Page 1

OPERATING MANUAL

for

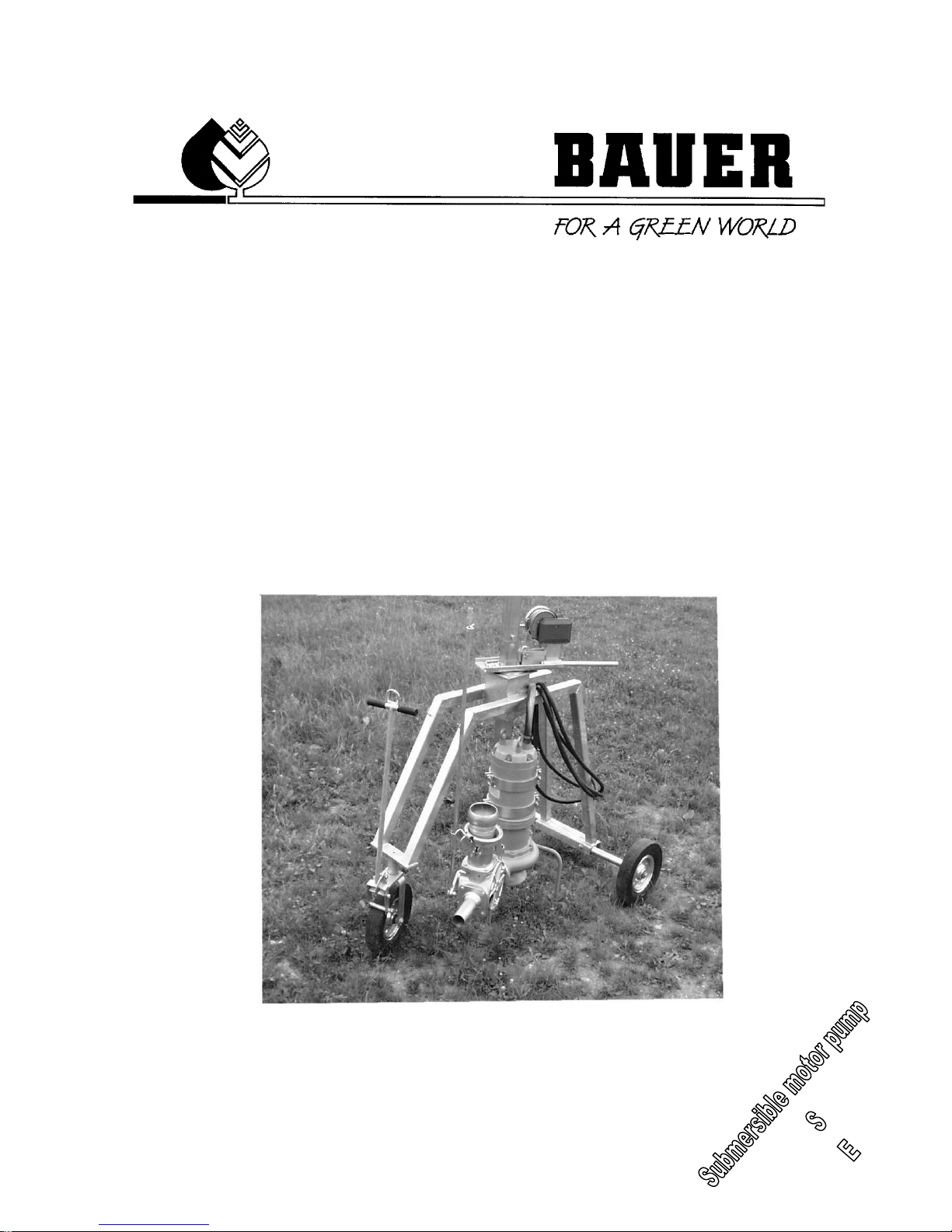

Submersible motor pump

Magnum S

Page 2

Operating manual BAUER Submersible Motor Pump / Version X-2010

2

INTRODUCTION

Thank you very much for purchasing a BAUER submersible motor pump!

We have pleasure to present to you a BAUER submersible motor pump that features state-of-art technology

and top quality. This manual describes how to operate and maintain your BAUER submersible motor pump.

For reasons of clearness and due to the many possibilities, this manual does not contain everything down into

detail. In particular, it cannot possibly deal with every conceivable aspect of operation and maintenance.

If you need further information or if you are faced with any special problem for which this manual does not give

sufficient details, please do not hesitate to contact BAUER company at Kowaldstraße 2, A-8570 Voitsberg for

the information you need.

We should also like to emphasise that the contents of this operating manual do neither form part of nor alter in

any way any previous or existing agreement, promise or legal relationship. Commitments on the part of BAUER

are based solely on the respective purchase contract, which also contains the complete and only valid warranty

arrangement. Said contractual terms of warranty are neither extended nor limited by the contents of the present

operating manual.

All information contained in the present manual is based on the latest product details available at the time of

printing.

BAUER reserves the right to change without notice, without assuming any liability!

BAUER submersible motor pumps are designed for safe and reliable performance provided they are

operated in compliance with the present instruction manual. In spite of the simplicity of the pump we therefore

request that you read this manual carefully before putting your BAUER submersible motor pump into

operation! All instructions given for handling, operating and servicing the pump must be strictly observed. On

condition that these instructions are followed the pump will operate trouble-free to your full satisfaction for many

years!

Non-observance of our instructions may cause personal injury or damage to the equipment!

Please make this manual available to your operating personnel. You are kindly requested to state the pump

type and serial number of the submersible motor pump in all inquiries, correspondence, warranty problems or

parts orders. These details are specified on the nameplate.

We hope you will enjoy working with your BAUER submersible motor pump!

This operating manual is considered an integral part of the submersible motor pump. Suppliers of new and

used submersible motor pumps are advised to put down in writing that this manual was handed over together

with the pump.

Page 3

Operating manual BAUER Submersible Motor Pump / Version X-2010

3

PRODUCT DETAILS

Type designation:

Submersible motor pump

Type number:

Magnum S

Serial number

1

:

Dealer:

Name:

Address:

Tel./Fax:

Date of delivery:

Manufacturer:

Röhren- und Pumpenwerk BAUER Ges.m.b.H.

Kowaldstr. 2

A - 8570 Voitsberg

Tel.: +43 3142 200 - 0

Fax: +43 3142 200 –320 /-340

e-mail: sales@bauer-at.com

www.bauer-at.com

Owner or operator:

Name:

Address:

Tel. / Fax:

Note: Please make a note of the type and serial number of your submersible motor pump and its accessories!

Be sure to specify these details every time you contact your dealer.

Printing date / Version: 2002

1

In all warranty claims and correspondence relating to this machine it is essential to specify the complete serial

number group including all letters. This applies to the machine itself and to any components involved. We

cannot emphasise this point often enough.

Page 4

Operating manual BAUER Submersible Motor Pump / Version X-2010

4

GENERAL SAFETY INSTRUCTIONS

Symbols and terms

The CE symbol that has to be affixed on the machine by the manufacturer outwardly

demonstrates compliance of the machine with the directives for machines and other relevant

EU directives.

This “Warning” symbol refers to important safety instructions in this manual.

Whenever you see this symbol be aware of possible injury hazards. Read the note

following the symbol very carefully and inform the other operators accordingly.

Non-observance of this instruction may cause damage to or destroy the machine or

individual components.

It is important to observe this note or condition!

Qualified operators are persons who on account of their training, experience and instruction as well as their

knowledge of relevant standards, rules, precautions to be taken for accident prevention and operating

conditions, have been authorised by the person in charge of plant safety to perform the individual tasks

required, and in doing so are able to recognise and avoid potential hazards. Among other things, knowledge of

first-aid procedures is also required.

Product liability

As defined by the product liability law every farmer is also an entrepreneur!

According to §9 PHG (Product Liability Law), liability for damage to corporeal things caused by defective

products is expressly excluded. This exclusion of liability also applies to parts not manufactured by BAUER

itself but purchased from external suppliers.

Duty to furnish information

Even if the customer passes on the machine later-on he is obliged to hand the operating manual on to the new

receiver too. The receiver of the machine must be instructed with reference to the mentioned regulations.

Intended use

BAUER submersible motor pumps are built exclusively for normal use in agricultural applications (intended

use).

Any use beyond such normal use is considered non-conforming. Manufacturer is not liable for damage

resulting from such non-conforming use, the sole liability for damage from non-conforming use lies with the

user.

Intended use also includes compliance with the manufacturer’s operating, maintenance and service

instructions.

The BAUER submersible motor pump may be used and operated only by persons who are familiar with the

device and aware of the hazards involved.

All rules relevant for accident prevention as well as any other generally valid specifications and regulations

relating to safety, work medicine and traffic law must be strictly observed.

Unauthorised modification of the machine releases the manufacturer from liability for damage resulting

therefrom.

WARNING!

CAUTION!

NOTE

Page 5

Operating manual BAUER Submersible Motor Pump / Version X-2010

5

TABLE OF CONTENTS

1 GENERAL INSTRUCTIONS FOR SAFETY AND ACCIDENT PREVENTION ............................................. 6

2 GENERAL ........................................................................................................................................................ 8

3 DESCRIPTION ................................................................................................................................................. 9

4 PUTTING INTO OPERATION .......................................................................................................................... 9

4.1 Manual operation .................................................................................................................................... 10

4.1.1 Control box components .................................................................................................................. 10

4.1.2 Controls ............................................................................................................................................ 11

4.1.3 Connections ..................................................................................................................................... 11

4.1.4 Settings ............................................................................................................................................ 11

4.1.5 Operation ......................................................................................................................................... 11

4.1.6 Malfunction ....................................................................................................................................... 12

4.1.7 Safety instructions ............................................................................................................................ 12

4.2 Level control ............................................................................................................................................ 12

4.2.1 Control box components .................................................................................................................. 12

4.2.2 Controls ............................................................................................................................................ 12

4.2.3 Connections ..................................................................................................................................... 13

4.2.4 Settings ............................................................................................................................................ 13

4.2.5 Manual mode ................................................................................................................................... 13

4.2.6 Automatic mode ............................................................................................................................... 13

4.2.7 Malfunction ....................................................................................................................................... 13

4.2.8 Safety instructions ............................................................................................................................ 13

4.3 Intermittent operation .............................................................................................................................. 13

4.3.1 Control box components .................................................................................................................. 13

4.3.2 Controls ............................................................................................................................................ 14

4.3.3 Connections ..................................................................................................................................... 14

4.3.4 Settings ............................................................................................................................................ 14

4.3.5 Manual mode ................................................................................................................................... 14

4.3.6 Intermittent operation ....................................................................................................................... 14

4.3.7 Malfunction ....................................................................................................................................... 15

4.3.8 Safety instructions ............................................................................................................................ 15

5 SERVICE AND MAINTENANCE ................................................................................................................... 16

6 TECHNICAL DATA ........................................................................................................................................ 16

7 CONFORMITY CERTIFICATE ...................................................................................................................... 19

Page 6

Operating manual BAUER Submersible Motor Pump / Version X-2010

6

1 GENERAL INSTRUCTIONS FOR SAFETY AND ACCIDENT

PREVENTION

Check the machine for operational safety before every start-up.

1. In addition to the instructions contained in this manual, all specifications generally valid for safety and

accident prevention must be observed!

2. The warning and instruction signs affixed to the machine give very important instructions for safe operation.

Observing them serves your own personal safety!

3. Never put the machine into operation unless all guards and safety devices are completely mounted and in

their proper working position!

4. Acquaint yourself with all equipment components and controls as well as their respective functions before

starting to work. It is too late when the device is already running!

5. The operator’s clothes should fit tightly. Avoid wearing loose clothes!

6. When handling slurry always keep in mind that the gasses produced are highly toxic and extremely

explosive in combination with oxygen. Therefore, open fires, light tests, sparking and smoking are strictly

forbidden!

7. Utmost care is required with regard to gasses in slurry and dung channels at open valves to the preliminary

pit, before the main pit, or at cross channels. The same applies to mixing and withdrawal points when

mixers or pumps are running!

8. When handling slurry always ensure sufficient ventilation!

9. Keep the machine clean to avoid fire hazards!

Tractor-driven machines

1. Before starting inspect the area around the machine (Children) ! Make sure your view is unrestricted!

2. Riding on the machine during transport is forbidden!

3. Couple the machine according to instructions and fasten it only at the specified points!

4. Be especially careful when coupling the machine to the tractor or uncoupling it!

5. Always adjust the supports in the proper position when coupling or uncoupling the machine (stability)!

6. Always mount balancing weights properly at the points provided!

7. Observe restrictions pertaining to axle load, total weight, and transport dimensions!

8. Inspect and mount all items required for transport such as lighting, warning signals and possible safety

devices!

9. Mounted or trailed machines as well as balancing weights influence road behaviour, steering and braking

capacity. Therefore make sure that proper steering and braking are possible!

10. Consider the projection and/or centrifugal mass of the machine when driving in curves!

11. It is forbidden to stay in the working range of the machine while it is operating !

12. Keep out of the turning and swivelling range of the machine!

13. Only operate hinged hydraulic frames when nobody is in the swivel range!

14. Externally powered machines (e.g. hydraulic) bear a crushing and shearing hazard!

15. Nobody is allowed between the tractor and the implement unless the tractor is secured by the parking brake

and /or wedges under the wheels!

16. Hinged supports must always be folded up and secured before driving away!

17. Secure the machine and the tractor against rolling!

Tractor-mounted machines:

1. Before a machine is linked to or detached from the three-point linkage, the control device must be shifted to

a position in which unintentional lifting or lowering is impossible!

2. When using the three-point linkage the linkage parameters of both tractor and attached machine must

correspond, if not, they have to be matched accordingly!

3. The three-point linkage bears crushing and shearing hazards!

4. When operating the external control of the three-point linkage never step in-between tractor and the

machine!

5. When the machine is in the transport position always make sure that the tractor’s links are always properly

secured on the sides.

6. When driving on the road with the machine lifted the control lever must be locked against lowering!

Trailed machines

1. When a machine is coupled to the drawbar make sure that the coupling point provides sufficient flexibility!

Page 7

Operating manual BAUER Submersible Motor Pump / Version X-2010

7

Power take-off (applies only to PTO driven machines)

1. It is not allowed to use any other types of PTO drive shafts except those prescribed by the manufacturer!

2. Drive shaft guard tube and guard cone as well as the PTO guard – also on the machine side - must be

mounted and in good working order!

3. When using a PTO drive shaft always observe the specified overlap in transport and working position!

4. Never connect or disconnect the PTO drive shaft unless the PTO is stopped, the engine turned off, and the

ignition key pulled out!

5. Make sure the drive shaft is always connected and secured properly!

6. Attach safety chain to keep the drive shaft guard from rotating with the shaft!

7. Before you turn on the PTO make sure that the selected tractor PTO speed corresponds with the permissible

implement speed!

8. Before starting the PTO make sure that nobody is standing in the danger zone of the machine!

9. Never turn on the PTO when the engine is turned off or during a transport drive!

10. When working with the PTO nobody is allowed near the turning PTO or drive shaft!

11. Warning! The PTO shaft may continue turning due to its centrifugal mass after the PTO has been turned off!

Keep clear of the machine during this time and do not touch until the PTO shaft stands absolutely still!

12. For cleaning, greasing, or adjusting the PTO driven implement or drive shaft, PTO and engine must be

switched off and the ignition key pulled out!

13. Place the disconnected drive shaft on the provided support!

14. When drive shaft has been removed put the guard on the PTO shaft!

15. If a defect occurs repair it immediately before starting to work with the machine!

Hydraulic system

1. Hydraulic system is under high pressure!

2. When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are connected as

specified!

3. Before coupling the hydraulic hoses with the tractor’s hydraulic system make sure that the entire hydraulic

system is pressureless both on the tractor and implement side !

4. Inspect the hydraulic lines at regular intervals and replace them immediately in case of defects or ageing.

Replaced hoses must comply with the technical specifications of the implement manufacturer!

5. When looking for leaks use only suitable equipment because of the injury hazard involved!

6. Liquids emerging under high pressure (hydraulic oil) may penetrate the skin and cause serious injuries! An

injured person must see a doctor immediately! Danger of infection!

7. Before working on the hydraulic system the machine must be lowered, the system depressurised and the

engine turned off!

Electric-driven implements

1. All work beyond normal maintenance of the implement should be performed only by a professional

electrician!

2. Defective or broken plugs and sockets must be replaced by a professional electrician!

3. Never pull a plug out of the socket at the flexible electric cord!

4. Extension cables for power supply should be used onl y temporarily! Never use such lines permanently as a

substitute for the required fixed installations!

5. Flexible lines laid across traffic areas on the farm must have at least 5 m ground clearance!

6. Always turn off the power supply before you do any work on the machine!

7. Check all electric lines for visible defects before you put the machine into operation! Replace defective

cables and do not start the machine before that!

8. Never use electric-driven implements in damp situations or locations exposed to fire hazard unless they are

adequately protected against moisture and dust!

9. Covering electric motors may cause heat concentration with high temperatures which could destroy the

operating equipment and cause fires!

Page 8

Operating manual BAUER Submersible Motor Pump / Version X-2010

8

Hand-operated devices (valves)

1. Because of the slurry gasses produced in the lines, no slurry is allowed to remain in closed pipelines –

bursting hazard!

2. Lay the pipelines with sufficient inclination and make sure that the selected closing order of valves allows all

lines to be drained completely!

3. Protect the valves against unauthorised handling!

4. If a valve gets jammed do not apply force! Use only the operating levers supplied with the implement!

5. Observe the permissible maximum operating pressure of valves and pipelines when pumps are operated!

6. Service only when the tanks are empty!

Maintenance

1. Never perform any maintenance, service or cleaning work or fault elimination steps unless the drive is

turned off and the engine is standing still!

2. Check proper fit of all nuts and bolts regularly and tighten them, if necessary.

3. If maintenance work is required on the lifted machine always secure it by means of appropriate supports!

4. When exchanging tools with cutting edges always use proper tools and wear safe protective gloves.

5. Dispose of oil, grease and filters according to local laws and regulations!

6. Always turn off power before working on the electric system!

7. Before electric welding on the tractor and mounted machines the generator and battery cables must be

disconnected!

8. Spare parts must meet manufacturer’s minimum technical specifications! This is the case for instance with

original spare parts for instance!

2 GENERAL

BAUER products are designed and manufactured carefully and subject to a system of continuous quality

control. MAGNUM slurry pumps fully meet the requirements of the agricultural practice. They are best suited

for delivering all kinds of slurries from thin liquid manure to viscous mixtures containing solids such as straw,

fibres or clots. A special chopper guarantees trouble-free performance without blockages. Short set-up times,

easy handling and maximum performance reliability are further advantages of this pump series. Pump drive is

electric by means of a three-phase submersible motor.

In order to be able to work efficiently with the maintenance-friendly submersible motor pump it is helpful to

operate it in connection with a lift pole or transport trolley.

Depending on the respective type of application, you can use either the lift pole alone, or the lift pole with

coupling foot and rising main.

Although the pump is simple in design you should study this manual carefully and strictly observe all operating

and service instructions contained. On this condition your slurry pump will operate to your full satisfaction for

many years!

Make this manual available to all operators handling the equipment. Serial number and pump type are stamped

in on the nameplate. Please specify these data in your inquiries, correspondence, warranty matters and parts

orders. We warrant for this pump according to our General Terms of Sale.

Page 9

Operating manual BAUER Submersible Motor Pump / Version X-2010

9

3 DESCRIPTION

The submersible motor pump MAGNUM S consists of a three-phase submersible motor with connecting cable,

and oil chamber, and the pump housing with cutter and impeller. The electric motor flanged onto the pump

housing has a motor output of 4 / 5.5 / 7.5 / 11 or 15 kW, depending on the respective model.

To motor is equipped with PTC thermistor detectors to protect if from overheating. Therefore the motor

protection will only be effective if the motor connecting cable is linked up not only with a star-delta starter but

also a suitable thermistor trip device.

The control box that is available as motor accessory, includes not only the starting contactor but also the

thermistor trip device. The red alarm lamp lights up when the thermistor tripping device has been actuated

NOTE

!

The motor cable should be linked up to the control box only by a qualified

technician. Check-up must be performed

according to the wiring diagram!

The wiring diagram is placed inside the control box. The control box should

preferably be mounted and tightly screwed under a roof where it is protected from

the weather.

When connecting the system to power supply ensure the connecting cable is amply

dimensioned and the motor’s direction of rotation is correct.

The motor is sealed by two mechanical seals mounted in series. The mechanical seal on the motor side is

lubricated only by the oil contained in the oil chamber, while the mechanical seal on the impeller side is

lubricated by the pumped medium in addition. The bearing of the SUBMERSIBLE MOTOR PUMP is lifelubricated.

Apart from pumping liquids into other tanks, the submersible motor pump M S can also be used for stirring the

pit content.

For this type of operation the equipment and fittings such as delivery line, delivery socket and elbow are

replaced by a nozzle with optional 50 or 80 mm diameter mounted on the pump housing.

4 PUTTING INTO OPERATION

When the pump is put into operation for the first time ensure that the supply voltage corresponds with the

voltage specified on the motor nameplate.

Before you connect the motor check the phase sequence for the motor’s direction of rotation.

For connecting the motor it is imperative that all regulations applying to electrical equipment as well as all

instructions of the drive manufacturer are strictly observed (e.g. motor protection switch, main disconnect

possibly lockable).

Check oil level in the gearbox and in the oil reservoir before every start! (Confer to

Technical Data for type and quantity of oil).

WARNING!

WARNING!

Page 10

Operating manual BAUER Submersible Motor Pump / Version X-2010

10

Place the pump in vertical position.

Open level inspection screw.

Oil level must be up to the opening.

In case of heavy oil loss or if the oil is soiled with slurry, the mechanical seal must be inspected. Check if

the pump is soiled or if foreign objects are in the pump. If necessary, rinse and clean it.

Break up the floating crust and lower the running pump.

(Lowering the pump idle can cause blockages – forming

of clots).

4.1 Manual operation

4.1.1 Control box components

Three contactors with timer for start-delta start-up.

Motor protection devices:

Current monitoring relay

Thermistor tripping relay for temperature monitoring

Page 11

Operating manual BAUER Submersible Motor Pump / Version X-2010

11

4.1.2 Controls

Green pushbutton for motor start

Red

pushbutton for motor shut-off

4.1.3 Connections

Power supply by means of 5-pole CEE plug-in connection.

4.1.4 Settings

Timer for start-delta changeover : approx. 3 seconds

Motor protection relay: see drawing no. 018 2565.4 automatic reset

4.1.5 Operation

Push the green pushbutton: the motor starts up and

changes automatically from “star” to “delta” after about 3

seconds . The green pushbutton is illuminated.

Page 12

Operating manual BAUER Submersible Motor Pump / Version X-2010

12

Push the red pushbutton: the motor stops.

4.1.6 Malfunction

The red pushbutton is alight:

The motor protection system has turned off the motor.

Eliminate the cause of the fault.

The red pushbutton goes out.

The motor cannot be started

:

Check power supply.

Check the control power fuse “F3”. „

4.1.7 Safety instructions

Always disconnect system from power before working on the starter.

4.2 Level control

4.2.1 Control box components

Three contactors with timer for star-delta start-up.

Motor protection devices :

Current monitoring relay

Thermistor tripping relay for temperature monitoring

4.2.2 Controls

Mode selector with following switching positions:

0: The motor is shut off.

1: Manual mode, the motor is turned on and off by means of the two pushbuttons.

2: Automatic mode, the motor is controlled by means of the float switch.

Green

pushbutton for starting the motor in manual and automatic mode.

Red

pushbutton for stopping the motor in manual mode.

Page 13

Operating manual BAUER Submersible Motor Pump / Version X-2010

13

4.2.3 Connections

Power supply by means of 5-pole CEE plug-in connection.

Pump connection by means of clamp rail.

Screw terminals for connection of float switches.

Screw terminals for connection of an alarm system (Optional).

4.2.4 Settings

Timer for start-delta changeover: approx. 3 seconds

Motor protection relay: see drawing no. 018 2565.4 automatic reset

4.2.5 Manual mode

Push the green illuminated button: The motor starts up and changes from “star” to “delta” automatically

after about 3 seconds. The green illuminated button is alight.

Push the red

illuminated button: The motor stops.

4.2.6 Automatic mode

Turn the selector switch to the “AUTOMATIC” position.

The upper float switches on the motor through the star-delta combination as soon as the pre-set liquid level

is reached. The green pushbutton is alight.

The lower float switches off the motor.

In the automatic mode the motor can also be started by pushing the green illuminated button.

Switching the selector switch to „0“ finishes the automatic mode and turns off the motor.

4.2.7 Malfunction

The red pushbutton is alight: The motor protection has switched off the motor.

Eliminate the cause of the fault.

Turn selector to „0“, the red button goes out and the alarm horn stops.

The motor cannot be started: Check power supply.

Check control power fuse “F3“.

4.2.8 Safety instructions

Always disconnect system from power before working on the starter.

In the automatic mode the motor starts up without a warning!

Mount a safety sign!

4.3 Intermittent operation

4.3.1 Control box components

Three contactors with timer for star-delta start-up.

Motor protection devices :

Overcurrent monitoring relay

Thermistor tripping relay for temperature monitoring

Impulse-rest relay for intermittent operation

WARNING!

Page 14

Operating manual BAUER Submersible Motor Pump / Version X-2010

14

4.3.2 Controls

Mode selector with following positions:

0: Motor is switched off

1: Manual mode, the motor is switched on and off by means of the two pushbuttons.

2: Intermittent operation, the motor is controlled by timer.

Green

pushbutton for starting the motor in manual mode.

Red

pushbutton for stopping the motor in manual mode.

4.3.3 Connections

Power supply by means of 5-pole CEE plug-in connection.

Pump connection by clamp rail.

Screw terminals for connection of alarm system (optional).

4.3.4 Settings

Timer for star-delta changeover: approx. 3 seconds

Motor protection relay: see drawing no. 018 2565.4 automatic reset

Clamp rail: see drawing no. 345 9601

4.3.5 Manual mode

Push the green illuminated button. The motor starts up and switches from “star” to “delta” automatically

after about 3 seconds. The green pushbutton is alight.

Push the red pushbutton. The motor stops.

4.3.6 Intermittent operation

The timer switches on the motor through the star-delta combination. After expiry of the selected operating time

the motor is switched off again automatically for the selected rest time. This sequence is repeated cyclically.

BAUER control with timer for interval operation

Logo programming

1.Time and date setting

In order to get access to the mode parameter, press the key ESC -> LOGO changes to the mode

parameter and displays the parameter menue.

Choose „SET CLOCK“ key AB, AB and OK

1. Choose the day: keys up and down

2. Move the cursor to the next position: keys RIGHT, LEFT

3. Change the value: keys UP or DOWN

4. Set the clock to the correct time, repeat steps 2 and 3

5. Set the date, repeat steps 2 and 3

6. Finish the task: key OK

2.WEEKLY TIMER and INTERVAL parameter setting

Parameter blocks: B09 Interval parameter

B11 Weekly timer parameter

B17 Operating hours meter value

Page 15

Operating manual BAUER Submersible Motor Pump / Version X-2010

15

Move: key or

Finished: key OK

Change value: key or

1.1.1 Current time of timer

The status of the timer is displayed

Timer OFF

(Status 0 at the exit)

timer ON

(Status 1 at the exit)

The status of the timer depends on all three cams

No1, No2 and No3.

In order to get access to the mode parameter, press the key ESC -> LOGO changes to the mode

parameter and displays the parameter menue.

Choose „SET PARAM“ key AB and OK.

1. In order to change a parameter, choose one parameter

2. Put the cursor to the position you want to change: keys RIGHT or LEFT.

3. Change the value at the position: keys UP or DOWN

4. Confirm value with the key OK.

Weekly timer:

Time of the interval TH = exposure time TL = time of break (if the timer is active)

Meter for hours of operation: Display of the expired hours of operation

4.3.7 Malfunction

The red pushbutton is alight: The motor protection has switched off the motor.

Eliminate the cause of the fault.

Turn selector to “0“, the red pushbutton goes out and the alarm horn stops.

Motor cannot be started: Check power supply.

Check control power fuse “F3“.

4.3.8 Safety instructions

Always disconnect system from power before working on the starter.

In the automatic mode the motor starts up without a warning!

Mount a safety sign!

WARNING!

Parameter

The set value of the parameter

Effective value of time in LOGO!

Page 16

Operating manual BAUER Submersible Motor Pump / Version X-2010

16

5 SERVICE AND MAINTENANCE

It cannot be emphasised often enough how much proper service and maintenance influence performance

reliability and service life of a machine.

The pump and all its accessories should be cleaned immediately after use. As long

as the slurry has not dried up it can easily be rinsed off with water.

The best way to clean the interior of pipes and fittings is to pump water through the system for a short while.

The pump should be stored in a weather-protected place under a roof, if possible. In areas where frost is likely

during the winter season the pump housing must be drained completely by turning out the drain plugs located at

the lowest points of the housing.

Observe local laws and regulations when disposing of pumps and pump components after repairs and service

or when a pump is withdrawn from service. This applies in particular to the treatment of residual slurry in the

pump body.

6 TECHNICAL DATA

Output kW 4 5,5 7,5 11 15

Discharge capacity

m

3

/h

20 - 140 20 - 160 20 - 190 20 - 220 20 - 240

Manometric head m 9,5 - 3 12,5 - 3,5 18 - 5 20 - 5 21 - 5

Impeller speed rpm 1440 1445 1450 1400 1450

Power required kW 3,3 - 4,2 3,7 - 5,2 4,6 - 7,1 7,4 - 11,3 8 - 11,4

Oil capacity 3,5 l motor oil- SAE 20 W-20 (SAE HD 30)

Engine Oil; Viscosity Grade SAE20W20 or SAE20; SAE HD30; Quality Level API CF/SF

WARNING!

Page 17

Operating manual BAUER Submersible Motor Pump / Version X-2010

17

FAULT DESCRIPTION

Fault Cause Remedy

The pump does not deliver Impeller blocked Remove foreign object

Cutter bell blocked Remove foreign object

Excessive difference in elevation

between pump and distributing

device.

Reduce difference in elevation.

Wrong direction of rotation. Reverse direction of rotation.

Excessive solids content. Add water.

The discharge capacity drops. Excessive counter pressure. Remove foreign object.

Excessive solids content. Add water.

Red pushbutton lights up. Motor protection has switched off

the motor.

Eliminate the fault.

In manual mode the red pushbutton

goes out.

In level and intermittent operation

turn the mode selector to “0”, then

the red pushbutton goes out and

the alarm horn stops

Page 18

Operating manual BAUER Submersible Motor Pump / Version X-2010

18

Submersible Motor Pump

22.06.01 Gw

Wiring diagram: 345 9900.4

Röhren- u. Pumpenwerk BAUER GmbH 8570 Voitsberg

PTC thermistor

Page 19

Operating manual BAUER Submersible Motor Pump / Version X-2010

19

7 CONFORMITY CERTIFICATE

EC Declaration of Conformity

according to EC Directive 2006/42/EC

The manufacturer

Röhren- und Pumpenwerk BAUER Gesellschaft m.b.H.

Kowaldstraße 2, 8570 Voitsberg, Austria

phone +43 3142 200-0; fax: +43 3142 200-320/-340

herewith confirms that the machine mentioned below

Designation of machine Submersible Motor Pump Magnum S

Machine type / basic units S4, S5,5, S7,5, S11 and S15

Consists of Submersible Motor Pump with lifting and

lowering device

corresponds analogously to the requirements of the Machinery Directive 2006/42/EC.

In case of a modification of the machine not accorded with FAN GmbH, this declaration will cease to be

valid.

The following standards as amended have been applied analogously:

DIN EN ISO 12100-1 Safety of machines – Basic concepts, general principles for design,

Part 1: Basic terminology, metodology

DIN EN ISO 12100-2 Safety of machines – Basic concepts, general principles for design,

Part 2: Technical principles and specfications

DIN EN 60204-1 Safety of machines - Electrical equipment of machines,

Part 1: General requirements

EN ISO 14121-1 Safety of machines – Risk assessment

Norms related to products

EN ISO 13857 Safety of machines, safety clearance to secure no touching hazard area with

upper extremities.

DIN EN 349 Safety of machine, minimum clearance to avoid crushing body parts

DIN EN 809 Pumps and pump units for liquids - Common safety requirements

The documents belonging to the machine according to annex VII, part B have been attached.

Person in charge of documentation: Thomas Theissl, Kowaldstraße 2, 8570 Voitsberg, Austria,

Technical Designer in Charge Commercial Manager

Loading...

Loading...