Page 1

Instruction Manual and Replacement Parts List

Mini Verticus

High Pressure Gas Compressor Units

G 120 II V

April 4, 2013 1st Edition, Rev. 0 Chg. 2 MNL-126509

© Bauer Compressors, Inc.

BAUER Compressors, Inc. Phone: (757) 855-6006

1328 Azalea Garden Road Fax: (757) 855-6224

Norfolk, Virginia 23502-1944 www.bauercomp.com

Page 2

G 120 II V

This information is believed to be accurate by Bauer Compressors, Inc., as of it’s date of publication, but

Bauer offers NO WARRANTY regarding the accuracy, or continuing accuracy, of the information set forth

herein. Bauer shall not be liable for inaccuracies in, or consequences resulting from, your use of this information. All information supplied is in connection with sales of Bauer’s products, and is thus subject to

Bauer’s standard terms and conditions of sale. Bauer reserves the right to change this information and has

no obligation to update these materials. This information is copyrighted by Bauer Compressors, Inc., and

Bauer reserves to itself all rights to this publication. Bauer’s customers have no right to reproduce, rewrite,

modify, license or permit anyone else’s use of this information, without the express written permission of

Bauer Compressors, Inc.

^ WARNING

This Instruction Manual and Replacement Parts List contains safety information and instructions

for the G 120 II V High Pressure Gas Compressor Units.

You must read, understand and follow all safety precautions and instructions.

1st Edition August 30, 2011

Rev Chg Date Notes Auth

0 1 Nov. 8, 2011 Added 50 Hz model SS

0 2 Apr. 4, 2013 Updated Block P/N’s SS

Page i 1st Edition, Rev. 0 Chg. 2

Page 3

MNL-126509

Table of Contents

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

1.1 HOW TO USE THIS MANUAL.........................................................................................................................................1

1.1.1 Manual Safety Notices .......................................................................................................................................................1

1.2 HOW TO USE THE REPLACEMENT PARTS LIST....................................................................................................2

1.3 HOW TO USE THE APPENDIX.......................................................................................................................................3

1.4 UNIT SPECIFICATIONS ..................................................................................................................................................4

1.4.0.1 Compressor Drive ..........................................................................................................................................................4

1.4.0.2 Purification System Applicability ..................................................................................................................................4

1.4.0.3 Pressure Switch Settings.................................................................................................................................................4

1.4.0.3.1 Inlet Pressure Switch Settings ........................................................................................................................................4

1.4.0.3.2 Final Pressure Switch Setting ......................................................................................................................................... 4

CHAPTER 2:- - - -OPERATING INSTRUCTIONS; MAPLE SYSTEM

2.1 DESCRIPTION.................................................................................................................................................................... 5

2.1.1 Emergency Stop Button .....................................................................................................................................................5

2.1.2 Operator Interface ..............................................................................................................................................................6

2.1.2.1 Run Screen...................................................................................................................................................................... 6

2.1.2.2 Main Menu Screen.......................................................................................................................................................... 7

2.1.2.2.1 Run..................................................................................................................................................................................7

2.1.2.2.2 Alarms History................................................................................................................................................................8

2.1.2.2.3 Status .............................................................................................................................................................................. 8

2.1.2.2.4 Contact............................................................................................................................................................................8

2.1.2.2.5 Login............................................................................................................................................................................... 8

2.1.2.2.6 Configuration..................................................................................................................................................................9

2.1.2.2.7 Parameters.....................................................................................................................................................................10

2.1.2.2.8 Tools .............................................................................................................................................................................10

2.2 STARTING AND STOPPING UNIT...............................................................................................................................10

2.2.1 Before Starting. ................................................................................................................................................................ 10

2.2.2 To Start Unit.....................................................................................................................................................................11

2.2.3 To Stop Unit. .................................................................................................................................................................... 11

2.3 SCREEN FLOW................................................................................................................................................................14

CHAPTER 3:- - - - - - - - - - - - - - - - - - - - - - IK120 II C & G

3.1 MAINTENANCE AND PARTS.......................................................................................................................................15

3.1.1 Description ....................................................................................................................................................................... 15

3.1.2 Component Location ........................................................................................................................................................15

3.1.3 Air Flow Diagram ............................................................................................................................................................ 16

3.1.4 Compressor Lubrication................................................................................................................................................... 17

3.1.4.1 Description....................................................................................................................................................................17

3.1.4.2 Oil Level Check............................................................................................................................................................17

3.1.4.3 Oil Change Interval.......................................................................................................................................................18

3.1.4.4 Oil Change.................................................................................................................................................................... 19

3.1.5 Venting the Oil Pump.......................................................................................................................................................19

3.1.5.1 Gas Intake System ........................................................................................................................................................ 19

April 4, 2013 Page ii

Page 4

G 120 II V

3.1.6 Inter-stage Separator.........................................................................................................................................................20

3.1.6.1 Maintenance..................................................................................................................................................................21

3.1.7 Cooling .............................................................................................................................................................................21

3.1.7.1 General..........................................................................................................................................................................21

3.1.8 Valves and Heads .............................................................................................................................................................21

3.1.8.1 Functional Description..................................................................................................................................................21

3.1.8.2 General Instructions for Changing the Valves..............................................................................................................22

3.1.8.3 Changing the IK120 II C & G, 1st Stage Valve ...........................................................................................................23

3.1.8.4 Removing the IK120 II C & G, 2nd Stage Valves. ......................................................................................................24

3.1.8.5 Reassembling the Valves of the 2nd Stage. ..................................................................................................................25

3.1.8.6 Removing the IK120 II C & G, 3rd Stage Valves ........................................................................................................26

3.1.8.7 Reassembling the Valves of the 3rd Stage....................................................................................................................27

3.1.9 Replacement Parts List.....................................................................................................................................................28

3.1.10 Troubleshooting and Repair .............................................................................................................................................47

3.1.10.1 Troubleshooting Table ..................................................................................................................................................47

3.1.10.2 Repair Instructions ........................................................................................................................................................48

3.2 THREE STAGE AUTOMATIC CONDENSATE DRAIN SYSTEM...........................................................................49

3.2.1 Description .......................................................................................................................................................................49

3.2.1.1 Normal Operation .........................................................................................................................................................50

3.2.1.2 Condensate Drain..........................................................................................................................................................50

3.2.1.3 Start Unloading .............................................................................................................................................................50

3.2.1.4 Standstill Drainage........................................................................................................................................................51

3.2.2 Component Description....................................................................................................................................................51

3.2.2.1 Condensate Drain Piping ..............................................................................................................................................51

3.2.2.2 Electrical Connection....................................................................................................................................................51

3.2.3 ACD Maintenance............................................................................................................................................................51

3.2.4 ACD Replacement Parts List............................................................................................................................................52

3.3 CONDENSATE COLLECTOR .......................................................................................................................................54

3.3.1 Condensate Collector Replacement Parts List .................................................................................................................55

CHAPTER 4:- - - - - - - - - - - - - - - - -PURIFICATION SYSTEM

4.1 INTRODUCTION..............................................................................................................................................................56

4.1.1 General Purification System Procedures..........................................................................................................................56

4.1.2 Chamber Safety Bore .......................................................................................................................................................56

4.1.3 Manual Condensate Drainage...........................................................................................................................................57

4.1.4 Model, Serial Number and Part Number Identification ...................................................................................................57

4.1.4.1 Compressor Dataplate...................................................................................................................................................57

4.1.4.2 Purification System Dataplate ......................................................................................................................................58

4.1.4.3 Cartridge Installation Dataplate ....................................................................................................................................58

4.1.5 Breathing Air Purification System Configurations ..........................................................................................................58

4.1.6 Industrial Purification System Configurations .................................................................................................................59

4.1.7 Cartridge Operating Life ..................................................................................................................................................59

4.1.7.1 Calculating the Maximum Cartridge Operating Hours.................................................................................................60

4.1.7.2 Calculating the Adjusted Cartridge Operating Hours...................................................................................................60

4.1.7.3 Air Purification Cartridge Operating Hours Form........................................................................................................62

4.2 P1 PURIFICATION SYSTEM.........................................................................................................................................63

4.2.1 Major Components ...........................................................................................................................................................63

4.2.2 Component Description....................................................................................................................................................64

4.2.2.1 Oil & Water (condensate) Separator.............................................................................................................................64

4.2.2.2 Chamber........................................................................................................................................................................65

Page iii 1st Edition, Rev. 0 Chg. 2

Page 5

MNL-126509

4.2.2.3 Cartridge .......................................................................................................................................................................65

4.2.2.4 Cartridge Handling ....................................................................................................................................................... 65

4.2.2.5 Condensate Drain Valve...............................................................................................................................................65

4.2.2.6 Check Valves................................................................................................................................................................ 65

4.2.2.7 Bleed Valve .................................................................................................................................................................. 66

4.2.2.8 Pressure Maintaining Valve..........................................................................................................................................66

4.2.2.9 Safety Valve..................................................................................................................................................................66

4.3 MAINTENANCE............................................................................................................................................................... 66

4.3.1 Oil and Water Separator...................................................................................................................................................66

4.3.2 Cartridge Replacement.....................................................................................................................................................67

4.3.2.1 Leaking at the Safety Bore ...........................................................................................................................................68

4.4 REPLACEMENT PARTS LIST......................................................................................................................................69

CHAPTER 5:- - - - - - - - - - - - COMPRESSOR DRIVE; G 120 II V

5.1 VERTICAL COMPRESSOR DRIVE.............................................................................................................................. 72

5.2 MAINTENANCE OF THE V-BELT AND SHEAVES.................................................................................................. 72

5.2.1 Check The Sheaves. ......................................................................................................................................................... 72

5.2.2 Check the V-belt...............................................................................................................................................................72

5.3 REPLACEMENT PART LIST ........................................................................................................................................73

CHAPTER 6:- - - - - - - - - - ELECTRICAL PANEL, ASY-1058 XL

6.1 OVERVIEW.......................................................................................................................................................................75

6.2 ELECTRICAL PANEL ....................................................................................................................................................75

6.2.1 Wiring Diagram................................................................................................................................................................76

6.2.2 Electrical Panel Interior Access .......................................................................................................................................76

6.2.3 Optional Equipment .........................................................................................................................................................76

6.3 AC POWER REQUIREMENTS...................................................................................................................................... 76

6.4 ELECTRICAL PANEL COMPONENTS....................................................................................................................... 77

6.4.1 Programable Logic Controller (PLC)...............................................................................................................................77

6.4.2 Replacing the PLC ...........................................................................................................................................................78

6.4.3 Installing a New Program.................................................................................................................................................78

6.4.4 Installing an EEPROM.....................................................................................................................................................78

6.4.5 Hourmeter.........................................................................................................................................................................79

6.4.6 Transformer and Fuses .....................................................................................................................................................79

6.4.7 Motor Starter. ................................................................................................................................................................... 80

6.4.8 Overload Relay................................................................................................................................................................. 80

6.4.9 Starter Reset .....................................................................................................................................................................80

6.4.10 Power Supply ................................................................................................................................................................... 81

6.5 ALARMS............................................................................................................................................................................81

6.5.1 Final Separator Warning ..................................................................................................................................................81

6.5.2 Securus

6.5.2.1 Securus® Cartridge ...................................................................................................................................................... 82

6.5.2.2 Securus II

6.5.3 Compressor High Temperature ........................................................................................................................................ 83

6.5.4 Compressor Low Oil Pressure..........................................................................................................................................83

6.5.5 Compressor Overrun Timer .............................................................................................................................................83

6.5.6 Condensate Fault ..............................................................................................................................................................83

6.5.7 Motor Starter Overload Trip ............................................................................................................................................84

®

Electronic Moisture Monitor System................................................................................................................82

®

Transmitter.................................................................................................................................................82

April 4, 2013 Page iv

Page 6

G 120 II V

6.6 PLC INPUTS AND OUTPUTS ........................................................................................................................................84

6.6.1 Analog Inputs to the PLC.................................................................................................................................................85

6.7 WIRING HARNESS LAYOUT .......................................................................................................................................86

6.8 REPLACEMENT PARTS LIST ......................................................................................................................................88

6.9 PARTS LIST FOR MODELS WITH A 5 HORSEPOWER MOTOR.........................................................................96

6.10 PARTS LIST FOR MODELS WITH A 7½ HORSEPOWER MOTOR......................................................................97

6.11 PARTS LIST FOR MODELS WITH A 10 HORSEPOWER MOTOR.......................................................................98

6.12 PARTS LIST FOR MODELS WITH A 15 HORSEPOWER MOTOR.......................................................................99

6.13 PARTS LIST FOR MODELS WITH A 20 HORSEPOWER MOTOR.....................................................................100

CHAPTER 7:- - - - - - - - - - - - - - - - -INDICATORS & VALVES

7.1 DESCRIPTION................................................................................................................................................................101

7.2 REPLACEMENT PARTS LIST ....................................................................................................................................101

7.1 NONADJUSTABLE VALVES .......................................................................................................................................103

7.2 PRESSURE MAINTAINING VALVE...........................................................................................................................103

7.3 SAFETY VALVES...........................................................................................................................................................104

CHAPTER 8:- - - - - - - - - - - - - - - - - - - - - - - - -APPENDIX

8.1 SAFETY............................................................................................................................................................................105

8.1.1 General Safety Precautions.............................................................................................................................................105

8.1.2 Safety Warning Labels ...................................................................................................................................................107

8.2 UNPACKING, HANDLING AND INSTALLATION..................................................................................................108

8.2.1 Unpacking and Handling................................................................................................................................................108

8.2.2 Installation of the Compressor Unit ...............................................................................................................................109

8.2.2.1 General........................................................................................................................................................................109

8.2.2.2 Ventilation ..................................................................................................................................................................110

8.2.2.2.1 Outdoor Installation ....................................................................................................................................................110

8.2.2.2.2 Indoor Installation.......................................................................................................................................................110

8.2.2.2.3 Natural Ventilation .....................................................................................................................................................110

8.2.2.2.4 Forced Ventilation ......................................................................................................................................................111

8.2.3 Intake Air........................................................................................................................................................................111

8.2.3.1 Inside Air Source ........................................................................................................................................................111

8.2.3.2 Outside Air Source......................................................................................................................................................112

8.2.4 Compressor Intake Piping ..............................................................................................................................................112

8.2.5 Installation Procedures ...................................................................................................................................................113

8.2.6 Electrical Installation......................................................................................................................................................113

8.2.6.1 Electric Drive..............................................................................................................................................................113

8.2.6.2 Electrical Supply.........................................................................................................................................................113

8.2.7 Pneumatic Leaks.............................................................................................................................................................115

8.3 LONG TERM STORAGE...............................................................................................................................................116

8.3.1 General ...........................................................................................................................................................................116

8.3.2 Preparations ....................................................................................................................................................................116

8.3.2.1 Units Equipped with a Filter System ..........................................................................................................................116

8.3.3 Preserving the Compressor.............................................................................................................................................116

8.3.4 Preventive Maintenance During Storage........................................................................................................................117

8.3.5 Lubrication Oils for Preservation ...................................................................................................................................117

Page v 1st Edition, Rev. 0 Chg. 2

Page 7

MNL-126509

8.3.6 Reactivating the Compressor Unit .................................................................................................................................117

8.4 REPRODUCIBLE FORMS............................................................................................................................................118

8.4.1 Scheduled Maintenance Form........................................................................................................................................118

8.4.2 Air Purification Cartridge Operating Hours...................................................................................................................121

8.4.3 Record of Operating Hours ............................................................................................................................................122

8.5 REFERENCE DATA.......................................................................................................................................................123

8.5.1 Tightening Torque Values..............................................................................................................................................123

8.5.2 Torque Sequence Diagrams ........................................................................................................................................... 123

8.5.3 Conversion Formulas .....................................................................................................................................................123

8.5.4 Approved Lubricants Chart............................................................................................................................................124

8.5.5 Glossary of Abbreviations and Acronyms .....................................................................................................................124

8.6 ADDITIONAL DOCUMENTS ......................................................................................................................................125

8.6.1 Diagrams and Drawings.................................................................................................................................................125

8.6.2 Other Documents............................................................................................................................................................125

April 4, 2013 Page vi

Page 8

G 120 II V

List of Figures

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

Figure 1-1 Compressor Identification Label .............................................................................................................................2

CHAPTER 2:- - - - OPERATING INSTRUCTIONS; MAPLE SYSTEM

Figure 2-1 MNR-0053...............................................................................................................................................................5

Figure 2-2 PLC & Battery .........................................................................................................................................................5

Figure 2-3 Maple System; Run Screen......................................................................................................................................6

Figure 2-4 Maple System; Home Screen...................................................................................................................................7

Figure 2-5 Status Screen............................................................................................................................................................8

Figure 2-6 Login Screens ..........................................................................................................................................................9

Figure 2-7 Parameters Screen..................................................................................................................................................10

Figure 2-8 Operator Interface Screen Flow.............................................................................................................................14

CHAPTER 3:- - - - - - - - - - - - - - - - - - - - - - IK120 II C & G

Figure 3-1 IK120 II C & G Compressor Blocks, Front View .................................................................................................15

Figure 3-2 Air Flow Diagram..................................................................................................................................................16

Figure 3-3 Lubrication Oil Circuit ..........................................................................................................................................17

Figure 3-4 Oil Sight Glass.......................................................................................................................................................18

Figure 3-5 Oil Filler Cap .........................................................................................................................................................18

Figure 3-6 Removing the Oil Filter Cover ..............................................................................................................................18

Figure 3-7 Replacing the Oil Filter .........................................................................................................................................18

Figure 3-8 Inter-stage Separator..............................................................................................................................................20

Figure 3-9 Valve Operation.....................................................................................................................................................21

Figure 3-10 IK120II C & G, 1st Stage Valve............................................................................................................................22

Figure 3-11 IK120 II C 1st Stage Valve Head and Plate Valve................................................................................................23

Figure 3-12 IK120 II C & G, 2nd Stage Valve Head and Valves .............................................................................................24

Figure 3-13 Using the Special Valve Tool ................................................................................................................................25

Figure 3-14 Securing the Intake Valve......................................................................................................................................25

Figure 3-15 IK120 II C & G, 3rd Stage Valve Head and Valves..............................................................................................26

Figure 3-16 Removing the 3rd Stage Pressure Valve ...............................................................................................................27

Figure 3-17 Crankcase Assembly..............................................................................................................................................28

Figure 3-18 Piston and Cylinder, 1st Stage...............................................................................................................................30

Figure 3-19 Piston and Cylinder, 2nd Stage..............................................................................................................................31

Figure 3-20 Piston and Cylinder, 3rd Stage ..............................................................................................................................32

Figure 3-21 Piston and Sleeve, 3rd Stage..................................................................................................................................33

Figure 3-22 1st Stage Valve Head and Valve, IK120 II C & G................................................................................................34

Figure 3-23 2nd Stage Valves and Valve Head.........................................................................................................................36

Figure 3-24 3rd Stage Valves and Valve Head .........................................................................................................................38

Figure 3-25 Flywheel ................................................................................................................................................................39

Figure 3-26 Inter-Stage Separator .............................................................................................................................................40

Figure 3-27 Lubrication System Assembly...............................................................................................................................42

Figure 3-28 Cooling System......................................................................................................................................................44

Page vii 1st Edition, Rev. 0 Chg. 2

Page 9

MNL-126509

Figure 3-29 Inlet Assembly....................................................................................................................................................... 46

Figure 3-30 Automatic Condensate Drain ................................................................................................................................49

Figure 3-31 ACD Operation Diagrams .....................................................................................................................................50

Figure 3-32 ACD System..........................................................................................................................................................52

Figure 3-33 ACD Valve and Manifold Assembly ....................................................................................................................53

Figure 3-34 Condensate Collector.............................................................................................................................................54

Figure 3-35 Condensate Collector.............................................................................................................................................55

CHAPTER 4:- - - - - - - - - - - - - - - - PURIFICATION SYSTEM

Figure 4-1 Cartridge Safety Venting.......................................................................................................................................57

Figure 4-2 P0 & P31 Safety Venting ...................................................................................................................................... 57

Figure 4-3 Purification System Dataplates (typical) ............................................................................................................... 57

Figure 4-4 Correction Factor for Cartridge Operating Hours ................................................................................................. 61

Figure 4-5 Example Record of Adjusted Operating Hours.....................................................................................................61

Figure 4-6 P1 Purification System ..........................................................................................................................................63

Figure 4-7 Oil and Water Separator ........................................................................................................................................64

Figure 4-8 Oil and Water Separator Labels ............................................................................................................................65

Figure 4-9 Oil and Water Separator ........................................................................................................................................67

Figure 4-10 Sintered Metal Filter Assembly.............................................................................................................................67

Figure 4-11 Cartridge Replacement ..........................................................................................................................................67

Figure 4-12 P1 Purification System Parts List.......................................................................................................................... 69

Figure 4-13 Oil and Water Separator Parts List........................................................................................................................70

Figure 4-14 10” Chamber Parts List .........................................................................................................................................71

CHAPTER 5:- - - - - - - - - - - - COMPRESSOR DRIVE; G 120 II V

Figure 5-1 Vertical Drive with Idler (typical)......................................................................................................................... 72

Figure 5-2 G 120 II V Drive with Idler .................................................................................................................................. 73

CHAPTER 6:- - - - - - - - - - ELECTRICAL PANEL, ASY-1058 XL

Figure 6-1 ASY-1058 XL and MNR-0053 ............................................................................................................................. 75

Figure 6-2 Electrical Panel Label............................................................................................................................................ 76

Figure 6-3 PLC, CNT-0078 ....................................................................................................................................................77

Figure 6-4 Connector Block Removal ....................................................................................................................................77

Figure 6-5 Hourmeter..............................................................................................................................................................79

Figure 6-6 Transformer and Fuses ..........................................................................................................................................79

Figure 6-7 Motor Starter (typical) ........................................................................................................................................... 80

Figure 6-8 Overload Relay (typical) .......................................................................................................................................80

Figure 6-9 Power Supply......................................................................................................................................................... 81

Figure 6-10 Securus II

Figure 6-11 High Temperature Switch......................................................................................................................................83

Figure 6-12 Pressure Sensor (Typical)...................................................................................................................................... 83

Figure 6-13 Condensate Level Float Switch .............................................................................................................................84

Figure 6-14 Control Pane .......................................................................................................................................................... 88

Figure 6-15 Electrical Panel, Front View.................................................................................................................................. 89

Figure 6-16 Electrical Panel, Bottom View .............................................................................................................................. 90

®

Transmitter ......................................................................................................................................... 82

April 4, 2013 Page viii

Page 10

G 120 II V

Figure 6-17 Electrical Panel, Interior, 60 Hz ............................................................................................................................92

Figure 6-18 Electrical Panel, Interior, 50 Hz ............................................................................................................................94

CHAPTER 7:- - - - - - - - - - - - - - - - -INDICATORS & VALVES

Figure 7-1 Indicators .............................................................................................................................................................101

Figure 7-1 Check Valve.........................................................................................................................................................103

Figure 7-2 Pressure Maintaining Valves (PMV)...................................................................................................................103

Figure 7-3 Safety Valves .......................................................................................................................................................104

CHAPTER 8:- - - - - - - - - - - - - - - - - - - - - - - - -APPENDIX

Figure 8-1 Lifting Devices ....................................................................................................................................................108

Figure 8-2 Leveling Feet .......................................................................................................................................................109

Figure 8-3 Example of Air Intake Piping..............................................................................................................................113

Figure 8-4 Incoming Power Wiring Label ............................................................................................................................114

Figure 8-5 6 Bolt and 4 Bolt Torque Sequence.....................................................................................................................123

Page ix 1st Edition, Rev. 0 Chg. 2

Page 11

MNL-126509

CHAPTER 1: INTRODUCTION

1.1 How To Use This Manual

This manual contains the operating and maintenance instructions for the Bauer Compressors, Inc. products listed on the front cover.

All instructions in this manual should be observed and carried out as written to prevent damage or premature wear to the product or the equipment served by it.

If your unit is equipped with nonstandard accessories and or options, supplemental information is normally included in other documentation; i.e. OEM Manuals or additional Bauer Manuals.

While every effort is made to ensure the accuracy of the information contained in this manual, Bauer

Compressors, Inc. will not, under any circumstances be held accountable for any inaccuracies or the consequences thereof.

1.1.1 Manual Safety Notices

Important instructions concerning the endangerment of personnel, technical safety or operator safety will

be specially emphasized in this manual by placing the information in the following types of safety

notices.

^ DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or seri-

ous injury. This is limited to the most extreme situations.

^ WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

injury.

^ CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or mod-

erate injury. It may also be used to alert against unsafe practices.

NOTICE

NOTE advise of technical requirements that require particular attention by the operator or the mainte-

nance technician for proper maintenance and utilization of the equipment.

April 4, 2013 Page 1

Page 12

G 120 II V

1.2 How to Use the Replacement Parts List

• A lozenge in the Item Number column indicates the part number for a complete assembly.

• a dagger (†) in the Qty column with or without an ellipse (…) in the Part Number column means the

part is illustrated for assembly purposes only and is not available for sale as an individual component.

This part can be obtained by ordering the complete assembly.

• AR in the Qty column means that the item is cut or manufactured to the size which the customer specifies.

• A dash (—) in the Item Number column indicates that there is more than one part number applicable

to the preceding Item Number.

• The letters in the columns labeled Kit indicate the number of operating hours when the part is to be

replaced; a = replaced every 1,000 hours, b = replaced every 2,000 hours and c= replaced every 4,000

hours.

• NS in the Item Number column indicates the part is not illustrated but is available.

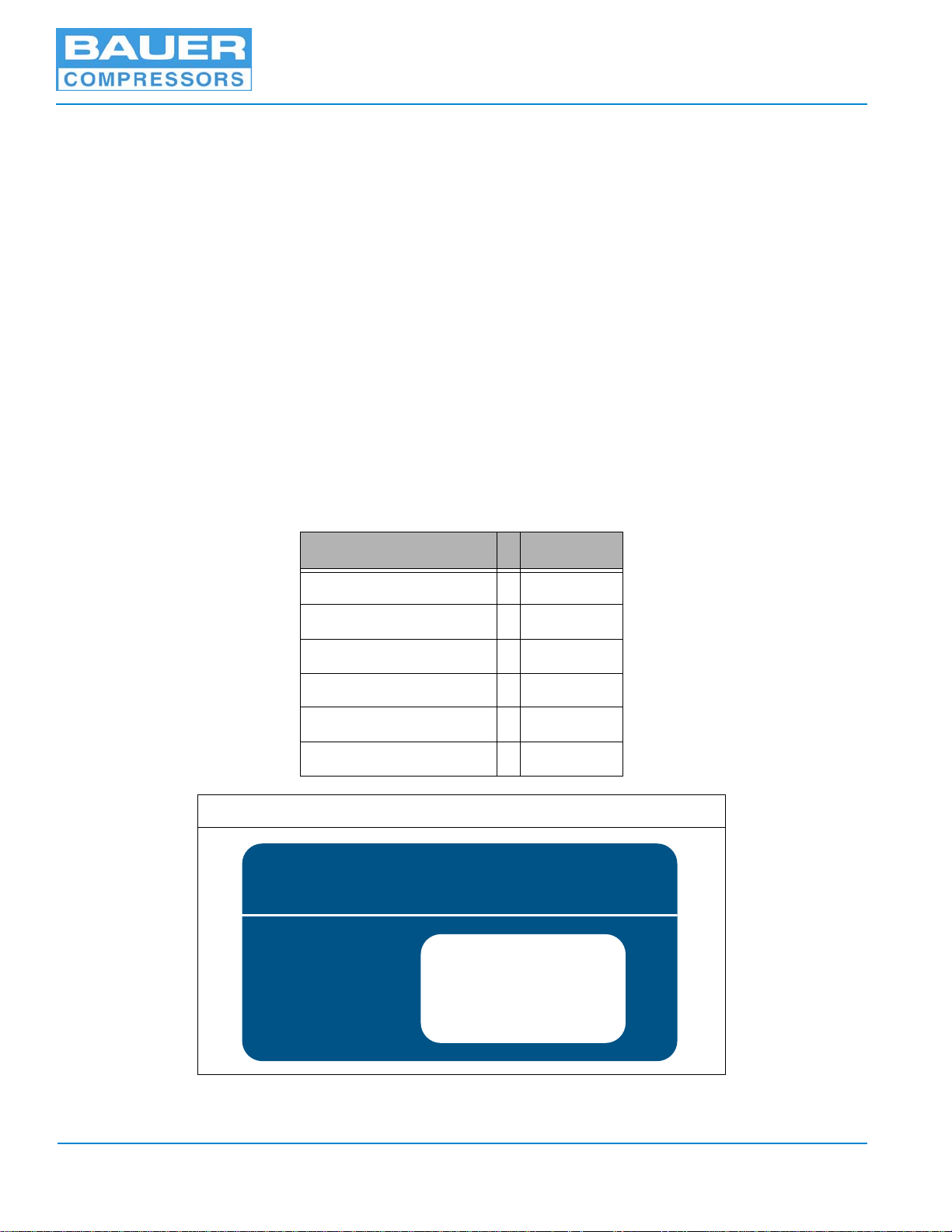

When placing an order for spare parts, please provide the following information to ensure delivery of the

correct parts. The model number, date of manufacture and serial number can be found of the compressor

unit identification plate on the compressor unit frame.

Information Example

Model Number VC 120

Serial Number 143156

Date of Manufacture 02/2013

Part Number VAL-0500

Part Description Valve

Part Quantity Required 1

Figure 1-1 Compressor Identification Label

BAUER COMPRESSORS, INC.

NORFOLK, VA 23502 U.S.A. (757) 855-6006

MODEL NO.

BLOCK NO.

SERIAL NO.

QUANTITY

MFG. DATE

Page 2 1st Edition, Rev. 0 Chg. 2

Page 13

MNL-126509

^ WARNING

The use of repair parts other than those included in the Bauer Replacement Parts Lists may create unsafe

conditions over which Bauer has no control. Such unsafe conditions can lead to accidents that may be life-

threatening, cause substantial bodily injury, and/or result in damage to the equipment. Therefore, Bauer

Compressors, Inc. can bear no responsibility for equipment in which unapproved repair parts are installed.

1.3 How to Use the Appendix

Information contained in the Appendix to this manual includes the following.

• The safety instructions applicable to this product. They must be read, understood and complied with

prior to operating the product.

• The instructions for installing this product. They must be read, understood and complied with prior to

operating the product.

• Reproducible Forms

• Reference Data

• Torque Values

• Torque Sequence

• Conversion Formulas

• Approved Lubricants

• Glossary of Abbreviations & Acronyms

• Additional Documents

April 4, 2013 Page 3

Page 14

1.4 Unit Specifications

All specifications are subject to change without prior notice.

G 120 II V 7.5 Hp

Medium Nitrogen, Helium and Argon

Capacity 6.8 scfm (193 l/min)

Inlet pressure 0 - 3 psig (0 - 0.21 bar)

Operating pressure, max. 5,000 psig (350 bar)

Ambient temperature range 40 - 115 °F (5 - 45 °C)

Compressor Block

IK120 II C Mod. 5

No. of stages 3

No. of cylinders 3

Cylinder bore, 1st stage 3.46 in. (88 mm)

Cylinder bore, 2nd stage 1.42 in. (36 mm)

Cylinder bore, 3rd stage 0.55 in. (14 mm)

Piston Stroke 1.57 in.(40 mm)

Intermediate pressure, 1st stage 85 - 100 psig (6 - 7 bar)

Safety valve setting, 1st stage 130 psig (9 bar)

Intermediate pressure, 2nd stage 580 - 710 psig (40 - 49 bar)

Safety valve setting, 2nd stage 870 psig (60 bar)

Direction of rotation when facing flywheel CCW

Compressor speed 1,200 RPM

Oil capacity 3 qts. (2.8 liter)

Oil Pressure 60 - 85 psig (4 - 6 bar)

Recommended oil BAUER OIL-0024

Maximum Inclination 15° in all directions

G 120 II V

1.4.0.1 Compressor Drive

Model Voltage Freq. Phase Power Type FL Amp Bauer P/N

-E3 208, 230, 460 VAC 60 Hz 7.5 Hp ODP 20, 18, 9 MTR-0033

-E3 380, 400, 415 VAC 50 Hz 7.5 Hp ODP 10.5, 10, 9.5 MTR-0208

1.4.0.2 Purification System Applicability

The G 120 II V is standardly equipped with the Bauer P1 or Oil Removal Filtration System.

1.4.0.3 Pressure Switch Settings

1.4.0.3.1 Inlet Pressure Switch Settings

Low Inlet Pressure 0.0 psig

High Inlet Pressure 1.5 psig

1.4.0.3.2 Final Pressure Switch Setting

Final Pressure 2,400 psig

Restart Pressure 1,900 psig

Final Safety Valve 2,800 psig

Page 4 1st Edition, Rev. 0 Chg. 2

Page 15

MNL-126509

SECURUS

CHAPTER 2: OPERATING INSTRUCTIONS; MAPLE SYSTEM

2.1 Description The following instructions apply to units that use the Maple System touchscreen operator interface, MNR-0053 with program 31L.

Figure 2-1 MNR-0053

The Electrical Panel Assembly will provide logical control and safety shutdowns for the compressor

equipment. All necessary time delays, counters, shutdowns, sequencing and safety features are incorporated into a proprietary software program permanently saved into PLC memory using EEPROM technology. The PLC is equipped with a 200 day in battery to maintain the PLC’s internal clock. The software

program is based on the pressure and use of the compressor. The operator uses the Operator Interface to

communicate with the PLC which is located in the electrical enclosure.

2.1.1 Emergency Stop Button

A Normally Closed switch when pulled out, when the E-Stop Button is pressed in, it disconnects the

main power source, turning off the compressor, draining the ACD system and stopping air delivery to

the consuming devices. This button is to be used in case of emergency. Normal operational stops should

be accomplished using the operator interface.

Figure 2-2 PLC & Battery

200 DAY

BATTERY

PLC

April 4, 2013 Page 5

Page 16

G 120 II V

2.1.2 Operator Interface

The Operator Interface is a 4.3 inch, 256 color, 8 bit LCD with touchscreen operation. The Operator

Interface is the input/output device for normal operation of the compressor unit. The compressor system

is ready and able to operate after the Emergency Stop Switch is pulled out and the red “COM” status light

illuminates. The red status light will continuously strobe to show that the unit is ready.

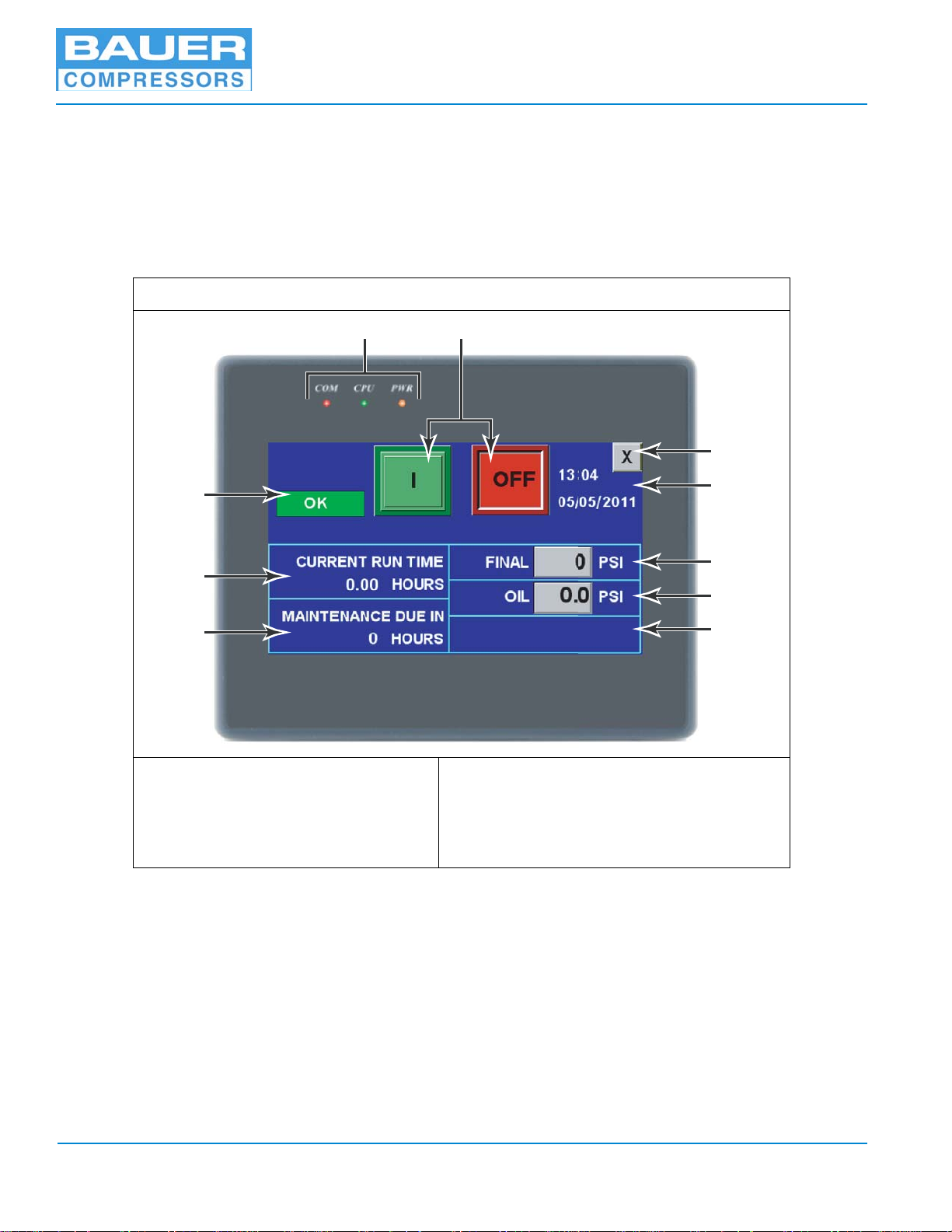

2.1.2.1 Run Screen

The initial screen after startup allows control and monitoring of the compressor unit.

Figure 2-3 Maple System; Run Screen

45

(CO) MONITOR

SECURUS

1

6

7

8

2

9

3

1. Securus / Secant Status

2. Current Run Time

3. Next Maintenance Due Status

4. Status Lights

5. ON & OFF Buttons

1. If the unit is equipped with a CO monitor, the words (CO) monitor are shown here. Also if the unit

is equipped with a Securus or Seccant monitor, the status of the monitor is shown here.

6. Closes Window (goes to main menu)

7. Current Time & Date

8. Final Pressure (from sensor)

9. Current Oil Pressure (from sensor)

10. Inlet Pressure (if equipped with sensor)

10

2. This reading shows the current run time of the compressor in hours. Once the compressor is turned

off this reading returns to zero. For total hours on the unit check the status screen.

3. This reading tells when the next maintenance is due on the compressor.

4. These lights show the status of electrical connections and communication. The red light strobes

continuously to show communication is established with the PLC. The green light indicates that the

PLC has power, and the yellow light indicates power is coming into the unit.

Page 6 1st Edition, Rev. 0 Chg. 2

Page 17

MNL-126509

5. The ON and OFF buttons control the compressor. These buttons should be used for normal starting

and stopping of the compressor. In an emergency the Emergency Stop button should be used.

6. This X button closes the Run screen and goes to the main menu screen. The compressor may still be

operating when returning to the main menu screen.

7. The current time and date are shown here. This data can be corrected only by user levels 2 and 3.

8. The final pressure reading is displayed here. It is received from the final pressure sensor near the

outlet.

9. This oil pressure reading displays a continuous pressure from the compressor. This reading is taken

from the oil pressure sensor on the compressor block.

10. This space a reserved for units with inlet pressure sensors. A continuous inlet pressure reading is

provided. This is mainly for units designed to compress natural or industrial gases.

2.1.2.2 Main Menu Screen Figure 2-4 Maple System; Home Screen

1

2

3

4

5

1. User Level Status

2. Run Screen Button

3. Alarm History Button

The home screen is the main screen used to navigate to the other 8 options. All of the option screens can

be viewed but critical changes can only be made by user levels 2 & 3. Critical changes control the functions of the compressor. This feature is added to prevent unintentional changes to the unit’s functions.

2.1.2.2.1 Run

This button returns the user to the RUN screen, See Paragraph 2.1.2.1 for further information.

4. Status Button

5. Contact Information Button

6. Login Button

7. Configuration Button

8. Parameters Button

9. Tools Button

6

7

8

9

April 4, 2013 Page 7

Page 18

G 120 II V

1

2

3

4

5

25.01

15.0

514

2.1.2.2.2 Alarms History

This button displays the history of alarms. The date of the alarm history can be changed with the drop

down arrow or the forward and backward arrows adjacent to the date. To return to the Main Menu screen

touch the X in the upper right corner.

2.1.2.2.3 Status

The status button takes the user to the status screen. The status screen allows the user to view the Current

Run Time, Total Run Time, Minutes till next ACD cycle, current Separator Count, and the Current Final

Pressure.

Figure 2-5 Status Screen

1. Calendar / Hour Selection

2. ACD Test Button

3. Return Button

4. View Maint. Schedule

5. Light ON / OFF Button

The options on the Status screen are shown in Figure 2-5. The Selection button allows the operator to

select maintenance warnings by the calendar schedule or the hourly maintenance schedule. The ACD

Test button is used to perform an ACD test. Pressing this button opens the ACD valve and the operator

should be able to hear the ACD draining. The Return button takes the user back to the Main Menu screen.

The Maintenance schedule buttons allow the user to view the Maintenance schedule by calendar days or

by hours (See Table 2-1& 2-2). The Light ON / OFF button is used on some models equipped with lights.

This button toggles the light on and off.

2.1.2.2.4 Contact

Pressing the contact button displays contact information for maintenance and assistance for your unit. It

can only be edited by users 2 & 3.

2.1.2.2.5 Login

The login button takes the user to the login screen. The default option is User l, Operator. No password is

needed to operate the compressor at this user level. At this user level the operator can operate the unit and

explore all the other menu screens but cannot change parameters or configuration settings. User 2, Level

1, can operate the compressor and also is allowed to change some parameters and configuration settings.

User 3, Factory Level, has total access to the unit and can change all parameters and configuration settings.

Page 8 1st Edition, Rev. 0 Chg. 2

Page 19

MNL-126509

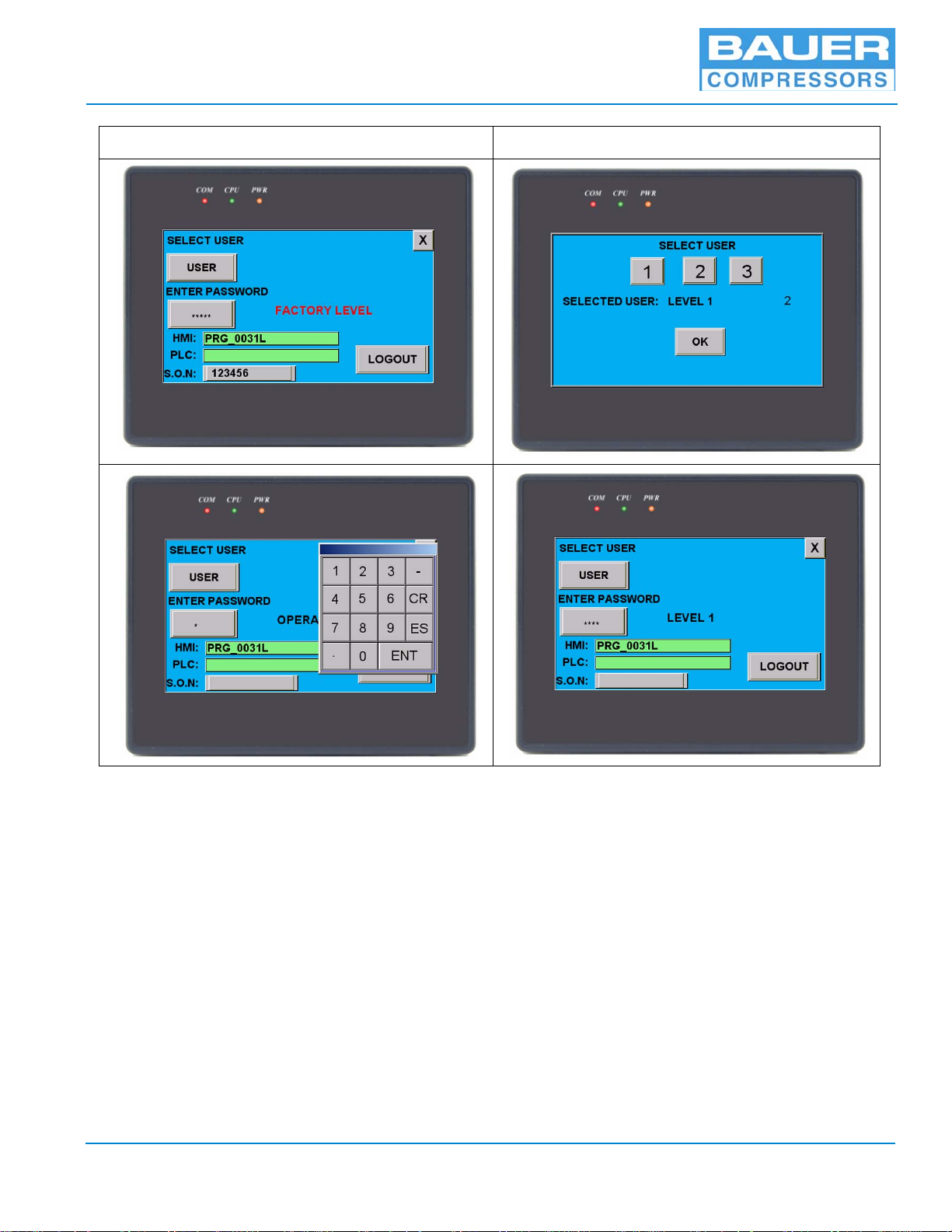

Figure 2-6 Login Screens

To change the user level press the “USER” button, select the desired user, and press “OK”. Then press the

button below the words “Enter Password” and press the password numbers on the keypad. After entering

the proper password press “ENT” on the keypad to enter the password. If the password is incorrect an

“Invalid Password” screen will pop up. The only option on the screen is to click “OK”. If the password is

accepted the screen will return to the login screen with the new user level shown.

2.1.2.2.6 Configuration

The Configuration button is used to setup the features that make the unit. There are a total of 4 pages in

this option. The first two pages consist of 8 features which a unit may have. The third page is used to set

the final pressure sensor limit. The fourth page is used to set the inlet pressure sensor limit. Similar to the

Parameter’s settings changing the Configuration settings will change how the unit operates so only users

2 & 3 are allowed to change them. Pressing the X button returns the user to the main menu screen.

April 4, 2013 Page 9

Page 20

G 120 II V

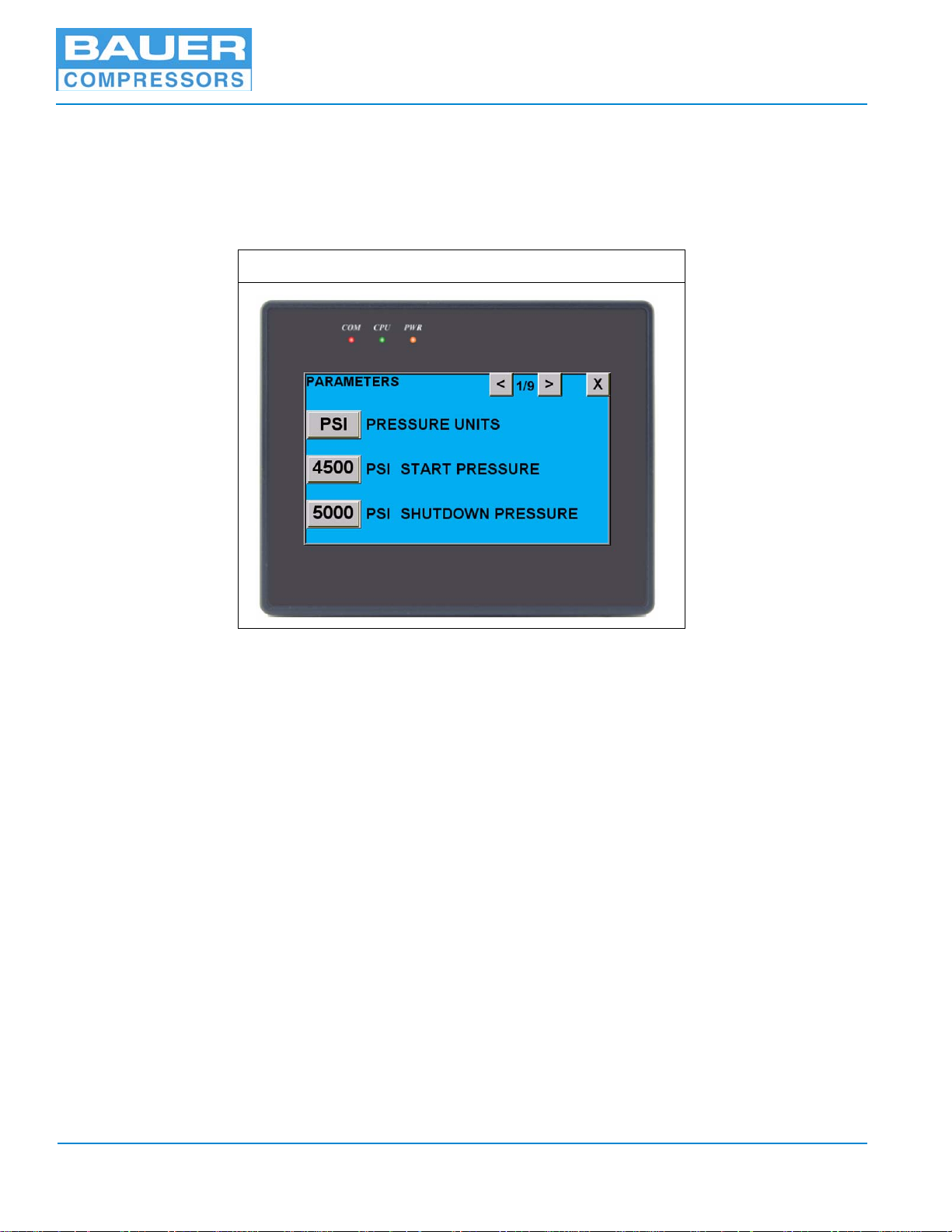

2.1.2.2.7 Parameters

This button takes the user to the parameters screens. There are a total of 9 screens. These parameters are

set at the factory for each specific unit. Changing these parameters will change how the unit operates, so

only users 2 and 3 are allowed to change them. If user 1, Operator, tries to change a parameter a window

will pop up stating “Access Denied”. To change a parameter just touch the number which needs to be

changed and a keypad will pop up. Punch in the new number and press the “ENT” key.

Figure 2-7 Parameters Screen

Pressing the Pressure Units button toggles the run screen pressures between PSI and BAR.

Pressing the X button will return the screen to the main menu.

2.1.2.2.8 Tools

Like the Parameters and Configuration options only users 2 & 3 can make changes or use this option. The

first page of the tools option is used for maintenance purposes. The buttons are used to check the PLC and

can only be used when the unit is OFF. The second page is used to set the internal calendar/clock and to

select the language displayed on the monitor. English, Spanish, and Portuguese are the current choices.

More languages may be added at a later date. The third page offers activation of the Anybus (internet)

Server, to turn off or on the key beeping sound, or to clear the alarm history. The final button “START” is

used to save the current set parameters to the internal EEPROM. If this button is pressed the current setting are saved to the memory and a status bar of the operation will be shown.

2.2 Starting and Stopping Unit

2.2.1 Before Starting.

1. Check the compressor oil level, See Chapter 3.

2. Ensure that all panels and guards are properly installed.

3. If the unit is equipped with doors, ensure all doors are closed.

4. Ensure that the E-Stop Button is pulled out.

Page 10 1st Edition, Rev. 0 Chg. 2

Page 21

MNL-126509

2.2.2 To Start Unit.

Press the green START Button on the Run Screen. (See Figure 2-3)

If the pressure in the system is lower than the set “Start Pressure”, the drive motor will start up powering

the compressor. If the system’s pressure is higher than the set “Start Pressure” or when the air pressure

has increased to the set “Operating Pressure”, the drive motor will automatically shutdown. The Compressor will automatically restart when the system’s pressure drops below the set “Start Pressure”.

^ WARNING

Once started the compressor and drive motor will start and stop automatically.

Stay clear of all moving parts whenever unit has power.

2.2.3 To Stop Unit.

Press the red STOP Button on the Run screen..

NOTICE

In an emergency the compressor is shutdown by pressing

in the Emergency Stop Button.

April 4, 2013 Page 11

Page 22

G 120 II V

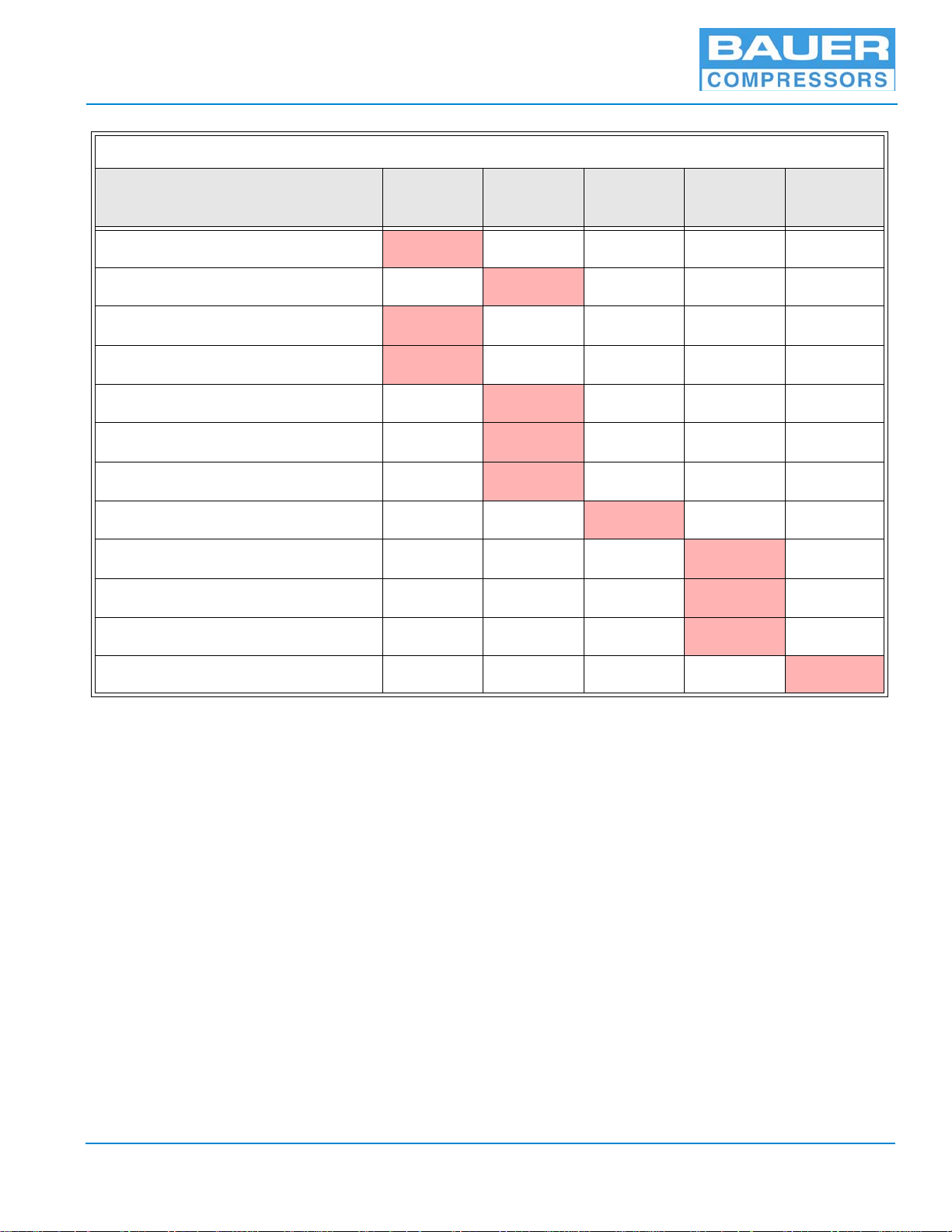

Table 2-1: Calendar Maintenance Interval Tasks

Task Monthly Annually Every Two Years

Calibrate CO Monitor

Check Oil Level

Check Final Pressure Shutdown

Check Automatic Condensate Drain

Check V-belt

Service Intake Filter

Check all connections for leaks

Inspect Compressor Valves

Check all fasteners for tightness

Change Synthetic Oil

Replace Compressor Oil Filter

Replace Compressor Valves

X

X

X

X

X

X

X

X

X

X

X

X

Replace CO Monitor Sensor

X

Page 12 1st Edition, Rev. 0 Chg. 2

Page 23

MNL-126509

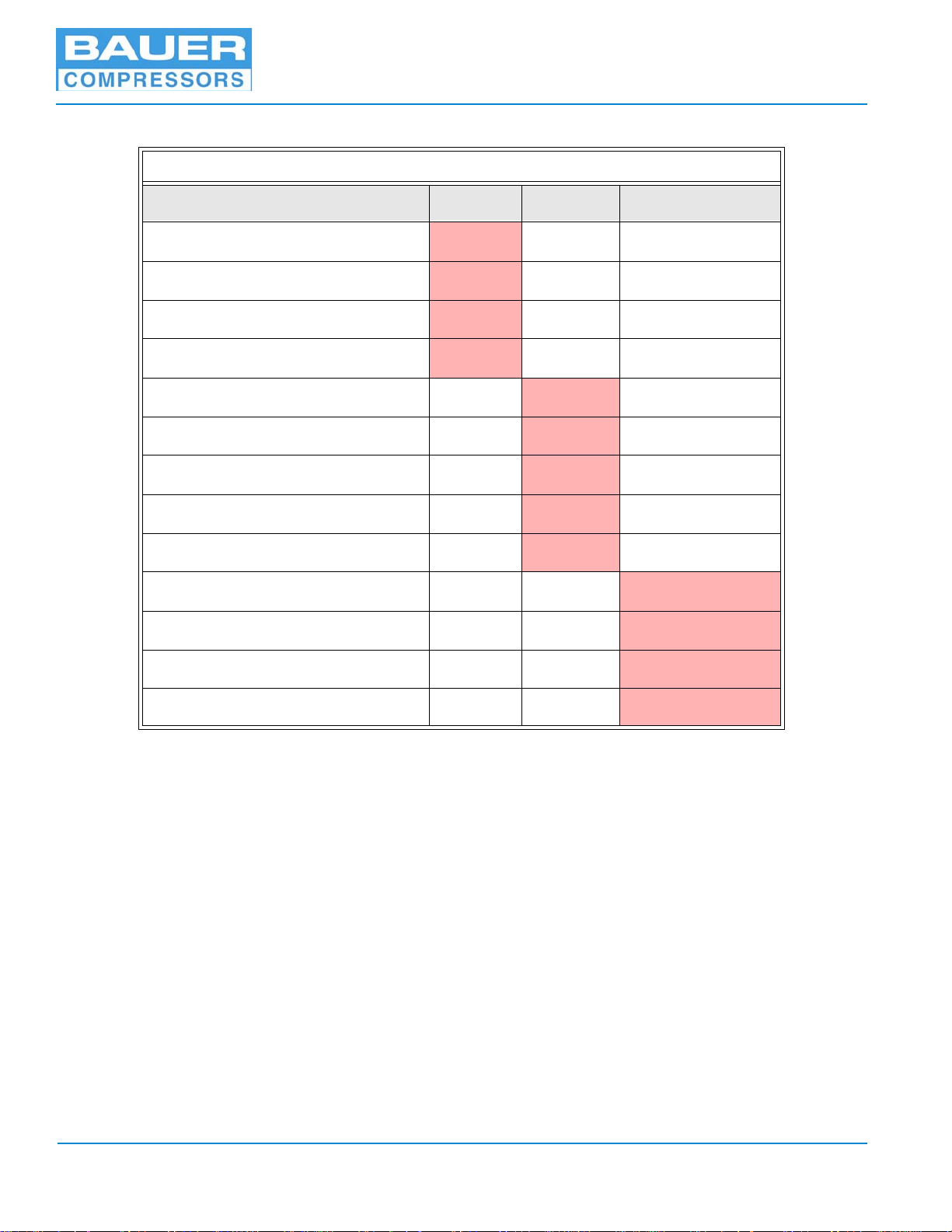

Table 2-2: Operating Hours Maintenance Interval Tasks

Task

Check Oil Level

Check Final Pressure Shutdown

Check Automatic Condensate Drain

Check V-belt

Service Intake Filter

Check all connections for leaks

Check fasteners for tightness

Inspect Compressor Valves

Change Synthetic Oil

Replace Oil Filter

Replace Compressor Valves

250

Hours

X

X

X

500

Hours

X

X

X

X

1,000

Hours

X

2,000

Hours

X

X

X

3,000

Hours

Inspect Pistons and Pistons Rings

X

April 4, 2013 Page 13

Page 24

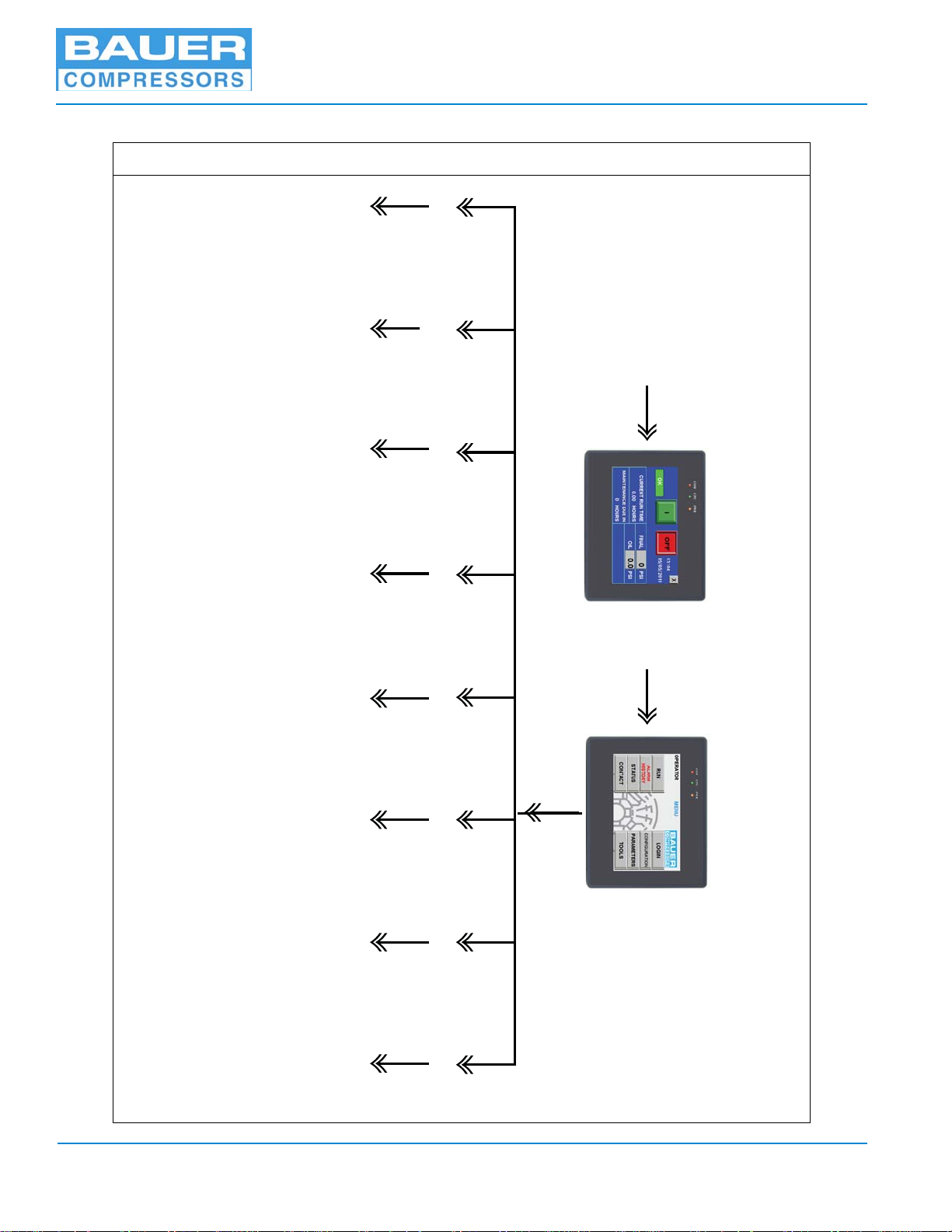

2.3 Screen Flow

START UP

RUN SCREEN

On

Off

MAIN MENU

RUN

Changable

Date

LOGIN

STATUS PARAMETERSCONFIGURATION TOOLSCONTACT

Return to

Run Screen

Above

ALARMS

HISTORY

Users

1, 2, & 3

Current

Status

ACD Test

Light

Unit Settings

9 pages

Unit Setup Maint.

Check

PLC

Set Internal

Clock

Set Language

Contact

Info

for Help

Pressure

Sensor

Limits

Figure 2-8 Operator Interface Screen Flow

G 120 II V

Page 14 1st Edition, Rev. 0 Chg. 2

Page 25

MNL-126509

CHAPTER 3: IK120 II C & G

3.1 Maintenance and Parts

3.1.1 Description

The IK120 II C & G compressors are used to compress gases up to a maximum of 5,000 psi. Both compressors are three cylinder, three stage air cooled, oil lubricated reciprocating compressors. The 3rd stage

cylinder is lubricated by means of the forced feed lubrication system, while the other cylinders are splash

lubricated. The cylinders are arranged in a “W” configuration, the 1st stage is in the center, 2nd stage on

the right and 3rd stage on the left looking from the filter side.

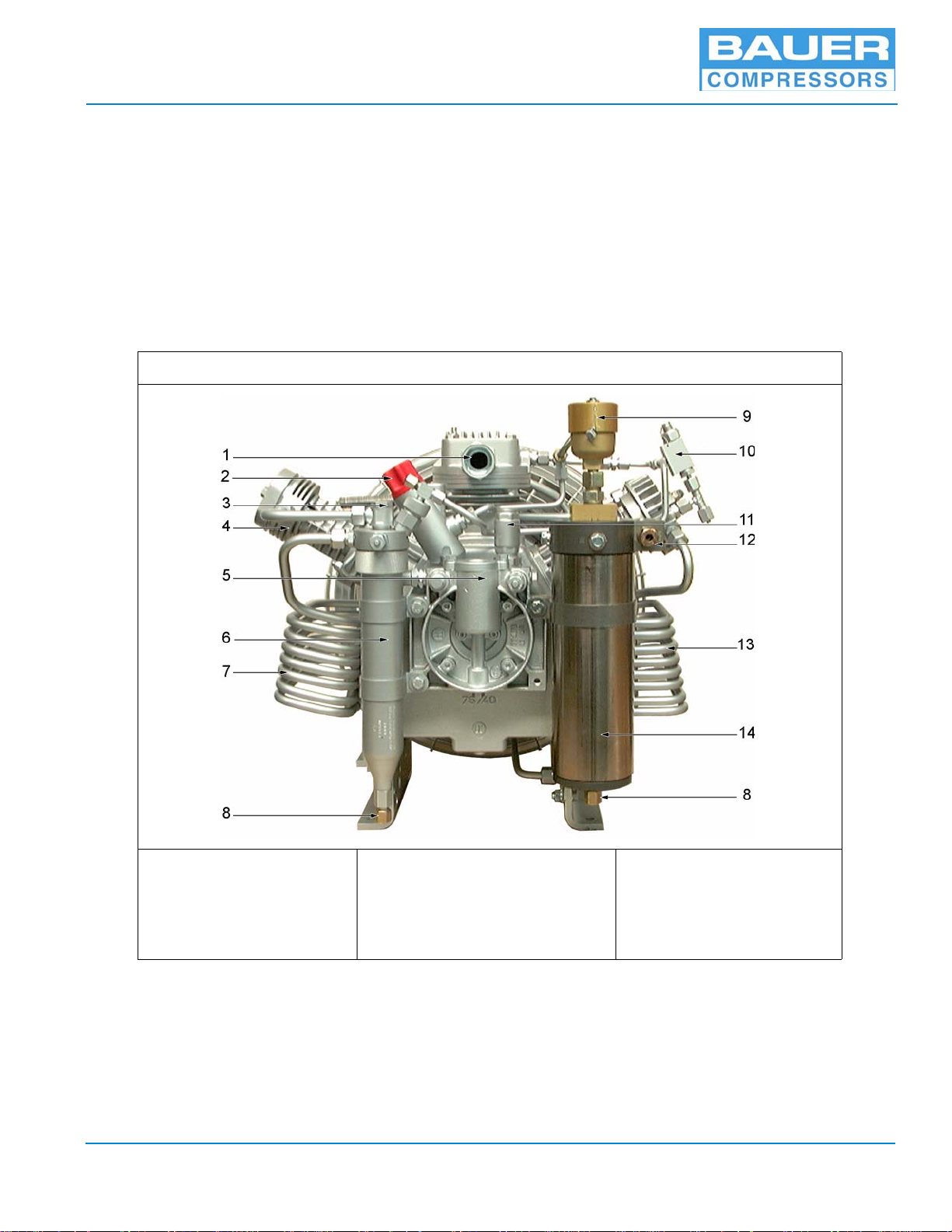

3.1.2 Component Location Figure 3-1 IK120 II C & G Compressor Blocks, Front View

1. Intake Connector

2. Oil Filler

3. 2nd Stage Safety Valve

4. 3rd Stage Cylinder

5. Oil Filter Housing

April 4, 2013 Page 15

6. Inter-stage Separator

7. 2nd Stage Intercooler

8. Condensate Drain Connector

9. Final Safety Valve

10. 1st Stage Safety Valve

11. Crankcase Relief Valve

12. Gas Outlet Connector

13. 1st Stage Intercooler

14. Oil and Water Separator

Page 26

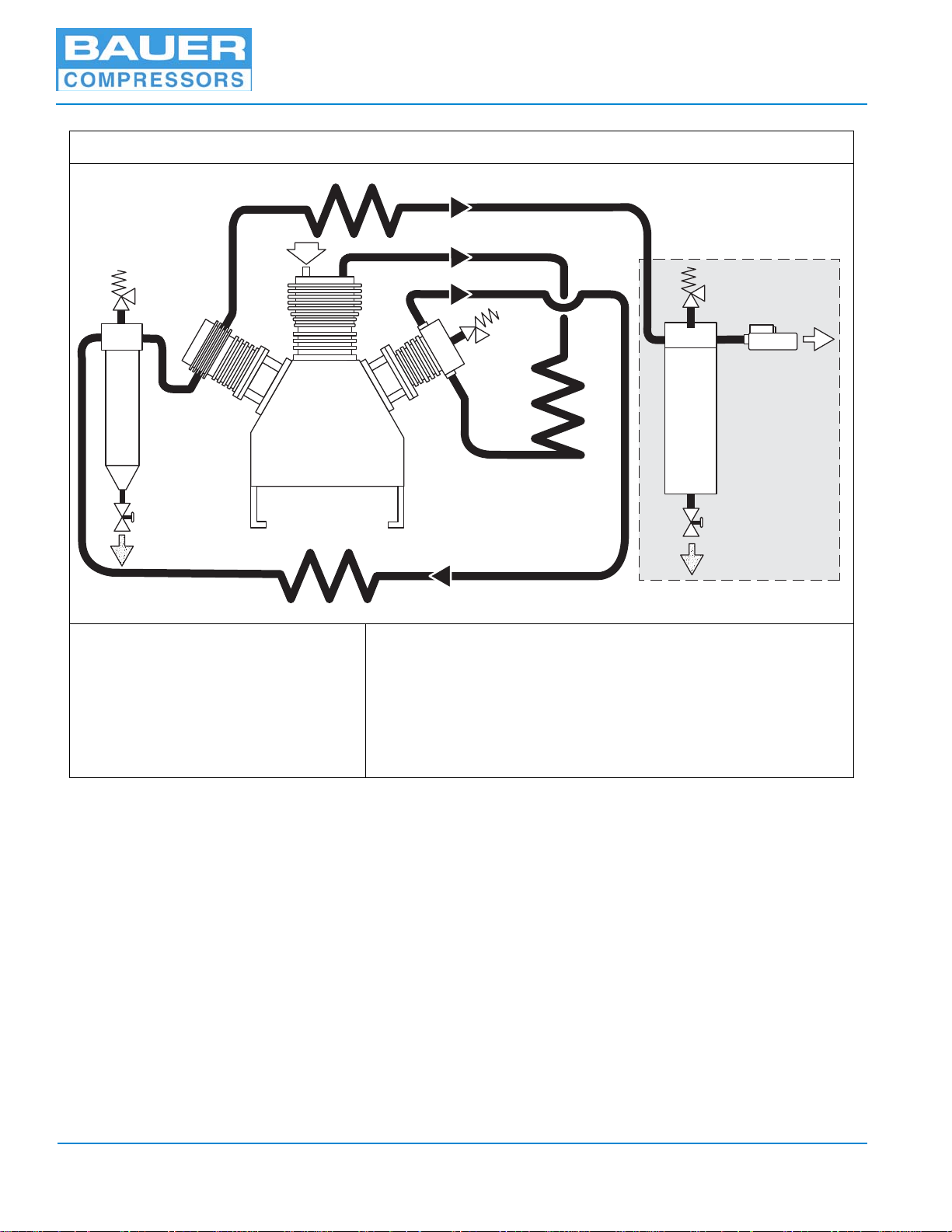

Figure 3-2 Air Flow Diagram

14

11

4

9

2

1

3

8

5

14

12

Purification

System

13

10

6

7

G 120 II V

1. Intake Manifold

2. 1st Stage Cylinder

3. 2nd Stage Cylinder

4. 3rd Stage Cylinder

5. 1st Stage Intercooler

6. 2nd Stage Intercooler

7. 3rd Stage Aftercooler

3.1.3 Air Flow Diagram

Refer to Figure 3-2. The gas is drawn in through intake connector (1), compressed to the final pressure in

cylinders (2, 3, 4,) and cooled by intercoolers (5, 6) and after cooler (7). The safety valves (8,9, 10) protect from overpressure in the individual stages. The compressed gas is purified by Inter-stage separator

(11) and oil and water separator assembly (12). The Inter-stage separator (11) and oil and water separator

(12) are drained by condensate valves (14). An Automatic Condensate Drain system is available as an

option. The pressure maintaining valve (13) ensures that pressure is built up in the HP drying system

from the start of delivery, thus achieving constant optimum drying.

8. 1st Stage Safety Valve

9. 2nd Stage Safety Valve

10. 3rd Stage Safety Valve (Final Pressure)

11. Inter-stage Separator

12. Oil and Water Separator

13. Pressure Maintaining Valve

14. Manual Condensate Drain Valve

Page 16 1st Edition, Rev. 0 Chg. 2

Page 27

MNL-126509

3

2

4

1

5

5

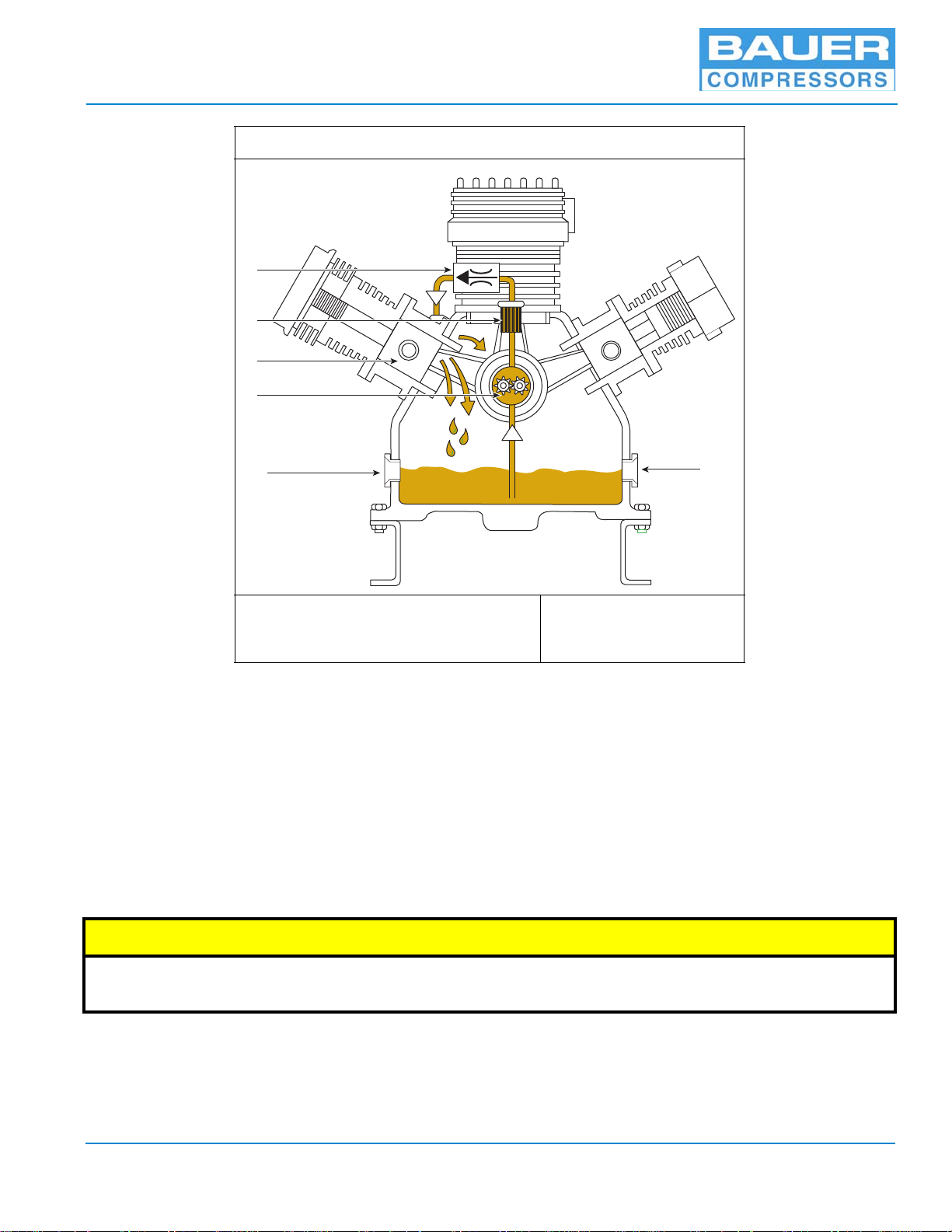

Figure 3-3 Lubrication Oil Circuit

1. Oil Pump

2. Oil Filter

4. Guide Piston

5. Oil Sight Glass

3. Minimum Pressure Valve

3.1.4 Compressor Lubrication

3.1.4.1 Description

Refer to Figure 3-3. The compressor is provided with forced-feed lubrication. The oil pressure is produced by a low speed gear pump (1). The oil pressure is approximately 73 psi (5 bar).

The oil pump (1) is coupled to and driven by the crankshaft. It pumps oil through the oil line filter (2) and

a minimum pressure valve (3) to the 3rd stage cylinder. The oil is then distributed by the guide piston (4)

of the 3rd stage and lubricates all the moving parts of the compressor block.

The minimum pressure valve (3) allows for oil pressure indication at a pressure gauge and/or electronic

oil pressure monitoring.

^ CAUTION

The Oil Pump operates only when the compressor is rotating in the correct direction. If the compressor is

rotating backwards, no oil pressure will build up damaging the compressor.

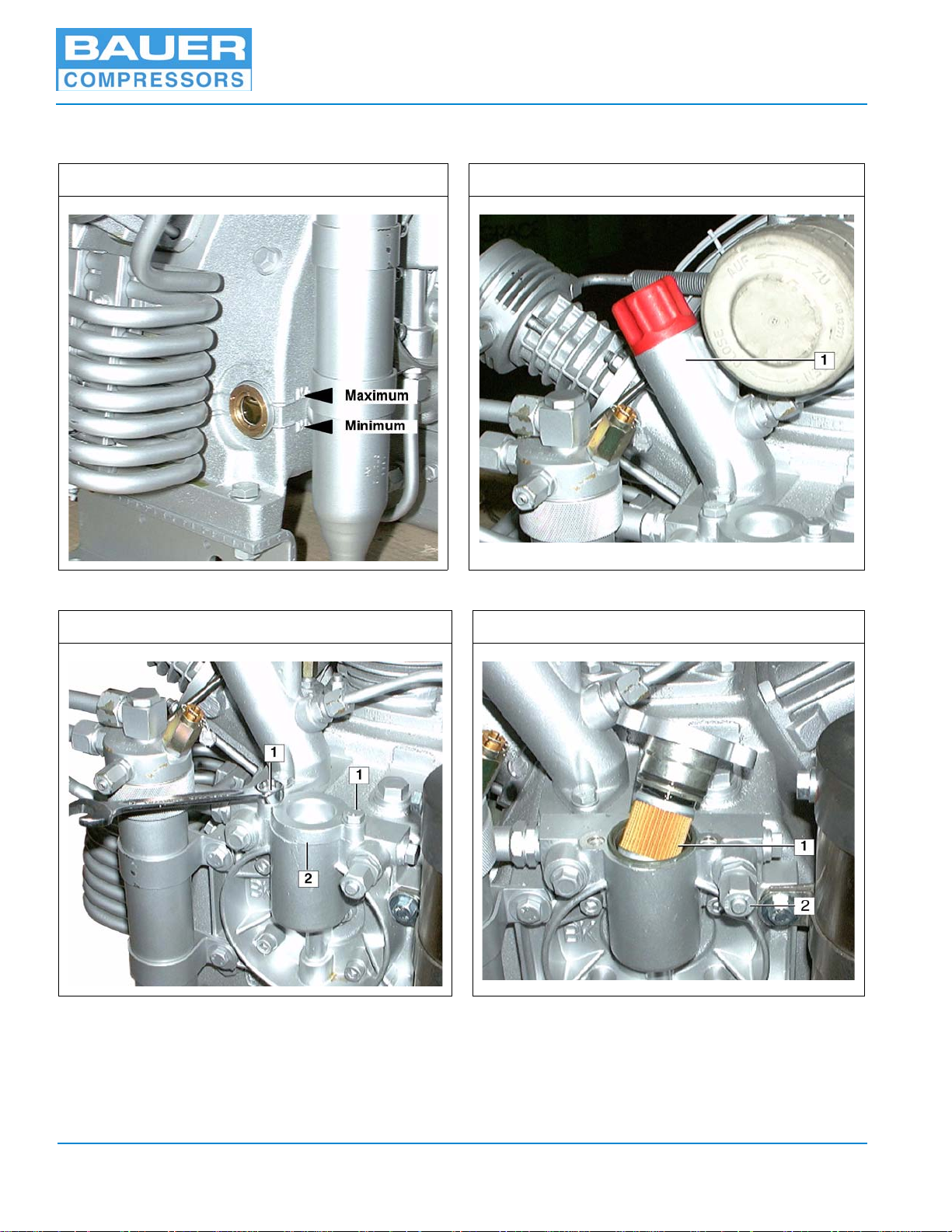

3.1.4.2 Oil Level Check

Check the oil level at the sight gauge on either side of the compressor block (See Figure 3-4) every day

before putting the compressor into operation. Oil level must be between the minimum and maximum

notches. Oil level must never be below the minimum mark as this will cause severe damage due to lack of

April 4, 2013 Page 17

Page 28

G 120 II V

lubrication. Oil level must also not exceed the maximum mark as this will cause excessive lubrication of

the compressor and may result in a carbon buildup on the valves.

Figure 3-4 Oil Sight Glass Figure 3-5 Oil Filler Cap

Figure 3-6 Removing the Oil Filter Cover Figure 3-7 Replacing the Oil Filter

3.1.4.3 Oil Change Interval

Every 2,000 operating hours or biennially; whichever comes first.

Page 18 1st Edition, Rev. 0 Chg. 2

Page 29

MNL-126509

3.1.4.4 Oil Change

1. Run the compressor until it is warm then shut it down.

2. (See Figure 3-5). Remove the cap (1) from the oil filler neck.

3. Drain oil while it is still warm by means of the oil drain plug.

^ CAUTION

Replace the oil filter every oil change. Failure to do so will cause the filter to clog and the bypass valve to

open resulting in unfiltered oil being circulated and possible damage to the compressor.

4. (See Figure 3-6). Remove the two bolts (1) with a 13 mm wrench. Remove the oil filter cover (2)

5. (See Figure 3-7). Remove the oil filter (1) from the rubber gasket at the cover.

6. Mount a new filter element (P/N N25326) and replace and fasten oil filter cover.

7. Slowly pour new oil through the oil filler neck until the level reaches the maximum mark on the

sight gauge.

8. Wait a few minutes and adjust the oil level if necessary before putting the unit into operation.

3.1.5 Venting the Oil Pump

(See Figure 3-7) If no or low oil pressure builds up after starting the unit, especially after maintenance

or repair or if the compressor has been run the wrong direction, venting the oil pump may be necessary.

1. Run the compressor with all condensate drains open to avoid building up pressure.

2. Unscrew Screw Cap (2) and Plug and wait until Oil comes out free of air bubbles.

3. Retighten Plug and Screw Cap.

4. Check Oil Level (See Paragraph 3.1.4.2) and replace oil as necessary.

3.1.5.1 Gas Intake System

In order for these compressors to work satisfactorily, it is absolutely essential to supply the medium at a

constant pressure. Therefore a pressure reducer in the intake line is necessary if the supply pressure is

above atmospheric pressure or fluctuating. An intake expansion tank between the pressure reducer and

the compressor may also be necessary to compensate for the pressure surges caused by the 1st stage piston.

April 4, 2013 Page 19

Page 30

G 120 II V

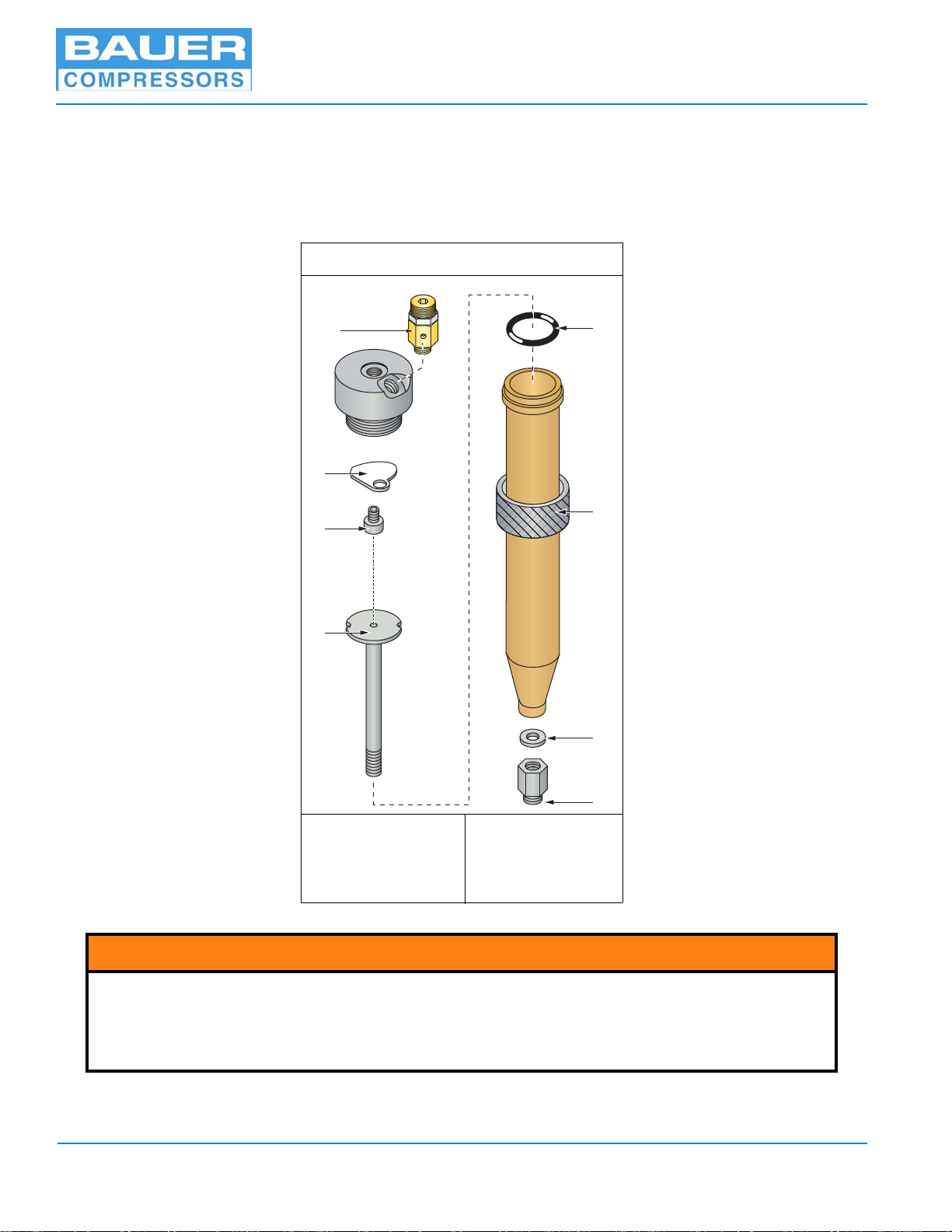

1

2

3

4

5

6

7