Page 1

SCATEC-10 / 15

Laser Copy Counter

FLDM 170G1011/S42 Scatec-10

FLDM 170C1011/S42

FLDM 170G1030/S42 Scatec-15

FLDM 170C1030/S42

FLDM 170x10/xxxxxx customized

User manual

Page 2

General notes

Rules for proper

usage

This product represents a precision measuring device which has been designed for

the detection of objects and parts. It generates and provides measured values

issued as electrical signals for following systems.

Unless this product has not been specifically marked it may not be used in

hazardous areas.

Set-up

Installation

Installation, mounting and adjustment of this product may only be executed by

skilled employees.

Only mounting devices and accessories specifically provided for this product may

be used for installation.

Unused outputs may not be connected. Unused strands of hard-wired sensors must

be isolated. Do not exceed the maximum permissible bending radius of the cable.

Before connecting the product electrically the system must be powered down.

Where screened cables are mandatory, they have to be used in order to assure EMI

protection. When assembling connectors and screened cables at customer site the

screen of the cable must be linked to the connector housing via a large contact

area.

User manual Scatec-10 / -15 2 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 3

Table of contents

1 Safety information

2 Certifications

3 Introduction

4 Principle of operation

5 Part identification

6 Terms and definitions

7 Signal sequence

8 Installation

9 Setting the operational parameters

10 Display and user menu

11 Specifications

12 Accessories

13 Maintenance

14 Troubleshooting

15 Varying data for customized FLDM 170x10/xxxxxx

16 Supplements

customized FLDM 170x10/xxxxxx: Data and information varying from the standard

manual are listed in section 15 !

User manual Scatec-10 / -15 3 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 4

1 Safety information

The laser diode installed in the Scatec-10 / -15 emits visible red light. This laser belongs to the Class 2 laser

standard specified by the IEC 60825-1 / 2007.

Avoid looking directly into the beam for long periods. Brief irradiation of the eye (0.25 sec) that can

occur during an accidental glance is not regarded to be dangerous.

However, the laser should not be aimed deliberately at people. The laser beam should also be blocked at the

end of its intended path.

2 Certifications

Scatec-10 / -15 complies with the following safety standards:

Complies with 21CFR 1040.10 and 1040.11

User manual Scatec-10 / -15 4 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 5

3 Introduction

As a member of the Scatec family, the Scatec-10 / -15 generally provides a means of detecting object

edges. These sensors are best suited for non-contact counting of overlapping paper sheets and newspapers

in the printing industry.

If an object with an edge facing the laser beam passes through the beam, the sensor reacts with an electrical

output pulse. The user has several options to set the Scatec-10 / -15 in such a way that certain edges are

recognized as “false edges” and consequently do not initiate an output pulse. This option of suppressing

certain edges allows the sensor to count newspapers to the highest degree of accuracy.

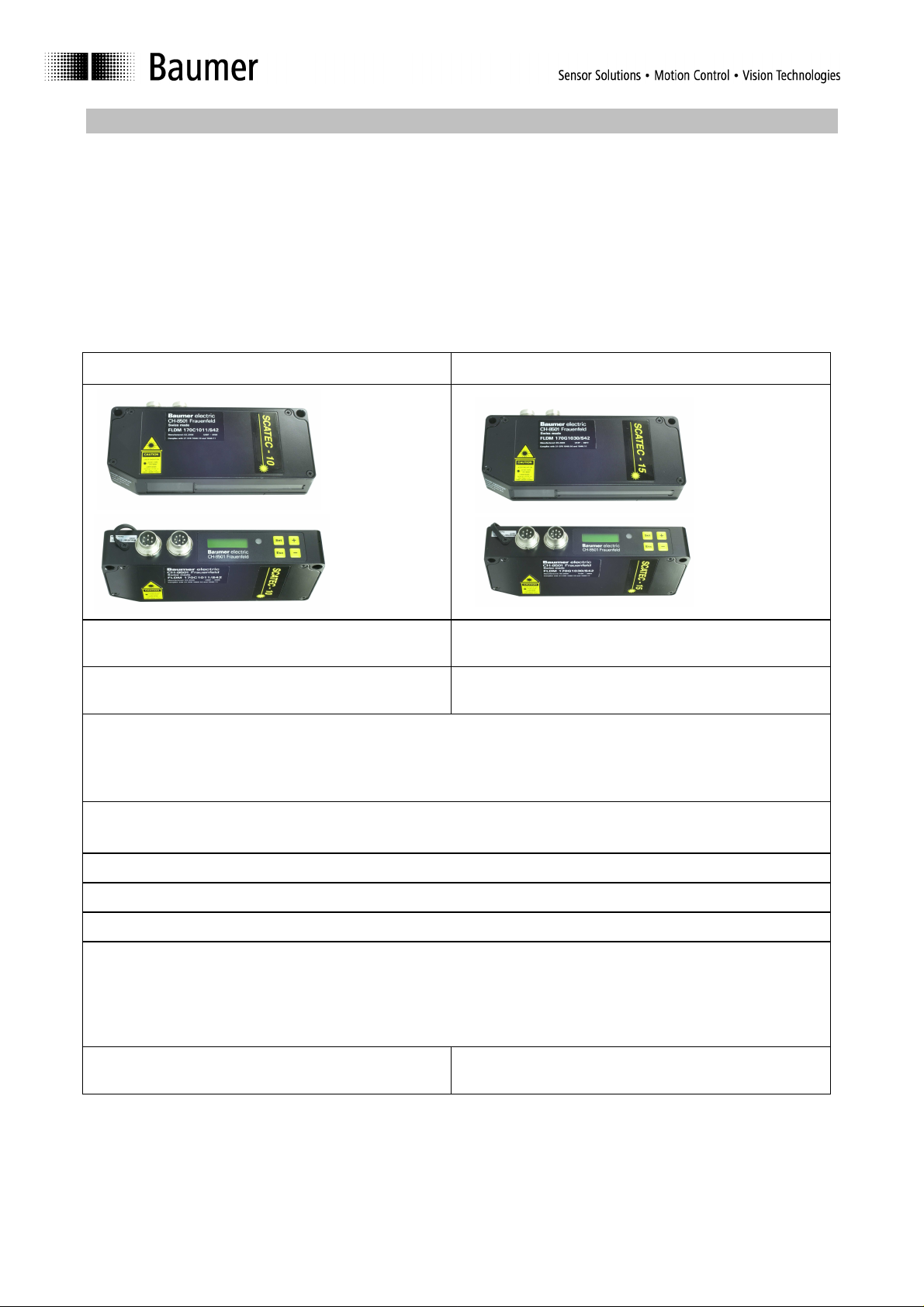

Within the Scatec family, the Scatec-10 and the Scatec-15 distinguish themselves by the following features:

Scatec-10 FLDM 170x1011/S42 Scatec-15 FLDM 170x1030/S42

• detects edges from a thickness of

0.1mm and thicker

• optimum working distance:

70 mm

• reliable gap detection via the built-in retroreflective sensor

(allowing consistent recognition of certain edges

as “false edges”)

• can be synchronized to the conveying speed

(allowing for enhanced false pulse suppression)

• high precision timing of pulse output

• counting rate up to 1.5 million copies per hour

• keypad and display for easy parameter setting

• detects edges from a thickness

of 0.1mm and thicker

• optimum working distance:

100 mm

• with interface for remote control and data

collection

(allowing analysis of product conditions while

production is running. Indispensable for test and

“trouble shooting”

User manual Scatec-10 / -15 5 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

• with CAN-interface for

remote control

Page 6

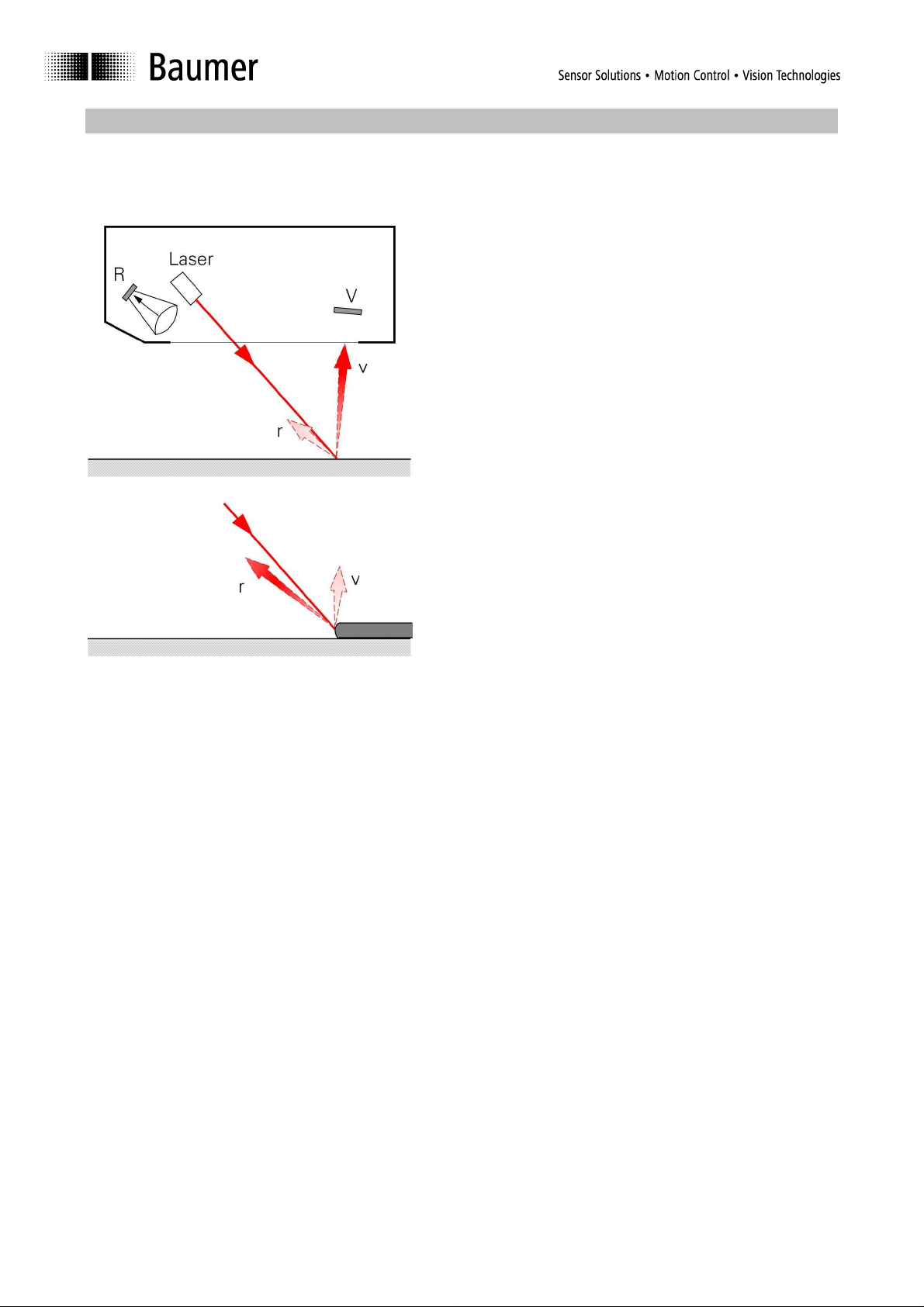

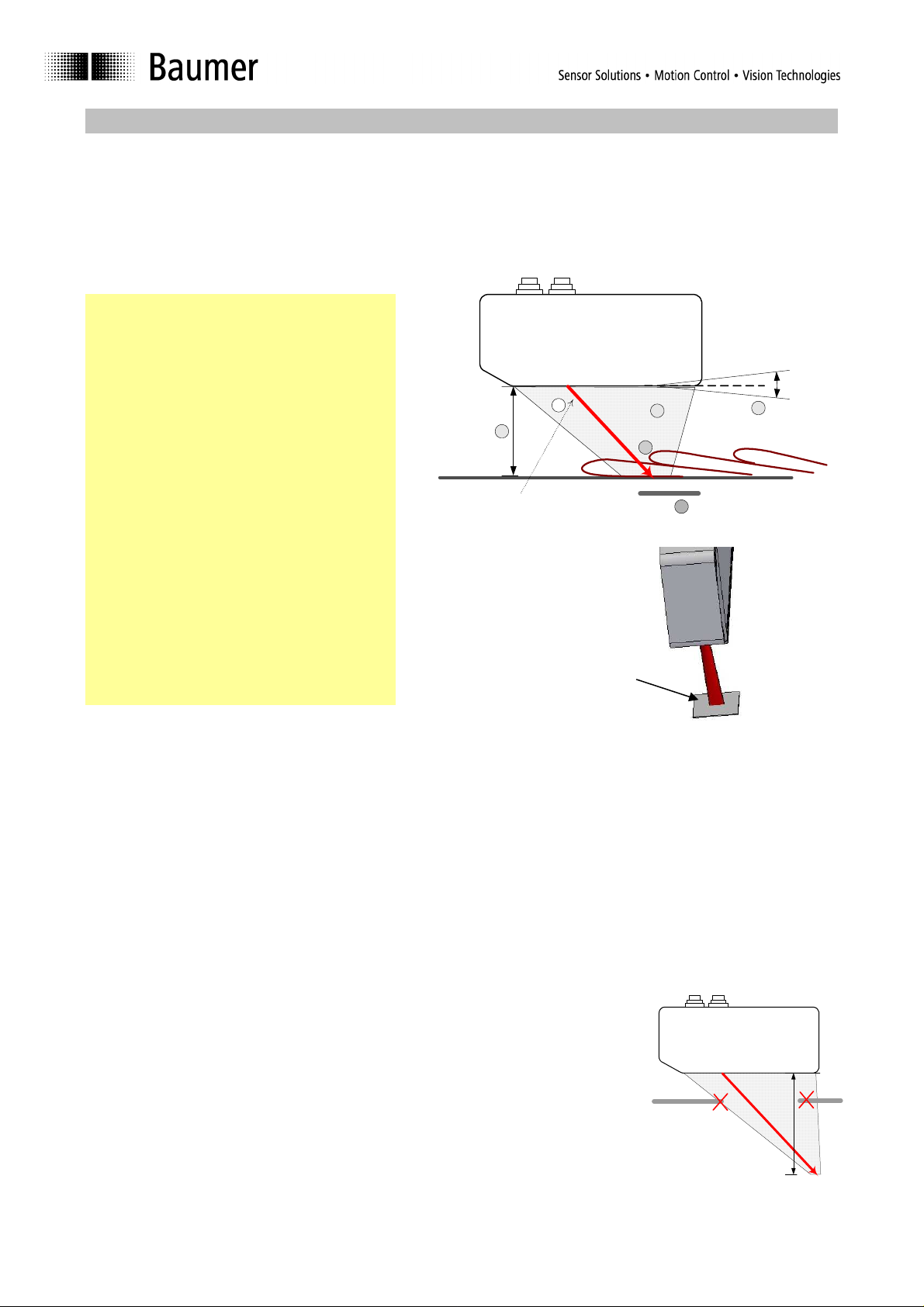

4 Principle of operation

Described simply, the SCATEC-10 / -15 consists of a laser light source and two photo detectors. The beam

is aimed diagonally at the objects to be detected.

The photodetectors V and R detect laser light

scattered by an object in the forward and backward

direction, respectively. The ratio of light received by

these two detectors differs widely depending on

whether the beam strikes a flat surface or an edge.

Compared to a flat surface, an edge obstructs the

direct line of sight from the point of contact of the laser

to the detector V and hence detector V receives less

light. At the same time, an edge scatters more light

toward detector R than a flat surface. Both effects

cause the ratio of forward to backward scattered light

v/r to become substantially smaller than with a flat

surface. Therefore an edge is characterized by a value

of this ratio below a specific threshold.

This principle of operation clearly demonstrates that:

• The orientation of the object to the beam is

significant. An edge facing towards the beam

creates a small ratio v/r, in contrast to an edge

facing away from the beam.

• Edge detection is independent of the color, as only

the ratio of the light intensities and not the absolute

value is used for detection.

User manual Scatec-10 / -15 6 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 7

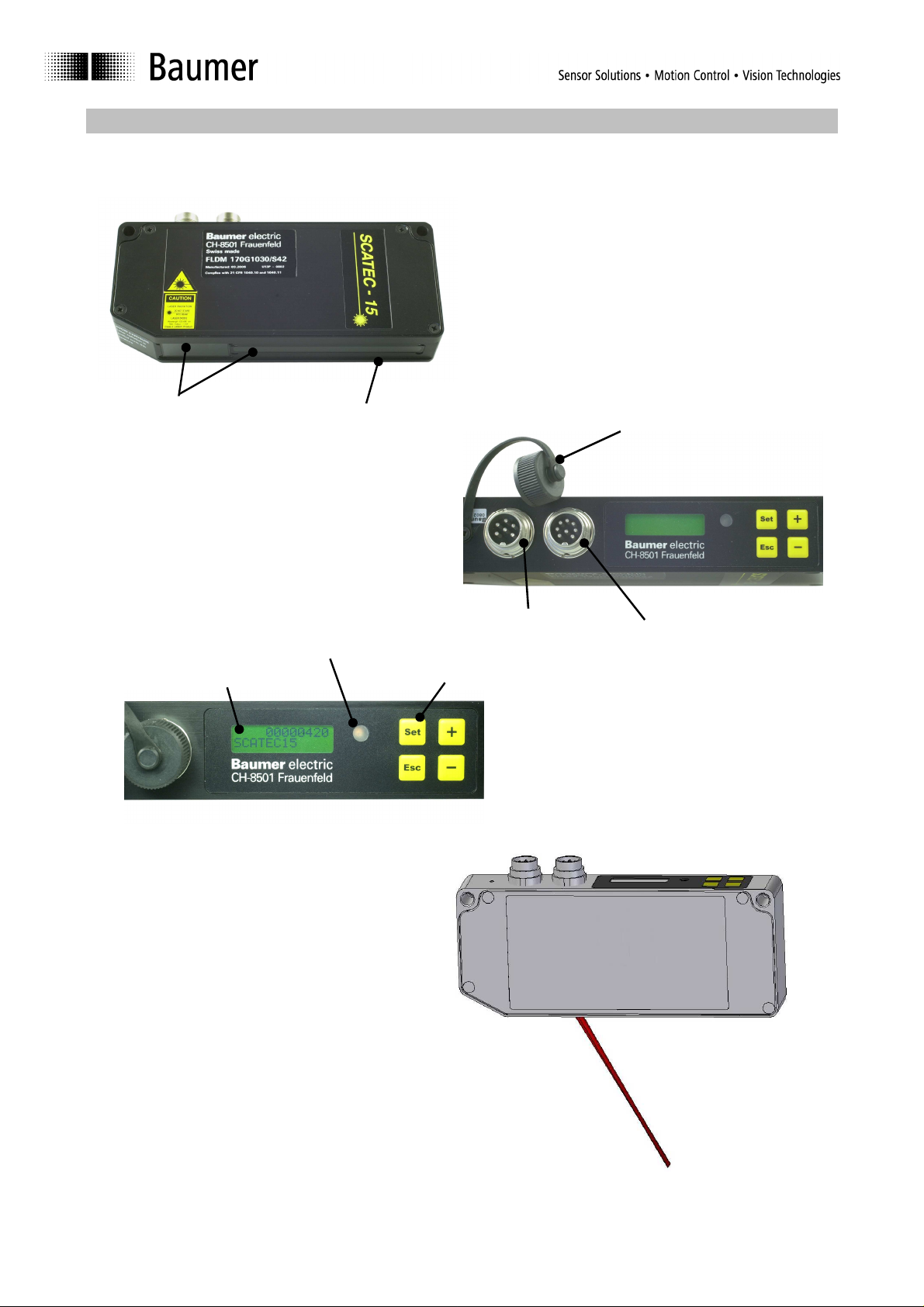

Frontwindow

Lower edge of

sensor

Display

Keypad

Main connector

Laser beam

5 Part identification

Edge-LED (amber)

Protection cap for

Interface connector

User manual Scatec-10 / -15 7 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Line focus

(transverse to the Scatec)

Page 8

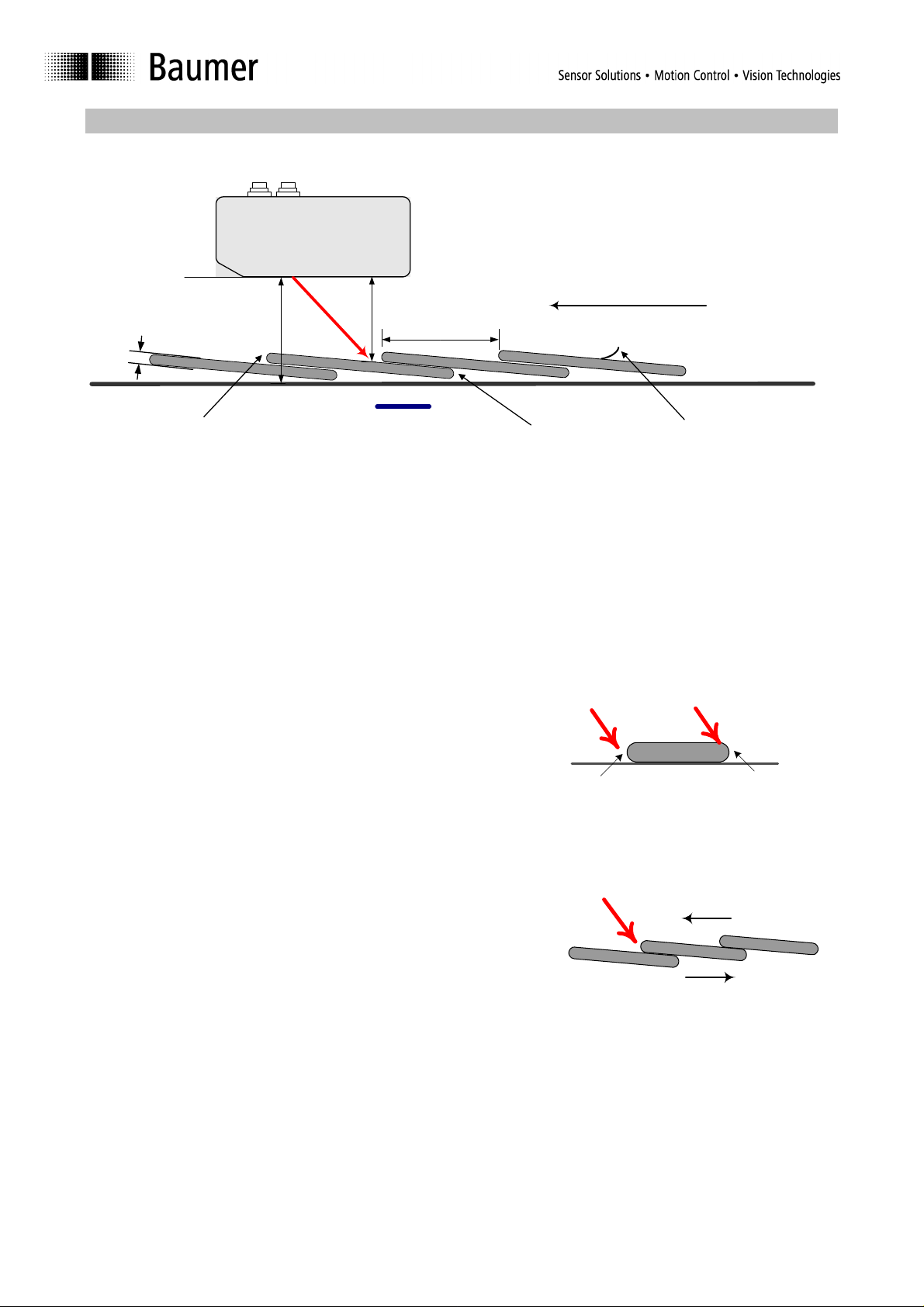

6 Terms and definitions

Scatec-1x

h

k

Running direction

d

a

Conveying plane

Front edge

Beam blocker

Tail edge

Interfering edge

Mounting height h Distance between the lower edge of the sensor and the conveying plane.

Working distance d Distance between the lower edge of the sensor and the plane where the edge

lies on. Note that the working distance equals the mounting height only if the

edge lies directly on the conveying plane.

Overlap a Interval between two successive edges, measured along the conveying plane.

Edge thickness k Thickness of the copy at the point where the edge is to be detected.

Front edge The edge of an object which faces the laser beam. In principle, edges facing

the laser beam can be detected

by the Scatec, independently of

Laser beam

the running direction.

Tail edge The edge of an object which

faces away from the laser beam.

Edges facing away from the

laser beam cannot be detected

by the Scatec and do not initiate

Front edge:

detectable

Tail edge:

non-detectable

output pulses no matter the

running direction is.

Running direction For Scatec-10 / -15 both running

directions are allowed, with the

Laser beam

Running direction of copy:

front edge leading (a) or trailing

(b). A front edge is detected

(a) leading

independently of the running

direction. However, for certain

false pulse suppression modes to

(b) trailing

operate properly, the running

direction must be set correctly.

Interfering edge Folds, fissures, creases, or other imperfections on a newspaper can form

edges which will be detected by the Scatec but should not be counted. Such

edges are termed “interfering edges” and cause so called “false pulses”.

Scatec-10 / -15 offers several possibilities to efficiently suppress these false

pulses.

User manual Scatec-10 / -15 8 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 9

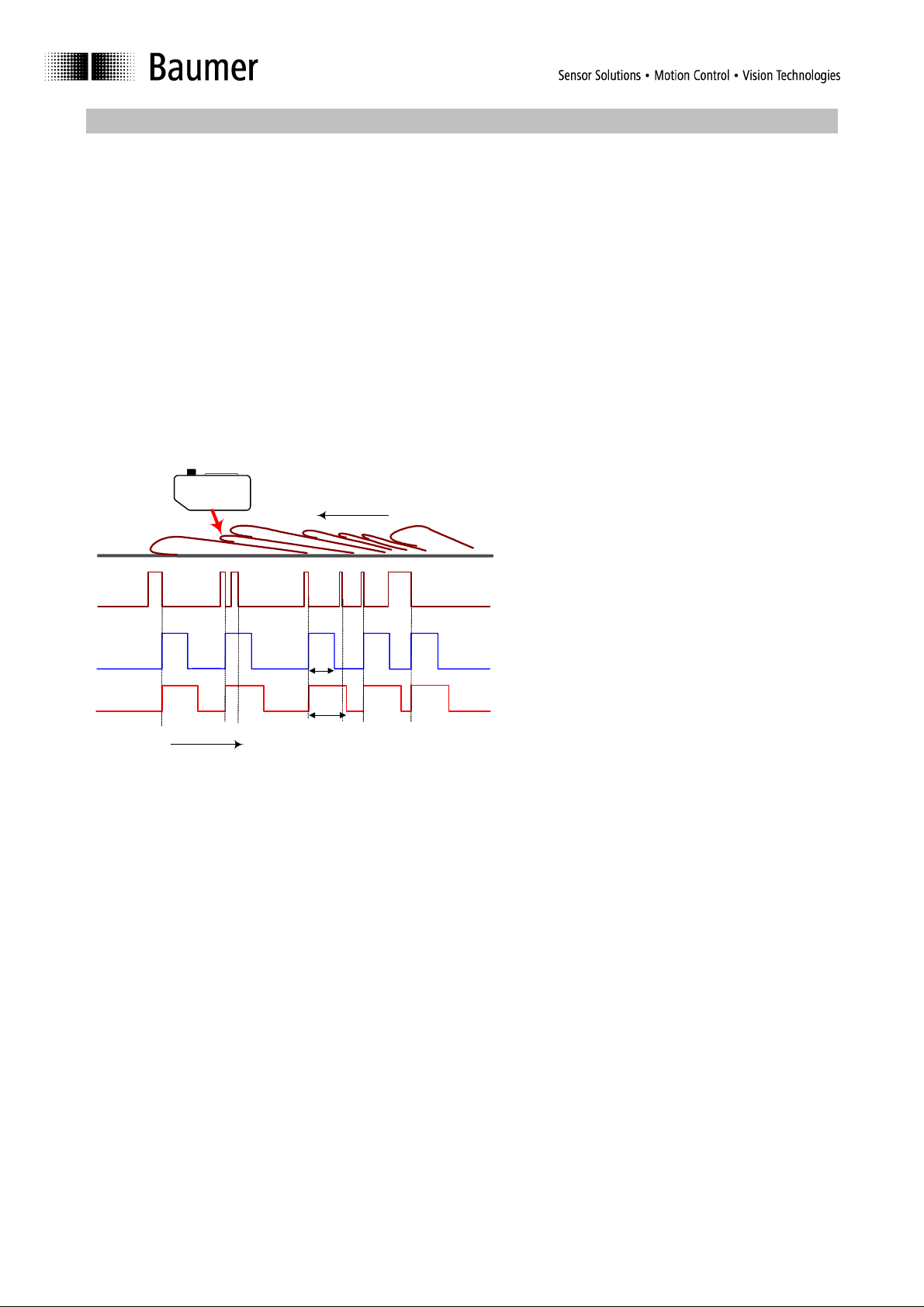

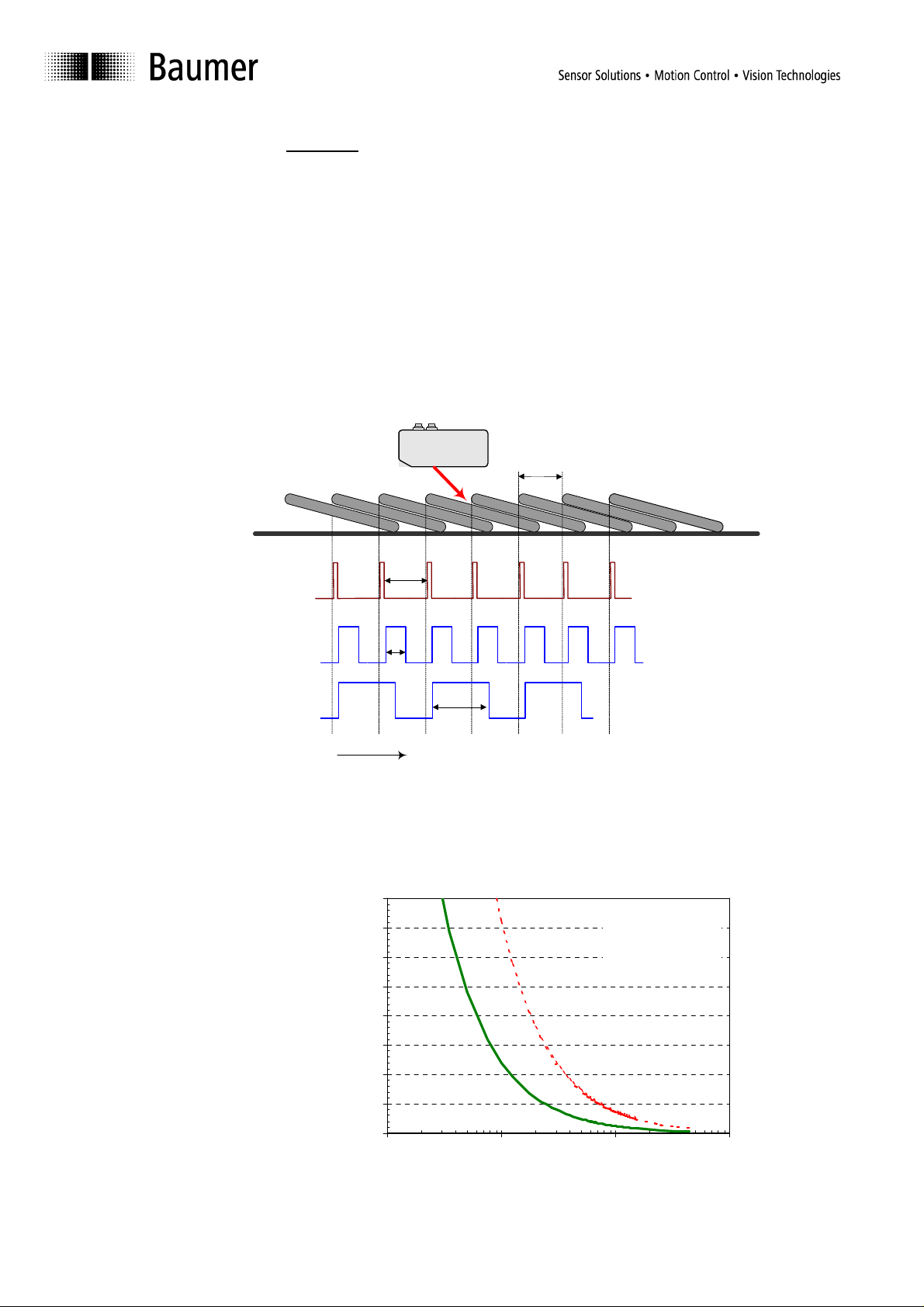

7 Signal sequence

The yellow edge indicator LED lights as long as the laser beam strikes an edge. The end of an edge (amber

edge LED turns off) triggers the output pulse and the dead time. The dead time starts immediately with the

trigger, while the delivery of the output pulse can be delayed (pulse delay adjustable by the customer).

During the dead time, SCATEC-10 /-15 is inactive, i.e. an edge ending during the dead time will not initiate

an output pulse and is therefore suppressed. As a consequence output pulses are separated in time by at

least the length of the dead time. Please note, the Scatec-10 / -15 cannot deliver the next pulse before the

preceding output pulse has elapsed. Therefore, an edge following after a time shorter than the output pulse

length will be suppressed, even when the dead time is set to zero. Suppressed edges do not trigger a dead

time.

The schematic below shows a pulse sequence where output pulses are delivered with no pulse delay and

where some edges are suppressed because they occur during a dead time.

For in-depth explanations of pulse length and dead time, please refer to section 9.2 Comments on the

operational parameters.

Running direction

on

off

high

low

on

off

time

amber edge-LED

p

t

output pulse (pulse period: p)

dead time (period: t )

User manual Scatec-10 / -15 9 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 10

8 Installation

8.1 Electrical connection

Make the electrical connections as specified in Sections 11.2 Electrical data, 11.3 Pin assignment, and 11.6

Wiring instructions.

8.2

Mounting

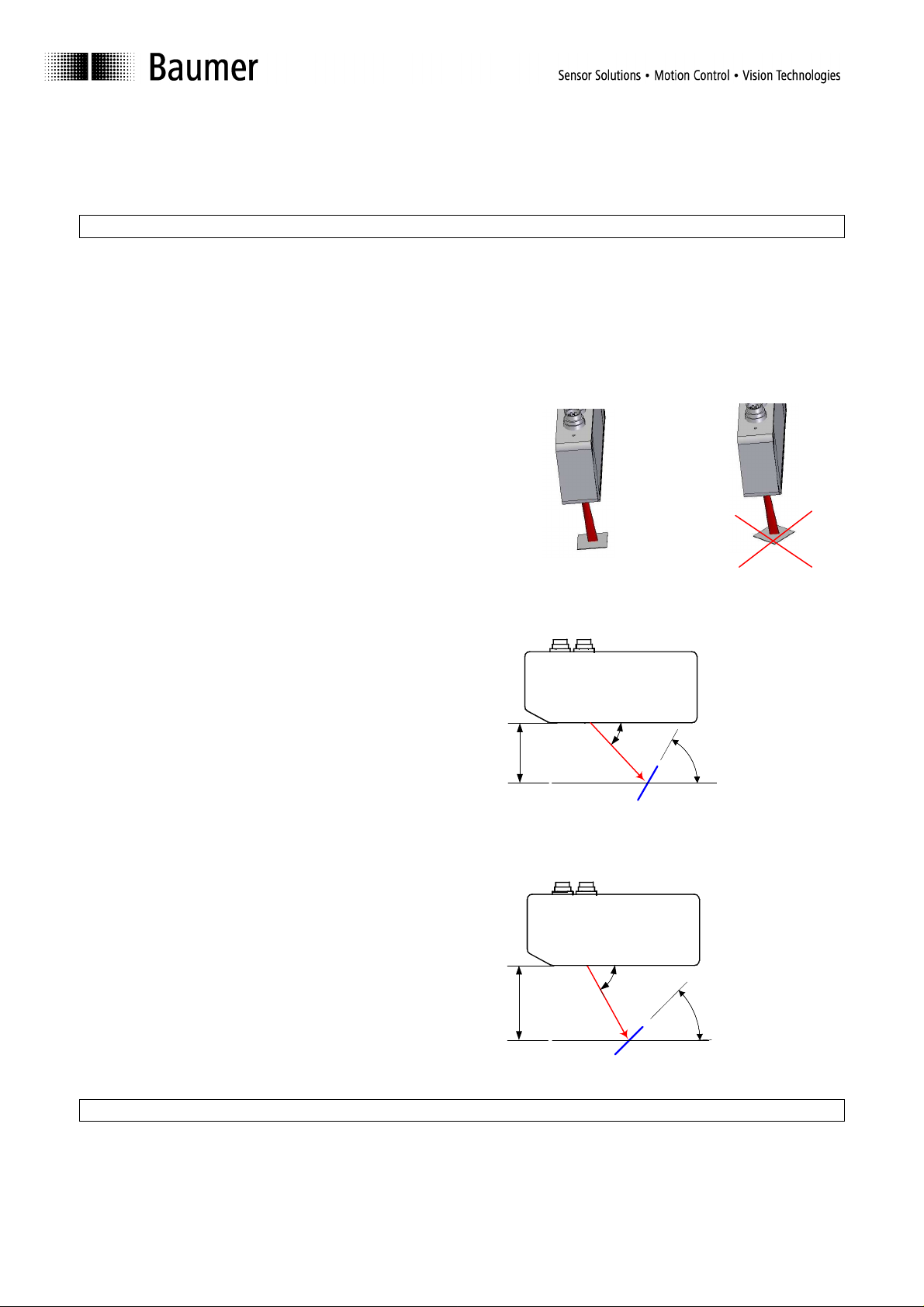

(1) Scatec-10: Mount the sensor at a

mounting height h of 70 +/-2mm above

or below the conveying plane with the

front windows parallel (+/-3°) to the

conveying plane.

Scatec-15: Mount the sensor at a

mounting height h of 100 +/-2mm above

or below the conveying plane with the

front windows parallel (+/-3°) to the

conveying plane.

(2) Adjust the sensor so that the laser

beam is aimed towards the edges to be

counted. Note that the laser beam is

focused into a line which must be

aligned in parallel to the edges to be

detected!

(3) Block the laser beam after the objects

whenever possible.

(4) Keep the window clean (no fingerprints).

(5) A direct line of sight from the laser

impact point to the entire front window

must be ensured.

Comments:

Mounting height: h Scatec-10: 70 +/-2mm above or below the conveyor belt

Scatec-15: 100 +/-2mm above or below the conveyor belt

Scatec-1x

Scatec-15:

h=100 mm

Scatec-10:

h= 70 mm

1

Clean windows

Laser line focus

transverse to the Scatec

The resolution depends on the working distance. The highest resolution of 0.10 mm

edge thickness is achieved at a working distance d of 68 – 72 mm. (See also section

11.8 Application data)

The resolution depends on the working distance. The highest resolution of 0.15 mm

edge thickness is achieved at a working distance d of 97 – 103 mm. (See also

section 11.8 Application data)

4

5

2

3

Beam blocker

+/- 3°

1

Tilting tolerance max. +/- 3°

Overlap orientation The edges to be counted must face toward the laser beam (front edges) whether

they are leading or trailing.

Make sure, that the laser line is parallel to the edge to

be detected!

Scatec-1x

Front windows The direct line of sight from the impact point of the

laser to the entire front window must not be obstructed

by any hardware for potential laser impact points in a

distance range d of 0 – 150 mm (for Scatec-10) or 0 –

200 mm (for Scatec-15) If mounting brackets or other

components are close, consult a technician from

Baumer Electric.

Scatec-15: d=200 mm

Scatec-10: d=150 mm

d

User manual Scatec-10 / -15 10 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 11

8.3 Beam blocker

Uncontrolled reflections of the laser beam can cause malfunctioning of the sensor or disturb people.

Therefore, a beam blocker should be fitted whenever possible to block the beam when there is no target

present. A beam blocker is a flat surface (at least 25mm x 25mm) made of any matte non-reflecting material.

It is mounted parallel to the sensor at any convenient distance.

The amber edge-LED must not light while the laser beam hits a beam blocker!

8.4 Retro-reflective foil (Part # FTDF 025F025)

Gaps in a lap stream can be clearly detected by a Scatec-10 / -15 if the retro-reflective foil (part number

FTDF 025F025, shipped with the sensor) is mounted as a beam blocker.

Certain false pulse suppression modes are based on a clear gap detection (for detailed explanation of these

modes, refer to section 9.2 Comments on the operational parameters.)

Correct mounting of the retro-reflective foil:

1.) One side of the foil must be aligned parallel

to the laser line.

CORRECT FALSE

2.) Scatec-10:

Mounting distance: 70mm – 120mm away

from the sensor’s lower

edge.

Tilt: 10° - 60° relative to the

conveying plane

70 – 120 mm

Scatec-10

47°

Tilt :

10° - 60°

Retro-reflective foil

Conveying plane

Scatec-15:

Mounting distance: 100mm – 150mm away

Scatec-15

from the sensor’s lower

edge.

Tilt: 0° - 45° relative to the

conveying plane

100 – 150 mm

61°

Tilt :

0° - 45°

Retro-reflective foil

Conveying plane

The amber edge-LED must light while the laser beam hits the retro-reflective foil!

User manual Scatec-10 / -15 11 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 12

8.5 Cleaning the front windows

Fingerprints, dust and other forms of dirt on the front window can impair the function of the sensor. It is

normally sufficient to wipe the glass pane dry with a clean (!), soft cloth. Alcohol may be used for heavier

soiling.

9 Setting the operational parameters

Various parameters allow the customer to fully adjust the Scatec-10 / -15 to the specific demands of the

actual application.

Parameter adjusting can be done in the following ways:

• via a PC, an interface, and the application software ScaDiag (consult the ScaDiag-manual)

• via the CAN-interface (only for Scatec-15) (consult the Scatec CAN-manual)

• via the sensor’s key pad and display (described below)

Parameter setting via the sensor’s key pad and display

The setting of the operational parameters is done within a user’s menu, using the four key pads [set], [Esc],

[+], and [–].

The user’s menu and the navigation are described in detail in section 10 Display and user menu of this

manual.

The Scatec’s operational parameters are all grouped together in menu C.

This section of the manual describes in detail the characteristics of all the operational parameters. The

procedure of how to enter a specific parameter value by means of the key-pad is described in section 10

Display and user menu of this manual.

Note that usually the input has to be unlocked before any operational parameters can be changed.

The unlocking is done by setting setting parameter [B1] to off as follows:

1.) press [+] until B Locks is shown in the display

2.) press [set] : the display shows now B1: 1 = on Input lock

3.) press [set] : 1 = on is blinking

4.) press [+] until 0 = off is shown blinking in the display

5.) keep [set] pressed until blinking stops

Now the input is unlocked and the desired operational parameters can be set in menu C.

The input will be locked again if no key is pressed for 30 minutes.

User manual Scatec-10 / -15 12 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 13

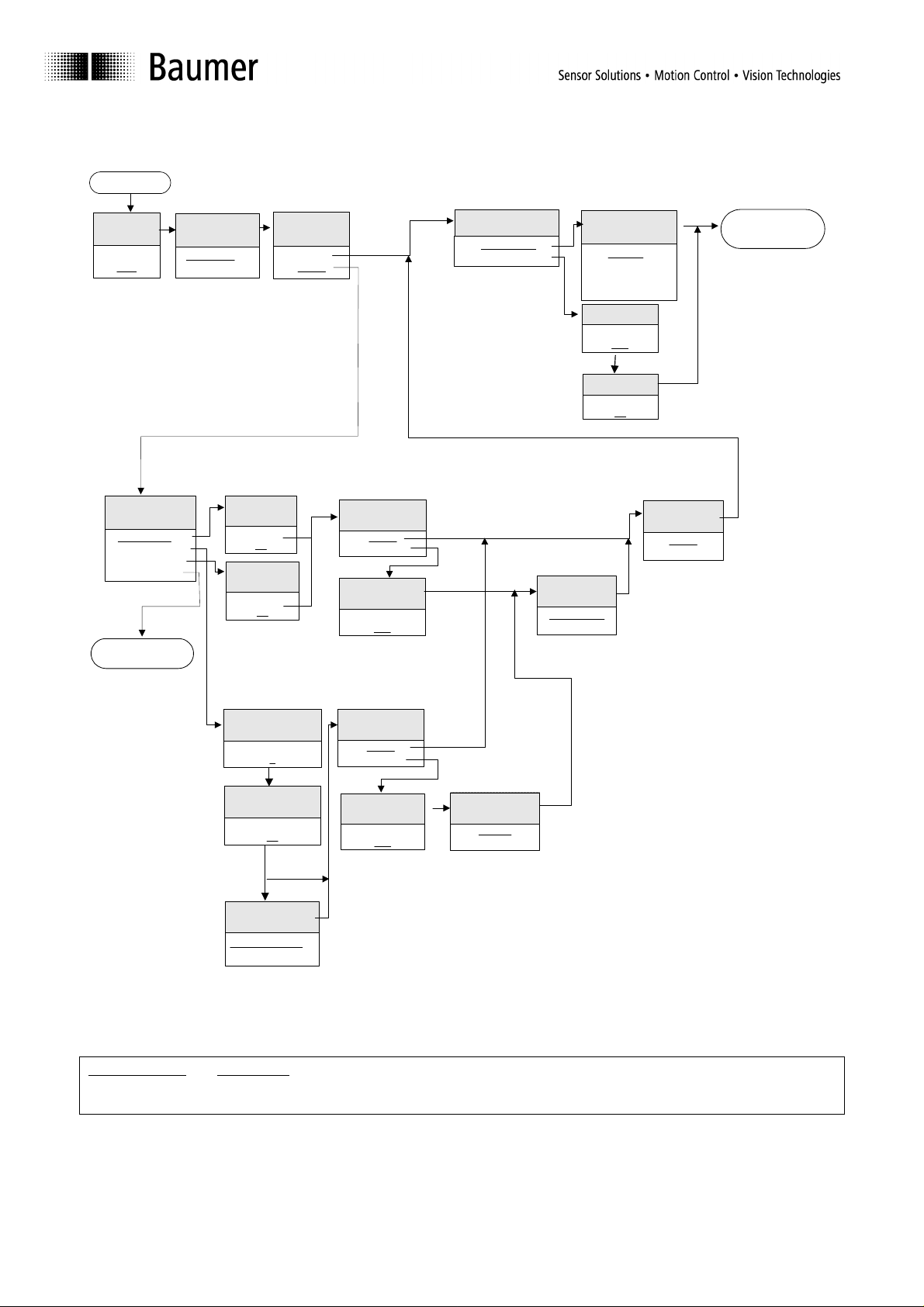

Flow chart for setting the operational parameters

C Parameters

C0 Pulse

Length [msec]

value

10.0

C3 Suppression

Mode

00 dynamic

01 synchronous

02 fixed

03 reflective

Operational

parameters are set !

C1 Running

Direction

0 = leading

1 = trailing

C2 False Pulse

C4 Dead Time

[%]

value

18

C8 Dead Time

[ms]

value

20

Suppression

0 = off

1 = on

C9 Pulse Delay

0 = off

1 = on

C10 Pulse Delay

[ms]

value

100

C15 Sensitivity Mode

0 = standard

1 = customized

C16 Sensitivity

01 high

02 medium

03 low

04 very low

C17 Threshold

C18 Hysteresis

C13 Tail Edge

Suppression

0 = standard

1 = extended

Setting

value

179

value

32

C14 Short Pulse

Suppression

0 = off

1 = on

Operational

parameters are set !

resolution [mm/pulse]

C6 Dead Path [mm]

FLDM 170G....

C7 Encoder A/B

0 = off (A only)

1 = on (A/B)

C5 Encoder

value

1

value

20

FLDM 170C....

C9 Pulse Delay

0 = off

1 = on

C11 Pulse Delay

[mm]

value

100

C12 Output at End

of Pulse Train

0 = first

1 = last

Default values are underlined. In most cases, the default setting will provide good results.

The factory preset default values can be reset anytime in submenu F4.

The names in the flow chart appear on the display as shown in square brackets in the next section.

User manual Scatec-10 / -15 13 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 14

r

9.1 Explanations on the operational parameters

Default values are either the underlined input values or the input value in [square brackets].

C0: Pulse Length [Pulse Length]

Input values: 0.3ms – 99.9ms in increments of 0.1ms [10ms]

Function: to set the duration of an output pulse

Comments: On the one hand, the duration of an output pulse must be long enough so that the

customer’s control system can process it. On the other hand, the length of the

output pulse limits the maximum counting rate. Because output pulses must not

overlap, the interval between edges must be at least as long as one output pulse

length. If the interval is shorter, then this edge will be suppressed meaning that the

edge will not initiate an output pulse.

The following figure illustrates how every other edge is suppressed because of a too

long of an output pulse length.

Scatec-1x

a

on

off

high

low

high

low

a

p

p

time

amber edge-LED

output pulse

pulse length p < interval a

output pulse

pulse length p > interval a

some edges are suppressed!

The maximum acceptable output pulse length for a given production rate can be

read from the diagram below.

Maximum acceptable output pulse length and

40

35

30

25

20

production rate

t

t: theoretical

r: recommended

15

10

5

maximum output pulse length [ms]

0

0.010 0.100 1.000 10.000

production rate [million copies / h]

User manual Scatec-10 / -15 14 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 15

A helpful rule of thumb is:

Output pulse length p in milliseconds must be shorter than 1.2 million divided by the

intended production rate given in copies per hour

Example: production rate: 130,000 copies/hour

resulting maximum output pulse length: 1,200,000 / 130,000 = 9.2

This relation is represented by the solid line in the diagram above. The theoretical

value (dashed line) represents the case where the interval between copies becomes

equal to the length of an output pulse. Exceeding the recommended value of the

output pulse length increases the risk of missing edges due to irregular intervals

between copies. Very often the reason for missed copies is not a flaw of the sensor

but such fluctuations of the interval in combination with too long an output pulse

length.

C1: Running direction [RunDirection]

Input values: 0 = lead leading

1 = trail trailing

Function: to define the direction in which the copies are transported.

Comments: A front edge (i.e. an edge facing the laser beam) is detected independently of the

running direction. However, for certain false pulse suppression modes to operate

properly, the running direction must be set correctly.

The terms leading and trailing are used according to the following sketch:

mounted above conveyor:

Front edge

(detectable)

Tail edge

(non-detectable)

mounted below conveyor:

conveyor

Front edge

(detectable)

Tail edge

(non-detectable)

Scatec-1x

Running direction of

copies

Scatec-1x

leading

trailing

conveyor

Running direction of

copies

leading

trailing

User manual Scatec-10 / -15 15 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 16

C2: False pulse suppression [FP-Suppress.]

Input values: 0 = off no false pulse suppression mode will be activated

1 = on a false pulse suppression mode as defined in C3 will be activated

Function: To specify whether or not any kind of false pulse suppression mode will be

activated.

Comments: The specific mode of the false pulse suppression will be defined in menu C3.

C3: Suppression mode [Suppr. Mode]

Input values: 00 = dyn dynamic dead time

01 = sync synchronous dead time

02 = fixed fixed dead time

03 = refl retro-reflective foil only

Function: To select the type of dead time to be used or if the Scatec should react exclusively

to the retro-reflective foil.

Comments: This menu is accessible only if menu C2 false pulse suppression was previously

activated (C2 = 1)

General concept of dead time: The time span during which the Scatec does not

respond to any occuring edges (output set inactive) is named dead time. By starting

a dead time by the end of an edge, a minimum interval between output pulses can

be enforced because edges occurring during the dead time will be suppressed, i.e.

do not initiate an output pulse nor trigger a dead time.

For example, setting a dead time allows counting the cut side of a newspaper,

because the multiple edges formed by the individual sheets do not initiate multiple

output pulses as long as they occur within the dead time triggered by the first edge

as illustrated in the following sketch.

The dead time always starts with the end of an edge.

Scatec-1x

Running direction

on

off

p

with

dead time

t

no

dead time

time

high

low

on

off

high

low

on

off

amber edge-LED

output pulse

(pulse length: p)

dead time

(length: t)

output pulse

(pulse length: p)

dead time

(length: t = 0)

The amber edge-LED lights as long as the laser beam strikes an edge.

Nevertheless, not every flash of the edge-LED is followed by an output pulse,

because the edge might be suppressed!

User manual Scatec-10 / -15 16 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 17

There are three different types of dead time depending on how the dead time is

specified.

Dynamic dead time (00 = dyn):

The length of the dead time corresponds to a certain percentage of the mean

interval between copies.

If dynamic dead time is set as the suppression mode, then the percentage will be

set subsequentely in menu C4 (dead time %) . The mean interval between copies is

calculated continuously by the internal micro controller of the Scatec-10 / -15 itself

and is therefore simultaneously adapted to changes of the conveyor speed. This

type of dead time is recommended as long as there is no possibility to synchronize

the Scatec. With dynamic dead time as the suppression mode, occasionally, a

counting error may occur if the lap-stream starts up very quickly from a standstill

(particularly if the conveyor belt initially runs with no load and accelerates to

maximum speed before copies appear on the conveyor belt) or when the conveyor

belt stops abruptly. Do not use the dynamic dead time mode if the lap stream is

highly irregular (i.e. highly varying intervals between copies). Taking single copies

out of the otherwise regular lap stream does not cause any problems.

Synchronous dead time (01 = sync):

The output does not become active again until the conveyor has run a

defined distance (regardless of the time it takes the conveyor to do this!).

Scatec-10 / -15 can be connected to an encoder, which permits synchronization of

the sensor to the conveyor speed. The big advantage of synchronization is that a

false pulse suppression mode can be set which is completely independent of the

conveyor speed, because now the output is set inactive not for a specific time but for

a specifc distance. In the synchronous dead time mode, the output is not set active

again until the conveyor has run the dead path defined in menu C6. For example,

the problem of multiple pulses generated by vibrations if the conveyor comes to a

stand still with an edge exactly in the laser beam can be easily solved this way.

Note: Whenever possible, use the synchronous dead time mode!

If in menu C3 the synchronous dead time mode has been choosen, then

subsequently in menu C5 the encoder resolution in millimeters per encoder pulse, in

menu C6 the dead path, and in menu C7 the type of encoder (encoder with A/B-

channel or A-channel only) has to be set. Based on the values for the encoder

resolution and the dead path, the sensor will calculate internally for how many

encoder pulses possible false pulses will be suppressed. Note, that with encoder

type A/B choosen, the direction of transportation is taken into account. After an

edge, the output is not set active again until the conveyor has run the dead path in

the forward direction. If a Scatec-10 / -15 with C7 set on (encoder with A/B-channel)

does not give out any pulses although it detects edges (amber LED lights up), then

the connections of the A/B channels have been mixed up. In his case the application

software ScaDiag would display the warning “conveyor in reverse”.

Fixed dead time (02 = fixed):

The length of the dead time is set to a fixed value in milliseconds.

Note: A fixed dead time imposes a limit to the maximum counting rate in the same

way as the output pulse length. The same rule of thumb given in the describtion of

C0 applies also to the fixed dead time, just substitute output pulse length by fixed

dead time.

Retro-reflective foil only (03 = refl):

The Scatec-10 / -15 reacts only to the retro-reflective foil and no longer to

any edges.

Because the Scatec-10 / -15 is equipped with a retro-reflective sensor, the sensor

can unambiguously detect gaps in a lap stream, provided that there is a retro-

reflecting tape (part number: FTDF 020F020) mounted as a beam blocker. This

built-in retro-reflective sensor allows for a counting mode on its own. In the reflective

mode, Scatec- / -15 no longer detects edges, but reacts only to shadowing the

retro-reflecting tape. As soon as the laser beam no longer strikes the retro-reflecting

User manual Scatec-10 / -15 17 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 18

tape, an output pulse is generated. This mode makes it possible to reliably count

copies as long as each copy is preceded by a gap. The advantage of reacting solely

to the retro-reflective tape is, that copies may have a surface and form of any kind,

even heavily wrinkled (such as thick newspapers in a bag), without causing any

false pulses, because the sensor does not react to edges in this mode.

With the running direction leading, the pulse is issued as soon as the copy enters

the laser beam, whereas with the running direction trailing, the pulse issue occurs as

soon as the copy exits the laser beam.

With retro-reflective foil only as false pulse suppression mode, copies are counted

correctly only if every copy is preceded by a gap and if the retro-reflective foil is

mounted as beam blocker.

C4: Dead time in % [Dead time %]

Input values: 0 to 50 in steps of 1 [18%]

Function: defines the duration of the dead time as percentage of the mean interval between

copies.

Comments: This parameter is accessible only if menu C3 dynamic dead time (C3 = 00) was

previously activated.

Note: Be careful setting this parameter to a value higher than 35%. Otherwise, fast

reduction of the conveyor speed might lead to unintentional suppression of edges.

C5: Encoder resolution (mm/pulse) [Encodr Resol]

Input values: 0.10 to 9.99 in steps of 0.01 [1mm/step]

Function: to define the resolution of the encoder given as distance in millimeters which the

conveyor travels per encoder pulse.

Comments: This parameter is accessible only if menu C3 synchronous dead time (C3 = 01) was

previously activated.

Make sure that the frequency of the synchronization input does not exceed the

specified maximum of 50 kHz. With an encoder resolution of 0.10mm/pulse this

frequency is reached at a conveyor speed of 5m/s.

C6: Dead Path (mm) [Dead Path mm]

Input values: 0 to 499 in steps of 1 [20mm]

Function: to define the path in millimeters which the conveyor first has to travel before the

output is set active again.

Comments: This parameter is accessible only if previously in menu C3 synchronous dead time

(C3 = 01) was activated.

C7: Encoder A/B [Encoder A/B]

Input values: 0 = A only A-channel of the encoder is used

1 = A/B A- and B-channel of the encoder are used

(not applicable in case of a FLDM 170C…)

Function: to define the type of encoder connected to the Scatec-10 / -15 for synchronization

Comments: This parameter is accessible only if menu C3 synchronous dead time (C3 = 01) was

previously activated.

With A- and B-channel of the encoder used, Scatec will take into account the

moving direction of the conveyor and count the distance traveled by the conveyor

either positive or negative. The regular running direction of the conveyor has to be

positive. The application software ScaDiag shows if the conveyor is moving in

reverse direction.

If a Scatec-10 / -15 with C7 set on (encoder with A/B-channel) does not give out any

pulses although it detects edges (amber LED lights up), then the connections of the

A/B channels might have been mixed up. In this case the application software

User manual Scatec-10 / -15 18 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 19

ScaDiag would display the warning “conveyor in reverse”.

C8: Dead time (msec) [Dead time ms]

Input values: 0 to 999 in steps of 1 [20ms]

Function: to define the dead time as fixed value in milliseconds.

Comments: This parameter is accessible only if previously in menu C3 fixed dead time (C3 = 02)

was activated.

C9: Pulse delay [Pulse Delay]

Input values: 0 = off output pulse issued immediately after end of the edge

1 = on output pulse issued with delay relative to end of the edge

Function: to define whether the output pulse is issued right after the end of an edge or with the

delay as specified in menu C10 or C11.

Comments: A delayed output pulse is required in the following two applications:

1.) to trigger an action which is delayed relative to the end of the edge (for

example: to trigger an ink jet printer for labeling newspapers)

2.) to suppress tail edges (for details see C13)

This parameter is accessible only if menu C2 false pulse suppression was

previously activated (C2 = on). Depending on the mode of false pulse suppression

choosen in menu C3, the output pulse delay will be specified in menu C10 in

milliseconds or in menu C11 in millimeters.

The following sketch shows schematically the signal sequence of undelayed and

delayed output pulse sequences. Note that both dead time and the output pulse are

triggered with the end of an edge. However, the output pulse issue might be delayed

while the dead time always starts right with the trigger.

on

off

on

off

high

low

high

low

Scatec-1x

t

p

z

time

Running direction

amber edge-LED

dead time

(length t)

undelayed output pulse

(pulse length p)

z

delayed output pulse

(delay z)

C10: Pulse delay (msec) [Pulse Delay ms]

Input values: 0 to 999 in steps of 1 [100ms]

Function: to define the value of the output pulse delay in milliseconds.

User manual Scatec-10 / -15 19 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 20

Comments: This parameter is accessible only if previously in menu C9 delayed output pulse (C9

= on) and in menu C3 either dynamic dead time (C3 = 00) or fixed dead time (C3 =

02) was chosen.

A maximum of 10 further edges may occur between the end of an edge and the

delayed output pulse.

C11: Pulse delay (mm) [Pulse Delay mm]

Input values: 0 to 999 in steps of 1 [100mm]

Function: to define the value of the output pulse delay in millimeters.

Comments: This parameter is accessible only if menu C9 delayed output pulse (C9 = on) and

menu C3 synchronous dead time (C3 = 01) were previously activated.

A maximum of 10 further edges may occur between the end of an edge and the

delayed output pulse.

C12: Output pulse triggered by last edge [Out@PlsTrain]

Input values: 0 = first output pulse triggered by first edge of edge train

1 = last output pulse triggered by last edge of edge train

Function: to define whether the output pulse is triggered by the first or the last edge of a group

of multiple edges occurring within one dead time.

Comments: This parameter is accessible only if menu C9 delayed output pulse (C9 = on) and

menu C3 synchronous dead time (C3 = 01) were previously activated.

This parameter should be set to on if thick copies are processed and the Scatec is

used to trigger another action (for example: labeling) where as little jitter as possible

of the trigger point is required.

The following sketch shows the case where the fold of a thick newspaper breaks up

into two edges because of a slight indentation. The second edge falls within the

dead time triggered by the first edge. With parameter C12 set to 0=first, the output

pulse is triggered by the end of the first edge and the second edge is suppressed. If

parameter C12 is set to 1=last, the output pulse is initiated by the second edge while

it is the first edge which is suppressed. This way, it has been achieved that although

the fold is split up into two edges, it is still at the end of the fold where the output

pulse is initiated as if the fold would form only one continuous edge.

Scatec-1x

Running direction

on

off

on

off

high

low

high

low

User manual Scatec-10 / -15 20 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

t

z

z

time

z

z

delayed output pulse

amber edge-LED

dead time

(length t)

C12 = first :

output pulse triggered

by the first edge

(delay: z)

C12 = last :

output pulse triggered

by the second edge

Page 21

C13: Tail edge suppression [Tail Suppr.]

Input values: 0 = stand edge suppressed if it is followed by a retro-reflective foil within the

dead time

1 = extnd edge suppressed if it is followed by a retro-reflective foil within the

output pulse delay time

Function: to define whether the area checked for tail edges extends for a dead time (0 =

stand) or for an output pulse delay time (1 = extnd).

Comments: This parameter is accessible only if menu C9 delayed output pulse (C9 = on) was

previously activated.

Delaying the output pulse (C9 = on) also automatically activates a tail edge

suppression. Parameter C13 decides which area is checked for tail edges. Tail edge

suppression does not only suppress tail edges that are sticking up, but also edges

generated by small paper scraps on the otherwise empty conveyor.

• Tail edge suppression works only with a mounted retro-reflective foil.

• Extended tail edge suppression works only with the front edges leading.

This configuration is sketched below.

Fold

conveyor

Scatec-1x

Bent up tail edges

Retro-reflective

foil

Cut side of the

newspaper

running direction

Usually newspapers are conveyed shingled and with the folded side facing the laser

beam. As a consequence, the cut side of a copy is covered by the next copy and

exposed to the laser beam only if there is a gap in the lap stream. The cut side of

the newspaper is facing away from the laser beam, forming a tail edge and usually

not detectable by the Scatec. However, some of these cut pages might be bent up.

In the case of gaps in the lap stream, there is a risk of tail edges generating output

pulses. Such bent up tail edges can not be suppressed by means of a dead time

because the dead time would be triggered by the fold and had to practically cover

the whole length of a copy. But that means a dead time bigger than the overlap

leading to the unacceptable suppression of regular copies. However, if the pulse

output is delayed and a retro-reflective foil mounted, then the Scatec-10 / -15 can

nevertheless be set in such a way that bent up tail edges are completely

suppressed.

Therefore Scatec-10 / -15 is able to suppress interfering tail edges provided:

a retro-reflective foil mounted is mounted

the output pulse is delayed (C9 = on)

a suitable zone checked for tail edges is chosen (C13 = on or off)

A bent up tail edge is suppressed if it is followed by a gap within a specific time (or

distance). This time or distance therefore defines a zone on the copy where edges

will be suppressed as tail edges and can be set either equal to the dead time (dead

path) or equal to the ouput pulse delay chosen earlier.

In order to set the tail edge suppression correctly, follow the subsequent flowchart

and refer to the sketch below.

User manual Scatec-10 / -15 21 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 22

Overlap

Dead time

Copy length

Tail edge suppression zone

Running direction

Laser beam

Interfering edges

Retro-reflective foil

C9 Output pulse delay

set

to

1 = on

is the intended tail edge

suppression zone

shorter than the dead path or

the distance run by the conveyor

within a dead time set in menu

C4, C6, or C8 ?

yes

set

C10 or C11 Output pulse delay

to value

bigger than dead time

C4, C6, or C8

set

C13 Tail edge suppression

to

0 = standard

is this intended zone

no

shorter than 2/3 of

the copy length ?

C10 or C11 Output pulse delay

to value

equal to

the intended tail edge

suppression zone

C13 Tail edge suppression

1 = extended

C1 Running direction

set to

0 = leading ?

yes

set

set

to

is

no

invalid

configuration !

no

yes

Edge will be suppressed if it is followed

by a gap in the lap stream

within the dead time or the dead path

Edge will be suppressed if it is followed

by a gap in the lap stream

within the output pulse delay

User manual Scatec-10 / -15 22 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 23

C14: Short pulse suppression [ShrtP.Suppr.]

Input values: 0 = off short edges are not suppressed

1 = on short pulses are suppressed

Function: to define whether short edges should be considered as interfering edges and be

suppressed (1 = on) or not (0 =off). An edge is short if its duration is shorther than

25% of the mean edge duration.

Comments: This parameter is accessible only if menu C2 False pulse suppression was

previously activated (C2 = on).

The duration of an edge can be a characteristic which clearly shows whether an

edge should be suppressed or not. For example: thick newspapers will always

generate long edges, so that a rather short edge within many long edges will most

likely be an edge caused by some imperfections on the newspaper. With C14 short

pulse suppression activated (C14 = on), edges with a duration of less than 25% of

the mean edge duration will be suppressed. The mean edge duration is continuously

calculated by the sensor and adapted to the conveyor speed.

Short pulse suppression works properly only if the running direction is leading!

C15: Sensitivity mode [Sensvty Mode]

Input values: 0 = stand standard

1 = custm customized

Function: to define whether one of the standard sensitivity levels defined in C16 will be

activated or if the sensitivity level will be set specifically by the customer in C17 and

C18.

Comments: A sensitivity level other than standard should be choosen only if the signals can be

controlled by the application software ScaDiag.

C16: Sensitivity setting [Sensvt Settg]

Input values: 01 = high highest sensitivity

02 = mid medium sensitivity

03 = low low sensitivity

04 = v. low very low sensitivity

Function: to define the actual sensitivity of the sensor.

Comments: This parameter is accessible only if previously in menu C15 standard sensitivity

mode was activated (C15 = 0).

Paper sheets of at least 0.1 mm thick will be detected with the Scatec-10 set to its

highest sensitivity and mounted at a distance of 68mm to 72mm. The Scatec-15 set

to the highest sensitivity will detect sheets 0.15mm thick and larger at a distance of

97mm to 103mm. However, if set to the highest sensitivity, folds or wrinkles could

cause interfering edges. If the edges to be detected are thick enough, than it might

be an advantage to reduce the sensitivity to become less sensitive to interferences.

Note: The sensitivity is dependant on the working distance. Please refer to the

diagram in section 11.7 Application data.

User manual Scatec-10 / -15 23 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 24

C17 Threshold [Threshold]

Input values: 20 to 799 in steps of 1

Function: to define the value which marks the

beginning of an edge when the ratio v/r

drops below this value.

Comments: This parameter is accessible only if menu

C16 customized sensitivity mode was

previously activated (C15 = 1).

C18: Hysteresis [Sens. Hyster.]

Input values: 1 to 499 in steps of 1

Function: to define how much the ratio v/r must rise

above threshold in order to initiate the end

of an edge.

Comments: This parameter is accessible only if

previously in menu C16 customized

sensitivity mode was activated (C16 = 1).

Scatec-1x

R

Laser

v/r

Hysteresis

Beginning of edge

V

Threshold

time

End of edge

10 Display and user menu

Scatec-10 /-15 allows the user to set the parameters in two ways:

-

manually by means of the keypad and the display (described in this manual)

-

by means of a PC, an adapter set, and the application software ScaDiag (refer to the ScaDiag-manual)

10.1 General

In its normal state, the 2-line LCD- display shows the total number of detected edges on the upper line since

the last counter reset and the name of the sensor (either Scatec-15 or Scatec-10) on the lower line.

The parameter setting is performed within a user menu. To navigate to a submenu in order to change a

parameter value is shown in section 10.2 Navigation.

User manual Scatec-10 / -15 24 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 25

10.2 Navigation

The graph below illustrates how to navigate and change a parameter value based on an example where the

value of the pulse length is changed from 12.3ms to 45.6ms in submenu C0.

Normal state Menu

12345678

SCATEC10

S

A Summary

E

B Locks

C Parametrs

Submenu

S

S

S

A1: -----------------

-----------------

E

B1: ---------------

-------------------

E

C0: 12.3 ms

Pulse Length

E

A5: ---------------

-------------------

S

E

C0: 12.3 ms

Pulse Length

C0: 45.6 ms

Pulse Length

S

C0: 45.6 ms

Pulse Length

C0: 45.6 ms

Pulse Length

C18: -------------

---------------------

D Interface

E Counters

F Options

S

S

S

D1: ----------------

------------------

E

E1: ---------------

-------------------

E

F1: ---------------

-------------------

E

D3: ---------------

-------------------

E4: --------------

--------------------

F6: ---------------

-------------------

S

E

S

Set +

Esc

blinking

Push set until

blinking stops

-

• Submenus not applicable in the present setting will be skipped on the display!

• Before parameters can be changed, the key pads have to be unlocked in menu B. With locked key pads,

upon pressing set, the reminder input locked will be displayed.

User manual Scatec-10 / -15 25 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 26

10.3 Menus

10.3.1 Menu A: Summary [Summary]

Menu A presents a summary of the current parameter setting.

In menu A, no parameters can be set. It serves only as a display.

Submenus that are not applicable in the current setting are not shown. For example: submenu A3 does not

show up if a factory preset level was chosen for sensitivity.

If you have to contact a technician from Baumer Electric because of a problem with the Scatec, always have

the parameter values on hand shown in this summary menu.

Submenu Values Comments

A1:

A2:

Length Resol

A3:

Thresh/Hyst.

abcd efg

hhhhh iiiii

aa.a b.bb

aaa bbb

a False pulse suppression mode

0 = dynamic dead time

1 = synchronous dead time

2 = fixed dead time

3 = retro-reflective foil only

* = not activated

b Pulse delay

0 = immediate pulse delivery

1 = delayed pulse delivery

* = not activated

c running direction

0 = leading

1 = trailing

* = not activated

d Output pulse triggered by last edge

0 = first edge triggers output pulse

1 = last edge triggers output pulse

* = not activated

e Short pulse suppression

0 = no short pulse suppression

1 = short pulses will be suppressed

* = not activated

f A/B Encoder

0 = only A-channel of the encoder is used

1 = A- and B-channel of the encoder are used

* = not activated

g Sensitivity level

1 = highest

2 = medium

3 = low

4 = very low

* = customized

h Dead time or path

xxxyy length of dead time or path with unit

i Output pulse delay

xxxyy delay of the output pulse with unit

Output pulse length and encoder resolution

aa.a output pulse length in milliseconds

b.bb encoder resolution in millimeters /

pulse

Threshold and hysteresis

aaa customized threshold

bbb customized hysteresis

User manual Scatec-10 / -15 26 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 27

A4:

SW-Revision

A5:

Type

A6:

Remote Param

aaaaaaa

FLDM170

abcd CAN

Version of the Scatec operation software

version consists of 6 numbers plus one

letter (example: 060421a)

Scatec type

CAN Interface

a CAN mode

0 = value of CAN Object 2000 is 3

1 = value of CAN Object 2000 is not 3

b Compensation of synchronization point

(CAN-object2300, subindex 02, bit 0)

0 = off

1 = on

c Inserting missing counts

(CAN-object2300, subindex 02, bit 1)

0 = off

1 = on

d Automatic sensitivity adjustment

(CAN-object2300, subindex 02, bit 2)

0 = off

1 = on

10.3.2 Menu B: Locks [Locks]

To protect the sensor against accidental or unauthorized manipulation of the parameter settings, the input

can be blocked in this menu. With a locked sensor, navigation is still possible.

There are two security levels. By default, the sensor is on the lower security level where unlocking is done by

setting parameter [B1] to off.

The sensor will be locked again if no key is pressed for 30 minutes

On a higher security level, the sensor can be protected against unauthorized tampering by requiring the user

to enter an ID code before the sensor will be unlocked. This higher security level can be activated by setting

parameter [F5], Lock-ID-code, to on.

The ID-code (which is asked for) is 55 and cannot be changed.

Submenu Values Comments

B1:

Input Lock

B2:

Unlock Code

0 = off

1 = on

xxx

sensor unlocked

sensor locked

ID-code is 55 and can not be changed.

(the ID-code-locking is activated in submenu

F5).

User manual Scatec-10 / -15 27 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 28

output pulse issued with delay relative to end of the

10.3.3 Menu C: Parameters [Parametrs]

Operational parameters are set in menu C. A detailed description of these parameters is given in section 9

Setting the operational parameters.

• Submenus not applicable in the present setting will be skipped in the display!

• With the sensor locked, no parameters can be changed while navigation is still possible. The sensor can

be unlocked in menu B. When trying to change a parameter of a locked Scatec, the message “input

locked” will show up as reminder.

• The sensor will be locked again if no key is pressed for 30 minutes

Submenu values

C0:

Pulse Length

C1:

RunDirection

C2:

Fp-Suppress

xx.x ms

0 = lead

1 = trail

0 = off

1 = on

C3:

Suppr.Mode

C4:

Dead Time %

C5:

Encodr Resol

C6:

Dead Path mm

C7:

Encoder A/B

C8:

Dead Time ms

C9:

Pulse Delay

00 = dyn

01 = sync

02 = fixed

03 = reflx

xxx

x.xx mm

xxx mm

0 = off

1 = on

xxx ms

0 = off

1 = on

Comments

Output pulse length in ms

value of output pulse length in milliseconds

Running direction of the copies

leading

trailing

False pulse suppression

no false pulse suppression mode will be activated

a false pulse suppression mode as defined in [C3]

will be activated

False pulse suppression mode

dynamic

synchronous

fixed

retro-reflective foil only

Dead time in percentage

value of dynamic dead time in percentage of the mean

interval between copies

Encoder resolution in mm/pulse

value of encoder resolution in millimeters per

encoder pulse

Dead path in mm

value of synchronized dead path mm

Encoder A/B

only A-channel of encoder is used

A- and B-channels of encoder are used

Dead time in ms

value of fixed dead time in milliseconds

Output pulse delay

output pulse issued immediately after end of the edge

edge

User manual Scatec-10 / -15 28 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 29

sensitivity levels as defined in C16 will be

C10:

Pulse Delay

C11:

Pulse Delay

C12:

Out@PlsTrain

C13:

Tail.Suppr.

C14:

ShrtP.Suppr.

C15:

Sensvty Mode

C16:

Sensvt Level

C17:

Threshold

C18:

Hysteresis

xxx ms

xxx mm

0 = first

1 = last

0 = stand

1 = extnd

0 = off

1 = on

0 = stand

1 = custm

01 = high

02 = mid

03 = low

04 = v.low

xxx

xxx

Output pulse delay in ms

value of output pulse delay in milliseconds

Output pulse delay in mm

value of output pulse delay in millimeters

Output pulse triggered by last edge

output pulse triggered by first edge of edge train

output pulse triggered by last edge of edge train

Tail edge suppression

edge suppressed if it is followed by a retro-

reflective foil within the dead time

edge suppressed if it is followed by a retro-

reflective foil within the output pulse delay

time

Short pulse suppression

short edges will not be suppressed

short edges will be suppressed

Sensitivity mode

standard

activated

sensitivity as defined by customer in C17 and in C18

will be activated

Sensitivity level

highest

medium

low

very low

Threshold

Hysteresis

value of the hysteresis

User manual Scatec-10 / -15 29 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 30

The counters are automatically reset upon power up of

10.3.4 Menu D: Interface [Interface]

Parameters concerning the CAN-interface are set in menu C

Only Scatec-15 is equipped with a CAN interface.

Submenu Values Comments

D2:

CAN Baud

D3:

CAN-Node-Id

00 = 10 kBaud

01 = 20 kBaud

02 = 50 kBaud

03 = 100 kBaud

04 = 125 kBaud

05 = 250 kBaud

06 = 500 kBaud

07 = 800 kBaud

08 = 1000 kBaud

xxx

CAN Baudrate

default value: 01 = 20 kBaud

CAN-Node-Id

Node-ID must be a number between 1 and 127

(default value: 1)

10.3.5 Menu E: Counter [Counters]

In menu E, several counters can be read and reset.

Submenu Values Comments

E1:

Copy Counter

E2:

marg.counted

E3:

marg. missed

E4:

Reset Cntrs.

xxxxxxxx

xxxxxxxx

xxxxxxxx

0

= no

1 = yes

Copy counter

Total number of counted edges or output pulses since

last reset

Marginally counted edges

Total number of edges which where counted but which

dropped only marginally below threshold

Marginally missed edges

Total number of edges which were not counted because

they marginally missed the threshold

Counter reset

counters will not be reset

counters will be reset to 0

the sensor

User manual Scatec-10 / -15 30 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 31

10.3.6 Menu F: Options [Options]

In menu F, the operational parameters (set in menu C) can be reset to the factory preset default values.

Such a reset does not affect any CAN parameters set in menu D.

In addition, this menu contains a security code that can be activated to lock the key pad securely.

Submenu Values Comments

F4:

SensrDefault

F5:

Lock-ID-Code

F6:

Code Confirm

0 = no

1 = yes

0 = no

1 = yes

xxx

Reset of the operational parameters

No reset is initiated

The factory preset default operational parameter

values are loaded

Sensor locking by ID-Code

sensor not locked by ID-Code

sensor locked by ID-Code

ID-Code confirmation

The code is 55 and can not be changed.

User manual Scatec-10 / -15 31 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 32

11 Specifications

11.1 Mechanical and thermal data

Sensor size 170 x 70 x 30 mm

Housing material zinc die-cast

Front windows glass

Weight approximately 700 g

Protection class IP 54

Working temperature range 0°C to +50°C (non-condens ing)

Storage temperature -20°C to +60°C

Scatec-10:

Scatec-15:

∅06.4

30

6

13

12

6M

17

30 70

6

13

∅ 6.4

17

6M

70

Laser

beam

4

7

°

Laser

beam

6

1

°

68

59

6158

Keypad

and display

170

Interface

connector

Main

connector

6

Keypad

and display

170

158

Interface

connector

Main

connector

User manual Scatec-10 / -15 32 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 33

11.2 Electrical data

Operating voltage VS

Limits: +10 VDC to +30VDC

Reverse-protected yes

Ripple VS 10% within the limits of VS

Power consumption < 2 W

Current consumption

Average: < 170 mA

Peak (after switching on) < 180 mA

Connectors

Main connector DIN 45322, 6-pole, male

Interface connector DIN 45326, 8-pole, male

Output circuit

FLDM 170G... push-pull

normal state low

FLDM 170C... opto-isolated

switchable voltage maximum 40 V

Load resistance maximum 50 kOhm

Current load: max. 100 mA

Short-circuit protected yes

Output pulse length selectable 0.3 … 100ms

11.3 Pin assignment (looking at connector on Scatec)

Main connector DIN 45322, 6 pole, male

1

2

5

6

4

3

Interface connector DIN 45326, 8 pole, male

6

1

7

8

3

5

4

2

Pin Assignment

1 output signal +Vout

2 encoder input B (FLDM 170G...)

output signal -Vout (FLDM 170C...)

3 operating voltage +Vs

4 encoder GND

5 encoder input A

6 operating voltage GND (0V)

Pin Assignment

1 CAN_H

2 not connected

3 serial TxD (sensor)

4 CAN_L

5 serial RxD (sensor)

6 CAN_GND

7 serial GND

8 GND

User manual Scatec-10 / -15 33 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 34

11.4 Output connection

11.4.1 Push-pull output (FLDM 170G...)

Sensor

Polyfuse

Pin 3

Pin 1

+ V

S

Output

Output connected as

Current source Current sink

+V

S

V

+V

V

S

Load

Load

Main connector

+V

V

I

s

out

Load

Operating voltage (+10VDC ... +30VDC)

Output signal

maximum 100 mA

11.4.2 Opto-isolated output (FLDM 170C...)

Sensor

Polyfuse

Pin 6

GND

Main connector

Pin 3

Pin 1

Output voltage at VS = 24V

V

Out

24 V

min. 19 V

max. 1 V

GND GND

max. 4.5 V

Output connected as

Current source

+V

+V

+V

S

out

out

V

24 V

min. 23 V

Pin 1

V

Out

Current sink

+V

out

V

load

+VS Operating voltage (+10VDC ... +30VDC)

+V

Output signal +

out

-V

Output signal -

out

Pin 2

Pin 6

-V

out

GND

Vout

min. Vout - 4V

V

2

load

Pin 2

typ. Vout

V

1

GND 0 V

R

Load

I

Load

Switchable voltage (+Vout minus -Vout) maximum 40 V

User manual Scatec-10 / -15 34 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

maximum 50 kOhm

maximum 100 mA

typ. 0V

GND

max. 4V

GND

Page 35

11.5 Synchronization input

• opto-isolated input

• input signals between 5V and 30 V

• for NPN- or PNP-open collector, push-pull, or TTL encoder output

• Scatec FLDM 170G…… (push-pull output) accepts an A/B-channel encoder

• Scatec FLDM 170C…… (opto-isolated output) accepts an A-channel encoder only.

• synchronization input signal levels logical high: > 3.8 V (> 2.2 mA)

logical low: < 1.8 V (< 0.7 mA)

• frequency max. 50 kHz

• reverse polarity: protected

NPN open

collector

+ V

E

PNP open

collector

+ V

Push-pull

E

+ V

E

TTL

+ V

Scatec-10/ -15

E

Main connector

Pin 5

Pin 5

( Pin 2 )

Pin 5

( Pin 2 )

Pin 5

( Pin 2 )

Pin 5

( Pin 2 )

Pin 4

Pin 4

GND

E

Scatec-10/-15

+ V

: Output voltage of the encoder

E

GND

: GND of the encoder

E

GND

Main connector

Pin 4

E

Scatec-10/-15

Main connector

GND

Pin 4

E

Scatec-10/-15

GND

Main connector

Pin 4

E

Scatec-10/-15

Main connector

(FLDM 170G...

Pin 2

only! )

11.6 Wiring instructions

In order to achieve optimum protection of the Scatec against electromagnetic interference

• use shielded cables

• keep the ground impedance sufficiently low

We suggest the following two grounding schemes:

Version 1

Controller

Main connector

Scatec-1x

• Scatec housing is grounded (use teeth lock washers when

mounting the Sactec).

• Cable shield not grounded at the controller end.

• Cable shield properly attached to the connector plugging

into the Scatec.

Scatec

positive

negative

positive

User manual Scatec-10 / -15 35 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 36

Version 2

Control unit

• Scatec housing is grounded (use teeth lock washers

when mounting the Sactec)

• Cable shield properly grounded at the controller end

• Cable shield properly attached to the connector plugging

Main connector

Low-impedance

interconnection

Scatec-1x

into the Scatec.

• Keep the impedance of the interconnection between the

control unit’s ground and the Scatec ground sufficiently

low.

11.7 Optical data

Laser

Wavelength 650 nm - 680 nm (visible red)

Pulse frequency 50 kHz

Duty cycle 50%

Average power < 1.0 mW

Laser class 2 (to IEC 60825-1 / 2007)

Beam dimensions

at emission point about 2.5 x 4.0 mm

Scatec-10: 70 mm beneath sensor Line focus, 6 mm long

Scatec-15: 100 mm beneath sensor Line focus, 8 mm long

Focus position

Scatec-10: 70 mm beneath sensor

Scatec-15: 100 mm beneath sensor

Optical receiver equipped with near infrared suppression and daylight suppression filter

11.8 Application data

Measuring range

Scatec-10: 0 to 90 mm beneath sensor

Scatec-15: 0 to 120 mm beneath sensor

Mounting height

Scatec-10: 70 mm

Scatec-15: 100 mm

Object speed 2 m/s maximum (5 m/s maximum for thicker edges)

Minimum object spacing 10 mm @ v = 1 m/s and output pulse length 10 ms, or proportional to the

speed and output pulse length

Counting rate 1.5 million maximum copies/h (@ 2 ms output pulse length and 0 ms dead

time)

Product orientation Folded or cut edge facing laser beam

Output pulse length 0.2 … 100 ms adjustable

User manual Scatec-10 / -15 36 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 37

Sensitivity

Scatec-10: edge thickness 0.1 mm and greater

highest sensitivity 68 … 72 mm beneath sensor

product speed for edge thickness 0.10 mm … 0.2 mm slower than 1 m/s

Scatec-15: edge thickness 0.15 mm and greater

highest sensitivity 97 … 103 mm beneath sensor

product speed for edge thickness 0.15 mm … 0.2 mm slower than 1 m/s

The sensitivity is dependant on distance and product speed.

Typical sensitivity characteristic see diagram below.

Scatec-10 FLDM 170x1011/S42

typical sensitivity characteristics for object speed < 2m/s

1.2

1.0

0.8

0.6

0.4

Edge thickness k [mm]

0.2

0.0

20 30 40 50 60 70 80 90 100 110 120 130

Working distance d [mm]

Sensitivity

mediumlow

highest

How to read the graphics: An edge with thickness k at distance d will typically be detected if the

corresponding point in the graphics is above the curve representing the configured sensitivity level.

Test objects: cleanly trimmed flat matt paper sheet tightly lying on a flat matt white sheet of paper.

11.9 Default values

Operational parameters see section 9.1 Flow chart for setting the operational parameters

CAN-interface parameters refer to the Scatec-15 CAN-Manual

User manual Scatec-10 / -15 37 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 38

12 Accessories

Article-Nr.

Connectors

Straight connector (6-pin) 10104236 (enclosed)

Straight connector (8-pin) 10153202

Right angle connector (6-pin) 10153094

Right angle connector (8-pin) 10153095

(all connectors metal casing and shielded)

Cables

ESG 16DP1000G 10156266 Main-cable; 10m long, shielded, with straight connector

(6-pin)

Retro-reflective foil

FTDF 025F025 10156653 retro-reflective foil; 25mx25mm; self adhesive

ScaDiag-Kits

ScaDiag-Kit SCATEC-10 10156490 complete set for connecting a Scatec-10 to a PC

ScaDiag-Kit SCATEC-15 10156491 complete set for connecting a Scatec-15 to a PC

13 Maintenance

The Scatec-10 / -15 requires no maintenance apart from keeping the front windows clean. Dust or

fingerprints can impair the sensor function. It is normally sufficient to wipe the windows dry with a clean (!)

soft cloth. Alcohol may be used for heavy soiling.

14 Troubleshooting

Whenever possible use the application software ScaDiag for troubleshooting!

The software ScaDiag allows the user to record and to graphically display data without interfering with the

running production. This is a tremendous help if there is a need to take a closer look at certain aspects of a

production run. The collected data can be analyzed by the customer himself or they can be forwarded by email to Baumer electric for that purpose. Troubleshooting is considerably faster if there is real data available

of the production causing problems.

User manual Scatec-10 / -15 38 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 39

15 Varying data for customized FLDM 170x10/xxxxxx

User manual Scatec-10 / -15 39 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 40

User manual Scatec-10 / -15 40 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 41

User manual Scatec-10 / -15 41 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 42

16 Supplements

User manual Scatec-10 / -15 42 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 43

User manual Scatec-10 / -15 43 / 44 Baumer Electric AG

Version 2011-03 www.baumer.com Frauenfeld, Switzerland

Page 44

Denmark

Baumer A/S

DK-8210 Aarhus V

Phone +45 (0)450 392 466

France

Baumer SAS

FR-74250 Fillinges

Phone +33 (0)450 392 466

Germany

Baumer GmbH

DE-61169 Friedberg

Phone +49 (0)6031 60 07 0

Italy

Baumer Italia S.r.l.

IT-20090 Assago, MI

Phone +39 (0)245 70 60 65

United Kingdom

Baumer Ltd.

GB-Watchfield, Swindon, SN6 8TZ

Phone +44 (0)1793 783 839

China

Baumer (China) Co., Ltd.

CN-201612 Shanghai

Phone +86 (0)21 6768 7095

Austria

Baumer GmbH

AT-2514 Traiskirchen

Phone 0800 0700020

Sweden

Baumer A/S

SE-56122 Huskvarna

Phone +46 (0)36 13 94 30

Canada

Baumer Inc.

CA-Burlington, ON L7M 4B9

Phone +1 (1)905 335-8444

India

Baumer India Private Limited

IN-411038 Pune

Phone +91 20 2528 6833/34

Brasil

Baumer do Brasil Ltda

BR-04726-001 São Paulo-Capital

Phone +55 11 56410204

Switzerland

Baumer Electr

ic AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

USA

Baumer Ltd.

US-Southington , CT 06489

Phone +1 (1)860 621-2121

Singapore

Baumer (Singapore) Pte. Ltd.

SG-339412 Sin

gapore

Phone +65 6396 4131

www.baumer.com/worldwide

Technical data subject to change Printed in Switzerland No. 10159883

User manual Scatec-10 / -15 44 / 44 Baumer Electric AG

Version 2011-03 dnalreztiwS ,dlefneuarF moc.remuab.www

Loading...

Loading...