Page 1

Assembly & Adjustment

SCATEC – double copy counter

FLDK 110G1903/S42

Page 2

Contents

1 Mechanical Setting & Adjustment..................................................................3

2 Adjustment of the synchronization sensor...................................................5

2.1

2.2

2.3

3 DIP-Switches....................................................................................................8

4 Outputs and LED indicators ...........................................................................9

5 Data sheet....................................................................................................... 10

Version A.......................................................................................................................................6

Version B.......................................................................................................................................7

Checking the adjustment ..............................................................................................................8

20101215_Shortmanual_ScatecDCC_EN.doc 2/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 3

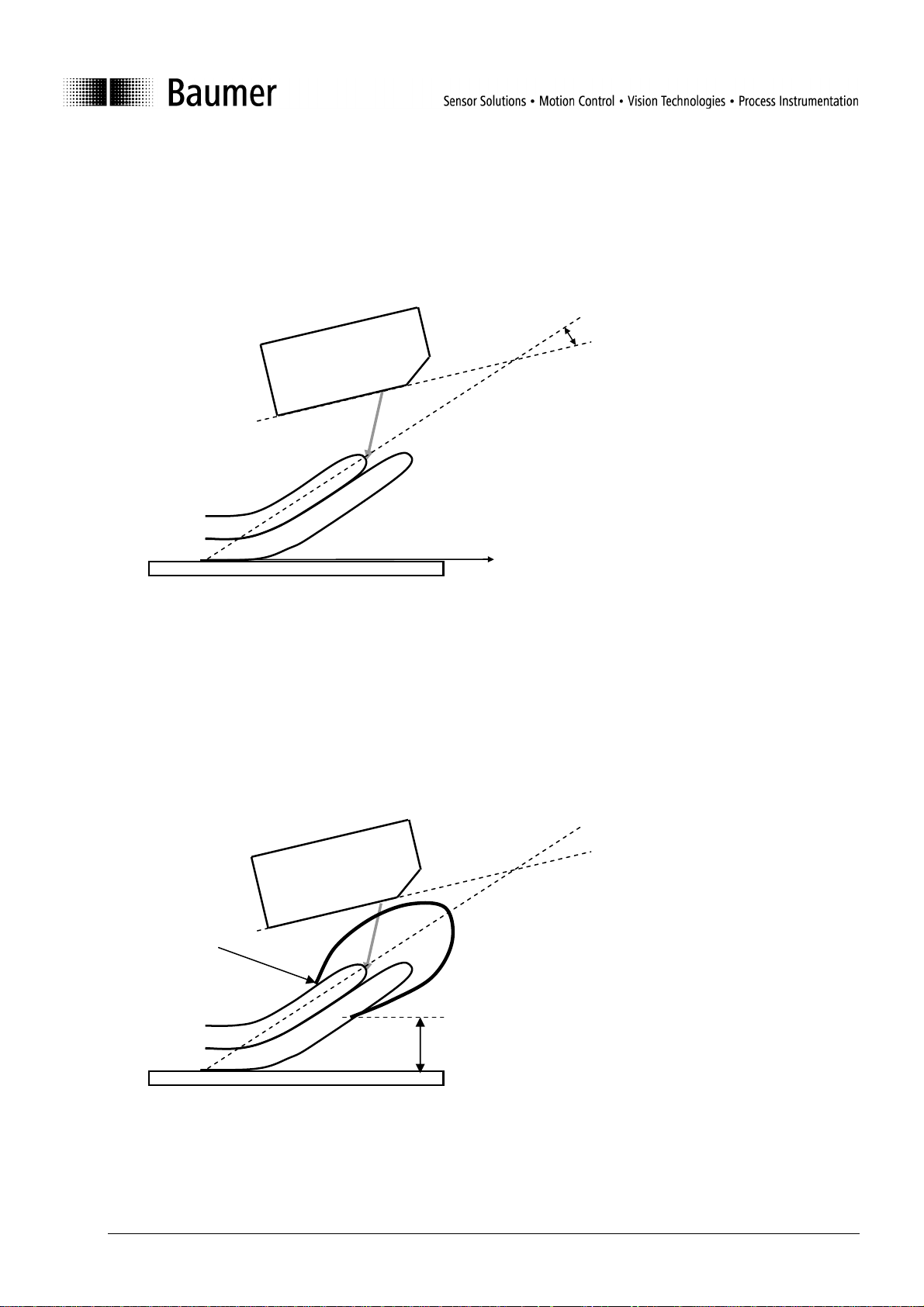

1 Mechanical Setting & Adjustment

Typically, the Scatec is mounted in an angle of 20 ° to the magazine’s position.

about 20°

Scatec

magazines

direction of

Leading plate

Among the products a leading plate should be installed. These should be mounted close under the gripper

(eg he = 50 mm to 70 mm below the lowest point of the gripper).

The leading plate should have a bright, matte surface (eg matte aluminum plate).

Scatec

Holding point

transportion

(ill. 1)

gripper

magazines

Leading plate

20101215_Shortmanual_ScatecDCC_EN.doc 3/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

he

(ill. 2)

Page 4

Position of Scatec or mounting angle of the Scatec is set that the laser spot hits the magazines 10 mm (a)

h

a

outside of the gripper. The angle of the Scatec to the vertical (gripper) has not to be greater than 20°.

< 20°

Scatec

gripper

magazine

(ill. 3)

For the best result, the nominal mounting height (h) of the Scatec is 70 mm.

Scatec

(ill. 4)

20101215_Shortmanual_ScatecDCC_EN.doc 4/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 5

2 Adjustment of the synchronization sensor

The synchronization sensor has to detect each gripper for synchronizing the Scatec. Per gripper the

synchronization sensor only sends one puls to the Scatec.

Examples:

Synchronization

Sensor

The synchronization

sensor detects the metal

part off the wheels

The synchronization

sensor detects the metal

part off the gripper

20101215_Shortmanual_ScatecDCC_EN.doc 5/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 6

2.1 Version A

Situation:

Position of Scatec is fixed

The synchronization sensor can be moved along the conveyor

Testobjects:

put bright products in gripper

Adjustment:

Move the gripper slowly and stop it when the laser spot lies about 5 mm (b) behind the holding point.

Now move the synchronization sensor along the canveyor in transport direction until the sensor switch ON.

Scatec

Holding point

magazines

Leading plate

gripper

direction of

transport

b

20101215_Shortmanual_ScatecDCC_EN.doc 6/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 7

2.2 Version B

Situation:

Scatec can be moved along the conveyor

Position of the synchronization sensor is fixed

Test objects:

Put bright products in gripper

Adjustment:

Move the gripper slowly and stop immediately when the synchronization sensor switchs ON.

Adjust the position of the Scatec along the conveyor until the laser spot lies about 5 mm (b) behind the

holding point. Behind the gripper means, that the light spot is lower than the holding point. . The optimum

setting accuracy is + / - 5 mm.

Holding point

magazines

Leading plate

Scatec

gripper

direction of

transport

b

20101215_Shortmanual_ScatecDCC_EN.doc 7/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 8

2.3 Checking the adjustment

In normal use with magazines in the gripper the functional LED has not to blink.

100%

85%

15%

Signal from

synchronization sensor

Signal from magazin

Signal from magazin

Signal from magazin

It is ok.

green LED flashing: Position to close

orange LED flashing: Position to fare away

3 DIP-Switches

Parameter Dip-Switch Position Value Remark to dead time

Inactive 15% if DIP 3 = ON

Double copy counting

Active 7% if DIP 3 = ON

Pulse

Counting signal output

Synchronous

Minimal 1%

Dead time

Maximal Defined by DIP 1

Maximal

Sensitivity

Reduced

20101215_Shortmanual_ScatecDCC_EN.doc 8/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Page 9

4 Outputs and LED indicators

Output 1: switches ON with 1 or 2 copies

Output 2 switches ON with more than 2 copies

Remark:

Output 1 and 2 will be updated with the next following pulse of the synchronization sensor if synchronous

counting signal output (DIP 2) is chosen.

Synchronization signal

Counting

signal output

synchron

outputs

Pulse

synchron

Double copy

counting

active

inactive

active

inactive

Copies

LED / output signal

Out 1

Out 2

Out 1

Out 2

Out 1

Out 2

Edge

LED

Edge

LED

off

off green orange orange

0

off

off

1

2 3.

green

orange red

Pulse

LEDs

In case of too low supply voltage the functional and edge LED is orange

20101215_Shortmanual_ScatecDCC_EN.doc 9/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Edge

LED

Functional

LED

Orange as long the Scatec detects an edge

Green: normal Situation

Orange: special setup via ScaDiag

Green blinking: position of magazines to close

Orange blinking: Position of magazines to fare away

Page 10

5 Data sheet

SCATEC – double copy counter FLDK 110G1903/S42

Dimension drawing

General data

Measuring distance sd 0 … 120 mm

Optimum operating distance 70 mm

Object speed < 5 m/sec

Sensitivity Single sheet / edge thickness

0.25 mm

Synch. Input Yes

Measuring point Visible red laser line 2 mm

Light source Pulsed red laser diode

Wave length 650 nm

Laser class 2

Edge indicator LED yellow

Power on indicator LED green

Electrical data

Voltage supply range +Vs 10 … 30 VDC

Power consumption < 2 W

Output circuit 2 x push pull

Short circuit protection Yes

Reverse polarity protection Yes

Synch. Input PNP

Mechanical data

Type Rectangular

Housing material PA 6

Connector base DIN 45326, 8 pin and M8

Front (optics) glass

Ambient conditions

Operating temperature 0 … +50°C

Protection class IP 54

Photo

Connection diagram

Connector M16 / S42

1 synch. +

2 voltage supply +Vs

3 serial interface TxD

4 GND (for synch.)

5 serial interface RxD

6 output 1

7 GND

8 output 2

Connector M8 / S35

1 voltage supply +Vs

3 GND

4 synch. +

20101215_Shortmanual_ScatecDCC_EN.doc 10/10 Baumer Electric AG

15.12.2010 / wej Frauenfeld, Switzerland

Loading...

Loading...