Page 1

OPERATING MANUAL

for

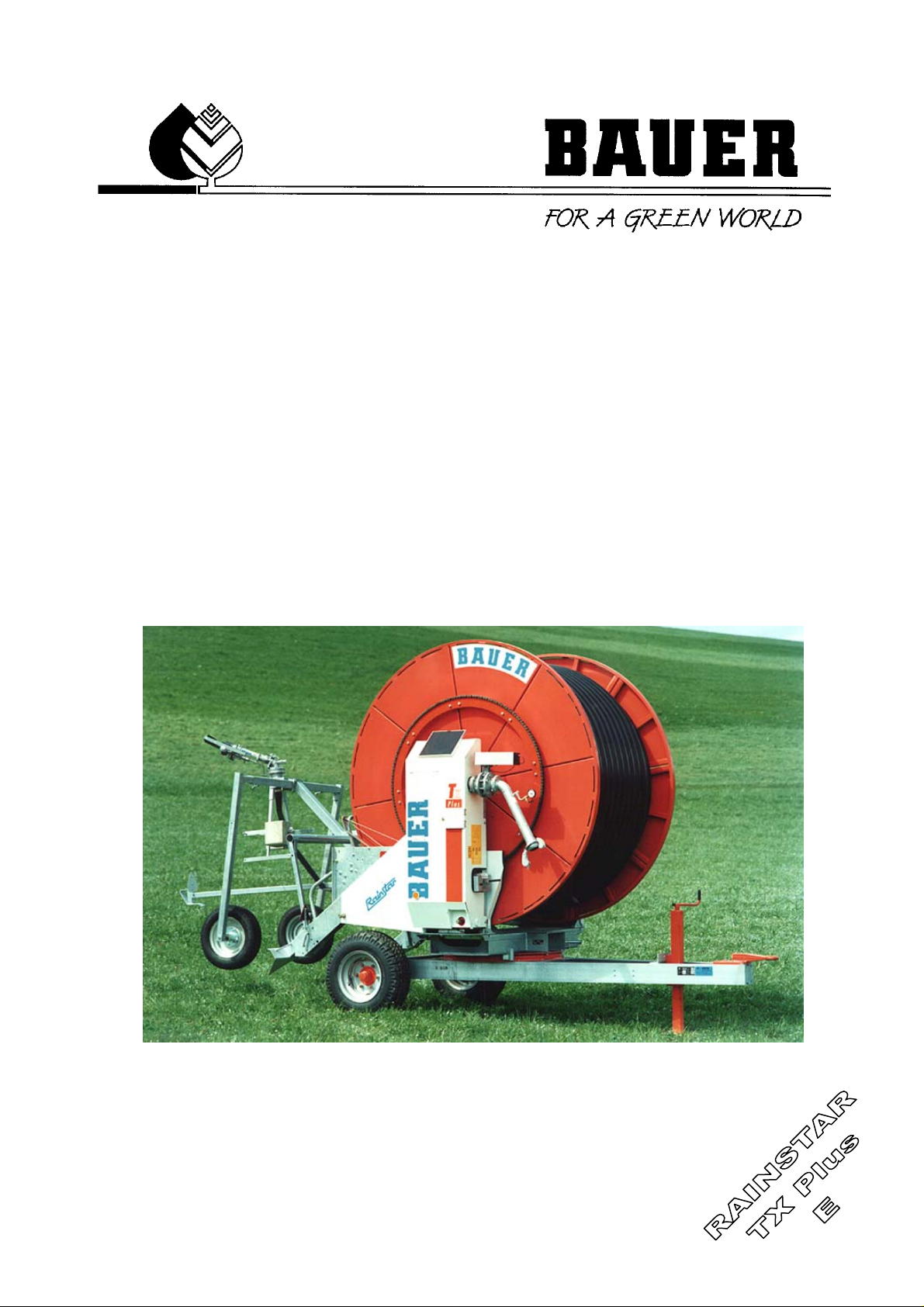

RAINSTAR

Series TX Plus

Page 2

Introduction

Thank you very much for purchasing a BAUER RAINSTAR!

We have pleasure to present to you the BAUER RAINSTAR, an irrigation machine that features state-of-art

technology and top quality. This manual describes how to assemble, operate and service your BAUER

RAINSTAR. For reasons of clearness and because of the many possibilities this manual does not cover every

information down into detail. In particular, it cannot possibly deal with every conceivable aspect of operation

and maintenance.

If you need further information or if you are faced with any special problem for which this manual does not offer

sufficient details, please do not hesitate to contact BAUER company at Kowaldstraße 2, A-8570 Voitsberg

in Austria for the information you need.

We should also like to emphasise that the contents of this operating manual neither form part of or alter in any

way, previous or existing agreements, promises, or legal relationships. Any commitment on the part of BAUER

is based solely on the respective purchase contract, which also contains the complete and only valid warranty

arrangement. The contents of the present operating manual neither extend nor limit said contractual terms of

warranty.

All information contained in the present manual is based on the latest product details available at the time of

printing.

BAUER company reserves the right to change without notice, without assuming any liability!

BAUER RAINSTAR is designed for safe and dependable performance provided it is operated according to the

present instruction manual. Therefore, in spite of the simplicity of the RAINSTAR, we request that you read this

manual carefully before putting your BAUER RAINSTAR into operation! All instructions given for handling,

operating and servicing the machine must be strictly observed. On condition that these instructions are followed

your BAUER RAINSTAR will operate trouble-free to your full satisfaction for many years!

Non-observance of these instructions may cause personal injury or damage the equipment!

This operating manual is considered an integral part of the RAINSTAR. Suppliers of new and used RAINSTAR

machines are advised to put down in writing that this manual was handed over together with the device.

Please make this manual available to your staff. You are kindly requested to state RAINSTAR type and serial

number in all inquiries, correspondence, warranty problems or parts orders. These details are specified on the

nameplate.

We wish you success and hope you will enjoy working with your BAUER RAINSTAR!

II

Manual for BAUER RAINSTAR TX Plus

Page 3

Product details

Type designation:

Type number:

Serial number

1

:

Dealer:

Date of shipment:

Manufacturer:

RAINSTAR

Series TX Plus

Name:

Address:

Tel./Fax:

Röhren- und Pumpenwerk BAUER Ges.m.b.H.

Kowaldstr. 2

A - 8570 Voitsberg

Tel.: +43 / 3142 / 200 - 0

Fax: +43 / 3142 / 23 0 95

Owner or operator:

Name:

Address:

Tel. / Fax:

Note: Please make a note of the type and serial number of your RAINSTAR and accessories. Be sure to specify

these details every time you contact your dealer.

Printing date / revised: January 1999 / 00

1

In all warranty claims and correspondence relating to this machine it is essential to specify the full serial number group including all letters.

This applies to both the machine and the components concerned. We cannot emphasise this point often enough.

Manual for BAUER RAINSTAR TX Plus III

Page 4

General Safety Instructions

Symbols and terms

The CE symbol that has to be affixed on the machine by the manufacturer outwardly

demonstrates compliance of the machine with the directives for machines and other

relevant EU directives.

WARNING!

This “Warning” symbol refers to important safety instructions in this manual.

Whenever you see this symbol be aware of possible injury hazards. Read

the note following the symbol very carefully and inform the other operators

accordingly.

CAUTION

Non-observance of this instruction may cause damage to or destroy the

machine or individual components.

NOTE

Qualified operators are persons who on account of their training, experience and instruction as well as their

knowledge of relevant standards, rules, precautions to be taken for accident prevention, and prevailing

operating conditions, have been authorised by the person in charge of plant safety to perform the respective

tasks required, and in doing so are able to recognise and avoid potential hazards. Among other things,

knowledge of first-aid procedures is also required.

It is very important to observe this note or condition!

Product liability

As defined by the product liability law every farmer is also an entrepreneur!

According to §9 PHG (Product Liability Law), liability for damage to corporeal things caused by defective

products is expressly excluded. This exclusion of liability also applies to parts not manufactured by BAUER

itself but purchased from external suppliers.

Duty to furnish information

Even if the customer passes on the machine later-on he is obliged to hand the operating manual on to the new

receiver, too. The receiver of the machine must be instructed with reference to the mentioned regulations.

Intended use

BAUER RAINSTAR is built exclusively for normal agricultural applications (intended use).

Any use beyond this normal use is considered non-conforming. Manufacturer is not liable for damage

resulting from such non-conforming use, the sole liability for damage from non-conforming use is with the

user.

Intended use also includes compliance with the manufacturer’s operating, maintenance and service

instructions.

The BAUER RAINSTAR may be used and operated only by persons who are familiar with the device and

aware of the hazards involved.

All rules for accident prevention as well as any other generally valid specifications and regulations relating to

safety, work medicine and traffic law must be strictly observed.

Unauthorised modifications on the machine release the manufacturer from liability for damage resulting

therefrom.

IV

Manual for BAUER RAINSTAR TX Plus

Page 5

Index

1 GENERAL INSTRUCTIONS FOR SAFETY AND ACCIDENT PREVENTION ................. 1

2 GENERAL ......................................................................................................................... 3

3 SAFETY PRECAUTIONS FOR RAINSTAR TX PLUS ...................................................... 4

4 DESCRIPTION .................................................................................................................. 5

5 PUTTING INTO OPERATION ........................................................................................... 7

5.1 STEPS TO BE PERFORMED ONCE OR AS REQUIRED .................................................................................. 7

5.2 OPERATING MODE I: PE-PIPE PULL-OFF ...................................................................................................... 8

5.2.1 Machine transport to set-up position ................................................................................................................... 8

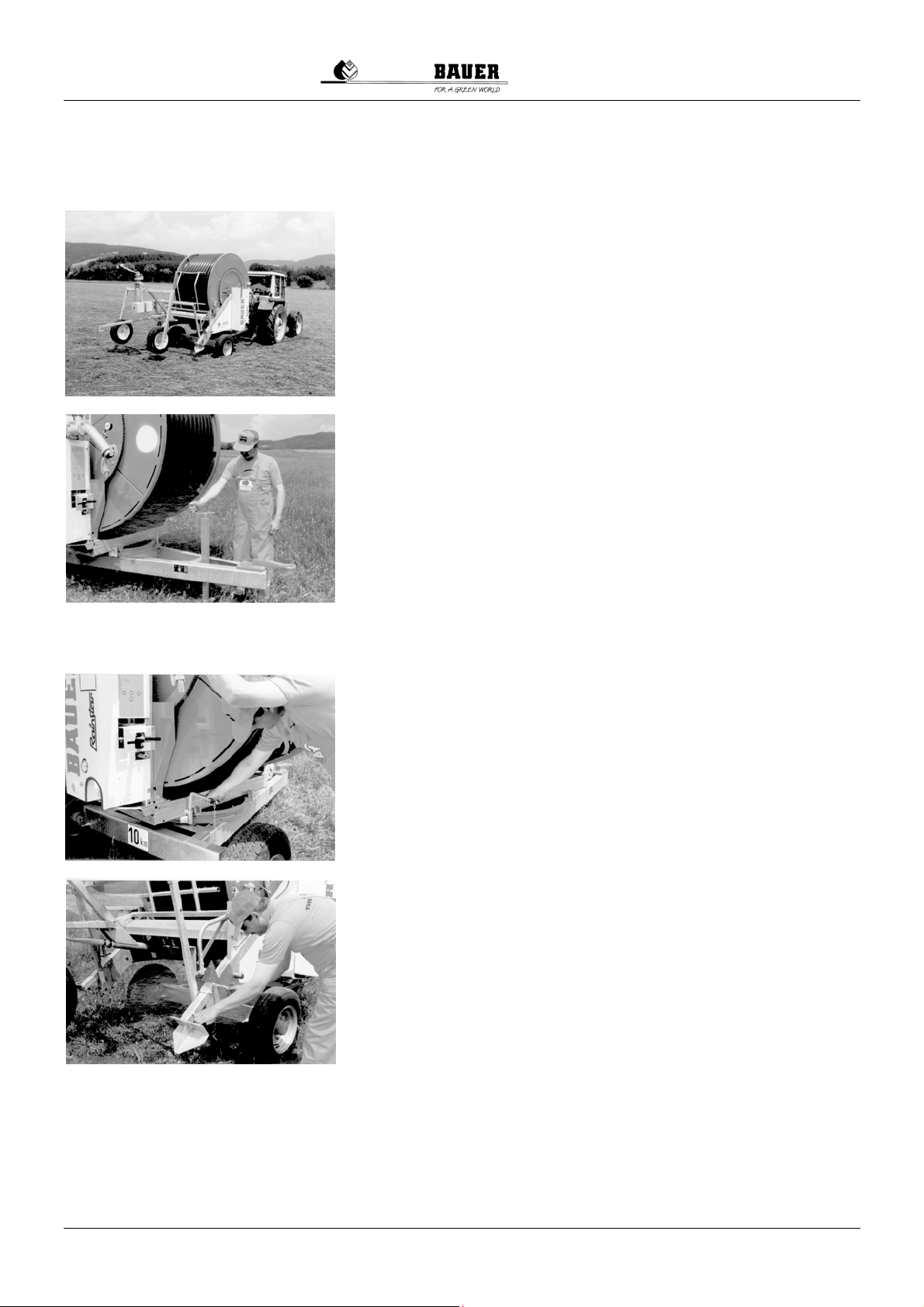

5.2.2 LOWERING THE CART .................................................................................................................................... 9

5.2.3 PE-PIPE PULL-OFF ......................................................................................................................................... 11

5.2.4 SPEED CONTROL WITH ECOSTAR 4300 .................................................................................................... 13

5.2.5 SPEED ADJUSTMENT with mechanical regulation ( Optional ) .................................................................... 13

5.3 OPERATING MODE II: LAYING DOWN THE PE-PIPE ................................................................................ 15

5.3.1 FUNCTIONAL DESCRIPTION OF THE MAIN COMPONETNS ................................................................ 16

6 ECOSTAR 4300 .............................................................................................................. 20

6.1 General ...................................................................................................................................................................... 20

6.2 DISPLAY WINDOWS AND MENU OVERVIEW ............................................................................................... 21

6.3 PROGRAMMING OF 4 DIFFERENT SPEEDS .................................................................................................. 25

6.4 STATUS DISPLAY .................................................................................................................................................. 26

6.5 The MOST COMMON COMBINATION OF DIFFERENT CONSTANTS ...................................................... 27

6.6 STOP - SENSOR ...................................................................................................................................................... 28

6.7 Operation of the BAUER ECOSTAR 4300 ............................................................................................................ 29

6.7.1 SPEED ADJUSTMENT .................................................................................................................................... 30

6.7.2 PRE – OR POST IRRIGATION ....................................................................................................................... 30

6.7.3 START ............................................................................................................................................................... 31

6.7.4 MONITORING .................................................................................................................................................. 31

Manual for BAUER RAINSTAR TX Plus V

Page 6

6.7.5 STOP ................................................................................................................................................................. 32

6.8 Pressure SWITCH ( OPTIONAL EQUIPMENT) ................................................................................................ 33

6.9 ERROR DESCRIPTION – ECO STAR 4300 ....................................................................................................... 33

6.10 Programming procedure ......................................................................................................................................... 34

6.11 BATTERY................................................................................................................................................................. 37

6.11.1 SOLAR PANEL ................................................................................................................................................ 38

6.11.2 CHECKING THE CONNECTIONS ................................................................................................................ 38

6.11.3 CHECKING THE LENGTH SENSOR ............................................................................................................ 38

6.11.4 LIMIT STOP FOR TURBINES – REGULATING VALVE WITH ECOSTAR 4300 .................................... 39

6.11.5 SHORT CHECKLIST fOR ECOSTAR 4300 ................................................................................................... 39

7 OPTION - SMS ................................................................................................................ 40

8 CABLE CONNECTIONS –CONNECTION DIAGRAM .................................................... 43

8.1 Checklist fOR ECOSTAR 4300 ............................................................................................................................. 45

8.2 TABLE FOR PRE-AND POST-IRRIGATION .................................................................................................... 49

9 MECHANICAL CONTROL .............................................................................................. 50

9.1 TACHOMETER ( OPTIONAL ) ............................................................................................................................ 51

10 EMERGENCY SHUT-OFF ............................................................................................ 53

11 WINDING MECHANISM ............................................................................................... 54

12 SHUT-OFF AND SAFETY EQUIPMENT ...................................................................... 54

13 CART ............................................................................................................................ 55

14 OVERPRESSURE SHUT-OFF VALVE (OPTIONAL ON ECOSTAR STAR 4300) ..... 55

15 OVERPRESSURE SHUT-OFF VALVE (OPTIONAL WITH MECHANICAL SPEED

CONTROL) ............................................................................................................................ 56

16 LOW-PRESSURE OR UNDERPRESSURE SHUT-OFF VALVE (OPTIONAL WITH

ECOSTAR 4300) ................................................................................................................... 57

17 LOW-PRESSURE OR UNDERPRESSURE SHUT-OFF VALVE (OPTIONAL WITH

MECHANICAL SPEED CONTROL) ...................................................................................... 57

VI

Manual for BAUER RAINSTAR TX Plus

Page 7

18 WINTERIZATION – DRAINING .................................................................................... 58

19 SETTING INSTRUCTIONS FOR RAINSTAR TX WITH GEARBOX G2 ..................... 59

19.1 SETTING THE BAND BRAKE (1) ........................................................................................................................ 59

19.2 SETTING THE THREADED ROD (4) .................................................................................................................. 59

19.3 SETTING THE SHIFTING GATE (8) ................................................................................................................... 60

19.4 SETTING 1st GEAR SHUT-OFF ............................................................................................................................ 61

19.5 SETTING 2nd GEAR SHUT-OFF ........................................................................................................................... 61

19.6 SHUT-OFF FRAME (14) ADJUSTMENT ............................................................................................................ 62

19.7 SHUT-OFF ROD ADJUSTMENT (20) .................................................................................................................. 62

19.8 TESTING 2nd GEAR SHUT-OFF ........................................................................................................................... 63

20 WINDING MECHANISM - STARTING POSITION ...................................................... 64

21 90 TX PLUS WITH G4 GEARBOX PUTTING INTO OPERATION .............................. 65

21.1 OPERATING MODE I: PE-PIPE PULL-OFF .................................................................................................... 65

21.2 LOWERING THE CART ........................................................................................................................................ 65

21.3 POSITIONS OF THE SHUT-OFF LEVER ........................................................................................................... 65

21.4 PE-PIPE PULL-OFF ................................................................................................................................................ 65

21.4.1 SPEED ADJUSTMENT .................................................................................................................................... 68

21.5 OPERATING MODE II: LAYING DOWN THE PE-PIPE ................................................................................ 68

21.5.1 FUNCTIONAL DESCRIPTION OF THE MAIN COMPONENTS ................................................................ 68

21.5.2 PTO REWIND: .................................................................................................................................................. 71

21.6 SPEED CONTROL .................................................................................................................................................. 72

21.7 TACHOMETER ....................................................................................................................................................... 72

21.8 EMERGENCY SHUT-OFF ..................................................................................................................................... 73

22 SETTING INSTRUCTIONS FOR RAINSTAR TX WITH G4 GEARBOX ...................... 74

22.1 SETTING THE SHIFTING GATE ........................................................................................................................ 75

22.2 SETTING THE BAND BRAKE .............................................................................................................................. 75

22.3 SETTING THE THREADED ROD ........................................................................................................................ 76

22.4 TESTING THE BAND BRAKE for release of the brake band ............................................................................ 76

22.5 SETTING THE GEARBOX SHUT-OFF ............................................................................................................... 77

Manual for BAUER RAINSTAR TX Plus VII

Page 8

22.6 TESTING THE SHUT-OFF .................................................................................................................................... 78

23 SERVICE AND MAINTENANCE .................................................................................. 78

24 TROUBLESHOOTING .................................................................................................. 79

25 CONFORMITY CERTIFICATE ..................................................................................... 84

VIII

Manual for BAUER RAINSTAR TX Plus

Page 9

1 General instructions for safety and

accident prevention

CHECK THE OPERATIONAL SAFETY OF THE MACHINE BEFORE EVERY START-UP.

1. In addition to the instructions contained in this manual, all specifications generally valid for safety and accident

prevention must be observed!

2. The warning and instruction signs affixed to the machine give very important instructions for safe operation.

Observing them serves your own personal safety!

3. Never put the machine into operation unless all guards and safety devices are completely mounted and in their

proper working position!

4. Acquaint yourself with all equipment components and controls as well as their respective functions before

starting to work. It is too late when the device is already running!

5. The operator’s clothes should fit tightly. Avoid wearing loose clothes!

6. When handling slurry always keep in mind that the gasses produced are highly toxic and extremely explosive in

combination with oxygen. Therefore, open fires, light tests, sparking and smoking are strictly forbidden!

7. Utmost care is required with regard to gasses in slurry and dung channels at open valves to the preliminary pit,

before the main pit, or at cross channels. The same applies to mixing and withdrawal points when mixers or

pumps are running!

8. When handling slurry always ensure sufficient ventilation!

9. Keep the machine clean to avoid fire hazards!

Power take-off (applies only to PTO driven machines)

1. It is not allowed to use any other types of PTO drive shafts except the ones prescribed by the manufacturer!

2. Drive-shaft guard tube and guard cone as well as the PTO guard – also on the machine side - must be mounted

and in good working order!

3. When using a PTO drive shaft always observe the specified overlap in transport and working position!

4. Never connect or disconnect the PTO drive shaft unless the PTO is stopped, the engine turned off, and the

ignition key pulled out!

5. Make sure the drive shaft is always connected and secured properly!

6. Attach the safety chain to keep the drive shaft guard from rotating with the shaft!

7. Before you turn on the PTO make sure that the selected tractor PTO speed corresponds with the permissible

implement speed!

8. Before starting the PTO make sure that nobody is standing in the danger zone of the machine!

9. Never turn on the PTO when the engine is turned off or during a transport drive!

10. When working with the PTO nobody is allowed near the turning PTO or drive shaft!

11. Warning! The PTO shaft may continue turning due to its centrifugal mass after the PTO has been turned off!

Keep clear of the machine during this time and do not touch until the PTO shaft stands absolutely still!

12. For cleaning, greasing, or adjusting the PTO driven implement or drive shaft, PTO and engine must be switched

off and the ignition key pulled out!

13. Place the disconnected drive shaft on the provided support!

14. When drive shaft has been removed put the guard on the PTO shaft!

15. If a defect occurs repair it immediately before starting to work with the machine!

Hydraulic system

1. Hydraulic system is under high pressure!

2. When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are connected as specified!

3. Before coupling the hydraulic hoses with the tractor’s hydraulic system make sure that the entire hydraulic

system is pressureless both on the tractor and implement side !

4. Inspect the hydraulic lines at regular intervals and replace them immediately in case of defects or ageing.

Replaced hoses must comply with the technical specifications of the implement manufacturer!

5. When looking for leaks use only suitable equipment because of the injury hazard involved!

6. Liquids emerging under high pressure (hydraulic oil) may penetrate the skin and cause serious injuries! An

injured person must see a doctor immediately! Danger of infection!

7. Before working on the hydraulic system the machine must be lowered, the system depressurised and the

engine turned off!

Operating manual for BAUER RAINSTAR Series TX Plus

1

Page 10

Electric-driven implements

1. All work beyond normal maintenance of the implement should be performed only by a professional electrician!

2. Defective or broken plugs and sockets must be replaced by a professional electrician!

3. Never pull a plug out of the socket at the flexible electric cord!

4. Extension cables for power supply should be used only temporarily! Never use such lines permanently as a

substitute for the required fixed installations!

5. Flexible lines laid across traffic areas on the farm must have at least 5 m ground clearance!

6. Always turn off the power supply before you do any work on the machine!

7. Check all electric lines for visible defects before you put the machine into operation! Replace defective cables and do not

start the machine before that!

8. Never use electric-driven implements in damp situations or locations exposed to fire hazard unless they are adequately

protected against moisture and dust!

9. Covering electric motors may cause heat concentration with high temperatures which could destroy the operating

equipment and cause fires!

Hand-operated devices (valves)

1. Because of the slurry gasses produced in the lines, no slu rry is allowed to remain in closed pipelines – bursting

hazard!

2. Lay the pipelines with sufficient inclination and make sure that the selected closing order of valves allows all

lines to be drained completely!

3. Protect the valves against unauthorised handling!

4. If a valve gets jammed do not apply force! Use only the operating levers supplied with the implement!

5. Observe the permissible maximum operating pressure of valves and pipelines when pumps are operated!

6. Service only when the tanks are empty!

Maintenance

1. Never perform any maintenance, service or cleaning work or fault elimination steps unless the drive is turned

off and the engine is standing still!

2. Check proper fit of all nuts and bolts regularly and tighten them, if necessary.

3. If maintenance work is required on the lifted machine always secure it by means of appropriate supports!

4. When exchanging tools with cutting edges always use proper tools and wear safe protective gloves.

5. Dispose of oil, grease and filters according to local laws and regulations!

6. Always turn off power before working on the electric system!

7. Before electric welding on the tractor and mounted machines the generator and battery cables must be

disconnected!

8. Spare parts must meet manufacturer’s minimum technical specifications! This is the case for instance with

original spare parts for instance!

Operating manual for BAUER RAINSTAR Series TX Plus 2

Page 11

2 General

BAUER products are designed and manufactured carefully, subject to a system of continuous quality control.

BAUER RAINSTAR models 65/75/85/90 TX Plus are turbine-driven machines designed for fully mechanised and

labour-saving irrigation. Individual pipe sets are no longer laid down by hand; system set-up, repositioning, and

operation are all done with the tractor only.

BAUER RAINSTAR is a universal machine capable of covering fields of varying lengths and widths. There is no

need for supervision while the system is operating.

Strict observance of all operating and service instructions in this manual is the basic prerequisite for many years of

trouble-free operation. Therefore please make sure that all operators on your staff are familiar with the instructions

given in this manual.

The model number as well as the serial number (Vehicle identification number) are stamped into the nameplate. In

addition, the serial number is stamped into the frame of the undercarriage. Please state these data in all your

inquiries, correspondence, warranty matters and parts orders.

We warrant for this RAINSTAR according to our General Terms of Sale.

Operating manual for BAUER RAINSTAR series TX Plus 3

Page 12

3 SAFETY PRECAUTIONS FOR RAINSTAR TX PLUS

1. Read this manual before you put the system into operation for the first time.

2. Never handle the PE-pipe near the device or the device itself during pull-off or retraction.

3. During PE-pipe rewind with the tractor’s PTO or during pipe pull-off, always make sure that the gear shift

lever is in the proper position. Moreover, the maximum permissible speed must not be exceeded.

WARNING!

4. Never service or set any part of the system while it is operating.

5. Keep clear of all moving parts.

6. Never expose any moving parts by removing protective elements.

7. Keep a safe distance from the sprinkler during operation.

8. Be careful in case of high connecting pressure!

9. Make sure that the sprinkler’s water jet does not hit public roads.

10. The RAINSTAR is licensed for transport in agricultural operation only.

For transportation on public roads all applicable traffic requirements must be strictly adhered to.

WARNING!

Danger by improper handling!

For safety reasons it is not allowed to transport the RAINSTAR by pulling it with a

fork-type drawbar (OPTIONAL) and the toolbar!

11. When loading the machine on a trailer note that the water remaining in the pipe shifts the system’s centre of

gravity upward.

12. When driving in curves with the RAINSTAR loaded on a trailer the permissible maximum driving speed is

considerably reduced dependent on the position of the RAINSTAR’s centre of gravity!

13. Always ensure that the locks and stops are secured according to the machine’s general conditions for

transport.

14. Before starting to irrigate near electric power lines you should contact your local power supply company

regarding safe distances that have to be allowed.

15. Maximum permissible speed: 10 km/h

Operating manual for BAUER RAINSTAR Series TX Plus 4

Page 13

4 DESCRIPTION

The RAINSTAR is a universal irrigation machine for varying lengths and widths of fields and best suited for

irrigating seedbed and garden crops, park areas and horticultural plantations as well as any kind of grassland.

The main components of the RAINSTAR are a two-wheel undercarriage on which is mounted the turntable

swivelling through 270°, and the reel with the special PE-pipe, the multifunctional compact gearbox with

TX20 turbine, and the high-rise cart that is ideal particularly for high crops, with the BAUER wide-range gun.

The material of the PE-pipe corresponds to the latest findings of the art. One end of the pipe connects to the reel

drum and to the water supply through its axle. The other end of the pipe is coupled with the high-rise cart. The

cart’s track width is infinitely adjustable (See Technical Data).

The heart of the RAINSTAR is the TX 20 turbine. It is a full-flow turbine mounted in a flow-promoting position

directly on the reel. This turbine is nearly insensitive to soiled water and offers maximum efficiency. The drive

shaft is made of stainless steel. The regulating cam inside the turbine is coated with a wear-proof rubber lining.

The lifetime lubricated drive shaft bearing is sealed by a maintenance-free mechanical seal.

TX 20 turbine is designed for water flow rates from 13 to over 60 m³/h and features a wide control range. Impeller

speeds range from 200 to 800 rpm.

The cart retraction speed is infinitely variable. It is adjusted by means of the ECOSTAR 4300 and can be read

from the display. Depending on the available water flow and connecting pressure, it may vary between 8 and

150 m/h. The connecting pressure at the machine should not exceed 11 bar.

Power is directly transmitted from the turbine to the change-speed gearbox and the chain drive onto the reel. A

band brake prevents fast reverse rotation of the reel in the final shut-off position, when the PE-pipe is stretched.

The band brake as well as the gear wheels in the oil-filled change-speed gearbox act like a brake and prevent the

PE-pipe windings on the reel from loosening during pipe pull-off.

For safety reasons the drive is fitted with an emergency stop and a reversing stop as well. With this emergency

stop device the drive can be stopped immediately by hand.

WARNING!

Never remove the drive cover before you have turned off the water supply to the

machine and slackened the stretched PE-pipe.

To slacken the stretched PE-pipe move the gear shift lever downward carefully (see proper procedure).

A winding carriage moved by a helically grooved spindle ensures that the PE-pipe is wound up properly on all

layers.

Operating manual for BAUER RAINSTAR series TX Plus 5

Page 14

ECOSTAR 4300 keeps the retraction speed constant on all layers independent of the pipe length still lying on the

field.

Mechanical control option: In order to ensure that the retraction speed remains constant on all layers

independent of the length of PE-pipe still lying on the ground, RAINSTAR machines with this option are equipped

with a special layering mechanism. This compensating mechanism is activated by the speed compensating bar of

the shut-off frame that fits closely on the pipe on all layers and activates the regulating cam of the turbine through

the regulating rod.

At the end of the irrigation strip the cart is automatically lifted into the transport position. Thereby the automatic

drive shut-off is activated by rods. After being lifted automatically the cart is locked in the transport position.

If the machine is equipped with a shut-off flap (ECOSTAR) or a shut-off valve (mechanical speed regulation) the

water supply to the machine is shut off simultaneously.

After shut-off the RAINSTAR can be transported to its next setting-up position immediately. Then the PE-pipe can

be pulled or laid down again, the water supply connected, and the machine is ready for the next run.

When driving on public roads the reel must be turned into the driving direction and secured with the lock bolt. The

PE-pipe must be fully wound up on the reel and the cart lifted and locked. The jack and both rear machine

supports must be withdrawn to their uppermost position.

On public roads the drawbar and coupling ring must be hitched to the tractor’s yoke and secured with the pin.. The

maximum permissible driving speed of 10 km/h must be observed. For increased safety against overturning in

curves we recommend to set the maximum possible track width.

On principle, it is possible to transport the machine between hydrants in the field with the cart lifted on the side. In

this configuration the driving speed must always be adapted to the existing conditions and should never exceed 5

km/h. You must also take into consideration that this type of transport requires a wider driving lane.

Operating manual for BAUER RAINSTAR Series TX Plus 6

Page 15

65 TX Plus – 90 TX Plus with gearbox G2

5 PUTTING INTO OPERATION

Before and during the first start-up grease all bearings, chains and guide parts of the winding mechanism. Use

normal ball bearing grease for all bearing assemblies with grease nipples, and a viscous and durable type of

grease for chains, guide rods and joints.

Tighten the wheel nuts before the first operation and check the tires for specified pressure (see Technical Data).

Tighten also the connecting bolts, the connection of the turntable side member on the undercarriage, the ball race

on the undercarriage, and the fastening of the hitch eye, according to the “Service and Maintenance“ table.

5.1 STEPS TO BE PERFORMED ONCE OR AS REQUIRED

Set the required track width on high-rise cart and RAINSTAR

undercarriage, depending on the existing type of crop.

Place the appropriate number of balancing weights on the

balancing pendulum of the cart. Two weights will do for

nozzle diameters from 14 to 24 mm. For diameters larger

than 24 mm two additional weights should be placed on the

pendulum when the smallest track width setting is used.

Nozzle DIA Track 1500

14 - 24 mm 2 weights

from 25 mm 4 weights

If the asymmetric cart design is used, the cart pendulum must

be loaded with two weights and the opposite cart wheel with

two additional weights.

Set the part circle on the wide-range sprinkler (approx. 220°

for full strip width). Confer to separate sprinkler manual for

detailed sprinkler instructions. Adjust the WINDGUN to

prevailing wind conditions by adjustment of the trajectory

angle.

Operating manual for BAUER RAINSTAR series TX Plus 7

Page 16

5.2 OPERATING MODE I: PE-PIPE PULL-OFF

5.2.1 Machine transport to set-up position

During transport the reel should be turned into the driving

direction and secured with the lock bolt. Cart, jack, and both

rear support legs must be lifted or withdrawn.

For lateral PE-pipe pull-off, set up the RAINSTAR on the

headland at right angles to the selected irrigation strip and

detach it from the tractor.

When you position the RAINSTAR make sure that the machine’s vertical axis of rotation is in the middle

of the driving lane or centred between two crop rows.

Adjust the undercarriage about level with the jack.

For lateral pull-off remove the lock bolt, turn the reel into the

direction of the driving lane and secure it again with the lock

bolt.

Operating manual for BAUER RAINSTAR Series TX Plus 8

Remove transport lock bolts from support legs.

Page 17

WARNING!

If your RAINSTAR 90 TX Plus is equipped with the „hydraulic machine supports“ option, couple both hydraulic

hoses with the tractor’s hydraulic system and extend the supports.

WARNING!

On very hard soil the machine supports must be lowered or extended into the holes dug into the ground for this

purpose.

Machine supports are equipped with a spike which penetrates the soil very easily with the „hydraulic supports“

option.

Machine supports slide to the ground automatically.

Drive the supports into the ground with the detachable hand

wheel ...

......... and secure the supports with lock bolts.

The standard RAINSTAR equipment does not include a control unit (Optional).

Therefore the tractor’s hydraulic system must be switched over accordingly after the

hoses have been coupled. If this is not possible exchange the two hoses.

5.2.2 LOWERING THE CART

Disengage the mechanical locking of the cart in the operating

position.

Operating manual for BAUER RAINSTAR series TX Plus 9

Page 18

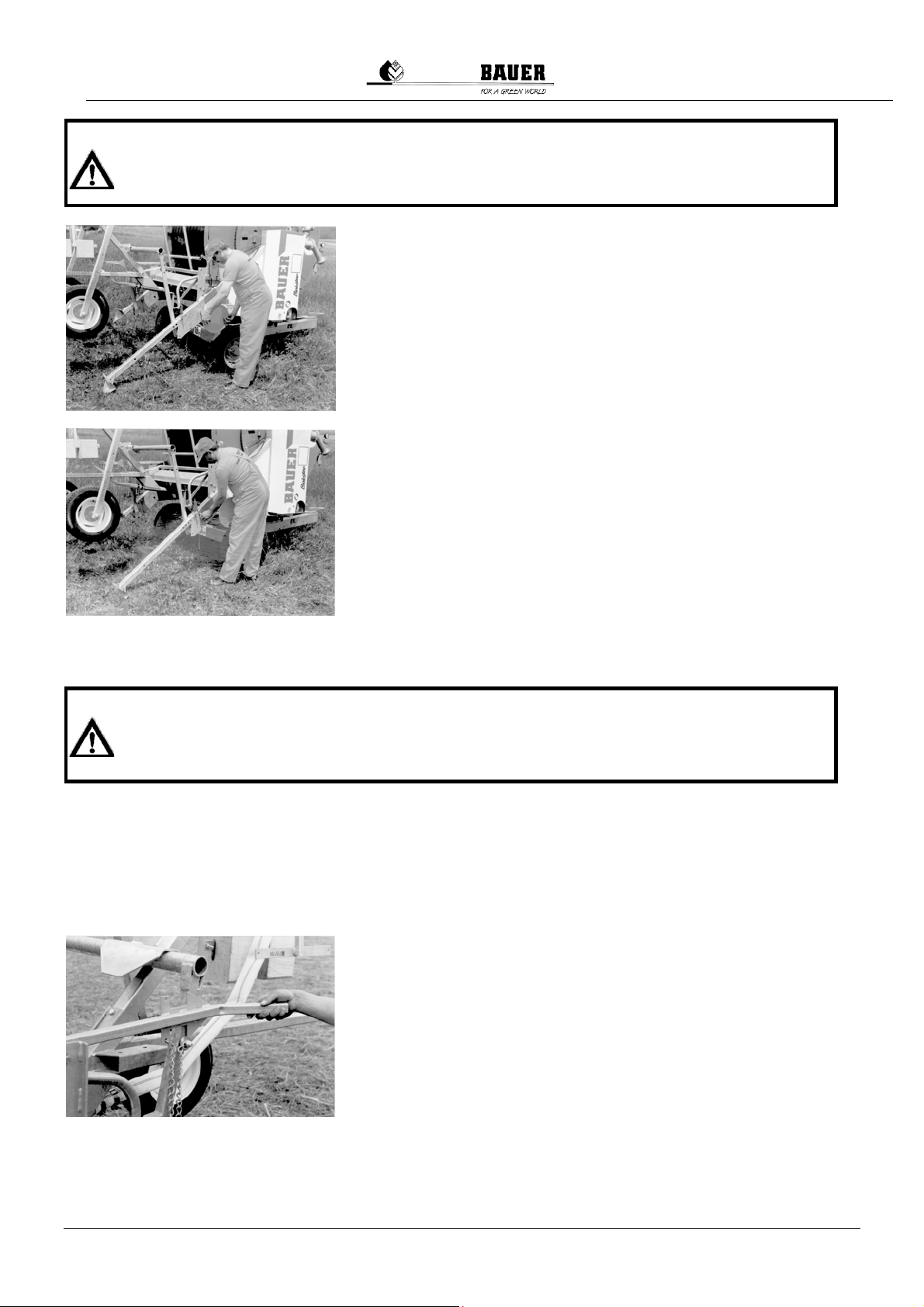

WARNING!

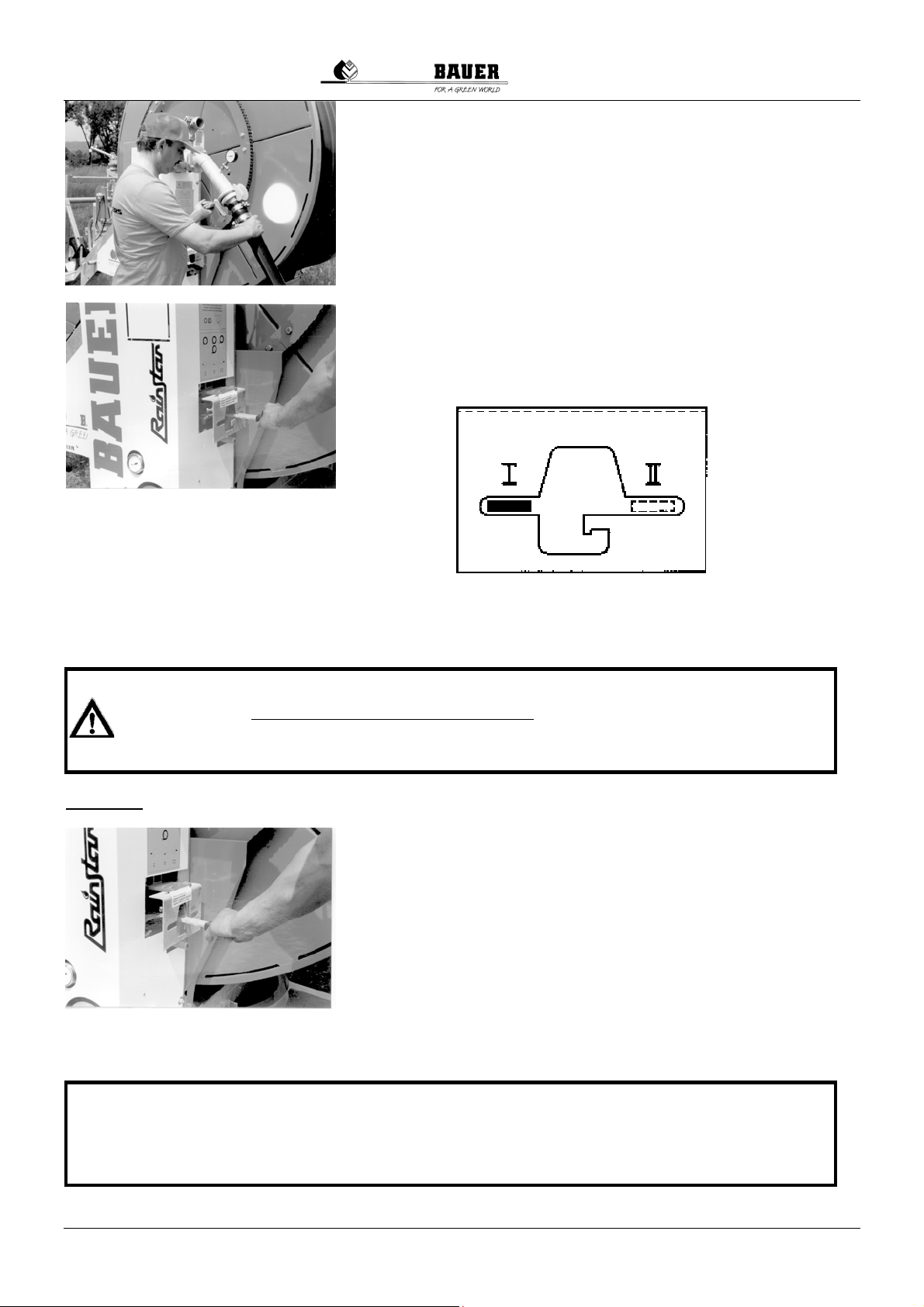

POSITIONS OF THE GEAR SHIFT LEVER

Slackening the PE-pipe

Gear stage I

In doing so the operator’s position should be outside of the machine supports.

Shut-off position

Transport position

Gear stage II

PE-pipe pull-off

Push the gear shift lever downward carefully - the carts moves

down slowly.

PTO rewind

Operating manual for BAUER RAINSTAR Series TX Plus 10

Page 19

Move the gear-shift lever to the „PE-pipe pull-off“ position. A

spring presses the lever up and locks it.

5.2.3 PE-PIPE PULL-OFF

Pick up the draw-out hook with the toolbar and start pulling

the cart .

Do not stop abruptly. Always slow down gradually at an intermediate stop in the field or at the end of the pull-off.

Stop pulling off the pipe when the white marking line becomes visible on the reel.

If the PE-pipe has been exposed to the sun for a longer period or if its surface

WARNING!

temperature rises above 35 °C for some other reason you must let water run

through the pipe to cool it off before the unwinding or retraction procedure.

The standard wheel cart or the asymmetric wheel cart need

not be hoisted (therefore 1 draw-out hook is sufficient).

Pull-off speed: do not exceed 5 km/h!

Operating manual for BAUER RAINSTAR series TX Plus 11

Page 20

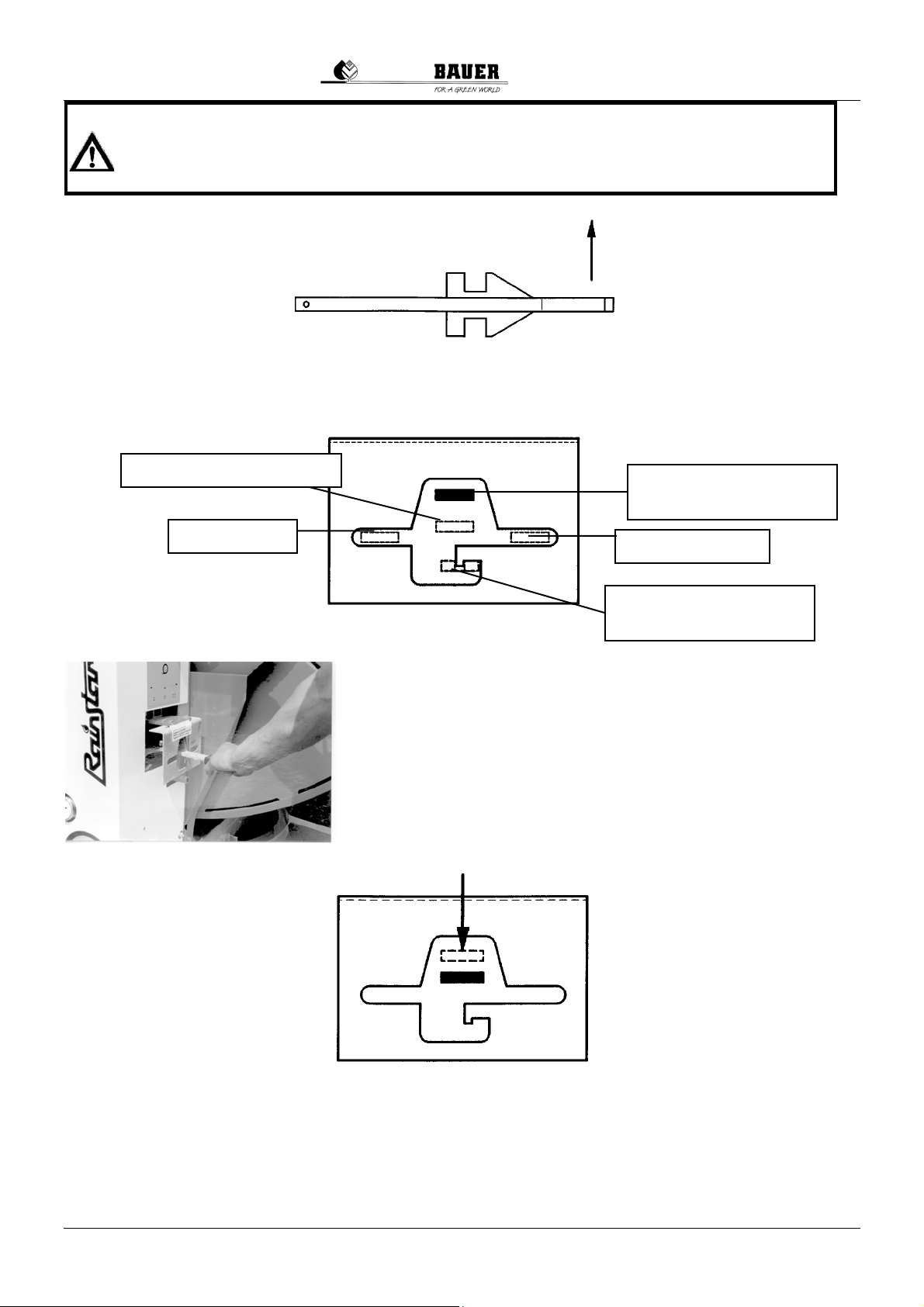

Couple the pressure hose. Open the water supply.

Position I slow retraction

Position II fast retraction

If a wrong position has been selected:

WARNING!

CAUTION WHEN CHANGING GEARS: never change gears when the PE-pipe is

stretched!

When the full operating pressure has been reached and clear

water is discharged at the sprinkler’s nozzle in a full jet without

air bubbles, push the gear shift lever to the “PE-pipe

retraction“ position.

Procedure

I - O - slackening the PE-pipe - II

II - O - slackening the PE-pipe - I

Slackening the PE-pipe – see „Proper procedure“ on following page.

Shifting into gears I and II is only possible when the cart is lowered and the turbine rotating!

CAUTION!

The reel starts pulling in the PE-pipe .

When the cart is lifted in the shut-off position the gear-shift lever is held in the

0 position and shifting is not allowed!

Operating manual for BAUER RAINSTAR Series TX Plus 12

Page 21

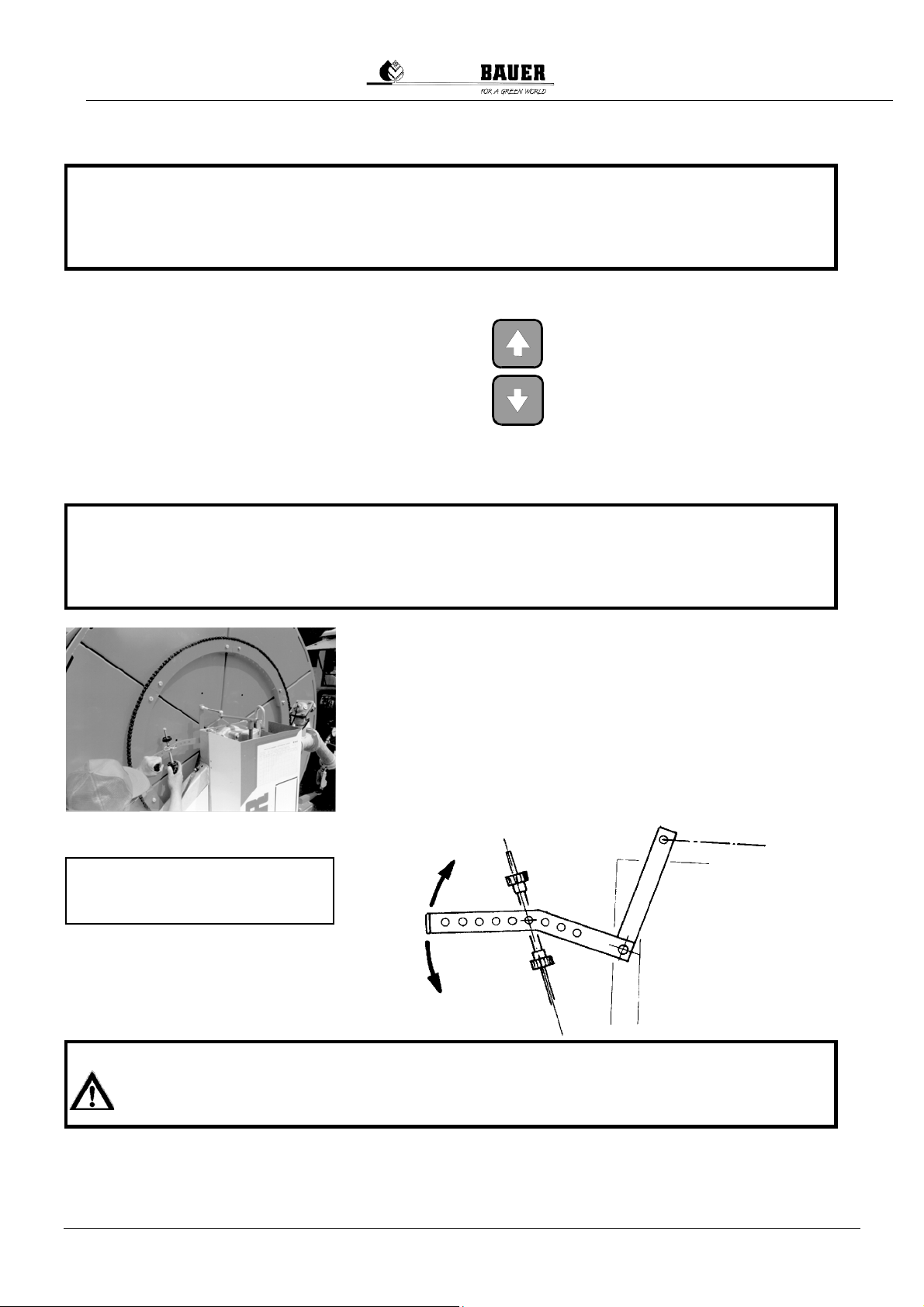

5.2.4 SPEED CONTROL WITH ECOSTAR 4300

CAUTION!

Set the required retraction speed with the arrow keys

in the operating mode of ECOSTAR 4300.

You can readjust the speed any time while the

machine is operating.

See Retraction speed control with ECOSTAR

Do not set the speed until half a PE-pipe winding has been wound up on the reel

and the pipe is already stretched.

5.2.5 SPEED ADJUSTMENT with mechanical regulation ( Optional )

CAUTION!

Do not set the speed until half a PE-pipe winding has been wound up on the reel

and the pipe is already stretched.

Loosen the knurled nuts that secure the adjusting lever. Set

the desired retraction speed with the adjusting lever – the

speed is indicated on the tachometer (optional equipment).

Afterwards secure the adjusting lever again with the knurled

nuts.

Lever up = slower

Lever down = faster

WARNING!

Operating manual for BAUER RAINSTAR series TX Plus 13

The drive has four speed ranges (see Functional Description on page 16).

Page 22

Therefore the speed reading on the tachometer (optional)

must be applied to the appropriate chart.

At the end of the run the cart is lifted automatically and the

drive is shut off through shut-off rods.

The water supply is stopped by means of the „overpressure

shut-off valve“ option, or the pumping unit is shut down by the

„low-pressure shut-off valve“ option in combination with a

pressure switch in the supply line.

When the pipe has been fully rewound, relieve the machine

supports with the hand wheel, move them into the transport

position and secure them with the locking bolts.

If the RAINSTAR becomes misaligned or pulled aslant during the irrigation run, it must be realigned. For this

purpose you have to slacken the PE-pipe first.

Operating manual for BAUER RAINSTAR Series TX Plus 14

Page 23

Proper procedure:

1. Shut off water supply to the RAINSTAR. The PE-pipe slackens only slightly through the turbine acting as a

hydraulic brake.

2. Move gear shift lever to the middle position and slacken

the pipe by pushing the lever down slowly and carefully.

3. Realign the machine and support it adequately.

4. Open the water supply again. PE-pipe retraction continues.

5. Put the gear shift lever into the desired position.

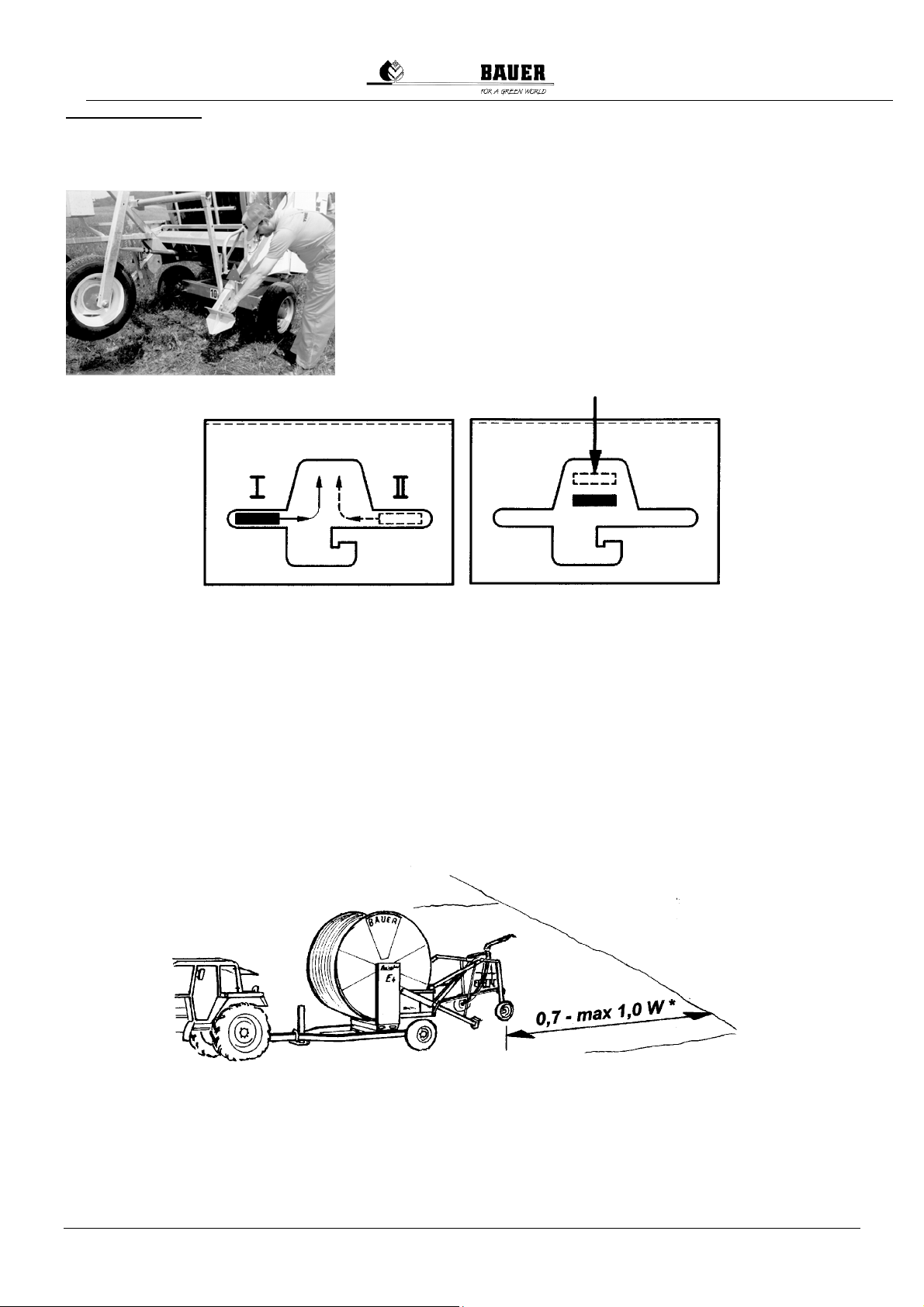

5.3 OPERATING MODE II: LAYING DOWN THE PE-PIPE

In addition to the pull-off method the PE-pipe can also be laid down on the ground while the machine is hauled over

the field. This method is mostly used in situations where heavy soil makes it impossible to pull the cart across the

field or where the field is longer than one or two times the PE-pipe length. Moreover, the laying down method

allows using smaller tractors because no pulling forces are applied on the pipe.

Drive the RAINSTAR into the field allowing for the sprinkler’s distance of throw.

*) W = distance of through of the sprinkler

Operating manual for BAUER RAINSTAR series TX Plus 15

Page 24

Lower the cart as described in Operating mode I, chapter

“Lowering the cart” and anchor it slightly. Now drive over the

field with the machine.

Carry out all other steps as described before.

5.3.1 FUNCTIONAL DESCRIPTION OF THE MAIN COMPONETNS

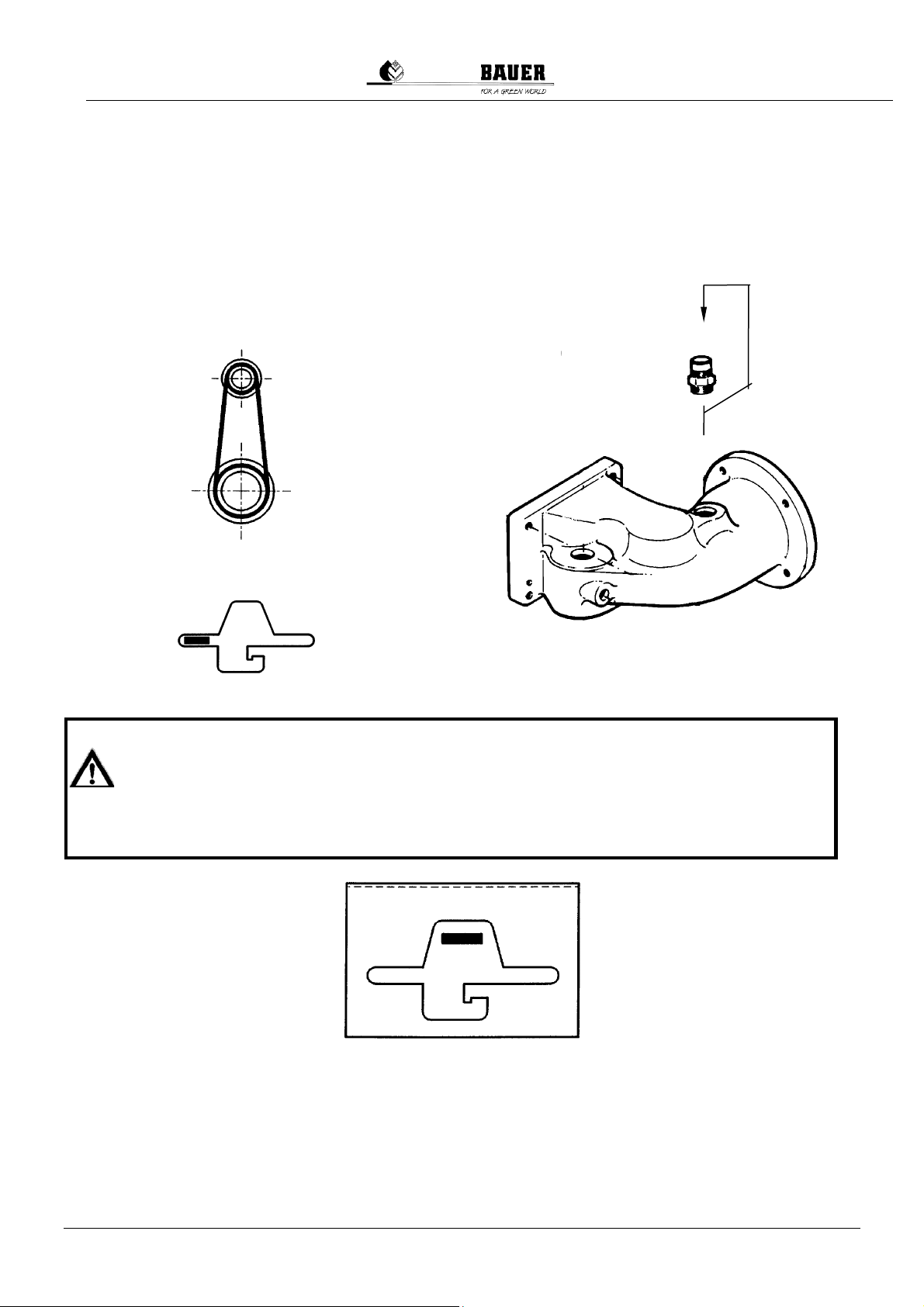

5.3.1.1 MACHINE DRIVE - FULL-FLOW TURBINE

The change-speed gearbox contains gear wheels which

X20 full-flow turbine is a specifically designed turbine with

large cross sections and minimum pressure loss. Therefore it

can reach high retraction speeds also at very low flow rate. It

features a highly flow-promoting design and is mounted

directly on the reel shaft. The turbine provides the energy

needed for PE-pipe retraction. Speed is taken directly off the

impeller shaft and transmitted over a two-stage (three-stage)

V-belt drive to the change-speed gearbox.

reduce the turbine’s speed accordingly. The gearbox features

two speeds. Reel drive stop at the end of the irrigation strip is

achieved by disengagement of the toothed clutch.

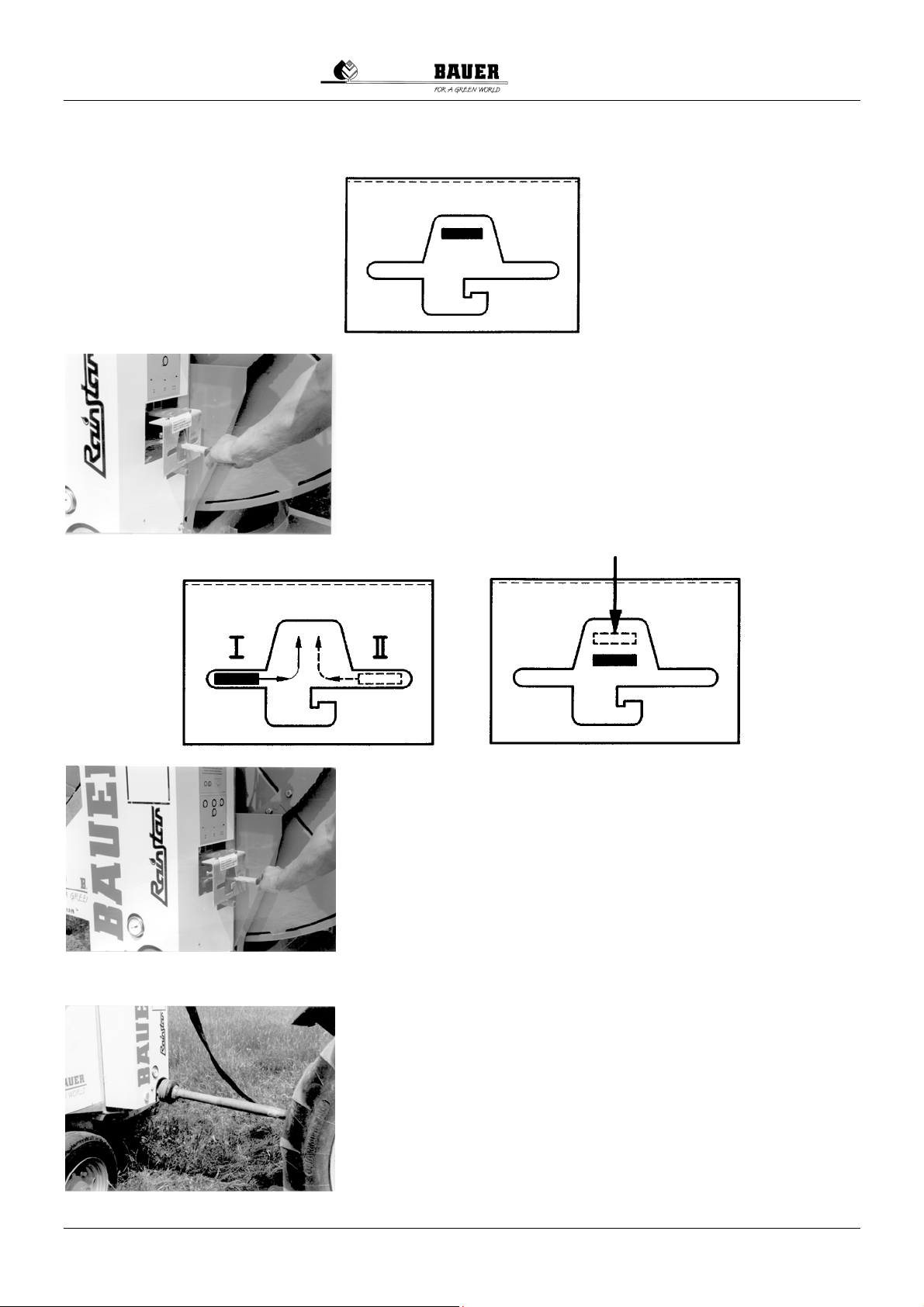

In combination with the two belt stages the two-speed gearbox allows precise adaptation to existing operating

conditions. As a result, the following retraction speeds (m/h) can be reached:

65 TX Plus , 75 TX Plus , 85 TX Plus

8 - 30 22 - 45 40 - 80 50 - >100

vE = [ m/h ] vE = [ m/h ] vE = [ m/h ]

vE = [ m/ h ]

833 5804 . 4

90 TX Plus , PE Ø 8 5 - 90 , Getriebe / gea rbox G2

85 TX Plus , PE Ø 90

90 TX Plus [ m/h ]

9 - 23

11 - 30 22 - 55

18 - 45

85 TX Plus , PE Ø 90 [ m/h ]

12 - 30

15 - 40

25 - >100

30 - >100

vE = <10

833 5861 . 4

Operating manual for BAUER RAINSTAR Series TX Plus 16

Page 25

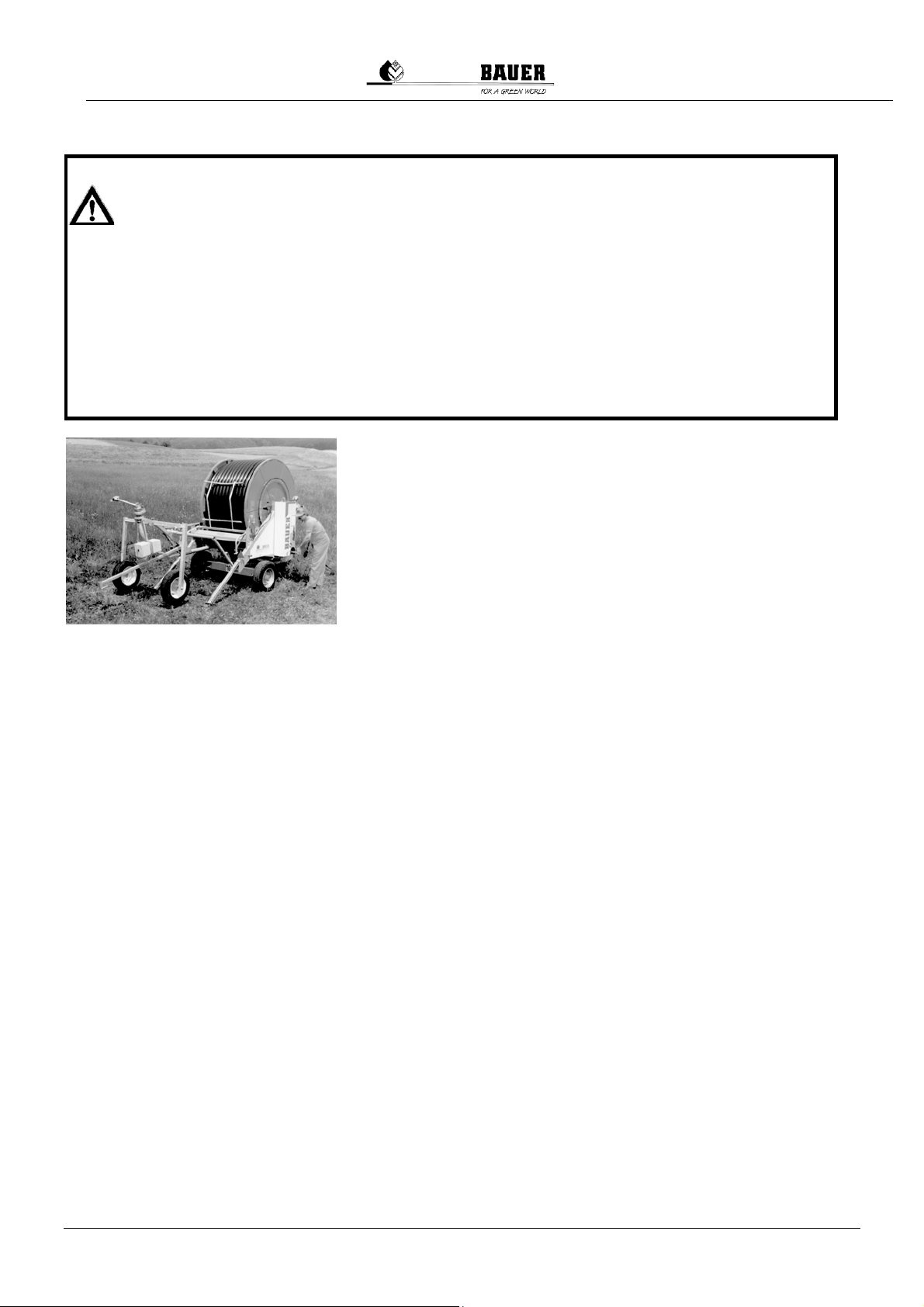

On RAINSTAR models with 90 mm PE-pipe diameter (basic units 85 TX and 90 TX ) the turbine is fitted with a

special connecting bend as well as a three-stage V-belt drive.

This design allows low retraction speeds and as a result precipitation rates of up to 50 mm, even in case of large

flow rates (up to nozzle dia. 30 mm).

For this purpose you screw out the regulating screw (1) which is easily accessible, and screw it back into the hole

after turning it around 180° with the sealing cone side pointing outward.

As a result, part of the water flow is redirected above the turbine’s impeller.

This reduces the output of the turbine and consequently also the retraction speed.

Moreover, the 3-grooved V-belt pulley provides an additional reduction stage so that the low retraction speed

required for such extreme conditions can be reached (for 50 mm precipitation height).

WARNING!

Never remove the drive cover for service work or change of the transmission unless

the PE-pipe has been completely slackened! Put the gear shift lever into the shutoff position! This shut-off position applies also for transporting the machine on

streets and roads!

Switching from I to II or the other way round is easy to do with the gear shift lever when the cart is lowered and the

turbine rotating.

Operating manual for BAUER RAINSTAR series TX Plus 17

Page 26

But note:

When the cart is lifted and in the shut-off position, the gear-shift lever is held in “0” position and shifting is

impossible! If the PE-pipe is stretched you have to slacken it first, before engaging the next gear

Move the gear shift lever from a gear stage to the middle

position. A spring presses the gear shift lever up and

prevents fast reversing of the reel and PE-pipe by means of

the band brake. By pushing the gear shift lever down very

slowly you release the brake and slacken the PE-pipe.

Afterwards you can change into the required gear.

PTO DRIVE

Operating manual for BAUER RAINSTAR Series TX Plus 18

If required, you can rewind the PE-pipe with the tractor and a

PTO shaft. Move the gear shift lever to zero position. A

spring presses the gear shift lever into the locking recess. In

this position the band brake is released. This gear shift lever

position serves also for PE-pipe pull-off.

Page 27

Rewinding the PE-pipe with the PTO shaft becomes necessary if irrigation is no longer necessary due to natural

rainfall or if the PE-pipe has been pulled off to drain the machine for winterization

WARNING!

Rewind at lowest possible PTO speed – start slowly and smoothly – always

avoid jerky start-up.

Maximum PTO speed = 540 rpm

Avoid extra strain by smallest possible PTO shaft articulation.

If the PE-pipe is covered with mud it should be loosened and set free before the

rewind operation to reduce the pulling forces.

If the soil is deep and heavy the rewind must be carried out at a lower speed in

order to ensure that the permissible loads and pulling forces for PE-pipe and

RAINSTAR are not exceeded.

If you disengage the tractor’s PTO during PE-pipe rewind the reel must stand

absolutely still when the PTO shaft is re-engaged. Double motion may cause

severe damage.

When you drive the reel with the PTO, the automatic final

shut-off is inactive. Therefore you must stop the PTO in time

and wind up the end of the PE-pipe with the hand wheel. This

will prevent damage to cart, shut-off, gearbox, etc.

Operating manual for BAUER RAINSTAR series TX Plus 19

Page 28

6 ECOSTAR 4300

ReTRACTION SPEED CONTROL

6.1 General

BAUER ECOSTAR 4300 allows you to operate your irrigation machine with ease at the touch of a

The

button.

An illuminated four-line display offers you comprehensive indication of the machine’s current operational status.

Through permanent comparison of set-point and actual value of the retraction speed you can administer the

precipitation rate you need.

The ECOSTAR 4300 consists of the electronic box, a cable harness with the connected sensors for the PE- pipe

length retraction speed and shut-off as well as connections for battery, solar panel and the turbine regulation

motor.

Connections are also provided for installing a pressure switch and an electric shut-off valve (both optional).

The electronic system of the ECOSTAR 4300 is rigidly built and has been tested under different climatic conditions.

If problems still occur it is advisable to exchange the complete electronic box. If a sensor is defective it is possible

to exchange only the sensor, too.

Operating manual for BAUER RAINSTAR Series TX Plus 20

Page 29

6.2 DISPLAY WINDOWS AND MENU OVERVIEW

SPEED 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS Operation

ZONE 1 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS Operation

DISTANCE 123m

BATTERY 12.8V

CHARGE ON 0.231A

PRE- 0:45 NACH- 0:45

PRESSURE SENSOR █

STOP SENSOR █

SPEED SENSOR █ █

MOT1 0.0A MOT2 1.8A

ACT. SPEED 22m/h

START 0:00

OPERATING HOURS 123h

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

SIGNAL 23

NETWORK HOME

A: +45123456

B: +45234567

When the sign █ appears on the display, it means that the respective function is turned on.

Standard display

Standard display, Zone active

Press button MENU one time, in order to get to the

display of menu 2.

Press button MENU two times, in order to get the

display of menu 3.

Press button MENU

display of menu 4.

Press button MENU four times, in order to get to display

of menu 5.

Press the button MENU five times, in order to get to

display of menu 6.

(Only if GSM has been selected)

three times, in order to get to

Operating manual for BAUER RAINSTAR series TX Plus 21

Page 30

Standard MENU:

SPEED 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS operation

SPEED

Speed can be changed at any time during the irrigation, using the keys „+“ und „ –“.

ZONE

Current Zone 1 – 4, with corresponding speed. The speed cannot be changed. (zone active)

DOSE

The precipitation rate is calculated by means of constants, and shows the current mm for irrigation.

If the SPEED increases, the DOSE decreases. (constant 11 and 12)

TIME

To set the time: first set the speed to 11,1 m/h, and then press the

<CONST 1 TIME>. The time can be set with the buttons „+“ and „ –“. When the battery has

been removed the time is 00:00, and remains zero until it is set.

STOP

Time when the irrigation is finished incl. pre- and post irrigation.

STATUS

Irrigation status:

<Stop sensor >

<Running >

<PRE Irrigate >

<POST Irrigate>

<LOW Pressure >

Explanation see STATUS chapter

If the display shows LOW BATTERY instead of SPPED, the voltage in the battery is less than 11,8 V and the

battery needs to be charged.

Standard display

PROG- button 3 times to get to

MENU 2

DISTANCE 123m

BATTERY 12.8V

CHARGE ON 0.231A

PRE- 0:45 POST- 0:45

DISTANCE

The remaining length of the pipe. Distance can be changed immediately after pressing PROG three

times, then it can be changed with keys „+“ and„ –“.

BATTERY

Battery voltage.

CHARGE ON

Shows if the battery is charged from the solar panel. The battery is charged when the voltage is

below 14,0 volt.

PRE-

Current pre irrigation time.

POST-

Current post irrigation time.

Pre- and post irrigation time can be changed immediately after pressing PRE- or POST – with keys

„+“ and „–“.

Operating manual for BAUER RAINSTAR Series TX Plus 22

Page 31

MENU 3

PRESS SENSOR █

STOP SENSOR █

SPEED SENSOR █ █

MOT1 0.0A MOT2 1.8A

PRESS SENSOR

Shows if the pressure is high.The marker is on when the water pressure is high.

The machine can only work when the pressure is high.

STOP SENSOR

Shows if the stop switch is activated. The marker is on when the stop switch is on.

The machine can only work when the stop switch is on.

The stop switch has three functions:

SPEED SENSOR

Test speed sensor. The marker is on when the magnates activate the speed sensor.

MOT1, MOT2

Shows the current power consumption of the motor. The motor is stopped when the power

consumption exceeds 4,5 A. If the power consumption exceeds 4,5 A, and the motor has not

reached its end position the shut off valve is blocked.

1: Resets the distance counter

2: Post-irrigation

3: Inhibits the pulses to the regulating motor.

MENU 4

ACtual speed 22m/h

START 0:00

WORKING HOURS 123h

ACTUAL SPEED

Shows the current speed of the machine. Furthermore, the maximum running speed of the machine

can be checked if the ECOSTAR 4300 is set to a much higher speed than the machine can run.

The current speed can differ from the set speed, especially at the start. This is not an error because

the ECOSTAR 4300 ensures that the medium speed over a distance of 10 m is correct.

START

With this function the starting time of the machine can be delayed for up to 24 hours.

To set the start time press „PROG“-key three times and the time can be set with the keys „+“ and „–

“.

WORKING HOURS

The total working hour since the electronic was started for the first time.

Operating manual for BAUER RAINSTAR series TX Plus 23

Page 32

MENU 5

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

In this menu the irrigation can be set and four different retraction speeds are possible.

Press the „PROG“ key three times.

Further details see below.

MENU 6

SIGNAL 23

NETWORK HOME

A: +45123456

B: +45234567

SIGNAL GSM-signal strength

NETWORK GSM-Network type

A: First phone number on the SMS-list

B: Second phone number on the SMS-list.

Detailed description in the chapter GSM.

START:

The turbine can only start if the magnet activates the stop sensor (or stop sensors), see Menu 3 for controlling the

function of the stop sensor. When the „START key is pressed the shut-off valve opens. Next the by-pass valve

closes (the turbine starts). If the magnet does not activate the stop sensor only the shut-off valve opens. This is

used if the pressure should be released before disconnecting the hose at the hydrant.

DELAYED START TIME OF IRRIGATION:

First press „STOP“-key for closing the inlet of water. Next press „MENU“-key 3 times (Menu 4), „PROG“-key 3

times and you can start time. Finally, pre- and post- irrigation can be selected.

STOP:

When the magnet is removed from the stop sensor, the turbine stops and the shut-off valve over-pressure closes

(or if available the shut-off valve low-pressure opens).

If post-irrigation is chosen, the turbine stops and after the post-irrigation time the shut-off valve closes. If the key

„STOP“ is pressed, the turbine stops and the shut-off valve closes, regardless if post-irrigation was selected.

SUPERVISON:

The ECOSTAR 4300 has an integrated supervison system. SUPERVISON is activated if for some reason the

machine irrigates at the same place longer than a specified time. This time is factory adjusted to 20 minutes, see

programming for changing this time. If it set to 0 there is no supervison.

SPEED :

The speed is set with keys „+“ and „ –“, at first the speed changes step by step 0,1 m/h, after 10 steps for 1,0 m/h.

The speed can be changed at any time, even while the machine is running. If the time is checked it shows the new

time for the remaining irrigation.

Operating manual for BAUER RAINSTAR Series TX Plus 24

Page 33

PRE-IRRIGATION:

Pressing the key PRE- can activate pre-irrigation. The time for pre-irrigation is calculated by the ECOSTAR 4300

as 8 x the time for running 1 meter with the current speed.

The constant „8“ (constant no. 2) can be changed, see programming. If the pre-irrigation is on the machine starts

and runs 1/2 pm enter and then it stops for the pre-irrigation time. By pressing the key „START“ the pre-irrigation

is cancelled. The magnet at the stop sensor should be in place, before activating the pre-irrigation.

POST-IRRIGATION:

The post-irrigation can be activated by pressing the key „POST-“. The time for post-irrigation is calculated by the

ECOSTAR 4300 as 8 x the time for running 1 meter the current speed. The constant „8“ (constant no.3) can be

changed, see programming. The post-irrigation starts to count down when the magnet is removed from the stop

sensor. When the magnet is removed, the motor for speed regulation stops the turbine. After the post-irrigation

time the shut-off valve closes ( or opens, is available, the valve low pressure) At machines with only one motor for

speed regulation the turbine starts after the post-irrigation. By pressing the key „START“ the post irrigation is

cancelled. The magnet at the stop sensor should be in place before activating the post-irrigation. If the constant

no.8 “early stop” is selected, this function is activated. The machine shuts down if the distance is reached.

6.3 PROGRAMMING OF 4 DIFFERENT SPEEDS

Display must show menu 5.

The pipe should be pulled out before programming, so the computer can calculate the distance of the field to be

irrigated.

In the following example the length of the field to be irrigated is 400 m.

Press the „PROG“-Key 3 x. The display shows.

400m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

The desired speed can now be set, here 25,0 m/h. Then press the „PROG“-key 1 x. The display shows:

400m 25.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

The desired distance can now be set, here 300 m. Then press the „PROG“-key 1 x. The display shows:

400m 25.0m/h 300m

300m 30.0m/h 0m

0m 30.0m/h 0m

0m 30.0m/h 0m

Now the first zone is programmed and the procedure is continued for all 4 zones.

Zone 4 automatically ends at 000m.

When zone 4 is programmed press again the „PROG“-key. The display shows:

DLETE MENU PRESS

SAVE PROG PRESS

By pressing the key “PROG“- the program is saved and the irrigation is carried out according to the program. By

pressing the key „MENU“-the program is deleted and the speed stays the same for the whole field.

Operating manual for BAUER RAINSTAR series TX Plus 25

Page 34

6.4 STATUS DISPLAY

STATUS: Status messages in display

EMERGENCY: machine has not been started, speed impulses, however, are being received and it is trying

to maintain the speed requested.

RUNNING: Machine is irrigating, everything is working properly.

LOW PRESSURE: Water pressure is below pressure switch threshold. Machine acts depending on machine

data.

START: Operator has pressed „START“-button and the start sequence is in progress

START REMOTE: Machine is starting due to an SMS.

START DELAY : Machine is waiting for start delay to elapse (see menu 4).

START PRESSURE : Machine has started due to pressure rise. Machine uses pressure level to start 2

machine on string.

START DENIED: Operator is holding „STOP“-button to prevent PRESSURE- and REMOTE start

zu verhindern.

STOP USER: Machine has stopped due to operator STOP.

STOP REMOTE: Machine has stopped due to an SMS.

STOP SENSOR: Machine has reached end and is stopped by STOP SENSOR.

STOP DISTANCE: Machine has reached distance for stop (see constant No. 8 for early stop).

STOP DELAY: Machine has reached stop but waits nn seconds to proceed stop sequence..

STOP DENIED: Operator is pressing „START“-button to prevent REMOTE stop.

SUPERVISION TIME: Machine has stopped due to supervision time is elapsed. Machine has not moved in

nn minutes (see constant for supervision time)

FORCE LOW PRESSURE: Machine opens shut-off valve to force pressure drop in order to stop the pump. After

2 minutes valve closes to prevent draining of pipe.

PRE IRRIGATION: Machine is performing pre irrigation.

POST IRRIGATION: Machine is performing post irrigation.

There are different constants that can be set by the user.

These constants will be saved for years even if the battery is disconnected.

nd

Operating manual for BAUER RAINSTAR Series TX Plus 26

Page 35

6.5 The MOST COMMON COMBINATION OF DIFFERENT CONSTANTS

The machine will always run with the constants adjusted in the factory. But there are different conditions from farm

to farm and farmers also have different requirements. Therefore, some constants can be adjusted to the local

wishes.

1. Slow start of turbine. Machine data no.13. Adjust the value to 4sec to start.

Now the valve for control of speed will close about half and continue to close stepwise until the adjusted speed is

reached. Correct adjustment is: Continuously closing of the valve until the turbine starts running and stepwise until

adjusted speed is reached.

2. Slow opening for the inlet of water. Machine data No. 17 . Set the value to 1. =

The opening is done stepwise.

3. Only 1 motor for speed regulation. Machine data no. 12. Value 0

Post-irrigation must take place as follow: when the stop sensor is activated only the retraction stops. When the

post-irrigation is finished the machine starts again and runs to the mechanic stop.

4. Start of the 2

Machine data No. 14. value 2.

The machine must be equipped with an adjustable pressure switch. Adjust the pressure switch to a point between

the normal pressure and the pressure when the pump will stop. Example: the normal pressure is 7 bar, the

pressure for pump stop 9 bar. Adjust the pressure switch to 8 bar on both machines. Start the 1

pressing start. Adjust the 2

as soon as its pressure has reached 8. Please note: 10 m of height difference make a pressure of 1 bar.

5. Stop of the machine when pressure is low and a pressure switch is mounted. Constant no.6 = value 1

Machine data No. 12 must be adjusted to a value of 2. Now the shut-off motor turns into the opposite

direction. This means that when the cable connection stays the same the shut-off valve opens. After two minutes

the shut-off valve closes again.

Only the combination of stop sensor, stop button and supervision can open the shut-off valve. The pressure switch,

however, cannot open the valve.

6. Pre-irrigation before machine reaches the stop

Constant No. 9 can be set to the meter number where the post-irrigation should take place.

nd

machine when the 1st machine has reached stop.

nd

machine, but press stop. When the first machine is ready the second machine starts

st

machine by

ATTENTION!

ATTENTION!

Open the front plate very carefully.

In order to ensure moisture protection by the cover gasket also the cover must be

closed carefully!

Welding – and repair works at the RAINSTAR should only be done when the

battery is disconnected!

Operating manual for BAUER RAINSTAR series TX Plus 27

Page 36

6.6 STOP - SENSOR

The machine can only work if the stop sensor is activated or in operating position.

Operating position Shut-off position

The Stop - Sensor has three functions:

1. Reset for the laid-down PE-pipe length:

When operated the laid-down pipe length is set to zero.

2. Post irrigation:

If the post-irrigation procedure is carried out at the end of the run (0 m laid-down PE-pipe length) the postirrigation function is activated first and then the ECOSTAR is shut-off.

In the standard program the post-irrigation is activated 8m before the irrigation ends.

3. Prevents pulses to the regulating motor.

After the stop sensor is activated, no pulses are passed on to the regulating motor.

Press the key MENU 2 x, to get to the display of menu 3. Her it shows if the speed sensors are working . The sign

shows if a magnet activated the two speed sensors.

Line four shows if motors 1 and 2 are switched off after they have reached their mechanical stop.

If sign shows and one motor has not

reached its end position there is a blockage on the inside of the turbine ( MOTOR 1 ) or the valve( MOTOR 2 ).

The motor switches off when the power consumption exceeds 4,7 ampere and appears on the display.

If the display shows a flashing MOTOR 1 it means that the motor is running

SPEED 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS MOTOR 1

If the display shows a flashing MOTOR 2 it means that the motor for the shut off valve is running.

SPEED 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS MOTOR 2

By pressing the key PROG/POWER ON

The battery is charged only if the electronics is activated. There is no charging when in standby.

Operating manual for BAUER RAINSTAR Series TX Plus 28

or the PE-Pipe is laid out, the electronics is activated again.

Page 37

6.7 Operation of the BAUER ECOSTAR 4300

Summary:

Pull off or lay down the PE – pipe

Connect water supply

Engage gearbox

ECOSTAR: make settings only in the standard menu:

Take over retraction speed from the last retraction or set again.

Press "START-RESET“

key

Activate pre-irrigation if required

Activate post-irrigation if required

Open water inlet

Irrigation runs automatically

FURTHER OPERATING INSTRUCTIONS

After a longer standstill the electronic system of the ECOSTAR 4300 is on standby.

Pulling off or laying down the PE – pipe activates the electronic system and the length of the pulled off or laid down

pipe is metered.

For display of laid out PE-pipe, press key Menu 1 x:

DISTANCE 123m

BATTERY 12.8V

CHARGE ON 0.231A

PRE- 0:45 POST- 0:45

Operating manual for BAUER RAINSTAR series TX Plus 29

Page 38

6.7.1 SPEED ADJUSTMENT

The pre-adjusted speed of 30 m/h can be increases or decreased with the arrow keys

.

At first the speed changes step by step for 0,1 m/h, then after ten steps there is a change of 1,0 m/h.

The speed can be changed at anytime while the machine is running.

The remaining time until the end of irrigation is also changed.

The speed cannot be changed while one of the servo motor for the turbine regulation or shut-off valve is running.

The display shows MOTOR 1 or MOTOR 2.

When changing the speed also the corresponding time changes.

SPEED 30.0m/h

DOSE 22 mm

TIME 14:10 STOP 7:43

STATUS OPERATION

Important!

When setting the speed it is necessary to check on the speed that is actually possible

according to the test window (press menu key 3 x).

In case of variation the set speed must be reduced to the speed that is actually

possible.

6.7.2 PRE – OR POST IRRIGATION

With the keys PRE – or. POST IRRIGATION

The time for the pre- and post is pre-programmed and is calculated by the ECOSTAR 4300 as 8 times the time for

covering a distance of 1 meter with the actual speed.

e.g: for vE = 20 m/h there is a time of 3 min for 1 m retraction

This makes a pre-irrigation time of 8 x 3 min = 24 min

and a post irrigation time of also 8 x 3 min = 24 min

This value “8” can be changed in the program (program constant No 2 and No 3) –

See parameter sheet 1: constants.

If the pre irrigation function is activated, the machine runs approx. ½ meter after the start and then stands still for

the pre irrigation time.

these functions can be activated.

When pressing the button “START-RESET”

Operating manual for BAUER RAINSTAR Series TX Plus 30

, during pre-irrigation the pre-irrigation function is deleted.

Page 39

Before activating the pre-irrigation mode the PE – pipe should be pulled off (the shut-off frame and thus also the

shut-off sensor should be in the operating status) and the “START-RESET” key should have been pressed.

If the post-irrigation mode is activated the machine stops 8m before the end of the run for the post-irrigation time.

This value is pre-adjusted and can be changed in the program constant no.9, see parameter sheet 1: constants.

If you press the key “START-RESET”

, the post irrigation is cancelled.

6.7.3 START

If the PE – pipe has been pulled off and the desired speed has been set you can start the irrigation with the

“START–RESET“

If pre- or post- irrigation is required, press the following keys

The turbine can only start if the shut-off frame and thus also the shut-off sensor are in the operating state (PE-pipe

pulled off).

If the „START–RESET“ key is pressed the turbine flap closes, the tooth segment on the regulating motor rotates to

the limiting bolt head and the shut-off valve (if existing-optional) opens.

key.

6.7.4 MONITORING

The program has a built-in monitoring system.

It only works in connection with the shut-off valve- overpressure.

The standard factory setting of the monitoring is 20min. (parameter sheet 1, machine data 4).

In this mode monitoring will start if the RAINSTAR does not reach the set speed within the programmed monitoring

time. After this time the shut-off valve is closed and the machine stops.

In most cases the reasons are excessively high retraction speeds or a blocked regulation flap etc.

In order to ensure that the set retraction speed is actually reached and the system is not switched off after the

monitoring time, it is necessary to check the retraction speed that is actually possible by pressing the menu key

three times.

If the system is equipped with a pressure switch the machine will start when a preset minimum pressure is

reached, or it stops irrigating when water pressure is too low. As soon as the pressure returns to normal level,

irrigation is continued.

Operating manual for BAUER RAINSTAR series TX Plus 31

Page 40

6.7.5 STOP

At the end of the irrigation run the shut-off sensor is activated through shut-off frame and shut-off rods.

Sensor in shut-off position

As a result the turbine stops and the shut-off valve overpressure closes slowly and remains in this position until the

next operation.

If the RAINSTAR is connected to a hydrant you can release the water pressure which is remaining in the line after

closing the hydrant by pushing the „START-RESET“

The shut-off valve opens and pressure is released through the PE-pipe.

If a low-pressure shut-off valve is mounted, it opens quickly.

It closes again after approx. 15 min.

By pressing the key „STOP“

The turbine flap opens (the turbine stops), the over-pressure shut-off valve closes, the low-pressure shut-off valve

opens.

The laid down PE – pipe length remains saved. It is set to 000 only when the shut-off sensor is actuated ( shut-off

position).

ATTENTION !

If the „STOP“ key is used while retraction on a machine without shut-off valve the retraction stops but the sprinkler

is still in operation. In order to prevent “over irrigation” around the sprinkler the machine should only work for a

limited period of time without retraction. Then start the machine again by pressing the„START“ key!!

the irrigation process can be stopped at any time.

key.

ATTENTION !

With machine data adjustments Pos. 12, adjustment „0“, the retraction stops only for a short period of

time when pressing „STOP“ key. After a few seconds the retraction starts again automatically.

ATTENTION: when working on the machine the whole drive needs to be switched off!!

STOPPING THE CONTROL FUNCTIONS,

By pressing the keys „STOP“ and „PROG.“ at the same time all functions of the ECOSTAR stop, this means that

the regulating motors of the turbine and the shut-off valve remain in their current position. With this combination of

keys the turbine regulation is stopped when the turbine rotation speed is low in order to change gears.

Operating manual for BAUER RAINSTAR Series TX Plus 32

Page 41

6.8 Pressure SWITCH ( OPTIONAL EQUIPMENT)

If the RAINSTAR, after having been positioned for the run, is supposed to start-up only after the required pressure

has built up in the supply line (Pressure start) a pressure switch must be installed.

If such a switch is available, the monitoring system will also interrupt the irrigation cycle in case of low water

pressure. As soon as the pressure returns to normal the irrigation is continued.

IMPORTANT: the pressure switch should only be used together with a shut-off valve over pressure!!

6.9 ERROR DESCRIPTION – ECO STAR 4300

Error Cause Remedy

Solar panel dirty clean

Battery is not charging

Electronic system defective Electronic error

Device switches off early

Retraction speed is not reached

Solar panel defective

Battery defective Charge, exchange

Overwinding fault

Shut-off frame has been

activated unintentionally

Net or pump station does

not have enough pressure

Incorrect gear ratio Change ratio

Leave machine in the sun

Change solar panel

Cover solar panel,

Disconnect battery and connect it

again.(reset)

Call customer service, exchange

E-Box

Turn off water supply

Slacken PE–Pipe

Readjust machine

Put shut-off frame into the

operating position, enter laiddown pipe length and press

„START“

Increase pressure or enter

retraction speed according to the

performance chart

Blocked turbine regulation Remove foreign object

Operating manual for BAUER RAINSTAR series TX Plus 33

Page 42

6.10 Programming procedure

The electronic system is factory-programmed.

However, if site conditions require settings which deviate from these data it is possible to modify the program

constants and machine data accordingly.

Proceed as follows:

In order to reach the constants the speed must be set at 11,1 m/h or 11f/h

Immediately press the “PROGRAMM”-key

parameter sheet No. 1 )

By pressing the “PROGRAM”-key again shortly to select constant numbers 01 – 12 see parameter sheet No. 1.

With the arrow keys

If you press the “MENU”

display.

If you do not press “MENU” the changes are not saved and the program returns to the standard display after one

minute.

The constants remain saved, even if the battery is disconnected for a longer time. The program constant 0 with the

value 111 gives access to the machine data.

By pressing the key PROGRAM

See parameter sheet No. 2

By pressing the “PROGRAMM”-key again the machine data numbers 0 – 19 are selected.

With the arrow keys the values can be changed according to the requirements.

By pressing the key “MENU” the program returns to the standard display and saves the changed machine data.

If the key „MENU“ is not pressed the ECOSTAR 4300 returns to normal mode after one minute and the

adjustments of the constants are not saved.

the values can be changed according to the requirements.

key the changed constants are saved and the program returns to the standard

you can access the machine data mode.

three times in order to get to program constant 0 ( see

Operating manual for BAUER RAINSTAR Series TX Plus 34

Page 43

CONSTANTS

Konst.

Anm. Werks

Nr.

0 100 - - 111 code for reaching the machine data

1 00:00 00:00 24:00 Time

2 8 1 15 Pre-irrigation

3 8 1 15 Post-irrigation

4 20 0 99 Monitoring time [Minutes]

5 1 1 15 1 English, 2 Danish, 3 German, 4 French, 5 Dutch,

6 0 0 2 0 = slow shut-off, for option shut-off valve-over pressure