Page 1

GAS INJECTION TECHNOLOGY – GIT

Innovative and complete solutions

ECONOMICAL

MODULAR

RELIABLE

www.bauer-kompressoren.de

BAUER KOMPRESSOREN

offer Gas Injection Technology

as a solution to the problems

of plastic part production.

The end user will benefit from

BAUER’s years of manufacturing

experience in the field of GIT and

compressor technology with tailormade systems from one source.

Bauer offer starter packs to complex

large-scale systems.

For a perfect system design, the

BAUER team is available and willing

to provide on site advice.

Page 2

GIT-SYSTEMSBAUER KOMPRESSOREN

GIT technology from BAUER - solutions from one source

BRIEF OVERVIEW OF GIT TECHNOLOGY

A procedure similar to GIT was described for the

first time in 1972. This technology has a proven

reliability and market growth from the 1980’s.

We denote by GIT, the method of blowing gas,

especially nitrogen in the plastic, so that a hollow

tubular channel is created.

Previously, the plastic had been melted and injected

into a mould, which for thick pieces of plate, it was not

possible to produce a flattened bubble.

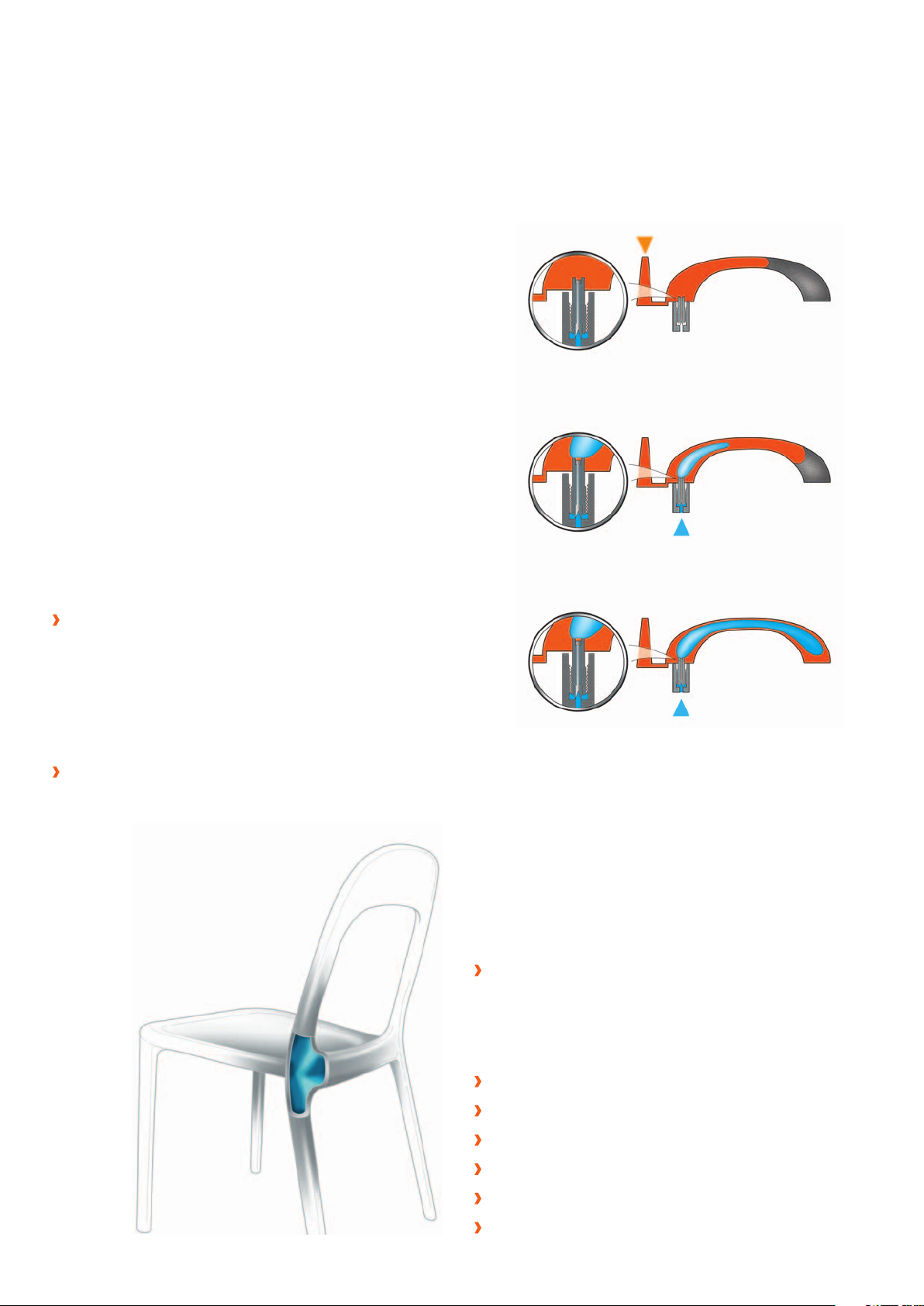

THE DIFFERENT TECHNIQUES

There are at least 10 variants of GIT, based on

the type of piece produced and its needs. The

two most commonly used techniques are briefly

explained as follows:

The partial original method, which is to fill 50-90%

of the cavity with plastic. By moving the mass of hot

plastic, the gas can finish filling 100% while creating

a hollow tubular channel. The holding phase under

pressure during the cooling phase is carried by the

gas, whose pressure drop just before opening

the mould.

Plastic

1

2

Gas

3

Gas

The over flow cavity, which requires the addition of

an annex cavity in the tool. After filling the part

cavity at 100% with polymer, the gas is injected

under pressure and the overflow cavity is

open to collect the superfluous plastic.

The gas ensures the holding phase

pressure during cooling and is

purged immediately

before opening

the mould.

BENEFITS OF GIT

The use of gas assisted injection technology

allows production of technical parts with

the appearance of superior quality. The

manufacturing process is also more efficient,

improving productivity and thus significantly

increasing profitability.

A better quality of injected part:

- High strength and rigidity

- Dimensional stability, no warpage

- Elimination of sink marks

- No assembly, single parts

Simplification of tools

Freedom in design

Lower clamping force (in partial)

Reduced cycle time

Material saving

Realization of hollow (pipe)

Page 3

GIT-SYSTEMS

BAUER EXPERIENCE

Our outstanding expertise in purifying gases

coupled with software-based control technology developed by our BAUER specialists

guarantee you outstanding product quality

which will improve profitability.

HIGH PRESSURE COMPRESSOR

AND BOOSTER UNITS

Ready for use; compact and autonomous.

A compression of high quality nitrogen thanks

to our P-filter system.

Booster units with low power consumption by

using the inlet pressure of a nitrogen generator

or evaporator.

A security operation through an integrated

controller (B-CONTROL).

FCC CONTROL UNIT

A mobile and compact panel.

An adaptive control and therefore very precise

(reactivity adjustable).

Easy and intuitive programming.

A full connectivity to transfer files (USB and Ethernet).

Continuous process monitoring with quality data

storage.

EXCELLENT SERVICE GUARANTEED

For BAUER, „quality“ does not end with the production and delivery of the system. Independent

of the location of the installation, the customer

benefits from the excellent and comprehensive

after sales service support:

All major spare parts, including wearing parts, for all

models are permanently in stock, and available for

immediate dispatch. Parts are guaranteed to be

available for up to 25 years after delivery.

An integrated distribution network comprising of

over 50 overseas agencies, plus 360 support

distributors are continually available to support

our customers.

Maintenance kits for all systems are available

worldwide.

BAUER daughter companies worldwide

Page 4

GIT-SYSTEMSBAUER KOMPRESSOREN

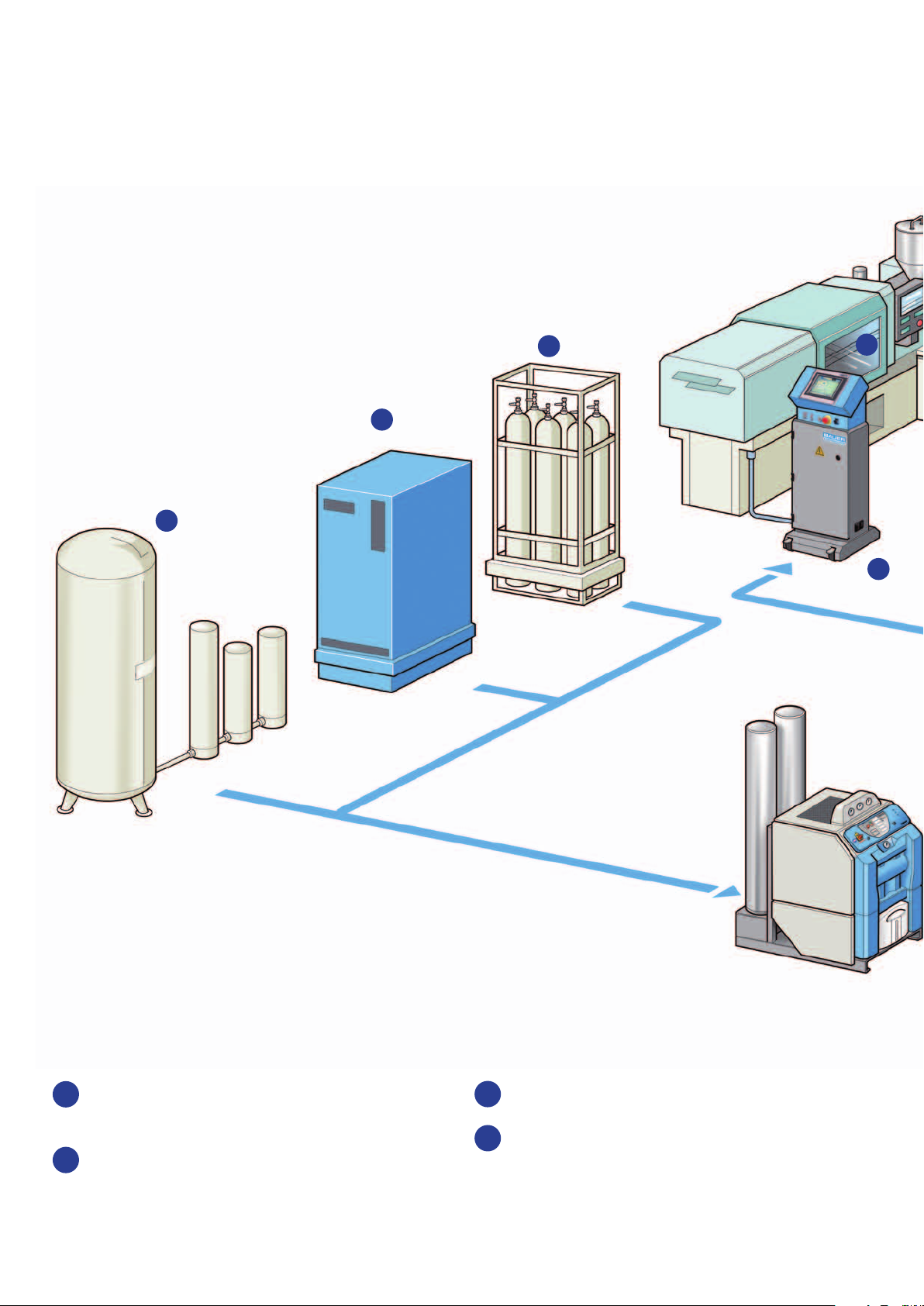

Structure of the system

System requirements: The following equipment is required to employ gas injection technology

in your process.

1

1

1

1

1

1

1

1

5

5

5

5

1

1

1

1

4

4

4

4

1

Source of nitrogen: Liquid tank, nitrogen

bottles or nitrogen generator.

2

A high pressure compressor with a suitably

sized gas receiver facility for the compression

and safe storage of nitrogen at high pressures.

3

High pressure lines to transport the nitrogen.

4

Distribution panel that generates a pressure- /

time profile to dispense the nitrogen.

Page 5

GIT-SYSTEMS

5

5

5

5

5

5

5

5

6

6

6

6

7

7

7

4

4

4

4

4

4

4

4

8

8

8

8

3

3

3

3

2

2

2

2

7

5

Gas injectors to fill nitrogen into the plastic

parts for hollowing.

Bypass valve available to prevent the

6

ingress of dirt into the proportional

regulating valve.

7

Flushing Module FM1 assures quick cooling,

which it turn reduces the cycle times.

8

Mass flow meter MF II for exact measurement of the nitrogen consumption.

Page 6

GIT-SYSTEMSBAUER KOMPRESSOREN

Product range for nitrogen compression

Wherever high pressure nitrogen needs to be generated in a confined space providing economically efficient continuous and autonomously nitrogen supply, BAUER high pressure compressors

and booster will perform the task quietly and reliably to meet the demands of one or multiple

injection moulding machines.

THE MINI-VERTICUS III-RANGE

Soundproof and compact

The perfect unit for confined areas in industrial

applications – available as a compressor with

atmospheric or booster inlet conditions.

Multi stage piston compressor units, lubricated,

soundproof <70 dB (A), with a final separator

and filtration system P61 type for securing a

compressed gas with high purity.

Complete system mounted on skid with up to

two HP cylinders, compact and limited to small

compressor block range.

Directly connectable to the source of nitrogen.

Designed for long life and low operating costs.

Model

350 bar / 5000 psig, High pressure compressor for nitrogen

MV-GI 100-3-3 85 5 3 900 3 2,2 255

MV-GI 100-4-3 125 7,5 3 1270 4 3,1 255

MV-GI 120-4-3 170 10 3 1200 4 3,7 260

MV-GI 120-5,5-3 215 13 3 1470 5,5 4,7 260

1)

F.A.D.

l/min m

Number

of stages

3

/h r.p.m kW kW kg

Speed Motor

power

Power

consumption

Net weight

approx.

Model

350 bar / 5000 psig, High pressure booster for nitrogen

MV-GIB 12.2-5,5-3 200-475

1) Measured acc. to ISO 1217.

1)

F.A.D.

l/min m

2)

12-28,5 2 5-11 90-350 1230 5,5 3,3-5,1 275

Number

of stages

3

/h (bar g) bar r.p.m kW kW kg

Intake

pressure

Operating

pressure

2) Maximum capacity according to the

combination of intake and final pressure.

Speed Motor

power

Power

consumption

Net weight

approx.

Page 7

GIT-SYSTEMS

THE VERTICUS 5 RANGE

The high pressure compression under control.

Multi stage piston compressor/booster units,

lubricated, with a final separator and filtration

type P61 / P81 for securing a compressed gas

with high purity.

Complete system mounted on skid with up to

two HP cylinders.

Available as soundproof version 72-76 dB(A).

Directly connectable to the source of nitrogen.

The B-CONTROL controller allows to monitor

the operation of the compressor and to

indicate the alarms such as temperatures,

operating pressures, oil pressure and

maintenance, etc.

500 bar discharge pressure version optional.

Model

GI - Range, 90 - 350 bar / 1300 - 5000 psig

GI 100-3-5 85 5,1 3 900 3 2,2 335

GI 100-4-5 125 7,5 3 1270 4 3,3 340

GI 120-5,5-5 215 13 3 1470 5,5 4,7 355

GI 15.1-7,5-5 340 20,4 4 1050 7,5 6,9 440

GI 15.1-11-5 420 25,2 4 1320 11 9,6 450

GI 150-11-5 500 30 4 1230 11 10,2 460

GI 180-15-5 610 36,6 4 1320 15 12 470

GI - Range, 350 - 500 bar / 5000 - 7200 psig

GI 15.11-7,5-5 310 18 ,6 4 960 7,5 7 470

GI 15.11-11-5 420 25,2 4 1320 11 10,4 470

GI 18.1-15-5 550 33 5 1320 15 12,4 470

Model

Intake

pressure

bar(g) l/min m

BOOSTER GIB, 90-350 bar / 1300-5000 psig

GIB 12.2-5,5-5 5 - 11 200 - 475

GIB 15.3-11-5 7 - 10 510 - 750

GI B 15.4-15-5 2 - 4 450 - 800

1)

F.A.D

l/min m

Number

of stages

3

/h r.p.m. kW kW kg

1)

F.A.D.

2)

12 - 28,5 2 1230 3,3 - 5,3

2)

30,6 - 45 2 114 0 6,6 - 8,2

2)

27 - 48 3 1320 7,6 - 12,2

Speed Motor Power

consumption

Number

of stages

3

/h r.p.m. kW

Speed Power

consumption

Net weight

approx.

1) Measured acc. to ISO 1217.

2) Maximum capacity according to the

combination of intake and final pressure.

Page 8

GIT-SYSTEMSBAUER KOMPRESSOREN

The FCC 5 - the latest first-class controller

THE DISTRIBUTION PANEL

BAUER distribution panels have been in operation worldwide for the past 10 years. These mature

and well proven control systems guarantee the user maximum reliability, with minimum downtime.

INTERFACE AND CONTROLLER

Seven levels of time pressure with ramps

transition in time.

Password protection (3 profiles).

Cleaning cycle with clogged injector

detection (patented).

Graphic displays for pressure versus time.

Screen quality on the relevant current

values and last 100 cycles.

Alarms (message, sound 97 dB, cycle stopped)

with history.

Programs and data quality storage on

internal memory Compact Flash, USB key

or via Ethernet.

Screen service with maintenance history

and display technician diagnostic.

Support and diagnosis via the Internet in

real time.

Usage with 2 moulding machines

possible (option).

CONNECTIONS

Start signal: screw position or the start of

plastic injection.

Compatible with all injection moulding

machines including EUROMAP 62 standard.

Page 9

GIT-SYSTEMS

All informations at a glance!

The high resolution touch screen shows all relevant parameters. It provides clear user guidance

and allows a comprehensive range of settings for controlling and monitoring the process.

Time/pressure levels can be easily programmed.

Various alarm settings can be selected by the user.

REGULATING MODULE

Built as a modular construction, the valve

module can be mounted separately from the

distribution panel, or near to the mould.

The set-actual graph informs about the process quality.

Alarms messages on the last 1000 events

Electrical proportional regulating valve.

High reproducibility of parts guaranteed.

High precision from 5 to 400 bar.

1 to 4 proportional valves, exchangeable

and also available for retrofit.

1-2 proportional valves per valve module.

Integrated filtration of 25 µm.

Low maintenance costs with fast service support.

Page 10

The new Flushing Module FM I

The flushing module FM I accelerates the

cooling of the mould by up to 50%, thus

decreasing the cycle time of GIT parts.

Two injectors are needed to flush, one

at each end.

Initially, an injector introduces nitrogen, as

found in the classical GIT process. Then pressure

is switched on the second injector to break into

the first bubble and to achieve a leakage rate

through the first injector.

This movement generates heat exchange by

forced convection inside the part in the hottest

zone. This is considerably more effective than

conduction through the mould with a mass of

highly insulating plastic.

GIT-SYSTEMSBAUER KOMPRESSOREN

The FM I can be easily integrated into an existing

process that requires only the installation

of a second gas injector. The flushing module

is driven directly by the panel of gas

assisted injection.

Additional cooling of the flushing gas is not

necessary!

Data line

Flushing module FM1

cooling

down

feed line

N

2

injection

N

2

N

flushing

2

Page 11

GIT-SYSTEMS

Keep it simple –

our economically priced starter pack

LCC I – LIGHT CLASS CONTROLLER

Equipped with 1 or 2 valves, this small distribution panel is programmed via an external laptop.

The LCC I can be directly mounted on the injection moulding machine, which minimizes the

nitrogen consumption.

INTERFACE AND PLC

Programmed via an external laptop which can

be removed during production.

Five time and pressure stages with ramp

transitions in time.

Quality and alarms screens are available.

Remote control for Start/Stop, Injector test,

Reset IP address functions. Green and

red lights inform on panel status (ready,

cycle in progress, alarms, etc.).

Programs and quality data storage on

internal memory Compact Flash.

CONNECTION

Start signal: start of plastic injection.

Compatible with all injection moulding machines

including EUROMAP 62 standard.

Ethernet port on remote control to

connect a laptop.

LCC I, with remote control and optional laptop

Page 12

GIT-SYSTEMS

PRODUCT SERVICE

DIN EN ISO 9001

The GIT technology accessory range

GAS INJECTORS

The stainless steel injectors can be

used for all gas injection processes.

No penetration of melt.

Diameter: 2 – 12 mm.

Quick and easy cleaning.

Optional with seal.

Specific size on demand.

BAUER gas injectors

BYPASS VALVE

The bypass valve has to be placed between

the mould and the distribution panel.

Protects the valve module from from plastic

degassing pollution.

No external energy needed.

Increases the system availability.

MF II FLOW METER

Patented system optional on FCC 5

Allow to follow nitrogen consumption and to

control the process repeatability.

This flow meter and its interface are completely

integrated to the panel FCC 5 (alarms, graphic,

quality and statistic screens).

Bypass valve

For 1- 4 channels.

BAUER KOMPRESSOREN GmbH

P.O. Box 710260 | 81452 München

Phone +49 (0) 89 / 7 80 49 - 0

Fax +49 (0) 89 / 7 80 49 - 167

industry@bauer-kompressoren.de

www.bauer-kompressoren.de

MF II flow meter

GIT-E

10.10 PR 0094

Subject to technical modifications

Loading...

Loading...