Page 1

BCG625-SS/W/BL/R/IV

60 cm Twin cavity gas

cooker

y

1

Page 2

User Manual for your Baumatic

BCG625-SS/W/BL/R/IV

60 cm Twin cavity gas cooker

NOTE: This User Instruction Manual contains important

information, including safety & installation points, which will

enable you to get the most out of your appliance. Please keep it

in a safe place so that it is easily available for future reference; for

you or any person not familiar with the operation of the appliance.

JW 20/05/13

2

Page 3

Contents

Environmental note 4

Important safety information 5 – 8

Specifications 9 – 12

Dimensions 9

Product specifications 9

Standard accessories 10

Electrical details 10

Gas details 10

Product features 10

Control panel 11 - 12

Oven timer 12

Setting and using the oven programmer/timer 13

Setting the time of day 13

Setting the minute minder function 13

Using the oven 14 - 17

Before first use 14

Using the main oven 15

Base burner appliances 16

Using the grill 17

Cooking guidelines 18

Warnings 18

Using the hob top 19 – 20

Before first use 19

Using the hob top zones 19

Hob guidelines 20

Cleaning and maintenance 20 – 24

Cleaning the gas hob top 21

After each use 21

Cleaning the burners 22

Cleaning the oven 22

Replacing the oven bulb 23

Removing the oven door for cleaning 23 - 24

Installation 24 - 37

Positioning 24 - 26

Ventilation requirements 26

Safety chain anchors 26 - 27

Securing the safety chains 27

Electrical connection 28 - 29

Gas connection 29

Gas safety 30

Gas connection 30 - 31

Gas adjustment (conversion to LPG for the hob top) 32

Minimum flow adjustment for hob gas taps 33

Gas adjustment (conversion to LPG for the oven and grill) 34 - 35

Minimum flow adjustment for the oven and grill burners 35 - 37

My appliance isn’t working correctly 37 - 39

Baumatic consumables 40

Contact details 43

3

Page 4

Environmental note

o The packaging mater ials that Baumatic uses are e nvironmentally

friendly and can be recycled.

o Please discard all packaging material with due regard for the

environment.

4

Page 5

Important safety information

Your safety is of the utmost importance to Baumatic.

Please make sure that you read this in struction booklet

before attempt ing to instal l or use the applianc e. If yo u

are unsure of any of the information contained in this

booklet, please contact the Baumatic Advice Line.

General Information

o This appliance is designed for domestic household use and for

the cooking of domestic foodstuffs.

o IMPORTANT: The adjacent furniture and all materials used in

the installation must be able to withstand a minimum

temperature of 85°C above the ambient temperature of the

room it is located in, whilst in use.

o Certain types of vinyl or laminate kitchen furniture are

particularly prone to heat damage or discolouration at

temperatures below the guidelines given above.

o IMPORTANT: Baumatic Ltd. DO NOT recommend that this

appliance is installed on any type of marine vessel.

o The use of this appliance for any other purpose or in any other

environment without the express agreement of Baumatic Ltd.

will invalidate any warranty or liability claim.

o Your new appliance is guaranteed against electrical or

mechanical defects, subject to certain exclusions that are noted

in Baumatic’s Conditions Of Guarantee. The foregoing does not

affect your statutory rights.

o Repairs may only be carried out by Baumatic service

engineers or their authorised service agents.

Warning and safety instructions

o This appliance complies with all current European safety

legislation. Baum atic do wish to emphas ise that this compliance

does not remove the fact that the appliance surfaces will

become hot during use and retain heat after operation.

5

Page 6

o This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision o r instruction concerning use of the appliance

by a person responsible for their safety.

Child Safety

o Baumatic strongly recommend that babies and young children

are prevented from being ne ar to the appliance and not a llowed

to touch the appliance at any time. During and after use, all

surfaces will become hot.

o If it is necessary for younger family members to be in the

kitchen, please ensure that they a re kept unde r clos e supe rv ision

at all times.

General Safety

Make sure that you understand the controls before using the

appliance.

Check that all of the controls on the appliance are turned off

after use.

Always stand back when opening the oven door, this will allow

heat to disperse.

Take care when removing items from the oven, as the contents

may be hot.

Always keep the oven doors closed when the oven is not in use.

Always follow the basic pri nciples of food handlin g and hygiene;

this will prevent the possibility of bacterial growth.

Always keep ventilation slots clear of obstructions.

Keep fingers away from the hinge ar eas when closing the door,

otherwise you may trap them.

Oven gloves should be used when placing food in the oven cavity

and when removing it. Care should be taken to avoid direct

contact with any of the elements in the appliance.

o DO NOT LEAVE THE APPLIANCE UNATTENDED WHILST IN

USE.

6

Page 7

o Do not place heavy objects on the oven door or lean on the

oven door when it i s o pe n, as this can cause damage to the ove n

door hinges. Nobody should be allowed to sit or stand on any

part of the cooker.

o Do not store chemicals, food stuffs, pressurised containers in or

on the cooker or in cabinets immediately above or next to the

cooker.

o Do not heat up uno pened food c ontaine rs, as pre ssure c an build

up which may cause the container to burst.

o Do not place flammable or plastic items on or near the hob

burners, these types of materials should also not be placed in

the oven or the compartment below the oven.

o Do not leave heated oil or fat u nattended, as this is a fire risk.

You should not fill a deep fat frying pan mo re than one third full

of fat or oil; you should also not use a lid.

o Do not allo w fat or oil to build up in t he oven trays, grill pan o r

oven base.

o Do not place pans or baking trays directly on the base of the

oven cavity, or line it with aluminium foil.

o Do not grill food containing fat without using a grill trivet. The

grill trivet should never be covered with aluminium foil.

o Do not place hot parts in water, leave them to cool first.

o Do not allow vinegar, coffee, milk, saltwater, lemon, tomato

juice or any liquid with high su gar content to remain in contact

with the enamel parts of the appliance. Spillages should be

wiped up immediately.

o Do not allow electrical fittings or cables to come into contact

with areas on the appliance that get hot.

o Do not use the applia nce to heat the r oom it is located in o r to

dry clothing. No clothing should be placed over or near to the

hob burners or oven door.

o Do not install the appliance next to curtains or soft furnishings.

o Do not attempt to lift or move cooking appliances by usi ng the

oven door or handle, as this may cause da mage to the appliance

or result in injury to the person lifting the appliance.

7

Page 8

Cleaning

o Cleaning of the oven should be carried out on a regular basis.

o Great care should be take n whilst using this appliance and when

following the cleaning procedure.

o IMPORTANT: The appliance must be disconnected from the

mains before following the cleaning procedure.

o IMPORTANT: Care must be take n when cleaning between

the door glasses, and inside the inner frame as some of

the edges maybe sharp due to the manufacturing process.

Installation

This appliance must be correctly installed by a suitably

qualified person, strictly in accordance with the

manufacturer’s instructions. Please see the specific

section of this booklet that refers to installation.

o Baumatic Ltd. declines any responsibility for injury or

damage, to person or property, as a result of improper

use or installation of this appliance.

o Heat, steam and moisture will be created during use of the

appliance, take care to avo id injury and ensure that the room is

adequately ventilated. If the appliance is going to be used for

prolonged periods of time, then additional ventilation may be

required.

o Please consult with y our qualif ie d installer if you are in any doubt

about the amount of ventilation that you will require.

Declaration of conformity

This appliance complies with the following European Directives:

-73/23/EEC regarding “low voltage”

-89/336/EEC regarding “electromagnetic disturbances”

-89/109/EEC regarding “materials in contact with food”.

o The above directives comply with 93/68/EEC regarding CE

marking.

o The manufacturer declares that the oven is built using certified

materials and requires the appliance to be installed in

accordance with the standards currently in force . This appliance

must be used by a trained person for domestic purposes only.

8

Page 9

Specifications

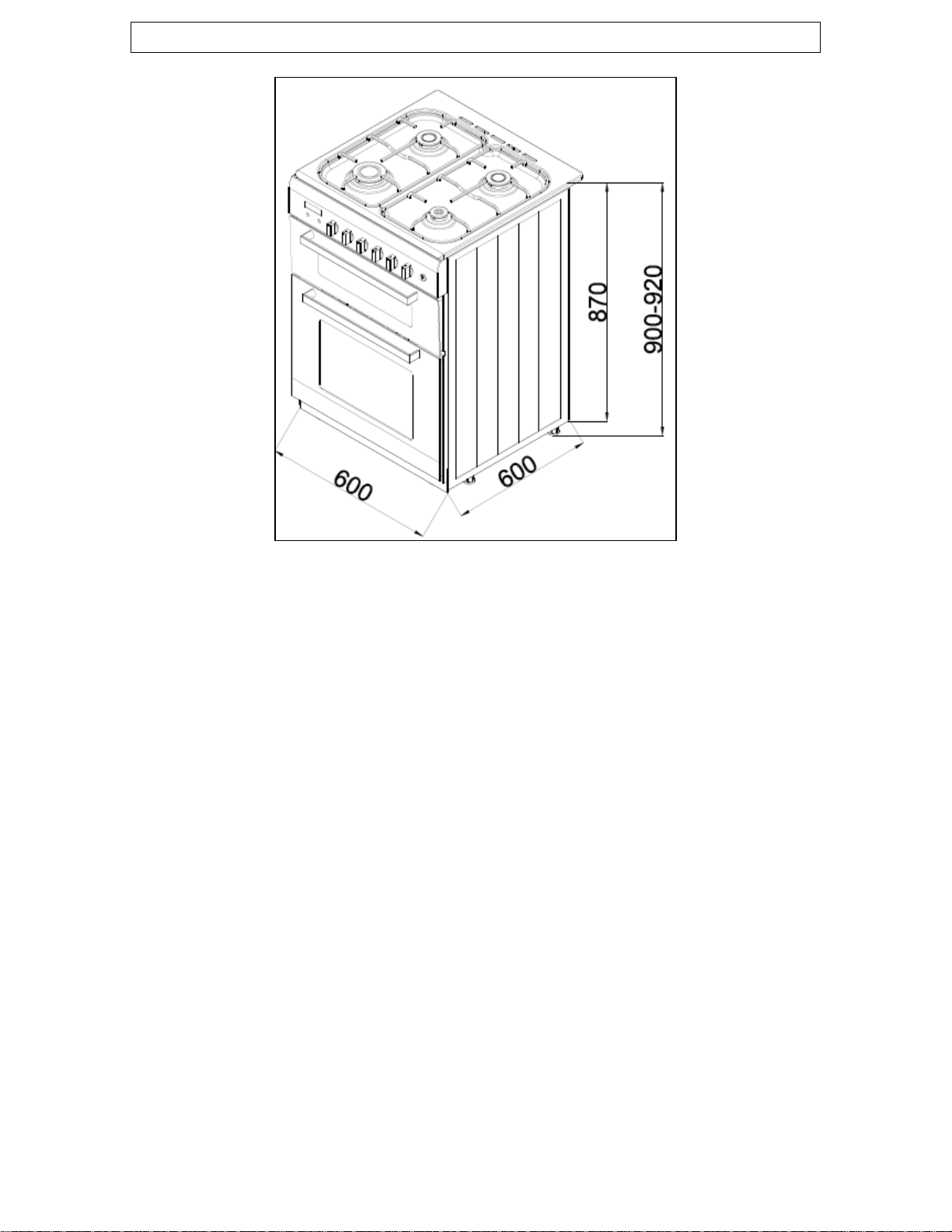

Product dimensions:

Height: 900 - 920 mm

Width: 600 mm

Depth: 600 mm

Product specifications:

o 4 zone gas hob:

o 1 x 3.00 kW rapid burner

o 2 x 1.75 kW semi-rapid burner

o 1 x 1.00 kW auxiliary burner

o Enamelled pan stands

o Push button ignition

o Flame failure safety device on all burners

o Main oven gross / net capacity: 70 / 58 litres

o Top oven gross / net capacity: 32 / 28 litres

o LED minute minder

o Thermostatically controlled grill

o Heat deflector

o Pushbutton ignition

o Double-glazed removable doors

o Adjustable feet

o Flame failure safety device on oven and grill

9

Page 10

Standard accessories

o 2 x Enamelled baking tray with handle

o 2 x Wire shelves

o 1 x Trivet

o LPG conversion jets

Electrical details

Rated Voltage: 220 - 240 Vac 50 Hz

Supply Connection: 3A (double pole switched fused

outlet with 3mm contact gap)

Max Rated Inputs: 0.030 kW

Mains Supply Lead: 3 core x 1.5 mm²

Oven Light Bulb: E14 15 W/300°C screw t ype pygmy

Gas details

Gas Connection Type: 1/2” BSP

Gas Type (Natural Gas): 20 mbar

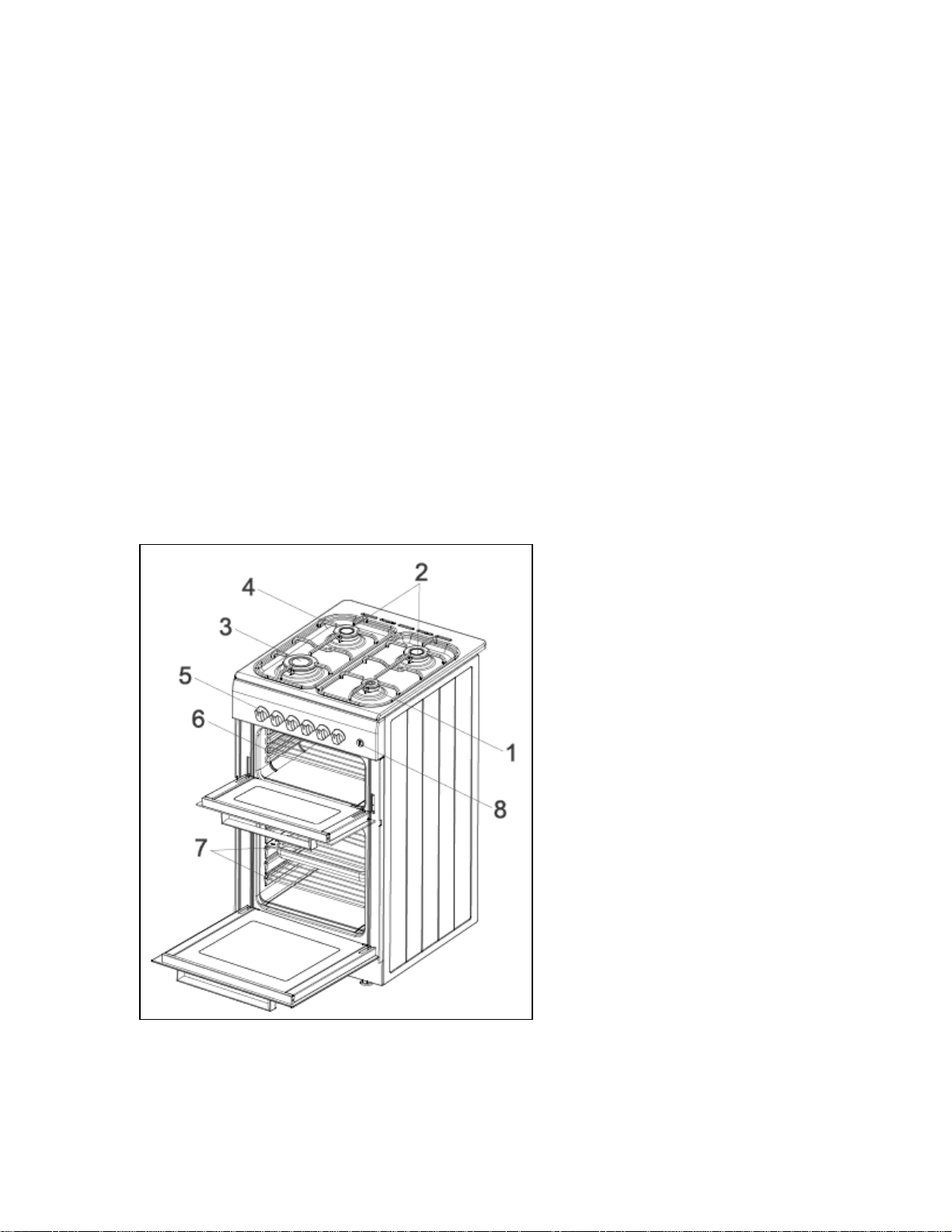

Product features

1) 1.00 kW auxiliary

burner

2) 1.75 kW semi-rapid

burners

3) 3.00 kW rapid burner

4) Pan stand

5) Control knob

6) Grill pan

7) 2 x wire shelves

8) Igniter and light

control

10

Page 11

For future reference please record the following information which can

be found on the rating plate and the date of purchase which can be

found on your sales invoice. The rating plate for your oven can be

located on the front frame of the oven cavity.

Model Number ……………………………….

Serial Number ……………………………….

Date of Purchase ……………………………….

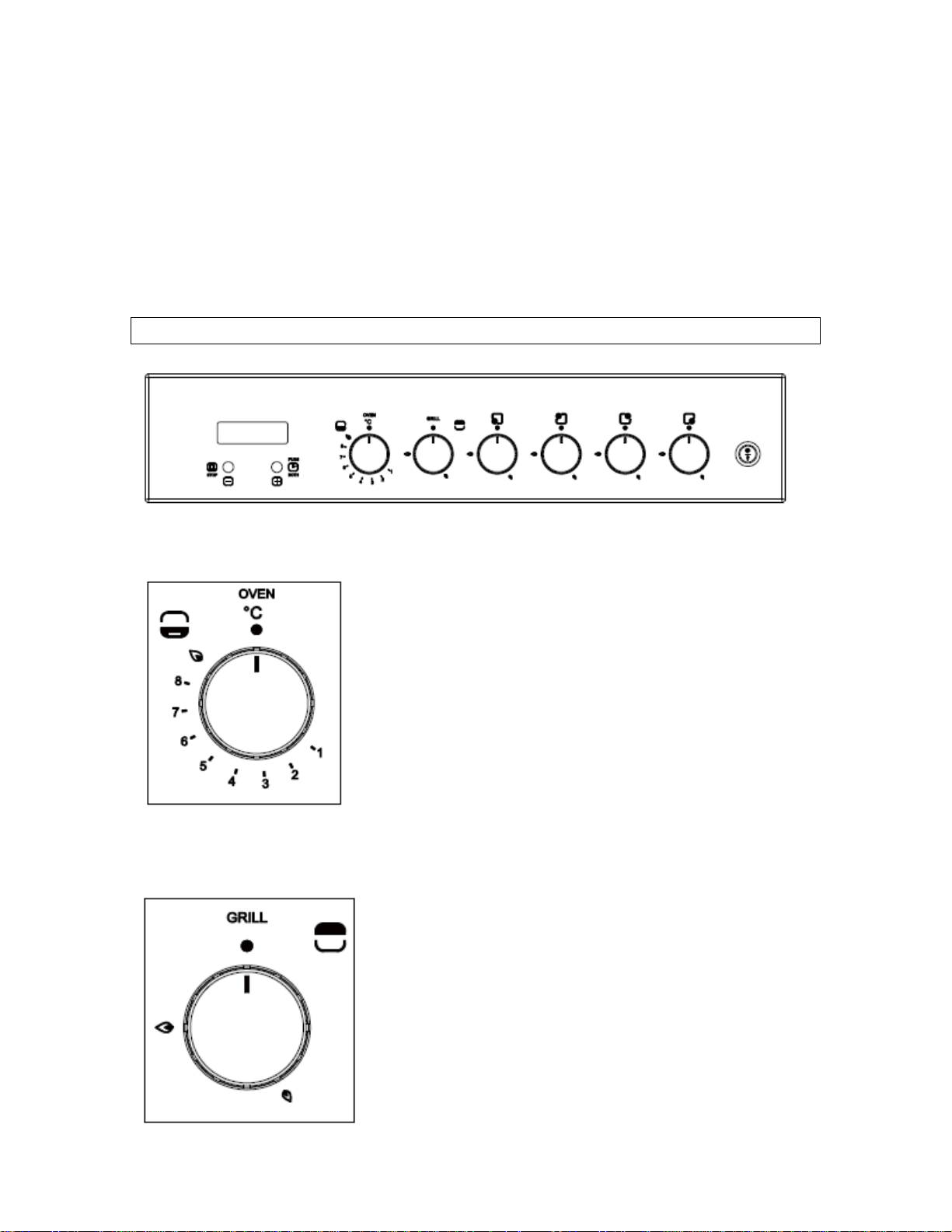

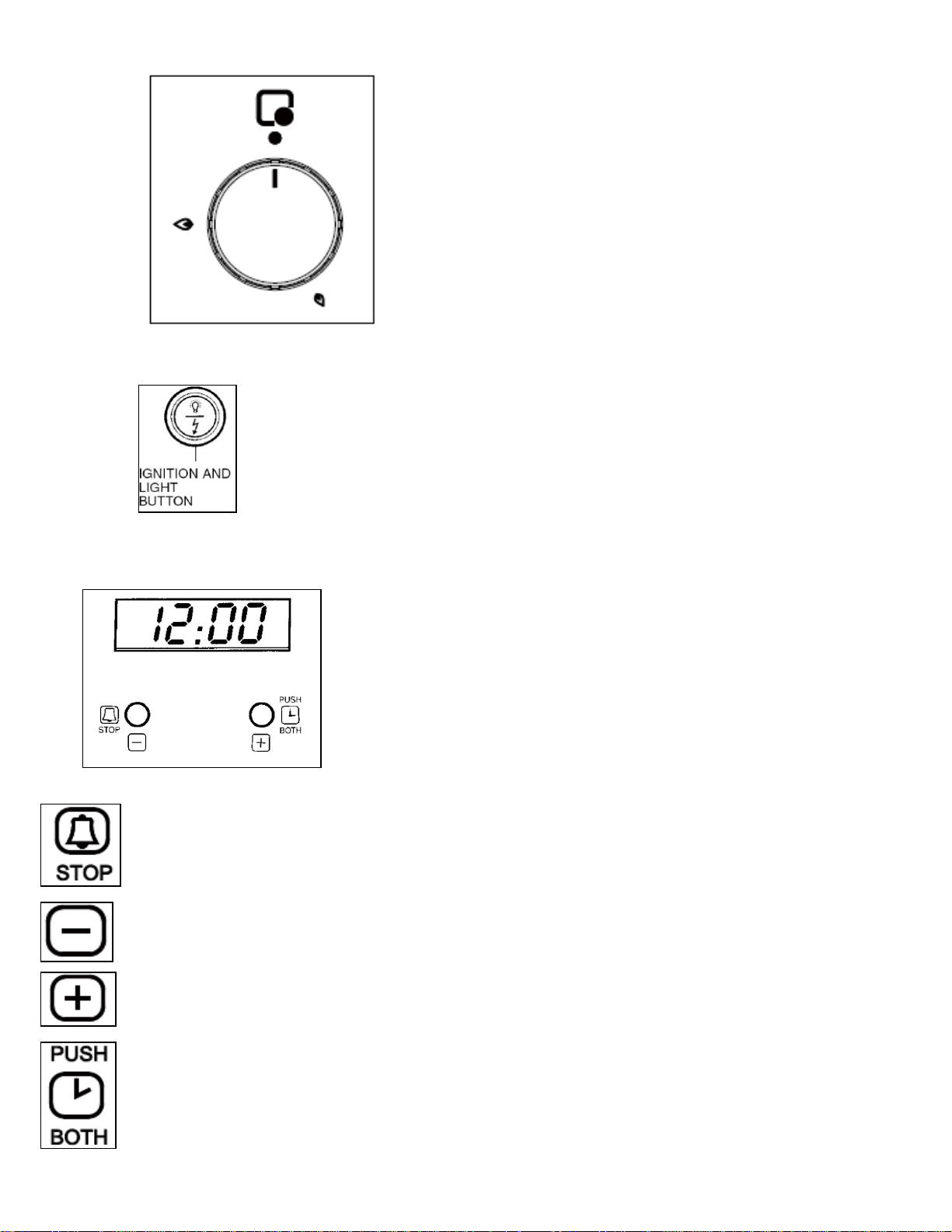

Control Panel

Oven control knob (main oven)

o Use this control knob to control the

temperature in the oven.

Grill control knob (top cavity)

o Use this control knob to select the grill

intensity in the secondary oven.

11

Page 12

Thermostat control knob (hob)

o Use the control knob of the relevant

cooking zone to set the temperature

intensity.

Oven light / gas ignition

o Use this switch to turn the oven light on and off, and t o

ignite the gas hobs or the gas ovens.

Oven timer

1) Alarm stop icon (press minus button to stop alarm).

2) Timer minus button.

3) Timer plus button.

4) Time-setting mode indicator (press plus and minus buttons

together to enter this mode).

12

Page 13

Setting and using the oven programmer/timer

Setting the time of day

Before using the oven fo r the first tim e you should set t he time

of day.

o Press the plus (3) and minus (2) buttons simultaneously to

enter the time-se tting mode. The displa y will automa tically show

“12.00”.

o Use the plus (3) and minus (2) buttons to adjust the time to the

correct hour. Release all buttons and after a few seconds the

time will be set.

Setting the minute minder function (main oven and grill)

You are able to set the minute minder at any time, regardless

of whether an oven function has been selected. You can set a

period of time using the minute minder function and an alarm

will sound when this period of time has elapsed.

o Press the plus button to enter the minute minder mode.

o Continue pressing t he plus but to n u nti l the r e quire d co o kin g ti me

is shown on the display. Release all buttons and after

approximately five seconds the countdown will begin.

o At the end of the countdown an alarm will sound. Press the

minus button once to silence the alarm.

o Important: The oven will continue to heat once the alarm has

been silenced. If you have finishe d co o king, the n yo u sho u ld turn

the thermostat control knob t o 0

13

Page 14

Using the oven

Before first use

o To remove any residue from the oven that may have been left

from the manufacturing process, you should select the main

oven, and the grill, and tur n the thermos tat dial to its ma ximum

temperature setting.

o IMPORTANT: You should not burn off both oven cavities

simultaneously.

o It is perfectly normal for a smell to be produced during this

process.

o You should make sure that any windows in the room are left

open during this process.

o It is advisable for you not to remain in the room whilst the

burning off process is taking place.

o You should leave each oven on maximum setting for 30 – 40

minutes.

o After both cavi tie s have cooled, they s h o uld the n be cle an ed with

warm soapy water, using either a sponge or soft cloth. No

abrasive cleaners should be used.

o Outer parts of the oven should be cleaned with warm soapy

water, using either a sponge or soft cloth. No abrasive cleaners

should be used.

o We would recommend tha t an appropri ate stainless ste el cleaner

and polish is regular ly used o n the s tai nless ste el surfa ces of thi s

appliance (BCG625SS only).

14

Page 15

Using the main oven

Setting

1 2 3 4 5 6 7 8 Temp (°C)

130

140

150

170

190

230

245

250

o To turn the main oven on, press and

turn the control dia l to the la rge flame

position.

o While still holding the dial inwards, press and

hold the bottom ha lf of the ignition bu tton until

the oven burner ignites.

o If the flame goe s ou t, re p e at all the steps above

keeping the dial pressed in for about five

seconds longer.

o Once the burner is lit, turn the knob to a settin g from 1 to 8 to

set the temperature.

o The table below shows what setting you should select for the

corresponding oven temperature:

o The oven light can be tur ned on any ti me by pre ssing the top hal f

of the ignition butto n. Press this button again to switch the ligh t

off.

o The oven has a flame failur e safety device to e nsure that no gas

escapes if the flames are extinguished. There is also a thermal

cut-off which prevents the oven from overheating if the

temperature exceeds safety li mits.

You should not place food inside the cavity, until the correct

cooking temperature has been reached.

15

Page 16

Base burner appliances

IMPORTANT: Your appliance is a Continental style/base burner gas

oven, please follow the guidance below, to achieve the best cooking

results.

o There are two different types of heatin g methods for gas ovens,

traditional U.K. style and Continental style.

o In U.K. style gas ovens, the ho t air moves around the oven and

the hottest part of the cavity is at the top.

o In Continental style gas ovens, the heat source is underneath

the base of the oven, which means that the hottest part of the

cavity is at the bottom.

o Your oven is a Continental style gas oven, which may require

some adjustment in your cooking method, if you are used to a

U.K. style gas oven.

o We would recommend that you plac e the enamelled baking tray

into the lowest shelf position.

o This will deflect some of the fierce heat generated by the base

burner away from the food that you are cooking.

o This will allow food to cook all of the way through, without

getting burnt on the base.

o You may also need to make small adjustments to the cooking

temperature and cooking times that you normally used

previously.

16

Page 17

Using the grill

IMPORTANT: You should always grill with the oven door

open. NEVER attempt the grill with the door closed.

o To turn the grill on pr ess and turn

the control dia l to the large flame

position.

o While still holdin g in the co ntro l knob, p re ss and

hold the bottom ha lf of the ignition bu tton until

the grill burner ignites.

o For a high heat temperature, leave the control

on the large flame sym bol. To set a lower heat

level, turn the control dial to the small flame

position.

o You can turn the l ig ht on any time by pr e ssing t he bo tto m half o f

the ignition button. Press this button again to turn the light off.

o The grill has a flame failure safety device. This ensures that no

gas escapes if the flames are extinguished. There is also a

thermal cut-off which prevents the grill from overheating if the

temperature exceeds safety li mits.

o Always remember t o use the ha ndle whe n removing the gr ill pan

and do not leave the grill unattended while in use.

o Your grill comes fitted with a heat defle ctor, which he lps pre vent

the control knobs becoming hot from the heat rising from the

front of the grill cavity.

CAUTION: The heat deflector can get very hot during use.

Avoid touching the heat deflector until the grill has cooled

down. DO NOT allow children to touch the cooker when in

use as exterior parts can become hot.

17

Page 18

Cooking guidelines

o Please refer to the information given on food packaging for

guidance on cookin g temperatures a nd times. Once fa miliar with

the performance of your applianc e, temperatures and times can

be varied to suit personal preferenc e.

o Make sure that frozen foods are thoroughly thawed before

cooking, unless the instructions on the food packaging advise

that you can “cook from f rozen”.

o You should pre-heat the ove n and no t place food ins ide o f it until

it is properly heated.

o Before cooking, check that any unused accessor ies are removed

from the oven.

o Place cooking trays in the centre of the oven and leave gaps

between the trays to allow air to circulate.

o Try to open the door as little as possible to view the dishes.

Warnings

o During cooking, never place pans or cookware directly onto the

bottom of the oven. They should always be placed on the shelves

provided.

o The grill heating element becomes extremely hot during

operation, avoid touching it inadvertently when handling the

food which you are grilling.

o Important: Be careful when opening the door , to avoid contact

with hot parts and steam.

o IMPORTANT: In case of fire, close the main valve of the gas

supply and switch off the electricity supply to the appliance.

NEVER pour water onto burning oil.

18

Page 19

Using the hob top

Before first use

IMPORTANT: You should clean the hob surface.

(Please see “Cleaning and maintenance” section).

o You should switch o n one cooking zone at a time, for 5 minutes

at the maximum setting. This will help to eliminate any new

smell that exists and evapor ate any humidity tha t has forme d on

the heating elements during transit.

o Do not burn off more than one zone at once.

o You must place a saucepan filled half full with cold water on

each zone as you burn it off.

Using the hob burners

o Each zone on the gas hob top is

controlled by a control knob.

o To turn on a cooking zone use the

relevant control k nob for the zone you

wish to use.

o Press and turn the control knob to the

large flame position.

o While still pressing in the control knob, press

and hold the bottom half of the ignition button

until the burner ignites.

o For a maximum temperature keep the dial

turned to the large flame position.

o For simmering, lower the heat by turning the

control dial to the small flame position.

o Always remember to turn t he control knob to the off position

when cooking is completed.

19

Page 20

Hob guidelines

o The diameter of the bottom of the pan should correspond to that

of the burner.

o The burner flame must never extend beyond the diameter of the

pan.

o Use flat bottomed pans only

o When possible, keep a lid on the pan whilst cooking.

o Cook vegetables with as little water as possible, to reduce

cooking times.

IMPORTANT: Always place pans centrally over the hob burners and

position them so that the handles cannot get accidentally caught or

knocked off. You should also make sure that the handle is not over one

of the other hob burner flames.

Cleaning and maintenance

Cleaning operations must only b e carried out when

the oven is cool.

The appliance should be disconnected from your

mains supply before commencing any cleaning

process.

o The oven should be thoro ughly cleaned before it is operated for

the first time and after each use. This will avoid residual food

stuffs becoming baked on the oven cavity. After residues have

been baked on several times, they are far more difficult to

remove.

o Never clean the oven surfaces by steam cleaning.

o The oven cavity sh ould only be cleaned wit h warm soapy water ,

using either a sponge or soft cloth. No abrasive cleaners should

be used.

20

Page 21

o Any stains that may appear o n the bottom of the oven will have

originated from food splashes or spilt fo od, these splashes occur

during the cooking process. These could possibly be a result of

the food being cooked at an excessively high temperature or

being placed in cookware that is too small.

o You should select a cooking temperature that is appropriate for

the food that you are cooking. You should also ensure that the

food is placed in an adequately sized dish and tha t you use the

enamelled baking tray where appropriate.

o Outer parts of the oven should only be cleaned with warm soapy

water, using either a sponge or soft cloth. No abrasive cleane rs

should be used.

o We would recommend tha t an appropri ate stainless ste el cleaner

and polish is regular ly used o n the s tai nless ste el surfa ces of this

appliance (BCG625SS only).

o If you use any form of oven cle aner on your appliance, then yo u

must check with the manufacturer of the cleaner that it is

suitable for use on your appliance.

o Any damage that is caused to the applianc e by a cleaning

product will not be fixed by Bauma tic free of charge, even

if the appliance is within the guarantee period.

Cleaning the gas hob top

o Remove the dirty pan supports fr om the hob and place in warm

soapy water for some time. Then wash and dry before replacing.

After each use

o Wipe the appliance over with a damp cloth and a little w ashing

up liquid.

o Dry the appliance by rubbing the surface with a clean cloth.

21

Page 22

Cleaning the burners

o Gas burners should be cleaned regularly and after each spillage

to remove cooking residues and dirt.

o To clean the burners,

remove the caps and rings

and place them separately in

warm soapy water. After

cleaning them, check that

the burner ports are clear.

o The body near the nozzle

should always be clean. Dirt

accumulating around the

nozzle may clog it, as a

result of which the burner

will not light or will light only

with a small flame. To clean

the nozzle use a brush

soaked in solvent.

o Dry all the elements of the burner carefully as wet elements may

not light properly. Assemble the clean and dry burners carrying

out the disassembly steps in reverse order.

Cleaning the oven

o The oven compartment is coated with vitreous enamel. To clean

particularly difficult burnt spots a special oven cleaning agent

may be used. However, as these agents are caustic, be careful

when using them and follow the manufacturer’s guidelines.

Warning: Do not steam pressure clean the oven.

Always wait until the oven cools down before cleaning.

22

Page 23

Replacing the oven bulb

IMPORTANT: The oven must be disconnected from

your mains supply before you attempt to either

remove or replace the oven bulb.

o Remove all oven shelves

and the drip tray.

o Unscrew the lamp cover.

o Unscrew the bulb and

remove it from its holder.

o Replace the bulb wi th a 15

W/300°C, screw type

pygmy.

o Do not use any other type of bulb.

o Screw the lamp cover back into its original position.

Removing the oven door for cleaning

To facilitate the cleaning of the inside of the cooker and the outer

frame of the oven, the door can be removed as foll ow s:-

o The hinges (A) have two movable bolts on them (B).

o If you raise both of the mo vable bolts (B), then the hinges (A)

are released from the oven housing.

o You should grip the sides of the door at the centre and then

incline it slightl y to w ar ds th e co o ke r cav ity and then pull it ge ntly

away from the cooker cavity.

o IMPORTANT: You should make sure that the do or is supported

at all times and that you place the door on some padded

material whilst cleaning it.

23

Page 24

o The oven door and door glass should only be cleaned using a

damp cloth and a small amount of detergent. The cloth MUST

NOT have come into contact with any form of cleaning product

or chemical previously.

o To refit the door you should slide the h inges back into t heir slots

and open the door fully.

o IMPORTANT: The movable bolts (B) must be closed back into

their original positions before closing the door.

o Take care not to dislodge the hinge locking

system when removing the do or, as the hinge

mechanism has a strong spring.

o Do not immerse the door in water at any time.

Installation

The installation must be carried out by a suitably

qualified person, in accordance with the current

version of the following.

o UK Regulations and Safety Standards or their European

Norm Replacements.

o Building Regulations (issued by the Department of the

Environment).

o Building Standards (issued by the Scottish Development

Department).

o IEE Wiring Regulations.

o Electricity At Work Regulations.

o Gas Safety (Installation and Use) (Amendment)

Regulations.

Positioning

The adjacent furniture and all materials us ed in the

installation must be able to withstand a minimum

temperature of 85°C above the ambient

temperature of the room it is located in, whilst in

use.

o Your appliance is heavy, so you should be careful w hen moving

or positioning it.

24

Page 25

o Do not try to move the cooker by pulling on either the door,

handle or control panel.

o The cooker is designed to slot in between 600 mm deep

cabinets, which are spaced approximately 600 mm apart.

o It can also be used as freestanding, wit h a cabine t to o ne side, in

a corner setting or with its back to a wall.

o IMPORTANT: It should not be ins talled at the end of a run of

cabinets, if there is a cabinet at immediate right angles to the

cooker door.

o The wall behind the cooker and 450 mm above and across the

width of the cooker should be an incombustible material and

preferably an easy clean surface, such as ceramic tiles.

o Any overhanging sur face or coo ker hood should be at least 700

mm above the highest point on the hob top (including the

burners).

o Baumatic do not recomme nd that the cooker is positione d below

wall cupboards, as the heat and steam from the appliance and

what is being cooked, may damage the cupboard and its

contents.

25

Page 26

o The cooker may be loc ate d in a k itc he n, o r a be dr oo m, but no t in

a room containing a bath or sho wer. The cooker must not be

installed in a bedroom of less than 20m³ in size.

o The cooker is fitte d with four feet

that can be adjusted to match

the height of your kitchen

cabinets.

o If the cooker is not level or is

unstable due to an uneven floor

surface, use the adjustable feet

to alter each corner until the

cooker is level.

Ventilation requirements

o The room containin g the appliance should have an air supply in

accordance with BS 5440: Part 2.

o For room volumes up to 5m³ a n air vent of 100cm² is required.

o If the room has a doo r that opens directly to the ou tside, or the

room exceeds 10m³ no air vent is required.

o For room volumes between 5m³ and 10 m³ an air vent of 50 cm²

is required.

Safety chain anchors

o In order to eliminate the risk of the oven falling forward, two

chains have been installed at the rear of the cooker. Before use,

these will need to be fastened securely to the wall behind the

appliance with the anchor brackets supplied.

26

Page 27

o Decide on a suitabl e wall location for fitting the anch or brackets

directly behind each cooker safety chain.

o Hold the chain anchor up to the wall where it will be required

and mark the fixing holes.

o Drill the fixin g holes and fix the chain anchors to the wall using

the screws provided and s uitable wall plugs for the type of wa ll

being fixed to.

o Leave the chains unattached until the installation process has

been completed.

Securing the safety chains

o Before securing the safety chains, check that you have

completed the installat ion process and that all connections have

been made successfully and that the cooker is in its final

operating position.

o To fix the security chains

to their anchor brackets:

Unscrew the hex nut at the

unattached end of the

safety chain.

o Insert the screw upwards into the top hole of the anchor bracket.

o When the screw is full y inserted in the bracket, tighten the he x

nut to secure the end chain link into position.

27

Page 28

Electrical connection

YOUR COOKER IS INTENDED FOR FITTED AND

PERMANENT INSTALLATION.

o Before connecting the appliance, make sure that the supply

voltage marked on the rating plate c orresponds with your mains

supply voltage.

o We recommend that the appliance is connected by a qualified

electrician, who is a member of the N.I.C.E.I.C. and who will

comply with the I.E.E. and local regulations.

o WARNING: THIS APPLIANCE MUST BE EARTHED.

o This appliance is supplied with a moulded plug, which must be

connected to an earthed socket.

o If in future you need to change the fuse in this plug, then a 3

amp ASTA approved (BS 1362) fuse must be used.

o If the earthed socket is not accessible after the appliance is

installed. Then the cooker must be wir ed into a 13A double pole

switched fused spur o utlet, having 3 mm co ntact separation an d

the fuse rating reduced to 3 amps. This shou ld be placed in an

easily accessible position adjacent to the appliance. The spur

outlet must still be accessible even when your cooker is installed.

o The wiring in the mains lead is coloured as follows:

Brown Live

Blue Neutral

Green and yellow Earth

o As the colours of the wire s in the appl iance ’s mains le ad may no t

correspond with the colo ured markings identifying the terminals

in your spur box, please proceed as follows:

The brown wire must be connected to the terminal marked “L”

(live), or coloured red.

The blue wire must be connected to the terminal marked “N”

(neutral), or colou red black.

The gr een and yellow wire must be conne cted to the terminal

marked “E” (earth), or by the earth symbol, or coloured green

and yellow.

28

Page 29

o When the connection is comple ted, no stray strands or cut wire

should be present. The cord clamp must be secured over the

outer sheath.

o Broken or damaged power leads must only be replaced by a

suitably qualified pe rson. A power lead o f a similar type must be

used in replacement.

Gas connection

This appliance must be installed by a competent

person in accordance with the current versions of

the following UK (United Kingdom) o r ROI (Republic

of Ireland) Regulations and Safety Standards or

their European Norm Replacements.

Important inform a tion

o This cooker is supplied to run on natural gas only and cannot

be used on any other type of gas without modification.

o Conversion for use on LPG and other gases must only be

undertaken by a qualif ied person. For information on the us e of

other gases, please contact the Baumatic Technical Department.

o The cooker must be installed by a qualified person, in

accordance with the current edition of the Gas Safety

(Installation and Use) (Amendment) Regulations and the

relevant building/I.E.E. Regulations.

o Failure to install the appliance correctly could invalidate

Baumatic’s guarantee and lead to prosecution under the

regulations quoted above.

o In the UK, GASSAFE registered installers are authorised to

undertake the installation and service work, in compliance with

the above regulations.

29

Page 30

Gas Safety (Installation and Use) Regulations

o It is the law that all gas appliances are installed by competent

persons in accordance w ith the cur r e nt edition of the Gas Safety

Installation and Use Regulations.

o It is in your interes t and that o f safe ty to ensure compliance with

the law.

o In the UK, GASSAFE registered installers wo rk to safe standards

of practice. The coo ker must also be installed i n accordance with

the current edition of BS 6172. Failure to install the cooker

correctly could invalidate the warranty, liability claims and lead

to prosecution.

o IMPORTANT: It is a requirement for a stability chain to be

fitted to the appliance. Please see pages 26-28 for more

detailed information on this.

Gas connection

ALL INSTALLATION AND SERVICE WORK MUST BE

CARRIED OUT BY A GASSAFE REGISTERED

ENGINEER.

o Prior to installation, ensure that the gas supply conditions

(nature of the gas and gas pressure) and the adjustment

conditions are compatible. The adjustment conditions for this

appliance are stated on the rating plate which can be found on

the back cover.

o This appliance is not de signed to be connected to a combustion

product evacuation device. Particular attention should be given

to the relevant requirements regarding ventilation.

o IMPORTANT: FIBRE

WASHERS MUST BE IN

PLACE WHEN CONNECTING

THE GAS HOSE.

o Connection to the cooker

should be made with an

approved appliance fle xib le

connection to BS669.

30

Page 31

o This cooker can be connected to the supply bo th on t he r ig ht and

left hand side at the rear of the cooker. To reverse the position,

remove the blanking plug and refit it to the opposite side to

where the hose is being connected.

o If the cooker has bee n c onve r te d fo r us e with L PG , then it should

be connected to the gas supply using an appropriate bayonet

type hose. The hose MUST be suitable for use with LPG gas,

these are identifiable by a red band or stripe.

o A hose length of 0.9m to 1.25m is recommended. The le ngth of

hose chosen should be such that when the cooker is in sit u, the

hose does not touch th e floor.

o Care should be taken to ensure that the temperature rise of

areas at the rear of the cooker that are likely to come in contact

with the flexible hose do not exceed 70°C.

o Gas pressure may be checked on a semi-rapid hob burner.

Remove the appropriate injector and attach a test nipple. Light

the other burners and observe that the gas pressure complies

with the gas standards in force.

31

Page 32

Gas adjustment (Conversion to LPG for the hob top)

Burner Type

Gas Type

Pressure

Injector

(1/100mm)

Power

Max Min

Auxillary (Small)

Natural

Gas

20

72

1

0.3

Liquid Gas

28..30/37

50

Semi Rapid

Natural

Gas

20

97

1.75

0.6

Liquid Gas

28..30/37

65

Rapid (Large)

Natural

Gas

20

115

3

1

Liquid Gas

28..30/37

85

All work must be carried out by a GASSAFE

registered engineer.

IMPORTANT: Always isolate the cooker from the electricity

supply before changing the injectors and/or adjusting the

minimum flow of the burners.

o Remove the pan supports, burner cap and burner rings.

o Unscrew the injector and replace it with the required injector for

the new gas supply according to the table below.

Mbar

(Medium)

o When all four jets ha ve been replaced, reassemble all the

burners carefully, taking particular care to make sure that the

burners and burner caps are aligned properly.

o After changing the injectors YOU MUST change the minimum

flow rate.

Marking

(Kw)

32

Page 33

Minimum flow adjustment for hob gas taps.

All work must be carried out by a GASSAFE

registered engineer.

o Ignite the large (rapid) burner and set the control knob to the

minimum position.

o Remove the control knob to access a small adjusting screw.

o Using a suitable screwdriver, turn the screw clockwise to

decrease the flow of gas and make the flame smaller. Turn the

screw anti-clockwise to increase the flow of gas and make the

flame bigger.

o To establish the correct adjustment, the flame should be

approximately 3 – 4 mm in length. For Butane / Propane gas,

the adjusting screw must be tightly screwed in.

o Refit the control knob.

o Turn the control knob to maximum and then back to minimum

two or three times to make sure the flame does not go out when

the control knob is set to minimum.

o If the flame does go out then remove the control knob and

repeat the procedure again.

o Repeat these steps for the semi-rapid and auxiliary burners.

33

Page 34

Gas adjustment (Conversion to LPG for the oven and grill)

All work must be carried out by a GASSAFE

registered engineer.

IMPORTANT: Always isolate the cooker from the electricity

supply before changing the injectors and/or adjusting the

minimum flow of the burners.

o Before you can change the injectors on the grill and oven

burners, you must unscrew the burners from their fixing

brackets.

Grill burner Oven burner

o The grill burne r is located at the top of the ca vity and the oven

burner is located under the bottom cavity. You should remove

the metal plate to access the oven burner.

o When you have removed the burners you will be able to see the

injector.

o U

n

34

Page 35

screw the injector and replace it with the required injector for

Burner Type

Gas Type

Pressure

Injector

(1/100mm)

Power

Max Min

Oven Burner

Natural

Gas

20

1.05

2.1

0.8

Liquid Gas

28..30/37

0.72

Grill Burner

Natural

Gas

20

1.00

1.8

0.6

Liquid Gas

28..30/37

0.66

the new gas supply according to the table below.

Mbar

o After changing the injectors YOU MUST change the minimum

flow rate.

Minimum flow adjustment for the oven and grill burners

All work must be carried out by a GASSAFE

registered engineer.

o In order to access the adjusting screws to change the minimum

flow rate of the gri ll and oven burners, you need to remove the

hob top and control panel.

o To take the hob top off, re move the screws fixing the hob to the

cooker.

o When all the screws have been re moved,

slide the hob from the back to the front

and lift it off the suppor t brackets which

hold the hob down at the front of the

cooker.

Marking

(Kw)

35

Page 36

o To take off the control panel, remove

the screws fixing the control panel.

o When the screws have been removed,

you can take off th e control knobs and

remove the control panel by pulling it

to the front.

o Locate the adjusti ng scr ews fo r the gr il l and o ven bur ners. The se

will be positioned to the left hand side of the grill and oven

thermostat taps.

o With the control panel removed, refit the oven and gas

thermostat control knobs. Ignite each burner s eparately and set

the control knob to the minimum position.

o Using a suitable screwdriver, turn the screw clockwise to

decrease the flow of gas and make the flame smaller. Turn the

screw anti-clockwise to increase the flow of gas and make the

flamer bigger.

36

Page 37

o To establish the correct adjustment, the flame should be

approximately 3 - 4 mm in le ng th. For B utane / Pr opa ne g as, th e

adjusting screw must be tightly screwed in.

o Turn the control knob to maximum and then back to minimum

two or three times to make sure that the flame does not go out

when the control knob is set to minimum.

o If the flame does go out, repeat the procedure again.

o Remove the control knobs for the oven and grill and refit the

control panel and hob top taking care to ensure they are fitted

correctly.

o Replace all the control knobs.

o Your cooker should now be adjusted correctly to work on LPG

gas.

37

Page 38

My appliance isn’t working correctly

The gas oven burner or grill burner do not light.

* Check that the oven is switched on at your mains supply.

* Check that the fuse in the spur outlet doesn’t need replacing.

* Check that there is not a problem with your gas supply

Food is cooking t oo quickly or too slowly.

* Check that you are cooking at an appropriate temperature and

shelf level.

The oven is not cooking evenly.

* Check that the oven is installed correctly.

* Check that you are cooking at an appropriate temperature and

shelf level.

The oven light is not working.

* Refer to the “Replacing the oven bulb” section.

I am getting condensation in my oven.

* Steam and condensation is a natural b y product of cooking any

food with high water content, such as frozen food, chicken etc.

* You may get condensation in the oven cavity and forming

between the oven door glasses. This is not necessarily a sign

that the oven is not working correctly.

* Do not leave food in the oven to cool after it has been cooked

and the oven has been switched off.

* Use a covered container, where practical, when cooking to

reduce the amount of condensation that forms.

38

Page 39

IMPORTANT: If your appliance appears not to be

operating correctly, then you should disconnect it

from your mains supply and then contact

Baumatic Customer Care on telephone number

(0118) 933 6911.

DO NOT ATTEMPT TO REPAIR THE APPLIANCE

YOURSELF.

Please note that if an e ngineer is asked to attend whilst t he product is

under guarantee and finds that the problem is not the result of an

appliance fault, then you may be liable for the cost of the call out

charge.

The appliance must be accessible for the engineer to perform

any necessary repair. If your appliance is installed in such a

way that an engineer is concer ned that damage will be caused

to the appliance or your kitchen, then he will not complete a

repair.

This includes situations where appliances have been tiled in,

sealed in with sealant, have wooden obstructions placed in

front of the appliance, like plinths. Or any installation other

than the one specified by Baumatic Ltd. has been completed.

Please refer to the conditions of guarantee that appear on the

warranty card that you receive with the appliance.

39

Page 40

Baumatic Consumables

o BC001 Degreaser for Dish w ashers (200 g)

o BC002 Descaler for Washing Machines and Dishwashers (200 g)

o BC003 Ceramic Hob Cleaner (250 ml)

o BC004 Oven Cleaner (250 ml)

o BC005 Stainless Steel Cleaner and Protector (250 ml)

o BC007 E-Cloth – General Purpose Cloth

o BC008 – Microwave Cover

To order a Baumatic consumables product ple ase call 0123 5437 244

and quote the product code. You can also order online from

eshop.baumatic.co.uk

40

Page 41

41

Page 42

42

Page 43

United Kingdom

Baumatic Ltd.,

Baumatic Buildings,

6 Bennet Road,

Reading, Berkshire

RG2 0QX

United Kingdom

Sales Telephone

(0118) 933 6900

Sales Fax

(0118) 931 0035

Customer Care Telephone

(0118) 933 6911

Customer Care Fax

(0118) 986 9124

Spares Telephone

(01235) 437244

Advice Line Telephone

(0118) 933 6933

E-mail:

sales@baumatic.co.uk

customercare@baumatic.co.uk

spares@baumatic.co.uk

technical@baumatic.co.uk

Website:

www.baumatic.co.uk

Facebook:

www.facebook.com/baumatic.uk

Republic of Ireland

Service Telephone

1-890 812 724

Spares Telephone

091 756 771

Czech Republic/Slovakia

Baumatic s.r.o.

Lípová 665/1

460 01 Liberec 4

Czech Republic

Panenská 34

811 03 Bratislava - Staré Mesto

Slovakia

+420 483 577 200 (CZ)

+421 255 640 618 (SK)

www.baumatic.cz

www.baumatic.sk

Germany

Kundendienst & Ersatzteile

Deutschland 0049(0)180-5888975

Oesterreich +43 (0) 820 / 420423

www.baumatic.de

Italy

Baumatic Italia S.R.L.

Via Galvani N.3

35011 Campodarsego (PD)

+3904 9920 2297

www.baumatic.it

Holland

Baumatic Benelux B.V.

Dukdalfweg 15d

1332 BH ALMERE

Nederland

+31(0)36 549 1553

www.baumatic.nl

43

Page 44

44

Loading...

Loading...