Page 1

SCATEC-2

Laser Copy Counter

FLDK 110G1003/S14

FLDK 110G1003/S42

FLDK 110C1003/S42

FLDK 110G1005/S14

FLDK 110G1005/S42

FLDK 110G1006/S14

FLDK 110x10/xxxxxx

User manual

Manual SCATEC-2 2 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

General notes

Rules for proper

usage

This product represents a precision measuring device which has been

designed for the detection of objects and parts. It generates and provides

measured values issued as electrical signals for following systems.

Unless this product has not been specifically marked it may not be used in

hazardous areas.

Set-up

Installation, mounting and adjustment of this product may only be executed

by skilled employees.

Installation

Only mounting devices and accessories specifically provided for this product

may be used for installation.

Unused outputs may not be connected. Unused strands of hard-wired

sensors must be isolated. Do not exceed the maximum permissible bending

radius of the cable. Before connecting the product electrically the system

must be powered down.

Where screened cables are mandatory, they have to be used in order to

assure EMI protection. When assembling connectors and screened cables

at customer site the screen of the cable must be linked to the connector

housing via a large contact area.

Page 2

Manual SCATEC-2 3 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

0 Table of Contents

1. Safety information and Certifications

2. Introduction

3. Principle of operation

4. Part identification

5. Terms and definitions

6. Signal sequence

7. Installation

8. Adjustments

9. Instructions for use

10. Specifications

11. Accessories

12. Maintenance

13. Troubleshooting

14. Varying data for customized FLDK 110x10/xxxxxx

FLDK 110x10/xxxxxx

Check section 14 for data

and information varying

from the standard manual !

Manual SCATEC-2 4 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

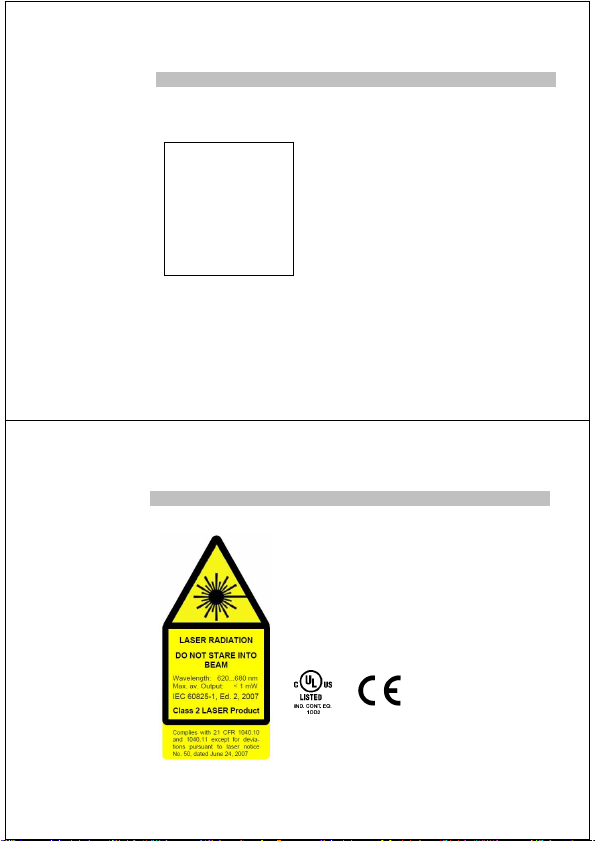

1 Safety information and Certifications

The laser diode installed in the SCATEC-2 emits visible red light.

This laser belongs to the Class 2 laser standard specified by the

IEC 60825-1 / 2007.

Avoid looking directly into the beam for long periods. Brief

irradiation of the eye (0.25 sec) that can occur during an

accidental glance is not regarded to be dangerous.

However, the laser should not be aimed deliberately at people. The

laser beam should also be blocked at the end of its intended path.

Scatec-2 complies with the following safety standards:

Complies with 21CFR 1040.10 and 1040.11 except for deviations

pursuant to laser notice No.50, dated June 24, 2007

Page 3

Manual SCATEC-2 5 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

2 Introduction

SCATEC-2 has the same key feature as all the other sensors from the SCATEC family: The capability

of non-contact detection of object edges. SCATEC is the sensor of choice when it comes to detect flat

objects conveyed in an overlapping stream or individually. The sensors in the SCATEC family were

developed and highly optimized particularly with regard to the specific demands of non-contact counting

of overlapping paper sheets and newspapers. Therefore the printing industry will be the ideal area of

application for the SCATEC.

Generally speaking a SCATEC sensor reacts to an edge facing the sensor’s laser beam. If the laser

beam strikes such an edge, SCATEC responds with an electrical output pulse of fixed duration.

However, built-in software allows the sensor among other things to suppress the reaction to certain

edges which were identified by the sensor as “false edges”. Therefore, SCATEC-2 makes it possible to

count newspapers to the highest degree of accuracy even at high conveyor speed.

Within the SCATEC family, the SCATEC-2 is characterized by the following properties:

(For details see specifications of the individual Scatec-2 types.)

• counts edges from a thickness of 0.2 mm and greater

• optimum working distance: 40 mm or 100 mm

• intelligent false pulse suppression

• parameter setting by means of DIP-switches

• counting rate up to 600,000 copies per hour

• with interface for remote control and data analysis

Manual SCATEC-2 6 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

3 Principle of operation

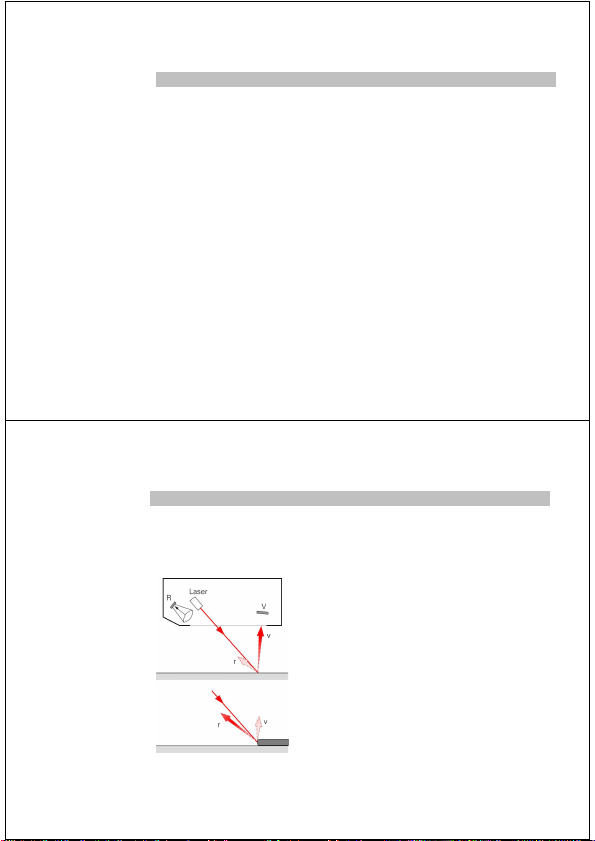

Described simply, the SCATEC-2 consists of a laser light source and two photodetectors. The beam is

aimed diagonally at the objects to be detected. Photodetector R is located close to the laser light source

and photodetector V a little further away. The sensor measures the ratio between signal v (light

scattered forward) and signal r (light scattered backward).

The ratio v/r differs widely depending whether the beam strikes on a flat surface or on an edge. When

an edge moves into the laser beam, the direct line of sight from detector V to the point of contact of the

laser is obstructed, which reduces signal v, and the edge

also increases the backward scattering, causing signal r to

increase. Both effects cause ratio v/r to become

substantially smaller than with a flat surface. If ratio v/r falls

below a specific level, the sensor interprets this as an edge.

This principle of operation clearly demonstrates that:

• The orientation of the object to the beam is significant.

An edge facing towards the beam creates a small ratio

v/r, in contrast to an edge facing away from the beam.

• Edge detection is independent of the color, as only the

ratio of the light intensities and not the absolute value

is used for detection.

Page 4

Manual SCATEC-2 7 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

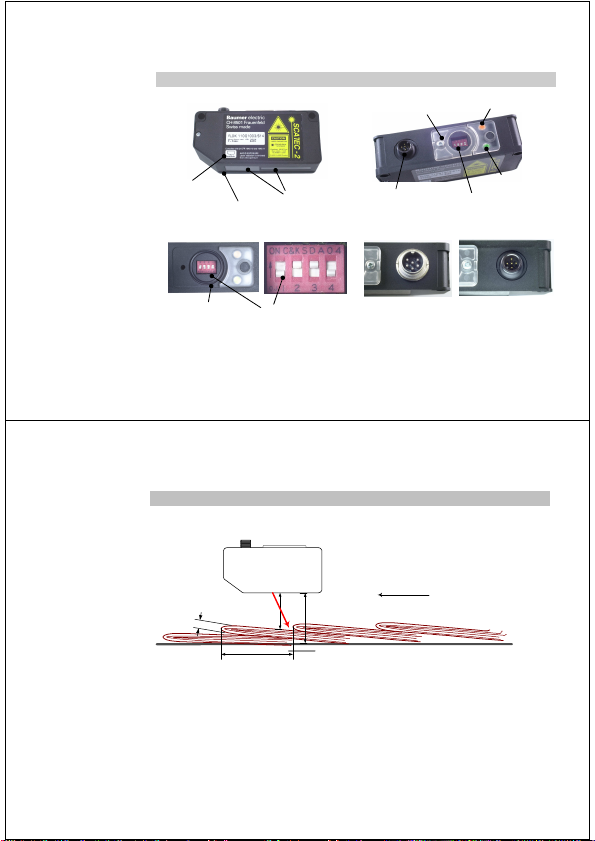

4 Part identification

Edge-LED (yellow)

Sensor plug

Front window

Alignment aid

Lower edge of sensor

DIP-switches

DIP-switch cover

with screw

DIP-switches

O-ring

Power-LED (green)

Connector : .../S42

.../S14

Manual SCATEC-2 8 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

5 Terms and definitions

For reference, the terms defined in this section are used throughout the manual.

Conveying plane

k

Front edge

Tail edge

d

Beam blocker

a

h

Running

direction

Mounting height: h Distance between the lower edge of the sensor and the conveying

plane.

Working plane The edge lies on the working plane. With thick overlapping copies, the

working plane is slightly higher than the top of the conveying plane on

which the copies are transported. Distance d is measured vertically to

the lower edge of the sensor.

Working distance: d Distance between the lower edge of the sensor and the working plane.

Page 5

Manual SCATEC-2 9 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

Overlap: a Distance between two successive edges, measured along the

conveying plane. (Also referred to as the object spacing.)

Edge thickness: k Thickness of the copy at the point where the edge is to be detected.

Front edge The edge of an object facing the laser beam. Front edges are detected

by the sensor.

Tail edge The edge of an object facing away from the laser beam. Tail edges are

not detected by the sensor unless they are pointing upwards.

Running direction The preferred running direction (front edges leading) is indicated. The

opposite direction is also permitted by the SCATEC-2.

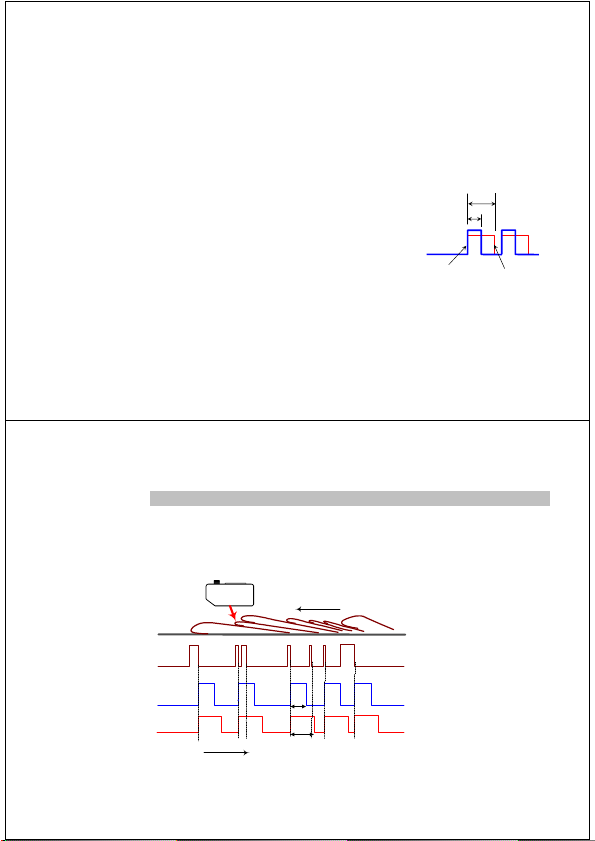

Dead time t The sensor responds to an edge with an output pulse with length p.

The dead time begins when the

pulse is issued. The sensor can

only issue the next pulse after

both the dead time t and the

output pulse p have expired. This

means: an edge detected by the

beam while still either the dead

time t or the the output pulse p is

on does not initiate an output

pulse.

False pulse Output pulse generated by an edge which should not be counted.

Output pulse

Dead time

p

Manual SCATEC-2 10 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

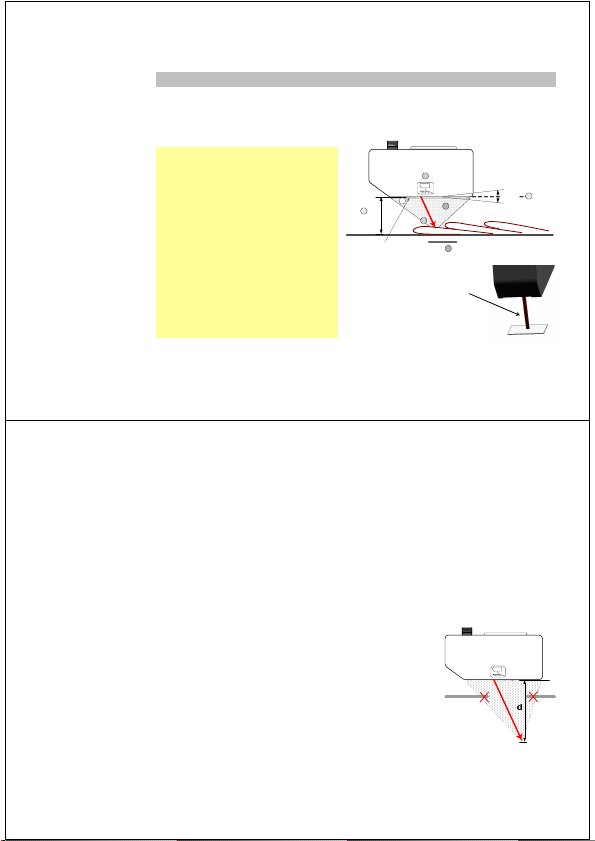

6 Signal sequence

The yellow edge indicator LED lights as long as an edge is located in the beam. The output pulse is

issued at the end of the edge. The dead time begins when the output pulse is issued. During the dead

time and when issuing the pulse, the SCATEC-2 is inactive, i.e. an edge ending during the dead time or

the pulse issue of the previous edge will not initiate an output pulse. Therefore, the next output pulse

can only be issued after the dead time has expired and the output pulse has been issued.

yellow edge-LED

output pulse

(pulse length: p)

dead time

(period: t )

Running direction

on

off

high

low

on

off

time

t

p

Page 6

Manual SCATEC-2 11 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

7 Installation

7.1 Electrical connection

Make the electrical connections as specified in Sections 10.2 Electrical data and 10.3 Pin assignement.

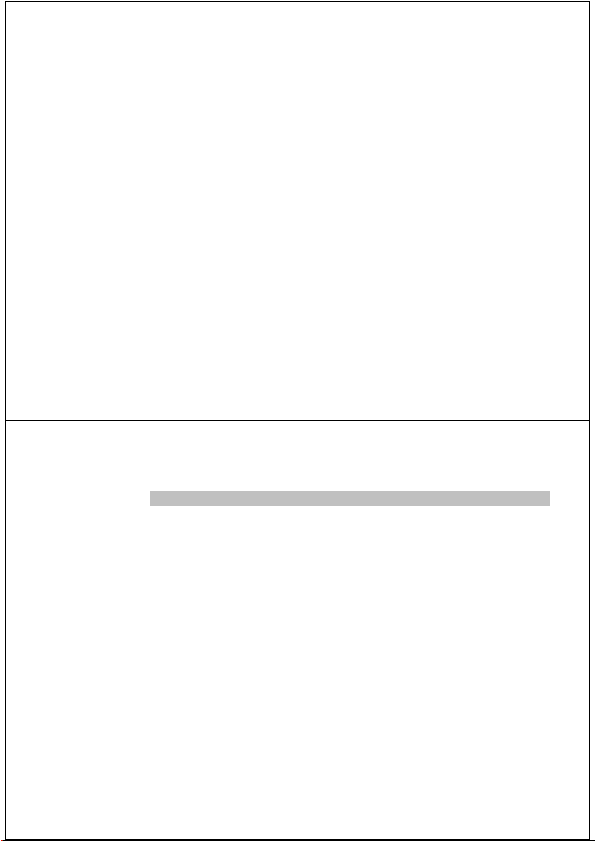

7.2 Mounting

(1) Mount the sensor at the nominal working

distance h (+/-3 mm) with the front

window parallel to the conveying plane.

(2) Adjust the sensor so that the laser beam

is aimed towards the edges to be

counted. When mounted correctly, the

overlap of the copies is facing in the

same direction as indicated in the

alignment aid. Note: the laser beam is

focused into a line which must be aligned

in parallel to the edge to be detected!

(3) Block the laser beam after the objects

whenever possible.

(4) Keep the window clean (remove any

fingerprints after mounting!).

(5) A direct line of sight from the laser impact

point to the entire front window must be

ensured.

Line focus perpendicular to

the

Scatec

housing

Beam blocker

+/- 3°

1

3

2

1

2

Clean window

4

5

Manual SCATEC-2 12 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

Nominal working distance h FLDK 110x1003/Sxx 40 mm above the conveyor belt

FLDK 110x1005/Sxx 100 mm above the conveyor belt

FLDK 110x1006/Sxx

The resolution is dependent on the distance. The highest resolution is

achieved at the nominal working distance. (See also Section 10.6

Specific application data)

Angular tolerance max. +/- 3°

Overlap orientation The copies are counted when the edge facing the laser beam moves

through the beam. If an edge faces away from the beam, it is not

detected. Tail edges are therefore not counted unless they face upwards.

Running direction The SCATEC-2 permits both running directions. The edges facing the

laser beam (front edges) are detected by the sensor regardless of the

running direction.

Front window The direct line of sight from the impact

point of the laser to the entire front window

must not be obstructed by any hardware in

a distance range

d = 0 – 80 mm FLDK 110x1003/Sxx

d = 0 – 120 mm FLDK 110x1005/Sxx

FLDK 110x1006/Sxx

If mountings or other components are close

to this zone for any reason, you should

consult a technician from Baumer Electric

AG.

Page 7

Manual SCATEC-2 13 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

7.3 Beam blocker

Uncontrolled reflections of the laser beam can cause malfunctioning of the sensor or disturb people.

Therefore, a beam blocker should be fitted whenever possible to block the beam when there is no target

present. A flat surface (at least approx. 25x25 mm) made of a matte, non-reflecting material is

recommended as the beam blocker. The beam blocker must be mounted parallel to the sensor. The

yellow edge indicator LED must not light when the laser beam strikes the beam blocker.

7.4 Cleaning the front window

Fingerprints, dust and other forms of dirt on the front window can impair the function of the sensor.

There is a high risk of accidentially leaving fingerprints on the windows when mounting the sensor.

Make sure that after the mounting the front windows are cleaned! It is normally sufficient to wipe the

glass pane dry with a clean (!), soft cloth. Alcohol may be used for heavier soiling.

7.5 Checklist for correct mounting

When the SCATEC-2 is mounted correctly:

• the green power LED lights as long as the electrical supply is connected

• the product overlap faces in the same direction as indicated on the sensor label

• the laser beam is focused on the conveying plane into a line about 2 (3) mm long

• the laser line focus must be aligned in parallel to the edges to be detected

• the yellow edge indicator LED does not light when the laser beam strikes the beam blocker

• the yellow edge indicator LED lights as long as an edge is located in the beam

• the front windows are clean

Manual SCATEC-2 14 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

8 Adjustments

With the SCATEC-2, the following parameters and operating modes can be adjusted:

• Output pulse length

• False pulse suppression

• Sensitivity

The parameters can be adjusted in two ways: via the interface or using DIP switches.

Parameter setting through the interface allows continuous choice of the parameters, whereas a

selection is made from a defined set when the parameters are set with the DIP switches. Parameter

setting through the interface using a computer is described in the user manual for the software package

ScaDiag.

Note: The sensor is only in DIP switch mode when the power LED lights green.

• If the power LED lights yellow instead of green, the parameters of the sensor have been set

through the interface. In this case, the DIP switches are inactive on the sensor and their settings

are irrelevant. The sensor can be reset to DIP switch mode, in which the parameters are defined

by the DIP switches, in two ways.

a) Through the interface (see user manual for the software package ScaDiag).

b) By setting the DIP switches in the following sequence:

1. Set all switches to OFF (at least one must have been ON previously)

2. Set all switches to ON within 16 seconds

3. Set all switches back to OFF within 16 seconds

4. The power LED should then light green after a brief delay. The parameters of the

sensor can then be adjusted with the DIP switches

• To prevent the loss of the DIP switch cover screw, do not fully remove it from the cover. The screw

is retained by the cover.

Page 8

Manual SCATEC-2 15 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

DIP-switch settings:

The effects of the various DIP-switch settings are

described in Section 9 Instructions for use below

FLDK 110x1003/Sxx

FLDK 110x1005/Sxx FLDK 110x1006/Sxx

Factory settings

Parameter

DIPswitch

Setting Value

off / off 5 ms

off / on 10 ms

on / off 15 ms

Output pulse

length

1 / 2

on / on 20 ms

off inactive False pulse

suppression

3

on Active

on reduced

Sensitivity 4

off maximum

Parameter

DIPswitch

Setting Value

off leading Running

direction

1

on trailing

off 5 ms Output pulse

length

2

on 10 ms

off inactive False pulse

suppression

3

on active

on reduced

Sensitivity 4

off maximum

Factory setting

o Do remount the cover after having set the

DIP-switch to avoid intrusion of dust

Manual SCATEC-2 16 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

9 Instructions for use

9.1 Output pulse length and maximum counting rate

On the one hand, the duration of an output pulse must be long enough so that the customer’s control

system can process it. On the other hand, the length of the output pulse limits the maximum counting

rate. Because output pulses must not overlap, the interval between edges must be at least as long as

one output pulse length. If the interval is shorter, then this edge will be suppressed meaning that the

edge will not initiate an output pulse.

The following figure illustrates how every other edge is suppressed because of a too long of an output

pulse length.

amber edge-LED

output pulse

pulse length p < interval a

on

off

high

low

time

p

high

low

output pulse

pulse length p > interval a

some edges are suppressed!

a

p

a

Scatec-2

Page 9

Manual SCATEC-2 17 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

A helpful rule of thumb is: Output pulse length p in milliseconds must be shorter than 1.2 million

divided by the production rate given in copies per hour

The theoretical maximum production rate where output pulses follow each other without any gap in

between is 3 times higher than the recommended value given by the rule of thumb. Exceeding the

recommended value of the production rate increases the risk of missing edges due to irregular intervals

between copies.

The following table lists the recommended maximum production rate for some values of the output

pulse length.

set

output pulse length

[milliseconds]

recommended maximum

production rate

[copies/hour]

1 1,200,000

2 600,000

5 240,000

10 120,000

15 80,000

20 60,000

If suddenly the Scatec starts to miss copies while the production rate is run up, the reason very often is

too short an output pulse length for the actual production rate in combination with fluctuations of the

interval between copies.

Manual SCATEC-2 18 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

9.2 False pulse suppression

It is generally recommended that the SCATEC-2 should be operated with the false pulse suppression

feature active. In this way, multiple pulses caused by thicker copies (newspapers, folded cardboard

boxes etc.) or by a small crease at the edge can be suppressed.

The false pulse suppression feature ensures that no further pulses can be issued when an output pulse

is active and during the dead time. Activating the false pulse suppression feature causes the sensor to

automatically initiate a dead time when each pulse is issued, whose duration is 18% of the average

overlap spacing. If an output pulse is followed by another in less than about 1/6 of the current average

overlap spacing time, this pulse is suppressed, as it lies within the dead time of the preceding pulse.

The average overlap spacing time is constantly recalculated automatically by the SCATEC-2. This

ensures that the dead time is adjusted if the conveying speed changes. In certain cases, one edge may

be suppressed if the conveying speed is very quickly accelerated, whereas one false impulse may not

be suppressed during very fast braking. However, gaps in the overlapping stream caused when

individual copies are removed or when the overlapping stream is briefly diverted have no effect. The

false pulse suppression feature has no effect on the maximum counting rate as the dead time is

shortened as the counting frequency rises and can even become shorter than the output pulse length.

This occurs when the average copy spacing time becomes less than 6 times of the output pulse length.

Ideally, the sensor would not issue further pulses after a valid output pulse for a specific length, as the

typical distance between two edges is often known regardless of the speed. Anything between these

would be false pulses. However, to allow the sensor to suppress pulses for a specific length and not for

a defined time, it must be synchronized to the conveying speed. This is possible with the Scatec-10 and

Scatec-15.

Always switch on false pulse suppression unless the overlap spacing is highly unregular.

Individual copies may be ignored during abrupt acceleration or if the overlap spacing suddenly

becomes smaller.

Page 10

Manual SCATEC-2 19 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

The following diagram shows a comparison of the pulse sequences for active and inactive false pulse

suppression with an identical lap stream.

yellow edge-LED

output pulse

(pulse period: p)

dead time

(duration: t = 18% of

the average overlap a)

on

off

Running direction

time

t

p

high

low

Scatec inactive

Scatec active

high

low

Scatec inactive

Scatec active

output pulse

(pulse period: p)

dead time

(duration: t = 0)

a

Manual SCATEC-2 20 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

9.3 Sensitivity

Because the Scatec cannot discern between a front edge (which the customer wishes to detect) and a

spot on the object similar to an edge (e.g. crests or creases in the paper, creases in a carton etc), the

sensitivity of the sensor should be adjusted to the edge thickness to be detected. This means that the

sensor should be set to a sensitivity at which it detects all leading edges without being sensitive enough

to react to edge-like spots on the object thinner than the actual edge thickness.

It is possible to choose between two different sensitivity levels with DIP switch 4.

A diagram of the sensitivity in relation to the working distance and transportation speed is shown in

Section 10.6.

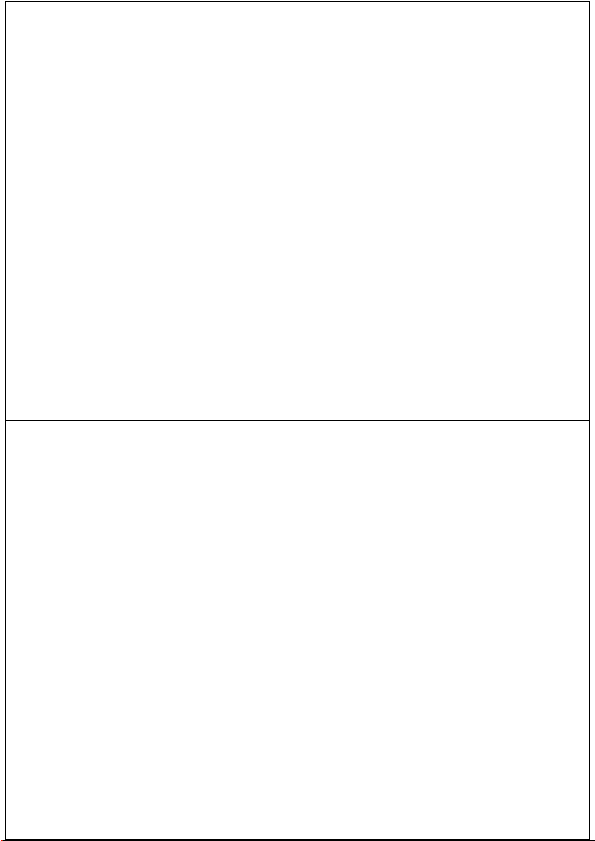

9.4 Variation of the working distance

The thickness that an edge must have to be detected by the SCATEC-2 depends on the working

distance. The SCATEC-2 is most sensitive at the nominal working distance which is 40mm for the FLDK

110x1003/Sxx and 100mm for the FLDK 110x1005/Sxx and FLDK 110x1006/Sxx. The relationship

between the sensitivity and the working distance is contained in the specifications in Section 10.6.

the sensitivity of the sensor varies with the working distance

Page 11

Manual SCATEC-2 21 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

9.5 Signal sequence

Every output pulse is preceeded by a flash of the yellow edge-LED, however, not every flash of the

yellow edge-LED is followed by an output pulse! The yellow edge-LED lights as long as an edge is

located in the beam. Whether this edge actually results in an output pulse or not depends on the current

settings. The pulse could still be suppressed due to restrictions imposed by the dead-time or pulse

length (see section 6).

Because the yellow edge-LED lights up exactly during the time an edge is in the laser beam, the

flashing of the yellow LED may become difficult to recognize by eye when fine edges pass the sensor at

high speed. Consequently, at high conveying speed and/or fine edges, supposedly absent flashing of

the yellow LED does not necessarily mean malfunction of the sensor.

not every flash of the yellow edge-LED is followed by an output pulse

at a high conveying speed the flashing of the yellow edge-LED may be difficult to recognize

9.6 Applications outside the paper processing industry

Due to the fundamental principle of edge detection employed by the SCATEC-2, the field of application

for the sensor is not restricted to the paper processing industry. For applications concerning high-gloss

surfaces (e.g. sheet metals), it is advisable to consult a technician from Baumer Electric AG on the

application.

Manual SCATEC-2 22 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10 Specifications

10.1 Mechanical and thermal data

Sensor size 110 x 50 x 30 mm

Housing material plastic (PA6.6)

Front window glass

Weight approx. 130 g

Protection class IP 54

Working temperature range 0°C to +50°C (non-condens ing)

Storage temperature -20°C to +60°C

15

13

50

45

30

B

Laser

beam

DIPswitches

LED

Sensor-Typ A B

FLDK .../S14 M12x1 8.5

FLDK .../S42 M16x0.75 11.8

Beam angle

α

FLDK 110x1003/Sxx 65°

FLDK 110G1005/Sxx 81°

FLDK 110G1006/Sxx 81°

Page 12

Manual SCATEC-2 23 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.2 Electrical data

Operating voltage VS

Limits: +10 VDC to +30VDC (UL-Class 2)

reverse-protected yes

Ripple V

S

10% within the limits of VS

Power consumption < 2 W

Current consumption

Average: < 170 mA

Peak (after switching on) < 180 mA

Output connector

FLDK.../S14 M12 connector, 5-pole

FLDK.../S42 DIN 45322, 6-pole

FLDK110x10/xxxxxx see section 14

Output circuit

FLDK 110G... Push-pull

normal state low

FLDK 110C... Opto-isolated

switchable voltage maximum 40 V

load resistance maximum 50 kOhm

current load: max. 100 mA

short-circuit protected yes

Output pulse length

FLDK...1003/…and ...1005/… 5, 10, 15, 20 ms selected by DIP switch

FLDK...1006/… 5, 10 ms selected by DIP switch

Manual SCATEC-2 24 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.3 Pin assignment

FLDK.../S14 M12-connector, 5-pole

FLDK.../S42 DIN 45322, 6-pole

Pin Assignment

1 Operating voltage +Vs

2 Seriell TxD (sensor)

3 GND (0V)

4 Signal output +Vout

5 Seriell RxD (sensor)

Pin Assignment

1 Signal output +Vout

2 not connected (FLDK 110G...)

Signal output -Vout (FLDK 110C...)

3 Operating voltage +Vs

4 Seriell RxD (sensor)

5 Seriell TxD (sensor)

6 GND (0V)

3125

4

3

4

2

1

5

6

Page 13

Manual SCATEC-2 25 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.4 Output connection

10.4.1 Push-pull output (FLDK 110G...)

Manual SCATEC-2 26 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.4.2 Opto-isolated output (FLDK 110C...)

Pin 2

Load

Pin 1

Load

Output connected as

Current source

Current sink

V

2

GND GND

V

1

typ. 0V

min. Vout -4V

typ. Vout

max. 4V

Vout

polyfuse

Pin 6

Pin 2

Pin 1

Pin 3

V

+V

out

Pin 1

+V

out

V

Pin 2

+V

out

-V

out

Sensor

+V

S

GND

+VSOperating voltage (+10VDC ... +30VDC)

+V

out

Signal output +

-V

out

Signal output GND 0 V

R

Load

maximum 50 kOhm

I

Load

maximum 100 mA

switchable voltage (+Vout minus -Vout) maximum 40 V

Page 14

Manual SCATEC-2 27 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.5 Optical data

Laser

Wavelength 650nm - 680 nm (visible red)

Pulse frequency 50 kHz

Duty cycle 50%

Average power < 0.5 mW

Laser class 2 (to IEC 60825-1 / 2007)

Beam diameter

FLDK110x1003/Sxx

at emission point about 2.5 mm

40 mm beneath sensor Line focus, 2 mm long, perpendicular to the Scatec housing

FLDK110x1005/Sxx

FLDK110x1006/Sxx

at emission point about 2.5 x 4 mm

100 mm beneath sensor Line focus, 3 mm long, perpendicular to the Scatec housing

Focus position

FLDK110x1003/Sxx 40 mm beneath sensor

FLDK110x1005/Sxx 100 mm beneath sensor

FLDK110x1006/Sxx

Optical receiver equipped with NIR suppression filter and

daylight suppression filter

Manual SCATEC-2 28 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

10.6 Application data

Measuring range

FLDK110x1003/Sxx 0 to 60 mm beneath sensor

FLDK110x1005/Sxx 0 to 120 mm beneath sensor

FLDK110x1006/Sxx

Mounting height

FLDK110x1003/Sxx 40 mm above conveyor

FLDK110x1005/Sxx 100 mm above conveyor

FLDK110x1005/Sxx

Object speed 2 m/s maximum (5 m/s maximum for thicker edges)

Minimum object spacing 10 mm @ v = 1 m/s and output pulse length 10 ms, or

proportional to the speed and output pulse length

Counting rate 600,000 maximum copies/h

Product orientation Fold facing laser beam

Output pulse length 5, 10, (15, 20) ms selected by DIP switch

Dead time 0 ms with inactive false pulse suppression, otherwise 18%

of the average product spacing time

Pulse issue time

FLDK110x1003/Sxx at the end of the edge

FLDK110x1005/Sxx at the beginning of the edge

FLDK110x1006/Sxx depending on the selected running direction

Page 15

Manual SCATEC-2 29 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

Sensitivity FLDK 110x1003/Sxx:

Edges from 0.20 mm thickness and greater are detected

FLDK 110x1005/Sxx and FLDK 110x1006/Sxx

Edges from 0.25 mm thickness and greater are detected

Sensitivity is dependant on distance and speed

Typical sensitivity characteristics see figure below

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0 5 10 15 20 25 30 35 40 45 50 55 60

Working distance d [mm]

Edge thickness k [mm]

Scatec-2 FLDK 110x1003/Sxx Sensitivity

maximum

sens itivity

reduce d

sens itivity

v = 1 ... 2 m/s

How to read the graphics:

An edge with thickness k (*) at distance d can be detected when in the

graphics k is above the curve at the corresponding distance d.

(*) Test object: cleanly cut white paper or cardboard

v = 2 m/s

v = 1 m/s

typical sens itivity character istics

Manual SCATEC-2 30 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

11 Accessories

Cable with plug

Article number Cable length L

ESW 33AH0200 4-pin 2m PUR/halogen-free

ESW 33AH0500 4-pin 5m PUR/halogen-free

ESW 33AH1000 4-pin 10m PUR/halogen-free

Article number Cable length L

ESG 34AH0200 4-pin 2m PUR/halogen-free

ESG 34AH0500 4-pin 5m PUR/halogen-free

ESG 34AH1000 4-pin 10m PUR/halogen-free

Page 16

Manual SCATEC-2 31 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

12 Maintenance

The SCATEC-2 requires no maintenance apart from keeping the front windows clean. Dust or

fingerprints can impair the sensor function. It is normally sufficient to wipe the windows dry with a clean

(!), soft cloth. Alcohol may be used for heavy soiling.

The cover of the DIP switch must be mounted, otherwise dust might intrude. Dust inside the housing

can cause the sensor to malfunction.

13 Troubleshooting

Whenever possible use the application software ScaDiag for trouble shooting !

Otherwise first try to resolve the problem using the following tables. If this is unsuccessful, consult

Baumer Electric AG (

www.baumerelectric.com) for technical support.

The search for fault causes can be substantially shortened if the following issues are clarified before you

make contact with a technician from Baumer Electric AG:

1. What is the part number and P-code of the sensor (see white area on the sensor label)?

2. Give exact description of the problem. (Does the SCATEC count more or less copies

than actually pass the sensor?)

3. Retain several samples of the products causing the counting error. (Mark the running

direction on one sample and the approximate line along which it passes the laser beam.)

4. If possible, take digital images of the installed sensor in operation and of the immediate

surroundings.

Manual SCATEC-2 32 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

Fault Possible causes Corrective actions (see manual section x.x)

a) Wrong sensitivity setting. Set DIP-swich 4 off. (8; 9.3)

b) Copies too close to or too far away

from the Scatec, so that the copies

are in a distance range at which the

sensitivity of the sensor is inadequate.

Set the distance of the copies in a range where

the sensor is sufficiently sensitive to detect the

copies. (10.6)

c) Overlap spacing sporadically too

small.

Increase the overlap spacing or reduce the

conveying speed (production rate). (9.1)

d) Some copies are completely

covered by another copy.

Prevent complete coverage of copies.

e) Conveying speed too high. Reduce conveying speed. (10.6)

1

Scatec counts less

copies than actually

pass the sensor

f) False pulse suppression active

while overlap a is highly irregular or

conveying speed is occasionally

accelerated very quickly.

Deactivate false pulse suppression (DIP-switch 3

set off) or make overlap a more regular or

accelaerate slower (9.2)

Page 17

Manual SCATEC-2 33 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

Fault Possible causes Corrective actions (see manual section x.x)

a) Apart from the edges, there are

other patches on the copies which

cause false pulses.

Prevent critical patches on the copies.

b) Laser beam on beam blocker

causes false pulses.

Adjust beam blocker correctly (yellow edge LED

must never light when the laser beam strikes the

beam blocker).

c) Unblocked laser beam is reflected

and causes false pulses.

Install beam blocker at proper distance.

2

Scatec counts more

copies than actually

pass the sensor

d) Conveyor belt stands still and

vibrates while an edge is still in the

laser beam.

This problem can be eliminated only by

synchronizing the sensor to the conveyor speed.

Scatec-10 and –15 can be synchronized.

Manual SCATEC-2 34 Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

14 Varying data for customized FLDK 110x10/xxxxxx

Page 18

Manual SCATEC-2 35 Baumer Electric AG

Version 2011-05 www.baumer.com Frauenfeld, Switzerland

Manual SCATEC-2 36 Baumer Electric AG

Version 2011-05 www.baumer.com Frauenfeld, Switzerland

Denmark

Baumer A/S

DK-8210 Aarhus V

Phone +45 (0)450 392 466

France

Baumer SAS

FR-74250 Fillinges

Phone +33 (0)450 392 466

Germany

Baumer GmbH

DE-61169 Friedberg

Phone +49 (0)6031 60 07 0

Italy

Baumer Italia S.r.l.

IT-20090 Assago, MI

Phone +39 (0)245 70 60 65

Sweden

Baumer A/S

SE-56122 Huskvarna

Phone +46 (0)36 13 94 30

Switzerland

Baumer Electric AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

United Kingdom

Baumer Ltd.

GB-Watchfield, Swindon, SN6 8TZ

Pho

ne +44 (0)1793 783 839

Canada

Baumer Inc.

CA-Burlington, ON L7M 4B9

Phone +1 (1)905 335-8444

USA

Baumer Ltd.

US-Southington , CT 06489

Phone +1 (1)860 621-2121

China

Baumer (China) Co., Ltd.

CN-201612 Shanghai

Phone +86 (0)21 6768 7095

India

Baumer India Private Limited

IN-411038 Pune

Phone +91 20 2528 6833/34

Singapore

Baumer (Singapore) Pte. Ltd.

SG-339412 Singapore

Phone +65 6396 4131

Austria

Baumer GmbH

AT-2514 Traiskirchen

Phone 0800 07000

20

Brasil

Baumer do Brasil Ltda

BR-04726-001 São Paulo-Capital

Phone +55 11 56410204

www.baumer.com/worldwide

Technical data subject to change Printed in Switzerland No. 10153594

Loading...

Loading...