Page 1

THE SECCANT RANGE

Regenerative dryer for air and gas

1500 – 3500 l/min

90 – 420 bar

EASY INTEGRATION

B-CONTROL COMPRESSOR CONTROL

OPTIONAL FILTER MONITORING

GAS-TIGHT HELIUM CONSTRUCTION

www.bauer-kompressoren.de

Drying air and gases economically. At high pressures and

high throughput. This is the

strong point of the SECCANT

regenerative dryer from Bauer.

For dehumidifying and purifying air,

nitrogen and rare gases, the SECCANT

regenerative dryers offer a tailor-made

system solution for every application.

For solutions requiring absolute continuous operation, where the processes do

not permit any interruption, can also be

used in combination with a bypass filter

system from BAUER.

By means of an external control room,

online control and online monitoring of

SECCANT and the compressor unit can

be implemented.

Page 2

THE SECCANT RANGEBAUER KOMPRESSOREN

Low-maintenance operation for more economic efficiency

The regenerative dryer

SECCANT from BAUER offers

efficiency and safety when

purifying air and gases.

All downstream consumers, pipes

and valves are highly effectively

protected from corrosion, icing

and soiling.

The SECCANT regenerative dryer

offers a gas purity which complies with the requirements of

sensor technology, medicine and

ultrapure gas applications.

Owing to the long service life

of the cartridges of 2,000 hours

and a minimal number of wearing parts, use is highly economically efficient.

When using with „inline applica-

tions“ in continuous operation,

a very high unit availability is

guaranteed. Filter cartridges are

regenerated instead of consumed. Thus, frequent changing of

the filter cartridges is not necessar y.

Optional: With the help of an

additional filter housing containing activated carbon, breathing

air quality according to DIN EN

12021 can be obtained.

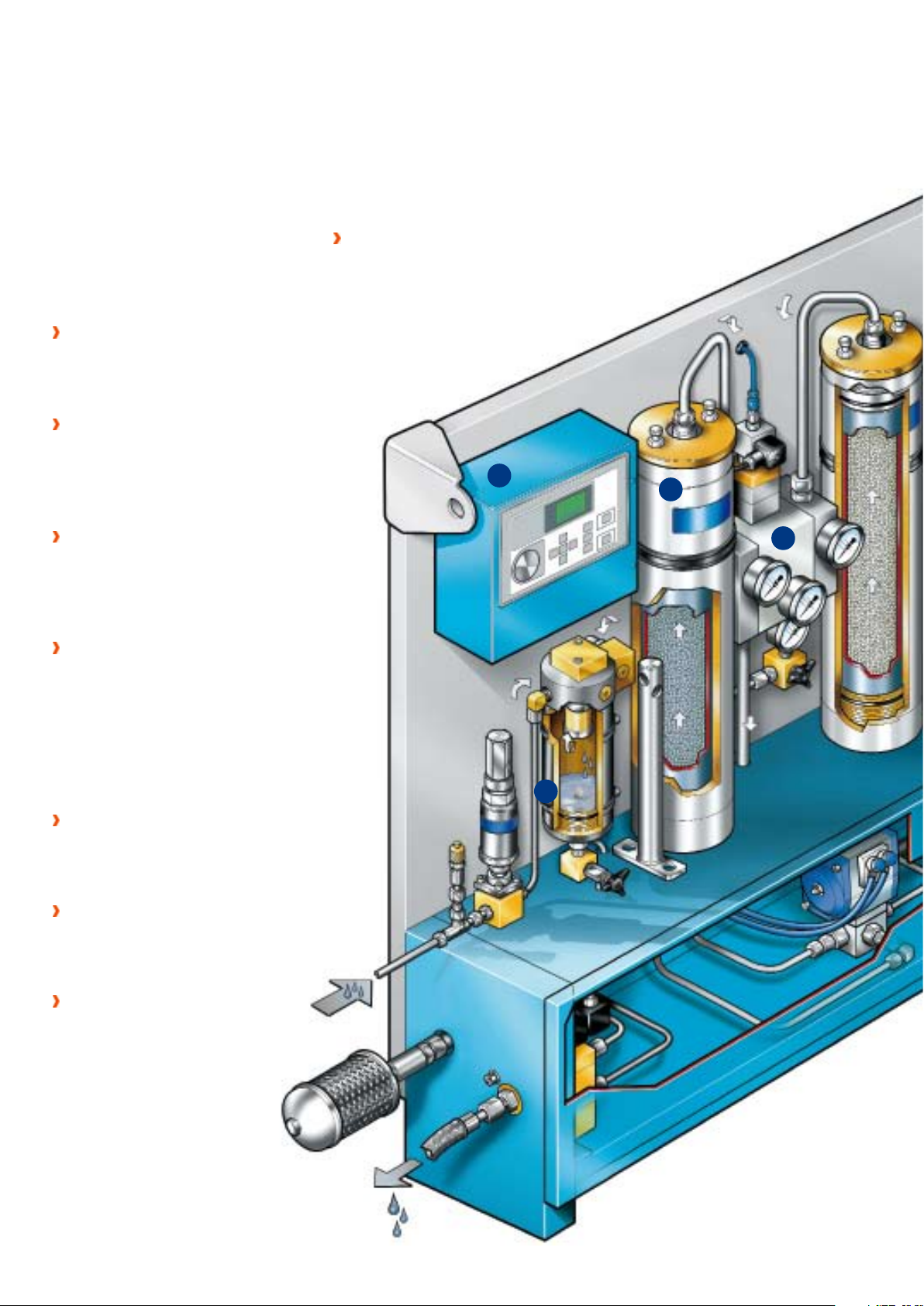

1

3

4

2

Regenerated gas is taken from

the process gas (approx. 5% of

throughput) and does not have

to be provided for separately.

Optionally, a pressure dew point

monitoring system and a realtime display of the current dew

point can be provided.

The pressure vessels are designed

and manufactured according to

most national and international

specifications for acceptance.

Page 3

THE SECCANT RANGE

7

5

BAUER KOMPRESSOREN

The filter housing

5

with activated carbon removes oil

1

The B-CONTROL

fully automatically controls all processes such as cycle times, pressure

compensation, change-over and

condensate draining. The large,

eight line LCD display with free lan-

6

guage choice* provides information

on all important parameters.

* 13 languages at present

vapour and hydrocarbons from the

process gas/air stream. The treated

air corresponds in quality to pure

air in accordance with

DIN EN 12021.

(Standard scope of supply of the

SECCANT 3A / 4A range).

The particle filter

6

filters all particles from dried and

deoiled gas.

1

B-CONTROL

2

CONDENSATE SEPARATOR

2

The condensate separator

removes condensed water and oil

drops from the incoming flow of

process gas/air.

3

The dryer chambers

are connected in a push-pull operation. The incoming process gas/air

flow is dried in the first chamber

(e.g. in left fig.) at the same time

as the second chamber is being

regenerated (e.g. in right fig.) using

a partial stream with already dried

gases/air.

The regenerated gas/air is channelled through the charged adsorption medium and regenerates the

absorber with the help of the partial decrease of line steam pressure.

The pressure maintaining

7

valve

guarantees, in the event of fluctuating final pressures, an optimal working pressure in the filter

housing, allowing for an efficient

absorption of the oil and water

molecules.

DRYER CHAMBERS

3

4

CHANGE-OVER MODULE

PURIFIER

5

PARTICLE FILTER

6

7

PRESSURE MAINTAINING

VALVE

The change-over module

4

consists of main stream - as well as

regeneration stream check valves

and compensates the pressure between the drying chambers with a

well designed change-over.

The quality seal of an original BAUER

cartridge stands for purest breathing

air acc. to DIN EN 12021.

Page 4

B-Control, the centre of communication

Continuous control maintains

operational security

B-CONTROL fully automatically

monitors and controls all SECCANT‘S internal functions like

- Operating hours

- Operating reports

- SECURUS (optional)

- Pressure dew point (optional)

At the same time SECCANT‘S

B-CONTROL communicates with

the compressor‘s respective unit

control: At start and stop the

compressor unit sends SECCANT

an On/Off signal. SECCANT permanently monitors itself during

operation and sends the compressor a release signal.

If a release signal is not received,

the compressor is automatically

stopped.

If the compressor unit is

equipped with a B-CONTROL

EXTENDED control and connected to SECCANT via a CANBus, online control and online

monitoring of SECCANT and the

compressor unit can be realised

via an external control room.

B-MESSENGER informs the operator online

the unit operator via SMS on his/

her mobile phone, pager or via

email about all important compressor data. About pending

maintenance work, for example

or malfunction.

The patented SECURUS system

(optional) reliably monitors the

service life of the cartridge.

With SECURUS it is impossible to

overuse the filter.

This can only be achieved with

a patented sensor technology,

which is integrated in the filter

cartridge. The integrated sensor

indicates the necessity for cartridge change prematurely, warning in time about the exhaustion of the cartridge capacity and,

finally switches the compressor

off.

THE SECCANT RANGEBAUER KOMPRESSOREN

Standard

connection

As an SPC control B-CONTROL

ensures the unit can be programmed according to customer

requirements.

2

SECCANT 3 / 3A / 4 / 4A

Page 5

THE SECCANT RANGE BAUER KOMPRESSOREN

1

On/Off signal from the compressor unit to SECCANT

2

Stand by report from SECCANT to the compressor unit

Status report from SECCANT to the B-CONTROL of the compressor unit

3

Forwarding of operating reports by B-MESSENGER via Fax, email or SMS

4

3

CAN-Bus

4

1

Compressur units

without B-CONTROL

Compressur units

with B-CONTROL

Page 6

Custommade solutions with system engineering

The appropriate configuration

for each purpose.

The four models 3, 3A, 4 and 4A

of BAUER‘S SECCANT range offer

a custommade system solution

for dehumidification as well as

purifying air, inert gases and noble

gases.

When wiring in the conventional

way up to three compressors can

be connected to the SECCANT,

when using a CAN-Bus as many

compressors needed to obtain the

maximum delivery quantity can be

connected.

VERTICUS / KAP Range

K22 Range

THE SECCANT RANGEBAUER KOMPRESSOREN

Interconnected operation can be

achieved with help of the

B-CONTROL using a CAN-Bus.

Two SECCANT and 2 compressors

can be installed in crosswise operation. That way, for maintenance mode

any combinations between the connected compressors and SECCANT

are possible.

For strictly continuous operation

solutions, where processes do not

allow any interruptions, there is

also the possibility of a combination

using a BAUER P range bypass filter

system.

For drying and removing oil from

valuable rare gases, a gastight version

is available with recirculation of the

safety valves and the regenerated gas.

For optimizing the throughput, the

regeneration intervals can be adjusted

dependent upon the humidity of the gas.

K23 Range

K25 /28 Range

Page 7

THE SECCANT RANGE BAUER KOMPRESSOREN

SECCANT 3 / 3A

Storage System

Bypass Filter System

SECCANT 4 / 4A

User

Page 8

THE SECCANT RANGE BAUER KOMPRESSOREN

Technical Data

SECCANT 3 3A 4 4A

Flow rate max.

l/min / scfm

Nominal pressure

bar /psig

Dimensions

D x W x H /cm

Weight

kg

Air-/gas connection

Ø mm

Condensate connection

Ø mm

Electric supply

HZ /V

Regeneration air/gas volume

% of the compressor flow

Filter change intervals

h

Pressure dew point

°C

Particle size

µm

Residual oil content

3

mg/m

1500

/55

90-420

1300 - 6100

26 x 115 x 126 26 x 135 x 126 26 x 165 x 129 26 x 165 x 129

150 182 330 360

10 10 12 12

15 15 10 10

1phase 50/60 Hz 230 V / 400 V or 24 V DC

5 5 5 5

2000 2000 2000 2000

-20 -20 -20 -20

1 1 1 1

1)

-

1500

/55

90-420

1300 - 6100

< 0,3 -

3500

/129

90-400

1300 - 5800

1)

3500

/129

90-400

1300 - 5800

< 0,3

Purification focus on:

SECCANT 3

SECCANT 3A

SECCANT 4

SECCANT 4A

required to fulfill the regulation

BAUER KOMPRESSOREN GmbH

P.O. Box 710260 | 81452 München

Phone +49 (0) 89 / 7 80 49 - 0

Fax +49 (0) 89 / 7 80 49 - 167

info@bauer-kompressoren.de

www.bauer-kompressoren.de

Breathing air

acc. to

DIN EN 12021

recommended

Medical air

acc. to

European Pharma-

cy Regulations

1) No oil removal

Industrial air Industrial air

acc.to

DIN EN ISO

8573-1,

Oil content class 3

Humidity class 3

Subject to technical modifications

Nitrogen /

Rare gases

SECCANT-E

9.09 PR 0059

Loading...

Loading...