Page 1

Manual

Absolute encoder with EtherCAT,

Power over EtherCAT (PoE)

(with bus cover)

Firmware version 5.00 and up

09.14 · 174.02.064/3

Subject to technical and design modifications.

www.baumer.com Errors and omissions excepted.

Page 2

Content Page

Introduction 4 1.

1.1 Scope of delivery 4

1.2 Product classification 4

Safety and operating instructions 5 2.

Bus cover – functional principle 6 3.

Encoder operating parameters 7 4.

Encoder data 8 5.

5.1 PDO (Process Data Object) 8

5.2 SDO (Service Data Objects) 9

5.3 Parameterization 17

5.4 Free Run Mode (default) 18

5.5 Distributed Clocks Mode 19

5.5.1 Activation Distributed Clocks under TwinCAT 19

5.6 Network management 21

Terminal assignment and commissioning 23 6.

6.1 Mechanical mounting 23

6.2 Electrical connection 23

6.2.1 Initialising under TwinCAT system manager 24

6.2.2 Terminal assignment 25

6.3 Display elements 26

6.3.1 State indicator 26

6.3.2 Link/Activity indicator 26

6.4 Bus cover Power over EtherCAT (PoE) 27

6.5 Cycle times 28

6.6 Configuration 10 Byte PDO / 4 Byte PDO / 2 Byte PDO by TwinCAT 29

6.7 Speed Value as an alternative to System Time 30

**TwinCAT is a trademark of the company BECKHOFF Industrie Elektronik

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 2/30 www.baumer.com

30.09.14

Page 3

Disclaimer of liability

The present manual was compiled with utmost care, errors and omissions reserved. For this reason

Baumer rejects any liability for the information compiled in the present manual.

Baumer nor the author will accept any liability for direct or indirect damages resulting from the use of the

present information.

At any time we should be pleased receiving your comments and proposals for further improvement of the

present document.

Created by:

Baumer IVO GmbH & Co. KG

Villingen-Schwenningen, Germany

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 3/30 www.baumer.com

30.09.14

Page 4

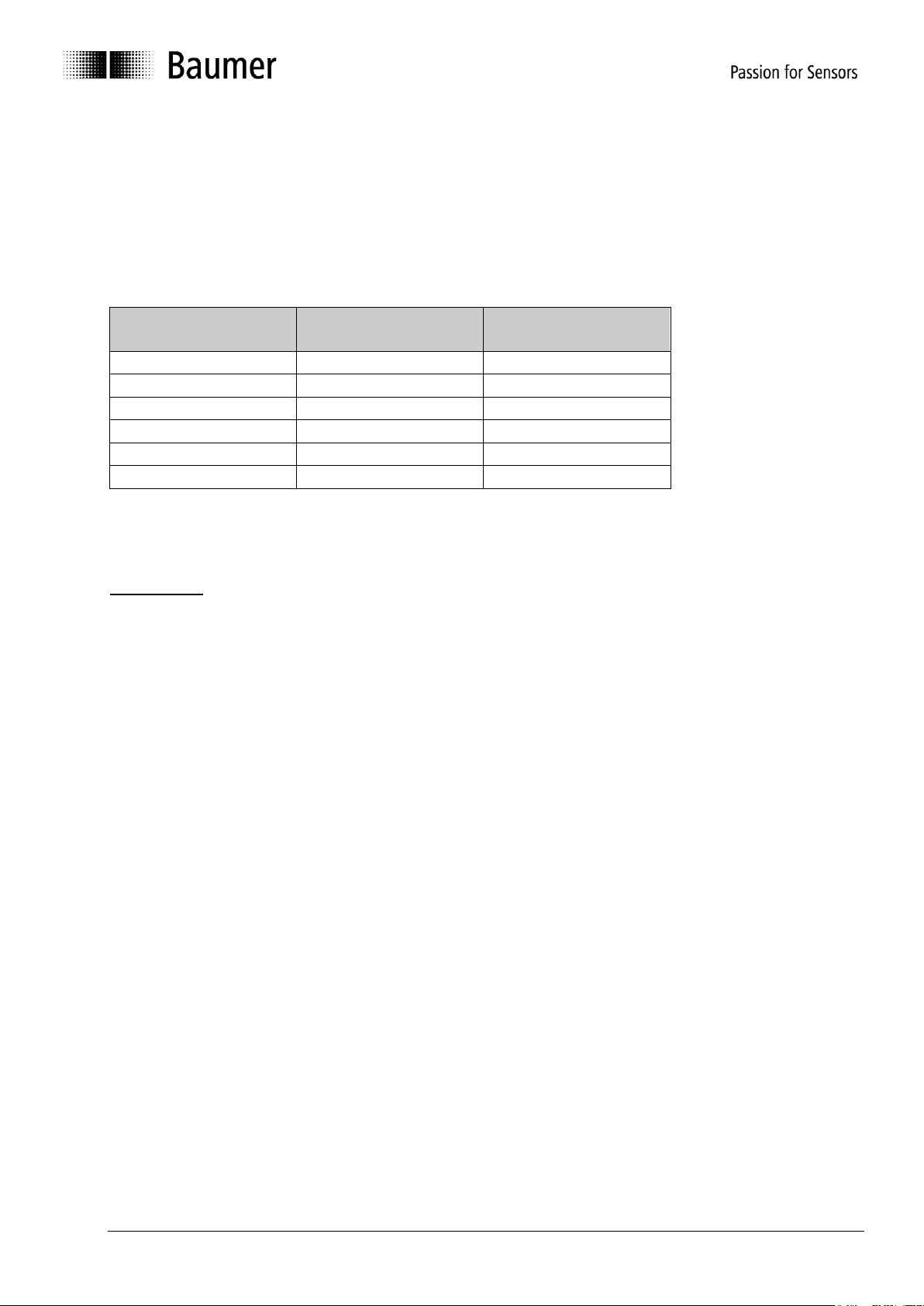

Product mechanics

Solid / Hollow shaft / Kit

Product name

(according to object 1008)

Description

BMMV / BMMH / BMMK

GCMMW_H

MT, MAGRES

BMSV / BMSH / BMSK

GCAMW_H

ST, MAGRES

GBMMW / GBMMS / -

GBMMW_H

MT, Optical, 18 Bit ST

GBAMW / GBAMS / -

GBAMW_H

ST, Optical, 18 Bit ST

GXMMW / GXMMS / -

GXMMW_H

MT, Optical, 13 Bit ST

GXAMW / GXAMS / -

GXAMW_H

ST, Optical, 13 Bit ST

Introduction 1.

1.1 Scope of delivery

Please check the delivery upon completeness prior to commissioning.

Depending on encoder configuration and part number delivery is including:

Basic encoder, bus cover and CD with describing file and manual (also available as download)

1.2 Product classification

Note:

Ever apply the matching device file (BAUMER Group absolute EtherCAT encoders.xml) on the above device

types.

Explanation:

MT Multiturn encoder

ST Singleturn encoder

MAGRES Extremely robust encoder with magnetic sensing principle

18 Bit ST High resolution encoder – up to 18 bit physical singleturn resolution, i.e. 218 steps / revolution

13 Bit ST Max. 13 bit physical singleturn resolution, i.e. 213 steps / revolution

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 4/30 www.baumer.com

30.09.14

Page 5

Safety and operating instructions 2.

Supplementary information

This manual is intended as supplement to already existing documentation (e.g. catalogues, data sheet

and mounting instructions).

The manual must be read carefully prior to initial commissioning of the equipment.

Intended purpose of the equipment

The encoder is a precision measurement device. It is used to determine angular positions and revolutions

and to prepare and supply measured values in the form of electrical output signals for control systems.

The encoder must not be used for any other purpose.

Commissioning

Encoders may only be installed and mounted by suitably qualified experts.

Observe the operating instructions of the machine manufacturer.

Safety remarks

Prior to commissioning of the equipment, check all electrical connections.

If installation, electrical connections or any other work performed at the encoder or at the equipment is not

correctly executed, this can result in encoder malfunction or failure.

Steps must be taken to exclude any risk of personal injury, damage to facility or operating appliances as a

result of encoder failure or malfunction by providing suitable safety precautions.

The encoder must not be operated beyond the specified limits (see further documentation).

Failure to comply with the safety remarks can result in malfunctions, personal injury or material damage!

Transport and storage

Only ever transport or store encoders in their original packaging.

Never drop encoders or expose them to major vibrations.

Mounting

Avoid impacts or shocks on housing and shaft.

Avoid any twist or torsion on housing.

Do not open the encoder or proceed any mechanical modifications.

Shaft, ball bearings, glass disc or electronic components might be damaged. In this case, safe and reliable

operation is no longer guaranteed.

Electrical commissioning

Do not proceed any electrical modifications at the encoder.

Do not proceed any wiring work while encoder is under power supply.

Never plug or unplug connector while encoder is under power supply.

Ensure that the entire system is installed in line with EMC/EMI requirements. Operating environment and

wiring have an impact on the electromagnetic compatibility of the encoder. Install encoder and supply

cables separately or far away from sources with high emitted interference (frequency converters,

contactors, etc).

When working with consumers with high emitted interference provide separate encoder supply voltage.

Completely shield encoder housing and connecting cables..

Connect encoder to protective earth (PE) using shielded cables. The braided shield must be connected to

the cable gland or connector. Ideally, aim at dual connection to protective earth (PE), i.e. housing by

mechanical assembly and cable shield by the downstream devices. In case of earth loop problems, earth

at least on one side.

Failure to observe these instructions can result in malfunctions, material damage or personal injury!

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 5/30 www.baumer.com

30.09.14

Page 6

Bus cover – functional principle 3.

The product family architecture is modular. Depending on what is required from the encoder, the basic

encoder and bus covers can be combined at will with the selected bus system.

The basic encoders differ in terms of accuracy, ambient conditions and the utilized sensing principle.

Bus cover

The bus cover accommodates the entire electronics for measured value processing and for Ethernet

communication.

The bus covers differ by the respectively integrated bus interface.

Available bus interfaces: CANopen®, DeviceNet, EtherCAT, Ethernet/IP, Profibus-DP, Profinet, Powerlink,

Power over EtherCAT, SAE J1939, SSI.

All encoders enable parameterization by bus interface.

Functional principle:

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 6/30 www.baumer.com

30.09.14

Page 7

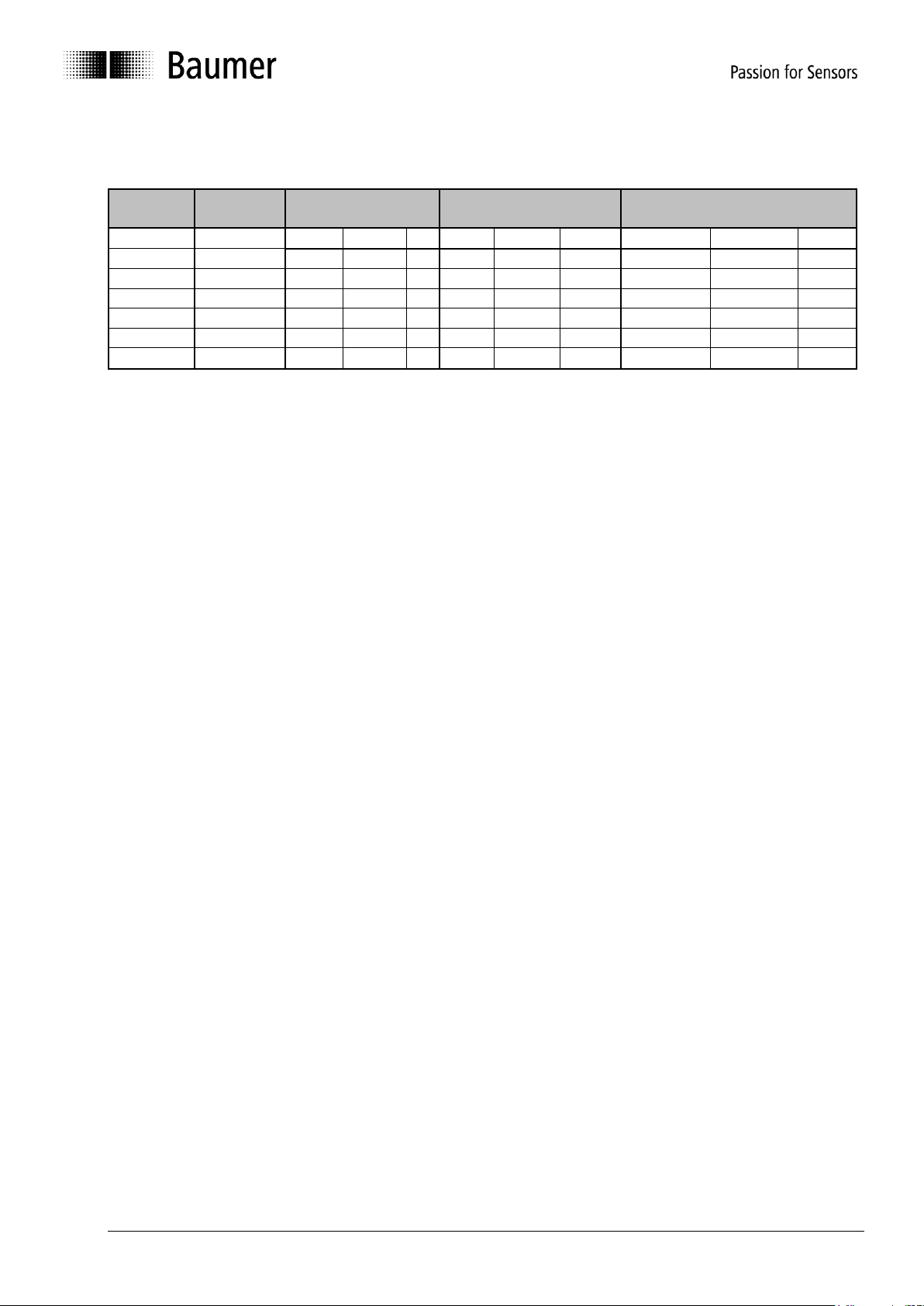

Product

Device

Name

Resolution per turn

0x6001

Number of turns

0x6502

Measuring range

0x6002

Dezimal

Hex

Bit

Dezimal

Hex

Bit

Dezimal

Hex

Bit

BMSx

GCAMW_H

4096

1000

12 1 1 0 4096

1000

12

BMMx

GCMMW_H

4096

1000

12

65536

10000

16

268435456

10000000

28

GXAMW(S)

GXAMW_H

8192

2000

13 1 1 0 8192

2000

13

GXMMW(S)

GXMMW_H

8192

2000

13

65536

10000

16

536870912

20000000

29

GBAMW(S)

GBAMW_H

262144

40000

18 1 1 0 262144

40000

18

GBMMW(S)

GBMMW_H

262144

40000

18

16384

4000

14

4294967296

100000000

32

Encoder operating parameters 4.

Significance of operating parameters

The enabled scaling functionality in CoE is prerequisite for further user-specific parameterization

such as resolution, total measuring range, direction of rotation and preset.

See chapter: SDO (Service Data Objects)

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 7/30 www.baumer.com

30.09.14

Page 8

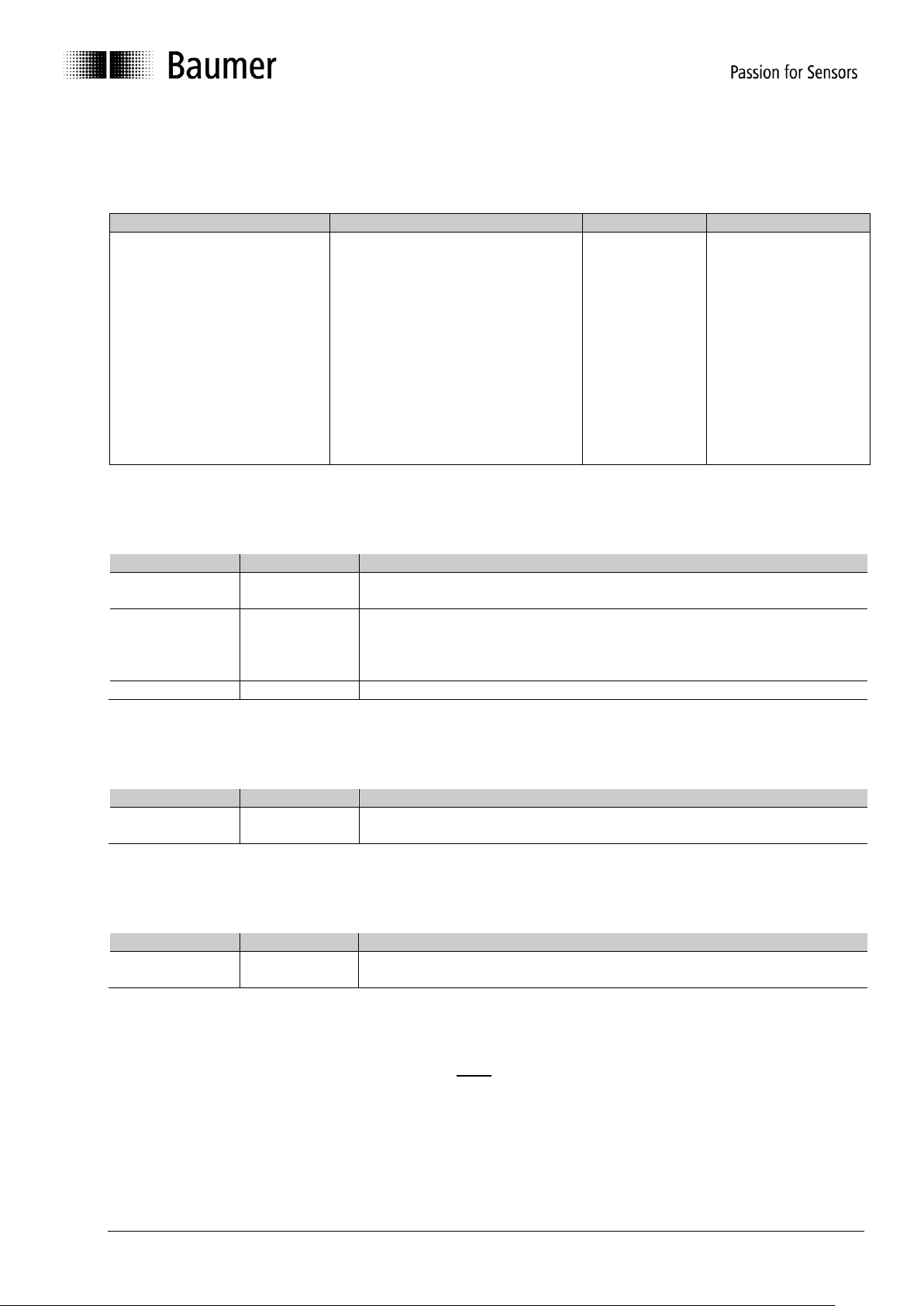

XML file

PDO Mapping

Product code

Applied in version

BAUMER Group absolute

EtherCAT encoders.xml

10Byte PDO: (default)

4 Byte Position value

2 Byte Warnings

4 Byte System Time/Speed value

or

4Byte PDO: (configurable)

4 Byte Position value

2Byte PDO: (configurable)

2 Byte Position value

20

25

30

V5.00 and up

Value

Data type

Explanation

Position value

UDINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Warnings

UINT

Warnings

Bit 2: 1 Lithium battery power low

Bit 4: 1 Excess shaft turns during power-off

Bit 5: 1 Incorrect encoder configuration

System Time

UDINT

Present system time, resolution in ns, alternative Speed Value DINT

Value

Data type

Explanation

Position value

UDINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Value

Data type

Explanation

Position value

UINT

Current absolute encoder position value. For range-related information

refer to „Encoder operating parameters“

Encoder data 5.

5.1 PDO (Process Data Object)

Depending on the configuration, the encoder will provide the following process data (input data):

10Byte PDO (Default)

4Byte PDO

2Byte PDO

The configuration 4Byte PDO / 2Byte PDO allows for shorter cycle times.

Cycle times are configuration-related, see chapter cycle times

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 8/30 www.baumer.com

30.09.14

Page 9

5.2 SDO (Service Data Objects)

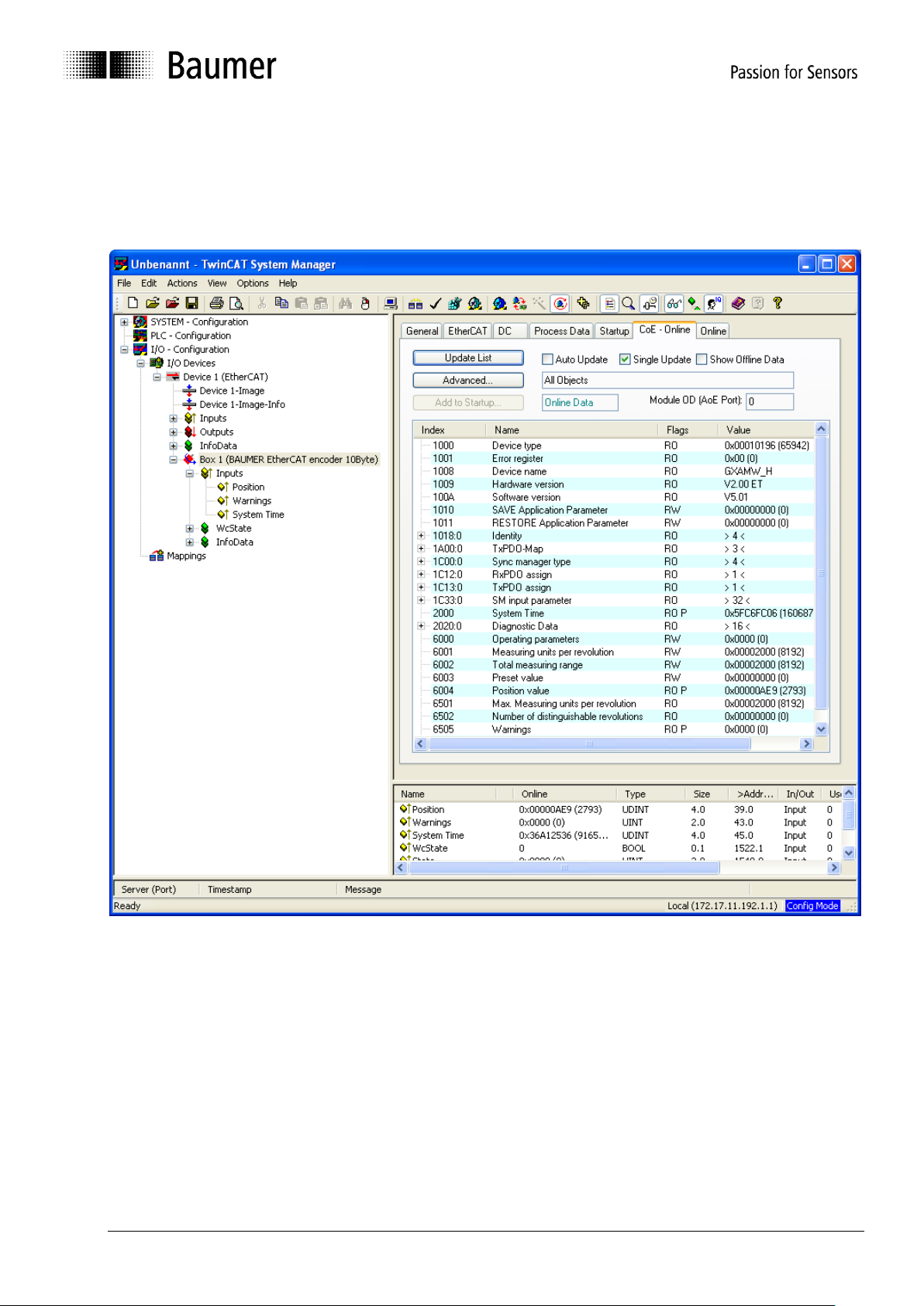

SDOs access is in the TwinCAT System under tab CoE - Online (CANopen over EtherCAT).

Since there is a large variety of CANopen device and application profiles they may be applied in EtherCAT

slaves.

EtherCAT encoders provide partial implementation of the CANopen DS406 encoder device profile.

Please consider that every CoE access (mailbox communication) will shortly interrupt generation of encoder

input data for the time of mailbox communication. With short cycle times in Distributed Clocks Mode this may

imply that not in every Sync cycle a new position is detected.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 9/30 www.baumer.com

30.09.14

Page 10

SubIndex

0

Data type

Unsigned 32

Access

ReadOnly

Default

Multiturn: 0x00020196

Singleturn: 0x00010196h

EEPROM

No

Significance

Information on device profile and device type

Values

SubIndex

0

Data type

VISIBLE_STRING

Access

ReadOnly

Default

According to connected basic encoder

"GXMMW_H","GXAMW_H","GCMMW_H ","GCAMW_H ",

“GBMMW_H ","GBAMW_H "

EEPROM

No

Significance

Device name in ASCII

Values

SubIndex

0

Data type

VISIBLE_STRING

Access

ReadOnly

Default

EEPROM

No

Significance

Hardware version in ASCII

Values

SubIndex

0

Data type

VISIBLE_STRING

Access

ReadOnly

Default

EEPROM

No

Significance

Software version in ASCII

Values

e v a s 0x65

0x76

0x61

0x73

1702257011

Object list Detailed explanations on the most important SDO objects

Object 0x1000 Device Type

Object 0x1008 Device Name

Object 0x1009 Hardware Version

Object 0x100A Manufacturer Software Version

Object 0x1010 SAVE Application Parameter

Object 0x1010 is utilized to save device-specific objects (0x6000..0x6FFF) out of RAM into non-volatile memory

(EEPROM). To prevent inadvertent saving operations the signature „save“ must be written into object 0x1010

Subindex 0.

Signature MSB LSB

ISO 8859 character

hex

dez

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 10/30 www.baumer.com

30.09.14

Page 11

SubIndex

0

Data type

Unsigned 8

Access

ReadOnly

Default

4

EEPROM

No

Significance

Maximum supported subindex

Values

4 = Maximum supported subIndex

SubIndex

1

Data type

Unsigned 32

Access

ReadOnly

Default

Ech

EEPROM

No

Significance

VendorID for Baumer IVO GmbH & Co. KG assigned by CiA

Values

0xEC (in the Internet under www.can-cia.de)

SubIndex

2

Data type

Unsigned 32

Access

ReadOnly

Default

0x0A GXMMW_H ; 0x0B GXAMW_H

0x0C GCMMW_H ; 0x0D GCAMW_H

0x0E GBMMW_H, 0x0F GBAMW_H

EEPROM

No

Significance

Product Code

Values

SubIndex

3

Data type

Unsigned 32

Access

ReadOnly

Default

EEPROM

No

Significance

Revision no.

Values

SubIndex

4

Data type

Unsigned 32

Access

ReadOnly

Default

EEPROM

No

Significance

Serial no.

Values

d a o l 0x64

0x61

0x6F

0x6C

1684107116

Object 0x1011 RESTORE Application Parameter

Object 0x1011 restores ROM default in device-specific objects (0x6000..0x6FFF) both in RAM and EEPROM.

To prevent any inadvertent restore, the signature „load“ must be written in object 0x1011 Subindex 0.

Signature MSB LSB

ISO 8859 character

hex

dez

Object 0x1018 Identity Object

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 11/30 www.baumer.com

30.09.14

Page 12

SubIndex

0

Data type

Unsigned 8

Access

ReadOnly

Default

EEPROM

No

Significance

Maximum supported subindex

Values

3

SubIndex

1

Data type

Unsigned 32

Access

ReadOnly

Default

EEPROM

No

Significance

Position value

Values

0x6004

SubIndex

2

Data type

Unsigned 16

Access

ReadOnly

Default

EEPROM

No

Significance

Warnings

Values

0x6505

SubIndex

3

Data type

Unsigned 32

Access

ReadOnly

Default

0x2000 System time

EEPROM

Yes

Significance

System time, Speed value

Values

0x2000 = System time, 0x6030 = Speed value

Sub

Index

Data Type

Access

Description

Measurand

Values

0

Unsigned 8

ReadOnly

SM Input Parameter

-

Maximum supported Subindex 32

1

Unsigned 16

ReadOnly

Sync Mode

-

0x00 Free Run (not synchronized)

0x03 DC SYNC1, synchronized with

SYNC1 Event

2

Unsigned 32

ReadOnly

Cycle time

Nanoseconds ns

SYNC0/SYNC1 cycle time

3

Unsigned 32

ReadOnly

Shift time

Nanoseconds ns

Shift time from SYNC1 until input data

latch (absolute position)

4

Unsigned 16

ReadOnly

Sync modes

supported

-

0x0009

Free run supported

Synchronous supported

DC SYNC1

Dynamic Cycle times

5

Unsigned 32

ReadOnly

Minimum cycle time

Nanoseconds ns

Minimum cycle time supported

6

Unsigned 32

ReadOnly

Calc and copy time

Nanoseconds ns

Calculation and copy time of process data

out of local memory into SyncManager

Object 0x1A00 TxPDO1 Mapping

Object 0x1C33 SM (Sync Manager) Input Parameter SM3

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 12/30 www.baumer.com

30.09.14

Page 13

SubIndex

0

Data Type

Unsigned 16

Access

ReadWrite

Default

0, scaling OFF, CW, Speed Value readout in steps /s

EEPROM

Yes

Significance

Operating parameters

Values

Bit 0: Direction of rotation

0 CW

1 CCW

Any parameter other than default will only become effective with enabled scaling function (0x6000).

Bit 2: Scaling function ON/OFF

0 scaling disabled, encoder provides raw data (w/o offset)

1 scaling enabled, encoder provides scaled, offset-related position values

Example: Value 0x0004 -> scaling On, CW

Bit 12: Unit for Speed Value readout

0 steps/s

1 rpm

SubIndex

0

Data type

Unsigned 32

Access

ReadWrite

Default

0x2000 = 8192 = 13bit GXxMW_H

0x1000 = 4096 = 12bit GCxMW_H

0x40000 = 262144 = 18bit GBxMW_H, GDxMW_H

EEPROM

Yes

Significance

Optional number of steps per revolution.

Values

1..n.. max. number of steps per revolution (0x6501)

Entries ≠ default values are only effective with enabled scaling function (0x6000).

Device-specific objects

Object Data in this area are hold volatile in RAM after any change. To save in non-volatile EEprom use

object SAVE Application Parameter 0x1010.

Object 0x6000 Operating parameters

User-settable parameters such as resolution, total measuring range, direction of rotation and preset

will not become effective until the scaling function is enabled (bit 2 =1).

See chapter parameterization.

The above parameters will be preliminarily saved in the volatile RAM memory and can optionally be saved

non-volatile in EEProm using object SAVE Application Parameter (0x1010).

Please note that with scaling ON the input data (TxPDO) will be produced much more slowly, i.e. PLC cycle

times for encoder readout should be correspondingly enlarged.

See chapter cycle times.

Object 0x6001 Measuring units per revolution

In general, when writing on this object any previously saved offset (0x6509) will be cleared (value = 0).

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 13/30 www.baumer.com

30.09.14

Page 14

SubIndex

0

Data type

Unsigned 32

Access

ReadWrite

Default

0x20000000 = 536870912 = 29bit GXMMW_H

0x2000 = 8192 = 13bit GXAMW_H

0x10000000 = 268435456= 28bit GCMMW_H

0x1000 = 4096 = 12bit GCAMW_H

0x80000000 = 2147483648 = 31bit ² GBMMW_H

0x40000 = 262144 = 18bit GBAMW_H

EEPROM

Yes

Significance

Total measuring range in steps optionally programmable.

Consequence: Number of revolutions = total measuring range / resolution

The maximum resolution (0x6502) must not be exceeded since otherwise the selected

total resolution range is too wide and will be rejected.

Values

1..n.. max. total measuring range in steps (0x 6502)

Entries ≠ default values are only effective with enabled scaling function (0x6000).

Object 0x6002 Total measuring range

² with disabled scaling 32 bit

Writing in these object will clear any previously saved offset (0x6509, value = 0)

Important for multiturn encoder operation:

Continuous operation will be automatically supported where required.

Consequently, no specific relationship between total measuring range and measuring units per revolution

must be observed in the parameterization.

With enabled continuous operation and during power off, the encoder shaft may be turned up to ¼ of

the maximum permissible turns. Any excess turn may entail void position values which will be

signaled by a warning and call for a new referencing operation.

Non-continuous operation allows for an unlimited number of turns during power-off.

Proceed as below to find out whether your parameterization enables continuous operation:

The „maximum possible number of turns“ provided by the encoder (depending on the configuration:

16 bits = 65536 or 13 bits = 8192) is multiplied by the parameterized measuring units per revolution.

The result is devided by parameterized total measuring range.

A remainder in the result (fractional digits) means continuous operation enabled.

Example: Parameterization with disabled continuous operation:

Max. possible number of turns 65536 (16 bits multiturn)

Measuring units per turn : 3600

Total measuring range 29.491.200 (8192 x 3600)

Calculation: 65536 x 3600 / 29.491.200 = 8 (no remainder)

Example: Parameterization with enabled continuous operation:

Max. possible number of turns 65536 (16 bits multiturn)

Measuring units per turn 3600

Total measuring range 100.000

Calculation: 65536 x 3600 / 100.000 = 2359 remainder 29600

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 14/30 www.baumer.com

30.09.14

Page 15

SubIndex

0

Data type

Unsigned 32

Access

ReadWrite

Default

0

EEPROM

Yes

Significance

Optionally programmable position value.

In this operation an offset value is calculated and saved in object 0x6509.

Values

0..actual total measuring range (0x6002) -1

Entries ≠ default values are only effective with enabled scaling function (0x6000).

SubIndex

0

Data type

Unsigned 32

Access

ReadOnly

Default

EEPROM

No

Significance

Value of actual position in steps

Values

0..actual total measuring range (0x6002) -1

SubIndex

0

Data type

Signed 32

Access

ReadOnly

Default

EEPROM

No

Significance

Current speed value

Values

Unit steps/s or rpm configurable by object 0x6000 Bit 12

SubIndex

0

Data type

Unsigned 8

Access

ReadOnly

Default

2

EEPROM

No

Significance

Largest supported Subindex

Values

2 = largest supported SubIndex

SubIndex

1

Data type

Unsigned 16

Access

ReadOnly

Default

2

EEPROM

No

Significance

Speed Source

Values

2: Speed is calculated out o raw data position

SubIndex

2

Data type

Unsigned 16

Access

Readwrite

Default

100

EEPROM

Yes

Significance

Integration time in ms, to generate the moving average speed value.

To enhance dynamic capabilities select an inferior value.

To improve smoothing select a larger value.

Values

1..1000

Object 0x6003 Preset value

Object 0x6004 Position value

Object 0x6030 Speed value

Object 0x6031 Speed Parameter

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 15/30 www.baumer.com

30.09.14

Page 16

SubIndex

0

Data type

Unsigned 32

Access

ReadOnly

Default

0x2000 = 8192 = 13bit GXxMW_H

0x1000 = 4096 = 12bit GCxMW_H

0x40000 = 262144 = 18bit GBxMW_H, GDxMW_H

EEPROM

No

Significance

Maximum singleturn resolution in steps

Values

SubIndex

0

Data type

Unsigned 32

Access

ReadOnly

Default

0x10000 = 65536= 16bit GXMMW_H

0x10000 = 65536= 16bit GCMMW_H

0x2000 = 8192 = 13bit ² GBMMW_H

EEPROM

No

Significance

Maximum number of revolutions

Values

With singleturn encoders =0, otherwise according to basic encoder

SubIndex

0

Data type

Unsigned 16

Access

ReadOnly

Default

0

EEPROM

No

Significance

Warnings

Values

Multiturn encoder

Bit 2: 1 Lithium battery voltage low

Bit 4: 1 Excess shaft turns during power off

Bit 5: 1 inappropriate sensor configuration

SubIndex

0

Data type

Unsigned 32

Access

ReadOnly

Default

0

EEPROM

Yes

Significance

Value is calculated upon writing on object Preset (0x 6003)

Values

Object 0x6501 Max. measuring units per revolution (max. resolution in steps)

Object 0x6502 Number of distinguishable revolutions

² with disabled scaling 14 bit

Object 0x6505 (Warnings)

Object 0x6509 Offset

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 16/30 www.baumer.com

30.09.14

Page 17

Scaling

Rotation

Value 0x6000

OFF

CW

0x0000

OFF

CCW

0x0001

ON

CW

0x0004

ON

CCW

0x0005

Object 0x6000 Operating parameters

Scaling: ON Bit 2 = 1

Rotation: Bit 0 = 0 CW , 1=CCW

Object 0x6002 Total measuring range

Mutiturn

Object 0x6001 Measuring units per revolution

Saved non-

volatile

Object 0x1010 SAVE

Value :0x65766173

Object 0x6003 Preset,

Referencing

J

J

J

N N N

CW = clockwise = increasing values with

clockwise shaft rotation

CCW = counterclockwise = increasing values

with counterclockwise shaft rotation

Reference: when looking at flange

5.3 Parameterization

Proceed as below for user-specific parameterization of direction of rotation, resolution, total resolution, preset:

Examples: Scaling ON in object 0x6000

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 17/30 www.baumer.com

30.09.14

Page 18

5.4 Free Run Mode (default)

In "Free Run" mode, a local timer interrupt of the application controller will trip the local cycle which in Free

Run is independent of communication cycle and/or master cycle. The encoder will generate the process data

in asynchronous cyclic manner.

Fig.: Wireshark Network session, encoder input data

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 18/30 www.baumer.com

30.09.14

Page 19

5.5 Distributed Clocks Mode

Distributed clocks mode enables exactly the same time with all bus users.

The encoder can be utilized and configurated as reference clock for synchronisation purposes of both other

users and master. Thus a high-precision time base is available throughout the network.

The encoder generates process data synchronously to a Sync Signal.

The local cycle will be tripped once SYNC0/SYNC1 Event has been received. Prior to receiving the next

SYNC0/SYNC1 Event the process data frame must be completely processed by the slave.

5.5.1 Activation Distributed Clocks under TwinCAT

Important:

Enable SYNC0 and SYNC1.

Ever proceed any cycle time modification in the SYNC0 settings only.

Do not alter any SYNC1 settings.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 19/30 www.baumer.com

30.09.14

Page 20

1C33:2 Cycle time

1C33:5 Minimum Cycle time

1C33:6 Calc and copy time

1C33:3 Shift time time

Input Latch

Sync 0 Event

Sync 0 Event

Sync 1 Event

Sync 1 Event

SSI CLK

SPI SS

Fig.: Local cycle synchronized with SYNC0/SYNC1

Cycle times corresponding to configuration, see chapter Cycle times

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 20/30 www.baumer.com

30.09.14

Page 21

EtherCAT State Machine

The EtherCAT State Machine (ESM) will control the state

of the EtherCAT slave with state-related access and

execution of several functionalities. Specific commands

by the EtherCAT master are required in each state

during slave bootup.

The states of an EtherCAT slave are:

Init

Pre-Operational

Safe-Operational and

Operational

Boot (not supported)

After bootup each EtherCAT slave will be in state Op.

5.6 Network management

The encoder’s State Machine can be switched in the TwinCAT System Manager under tab Online.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 21/30 www.baumer.com

30.09.14

Page 22

Init

Initial state of EtherCAT slave after switch on. There is neither mailbox nor process data communication. The

SyncManager channels 0 and 1 for mailbox communication are being initialized by the EtherCAT master.

Pre-Operational (Pre-Op)

The EtherCAT slave will verify proper mailbox initialising when changing from Init to Pre-Op. Pre-Op enables

mailbox communication but not process data communication. The EtherCAT master will initialize the

SyncManager channels (up from 2) for the process data, the FMMU channels and PDO mapping or

SyncManager PDO assignment, provided the slave supports configurable mapping.

Furthermore, the process data transmission settings as well as clamp-specific parameterization- other than

default and where appropriate - are transmitted in Pre-Op state

Safe-Operational (Safe-Op)

Upon changing from Pre-Op to Safe-Op, the EtherCAT slave will verify whether the SyncManager channels

for process data communication and the Distributed Clock settings are valid. Prior to confirming Safe-Op, the

slave will copy the current input data into the related DP-RAM areas of the EtherCAT Slave Controller (ESC).

In Safe-Op both mailbox and process data communication are enabled, however the slave will keep its

outputs safe (not relevant to encoder). Cyclic update of input data.

Operational (Op)

Process data and mailbox communication is in Op state.

Cyclic update of input data.

Boot (for firmware update): not supported.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 22/30 www.baumer.com

30.09.14

Page 23

Terminal assignment and commissioning 6.

6.1 Mechanical mounting

Shaft encoders

Mount encoder housing by help of the mounting holes and three screws (square flange: 4 screws)

provided at flange. Observe thread diameter and depth.

There is an alternative mounting option in any angular position by eccentric fixings, see under

accessories.

Connect drive shaft and encoder shaft by using an appropriate coupling. The shaft ends must not touch

each other. The coupling must equalize any shifts due to temperature as well as mechanical tolerances.

Observe the maximum permitted axial or radial shaft load. For appropriate couplings please refer to

accessories.

Tighten the mounting screws firmly.

Hollow shaft encoder

Clamping ring fixture

Prior to mounting the encoder open the clamping ring completely. Push encoder onto the drive shaft and

tighten the clamping ring firmly.

Encoder torque pin

Slide encoder onto the drive shaft and insert torque pin into the adjusting element provided by customer.

Adjusting element with rubberized spring element

Push the encoder on to the drive shaft and insert the parallel pin into the mounted adjusting element (not

supplied) (with rubberized spring element)

Adjusting bracket

Push the encoder over the drive shaft. Insert the adjusting bracket into the rubberized spring element of

the encoder and fasten the adjusting bracket on the contact surface (not supplied).

Shoulder screw

Push the encoder over the drive shaft and insert the shoulder screw (not supplied) in the rubberized spring

element of the encoder.

Coupling spring

Mount the coupling spring with screws onto the fixing holes of the encoder housing.

Push the encoder over the drive shaft and fasten the coupling spring on the contact surface.

6.2 Electrical connection

Assignment – M12 connector

Follow also the instructions of the respective supplier.

- Press mating connector softly into the plug.

- Turn mating connector carefully until the code mark is interlocking the corresponding space provided by the

plug. Insert bushing completely. Tighten the nut as far as possible.

Exchange bus cover

The bus cover is to be stored and transported whilst in the ESD bag only. The bus cover has to fit the case

tightly and has to be firmly secured by screws.

Remove bus cover

- Unscrew both fixing screws of the bus cover.

- Loosen bus cover carefully and remove it in axial direction.

Plug on bus cover

- Plug the bus cover carefully onto the D-SUB plug of the basic encoder, then push it over the rubber seal.

Avoid the case getting wedged. The bus cover has to fit tightly the basic encoder.

- Tighten both fixing screws firmly and conformable.

- An optimized connection between encoder case and the braiding shield of the supply cable is only achieved

by a complete and close fit of the bus cover onto the basic encoder (interlock).

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 23/30 www.baumer.com

30.09.14

Page 24

4

5 7 3 6 1

2

6.2.1 Initialising under TwinCAT system manager

The included XML file must be copied into the respective directory:

..\TwinCAT\Io\EtherCAT

Start TwinCAT system manager

Then proceed as described below.

EtherCAT devices should appear like in screen below

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 24/30 www.baumer.com

30.09.14

Page 25

Bus cover shaft / blind hollow shaft - EtherCAT

1 x M12 connector (male), a-coded

2 x M12 connector (female), D-coded

Pin

Assignment

Pin

Assignment

1

UB (10...30 VDC)

1

TxD+

2 N.C.

2

RxD+

3 GND

3

TxD-

4 N.C.

4

RxD-

1 x M12 connector (female), D-coded

Pin

Assignment

1

TxD+

2 RxD+

3 TxD-

4

RxD-

60

63

OUT

L/A

IN

Status-Anzei ge

Status di splay

DUO-LED

Li nk/Acti vi ty

Anzeige/displ ay

LED

OUT IN

L/A

6.2.2 Terminal assignment

Bus cover shaft / blind hollow shaft - Power over EtherCAT (PoE)

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 25/30 www.baumer.com

30.09.14

Page 26

RUN State

Status

Description

Category

Off

INIT

The device is in state INIT

Mandatory

Blinking

PRE-OPERATIONAL

The device is in state PRE-OPERATIONAL

Mandatory

Single Flash

SAFE-OPERATIONAL

The device is in state SAFE-OPERATIONAL

Mandatory

On

OPERATIONAL

The device is in state OPERATIONAL

Mandatory

Flickering

INITIALISATION or

BOOTSTRAP

The device is booting and has not yet entered the INIT

state, or the device is in state BOOTSTRAP.Firmware

download operation in progress

Optional

Double Flash

Reserved

Reserved for future use

reserved

Triple Flash

Reserved

Reserved for future use

reserved

Quadruple

Reserved

Reserved for future use

reserved

ERR State

Error

Description

Example

Category

Off

No error

The EtherCAT

communication of the

device is in working

condition

Mandatory

Flickering

Booting Error Booting

Error was detected. INIT

state reached, but

Parameter "Change" in the

AL status register is set to

0x01:change error

Checksum Error in Flash

Memory.

Optional

Blinking

Invalid Configuration

General Configuration Error

State change commanded

by master is impossible due

to register or object settings.

Mandatory

Single Flash

Unsolicited State

Change

Slave device application

has changed the EtherCAT

state autonomously:

Parameter "Change" in the

AL status register is set to

0x01:change/error.

Synchronisation Error,

device enters SafeOperational automatically.

Mandatory

Double Flash

Application Watchdog

Timeout

An application watchdog

timeout has occurred.

Sync Manager Watchdog

timeout

Mandatory

Triple Flash

Reserved

Reserved for future use

Reserved

Quadruple Flash

Reserved

Reserved for future use

Reserved

On

PDI Watchdog

Timeout

A PDI Watchdog timeout

has occurred

Application controller is not

responding any more

Optional

Link

Activity

State of Link/Activity indicator

Yes

No

On

Yes

Yes

Flickering

No

Not applicable

Off

6.3 Display elements

6.3.1 State indicator

The bus cover provides a DUO LED (green/red) operating in line with EtherCAT Indicator Specification V0.91.

DUO-LED green RUN State

DUO-LED red ERR State

6.3.2 Link/Activity indicator

One LED each for input and output.

Note: All LED´s are “off“ if the encoder is under power supply but not yet connected to Ethernet.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 26/30 www.baumer.com

30.09.14

Page 27

PoE encoder at EK1132 EtherCAT-branch

6.4 Bus cover Power over EtherCAT (PoE)

Based on the IEEE-standard 802.3af, the Baumer EtherCAT encoder with PoE bus cover is interacting as PD

(Powered Device) with a corresponding PSE (Power Sourcing Equipment) module. Signal and power

transmission is by 4-wire standard EtherCAT/Ethernet cable (for example CAT-5). The PSE will identify the

encoder as PD after power on by the procedure specified in IEEE standard 802.3af.

Encoder supply of 48 V must be provided by an auxiliary PSE module (for example Beckhoff EtherCAT

branch EK1132).

Features

- Functionality compliant to standard IEEE Std 802.3af

- Excess temperature protection

- PoE mains unit galvanically insulated

- Hot-Connect feasible (connecting/disconnecting the device during operation)

Technical data

PoE capacity class: 1 (max. 4 W)

PoE supply voltage: 44…57 VDC

Current consumption: 50 mA (48 VDC)

Cable length: max.100 m

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 27/30 www.baumer.com

30.09.14

Page 28

10 Byte PDO (default)

0x1C33:3

Shift time

0x1C33:5

Minimum cycle time

0x1C33:6

Calc and copy time

Basic encoder

Scaling OFF

Scaling ON

Scaling OFF

Scaling ON

Device name

21300

214500

419500

188700

393700

GCAM

41800

234000

413000

185200

364200

GCMM

25000

217000

419000

183000

385000

GXAM

41000

233000

410000

183000

360000

GXMM

33600

228000

416000

185400

373400

GBAM

50600

245000

423000

185400

363400

GBMM

4 Byte PDO

0x1C33:3

Shift time

0x1C33:5

Minimum cycle time

0x1C33:6

Calc and copy time

Basic encoder

Scaling OFF

Scaling ON

Scaling OFF

Scaling ON

Device name

21300

74500

279500

48700

253700

GCAM

41800

92000

271000

43200

222200

GCMM

25000

76000

278000

42000

244000

GXAM

41000

92000

269000

42000

219000

GXMM

33600

86000

274000

43400

231400

GBAM

50600

104000

282000

44400

222400

GBMM

2 Byte PDO

0x1C33:3

Shift time

0x1C33:5

Minimum cycle time

0x1C33:6

Calc and copy time

Basic encoder

Scaling OFF

Scaling ON

Scaling OFF

Scaling ON

Device name

21300

62500

267500

36700

241700

GCAM

41800

85000

264000

36200

215200

GCMM

25000

68000

270000

34000

236000

GXAM

41000

84000

261000

34000

211000

GXMM

33600

78000

266000

35400

223400

GBAM

50600

96000

274000

36400

214400

GBMM

6.5 Cycle times

Cycle times relate to the following settings:

Basic encoder type

Scaling on/off (0x6000 Bit 22)

Configuration 10 byte PDO/ 4 byte PDO/ 2 byte PDO

Scaling ON: 0x6000 22 =1; Scaling OFF: 0x6000 22 =0;

Chart on cycle times All times in ns

Note: Setting 2 byte PDO means input data will be limited to 2 bytes, no matter what the maximum

total encoder resolution is.

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 28/30 www.baumer.com

30.09.14

Page 29

2

Right mouse button

EEProm update

Choose configuration

OK

Wait until EEprom writing cycle has been finalized

1

mark

6.6 Configuration 10 Byte PDO / 4 Byte PDO / 2 Byte PDO by TwinCAT

Default encoder configuration is 10 Byte PDO.

As an option, the encoder configuration may be changed to 4 Byte PDO or 2 Byte PDO to enable shorter

cycle times where appropriate (see chapter cycle times).

Example: How to alter the 10 Byte PDO configuration (default) to 4 Byte PDO

OFF/ON, File new, device search using F5

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 29/30 www.baumer.com

30.09.14

Page 30

Enable Speed Value:

Bit 12 Speed value readout

: 0= steps/s

1= rpm

Integration time 100ms

6.7 Speed Value as an alternative to System Time

The only configuration to enable the speed value (speed transmission) is 10 Byte PDO. To do so, enter value

0x60300020 in TxPDO Mapping object 0x1A00:3. Enter the desired unit for speed value readout in object

0x6000 bit 12 and the integration time in object 0x6031.

Object SAVE Application Parameter (0x1010) will save the parameters in the non-volatile memory.

Example „The Speed Value as an alternative to System Time“ under TwinCAT

Baumer_EtherCAT_PoE_5-00_MA_EN.docx 30/30 www.baumer.com

30.09.14

Loading...

Loading...