Page 1

USER MANUAL

FOR DENEX VERSIONS: 2010

®

DENEX

MICRO

FLDM 180C1102/S42

Page 2

READ THIS FIRST

Before installing, operating, opening, or applying the DENEX MICRO sensor, read and

understand the contents of this manual.

Always observe the following warnings and cautions when operating or working on the

equipment.

CAUTION

Use of controls or adjustments or performance procedures other

than those specified herein may result in hazardous radiation exposure.

Do not stare into laser beam.

The DENEX MICRO must be applied, installed, adjusted, and maintained only by qualified

personnel who are familiar with the operation of the unit and its associated components.

User Manual DENEX MICRO 2/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 3

CONTENTS

1 INTRODUCTION _____________________________________________________ 4

2 RECEIVING AND HANDLING _________________________________________ 4

3 BASIC FUNCTION ___________________________________________________ 5

4 INSTALLATION ______________________________________________________ 6

4.1 General Precautions ____________________________________________________ 6

4.2 Mechanical Installation _________________________________________________ 6

4.3 Standard Mounting with Beam Stopper ___________________________________ 7

4.4 Mounting with a hole for the laser ________________________________________ 8

4.5 Mounting With Reference Surface _______________________________________ 9

5 Electrical installation _______________________________________________ 10

5.1 Power Connection ____________________________________________________ 10

5.2 Output Signal _________________________________________________________ 10

5.2.1 Output Signal - Connections _____________________________________ 10

5.2.2 Speed Sensor Input _____________________________________________ 11

6 SOFTWARE FUNCTIONS ____________________________________________ 12

6.1 Application Setting ____________________________________________________ 12

6.2 Blocking Function _____________________________________________________ 12

6.3 Back-Edge Check (In counting mode) ___________________________________ 12

6.4 DIP-Switch Settings ___________________________________________________ 13

7 LED INDICATORS __________________________________________________ 14

7.1 The POWER-LED ______________________________________________________ 14

7.2 The LASER OFF-LED __________________________________________________ 14

8 TECHNICAL SPECIFICATIONS ______________________________________ 15

9 LASER SAFETY ____________________________________________________ 16

10 SAFETY __________________________________________________________ 17

10.1 Safety Features _____________________________________________________ 17

10.1.1 Power Control ________________________________________________ 17

10.1.2 Visible Warning-LED __________________________________________ 17

11 MAINTENANCE AND REPAIRS _____________________________________ 17

11.1 Maintenance at Regular Intervals _____________________________________ 17

12 RETURNING EQUIPMENT _________________________________________ 18

13 WARRANTY ______________________________________________________ 18

14 TROUBLESHOOTING _____________________________________________ 19

15 APPENDIX _______________________________________________________ 22

16 Supplements _____________________________________________________ 23

User Manual DENEX MICRO 3/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 4

1 INTRODUCTION

We strongly recommend you to read section regarding laser safety before switching on the

equipment.

WARNING

When the DENEX MICRO is combined with user

selected components to form a system, the user is responsible for proper selection of parts

and subsequent operation. This unit shall be installed, adjusted and serviced only by

qualified personnel who are familiar with the operation of the DENEX MICRO and other

system components. Serious personal injury and equipment damage may result if this

procedure is not followed.

2 RECEIVING AND HANDLING

Upon delivery of the equipment, thoroughly inspect the shipping containers and contents

for indications of damage incurred in transit. If any concealed loss or damage is

discovered later, notify the freight or express agent.

User Manual DENEX MICRO 4/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 5

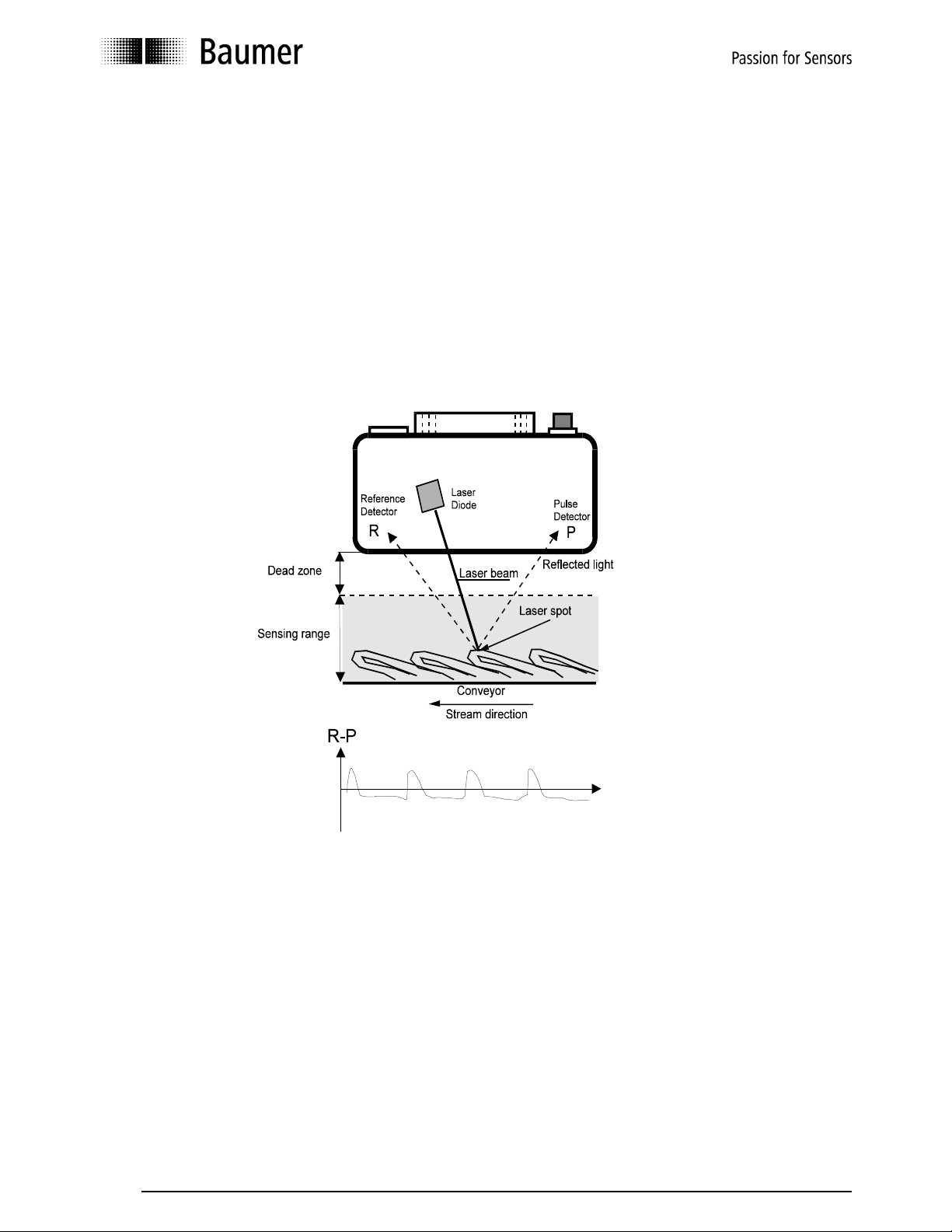

3 BASIC FUNCTION

The DENEX MICRO is a non-contact sensor which counts all kinds of printed products on

an overlapped stream. It senses the leading edge and generates one output pulse for

every product. Product thickness from a single folded sheet up to a maximum stream

thickness of 70 mm can be sensed without adjustments.

The laser diode that is used produces a visible and very intensive and focused light beam

which is projected onto the stream. The reflected light from the spot is collected by two

light sensitive detectors P and R and is analyzed by a microprocessor. The difference in

reflected light that occurs when the light spot is temporarily hidden behind the passing

product edge provides the basic data for the sensor to determine a count output pulse.

Figure 3.1 The principle of operation

The patented principle in utilizing two detectors - one for detecting the obstructed light and

the other for reference, enables the following unique benefits:

Wide operating range

High precision

Insensitive to color of paper or print

Insensitive to product thickness

Insensitive to variations in distance to copy stream

The use of a microprocessor further enhances the flexibility and reliability of the unit.

Through the use of the microprocessor, the DENEX MICRO can be adapted to different

operating modes by changing DIP-switch settings which can be reached from outside, via

the glass window.

User Manual DENEX MICRO 5/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 6

4 INSTALLATION

In order to assure the best possible operating conditions as well as personal safety, it is

essential that the following instructions are followed exactly.

4.1 General Precautions

The DENEX MICRO should be installed in an environment where:

1. The equipment ambient temperature does not exceed 40º C.

2. The equipment atmosphere is free from highly flammable or combustible vapors,

corrosive chemical flumes, oil vapor, steam, excessive moisture and particles.

Avoid mounting the unit in places with strong vibrations since they can produce miscounts,

especially when thin products are counted. Make sure that the mounting bracket and

means used are rigid to withstand vibrations.

The sensor should normally be mounted on a flat conveyor. It is possible to mount the

sensor on a bent part of the conveyor according to figures below. Do not mount according

to Figure 4.1.1 (right) since it will deteriorate the function of the unit.

YES NO

Figure 4.1.1 Mounting on a non-flat conveyor.

4.2 Mechanical Installation

The sensor should be mounted parallel to, and at a distance of 100 mm from the conveyor.

The sensor will then count folded sheets up to a maximum stream thickness of 70 mm. If

the sensor is to used as a gripper sensor, refer to Appendix 1 ”Mounting and using the

sensor on a gripper conveyor”. Contact Baumer if other mountings are considered. It is

most important that the sensor is mounted the right way. It can only count in one direction.

The connector side of the sensor should be the first to meet the copies.

The laser beam must not hit any moving part of the conveyor. The path of the laser must

end with a beam stopper. See chapters 4.3 and 4.4 for more information about the type of

beam stopper used. The laser beam must never be accessible to the user!

Make sure that the mounting bracket used is rigid and that the alignment of the unit cannot

be accidentally changed. There are brackets available from Baumer.

User Manual DENEX MICRO 6/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 7

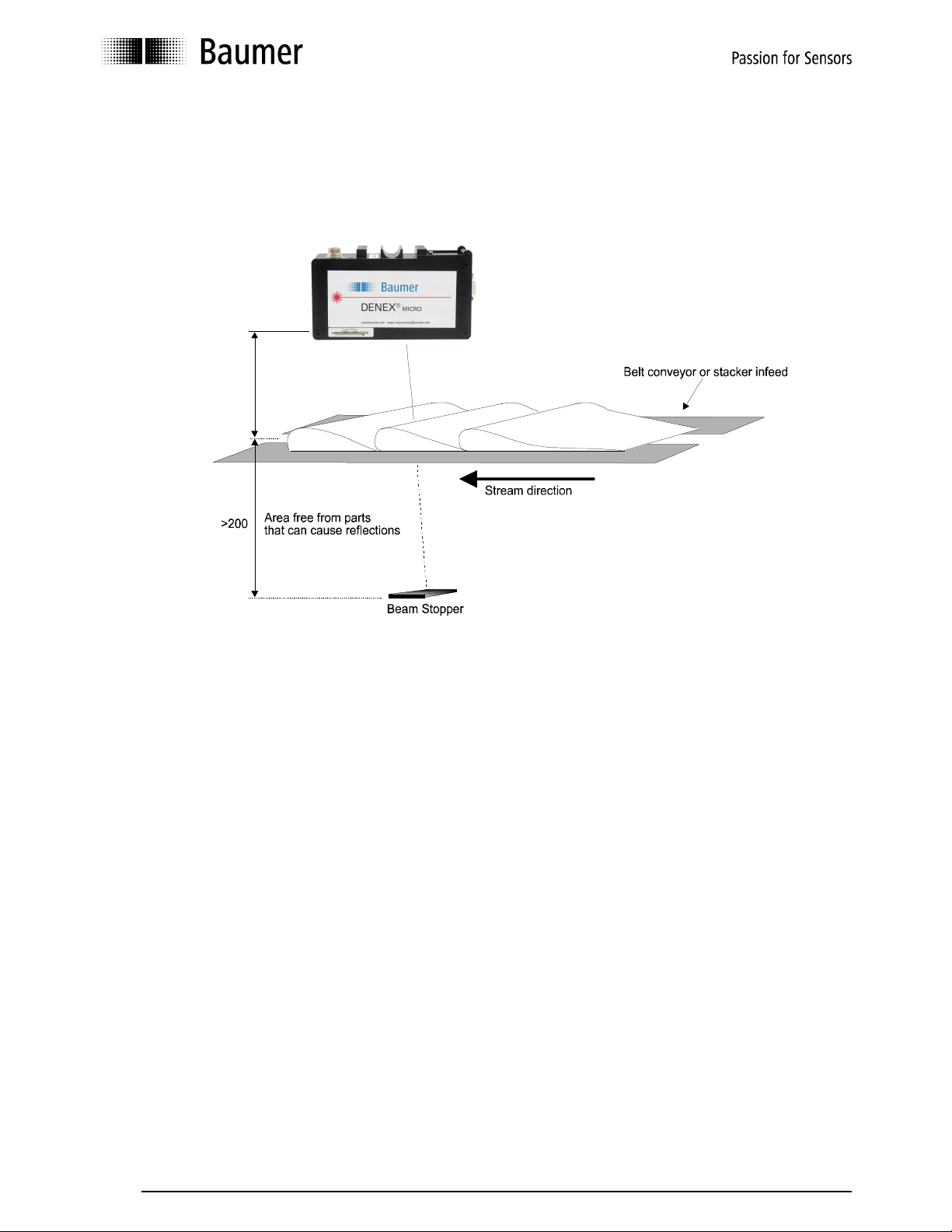

4.3 Standard Mounting with Beam Stopper

The laser does not hit anything except the beam stopper when no copies are present.

Normal back-edges will not be counted with this mounting. The beam stopper is a black

plate or dark surface no closer than 300 mm to the bottom of the sensor. See figure 4.3.1.

100

Figure 4.3.1 Standard mounting with beam stopper.

User Manual DENEX MICRO 7/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 8

4.4 Mounting with a hole for the laser

If there are mechanical parts 200-300 mm under the sensor that can cause reflections to

the detectors, the following mounting is recommended. It requires a small hole on the

conveyor, or a plate with a hole to screen off the reflection from the parts. The beam must

still be stopped with a dark plate or other material if there is any risk for a person to look

into the laser. Make sure that the laser goes through the hole properly. Normal back-edges

are not counted with this mounting.

100

Figure 4.4.1 Mounting with a hole to let the laser through.

User Manual DENEX MICRO 8/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 9

4.5 Mounting With Reference Surface

In some cases, the reflections from parts under the conveyor cannot be screened off. In

this case, the following is recommended. Let the laser hit a light, matte surface, reference

surface, like a white piece of paper or a light painted plate, at 100 mm below the sensor.

The reference surface must be smooth. If the surface is wrinkled or coarse, vibrations can

cause error pulses. Also, make sure that dust and paper pieces do not stay on the surface,

since they might create extra pulses. No extra beam stopper is needed.

The accuracy can be equally good if: no up-bent back edges are present, stream is regular

with few gaps.

Up-bended back edges can produce output pulses. This mounting is only recommended in

applications with few gaps in the stream.

100

Figure 4.5.1 Mounting with reference surface

.

User Manual DENEX MICRO 9/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 10

5 Electrical installation

The interface to the copy sensor is a 7-pin connector with the following pin-out:

Matching connector: Amphenol Tuchel T3476 001, delivered with the sensor.

Pin 1 : +24VDC power

Pin 2 : + Output (collector)

Pin 3 : + Speed Sensor Input

Pin 4 : - Speed Sensor Input

Pin 5 : - Output (emitter)

Pin 6 : 0V

Pin 7 : No function (connected to pin 6 internally)

5.1 Power Connection

Proper wiring techniques are essential for successful system installation. To reduce the

effects of electrical noise interference and static discharge, the procedures outlined in this

section must be strictly followed.

The sensor shall be connected to 19 - 30V DC regulated power.

It must be free from transients!

Never connect or disconnect any cables when the power is on!

The normal current consumption is around 200mA

5.2 Output Signal

The output is a normally open, opto-isolated transistor. Every output pulse is signaled as a

closing of the output for a certain time; see also “DIP-Switch Settings” in chapter 5.

The spec for the output opto coupler is as follows:

Max load current: 150mA, Max voltage: 35V DC

5.2.1 Output Signal - Connections

The output can be used for both "current source" and "current sink" depending on what is

required for the following equipment. In current source mode, the sensor output will give a

positive pulse to the stacker/totalizer when active. In current sink mode, the sensor output

will give a negative pulse. Figures 5.2.1.1 and 5.2.1.2 shows a common 24V as power

supply and as the supply for the pulse. It is of course possible to have different power

supplies. In that case, the 24V-power is connected to pins 1 and 6, and the totalizer is

connected to pins 2 and 5.

Figure 5.2.1.1 Electrical connection, common 24V-supply. Current source (PNP).

User Manual DENEX MICRO 10/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 11

Figure 5.2.1.2 Electrical connection, common 24V-supply. Current sink (NPN).

Copy Sensor

Figure 5.2.1.3 Electrical connection, separate supply for power and pulse.

5.2.2 Speed Sensor Input

There is a possibility to connect an input signal from a speed sensor, such as an encoder,

in order to give information of conveyor speed. The input can be used to obtain a fixed

blocking distance. In Mode 7 (see chapter 6, “SOFTWARE FUNCTIONS”) the input signal

is used as a control signal, if high, the blocking time is long, if low, the blocking time is

short. Normally, the dynamic blocking is used with equally good results. There are three

different modes of blocking, see chapter 6, ”SOFTWARE FUNCTIONS”.

The input is opto-isolated so that there is a separation between the sensor’s and the pulse

generator’s grounds.

The input should be min. 4.5V and max. 28V.

The maximum allowed frequency is 2.5 kHz.

Figure 5.2.2.1 Input stage for speed sensor input.

User Manual DENEX MICRO 11/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 12

6 SOFTWARE FUNCTIONS

The real power with a microprocessor-based sensor is that the sensor learns what the

products and the stream look like and make decisions according to this. Before actual

settings are discussed, first a short description of the major functions and terms.

6.1 Application Setting

The sensor can be optimized around certain applications. Things like output pulse width,

Blocking Function and Back Edge Check parameters are set a little different for each

application in order to reach the highest possible accuracy.

There are four DIP-switches that tell the sensor which application it should be set for.

It is very important to set the right application!

6.2 Blocking Function

This function will eliminate false counts due to double edges or a cut-edge-first delivery.

The sensor will count edges coming within the blocking zone as one product. In

productions using stitches, extra pulses due to the stitch are blocked out by this function.

The blocking zone is a dynamic value that constantly adapts to the average distance

between copies. It will be either 15% or 30 % of the mean lap, depending on application.

The average distance between copies is 100%, see figure 6.2.1.

Figure 6.2.1 The principle of the blocking function.

The blocking zone is marked with gray. 15% is the first half, and 30% is whole area.

6.3 Back-Edge Check (In counting mode)

Normal flat back-edges are never counted. However, if the back-edge is bent, this part of

the paper can result in a miscount. The sensor can be configured to wait a certain time to

decide whether the edge that was found was really a copy or if it was an up bent backedge of the product, or a pin hole on the back of the paper. DIP-switches must be set to

choose Newspaper-application in order to activate this function.

The Back-Edge Check will affect the timing of the output pulse also on normal edges, but

will give a higher counting accuracy. Therefore, in timing applications like edge detecting,

the Back-Edge Check is disabled.

User Manual DENEX MICRO 12/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 13

56 7 8

6.4 DIP-Switch Settings

An 8-pole DIP-switch can be reached via the lid on top of the sensor. Unscrewing the

screw opens the lid.

The software functions can be controlled via the DIP switches.

DIP-Switch positions

= OFF

= ON

DIP-switches 1-4 are reserved for factory

DIP-switches 5-8 are for selecting operation mode

All in OFF-position is the default setting.

DIP-Switches

Mode 0 =

Default

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Counting mode: 15% Blocking, short Back-Edge Check, Output 5ms

Thick newspapers: 30% Blocking time, long Back-Edge Check. Output 5 ms

Counting mode: speed pulses, Blocking pulses 5, Back-edge 16, Output: 5ms

Counting mode: speed pulses, Blocking pulses 5, Back-edge 5,Output: 20ms

Thick newspapers, Blocking pulses 20. Back-edge 16, Output: 5ms

Edge detecting: fixed trig, Blocking 15%,No back-edge check, Output: 5ms

Mode 6

Mode 7

Mode 8

Mode 9

Mode 10

Mode 11

Gripper Pulse mode: For gripper conveyors, Blocking 15%, Output 20 ms

Cut edge first mode: Blocking 30 %, Back-edge 15%, Output 5 ms

Counting mode: Speed pulses, Blocking 10, Back-edge 16, Output 5ms

Commercial: Fixed trig, No Blocking, No Back-edge, Output 20 ms

Counting mode: 15% Blocking, short Back-Edge Check, Output 20ms

Counting mode: speed pulses, Blocking pulses 5, Back-edge 16, Output: 5ms

Laser power save mode is activated in all Counting/newspaper modes.

This means the laser power will be reduced after a 60 seconds gap.

User Manual DENEX MICRO 13/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 14

7 LED INDICATORS

As a help for checking the operation of the sensor, there are four LED’s that are placed

close to the connector.

Figure 7.1 Position of LED:s.

7.1 The POWER-LED

The green POWER-LED indicates that the sensor has power and should be operating.

Never mount or adjust the sensor when this LED is on!

7.2 The LASER OFF-LED

The LASER OFF-LED is an indication that the laser is off. The laser will be shut off for the

following reasons:

The laser power has exceeded the allowed limits (electronic problem inside sensor)

The laser power has reached lower than acceptable level (laser is worn out, or

electronic problem)

If the laser levels are outside of the allowed limits, the sensor must be sent for repair.

The OUTPUT-LED is active when the output stage is active (set). The LED will flash for

every output pulse that is sent. The output pulse width can be set with the DIP-switches,

see chapter 5.4, ”DIP-Switch Settings”. By watching this LED, it is fairly easy to see that

the sensor is giving the correct amount of pulses.

User Manual DENEX MICRO 14/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 15

Maximum Count Rate

8 TECHNICAL SPECIFICATIONS

< 600.000 copies/hour

Maximum Product Speed

1 m/s (200 ft/min) for thinnest product, up to 2 m/s otherwise

Maximum Stream Thickness

70 mm (2.76”) standard range

Minimum Product Thickness

0,25 mm (0.01”) standard range,

Distance From Conveyor

100 mm (3.94”) standard range,

Minimum Spacing Between Copies

1-5 mm (0.039-0.20”) dep. on thickness, speed and pulse width

Stream Conditions

All conditions

Operating System

RISC microprocessor

Pulse Width

5 ms (preset) or 20 ms

Output Signal

Opto-isolated 5 to 30 V max. 150 mA

Speed Sensor Input

4.5 - 28 VDC, 3 mA, max. 2.5 kHz

Matching Connector

Amphenol-Tuchel C91A T 3476 001

Laser System

Visible, switched laser diode, 650 nm, with laser safety monitor

Laser Safety Class

Class II

Estimated Lifetime of Laser

> 30,000 h @ 20ºC

Weight

800 g, 1.75 lbs.

Size

175 x 96 x 31mm, 6.89 x 3.78 x 1.22”

Power

24 V DC. 150 mA typical

Temp. Range

+10 to 40ºC, 50 to 104ºF

DENEX MICRO is a Class II Laser Product.

User Manual DENEX MICRO 15/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 16

9 LASER SAFETY

The concentrated beam of optical radiation from the laser diode is potentially dangerous.

In considering the safety aspects of the use of such devices, it is the thermal effects of

absorption of this energy, which are important. However, in comparison with higher power

laser using different generating media, laser diodes are relatively safe.

A Class II-laser product as the DENEX MICRO is said to be safe if a person does not stare

into the beam. If a person accidentally would look into the laser, the strong light would

cause the eyes to shut automatically before any damage to the eyes could occur. If the

following precautions are followed, nothing can happen.

CAUTION

• Do not stare into the laser beam or a reflection of the beam from a mirror-like

surface!

• Do not move or adjust the DENEX MICRO, without first turning off the power!

The green LED must be off!

• Service on the sensor should be made by qualified personnel only!

•

The sensor must be installed in such way, that the laser does not hit a glossy,

mirror-like surface!

CAUTION

Use of controls or adjustments other than those specified herein may result in hazardous

radiation exposure.

Do not stare into beam!

User Manual DENEX MICRO 16/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 17

10 SAFETY

10.1 Safety Features

The following chapter describes the safety features of the DENEX MICRO. Make regular

checks to verify the function of these features.

10.1.1 Power Control

To power off the sensor, unplug the power connection.

10.1.2 Visible Warning-LED

The green LED is the POWER-LED, which indicates that the laser is on!

Never move or adjust the sensor when the green LED is on!

11 MAINTENANCE AND REPAIRS

Before any adjustments or maintenance is carried out on the DENEX MICRO, make sure

to follow the instructions below:

Switch off the power by removing the power plug.

11.1 Maintenance at Regular Intervals

The only maintenance on the sensor which is allowed by non-DENEX Sensor authorized

personnel is cleaning the glass window, but only after first turning the sensor off.

- Clean the glass aperture with alcohol

- Remove any loose pieces of paper that can produce false counts

- Check that the beam stopper is in place and that it is not covered with dust

CAUTION

Use of controls or adjustments other than those specified

herein may result in hazardous radiation exposure.

Diode laser power up to 1 mW at 670 nm can be accessible in the interior.

Avoid exposure to beam!

User Manual DENEX MICRO 17/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 18

12 RETURNING EQUIPMENT

If it is necessary to return a DENEX MICRO for repair, the following procedure should be

followed.

1. Tag the unit with the following:

• Company and contact person returning the item

• Phone, fax or email to the contact person for additional information

• Helpful information regarding the malfunction. A good description reduces

trouble shooting cost.

If the unit has been disassembled, reassemble it, making certain that all hardware is in

place. Missing parts will be charged at spare part prices.

2. Carefully pack the unit and apply appropriate cautionary stickers.

3. Advice way of returning the unit: Post (DPD), UPS, DHL or other.

4. Return unit to your dealer or directly to Baumer (see address on back page).

13 WARRANTY

Baumer Electric AG gives a warranty to the customer for quality and suitability of its

products within the scope of its technical specifications. A warranty is only given according

to prior agreement for parts which are used as safety parts within the meaning of the EU

Machinery Directive. The guarantee of Baumer Electric AG is limited to replacement or

repair of defective parts and causes which occurred before the passing of risk. Liability for

further direct and indirect losses are excluded to the extent permissible at law, more

particularly, no compensation shall be owed for any incidental loss, loss of production etc.

The guarantee lapses in any event if the customer does not use original Baumer Electric

AG replacement parts. The guarantee is not valid in any instance where the goods have

been tampered with. The customer is under a duty to examine the consignment for

completeness and transport damage immediately on receipt. Any complaints in connection

with the product shall be made in writing without delay, and evidence of such incidence

must be produced. Complaints may be made about product defects during the complete

period of guarantee at any time before and/or after processing and/or re-sale, but they are

to be notified in writing enclosing the defective part without delay after emergence. The

customer may only invoke these guarantee conditions if he proves that the defects

emerged despite proper assembly and use. The guaranty period is 24 months from

dispatch from Baumer Electric AG. The period of guarantee for replacement parts or

repairs delivered under guarantee ends with the period for the products originally supplied.

Baumer Electric AG reserves the right to charge the processing costs for sales returns and

performance tests without claim to guarantee.

User Manual DENEX MICRO 18/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 19

14 TROUBLESHOOTING

The green LED (POWER) is not lit

• The sensor does not receive +24V on pin 1 and 0V on pin 6 on the Tuchel connector,

see chapter 5, ”Electrical Installation”.

• If the sensor has been working and is suddenly dead, there could be transients

knocking out the sensor. Make sure that the voltage is between 20V and 30V and is

regulated.

The red LED (LASER-OFF) is lit constantly, and no laser is present

• Re-power the sensor. Check that the laser is lit. Is the laser turned off after a while,

the laser level has changed and the sensor must be sent for repair.

The orange LED (OUTPUT-signal) is never lit, or is lit once and then no more

• Is the input signal connected? Are the DIP-switches set the way they should? As

soon as one pulse is received, the sensor believes that input pulses are used, and it starts

to wait for more. Disconnect the input signal wires if not used. Re-power the sensor and try

again.

The orange LED (OUTPUT-signal) is lit for every copy, but no pulse, or a different number of

pulses, is received to the following equipment

• The interfacing is bad. Check again that the sensor is connected the way it should,

see chapter 5 ”Electrical Installation”.

• Is the sensor supposed to source or sink the signal? Should the pulse be positive or

negative? See chapter 5.2

• Is the totalizer (pulse counter) used, a battery powered device? It can be a problem

because of the voltage drop over the output transistor in the sensor. There is approx. 0.8V

voltage drop over emitter and collector at 2 mA which could mean that the totalizer does

not see any changes in state, i.e. from ”high” to ”low”. Check with a scope between pulse

and ground.

• The opto-coupler in the sensor can be faulty. See the specs of the opto-coupler.

First copy edge is not counted or back-edges are counted (does not apply for a mounting

with reference)

• Check that the laser does not hit anything within 300 mm below the sensor when no

products are present.

• If the laser hits a plate within 300 mm below the sensor, check the possibility of

making a hole in the plate. Drill a hole with a diameter of 5 mm, which the laser can pass

through. The laser must still be stopped by a black plate, because of safety regulations!

• If back-edges are counted, check the distance from the up-bent back-edge to the end

of the paper.

User Manual DENEX MICRO 19/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 20

The sensor does not read the Speed Sensor Input Signal

• Check polarity and levels according to chapter 5.2.2, ”Speed Sensor Input”. Is the

speed very high? It should be max. 2.5 kHz.

There is an overcount (too few copies in the bundle)

• Check the mechanical installation. The sensor must be parallel to the stream.

• For cut-edge first delivery, or with copies with stitches or other non-folded edges, try

changing the application so that the Blocking Zone is greater, see chapter 6, ”SOFTWARE

FUNCTIONS”.

• Back-edges could be counted. Check by running one paper at a time, and see if

there is an extra pulse sent at the end of the paper.

• If the surface of the product is wavy, try tilting the sensor 5 - 10° according to figure

below.

Some products are not counted (too many copies in the bundles)

• Check the mechanical installation. The sensor must be parallel to the stream.

• Check the interface. See previous page.

• If the product stream is very irregular, it could be that the sensor is blocking out

products coming too close. Try choosing an application with a shorter blocking, see

chapter 6, ”SOFTWARE FUNCTIONS”.

• Make sure that the stacker has not got an internal Blocking Zone which is set in a

way that it blocks out pulses from the sensor.

• If the product with the problem is very black and very thin, try lowering the sensor 10-

20 mm closer to the product stream.

• Are the products very tilted when they pass the sensor? The max angle allowed is

15° for a 0.25 mm product.

•

Still Problem?

Give your Baumer DENEX dealer a call.

User Manual DENEX MICRO 20/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 21

ACCESSORIES AVAILABLE FROM Baumer

There is a number of accessories available that can save you time and ensure a good

operation of the sensor:

Brackets

Baumer has standard brackets for mounting the DENEX sensors above the conveyor and

for many different brands Installation of a Totalizer beside the conveyor. Special brackets

for gripper conveyors are also available.

User Manual DENEX MICRO 21/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 22

15 APPENDIX

1. Size Diagram with Laser Beam Projection

RW 980130

919-06a.CDR

RW

LCS 919-06A

M8

DENEX Systems Technology AB

DENEX

DENEX CopySensor

DENEX

OUTLINE DRAWING

55 65

A-A

15,5

3/4" Shaft or 19 mm shaft

Suitable bracket available

from DENEX

Part no. 53C6014

120

100

70

175

19

92,7

98,8

103,2

101,4

12

A A

31

96

User Manual DENEX MICRO 22/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 23

16 Supplements

User Manual DENEX MICRO 23/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Page 24

Baumer Electric AG

Sensor Solutions

Hummelstrasse 17

CH - 8500 Frauenfeld

Phone +41 (0) 527281122

Fax +41 (0) 527281110

sales.copycounter@baumer.com

www.baumer.com

Technical data subject to change Printed in Switzerland No. 11084089

User Manual DENEX MICRO 24/24 Baumer Electric AG

Version 2013-02, V1.6 www.baumer.com Frauenfeld, Switzerland

Loading...

Loading...