werkseinstellungen der Sensitivität für die Medien können um bis zu ±5 % variieren. Wenn ein sehr genauer Sollwert erforderlich ist, muss daher ein neues Teach-in oder eine Anpassung durch FlexProgram durchgeführt werden.

Isolierung

Klumpige oder klebrige Medien

Page 14

Betriebsanleitung

CleverLevel switch, LFFS

Teach-In mithilfe von FlexProgram und FlexProgrammer 9701

Besondere Einstellungen für das Teach-In sowie Ausgangstyp, Diagnose, Datenerfassung, Messstellen-Nr. und Dämpfung können

mit dem FlexProgrammer 9701 konfiguriert werden. Eine vollständige Anleitung dazu ist im HILFE-Menü des Programms enthalten.

oder drücken, um durch das Menü zu navigieren

drücken, um den aktuellen Menüpunkt aufzurufen

drücken, um zum vorherigen Menü zurückzukehren

und gleichzeitig drücken, um FlexProgrammer

zurückzusetzen und in den Sleep-Modus zu schalten

Teach-In

Folgende Tasten drücken:

und gleichzeitig

Menü „Teach-In“ wählen

Produkt suchen

= Produkt LFFS/LBFS

Bei leerem Behälter Einstellung 0 %

Bei vollem Behälter Einstellung 100 %

Manuelles Teach-In

Vor Durchführung des Teach-In muss der Strom eingeschaltet werden.

Damit das Teach-In optimal durchgeführt wird, muss das Produkt in seiner endgültigen Anwendung montiert sein.

Während des Teach-In-Betriebs ist die Intensität der LED zum Schutz Ihrer Augen geschwächt.

Schritt Folgendes ausführen LED Ergebnis

1

Klemme „Teach-In“ für 3,5 Sek. an

-VDC (T1 oder T2) anschliessen

Blinkt 1-mal pro Sekunde

Bereit für Teach-In

2

Wenn noch keine Medien vorhanden sind,

„Teach-In“ kurz an -VDC anschliessen

Leuchtet 2 Sekunden

lang und blinkt danach

Registriert den Zustand „leer“. Bitte Anmerkung beachten

3

Wenn Medien vorhanden sind,„Teach-In“

kurz an -VDC anschliessen

Leuchtet 2 Sekunden

lang

Registriert den Zustand „gefüllt“, speichert den Wert und kehrt

mit den neuen Einstellungen zum Normalbetrieb zurück

ANMERKUNG:

Bei klebrigen, schäumenden, pulvrigen oder anderen Medien, von denen leicht Reste an der Sensorspitze haften bleiben, müssen

diese Bedingungen auch während des Teach-In-Verfahrens vorliegen. Andernfalls kann die Kalibrierung fehlerhaft werden.

Wenn das Teach-In nicht erfolgreich sein sollte, meldet der Füllstandsschalter LFFS einen „Fehlerstatus” und die Werkseinstellungen werden automatisch neu geladen. Die Werkseinstellungen können jederzeit neu geladen werden, indem die „Teach-In“-

Klemme länger als 6,5 Sekunden an -VDC angeschlossen wird. Neu geladene Werkseinstellungen werden durch dreimaliges Blinken bestätigt.

Beschreibung des

Fehlerstatus

LED Ergebnis

Fehlerstatus Blinkt 3-mal kurz und 1-mal

lang

Lässt sich in der Regel durch Aus- und Einschalten und erneutes TeachIn-Verfahren beheben.

Alternativ ist die Teach-In-Konfiguration mithilfe von FlexProgram und

dem FlexProgrammer 9701 erneut durchzuführen.

Verwendung des FlexProgrammer 9701 allein und zum Teach-In

FlexProgrammer 9701 - eigenständiges Gerät

Folgende Tasten drücken

Den FlexProgrammer einschalten, falls er sich im SleepModus befindet

Konfiguration löschen

Produkt suchen

LFFS/LBFS-Konfiguration

Produkt LFFS / LBFS

Messstellen-Nummer xxxxxxxxxxxxxxx

Messbereich min. xx.x%

Messbereich max. xx.x%

Dämpfung x,x sec

Ausgangskonfig. xxxxxxx

Trigger-Einstellung xx,x%

Messbereichs-Hyst. x,xx%

Trigger-Hyst. x.xx%

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 14 / 20

Page 15

Elektrischer Anschluss

Betriebsanleitung

CleverLevel switch, LFFS

M12-Stecker: 1 Braun

2 Weiss*

3 Blau

4 Schwarz

WARNUNG

* Um ein unbeabsichtigtes Teach-In

zu vermeiden, ist darauf zu achten,

den Teach-In-Kontakt nicht anzuschliessen und im Normalbetrieb

keinem Elektrorauschen auszusetzen.

Schliesser – NO

Öffner – NC

Elektrische Daten:

Spannungsversorgung 12,5...36 VDC, 35 mA max.

Ausgang PNP, NPN oder Digital

Max. 50 mA, kurzschlussfest und

hochtemperaturfest

Low-aktiv NPN- und digitaler Ausgang

(-VDC +2,5V) ±0,5V, R

load

= 1 kΩ

High-aktiv PNP- und digitaler Ausgang

(+VDC -2,5V) ±0,5V, R

load

= 1 kΩ

1

2

5

1

2

5

1

2

5

1

2

5

1

2

5

1

2

5

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 15 / 20

PNP Ausgang NPN Ausgang Digitaler Ausgang

Low-aktiv

High-aktiv

PNP Ausgang NPN Ausgang Digitaler Ausgang

Page 16

ATEX

Betriebsanleitung

CleverLevel switch, LFFS

Ex ia IIC T5, ATEX II 1G - Installation

Ein Füllstandsschalter LFFS-1xx.x ist zugelassen nach Ex ia

IIC T5, ATEX II 1G zur Anwendung in gefährlichen Bereichen,

gemäss den aktuellen EU-Richtlinien. Das Produkt ist den

üblichen Richtlinien für Zone 0 entsprechend mit Barriere zu

installieren.

Ex-Daten

Spannungsversorgung 24...30 VDC

Temperaturklasse T1...T5 siehe Tabelle oben

Interne Induktivität Li <10 µH

Interne Kapazität Ci <3 nF

Daten zur Barriere U < 30 VDC

I < 0,1 A

P < 0,75 W

Anschlussart Umgebungstemperatur Medientemperatur

(max. zulässig)

Anmer-

kung

G½ hygienegerecht -40 … +85 °C +85 °C

BHC 3A DN38

-40 … +60 °C +95 °C 1)

-40 … +40 °C +115 °C 1)

100 mm -40 … +85 °C +85 °C

verschiebbarer Anschluss

-40 … +60 °C +155 °C 1)

-40 … +40 °C +175 °C 1)

250 mm -40 … +85 °C +85 °C

verschiebbarer Anschluss

-40 … +60 °C +195 °C 1)

-40 … +40 °C +200 °C 1)

Bedingungen für ExZertifizierung

1) Gilt unter der

Voraussetzung,

dass die Sensorspitze am Gerät

als einziges Teil

mit dem Medium

in Berührung ist

ATEX Gas ia

LFFS-1xx.x

mit PNP Ausgang

Safe area

+ 22...120 VDC

or

- 90...253 VAC

ANMERKUNG:

Bei PNP-Ausgang ist das Isolationsmodul PFOFSI3-B25100-ALG-LS

erforderlich, um eine einwandfreie

Funktion zu gewährleisten.

PFOFSI3-B25100-ALG-LS

NPN out

LFFS-1xx.x

mit NPN Ausgang

ANMERKUNG:

Nur für NPN-Ausgang!

Standardbarriere kann verwendet

werden

Standard barrier

ZweikanalZENER-Barriere

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 16 / 20

ANMERKUNG

Es besteht aufgrund des Messprinzips eine elektrische

Verbindung zwischen eigensicherem Stromkreis und

Gehäuse

Page 17

ATEX Staub tD

Betriebsanleitung

CleverLevel switch, LFFS

ATEX Gas nA

Ex-Konfigurierung

Ein Füllstandsschalter LFFS-2xx.x ist zugelassen nach Ex tD A20

IP67 T100°C, ATEX II 1D zur Anwendung in gefährlichen Bereichen,

gemäss den aktuellen EU-Richtlinien. Das Produkt ist gemäss den

üblichen Richtlinien für Zone 20 ohne Barriere zu installieren.

Ex-Daten

Spannungsversorgung VDC 12,5...30

Last I <0.1 A

Temperaturklasse T1...T5 Siehe Tabelle oben

auf Seite 16

12,5...30 VDC

1

2

5

Ein Füllstandsschalter LFFS-3xx.x ist zugelassen nach Ex nA II T5,

ATEX II 3G zur Anwendung in gefährlichen Bereichen, gemäss den

aktuellen EU-Richtlinien. Das Produkt ist gemäss den üblichen Richtlinien für Zone 2 ohne Barriere zu installieren.

Ex-Daten

Spannungsversorgung VDC 12,5...30

Last I <0.1 A

Temperaturklasse T1...T5 Siehe Tabelle oben

auf Seite 16

Der FlexProgrammer 9701 darf in der gefährlichen Umgebung nicht an den Füllstandsschalter LFFS angeschlossen werden.

Vorgehensweise bei der Konfigurierung:

a) Netz vom 4...20 mA-Regelkreis trennen.

b) Füllstandsschalter im gefährlichen Bereich vom Kreislauf trennen.

c) Deinstallieren und Füllstandsschalter in einen sicheren Bereich bringen.

d) FlexProgrammer 9701 anschliessen und die Konfigurierung durchführen.

e) Füllstandsschalter wieder im gefährlichen Bereich installieren.

f) Versorgungsspannung an den Kreislauf anschliessen.

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 17 / 20

12,5...30 VDC

1

2

5

Ausserhalb des Gefahrenbereichs

Page 18

WHG leakage and overfill protection approval

Betriebsanleitung

CleverLevel switch, LFFS

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 18 / 20

Page 19

Betriebsanleitung

CleverLevel switch, LFFS

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 19 / 20

WHG leakage and overfill protection approval

Page 20

www.baumer.com Betriebsanleitung: 11109132 09 DE Page 20 / 20

For further information please refer to www.baumer.com

Loading...

Loading...