Page 1

Instruction Manual

UNCK 09G8914/IO

UNCK 09G8914/KS35A/IO

UNDK 09G8914/IO

UNDK 09G8914/KS35A/IO

Page 2

en_BA_UNXK 09-IO-Link.doc 2/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

Instruction Manual for UNxK 09 with IO Link

Content

1 General Information .....................................................................................................................3

1.1 About this Document ......................................................................................................................3

1.2 General Information........................................................................................................................3

2 IO Link Introduction .....................................................................................................................4

2.1 SIO Mode........................................................................................................................................4

2.2 IO Link Communication Mode ........................................................................................................4

2.3 IODD (IO Link Device Description).................................................................................................5

3 Sensor in the SIO Mode ...............................................................................................................5

4 Sensor in the IO Link Communication Mode.............................................................................5

4.1 Process Data..................................................................................................................................5

4.1.1 Process Data Structure...................................................................................................................5

4.2 Parameters and Commands...........................................................................................................6

4.2.1 Product Information ........................................................................................................................6

4.2.2 Parameters.....................................................................................................................................6

4.2.3 Commands .....................................................................................................................................6

4.2.4 Saving Modifications.......................................................................................................................6

5 Explanation of the Sensor Configuration ..................................................................................7

5.1 Teaching a User-Specific Measuring Range ..................................................................................7

5.1.1 Parameter.......................................................................................................................................7

5.1.2 Commands .....................................................................................................................................7

5.1.3 Description......................................................................................................................................7

5.1.4 Error handling.................................................................................................................................9

5.2 Teach-in of user specific switching points.....................................................................................10

5.2.1 Parameter.....................................................................................................................................10

5.2.2 Commands ...................................................................................................................................10

5.2.3 Description....................................................................................................................................10

5.2.4 Hysteresis.....................................................................................................................................13

5.2.5 Error handling...............................................................................................................................13

5.3 Averaging......................................................................................................................................13

5.3.1 Parameter.....................................................................................................................................13

5.3.2 Description....................................................................................................................................13

5.4 Temperature compensation..........................................................................................................14

5.4.1 Parameter.....................................................................................................................................14

5.4.2 Description....................................................................................................................................14

5.5 Locking/releasing of Teach-in button............................................................................................14

5.5.1 Parameter.....................................................................................................................................14

5.5.2 Description....................................................................................................................................14

6 Overview of SPDUs ....................................................................................................................15

6.1 Table of General Information SPDUs ...........................................................................................15

6.2 Table of Parameter SPDUs ..........................................................................................................15

6.3 Table of System Commands.........................................................................................................16

6.4 Table of error Codes.....................................................................................................................16

6.5 Table of Factory Settings..............................................................................................................17

7 Mounting......................................................................................................................................17

7.1 Mounting options and installation hints.........................................................................................17

Page 3

en_BA_UNXK 09-IO-Link.doc 3/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

1 General Information

1.1 About this Document

These instructions contain information related to commissioning and communications with the Baumer

Series 14 photoelectric distance sensor equipped with the IO Link interface. They supplement the installation

instructions, already provided with each sensor.

These instructions apply to the following sensor versions:

UNCK 09G8914/IO

UNCK 09G8914/KS35A/IO

UNDK 09G8914/IO

UNDK 09G8914/KS35A/IO

1.2 General Information

Rules for proper

usage

This product is a precision measuring device which has been designed for the

detection of objects and parts. It generates and provides measured values issued

as electrical signals for following systems. Unless this product has not been

specifically marked it may not be used in hazardous areas.

Set-up

Installation, mounting and adjustment of this product may only be executed by

skilled employees.

Installation

Only mounting devices and accessories specifically provided for this product may

be used for installation. Unused outputs may not be connected. Unused strands

of hard-wired sensors must be isolated. Do not exceed the maximum permissible

bending radius of the cable. Before connecting the product electrically the system

must be powered down. Where screened cables are mandatory, they have to be

used in order to assure EMI protection. When assembling connectors and

screened cables at customer site the screen of the cable must be linked to the

connector housing via a large contact area.

Page 4

en_BA_UNXK 09-IO-Link.doc 4/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

2 IO Link Introduction

In order to fully understand the various configuration options, these operating instructions describe the most

important aspects of the IO Link interface. More detailed information concerning IO Link, together with all

specifications, is available at www.IO-Link.com.

IO Link is a standard interface for sensors and actuators. Devices (sensors, actuators) are connected to an

IO Link master via point-to-point connections. Communications between the master and the device are

bidirectional, via the device switching line. This interface permits measuring values to be recorded. An option

to configure the sensor via the IO Link is also provided. There are two modes of sensor operation: the

standard input/output mode (SIO mode) and the IO Link communication mode.

The master switches the sensor to the IO Link communication mode. In this mode, process data

(measurement data) are now continuously transferred from the sensor to the master, while requirement data

(parameters, commands) are either written to the device or read from it.

2.1 SIO Mode

After start up, the sensor is automatically in the SIO mode. In this mode, the sensor operates as a standard

switching or measuring sensor. On the master side, the IO Link port is set as a normal digital input. The

sensor can be used like a standard sensor without IO Link. However, various functions can only be controlled

with the aid of IO Link.

2.2 IO Link Communication Mode

The sensor is switched to the “communication mode” by means of a so-called “wake up” signal sent by the

master. With this action, the master attempts to locate a connected device by means of a defined signal

transmitted along the switching line. If the sensor responds, communication parameters are exchanged, after

which the cyclic transmission of process data can begin.

The following can be performed in the IO Link communication mode:

Process data can be received;

Parameters (SPDUs) can be read from the sensor;

Parameters (SPDUs) can be written to the sensor;

Commands can be transmitted to the sensor (e.g., switching point teaching, resets to factory

settings, etc.).

The process data contain cyclic data such as measuring value; switch status or quality information which is

transferred to the higher level controller.

The master can exit the IO Link communication mode by using a “fall back”, after which the sensor once

again operates in the SIO mode until it receives the next “wake up”.

The sensor’s behavior in the SIO mode can be adjusted in the IO Link communication mode. This allows the

sensor to be easily adapted to the requirements of corresponding parameters, and to then continue

operating as a “normal” sensor, without the use of IO Link. Alternately, the sensor can also operate

continuously in the IO Link communication mode in order to fully utilize the entire functional scope provided

by the process data.

Page 5

en_BA_UNXK 09-IO-Link.doc 5/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

2.3 IODD (IO Link Device Description)

The IODD describes the IO Link device, and can be downloaded at www.baumer.com. It comprises a set of

XML and PNG files. An engineering or diagnostic tool reads a sensor’s IODD in order to determine the

following:

- Identification (manufacturer, designation, part number, etc.);

- Communication characteristics (communication speed, frame type, etc.);

- Parameters and commands;

- Process data;

- Diagnostic data (events).

The IODD determines who is permitted to review and modify which sensor data. How the data are presented

and how they are manipulated is defined by the sensor manufacturer and is therefore independent of the

sensor itself.

3 Sensor in the SIO Mode

In the SIO mode, the sensor operates in accordance with its factory settings or according to the settings

defined by the user via IO Link. The functional scope in the SIO mode is sensor specific.

4 Sensor in the IO Link Communication Mode

4.1 Process Data

With the sensor in the IO Link communication mode, data are periodically exchanged between the IO Link

master and the device. These data comprise process data and possibly commands and parameters for the

sensor. Process data transfer the current measuring value and status bits such as the switch status, quality

information, etc. to the master. The master does not need to explicitly request these process data.

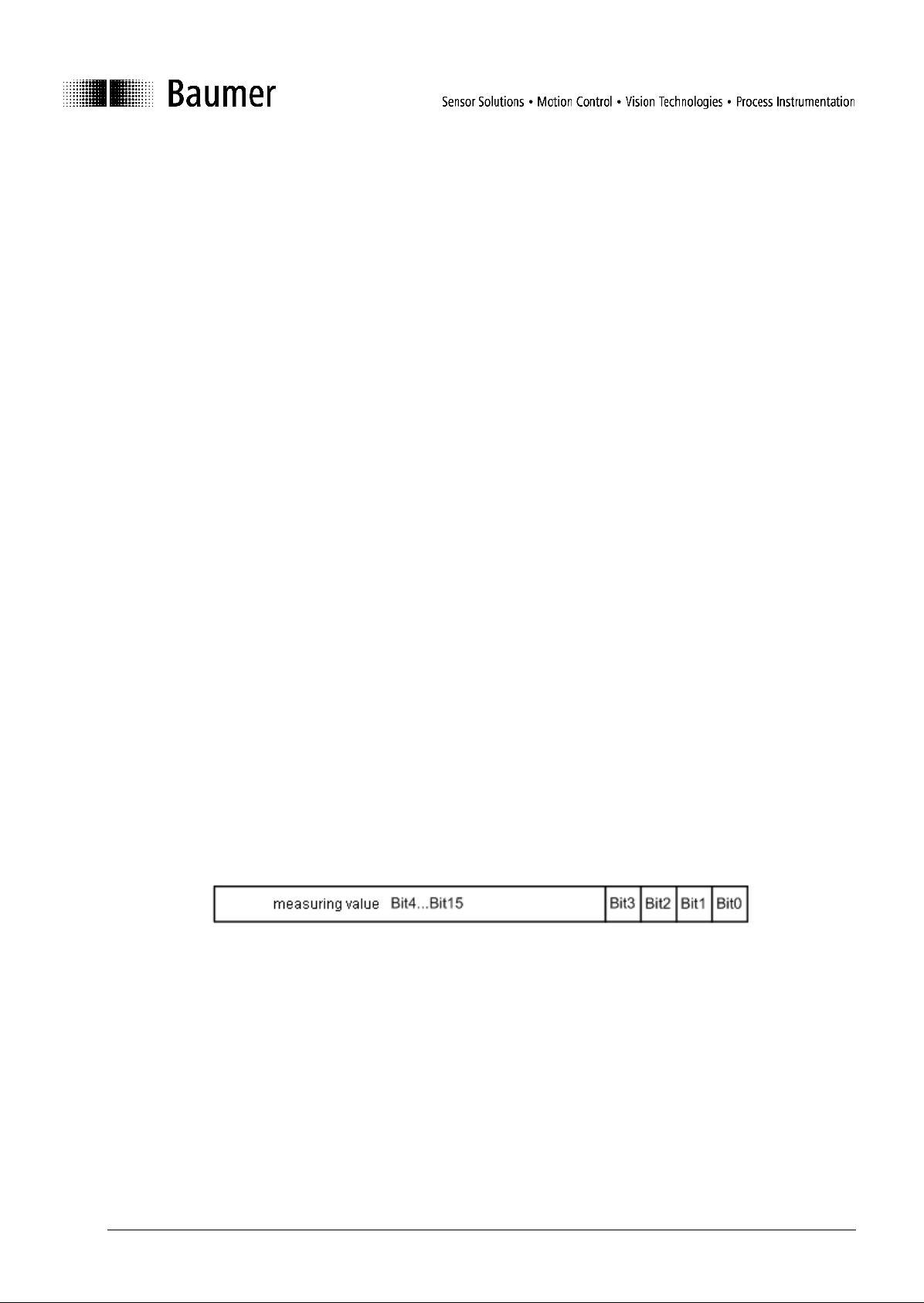

4.1.1 Process Data Structure

Figure 1 illustrates the structure of process data. The following provides a brief description of the individual

information.

Figure 1: Process data

4.1.1.1 Significance of the Measuring Value

The measuring value (Bit4…Bit15) has a range between 0…4095. The measuring value reflects the sensor’s

current measuring range. If the object being measured lies at the start of the measurement value range (e.g.,

30mm), a measuring value of 0 is output. If the object being measured lies at the end of the measurement

value range (e.g., 200mm) a measuring value of 4095 is output.

Page 6

en_BA_UNXK 09-IO-Link.doc 6/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

4.1.1.2 Significance of the Status Information

Bit 0: Alarm

The alarm bit indicates whether an object lies within the measurement value range.

Bit0 = 0 → An object lies within the specified measuring range.

Bit0 = 1 → There is no object within the specified measuring range.

Bit 1: Switch bit

In the IO Link communication mode, the switch bit performs the function of a switching output.

Bit1 = 0 → There is no object within the switching range.

Bit1 = 1 → An object lies within the switching range.

Bit 2: Quality

This bit provides information about the quality of the sonic echo reflected by the object.

Bit2 = 0 → The amount of reflected sonic is OK.

Bit2 = 1 → The amount of reflected sonic is critical.

Bit3: Not used

4.2 Parameters and Commands

Parameters and commands are either written to the device or read from it using SPDU (Service Protocol

Data Unit) indices. The read and write function is provided by the IO Link master. The user can write a value

to an index, or can have a value read from it.

4.2.1 Product Information

Some parameters contain product information such as the manufacturer’s name, the product name and

number, together with a user-specific sensor designation (refer to Table 6, Table of General Information

SPDUs).

4.2.2 Parameters

For a description of parameters, refer to Table 6.2, Table of Parameter SPDUs.

4.2.3 Commands

Commands are written to SPDU Index 0x02 (system commands). Refer to Table 6.3 Table of System

Commands.

4.2.4 Saving Modifications

Modification of parameters either by direct overwriting or by a command don’t have to be saved explicitly.

They remain automatically valid also after a restart.

Page 7

en_BA_UNXK 09-IO-Link.doc 7/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

5 Explanation of the Sensor Configuration

Parameters and commands can be used to configure the sensor functionalities. The following sections

provide a detailed description of the various configuration options.

5.1 Teaching a User-Specific Measuring Range

5.1.1 Parameter

Measuring range work: This parameter covers the currently used beginning and end values for the

measuring range. The beginning and end values can either be entered directly

into the parameter (numerical teaching), or they can be automatically set via

the interim register to teach an object the parameter comprises two 16 bit

components: Measuring range limit A and Measuring range limit B.

- Unit: 0.1mm

- Factory setting: 30 ... 200mm

Measuring range interim: This parameter serves as a supplemental register to teach the measuring

range for an object.

- Unit: 0.1mm

5.1.2 Commands

Teach-in measuring range limit A: Command used to teach measuring range limit A. The taught value is

transferred to the interim register, Measuring range interim.

Teach-in measuring range limit B: Command used to teach measuring range limit B. The taught value is

transferred to the interim register, Measuring range interim.

Transfer measuring range: The measuring range learned in the interim register, Measuring

range interim, is transferred to the Measuring range work register

and is set to active.

5.1.3 Description

There are two methods which the user can employ to adjust the measuring range of the UNxK 09:

Numerical teaching: The beginning and end values of the measuring range are written directly to the

Measuring range work parameter;

Teaching an object: the beginning and end values of the measuring range are learned for an object

by applying the corresponding measuring commands. If the object lies outside the original measuring

range, the minimum or maximum measuring distance are learned.

The measuring value between measuring value limits A and B is output as a relative value between 0 and

4095. Measuring value limits A and B are output as absolute distances from the leading sensor edge in 0.1

millimeter increments. Figure 2 illustrates possible characteristic measuring value curves.

Page 8

en_BA_UNXK 09-IO-Link.doc 8/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

Figure 2: Possible characteristic measuring value curves

5.1.3.1 Example numerical Teach-in:

1) The measuring range shall be defined from 50mm (A) to 180mm (B) -> (curve 2).

Point A absolute in tenth of mm: 500 01F4 hex (= Measuring range limit A)

Point B absolute in tenth of mm: 1800 0708 hex (= Measuring range limit B)

Parameter to be written:

Measuring range work: 01F40708 hex

2) The output signal shall be inverted; measuring range is from 60mm (B) to 120mm (A) -> (curve 3).

Point A absolute in tenth of mm: 1200 04B0 hex (= Measuring range limit A)

Point B absolute in tenth of mm: 600 0258 hex (= Measuring range limit B)

Parameter to be written:

Measuring range work: 04B00258 hex

30mm

200mm

Page 9

en_BA_UNXK 09-IO-Link.doc 9/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

5.1.3.2 Example Teach-in on object

The measuring range has to be taught against an object (curve 2).

Figure 3: Teach-in of output curve

In order to obtain an inverted output signal (curve 3) the distance from the sensor to the Measuring range

limit A must be bigger than the one to the Measuring range limit B.

5.1.4 Error handling

The measuring range limits taught lie beyond the sensor’s max. measuring range (Consult sensor

specification sheet for applicable range):

Numerical Teach-in: writing of Measuring range work not possible, error message Parameter

value out of range.

Teach-in on object: measured value in Measuring range interim is set to FFFF hex, error message

Parameter value out of range. Transfer of data from the interim register to the work register is not

possible, error message Parameter value out of range.

Position the object at the start of

measuring range.

Read the measured value with

command

Teach-in measuring

range limit A

in the interim register

Placing the object at the end of the

measuring range

Read the measured value with

command

Teach-in measuring

range limit B

in the interim

register

Transferring and activating the

measured values from interim

register to work register by the

command Transfer measuring

range

The interim register Measuring

range interim can be read at any

time for checking the teached

values

The interim register will be setting

to FFFF FFFF after transferring the

values to work register

Page 10

en_BA_UNXK 09-IO-Link.doc 10/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

5.2 Teach-in of user specific switching points

5.2.1 Parameter

Switching- /

Teach function: Using this parameter the function of the digital output can either be set to a

single switching point or the two trigger points of a window can be set.

- Values ranges: 0 (switching point), 1 (window)

- Factory setting: 0

Switching points work: This parameter contains the currently set ON and OFF trigger points of the

digital output. The parameter can directly be written on with the required ON

and OFF trigger thresholds (numerical Teach-in), or it is automatically set via

the interim register when teaching against an object. The parameter is

composed of the two 16Bit parameters Switching point A and Switching

point B.

- unit: 0.1mm

- factory setting: switching point A = FFFF hex, switching point B = 200mm

Switching points interim: This parameter acts as a helping register when teaching the switching points

against an object.

- unit: 0.1mm

5.2.2 Commands

Teach-in switching point A: Command for teaching in the switching point A. The taught value is

transferred to the interim register Switching points interim.

Teach-in switching point B: Command for teaching in the switching point B. The taught value is

transferred to the interim register Switching points interim.

Transfer switching points: The Switching points interim held by the interim register are transferred

to the work register and are then activated.

5.2.3 Description

Ex works the sensor has been programmed to have only one switching point like most standard digital

sensors. With the parameter Switching- / Teach function the switching function can be extended to window

function. By changing the switching function both the Teach-in procedure via the Teach-in button and also via

the Teach-in input in SIO mode are changed. The same applies for teaching in the switching points in the IOlink communication mode.

The UNXK 09 can be adjusted by the user in two ways:

Numerical Teach-in:ON and OFF thresholds are written directly into the Switching points work.

Teach-in against object: ON and OFF thresholds are written with the applicable commands for

measuring against an object.

The thresholds A and B define the switching pattern which again defines the state of the switching bit. Both

thresholds, A and B, are indicated as an absolute value, measured from the front edge of the sensor

enclosure, in tenth of mm.

Page 11

en_BA_UNXK 09-IO-Link.doc 11/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

Figure 4 shows all possible switching patterns.

Messdistanz

Schaltbit/Schaltausgang

30mm

200mm

0

1

A

B

Werkskennlinie

(Kennlinie 1)

0

1

Invertierte Kennlinie

(Kennlinie 2)

A

0

1

Kennlinie Schaltfenster

(Kennlinie 3)

B

B

0

1

A

Invertierte Kennlinie Schaltfenster

(Kennlinie 4)

Figure 4: all possible switching patterns

5.2.3.1 Examples for numerical Teach-in:

1) An “ON” threshold shall be set at 130mm distance (B) -> (characteristic 1).

Setting the switching function:

Switching- / Teach function: 0

Point A absolute in tenth of mm: 65535 FFFF hex (= Switching point A)

(Must be set to 65535 since only one switching point required)

Point B absolute in tenth of mm: 1300 0514 hex (= Switching point B)

Parameter to be written:

Switching points work: FFFF0514 hex

2) An “OFF” threshold shall be set at 70mm distance (A) -> (characteristic 2).

Setting the switching function:

Switching- / Teach function: 0

Point A absolute in tenth of mm: 700 02BC hex (= Switching point A)

Point B absolute in tenth of mm: 65535 FFFF hex (= Switching point B)

(Must be set to 65535 since only one switching point required)

Parameter to be written:

Switching points work: 02BCFFFF hex

factory characteristic

(characteristic 1)

inverted characteristic

(characteristic 2)

Switching window characteristic

(characteristic 3)

Inverted switching window

characteristic

(characteristic 4)

Measuring distance

switching bit / switching output

Page 12

en_BA_UNXK 09-IO-Link.doc 12/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

3) Two window thresholds shall be set at 40mm (A) and at 60mm (B) -> (characteristic 3).

Setting the window function:

Switching- / Teach function: 1

Point A absolute in tenth of mm: 400 0190 hex (= Switching point A)

Point B absolute in tenth of mm: 600 0258 hex (= Switching point B)

Parameter to be written:

Switching points work: 01900258 hex

5.2.3.2 Example Teach-in on object

The switching points are taught against an object.

Figure 5: Teaching the switching points

In order to obtain an inverted switching (characteristic 4) the distance from the sensor to Switching point A

must be bigger than the one to Switching point B.

Assigning of parameter

Switching-/Teach function

to a switching point or a

window threshold

Position the object at the

switching point.

Switching point

Window threshold

Position the object at the

switch-on point.

Teach switching point in interim

register using command

Teach-in switching point A.

Position the object at the switchoff point.

Teach switching point in interim

register using command

Teach-in switching point A or

Teach-in switching point B.

Interim register switching

points interim enables

reading and verification of

taught values at all times.

Teach switching point in interim

register using command

Teach-in switching point B.

Transfer switching points from

interim register to work register

using command Transfer

switching points and switch

to active.

Transfer switching points from

interim register to work register

using command Transfer

switching points and switch to

active.

After value export to work

register, the interim register will

be restored to FFFF FFFF hex.

Page 13

en_BA_UNXK 09-IO-Link.doc 13/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

5.2.4 Hysteresis

Switching point:

When moving towards the sensor/trigger point the sensor commutates exactly at the trigger point taught.

When moving away from the sensor’s trigger point the hysteresis is added (see figure 6).

Figure 6: Hysteresis of switching point

Switching window:

When moving towards the window trigger points from either direction the sensor commutates exactly at the

trigger points taught. Once the target is „leaving“ the window a hysteresis is added to either one of the two

trigger points (see: figure 7).

Figure 7: Hysteresis of switching window trigger points

5.2.5 Error handling

The measuring range limits taught lie beyond the sensor’s max. measuring range (Consult sensor

specification sheet for applicable range):

Numerical Teach-in: writing of Switching points work not possible, error massage Parameter

value out of range

Teach-in on object: measured value in Switching points interim is set to FFFF hex, error massage

Parameter value out of range. Transfer of data from the interim register to the work register is not

possible, error message Parameter value out of range.

5.3 Averaging

5.3.1 Parameter

Average: Number of measurements across which the measured value is being averaged.

- Range of values: 0, 2, 4, 8, 16, 32, 64

- Factory setting: 4

5.3.2 Description

By averaging an adjustable number of measured values the white noise in a measuring set-up can be

minimized resulting in increased sensor repeat accuracy and resolution. Signal averaging reduces the

response time whilst the measuring speed is unaffected by this method.

Averaging algorithm: Floating average (single sided floating average value)

Averaged value x: Y_n = (Yn + Yn-1 + Yn-2 +...+ Yn-x)/x

switching bit / switching output

measuring distance

Page 14

en_BA_UNXK 09-IO-Link.doc 14/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

5.4 Temperature compensation

5.4.1 Parameter

Temperature

compensation: With this parameter the temperature compensation can be switched on and off.

- Range of values: 0, 1

- Factory setting: 0 (off)

5.4.2 Description

The temperature compensation is used to compensate the speed of sound’s dependency on air temperature.

Provided the temperature compensation is active changes in the ambient temperature is compensated to 2%

of So (distance sensor to object). Note: the temperature compensation becomes active not until 15 minutes

after power-on. When temperature compensation is off the sensor provides correct measurements

immediately after power-on. But changing ambient temperature induces a measuring error of 0.18 % Sde/K.

5.5 Locking/releasing of Teach-in button

5.5.1 Parameter

Teach-in lock: With this parameter it can be configured if and when the Teach-in button is

locked.

- Range of values: 0 (Button always locked)

1 (Button always unlocked)

2 (Button locked 5 min after Power-On)

- Factory setting: 2 (Button locked 5 min after Power-On)

5.5.2 Description

The Teach-in button, which is required to teach the switching point and/or the two thresholds of the switching

window in SIO mode, has been factory set to lock automatically 5 minutes after power-on. This is to prevent

any accidental changes to the sensors’ settings being executed. Whether and when the Teach-in button has

to be locked is configurable in the IO-Link communication mode. Teach-in via Teach-in wire is remains

unlocked. Note: both ways of teaching - via button and via wire - are possible only provided the sensor is in

the SIO mode. Teach-in is not possible as long as the sensor remains in the IO-Link Communication mode.

Page 15

en_BA_UNXK 09-IO-Link.doc 15/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

6 Overview of SPDUs

6.1 Table of General Information SPDUs

SPDU name

SPDU index

Number of Bytes

Format

Range of values

R/W

Comments

General information on sensors

Vendor Name

0X1018String

ASCII

R

“Baumer Electric AG“ for all sensors

Product Name

0X1222String

ASCII

R

Corresponds with Baumer article

description

Product ID

0X138String

ASCII

R

Corresponds with Baumer article number

Serial Number

0X154String

ASCII

R

Baumer P-Code

Firmware Revision

0X178String

ASCII

R

Baumer Firmware Revision

Application Specific

Name

0X188--R/W

8 Byte at customer disposal

6.2 Table of Parameter SPDUs

SPDU name

SPDU index

Number of Bytes

Format

Range of values

R/W

Comments

Measuring range and switching points

Switching points

work

0X404Switching point A (HB, LB)

Switching point B (HB, LB)

300…2000,

65535

R/W

Distance information on switching points

Switching points

interim

0X414Switching point A (HB, LB)

Switching point B (HB, LB)

300…2000,

65535

R

Distance information on switching points

Measuring range

work

0X424Measuring range limit A (HB, LB)

Measuring range limit B (HB, LB)

300…2000

R/W

Distance information on measuring range

limits

Measuring range

interim

0X434Measuring range limit A (HB, LB)

Measuring range limit B (HB, LB)

300…2000,

65535

R

Distance information on measuring range

limits

Sensor functions

Average

0X501-

0,1,2,4,8,

16, 32, 64

R/W

Number of measuring cycles across which

it is being averaged.

Average value = 0 or 1: Average is

switched off.

Temperature

compensation

0X511-

0,1

R/W

Temperature compensation on/off

respectively.

0 = Temperature compensation off

1 = Temperature compensation on

Switching- / Teach

function

0X601-

0,1

R/W

Selection of switching function and Teach

mode

0 = one switching point

1 = window function

Page 16

en_BA_UNXK 09-IO-Link.doc 16/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

SPDU name

SPDU index

Number of Bytes

Format

Range of values

R/W

Comments

Teach-in lock

0X611-

0,1,2

R/W

Teach-in button lock/unlock respectively

0 = Teach-in button always locked.

1 = Teach-in button always unlocked.

2 = Teach-in button locked 5 min after

Power-On.

6.3 Table of System Commands

Name of

Command

SPDU Index

CMD Value

Comments

Restore factory setting

0X02

0X82

Restores all original factory settings of the sensor

Teach-in

switching point A

0X02

0XA0

Teach-in of switching point A. The measured distance is written into the interim switching

points register.

Teach-in

switching point B

0X02

0XA1

Teach-in of switching point B. The measured distance is written into the interim switching

points register.

Transfer

switching points

0X02

0XA2

Transfer of the switching points from the interim register to the working register.

Teach-in measuring

range limit A

0X02

0XA3

Teach-in of measuring range limit A. The measured distance is written into the measuring

range interim register

Teach-in measuring

range limit B

0X02

0XA4

Teach-in of measuring range limit B. The measured distance is written into the measuring

range interim register.

Transfer

measuring range

0X02

0XA5

Transfer of the measuring range from the interim register to the working register

6.4 Table of error Codes

Error Case

Error Code 1

Error Code 2

Description of

Error Codes

Communication error

(Checksum, …)

0x10

0x00

Communication error, No details

Length of written SPDU is wrong

0x10

0x00

Communication error, No details

Reading an unimplemented SPDU

0x80

0x11

Device error, Index not available

Writing to an unimplemented SPDU

0x80

0x11

Device error, Index not available

Reading Index 2

0x80

0x23

Device error, Access denied

Writing to a read only SPDU

0x80

0x23

Device error, Access denied

Writing an unimplemented System Command

0x80

0x23

Device error, Access denied

Written parameter out of defined range

0x80

0x30

Device error, Parameter value out of range

Page 17

en_BA_UNXK 09-IO-Link.doc 17/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

6.5 Table of Factory Settings

SPDU name

SPDU index

Default value

Application Specific Name

0X18

empty

Switching points work

0X40

Switching point A: FFFF hex

Switching point B: 200mm

Measuring range work

0X42

Measuring range limit A: 30mm

Measuring range limit B: 200mm

Average

0X50

4

Temperature compensation

0x51

0 (off)

Switching- / Teach function

0x60

0 (one switching point)

Teach-in lock

0X61

2 (locked 5 min after Power-On)

7 Mounting

7.1 Mounting options and installation hints

UNDK 09

Figure 8: Mounting options and installation hints for UNDK 09

UNCK 09

Figure 9: Mounting options and installation hints UNDK 09

Page 18

en_BA_UNXK 09-IO-Link.doc 18/18 Baumer Electric AG

24.04.2012/haa Frauenfeld, Switzerland

Baumer worldwide

Brasil

Baumer do Brasil Ltda

BR-04726-001 São Paulo-Capital

Phone +55 11 56410204

Canada

Baumer Inc.

CA-Burlington, ON L7M 4B9

Phone +1 (1)905 335-8444

China

Baumer (China) Co., Ltd.

CN-201612 Shanghai

Phone +86 (0)21 6768 7095

Denmark

Baumer A/S

DK- 8210 Aarhus V.

Phone +45 (0)8931 7611

France

Baumer SAS

FR-74250 Fillinges

Phone +33 (0)450 392 466

Germany / Austria

Baumer GmbH

DE-61169 Friedberg

Phone +49 (0)6031 60 070

India

Baumer India Private Ltd.

IN-411038 Pune

Phone +91 (0)20 2528 6833

Italy

Baumer Italia S.r.l.

IT-20090 Assago, MI

Phone +39 (0)245 70 60 65

USA

Baumer Ltd.

US-Southington , CT 06489

Phone +1 (1)860 621-2121

United Kingdom

Baumer Ltd.

GB-Watchfield, Swindon, SN6 8TZ

Phone +44 (0)1793 783 839

Singapore

Baumer (Singapore) Pte. Ltd.

SG-339412 Singapore

Phone +65 6396 4131

Sweden

Baumer A/S

SE-56122 Huskvarna

Phone +46 (0)36 13 94 30

Switzerland

Baumer Electric AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

Headquarters

Baumer Electric AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

www.baumer.com/worldwide

Technische Änderungen und Irrtum vorbehalten.

Technical data has been fully checked, but accuracy of printed matter not guaranteed.

Loading...

Loading...