Page 1

English

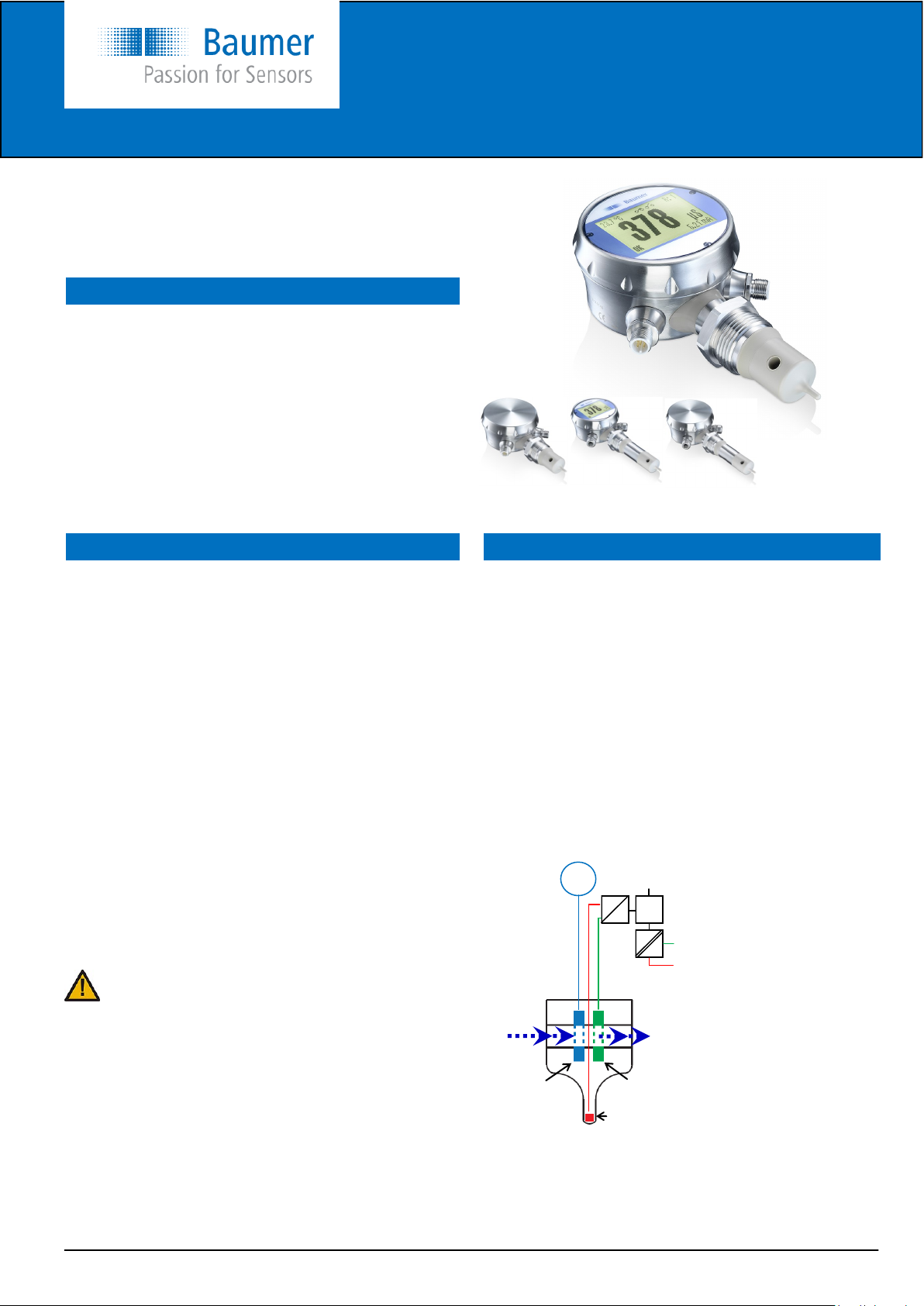

CombiLyz AFI4 conductivity transmitter is a compact sensor/transmitter,

based on inductive technology, which is designed and produced to meet

the requirements in hygienic and general industry where measuring of

medium range conductivity is used.

Description

CombiLyz AFI4 consists of a conductivity sensor and a transmitter built

into one compact unit.

The output from the transmitter are two 4...20 mA, which is available for

both conductivity, concentration and temperature.

The display features more user selectable modes and user specified

“product labels” and warnings. Further there are two switch outputs for

alarms or control.

The background colour can be set in three colours, white, green or red

- steady or flashing, controlled by the alarm settings. The transmitter and

display can be programmed by either the touch screen on the display or

by the FlexProgrammer programming unit and software.

CombiLyz, AFI4

Operators Instruction

English page 1...11

Deutsch Seite 12...22

Français page 23...33

Safety instruction

This instrument is built and tested according to the current EU-directives

and packed under technically safe conditions. In order to maintain these

conditions and to ensure safe operation, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed. Ignoring the warnings may lead to severe personal injury or substantial

damage of property.

The product must be operated by trained staff. Correct and safe operation of this equipment is dependent on proper transport, storage installation and operation.

All electrical wirings must conform to local standards. In order to prevent

stray electrical radiation, we recommend twisted and shielded input

cables and also to keep power supply cables separated from the input

cables. The connection must be made according to the connection diagrams.

Before switching on the power supply take care that other equipment is

not affected. Ensure that the power voltage, the conditions are the environment comply with the specification of the device.

Before switching off the power supply voltage, check the possible effects

on other equipment and the processing system.

WARNING

The device is not approved for electrical installations in explosion proof

areas.

After mounting of the device - do check that the housing has a ground

potential.

The product contains no direct replaceable parts, except for the DFON

display. In case of malfunction the product must be sent to Baumer for

repair.

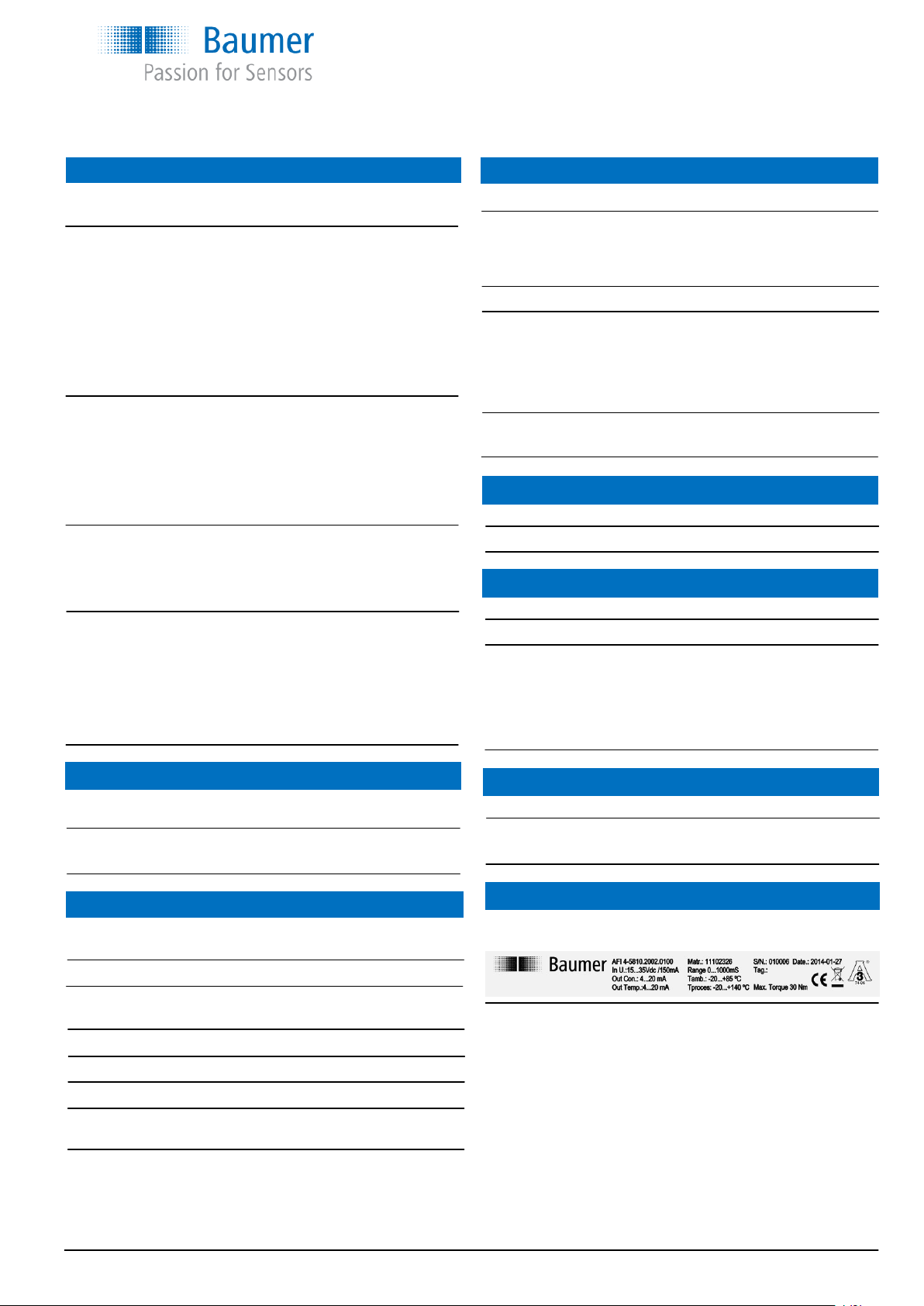

Working principle

The measuring cell is a homogeneous sealed body all in PEEK.

Through the body is a hole, through which the media is flowing. Built-in

around the hole are two coils; a primary coil supplied with an AC voltage and a secondary coil, which picks up a small signal through the

media inducted voltage. The size of this voltage is dependent on the

conductivity of the media. This signal is handled and amplified in the

electronics to a linear analogue 4...20 mA output signal. Also built into

the body is a Pt100 sensor placed in the tip of the sensor. This is measuring the media temperature to enable temperature compensation of

the conductivity signal, which is very temperature dependent. The

Pt100 sensor signal also features an analogue 4...20 mA output signal.

The coils and sensor are encapsulated in the PEEK sensor body, which

have a surface with surface roughness (Ra) <0,8 µm. It is therefore well

suited for use in hygienic processes or direct in concentrated acids or

alkalis.

~

A

D

Range setting

input R1 and R2

CPU

Conductivity/Concentration

D

4...20 mA output

A

4...20 mA output

Temperature

Media

Pt100

VAC

Primary coil Secondary coil

www.baumer.com

Operators Instruction: 11126179 00 Page 1 / 36

EN/2014-04-29 Design and specifications subject to change without notice

Page 2

CombiLyz, AFI4

English

Technical specifications

Housing FlexHousing, Ø80 mm

Material Stainless steel, AISI 304

Process connection G1A, rotating

(for other connections see adapters page 4)

Insertion length Standard 37 mm / 3A version 40,5 mm

Long version 83 mm / 3A version 87 mm

Material Not wetted Stainless steel AISI 304

Wetted parts 37… mm PEEK natura

83... mm PEEK narura+AISI 316L

Surface Wetted parts Ra <0,8 µm

Measuring range Conductivity 0...500 µS/cm … 0…1.0 S/cm

14 selectable ranges

Concentration 4 factory set medias/ranges

1 customer defined media/range

Temperature -30...150°C

Free programmable range

Accuracy Cond./conc. 0...500 µS/cm ≤1,5%

(sensor incl. transmitter) 0...1 / 0...500 mS/cm ≤1,0%

0...1 S/cm ≤1,5%

Temperature ≤0,4% selected range

Temperature compensation 0,0...5,0%/°C, free adjustable

Compensation range -20...150°C

Reference temperature 25°C (adjustable)

Response time Cond./conc. <2,0 seconds

Temperature, t90 <15 seconds

Start up time without display ≤10 seconds

Start up time with display ≤15 seconds

Operators Instruction

Electrical specifications

Power supply 15...35 VDC

Output Cond./Conc. 4...20 mA

4...20 mA + HART® (pending)

Temperature 4...20 mA

Relay 2 relays included in the display

Temperature drift ≤0,1%/°C

El. connection Left side M12, 5-pin

M16 or M20 cable gland

Right side M12, 5-pin

M12, 8-pin

M16 or M20 cable gland

Material Plastic

Stainless steel

Relay

Contacts 2 × solid state relays

Voltage 60 Vp

Display

Type FSTN Graphically LCD

Measuring range -9999...99999

Digit height Max. 22 mm

Temperature drift ≤0,0001%/°C inside optimal range

-10...70°C

≤0,00015%/C outside optimal range

-30…-10 / 70...80°C

(4...20 mA output only)

(4...20 mA + relay output)

Compliance and approvals

Apply to EU directives 10/2011, 1935/2004, 2023/2006

FDA PEEK: CFR 21.177.2415

Approvals 3A approval 74-06

EHEDG (pending)

General specifications

Media temperature -20...140°C

150°C up to 1 hour

Media pressure <10 bar (helium tested)

Ambient temperature Without display -40...85°C

With display -30...80°C

Isolation voltage 500 VAC

Protection class IEC 529 IP 67 / IP 69K

Humidity IEC 68.2.38 98% condensing

Vibrations IEC 60068.2.6 - test Fc

1,0 mm

(2-13,2 Hz)

0,7g

(13,2-100 Hz)

Mechanical data

Material Polycarbonate plastic

Protection class IP 10 on terminals

IP67/IP69K in FlexHousing

Product marking

The marking on the product is made by laser engraving.

Below see example:

www.baumer.com

Operators Instruction: 11126179 00 Page 2 / 36

Page 3

CombiLyz, AFI4

English

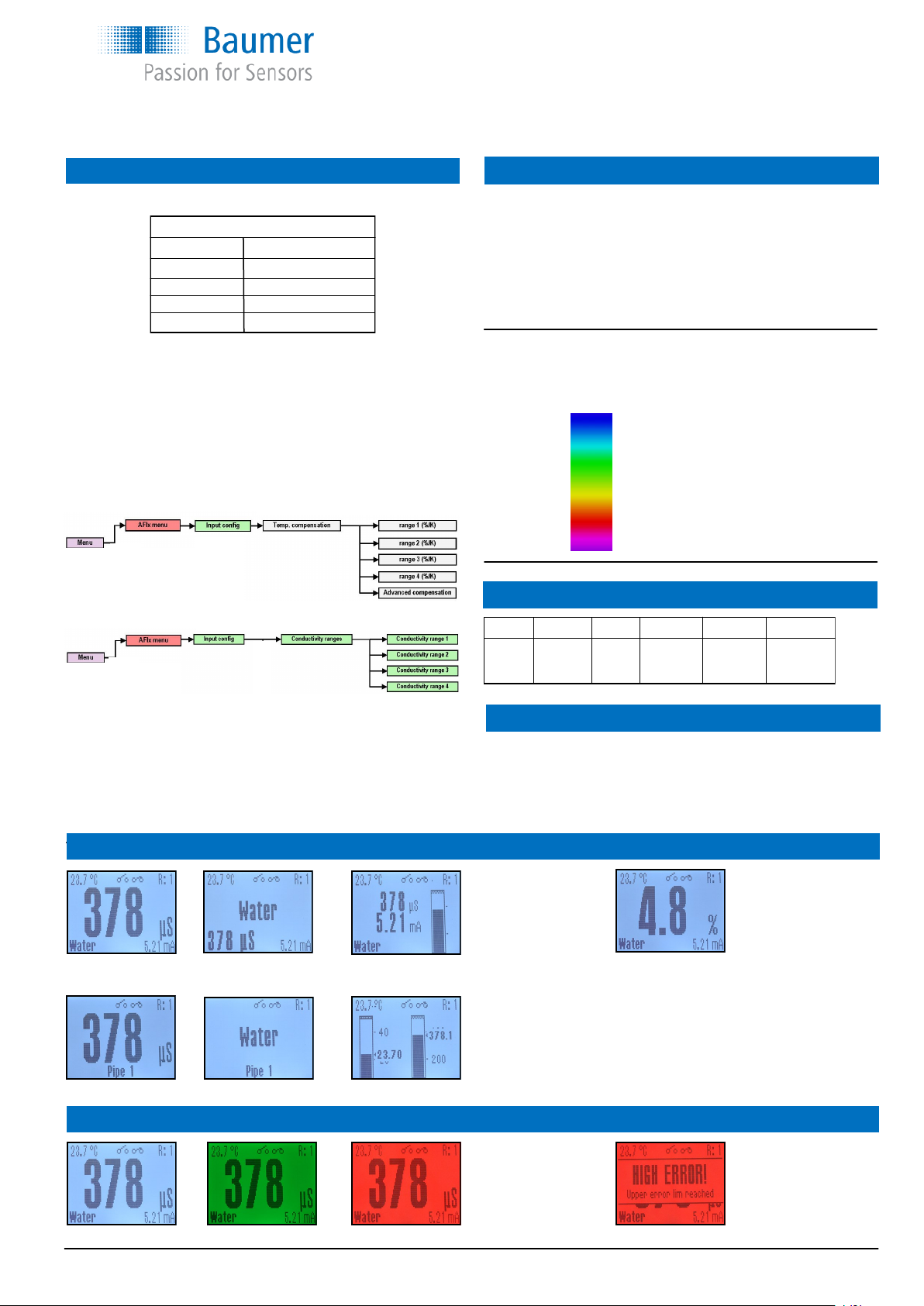

Set-up the AFI4

Conductivity measurement is very temperature dependent.

The factory set-up is 2,0%/°C.

This means that the AFIx will automatically compensate with this factor. If the temperature dependence is known for the media this factor

must be set. However if the factor is unknown, it is recommended to

use an average from above table.

It is possible to adjust the temperature compensation factor from 0,0 …

5,0 %/°C.

Configure the temperature compensation by the touch screen:

Configure the range by the touch screen:

Configuration by the FlexProgram and FlexProgrammer please see

HELP in the FlexProgram.

Concentration output can also be selected by the touch screen or programmed by the FlexProgram.

Programming of the display colours, warnings and relays can be done

by the touch screen (see page 8 and 9) or by the FlexProgrammer.

Typical temperature dependence

Media % change per °C

Acids 1,0 … 1,6

Bases 1,8 … 2,2

Salts 2,2 … 3,0

Neutral water 2,0

Operators Instruction

Conductivity ranges (selectable)

0…500 µS/cm

0...1 mS/cm 0...10 mS/cm 0...100 mS/cm 0...1 S/cm

0...2 mS/cm 0...20 mS/cm 0...200 mS/cm

0...3 mS/cm 0...30 mS/cm 0...300 mS/cm

0...5 mS/cm 0...50 mS/cm 0...500 mS/cm

Definition: 1.000 µS/cm = 1.0 mS/cm

1.000 mS/cm = 1.0 S/cm

Conductivity in different media:

Conductivity Media group Media

55 nS/cm Water Ultra-pure water

1 µS/cm Pure water

10 µS/cm Process water

100 µS/cm Food Drinking water

Beer

1 mS/cm Milk

Orange juice

10 mS/cm Apple juice

100 mS/cm Process Phosphoric acid

Hydrochloric acid

To set the external input for range selection

Range R1 R2 Range R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

Concentration ranges (selectable)

NaOH (caustic soda) 0...15% by weight (0...90°C)

25...50% by weight (0...90°C)

HNO3 (nitric acid) 0...25% by weight (0...80°C)

36...82% by weight (0...80°C)

1 × customer defined (30 point linearization)

AFIx

range

Selectable display views Conductivity Concentration

Value w. all values Media w. values Bar graph w. values Concentration value in %

same views available as for conductivity

Value w. TAG Media w. TAG Bar graph incl. temp.

Visual alerts and colours

White background Green background Red background Error message and red background

www.baumer.com

Operators Instruction: 11126179 00 Page 3 / 36

Page 4

CombiLyz, AFI4

English

Operators Instruction

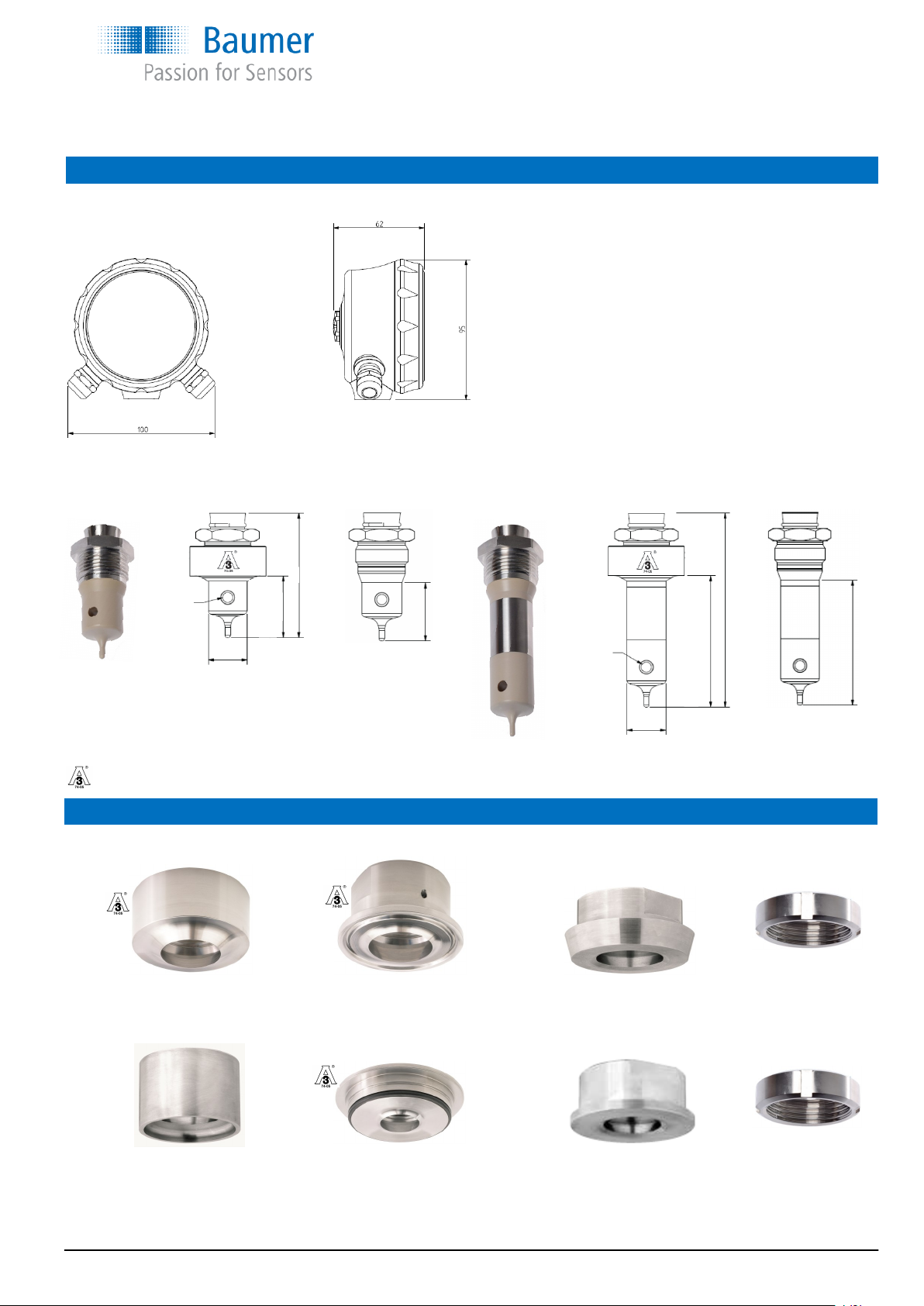

Dimensions

Front view Bottom connection

Short version 3A versions Standard Long version 3A versions Standard

40,5 mm 37 mm 87 mm 83 mm

82

Ø6,6

40,5

Ø25,5

The two above sensors are 3A approved when mounted in one of below 3A approved G1” mounting adapters

37

Ø6,6

Ø25,5

128

87

G1” mounting adapters

Welding connection Clamp connection Screwed connections Union nut

For tank

PM053 ISO 2852 DN38 CAM050-505 DIN 11851 DN 32 MAM050-032 MNF032

ISO 2852 DN51 CAM050-640 DIN 11851 DN 40 MAM050-040 MNF040

DIN 11851 DN 50 MAM050-050 MNF050

For tube

83

DN 40...50 PM052-1 Variline, type N VAM053 SMS 1145 DN 38 SAM-038-1 SNF038

DN 65...150 PM052-2 SMS 1145 DN 51 SAM-051-1 SNF051

More adapters are available, e.g. with standard industrial thread. Please see data sheet for Accessories.

www.baumer.com

Operators Instruction: 11126179 00 Page 4 / 36

Page 5

CombiLyz, AFI4

English

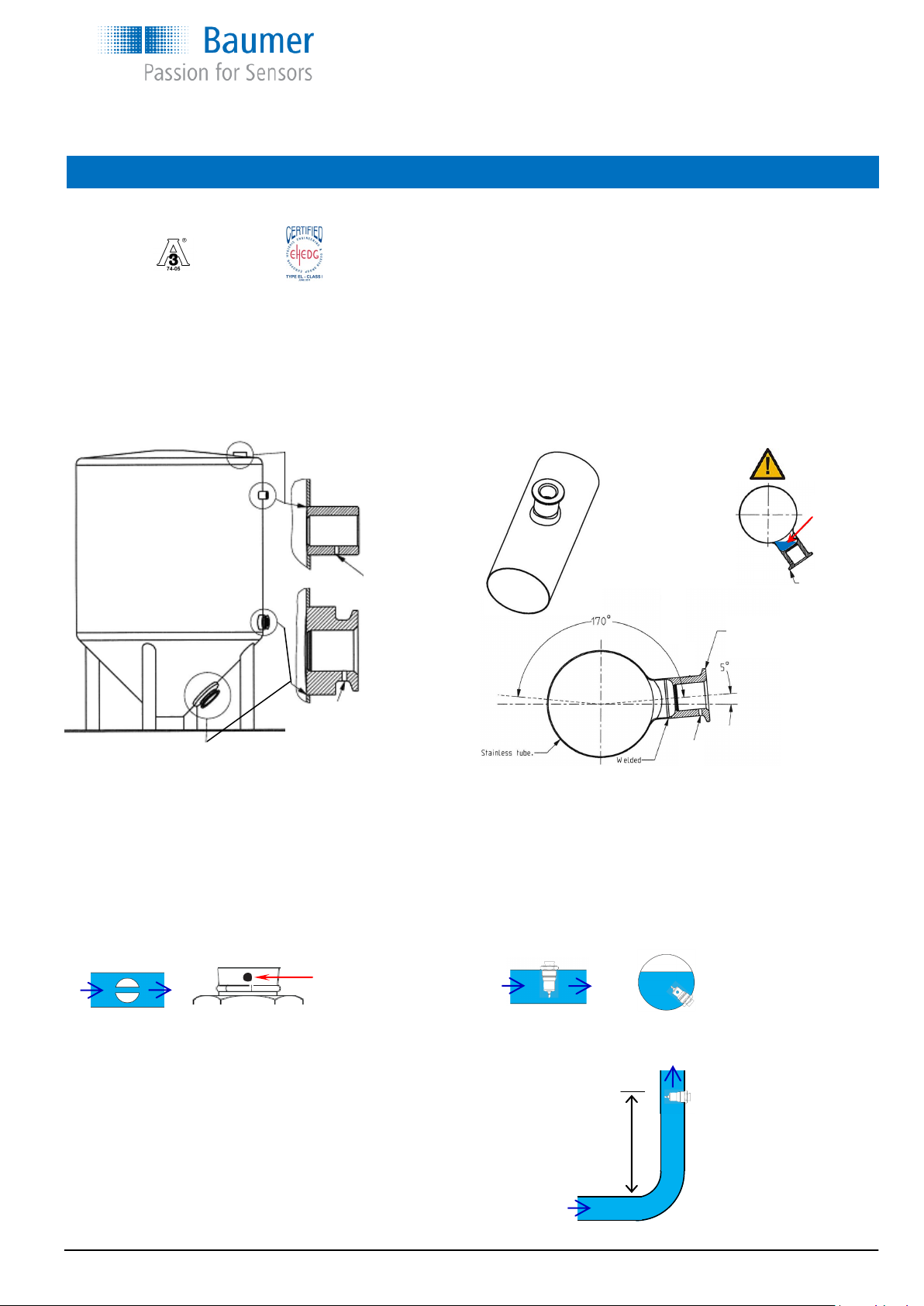

Mounting

Installation of 3A approved and EHEDG certified products:

1) Use only a 3A approved counter part

2) The inspection hole should be visible and drained

3) Mount the adapter in a self drained position/angle

4) Level the inner surface of the pipe with the counter part.

Example with

PM023 or PM053

Operators Instruction

5) The 3A mark or the arrow shall be placed upwards

6) Welding should be grinded to Ra= 0.8

7) Tighten the swirling nipple on the AFIx 20...25 Nm

8) Installed with correct torque the electrical connection

will point downwards

WARNING

Cannot be

drained

Example

with PM060-1

After installation

Check the leak tightness of the sleeve.

Leakage indication hole

must be places downwards

Check the tightness of glands or M12 plugs.

Check the tightness of the cover

The hole through the sensor must be in the flow direction

The marks on the

connection must

point in flow direction

There must be some bi-directional flow through the hole to ensure a

homogeneous media - i.e. correct measurement. There must be no

air-bubbles in the hole.

Example

with PM060-2

Fitted

incorrect

The sensor must be fully submersed in the media.

To avoid turbulence problems the sensor is recommended to mount in

a distance of >1 meter from a bend.

www.baumer.com

≥1 meter

Operators Instruction: 11126179 00 Page 5 / 36

Page 6

CombiLyz, AFI4

English

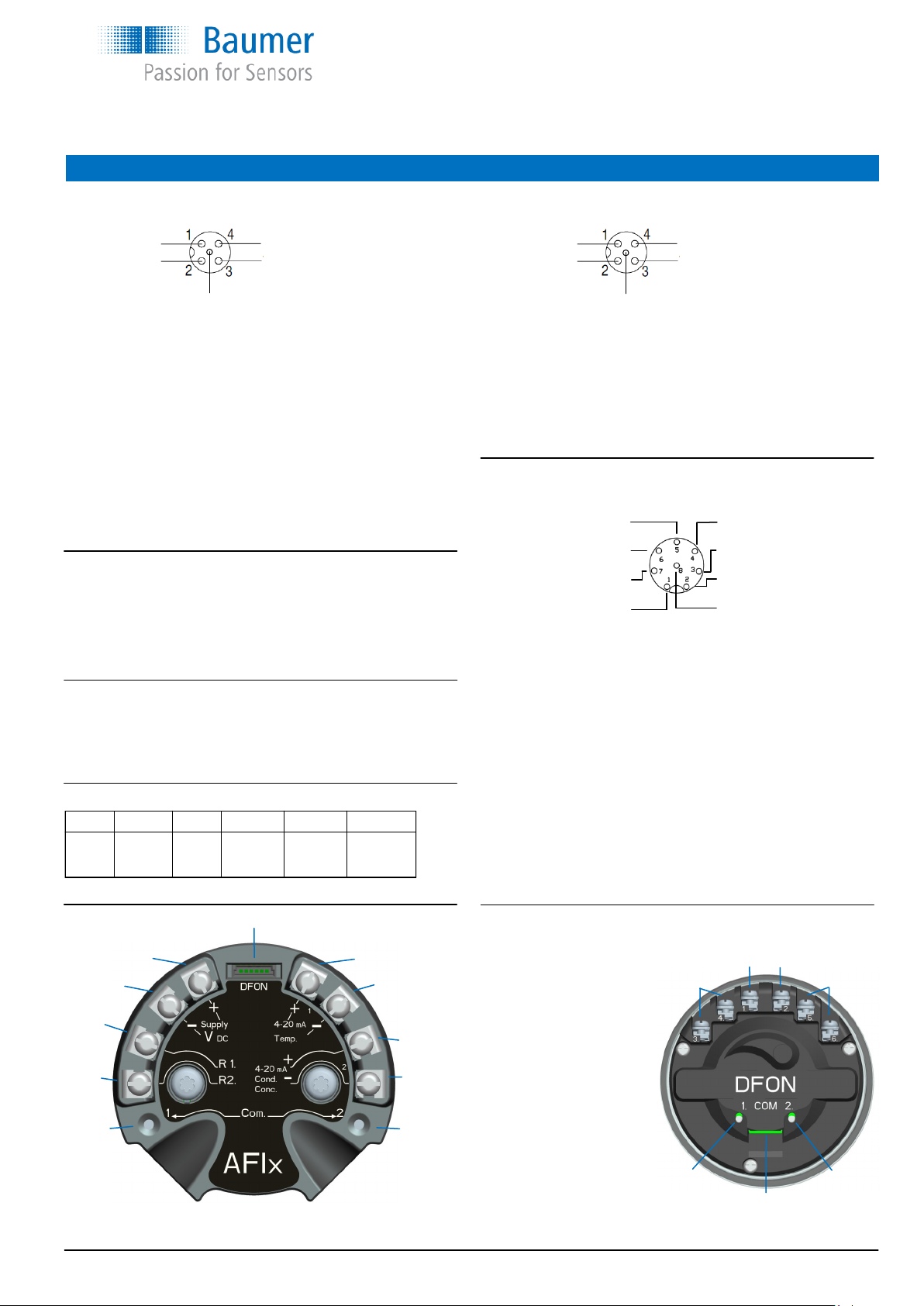

Electrical connection

Left side electrical connection (Front view) Right side electrical connection (Front view)

1 - 15...35 vdc (+)

2 - Cond. (-)

5 NC

Left side M12, 5-pin connector

1: Brown Supply (+) (15...35 vdc)

2: White Cond. (-) (4...20 mA)

3: Blue Supply (-) (15...35 vdc)

4: Black Cond. (+) (4...20 mA)

5: NC Not connected

Note:

If a M12 5-pin connector for left and right side is selected the

AFI4 is direct compatible with the old Baumer ISL conductivity

transmitter.

To connect the FlexProgrammer to the transmitter

Com 1 Red clip

Com 2 Black clip

Cond. (+) - 4

15...35 vdc (-) - 3

Operators Instruction

1 - R1

2 - °C (-)

5 NC

Right side M12, 5-pin connector

1: Brown R1 (external input)

2: White Temp. (-) (4...20 mA)

3: Blue R2 (external input)

4: Black Temp. (+) (4...20 mA)

5: NC Not connected

Right side electrical connection with relay output

Relay 1 - 5

Relay 1 - 6

Temp. (-) (4...20 mA) - 7

R1 (external input) - 1

°C (+) - 4

R2 - 3

4 - Relay 2

3 - Relay 2

2 - Temp (+) (4...20 mA)

8 - R2 (external input)

The data entered to the transmitter will automatically be uploaded to

the DFON display via the ribbon cable (UnitCom)

To connect the FlexProgrammer to the DFON display

Com 1 Red clip

Com 2 Black clip

For setting the colour changes, error messages, relay set-points etc.

To set the external input for range selection

Range R1 R2 Range R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

DFON (UnitCom)

Supply + Temp. +

Supply - Temp. -

R1

Cond. +

R2 Cond. -

Com 1 Com 2

Right side M12, 8-pin connector

1: White R1 (external input)

2: Brown Temp. (+) (4...20 mA)

3: Green Relay 2

4: Yellow Relay 2

5: Grey Relay 1

6: Light red Relay 1

7: Blue Temp. (-) (4...20 mA)

8: Red R2 (external input)

Note:

For ranges below 10 mS/cm a shielded cable must be used.

Electrical connection on the display with relay output

1: Not connected

2: Not connected

3: Green Relay 2

N.C. N.C.

Relay 2 Relay 1

4: Yellow Relay 2

5: Grey Relay 1

6: Light red Relay 1

(3 + 5 can be connected

common)

UnitCom Ribbon cable

to transmitter

To connect the

FlexProgrammer

COM 1 Red clip

Com 1 Com 2

UnitCom

COM 2 Black clip

www.baumer.com

Operators Instruction: 11126179 00 Page 6 / 36

Page 7

CombiLyz, AFI4

English

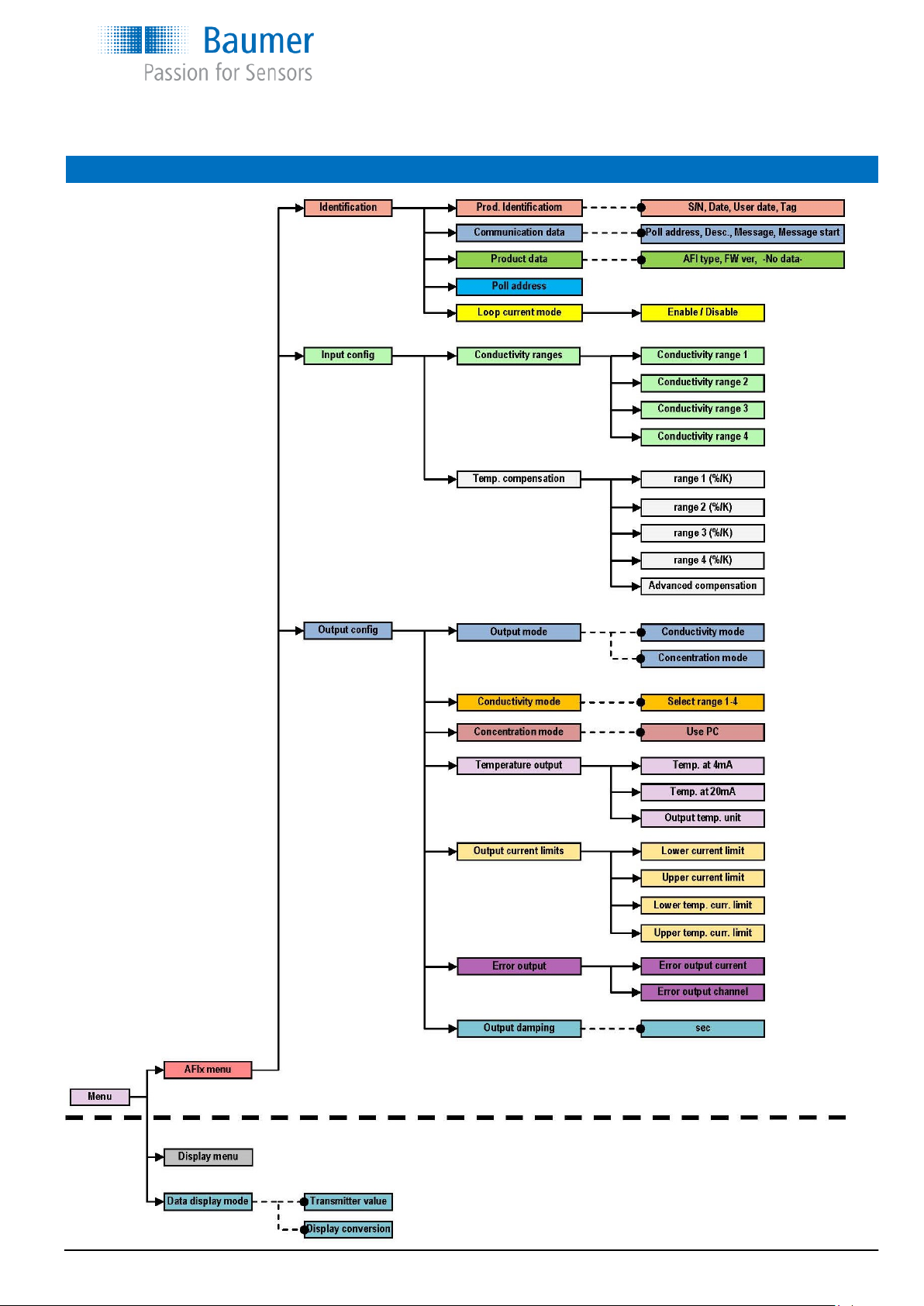

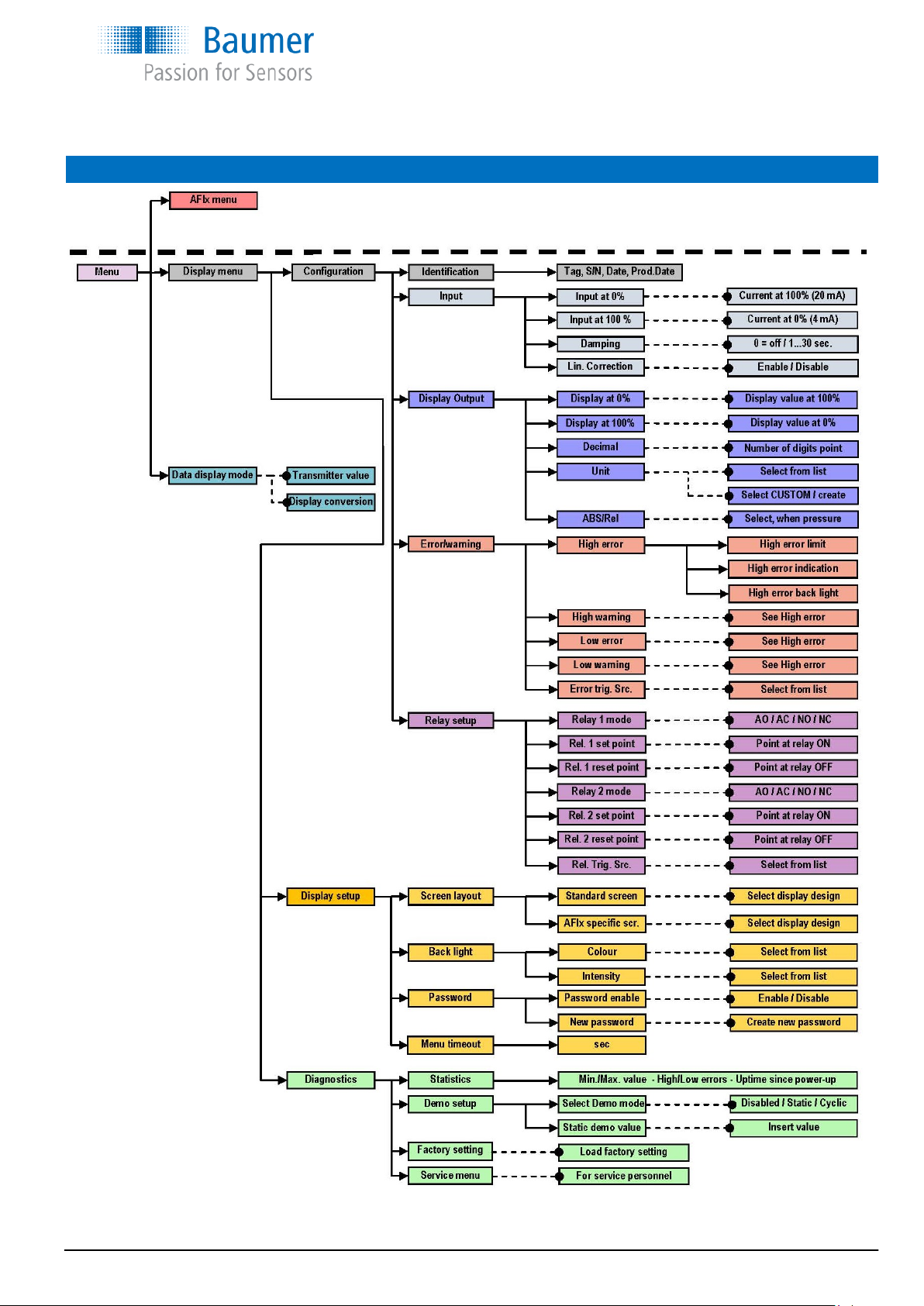

Operators Instruction

Programming the CombiLyz AFIx with touch screen on DFON display

www.baumer.com

Operators Instruction: 11126179 00 Page 7 / 36

Page 8

CombiLyz, AFI4

English

Operators Instruction

Programming the touch screen on DFON display on CombiLyz AFIx

www.baumer.com

Operators Instruction: 11126179 00 Page 8 / 36

Page 9

CombiLyz, AFI4

English

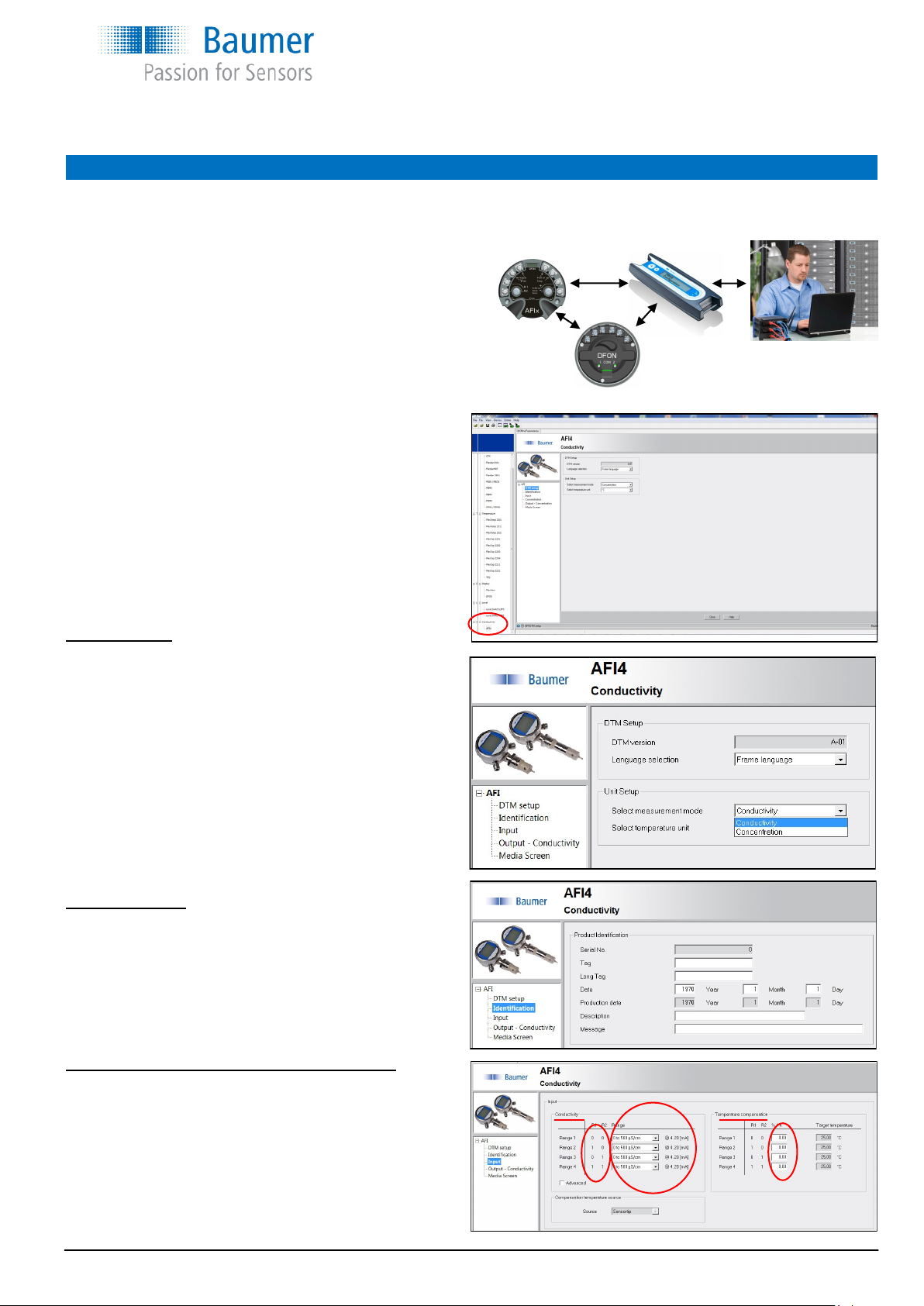

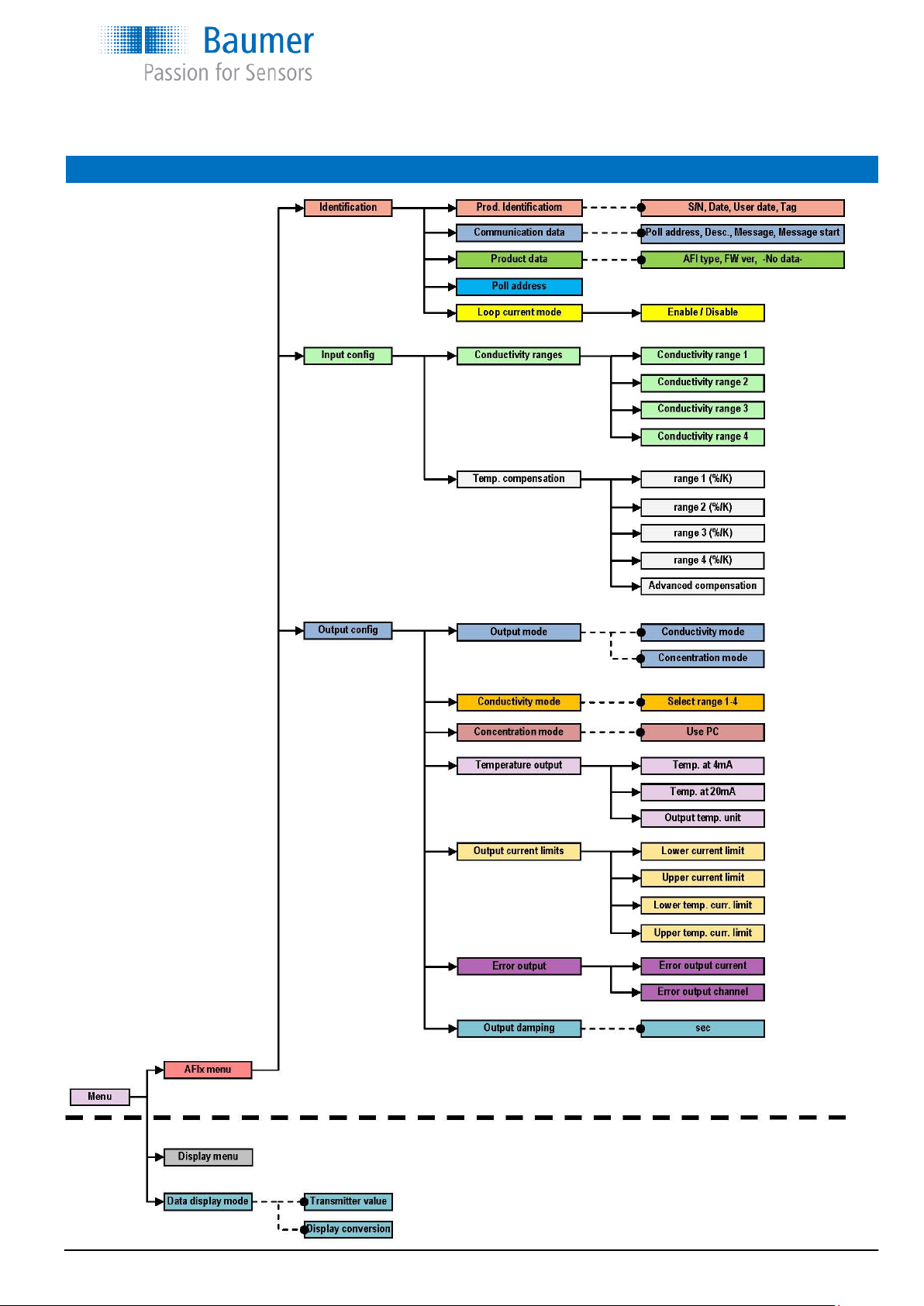

Programming the AFI4 with the FlexProgram

All settings can be individually programmed with the Baumer FlexProgram and programming unit FlexProgrammer 9701. All parameters, such as

conductivity range, concentration and output type, diagnostics, data logging, tag no., damping etc. can be configured using the FlexProgrammer

9701.

Integrated HELP-menus will give full instruction.

The programming entered to the AFIx transmitter will automatically

be uploaded to the DFON display through the UnitCom ribbon cable,

if Transmitter Value is selected in the programme or by the touch screen.

If Display Conversion is selected the DFON display can be programmed

individually, e.g. with other engineering units or ranges.

Open the FlexProgram

Select AFIx in the bottom and this screen will appear

Operators Instruction

Screen DTM setup

It is recommended to select

- “Frame language”

Select measurement mode:

- Conductivity or Concentration

Temperature unit °C or °F can also be selected.

Screen Identification

Enter TAG number Tag: 8 characters

Long tag: 30 characters

Date of 1

Description (16 characters)

Message (32 characters)

Screen Input (when conductivity is selected in DTM setup)

Setting for the 4 conductivity ranges. Selectable from drop

down menu with 14 defined ranges.

Factory setting will be

0...200 mS/cm

0… 20 mS/cm

0… 2 mS/cm

0…500 µS/cm

st

use (year/month/date)

How to connect the external input R1 and R2 is defined

in front of the ranges. (0=Not Connected / 1=24VDC)

www.baumer.com

Operators Instruction: 11126179 00 Page 9 / 36

Page 10

CombiLyz, AFI4

English

Operators Instruction

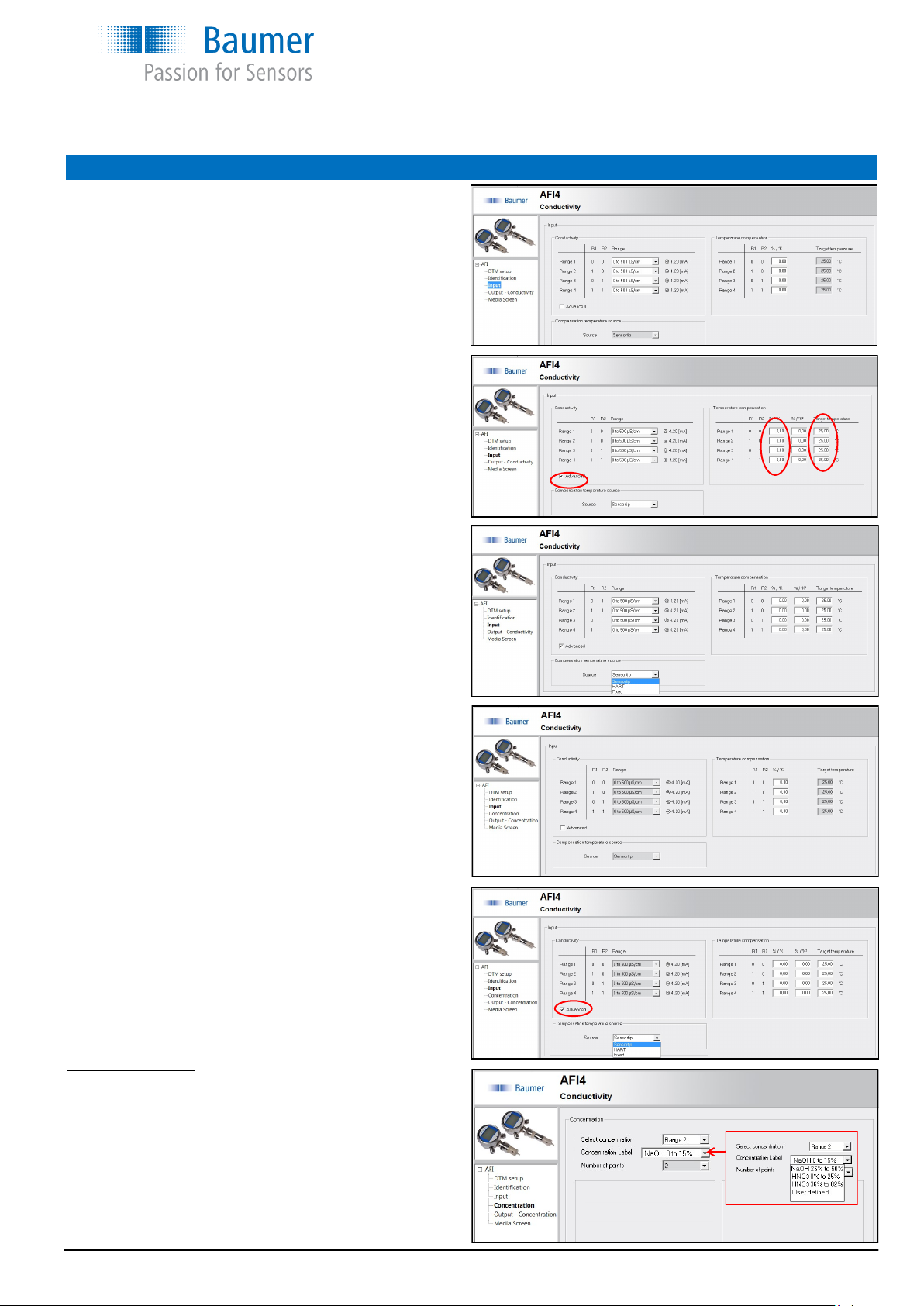

Programming the AFI4 with the FlexProgram

Setting of Temperature compensation for each range.

This will be factory set to 2%/°C as default.

If the box Advanced is ticked, it will be possible to enter an

other target temperature. This is as default set to 25°C, which is the

most common target temperature for most media. If another target

temperature is wanted, it can be entered.

NOTE:

This is not the specific media temperature, but the

“0-point” for the temperature compensation.

When the “Advanced” is ticked the “Compensation temperature

source” is accessible.

You can enter a value to the column %/K2 you will create a unlinear

curve.

These fields are not necessary to change for standard measurement.

Be careful if changing the default values, as wrong values in those

fields may course wrong measurement.

It is possible to select from where the temperature measuring shall

come from

Sensor tip (built in Pt100)

HART (external input via HART)

Fixed (no temperature measurement)

Screen Input (when concentration is selected in DTM setup)

No settings in this screen will be available as standard.

When user defined concentration is selected in screen concentration,

it will be possible to adjust temperature concentration.

The default setting will be 2%/°C.

Advanced settings

Here only “Compensation temperature source” will be available.

Screen Concentration

There is 4 selectable medias, for which the calibration curves

is default entered from factory.

NaOH (caustic soda) 0...15% by weight

NaOH - 25...50% by weight

HNO3 (Nitric acid) 0...25% by weight

HNO3 36...82% by weight

For user defined, please see next page.

www.baumer.com

Operators Instruction: 11126179 00 Page 10 / 36

Page 11

CombiLyz, AFI4

English

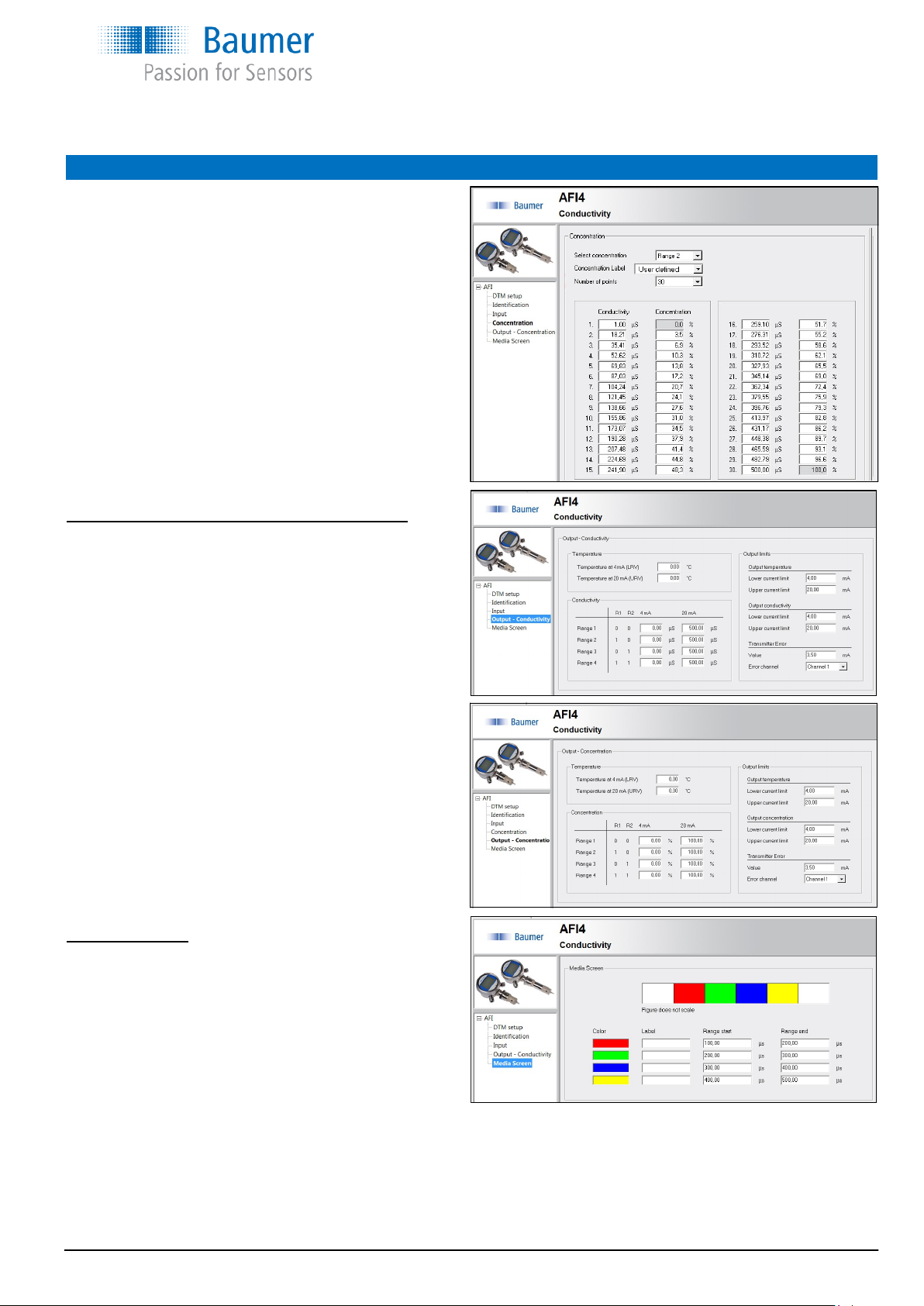

Programming the AFI4 with the FlexProgram

If user defined concentration is selected you may enter the number of

point (2...30 points) in which the media is to be calibrated.

Fill in conductivity in µS/cm and % for each point.

See example to the right.

Screen Output (when conductivity is selected in DTM setup)

Setting the temperature output range (4...20 mA)

Setting the conductivity µS/cm or mS/cm output 4 ranges (4...20 mA)

The ranges set under Input will appear, however can be overwritten if

wanted.

The transmitter error signal can be directed to either temperature output or conductivity output or both outputs.

Screen Output

Setting the temperature output range (4...20 mA)

Setting the concentration % output 4 ranges (4...20 mA)

The ranges set under Input will appear, however can be overwritten if

wanted.

The transmitter error signal can be directed to either temperature output or conductivity output or both outputs.

(when concentration is selected in DTM setup)

Operators Instruction

Screen Media screen

A product label can be entered in field “Label” e.g. Milk

and the values for the media entered in µS/cm in the two following

fields. Then the “Label” will appear on the display between the two

values (see media screens page 3)

(The colours is only informative, they will not appear on the display)

Example:

Water 600 µS/cm 700 µS/cm

Milk 4500 µS/cm 5500 µS/cm

CIP acid 9000 µS/cm 11000 µS/cm

CIP caustic 55000 µS/cm 65000 µS/cm

www.baumer.com

Operators Instruction: 11126179 00 Page 11 / 36

Page 12

CombiLyz, AFI4

Deutsch

Der CombiLyz AFI4 Leitfähigkeitstransmitter ist ein kompaktes Messgerät, basierend auf der Induktivtechnologie. Sowohl in hygienisch anspruchsvollen Applikationen als auch im industriellen Standard, liefert

der AFI4 zuverlässige Werte für die Leitfähigkeits- oder Medienkonzentrationsmessung.

Beschreibung

Der CombiLyz AFI4 besteht aus einem Leitfähigkeitssensor und einem

Transmitter in einer kompakten Einheit.

Der Transmitter ist mit zwei Analogausgängen ausgestattet. Einen für

die Temperatur- und einen für die Leitfähigkeits- bzw. Konzentrationsmessung.

Das Display zeichnet sich durch mehrere, vom Benutzer einstellbare

Modi sowie vom Benutzer definierbare „Produktetiketten“ und Warnmeldungen aus. Außerdem besitzt das Gerät zwei Schaltrelaisausgänge für

Alarm oder Steuerung.

Bei der Hintergrundfarbe hat der Benutzer die Wahl zwischen drei Farben - Weiß, Grün oder Rot - jeweils dauerhaft leuchtend oder je nach

eingestellten Warnwerten, auch blinkend.. Transmitter und Display können sowohl über den Touchscreen als auch mithilfe der FlexProgrammer Programmiereinheit und Software programmiert werden.

Bedienungsanleitung

Funktionsprinzip

Sicherheitshinweise

Dieses Gerät wurde gemäß den geltenden EU-Richtlinien gebaut und

geprüft und unter technisch sicheren Bedingungen verpackt. Um diese

Bedingungen aufrechtzuerhalten und einen sicheren Betrieb zu gewährleisten, muss der Anwender die in dieser Anleitung gegebenen Anweisungen und Warnhinweise befolgen.

Bei der Installation sind die im jeweiligen Land geltenden Vorschriften zu

beachten. Die Nichtbeachtung der Warnhinweise kann zu erheblichen

Personen- und Sachschäden führen.

Das Produkt darf nur von geschultem Personal bedient werden. Sachgemäßer Transport sowie eine sachgemäße Lagerung, Installation und

Bedienung sind entscheidend für einen korrekten und sicheren Betrieb

dieses Gerätes.

Die gesamte elektrische Verkabelung muss den örtlichen Standards

entsprechen. Um elektrische Störstrahlung zu vermeiden, empfehlen

wir, verdrillte und geschirmte Eingangskabel zu verwenden und die

Stromversorgungskabel von den Eingangskabeln getrennt zu halten. Die

Anschlüsse müssen gemäß den Schaltplänen ausgeführt werden.

Vor dem Einschalten der Spannungsversorgung ist darauf zu achten,

dass keine anderen Geräte beeinflusst werden. Es ist sicherzustellen,

dass die Versorgungsspannung und die Umgebungsbedingungen den

Spezifikationen für dieses Gerät entsprechen.

Vor dem Abschalten der Versorgungsspannung sind mögliche Auswirkungen auf andere Geräte und das gesamte System zu prüfen.

Die Messzelle ist ein homogener, versiegelter Korpus ganz aus PEEK,

welcher eine Bohrung aufweist, durch die das Medium fließt. Um diese

Bohrung herum befinden sich zwei Spulen: eine Primärspule mit ACSpannung und eine Sekundärspule, die durch die vom Medium induzierte Spannung ein kleines Signal aufnimmt. Die Größe dieser Spannung ist abhängig von der Leitfähigkeit des Mediums. Das Signal wird

in der Elektronik auf ein lineares analoges 4...20-mA-Ausgangssignal

verstärkt. Außerdem ist ein Pt100-Sensor eingebaut, der sich in der

Sensorspitze befindet. Dieser misst die Medientemperatur, um die

Temperaturkompensation des Leitfähigkeitssignals zu ermöglichen,

welches sehr temperaturabhängig ist. Das Pt100-Sensorsignal ist auch

als analoges 4...20-mA-Ausgangssignal verfügbar.

Die Spulen und der Sensor befinden sich im PEEK-Sensorgehäuse,

das eine Oberflächenrauheit (Ra) < 0,8 μm aufweist. Somit eignet sich

der Leitfähigkeitstransmitter ideal zur Verwendung in hygienischen

Prozessen oder direkt in konzentrierten Säuren oder Laugen

VAC

Bereichseinstellung

Eingang R1 und R2

~

A

D

CPU

Leitfähigkeit/Konzentration

D

4...20 mA Ausgang

A

4...20 mA Ausgang

Temperatur

Medium

WARNUNG

Das Gerät ist nicht für elektrische Installationen in explosionsgeschützten Bereichen zugelassen.

Nach der Montage des Gerätes ist unbedingt zu prüfen, ob das Gehäuse mit einem Erdpotenzial verbunden ist.

Das Produkt enthält mit Ausnahme des DFON-Displays keine direkt

austauschbaren Teile. Bei Fehlfunktion ist das Produkt zur Reparatur an

Baumer einzusenden.

www.baumer.com

Primärspule Sekundärspule

Pt100

DE/2014-04-29 Design und Spezifikationen können ohne vorherige Ankündigung geändert

Bedienungsanleitung: 11126179 00 Seite 12 / 36

Page 13

CombiLyz, AFI4

Deutsch

Technische Daten

Gehäuse FlexHousing, Ø 80 mm

Material Edelstahl, AISI 304

Prozessanschluss G1A, Druckschraube

(weitere Anschlussmöglichkeiten siehe, Seite 15)

Eintauchtiefe Standard 37 mm / 3A-Version 40,5 mm

Lange Version 83 mm / 3A-Version 87 mm

Material Nicht medienberührt Edelstahl AISI 304

Medienberührte Teile 37… mm PEEK Natura

83... Mm PEEK Natura+AISI 316L

Oberfläche Medienberührte Teile Ra < 0,8 µm

Messbereich Leitfähigkeit 0...500 µS/cm … 0…1,0 S/cm

14 Bereiche wählbar

Konzentration 4 Medien im Werk eingestellt

1 Bereich vom Kunden definierbar

Temperatur -30...150 °C

Frei programmierbarer Bereich

Genauigkeit Leitfähigkeit/Konzen. 0...500 µS/cm ≤ 1,5 %

(Sensor einschl. Transmitter) 0...1 / 0...500 mS/cm ≤ 1,0 %

0...1 S/cm ≤ 1,5%

Temperatur ≤ 0,4 % des gewählten Bereichs

Temperaturkompensation 0,0...5,0 %/°C, frei einstellbar

Kompensationsbereich -20...150 °C

Referenztemperatur 25 °C (einstellbar)

Ansprechzeit Leitfähigkeit/Konzentration

< 2,0 Sekunden

Temperatur, t90 < 15 Sekunden

Hochlaufphase ohne Display ≤ 10 Sekunden

Hochlaufphase mit Display ≤ 15 Sekunden

Normenkonformität und Zulassungen

Es gelten EU-Richtlinien 10/2011, 1935/2004, 2023/2006

FDA-Richtlinien PEEK: CFR 21.177.2415

Zulassungen 3A-Zulassung 74-06

EHEDG (beantragt)

Allgemeine Daten

Medientemperatur -20...140 °C

150 °C bis zu 1 Stunde

Mediendruck < 10 bar (heliumgeprüft)

Umgebungstemperatur Ohne Display-40...85 °C

Mit Display -30...80 °C

Isolationsspannung 500 VAC

Schutzart IEC 529 IP 67 / IP 69K

Bedienungsanleitung

Elektrische Daten

Spannungsversorgung 15...35 VDC

Ausgang Leitfähigkeit/Konzentration 4...20 mA

4...20 mA + HART

Temperatur 4...20 mA

Relais 2 Relais im Display enthalten

Temperaturdrift ≤ 0,1 %/°C

Elektr. Anschluss Linke Seite M12, 5-polig

M16 oder M20

Kabelverschraubung

Rechte Seite M12, 5-polig

(nur 4...20 mA-Ausgang)

M12, 8-polig

(4...20 mA- + Relais-Ausgang)

M16 oder M20

Kabelverschraubung

Material Kunststoff

Edelstahl

Relais

Kontakte 2 × Halbleiterrelais

Spannung 60 Vp

Display

Typ Grafisches LCD-Display, FSTN

Messbereich -9999...99999

Ziffernhöhe Max. 22 mm

Temperaturdrift ≤ 0,0001 %/°C innerhalb des

optimalen Bereichs -10...70 °C

≤ 0,00015 %/C außerhalb des

optimalen Bereichs

-30…-10 / 70...80 °C

Mechanische Daten

Material Polycarbonat

Schutzart IP 10 an den Klemmen

IP67/IP69K im FlexHousing

Produktkennzeichnung

Die Kennzeichnung auf dem Produkt erfolgt durch Lasergravur.

Siehe folgendes Beispiel

®

(in Arbeit)

Feuchtigkeit IEC 68.2.3898 %, kondensierend

Schwingungen IEC 60068.2.6 - Test Fc

1,0 mm

www.baumer.com

(2-13,2 Hz) 0,7g (13,2-100 Hz)

Bedienungsanleitung: 11126179 00 Seite 13 / 36

Page 14

CombiLyz, AFI4

Deutsch

Einrichtung des AFI4

Leitfähigkeitsmessungen sind sehr temperaturabhängig.

Die Werkseinstellung ist 2,0 %/°C

Das bedeutet, dass die Kompensation beim AFIx automatisch mit

diesem Faktor erfolgt. Ist die Temperaturabhängigkeit für das gemessene Medium bekannt, muss der betreffende Faktor eingestellt werden. Sollte der Faktor unbekannt sein, empfiehlt es sich, einen Durchschnittswert aus der obigen Tabelle zu verwenden.

Der Temperaturkompensationsfaktor kann von 0,0 … 5,0 %/°C eingestellt werden.

Konfiguration der Temperaturkompensation über den Touchscreen:

Typische Temperaturabhängigkeit

Medien Veränderung in % / °C

Säuren 1,0 … 1,6

Basen 1,8 … 2,2

Salze 2,2 … 3,0

Neutral. Wasser 2,0

Bedienungsanleitung

Leitfähigkeitsbereiche (wählbar)

0…500 µS/cm

0...1 mS/cm 0...10 mS/cm 0...100 mS/cm 0...1 S/cm

0...2 mS/cm 0...20 mS/cm 0...200 mS/cm

0...3 mS/cm 0...30 mS/cm 0...300 mS/cm

0...5 mS/cm 0...50 mS/cm 0...500 mS/cm

Definition: 1.000 µS/cm = 1.0 mS/cm

1.000 mS/cm = 1.0 S/cm

Leitfähigkeit in verschiedenen Medien:

Leitfähigkeit Mediengruppe Medium

55 nS/cm Wasser Ultrareines Wasser

1 µS/cm Reines Wasser

10 µS/cm Prozesswasser

100 µS/cm Nahrungsmittel Trinkwasser

Bier

1 mS/cm Milch

Orangensaft

10 mS/cm Apfelsaft

100 mS/cm Prozess Phosphorsäure

Chlorwasserstoffsäure

1000 mS/cm Natriumhydroxid

AFIx

Mess-

bereich

Konfiguration des Messbereichs über den Touchscreen:

Eine Anleitung zur Konfiguration mit FlexProgram und dem FlexProgrammer finden Sie im FlexProgram unter HILFE.

Der Ausgang für die Konzentration kann ebenfalls über den Touchscreen eingestellt oder mit FlexProgram konfiguriert werden.

Auch die Konfiguration der Displayfarben, Warnmeldungen und Relais

kann über Touchscreen (siehe Seite 8 und 9) oder FlexProgrammer

erfolgen.

Einstellung des externen Eingangs für die Bereichswahl

Bereich R1 R2 Bereich R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

Konzentrationsbereiche (wählbar)

NaOH (Natronlauge) 0...15 Gewichtsprozent (0...90 °C)

25...50 Gewichtsprozent (0...90 °C)

HNO3 (Salpetersäure) 0...25 Gewichtsprozent (0...80 °C)

36...82 Gewichtsprozent (0...80 °C)

1 x kundendefiniert

(30-Punkt-Linearisierung)

Wählbare Displayansichten, Leitfähigkeit Konzentration

Wert mit allen Werten Medium mit Werten Balkendiagramm mit Werten Konzentrationswert in %

gleiche Ansichten verfügbar wie für Leitfähigkeit

Wert mit Messstelle Medium mit Messstelle Balkendiagramm einschl. Temperatur

Visuelle Alarmmeldungen und Farben

Weißer Hintergrund Grüner Hintergrund Roter Hintergrund Roter Hintergrund und Fehlermeldung

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 14 / 36

Page 15

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Abmessungen

Vorderansicht Anschluss unten

Kurze Version 3A Versionen Standard Lange Version 3A Versionen Standard

40,5 mm 37 mm 87 mm 83 mm

82

Ø6,6

40,5

Ø25,5

Die beiden obigen Sensoren sind 3A-zugelassen bei Montage in einem der unten aufgeführten G1"-Montageadapter mit 3A-Zulassung

37

Ø6,6

Ø25,5

128

87

G1" Montageadapter

Schweißanschluss Clamp-Anschluss Schraubanschluss Überwurfmutter

Für Tanks

PM053 ISO 2852 DN38 CAM050-505 DIN 11851 DN 32 MAM050-032 MNF032

ISO 2852 DN51 CAM050-640 DIN 11851 DN 40 MAM050-040 MNF040

DIN 11851 DN 50 MAM050-050 MNF050

Für Rohre

83

DN 40...50 PM052-1 Variline, type N VAM053 SMS 1145 DN 38 SAM-038-1 SNF038

DN 65...150 PM052-2 SMS 1145 DN 51 SAM-051-1 SNF051

Weitere Adapter erhältlich, z. B. mit Standard-Industriegewinde. Siehe Datenblatt für Zubehör.

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 15 / 36

Page 16

CombiLyz, AFI4

Deutsch

Montage

Montage von 3A-zugelassenen und EHEDG-konformen Produkten:

1) Nur Montageteile mit 3-A Zulassung verwenden.

2) Es muss sichergestellt sein, dass alle Medien im Tank/Rohr

entleert sind.

3) Den Adapter und das Gerät in einer Position und einem Winkel

montieren, dass das Medium am und um den Sensorstutzen von

selbst ablaufen kann

4) Die innere Oberfläche des Rohres/Tanks mit dem Montageteil front-

bündig abschließen lassen.

Pending

Beispiel mit

PM023 oder PM053

Bedienungsanleitung

5) Die 3A-Markierung bzw. der Pfeil sollte nach oben zeigen

6) Schweißnähte sollten so bearbeitet werden, dass sie einen Wert

von Ra 0,8 aufweisen

7) Den drehbaren Anschluss am AFIx mit 20...25 Nm anziehen

8) Einer der elektrischen Anschlüsse sollte nun nach unten zeigen,

um die korrekte Flussrichtung zu gewährleisten.

WARNING

Kann nicht

abtropfen

Beispiel

mit PM060-1

Nach der Installation

Dichtigkeit der des Prozessanschlusses überprüfen.

Dichtigkeit der Kabelverschraubungen oder M12-Stecker

überprüfen.

Dichtigkeit des Deckels überprüfen.

Die Bohrung im Sensor muss in Fließrichtung zeigen

Die Kennzeichnungen

am Anschluss müssen

in Fließrichtung zeigen

Der Medienstrom durch die Bohrung muss in gewissem Maß bidirektional sein, um die Homogenität des Mediums und damit eine korrekte

Messung sicherzustellen. In der Bohrung dürfen keine Luftblasen

vorhanden sein.

Beispiel

mit PM060-2

Das Loch zur Undichtigkeits-

erkennung muss nach unten zeigen

Der Sensor muss vollständig in das Medium getaucht sein.

Um Probleme durch Verwirbelungen zu vermeiden, empfiehlt es sich,

den Sensor in einem Abstand > 1 Meter von eventuellen Biegungen

zu installieren.

Nicht korrekt

eingesetzt

www.baumer.com

≥1 Meter

Bedienungsanleitung: 11126179 00 Seite 16 / 36

Page 17

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Elektrischer Anschluss

Linksseitiger elektrischer Anschluss (Vorderansicht) Rechtsseitiger elektrischer Anschluss (Vorderansicht)

1 - 15...35 vdc (+)

2 - Cond. (-)

5 NC

Linke Seite, 5.poliger M12-Stecker

1: Brown Spannungsversorgung (+) (15...35 vdc)

2: Weiss Leitfähigkeit (-) (4...20 mA)

3: Blau Spannungsversorgung (-) (15...35 vdc)

4: Schwarz Leitfähigkeit (+) (4...20 mA)

5: NC Nicht belegt

Anmerkung:

Wenn für die linke und die rechte Seite ein 5-poliger M12-Stecker gewählt wird, ist der AFI4 direkt kompatibel mit dem Vorgängermodell,

dem Baumer Leitfähigkeitssensor ISL.

Anschluss des FlexProgrammer an den Transmitter

Com 1 Rote Klemme

Com 2 Schwarze Klemme

Cond. (+) - 4

15...35 vdc (-) - 3

1 - R1

2 - °C (-)

°C (+) - 4

R2 - 3

5 NC

Rechte Seite, 5-poliger M12-Stecker

1: Braun R1 (externer Eingang)

2: Weiß Temperatur (-) (4...20 mA)

3: Blau R2 (externer Eingang)

4: Schwarz Temperatur (+) (4...20 mA)

5: NC Nicht belegt

Rechtsseitiger elektrischer Anschluss mit Relaisausgang

Relais 2 - 5

Relais 2 - 6

Temp. (-) (4...20 mA) - 7

R1 (externer Eingang) - 1

4 - Relais 1

3 - Relais 1

2 - Temp (+) (4...20 mA)

8 - R2 (externer Eingang)

Die in den Transmitter eingegebenen Daten werden über das Flachbandkabel (UnitCom) automatisch in das DFON-Display hochgeladen.

Anschluss des Flexprogrammers an das DFON-Display

Com 1 Rote Klemme

Com 2 Schwarze Klemme

Zum Einrichten von Farbänderungen, Relais-Sollwerten usw

Einstellung des externen Eingangs für die Messbereichswahl.

Bereich R1 R2 Bereich R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

DFON (UnitCom)

Spannungsversorgung + Temperatur +

Spannungsversorgung - Temperatur -

R1

Leitfähig keit +

R2 Leitfähig-

keit -

Com 1 Com 2

Rechte Seite, 8-poliger M12-Stecker

1: Weiß R1 (externer Eingang)

2: Braun Temperatur (+) (4...20 mA)

3: Grün Relais 2

4: Gelb Relais 2

5: Grau Relais 1

6: Hellrot Relais 1

7: Blau Temperatur (-) (4...20 mA)

8: Rot R2 (externer Eingang)

Anmerkung:

Für Bereiche unter 10 mS / cm muss ein geschirmtes Kabel verwendet

werden.

Elektrischer Anschluss am Display mit Relaisausgang

1: Nicht belegt

2: Nicht belegt

3: Grün Relais 2

N.C. N.C.

Relais 2 Relais 1

4: Gelb Relais 2

5: Grau Relais 1

6: Hellrot Relais 1

(3 + 5 können gemeinsam

angeschlossen werden)

UnitCom Flachbandkabel

zum Transmitter

Zum Anschluss des

FlexProgrammer

COM 1 Rote Klemme

Com 1 Com 2

UnitCom

COM 2 Schwarze Klemme

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 17 / 36

Page 18

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Programmierung des CombiLyz AFIx mit Touchscreen auf dem DFON-Display

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 18 / 36

Page 19

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Programmierung des Touchscreens über das DFON-Display am CombiLyz AFIx

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 19 / 36

Page 20

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Programmierung des AFI4 mit FlexProgram

Alle Einstellungen können individuell mit dem Baumer FlexProgram und der Programmiereinheit FlexProgrammer 9701 vorgenommen werden.

Alle Parameter wie Leitfähigkeitsbereich, Konzentration und Ausgangstyp, Diagnose, Datenerfassung, Messstellen-Nr., Dämpfung usw. können mit

dem FlexProgrammer 9701 konfiguriert werden

Eine vollständige Anleitung dazu ist im HILFE-Menü des Programms

enthalten.

Die in den Transmitter AFIx eingegebene Programmierung wird automatisch

über das UnitCom-Flachbandkabel auf das DFON-Display hochgeladen,

wenn im Programm oder über den Touchscreen die Einstellung Transmitter Va

Value ausgewählt wurde.

Bei der Einstellung Display Conversion kann das DFON-Display

individuell programmiert werden, z. B. mit anderen Einheiten oder Messbereichen.

FlexProgram öffnen

Unten auf AFIx klicken, sodass der folgende Bildschirm erscheint

Bildschirm DTM Setup

Empfohlene Einstellung:

- „Frame Language“ (Rahmensprache)

Messmodus wählen:

- Conductivity (Leitfähigkeit) oder Concentration (Konzentration)

Außerdem kann die Temperatureinheit (°C / °F) eingestellt werden.

Bildschirm Identification

Folgende Daten eingeben:

Messstellen-Nr. (TAG) Tag: 8 Zeichen

Lange TAG-Nr. 30 Zeichen

Datum der ersten Verwendung (Jahr/Monat/Datum)

Bezeichnung (16 Zeichen)

Beschreibung (32 Zeichen)

Bildschirm Input (wenn im DTM-Setup „Leitfähigkeit“ (Conductivity)

gewählt wurde

Einstellung für die 4 Leitfähigkeitsbereiche. Auswählbar aus dem Drop

-down-Menü mit 14 vordefinierten Bereichen.

Werkseinstellung: 0...200 mS/cm

0… 20 mS/cm

0… 2 mS/cm

0…500 µS/cm

Wie die externen Eingänge R1 und R2 anzuschließen sind, ist

vor dem jeweiligen Bereich definiert. (0=Nicht belegt / 1=24VDC)

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 20 / 36

Page 21

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Programmierung des AFI4 mit FlexProgram

Einstellung der Temperaturkompensation für die jeweiligen Bereiche.

Die Werkseinstellung lautet standardmäßig 2 %/°C.

Wenn ein Haken in das Kontrollfenster vor Advanced (Erweitert) gesetzt wird, besteht die Möglichkeit, eine andere Solltemperatur einzugeben. Diese ist auf 25 °C voreingestellt, da dies die häufigste Solltemperatur für die meisten Medien ist. Wird eine andere Solltemperatur gewünscht, so kann diese eingegeben werden.

HINWEIS:

Hierbei handelt es sich nicht um die spezifische Temperatur des Medi-

ums, sondern um den „Nullpunkt“ für die Temperaturkompensation.

Wenn „Advanced“ markiert ist, kann auf die Option „Compensation

temperature source“ (Quelle für die Kompensationstemperatur) zugegriffen werden.

Sie können in die Spalte %/K2 einen Wert eingeben; dadurch entsteht

eine nicht lineare Kurve.

Für Standardmessungen ist es nicht erforderlich, diese Felder zu verändern. Gehen Sie sorgfältig vor, wenn Sie die voreingestellten Werte

verändern, da falsche Werte in diesen Feldern zu fehlerhaften Messungen führen können.

Es kann eingestellt werden, wo die Temperaturmessung stattfinden

soll

Sensor tip (eingebauter Pt100)

HART (externer Eingang über HART)

Fixed (feststehend keine Temperaturmessung)

Bildschirm Input (wenn im DTM-Setup

„Concentration“ (Konzentratrion) gewählt wurde

Standardmäßig sind auf diesem Bildschirm keine Einstellungen möglich. Wenn im Bildschirm „Concentration“ eine benutzerdefinierte Konzentration gewählt wurde, ist es möglich, die Temperaturkonzentration

einzustellen.

Die Standardeinstellung ist 2 %/°C

Advanced settings (Erweiterte Einstellungen)

Hier steht nur die Option „Compensation temperature source“ zur

Verfügung.

Bildschirm Concentration

Es gibt 4 wählbare Medien, für die die Kalibrierkurven

standardmäßig im Werk vorgegeben sind.

NaOH (Natronlauge ) 0...15 Gewichtsprozent

NaOH - 25...50 Gewichtsprozent

HNO3 (Salpetersäure) 0...25 Gewichtsprozent

HNO3 36...82 Gewichtsprozent

Für benutzerdefinierte Einstellungen siehe nächste Seite.

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 21 / 36

Page 22

CombiLyz, AFI4

Deutsch

Bedienungsanleitung

Programmierung des AFI4 mit FlexProgram

Wenn eine benutzerdefinierte Konzentration gewählt wurde, können

Sie die Anzahl der Punkte eingeben (2...30 Punkte), an denen das

Medium kalibriert werden soll.

Geben Sie für jeden Punkt die Leitfähigkeit in µS/cm und die Konzentration in % ein.

Siehe Beispiel rechts.

Bildschirm Output (wenn im DTM-Setup „Leitfähigkeit“ (Conductivity)

gewählt wurde

Einstellen des Temperaturausgangsbereichs (4...20 mA)

Einstellung des Ausgangs für die Leitfähigkeit in µS/cm oder mS/cm (4

Bereiche) (4...20 mA)

Hier erscheinen automatisch die unter „Input“ eingestellten Bereiche;

diese können aber bei Bedarf überschrieben werden.

Das Fehlersignal des Transmitters kann entweder auf den Temperaturausgang oder den Leitfähigkeitsausgang oder auf beide Ausgänge

gerichtet werden.

Bildschirm Output (wenn im DTM-Setup

„Concentration“ (Konzentration) gewählt wurde

Einstellen des Temperaturausgangsbereichs (4...20 mA)

Einstellen der 4 Konzentrationsausgangsbereiche (4...20 mA)

Hier erscheinen automatisch die unter „Input“ eingestellten Bereiche;

diese können aber bei Bedarf überschrieben werden.

Das Fehlersignal des Transmitters kann entweder auf den Temperaturausgang oder den Leitfähigkeitsausgang oder auf beide Ausgänge

gerichtet werden.

Bildschirm Media Screen

In das Feld „Label“ kann ein Produktetikett eingegeben werden, z. B.

Milch.

In den beiden folgenden Feldern können die Werte für die Medien in

µS/cm eingegeben werden. Das „Label“ erscheint dann zwischen den

beiden Werten auf dem Display (siehe Bildschirm „Media Screen“ auf

Seite 3).

(Die Farben haben nur informativen Charakter, sie erscheinen nicht

auf dem Display.)

Beispiel:

Wasser 600 µS/cm 700 µS/cm

Milch 4500 µS/cm 5500 µS/cm

CIP Säure 9000 µS/cm 11000 µS/cm

CIP Lauge 55000 µS/cm 65000 µS/cm

www.baumer.com

Bedienungsanleitung: 11126179 00 Seite 22 / 36

Page 23

CombiLyz, AFI4

Français

Le transmetteur de conductivité CombiLyz AFI4 est un capteur/

transmetteur compact basé sur la technologie inductive qui respecte les

exigences des secteurs hygiéniques et des industries qui ont recours à

la mesure de conductivité.

Description

CombiLyz AFI4 est composé d'un capteur de conductivité et d'un trans-

metteur intégrés dans une unité compacte.

La sortie du transmetteur est une sortie 4...20 mA pour la conductivité,

la concentration et la température.

L'afficheur possède davantage de modes sélectionnables par l'utilisateur, des « étiquettes produit » et des avertissements spécifiés par

l'utilisateur. En outre, il existe deux sorties de commutation pour les

alarmes ou la commande.

La couleur d'arrière-plan peut être réglée en trois couleurs, blanc, vert

ou rouge, de manière permanente ou clignotante, suivant les réglages

d'alarme. Le transmetteur et l'afficheur peuvent être programmés soit

par l'écran tactile sur l'afficheur, soit par l'unité de programmation et le

logiciel FlexProgrammer.

Instructions de sécurité

Ce produit est fabriqué et testé selon les directives européennes en

vigueur et conditionné dans des conditions sûres d’un point de vue technique. Pour le maintenir en bon état et garantir la sécurité de fonctionnement, l’utilisateur doit suivre les indications et les avertissements donnés

dans cette notice.

Les règlementations nationales applicables doivent être respectées au

cours de l'installation. Le non-respect de ces avertissements peut entraîner des blessures graves ou d’importants dommages matériels.

Ce produit doit être manipulé par un personnel ayant suivi une formation. De bonnes conditions de transport, de stockage, d'installation et

d'utilisation sont indispensables à un fonctionnement correct et sûr.

Tous les câblages électriques doivent être conformes aux normes locales. Pour éviter tout rayonnement électrique parasite, nous recommandons d'utiliser des câbles torsadés et blindés et aussi de maintenir

les câbles d'alimentation électrique séparés des câbles d'entrée. Le

branchement doit être réalisé conformément aux schémas de câblage.

Vérifiez que les autres parties de l’équipement ne seront pas affectées

avant de mettre en marche l’alimentation. Assurez-vous que la tension

d’alimentation et les conditions ambiantes respectent les spécifications

du dispositif.

Avant d’éteindre l’alimentation électrique, vérifiez les éventuels effets sur

le reste de l’équipement et sur le système de traitement.

Instructions pour les opérateurs

Principe de fonctionnement

La cellule de mesure est un corps étanche homogène, entièrement

fabriqué en PEEK. Le corps présente un trou à travers lequel s'écoulent

les fluides. Deux bobines sont intégrées autour du trou ; une bobine

principale alimentée en tension alternative et une bobine secondaire qui

capte un petit signal à travers la tension induite par les fluides. La grandeur de cette tension dépend de la conductivité des fluides. Ce signal

est traité et amplifié dans le système électronique pour donner un signal de sortie 4...20 mA analogique linéaire. Le corps contient également un capteur Pt100 positionné dans la pointe du capteur. Il est destiné à mesurer la température des fluides pour permettre la compensation de température du signal de conductivité qui dépend fortement de

la température. Le signal du capteur Pt100 présente également un

signal de sortie 4...20 mA analogique.

Les bobines et le capteur sont intégrés dans le corps de capteur PEEK,

avec une rugosité de surface (Ra) <0,8 μm. Il peut donc être utilisé

dans des process hygiéniques ou directement dans des acides ou des

alcalis concentrés.

VAC

Entrée de réglage

de plage R1 et R2

~

A

D

CPU

pour conductivité/

D

concentration

A

Sortie 4...20 mA

Sortie 4...20 mA

pour température

AVERTISSEMENT

Le dispositif n'est pas homologué pour des installations électriques dans

des zones antidéflagration.

Une fois le dispositif installé, vérifiez que le boîtier a un potentiel à la

terre.

Le produit contient des pièces non remplaçables, à l'exception de l'afficheur DFON. En cas de dysfonctionnement, le produit doit être renvoyé

à Baumer pour réparation.

www.baumer.com

Fluides

Bobine Bobine

principale secondaire

Pt100

FR/2014-04-29 Conception et les spécifications sont sujets à changement sans préavis

Instructions pour les opérateurs: 11126179 00 Page 23 / 36

Page 24

CombiLyz, AFI4

Français

Caractéristiques techniques

Boîtier FlexHousing, Ø80 mm

Matériau Acier inoxydable, AISI 304

Raccords de process G1A, rotatif

(pour les autres raccords, voir adaptateurs page 26)

Longueur d'insertion Standard 37 mm / version 3A 40,5

mmVersion longue 83 mm / version 3A 87 mm

Matériau,

Non en contact avec le fluide Acier inoxydable AISI 304

Pièces en contact avec le fluide 37… mm PEEK natura

83... mm PEEK natura+AISI 316L

Surface

Pièces en contact avec le fluide Ra <0,8 µm

Plage de mesure Conductivité 0...500 µS/cm … 0…1.0 S/cm

14 plages sélectionnables

Concentration 4 fluides/plages réglés en usine

1 fluide/plage défini par le client

Température -30...150°C

Plage librement programmable

Précision Cond./conc. 0...500 µS/cm ≤1,5 %

(capteur y comp. transmetteur) 0...1/0...500 mS/cm ≤1,0 %

0...1 S/cm ≤1,5 %

Température Plage sélectionnée ≤0,4 %

Compensation de température 0,0...5,0 %/°C, librement réglable

Plage de compensation 20...150°C

Température de référence 25°C (réglable)

Temps de réponse Cond./conc. <2,0 secondes

Température, t

Phase d'initialisation sans afficheur ≤10 secondes

Phase d'initialisation avec afficheur ≤15 secondes

<15 secondes

90

Conformité et homologations

Conforme aux Directives UE 10/2011, 1935/2004, 2023/2006

FDA PEEK : CFR 21.177.2415

Homologations Homologué 3A 74-06

EHEDG (en instance)

Caractéristiques générales

Température de fluide -20...140°C

150°C jusqu'à 1 heure

Pression du fluide <10 bar (testée à l'hélium)

Température ambiante Sans afficheur -40...85°C

Avec afficheur -30...80°C

Tension d'isolation 500 V CA

Classe de protection CEI 529 IP 67 / IP 69K

Instructions pour les opérateurs

Caractéristiques électriques

Alimentation électrique 15...35 V CC

Sortie Cond./Conc. 4...20 mA

4...20 mA + HART

Température 4...20 mA

Relais 2 relais inclus dans l'afficheur

Dérive en température ≤0,1 %/°C

Raccordement élec. Côté gauche M12, 5 pôles

Presse-étoupe M16 ou M20

Côté droit M12, 5 pôles

(sortie 4...20 mA uniquement)

M12, 8 pôles

(4...20 mA + sortie relais)

Presse-étoupe M16 ou M20

Matériau Plastique

Acier inoxydable

Relais

Contacts 2 relais statiques

Tension 60 Vp

Afficheur

Type LCD graphique FSTN

Plage de mesure -9999...99999

Hauteur des digits Max. 22 mm

Dérive en température ≤0,0001 %/°C

dans plage optimale

-10...70°C

≤0,00015 %/C

hors de plage optimale

-30…-10 / 70...80°C

Données mécaniques

Matériau Plastique polycarbonate

Classe de protection IP 10 sur terminaux

IP67/IP69K dans FlexHousing

Marquage du produit

Le marquage sur le produit est réalisé par gravure au laser.

Voir exemple ci-dessous :

®

(en instance)

Humidité CEI 68.2.38, 98 % avec condensation

Vibrations CEI 60068.2.6 - test Fc

1,0 mm

www.baumer.com

(2-13,2 Hz) 0,7 g (13,2-100 Hz)

Instructions pour les opérateurs: 11126179 00 Page 24 / 36

Page 25

CombiLyz, AFI4

Français

Mise en service de l'AFI4

La mesure de la conductivité dépend énormément de la température.

Le réglage en usine est de 2,0 %/°C.

Cela signifie que l'AFIx compensera automatiquement avec ce facteur.

Si la dépendance par rapport à la température est connue pour les

fluides, ce facteur doit être défini. Cependant, si le facteur est inconnu,

il est recommandé d'utiliser une valeur moyenne figurant dans le tableau ci-dessus.

Il est possible d'ajuster le facteur de compensation de température de

0,0 … 5,0 %/°C.

Configurer la compensation de température via l'écran tactile :

Dépendance typique par rapport à la température

Fluides % de changement par °C

Acides 1,0 … 1,6

Bases 1,8 … 2,2

Sels 2,2 … 3,0

Eau neutre 2,0

Configurer la plage via l'écran tactile :

Pour la configuration par le FlexProgram et FlexProgrammer, veuillez

consulter la rubrique AIDE dans le FlexProgram.

La sortie de concentration peut également être sélectionnée par

l'écran tactile ou programmée par le FlexProgram.

La programmation des couleurs d'affichage, des avertissements et des

relais peut être effectuée via l'écran tactile (voir pages 8 et 9) ou via le

FlexProgrammer.

Instructions pour les opérateurs

Plages de conductivité (sélectionnables)

0…500 µS/cm

0...1 mS/cm 0...10 mS/cm 0...100 mS/cm 0...1 S/cm

0...2 mS/cm 0...20 mS/cm 0...200 mS/cm

0...3 mS/cm 0...30 mS/cm 0...300 mS/cm

0...5 mS/cm 0...50 mS/cm 0...500 mS/cm

Définition: 1.000 µS/cm = 1.0 mS/cm

1.000 mS/cm = 1.0 S/cm

Conductivité dans différents fluides :

Conductivité Groupe de fluides Fluides

55 nS/cm Eau Eau ultra-pure

1 µS/cm Eau pure

10 µS/cm Eau de traitement

100 µS/cm Aliments Eau potable

Bière

1 mS/cm Lait

Jus d'orange

10 mS/cm Jus de pomme

100 mS/cm Traitement Acide phosphorique

Acide chlorhydrique

1000 mS/cm Hydroxyde de sodium

Pour régler l'entrée externe pour la sélection de plage

Plage R1 R2 Plage R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

Plages de concentration (sélectionnables)

NaOH (soude caustique) 0...15 % en poids (0...90°C)

25...50 % en poids (0...90°C)

HNO3 (acide nitrique) 0...25 % en poids (0...80°C)

36...82 % en poids (0...80°C

1 × défini par le client

Plage

AFIx

Vues d'affichage sélectionnables, Conductivité Concentration

Valur avec toutes Fluides avec valeurs Graphique en barre Valeur de concentration en %

les valeurs avec valeurs vues identiques à celles disponibles pour la conductivité

Vues avec TAG Fluides avec TAG Graphique en barre compr. temp.

Alarmes visuelles et couleurs

Arrière-plan blanc Arrière-plan vert Arrière-plan rouge Message d'erreur et arrière-plan rouge

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 25 / 36

Page 26

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Dimensions

Vue de face Raccordement inférieur

Version courte Versions 3A Standard Version longue Versions 3A Standard

40,5 mm 37 mm 87 mm 83 mm

82

Ø6,6

40,5

Ø25,5

Les deux capteurs ci-dessus sont homologués 3A lorsqu'ils sont montés dans un des adaptateurs de montage G1” homologués 3A ci-dessous

37

Ø6,6

Ø25,5

128

87

Adaptateurs de montage G1”

Raccord soudé Raccord clamp Raccords à visser Écrou-raccord

Pour réservoir

PM053 ISO 2852 DN38 CAM050-505 DIN 11851 DN 32 MAM050-032 MNF032

ISO 2852 DN51 CAM050-640 DIN 11851 DN 40 MAM050-040 MNF040

DIN 11851 DN 50 MAM050-050 MNF050

Pour tube

83

DN 40...50 PM052-1 Variline, type N VAM053 SMS 1145 DN 38 SAM-038-1 SNF038

DN 65...150 PM052-2 SMS 1145 DN 51 SAM-051-1 SNF051

Plus d'adaptateurs disponibles, p. ex. avec filetage industriel standard. Veuillez consulter la fiche technique relative aux Accessoires.

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 26 / 36

Page 27

CombiLyz, AFI4

Français

Montage

Installation de produits homologués 3A et certifiés EHEDG :

1) Utiliser uniquement une contre-pièce homologuée 3A

2) L'orifice d'inspection doit être visible et vidangé

3) Installer l'adaptateur dans une position / un angle permettant une

vidange automatique

4) Aligner la surface intérieure du tube et la contre-pièce.

Exemple avec

PM023 ou PM053

Instructions pour les opérateurs

5) La marque 3A ou la flèche doit être placée vers le haut

6) Les soudures doivent être polies au grain Ra ≤0,8 µm

7) Serrer le raccord à tourbillon sur l'AFIx à un couple de 20...25 Nm

8) Monté avec un couple approprié, le raccord électrique s'orientera

vers le bas

AVERTISSEMENT

Ne peut pas

être drainé

Exemple

avec PM060-1

Après installation

Vérifier l'étanchéité du manchon.

L'orifice d'écoulement doit

être dirigé vers le bas

Vérifier l'étanchéité des presse-étoupes ou des connecteurs M12

Vérifier l'étanchéité du couvercle

L'orifice à travers le capteur doit être dans le sens d'écoulement

Les marques sur le

raccord doivent être

dirigées dans le sens

d'écoulement

L'obtention d'un fluide homogène, c'est-à-dire d'une mesure correcte,

implique impérativement un écoulement bidirectionnel à travers l'orifice. Il ne doit pas y avoir de bulles d'air dans l'orifice.

Equipé

Exemple

avec PM060-2

incorrect

Le capteur doit être entièrement immergé dans le fluide.

Pour éviter les problèmes de turbulence, il est recommandé de monter le capteur à une distance supérieure à 1 mètre par rapport à un

coude.

www.baumer.com

≥1 mètre

Instructions pour les opérateurs: 11126179 00 Page 27 / 36

Page 28

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Raccordements électriques

Raccordement électrique côté gauche (vue de face) Raccordement électrique côté droit (vue de face)

1 - 15...35 vdc (+)

2 - Cond. (-)

5 NC

Connecteur M12, 5 pôles côté gauche

1 : Marron Alimentation (+) (15...35 V CC)

2 : Blanc Cond. (-) (4...20 mA)

3 : Bleu Alimentation (-) (15...35 V CC)

4 : Noir Cond. (+) (4...20 mA)

5 : NR Non raccordé

Remarque :

Si un connecteur M12, 5 pôles pour les côtés gauche et droit est sélectionné, le AFI4 est directement compatible avec l'ancien transmetteur

de conductivité ISL Baumer.

Cond. (+) - 4

15...35 vdc (-) - 3

1 - R1

2 - °C (-)

°C (+) - 4

R2 - 3

5 NC

Connecteur M12, 5 pôles côté droit

1 : Marron R1 (entrée externe)

2 : Blanc Temp. (-) (4...20 mA)

3 : Bleu R2 (entrée externe)

4 : Noir Temp. (+) (4...20 mA)

5 : NR Non raccordé

Raccordement électrique côté droit avec sortie relais

Relais 2 - 5

Relais 2 - 6

4 - Relais 1

3 - Relais 1

Pour raccorder le FlexProgrammer au transmetteur

Com 1 Clip rouge

Com 2 Clip noir

Les données entrées dans le transmetteur seront automatiquement

chargées dans l'afficheur DFON via le câble ruban (UnitCom)

Pour raccorder le FlexProgrammer à l'afficheur DFON

Com 1 Clip rouge

Com 2 Clip noir

Pour régler les changements de couleur, les messages d'erreur, les

valeurs de consigne des relais, etc.

Pour régler l'entrée externe pour la sélecon de gamme

Plage R1 R2 Plage R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

DFON (UnitCom)

Alimentation + Temp.

Alimentation - Temp. -

R1

Cond. +

R2 Cond. -

Com 1 Com 2

www.baumer.com

Temp. (-) (4...20 mA) - 7

R1 (entrée externe) - 1

2 - Temp (+) (4...20 mA)

8 - R2 (entrée externe)

Connecteur M12, 8 pôles côté droit

1 : Blanc R1 (entrée externe)

2 : Marron Temp. (+) (4...20 mA)

3 : Vert Relais 2

4 : Jaune Relais 2

5 : Gris Relais 1

6 : Rouge clair Relais 1

7 : Bleu Temp. (-) (4...20 mA)

8 : Rouge R2 (entrée externe)

7: Blue Temp. (-) (4...20 mA)

Remarque :

Pour les plages de moins de 10 mS / cm un câble blindé doit

être ulisé.

Raccordement électrique sur l'afficheur sans sortie relais

1 : Non raccordé

2 : Non raccordé

3 : Vert Relais 2

4 : Jaune Relais 2

5 : Gris Relais 1

6 : Rouge clair Relais 1

(3 + 5 peuvent être raccor

dés en commun)

UnitCom

Câble ruban

vers transmetteur

Pour raccorder le

FlexProgrammer

COM 1 Clip rouge

COM 2 Clip noir

Instructions pour les opérateurs: 11126179 00 Page 28 / 34

N.C. N.C.

Relais 2 Relais 1

Com 1 Com 2

UnitCom

Page 29

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Programmation du CombiLyz AFIx avec l'écran tactile sur l'afficheur DFON

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 29 / 36

Page 30

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Programmation de l'écran tactile sur l'afficheur DFON sur CombiLyz AFIx

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 30 / 36

Page 31

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Programmation de l'AFI4 avec le FlexProgram

Tous les réglages peuvent être programmés individuellement à l'aide du FlexProgram de Baumer et de l'unité de programmation FlexProgrammer

9701. Tous les paramètres, tels que la plage de conductivité, le type de concentration et de sortie, les diagnostics, la collecte de données, le n° de

tag, l'amortissement, etc. peuvent être configurés à l'aide du FlexProgrammer 9701.

Les menus d'AIDE intégrés présentent toutes les instructions.

La programmation entrée dans le transmetteur AFIx sera automatiquement

chargée dans l'afficheur DFON via le câble ruban UnitCom,

si la Valeur de transmission est sélectionnée dans le programme ou via

l'écran tactile.

Si on sélectionne Conversion afficheur, l'afficheur DFON peut être programmé

individuellement, p. ex. avec d'autres unités scientifiques ou d'autres

plages.

Ouvrir le FlexProgram

Sélectionner AFIx en bas pour faire apparaître cet écran

Écran Réglage DTM

Il est recommandé de sélectionner

- « Langage de programmation »

Sélectionner le mode de mesure :

- Conductivité ou Concentration

Il est également possible de sélectionner l'unité de

température °C ou °F.

Écran Identification

Saisir le numéro TAG Tag : 8 caractères

Tag long : 30 caractères

Date de 1ère utilisation (année/mois/jour)

Description (16 caractères)

Message (32 caractères)

Écran Entrée (lorsque conductivité est sélectionné dans le Réglage

DTM)

Réglage pour les 4 plages de conductivité. Sélection à partir du menu

déroulant avec 14 plages définies.

Les réglages d'usine seront les suivants :

0…200 mS/cm

0…20 mS/cm

0…2 mS/cm

0…500 µS/cm

La manière de raccorder l'entrée externe R1 et R2 est définie

devant les plages. (0=Non raccordée / 1=24 V CC)

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 31 / 36

Page 32

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Programmation de l'AFI4 avec le FlexProgram

Réglage de la compensation de température pour chaque plage.

Elle sera réglée en usine à 2 %/°C par défaut.

Si la case Avancé est cochée, il est possible de saisir une

autre température cible. Elle est réglée, par défaut, à 25°C, ce qui est

la température cible la plus courante pour la plupart des fluides. Il est

possible de saisir une autre température cible si on le souhaite.

REMARQUE :

Il ne s'agit pas de la température spécifique du fluide mais du

« point 0 » pour la compensation de température.

Lorsque la case « Avancé » est cochée, le champ « Source de température de compensation » est accessible.

Vous pouvez saisir une valeur dans la colonne %/K2 pour créer une

courbe non linéaire.

Ces champs ne sont pas nécessaires pour modifier la mesure standard. Attention : en cas de changement des valeurs par défaut, ne pas

saisir de mauvaises valeurs dans ces champs au risque d'entraîner

des erreurs de mesure.

Ces champs ne sont pas nécessaires pour modifier la mesure standard. Attention : en cas de changement des valeurs par défaut, ne pas

saisir de mauvaises valeurs dans ces champs au risque d'entraîner

des erreurs de mesure.

Il est possible de sélectionner l'origine de la mesure de la température,

à savoir

Pointe du capteur (intégrée dans Pt100)

HART (entrée externe via HART)

Fixe (pas de mesure de température)

Écran Entrée (lorsque concentration est sélectionné dans le Réglage

DTM)

Dans cet écran, aucun réglage n'est proposé de série.

Lorsque l'on sélectionne Concentration définie par l'utilisateur dans

l'écran Concentration,

il est possible de régler la concentration de température.

Le réglage par défaut est de 2%/°C.

Réglages avancés

Ici, seule la « Source de température de compensation » est disponible.

Écran Concentration

4 fluides sont proposés au choix, pour lesquels les caractéristiques

sont entrées par défaut en usine.

NaOH (soude caustique) 0...15 % en poids

NaOH - 25...50 % en poids

HNO3 (acide nitrique) 0...25 % en poids

HNO3 36...82 % en poids

Pour la concentration définie par l'utilisateur, voir page suivante.

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 32 / 36

Page 33

CombiLyz, AFI4

Français

Instructions pour les opérateurs

Programmation de l'AFI4 avec le FlexProgram

Si l'on sélectionne Concentration définie par l'utilisateur, il faut saisir le

nombre de points (2...30 points) auxquels le fluide doit être calibré.

Pour chaque point, remplir la conductivité en µS/cm et en %.

Voir exemple à droite.

Écran Sortie (lorsque conductivité est sélectionné dans le Réglage

DTM)

Réglage de la plage de sortie de température (4...20 mA)

Réglage des 4 plages de sortie de conductivité en µS/cm ou mS/cm

(4...20 mA)

Les plages définies à l'écran Entrée apparaîtront mais peuvent toutefois être écrasées si on le souhaite.

Le signal d'erreur du transmetteur peut concerner la sortie de température, la sortie de conductivité ou les deux sorties.

Écran Sortie (lorsque concentration est sélectionné dans le Réglage DTM)

Réglage de la plage de sortie de température (4...20 mA)

Réglage des 4 plages de sortie de concentration en % (4...20 mA)

Les plages définies à l'écran Entrée apparaîtront mais peuvent toutefois être écrasées si on le souhaite.

Le signal d'erreur du transmetteur peut concerner la sortie de température, la sortie de conductivité ou les deux sorties.

Écran Écran des fluides

Une étiquette de produit peut être entrée dans le champ « Étiquette »,

ex : lait et les valeurs du fluide saisies en µS/cm dans les deux

champs suivants. Ensuite, l'« étiquette » apparaît sur l'afficheur entre

les deux valeurs (voir Écran des fluides, page 3)

(Les couleurs sont uniquement indiquées à titre d'information, elles

n'apparaissent pas sur l'afficheur)

Exemple :

Eau 600 µS/cm 700 µS/cm

Lait 4500 µS/cm 5500 µS/cm

NEP acide 9000 µS/cm 11000 µS/cm

NEP caustique 55000 µS/cm 65000 µS/cm

www.baumer.com

Instructions pour les opérateurs: 11126179 00 Page 33 / 36

Page 34

CombiLyz, AFI4

Operators Instruction

www.baumer.com

Operators Instruction: 11126179 00 EN Page 34 / 36

Page 35

CombiLyz, AFI4

Operators Instruction

www.baumer.com

Operators Instruction: 11126179 00 EN Page 34 / 36

Page 36

CombiLyz, AFI4

Operators Instruction

Baumer AG

Hummelstrasse 17

8501 Frauenfeld

Switzerland

+41 51 / 75 81 122

+41 52 / 72 81 144

sales.ch@baumer.com

www.baumer.com

Baumer A/S

Runetoften 19

8210 Aarhus V

Denmark

+45 8931 7611

+45 8931 7610

sales.cc-lct@baumer.com

Contact your local Baumer company

or Baumer distributor.

Please see:

www.baumer.com/worldwide

Select your country

Select your contact

Operators Instruction: 11126179 00 EN Page 36 / 36

Loading...

Loading...