Page 1

THE NEW VE- / VSE RANGE

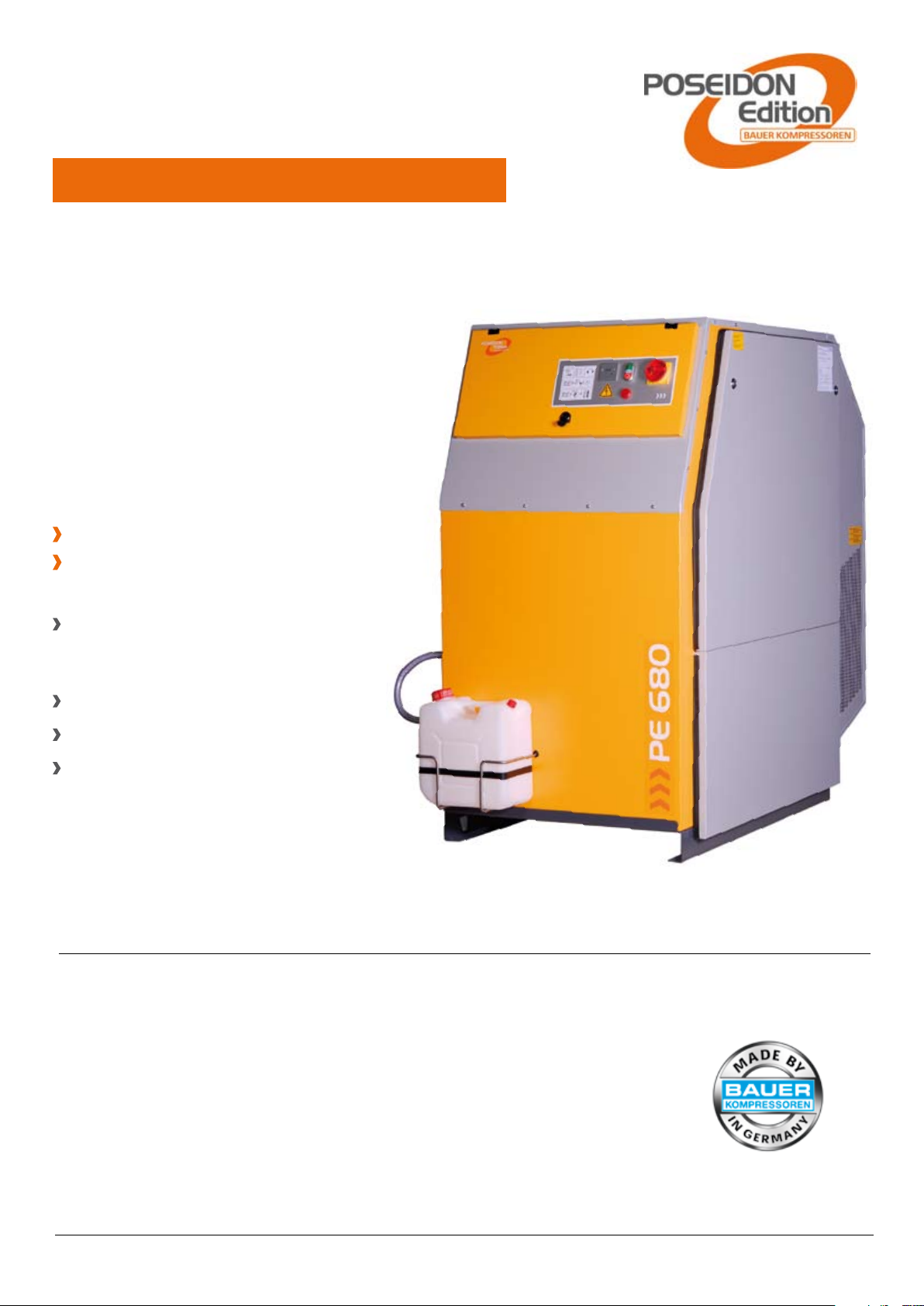

Pure Power, perfect price

320 - 680 l/min

225 / 330 / 420 bar

FULFILLS THE REQUIREMENT

FOR LARGE QUANTITIES OF

BREATHING AIR

OPEN OR SUPER SILENT

EASY OPERATION

BREATHING AIR ACC.

TO DIN EN 12021

Our new POSEIDON EDITION stands for an excel-

lent price/performance ratio at very high quality. This

product range has been developed for uncomplicated

operation combining proven core components from

BAUER with a simple and robust chassis.

The VE range excels through its excellent capacitiy rates of up

to 680 l/min. The effective noise reduction of the super silent

version allows its use in noise-sensitive environments.

www.bauer-kompressoren.com/poseidonedition

Page 2

The convincing features

AUTOMATIC OPERATION

Highest operational safety is achieved by

equipping the units with a robust and easy-to-use

control in combination with an automatic

condensate drain.

An automatic start/stop device controls the inde-

pendent switching-on /-off of the compressor.

For maximum convenience, condensate from all

interstage separators and the final separator is

automatically removed by the automatic condensate

drain during operation as well as during switching on

and off the compressor unit.

An indicator lamp signals low oil pressure and

warns immediately should the compressor block

rotate in the wrong direction.

VE-RANGEBAUER KOMPRESSOREN

Hour counter for reading off the pending

maintenance and service intervals.

ROBUST COMPRESSOR BLOCK

Maximum efficiency due to heavy duty compressor blocks meant for continuous operation.

Low thermal load on the 4-and 5-stage compres-

sors guarantees maximum life time of the unit,

even under the harshest ambient conditions.

Tempered cylinders with special plateau honing as

well as wear & tear-free high-tech polymer piston

rings in the final stage minimize oil consumption

and wear off.

Robust low pressure oil pump with oil filter for

extended life time and oil change intervals.

Indestructible industrial roller bearings suitable

for continuous operation during 30,000 operating

hours and more.

Corrosion resistant intermediate and final coolers

made of stainless steel.

PE VE 500 in open unit construction

4-stage high pressure compressor block K150

NOISE REDUCTION (optional)

For use in particularly noise-sensitive environments.

Super silent operation with less than 70 dB(A)*

due to high absorbent special insulation materials

in and efficient noise reducing construction of the

“super silent” cabinet.

*

( +/- 2 dB(A), measured at the distance of 1 meter )

Noise reducing construction with high absorbent insulation

Page 3

VE-RANGE

PURE BREATHING AIR THROUGH

THE BAUER P-SYSTEM

For a reliable supply with breathing air, with

higher purity than required by the strict

breathing air standards DIN EN 12021.

Our genuine cartridges safely remove humidity

and pollutants from the compressed air.

The filter housings made of special alloys are

designed for pressures up to 500 bar and for

thousands of load cycles. Fastidious all-embracing

production monitoring from the raw material up

to the finished vessel guarantees highest safety.

SECURUS PROVIDES SAFETY (OPTIONAL)

P-Filter system with SECURUS filter monitoring

The patented filter monitoring system continuously

controls the saturation of the filter cartridge.

Automatic shut-down of the unit after warning for

upcoming filter saturation, guarantees compliance with

the directives of the EN 12021 breathing air standard.

SECURUS assures economical plant operation:

Thanks to a sophisticated sensor technique, the filter

cartridge can be used until its complete saturation.

In contradiction to others, the integrated monitoring

sensor does not have to be calibrated. This provides

safety in continuous operation and saves costs.

Equipment variants

OPTIONS

Model PE 320 PE 500 PE 680 PE 320 PE 500 PE 600

Noise level

Noise reduction

Automation options

Compressor control

START/STOP

Automatic condensate drain

Air preparation options

Purification system P 41

Purification system P 61

SECURUS

Air distribution options

Filling panel with hose connections

Filling panel with direct connections

225 and 330 bar (simultaneous)

standard scope of supply | optional

225/330 bar range 420 bar range

Page 4

VE-RANGE POSEIDON EDITION

PRODUCT SERVICE

DIN EN ISO 9001

Features and options at a glance

4

2

1

Connection for external filling panel(s) and

storage bank(s).

2

Filling panel(s) for mounting on the compressor

or for external mounting.

Available as 200 bar or 300 bar version or with

pressure reducer 200 bar + 300 bar (optional).

Technical data

4

5

1

3

2

Storage bank(s).

3

4

AIR-KOOL refrigeration dryer for increased filter

cartridge life time

5

Automatic selector unit for quick automatic

filling from an intermediate buffer.

Model

200 / 300 bar version

PE 320-VE silent 4 320 1450 0,63 7,5 10 P41 148 83 152 400

PE 500-VE silent 4 500 1170 0,40 11 15 P41 455

PE-680-VE silent 4 680 1400 0,29 15 20 P61 455

PE 320-VE 4 320 1450 0,63 7,5 10 P41 114 83 152 305

PE 500-VE 4 500 1170 0,40 11 15 P41 345

PE-680-VE 4 680 1400 0,29 15 20 P61 360

420 bar version

PE 320-VE 420 silent 4 320 1450 0,63 7,5 10 P41 148 83 152 395

PE 500-VE 420 silent 4 500 1170 0,40 11 15 P41 450

PE-600-VE 420 silent 5 600 1320 0,33 15 20 P61 460

PE 320-VE-420 4 320 1450 0,63 7,5 10 P41 114 83 152 305

PE 500-VE-420 4 500 1170 0,40 11 15 P41 355

PE-600-VE-420 5 600 1320 0,33 15 20 P61 370

1) Cylinder filling from 0 to 200bar

Filling rate for 1l cylinder capacity from 0 to 200 bar

Number

of stages

F.A .D R.P.M Filling

rate

l/min1) min

-1

min

Drive Purification

system

1)

kW HP P-Range L W H

Dimensions

(app. cm)

Weight

net.

app. kg

BAUER KOMPRESSOREN GmbH

P.O. Box 710260 | 81452 München

Phone +49 (0) 89 / 7 80 49 - 0

Fax +49 (0) 89 / 7 80 49 - 167

info@bauer-kompressoren.de

www.bauer-kompressoren.de

PE-G II 320-680-E

12.09 PR 0154

Subject to technical modifications

Loading...

Loading...