Page 1

Operator’s Manual

High Pressure Breathing Air Compre ssors

Page 2

Page 3

Operator’s Manual

INTRODUCTION

This manual contains general information and instructions to operate

and maintain high pressure breathing air compressor units.

Before taking the compressor intooperation it is essentialto study the

instruction manual of that compressor.

All instructions should be observed and carried out in the order laid

down to prevent damage and premature wear to the equipment and

the units served by it.

While every effort is made to ensure the accuracy of the particulars

contained in this manual, the manufacturing company will not, under

any circumstances, be held liable for any inaccuracies or the consequences thereof.

WARNING

The breathing airproduced with thishigh pressure compressor issubject to strict quality standards.Ignoringtheoperatingand maintenance

instructions can lead to severe injury or in serious cases even death.

We reserve the right to make changes to the technology of our compressors as well as to this accompanying documentation in accordance to technical progress.

Edition January 2005

© 2005 BAUER Kompressoren GmbH, Munich

All rights reserved.

i

Page 4

Operator’s Manual

TABLE OF CONTENTS

1. GENERAL 1...................................................................................

1.1. PURPOSE AND SHORT DESCRIPTION 1.........................................................

1.2. THEORETICAL PRINCIPLES 2...................................................................

1.3. DESIGN AND MODE OF OPERATION 4...........................................................

2. SAFETY REGULATIONS 8......................................................................

2.1. GENERAL 8...................................................................................

2.2. NOTES AND WARNING SIGNS 9.................................................................

2.3. IDENTIFYING THE SAFETY NOTICES 9...........................................................

2.4. FUNDAMENTAL SAFETY NOTICES 9.............................................................

2.5. SAFETY REGULATIONS (EC; partly Germany, only) 12................................................

3. INSTALLATION, OPERATION 13..................................................................

3.1. INSTALLATION OF THE COMPRESSOR UNIT 13....................................................

3.2. COMPRESSOR ROOM CONDITIONS: 14...........................................................

3.3. NA TURAL VENTILATION 16.......................................................................

3.4. ARTIFICIAL VENTILATION 19.....................................................................

3.5. ELECTRICAL INSTALLATION 22...................................................................

3.6. TAKING INTO OPERATION 23.....................................................................

3.7. FILLING PROCEDURE 25........................................................................

3.8. SHUT--DOWN PROCEDURE 28...................................................................

4. MAINTENANCE 29..............................................................................

4.1. MAINTENANCE RECORD 29......................................................................

4.2. MAINTENANCE INTERVALS 29...................................................................

5. MAINTENANCE SCHEDULE 30...................................................................

5.1. MAINTENANCE INTERVALS 30...................................................................

5.2. MAINTENANCE RECORD 31......................................................................

6. STORAGE, PRESERVATION 32...................................................................

6.1. GENERAL 32...................................................................................

6.2. PREPARATION 32...............................................................................

6.3. PRESERVING THE COMPRESSOR 32.............................................................

6.4. PRESERVING THE MOTOR/ENGINE 32............................................................

6.5. PREVENTIVE MAINTENANCE DURING STORAGE 32...............................................

6.6. REACTIVATING THE COMPRESSOR UNIT 33......................................................

7. REPAIR INSTRUCTIONS 34......................................................................

7.1. GENERAL 34...................................................................................

8. TROUBLE--SHOOTING 35........................................................................

9. FILTER SYSTEM P21 37..........................................................................

9.

1. DESCRIPTION 37...............................................................................

9.2. CARTRIDGE SAFETY BORE 38...................................................................

9.3. LIFETIME 38....................................................................................

9.4. GENERAL INSTRUCTIONS FOR FILTER MAINTENANCE 39..........................................

9.5. CONDENSATE DRAINAGE 39.....................................................................

ii

Page 5

Operator’s Manual

9.6. FILTER CARTRIDGES 39.........................................................................

9.7. FILTER SERVICE LIFETIME 39....................................................................

9.8. CARTRIDGE CHANGE 40........................................................................

iii

Page 6

Operator’s Manual

TABLE OF CONTENTS

9.9. FILLING VALVE MAINTENANCE 40................................................................

9.10. REPLACEMENT INTERVALS 41...................................................................

9.11. CONDENSATE DRAINAGE 41.....................................................................

9.12. CARTRIDGE CHANGE 41........................................................................

10. FILTER SYSTEM P41 AND P61 42.................................................................

10.1. APPLICATION AND SUMMARY DESCRIPTION 42...................................................

10.2. FUNCTION 43...................................................................................

10.3. FILTER MAINTENANCE 48.......................................................................

10.4. TECHNICAL DATA 51............................................................................

11. LUBRICATING OIL LIST 52.......................................................................

11.1. GENERAL 52...................................................................................

11.2. TYPE OF OIL 53.................................................................................

11.3. O IL CHANGE 53.................................................................................

12. TRANSPORTING COMPRESSED AIR CYLINDERS 54...............................................

13. FURTHER FILLING POSSIBILITIES 55.............................................................

13.1. OVERFLOW 55..................................................................................

13.2. FILLING FROM STORAGE CYLINDERS 55.........................................................

iv

Page 7

Operator’s Manual

TABLE OF FIGURES

Fig. 1 Pressure-- and temperature increase 2.............................................................

Fig. 2 P--V Diagram 3.................................................................................

Fig. 3 Saving of work 3................................................................................

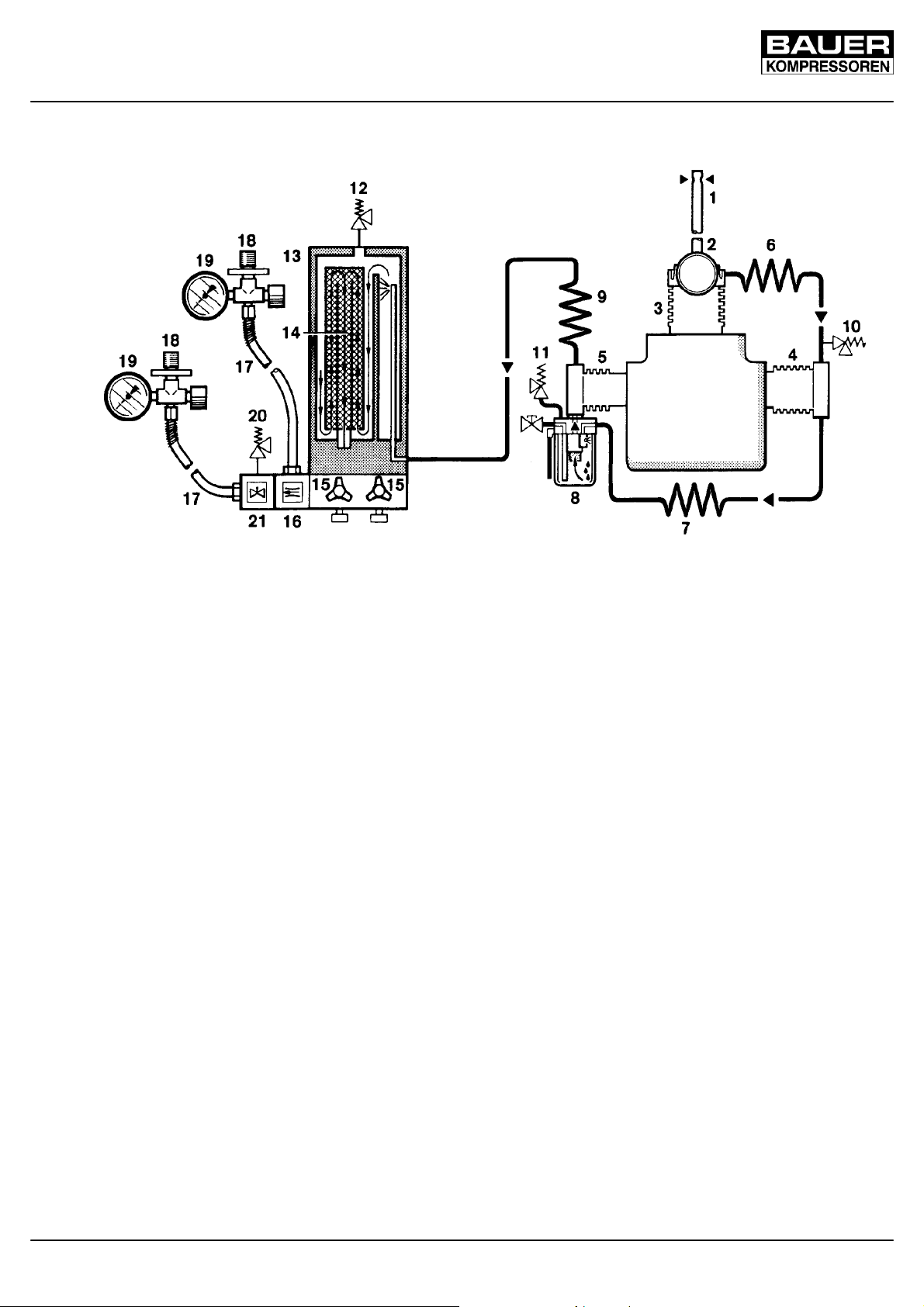

Fig. 4 Air flow diagram Purus, Utilus 10 and Junior 5.......................................................

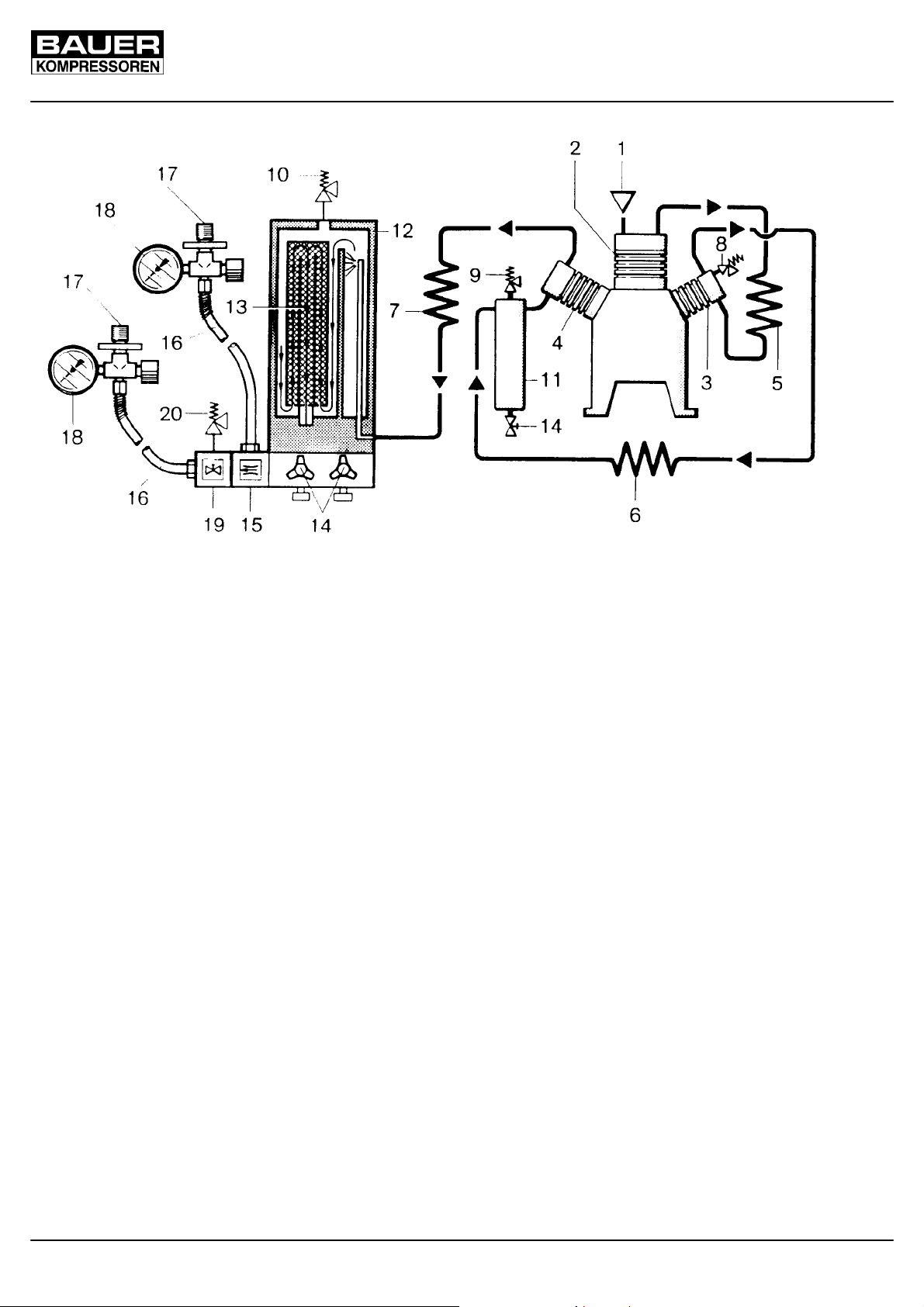

Fig. 5 Air flow diagram Utilus, Capitano und Mariner 6......................................................

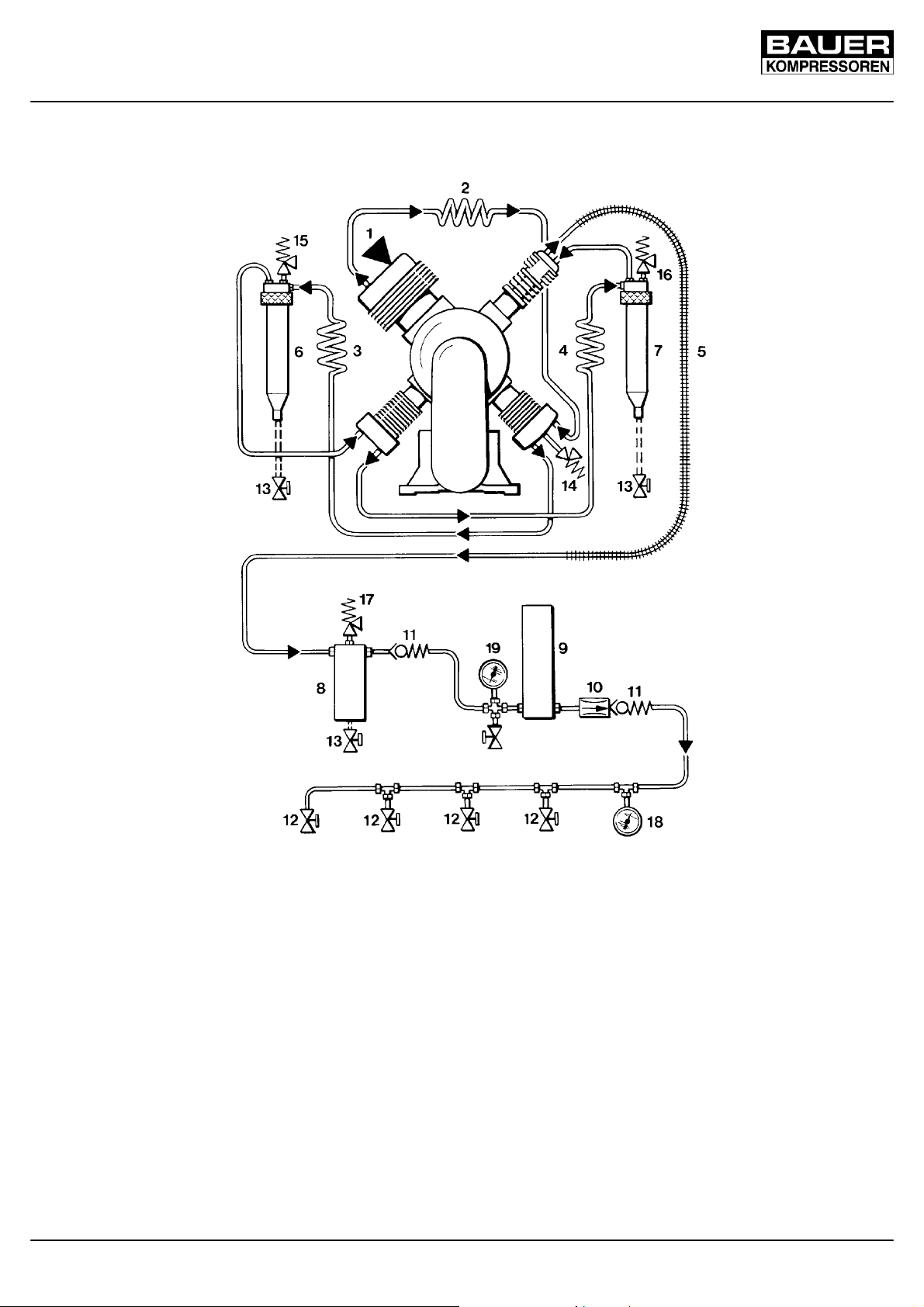

Fig. 6 Air flow diagram K14, K15, K150, K180 7..........................................................

Fig. 7 Locating air intake hose 13........................................................................

Fig. 8 Room temperature 14.............................................................................

Fig. 9 Locating the unit 15...............................................................................

Fig. 10 Cooling air flow 15................................................................................

Fig. 11 Installation of the compressor unit (natural ventilation) 16...............................................

Tab. 1 Air intake and outlet openings 17...................................................................

Fig. 12 Installation with natural ventilation, example 1 17......................................................

Fig. 13 Installation with natural ventilation, example 2 18......................................................

Fig. 14 Installation with natural ventilation, example 3 18......................................................

Fig. 15 Installation of the compressor unit (artificial ventilation) 20...............................................

Fig. 16 Installation with artificial ventilation, example 1 21......................................................

Fig. 17 Installation with artificial ventilation, example 2 21......................................................

Fig. 18 Solenoid valve plug 23............................................................................

Fig. 19 Connecting air bottle 26...........................................................................

Fig. 20 International filling connector 26....................................................................

Fig. 21 Connecting air bottle 26...........................................................................

Fig. 22 Opening of filling valve 27.........................................................................

Fig. 23 Opening of filling valve 27.........................................................................

Fig. 24 Removing air bottle 27............................................................................

Fig. 25 Removing air bottle 27............................................................................

Fig. 26 Filter system P21 37..............................................................................

Fig. 27 Safety bore 38...................................................................................

Fig. 28 Filter system P41 left, P61 right with SECURUS--monitoring unit 42......................................

Fig. 29 Oil and water separator 44.........................................................................

Fig. 30 Construction of the filter cartridges 45...............................................................

Fig. 31 Air flow diagram 47...............................................................................

Fig. 32 Cartridge change 49..............................................................................

Fig. 33 Danger label no.2 54..............................................................................

Fig. 34 Automatic switching device 56......................................................................

Fig. 35 Flow chart 56....................................................................................

Fig. 36 Filling from storage cylinders (overflow) 57

ig. 37 Filling with the compressor 57......................................................................

F

Fig. 38 Filling storage cylinders 57.........................................................................

...........................................................

v

Page 8

Operator’s Manual

ANNEX

Important notices for the TÜV (supervising authorities) inspections of filling stations (German

Pressure Vessels Regulations)

vi

Page 9

Operator’s Manual

1. GENERAL

1.1. PURPOSE AND SHORT DESCRIPTION

High pressure compressor units are complete units for filling air tanks in the high pressure ranges PN 200 and PN 300 bar. The compressors are mainly used to compress air for breathing as required in diving and fire fighting applications, for instance.

The heart of this unit is formed by a three-- or four stage, air--cooled high pressure compressor block.

The Purus, Utilus 10 and Junior range compressor units are splash--lubricated.

From the Utilus, Capitano and Mariner rangecompressor units onwards, the last stages are lubricated by means of theforced--feed

lubrication system, the other cylinders are splash--lubricated.

All units are equipped witha breathing air -- processing system(P--filter system), that surpassesthe quality requirements of DIN3188.

1

Page 10

1.2. THEORETICAL PRINCIPLES

Operator’s Manual

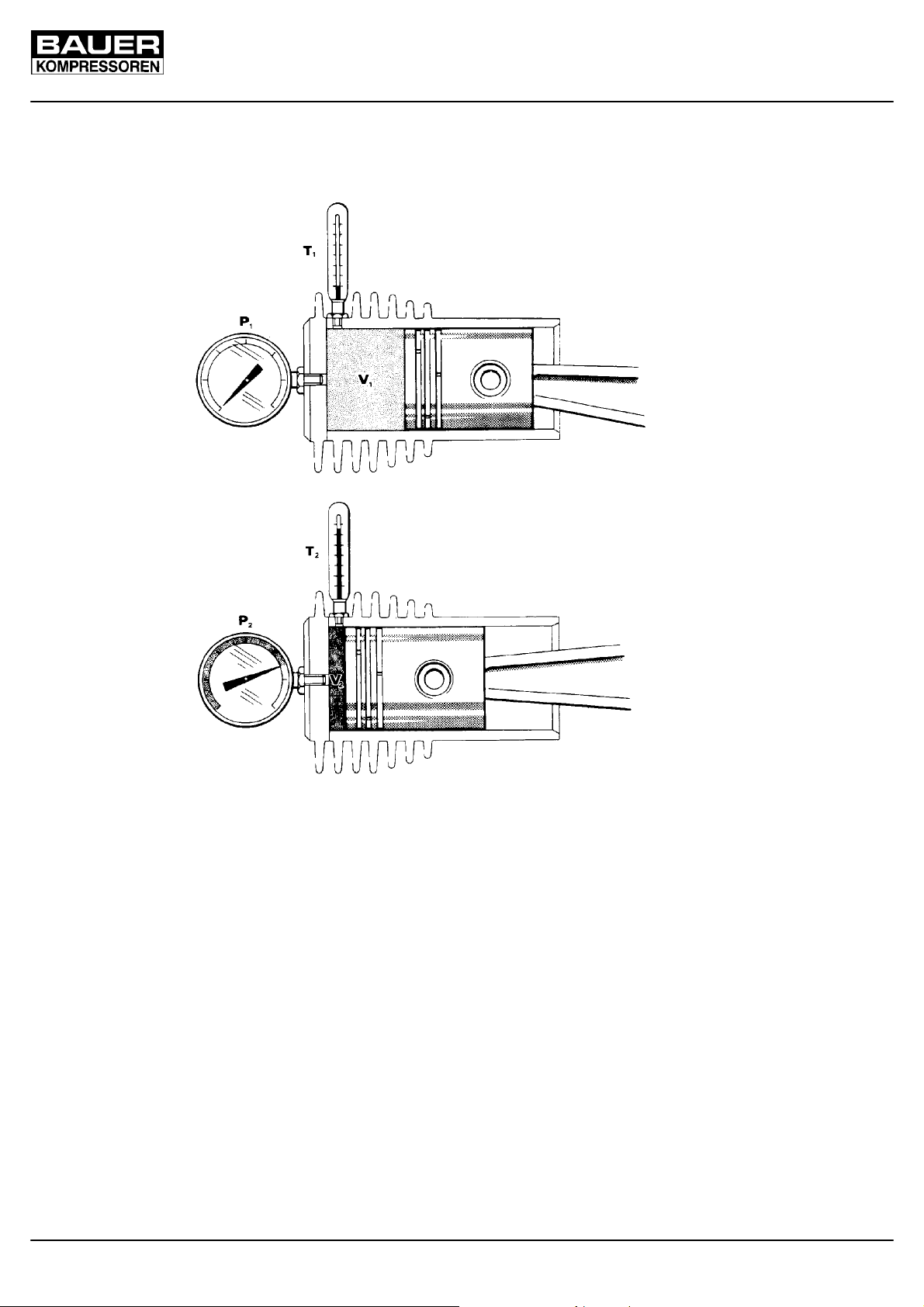

Fig. 1 Pressure-- and temperature increase

When the piston movesinto the cylinder,the pressure rises in thecylinder. Atthe same timehowever,the temperatureof the enclosed

gas also rises. This is a basic physical law (Gay--Lussac).

Since with increasing pressure, the occuring temperatures would soon reach inadmissibly high values, the compression has to be

divided into various stages. After every stage the gas is cooled back to approx. 10 -- 15 °C above ambient temperature. This is the

main reason for designing compressors with 3 or 4 stages.

2

Page 11

Operator’s Manual

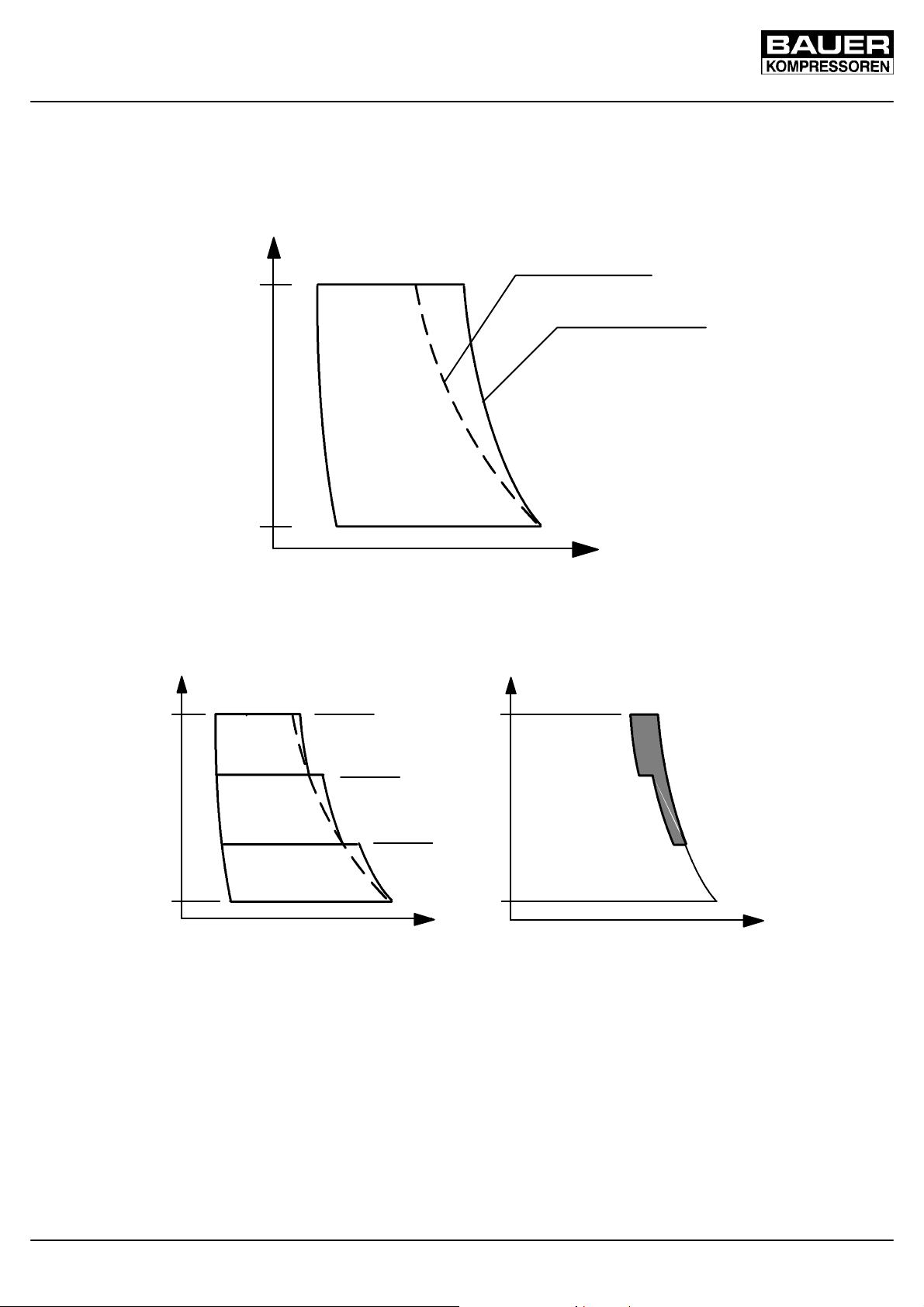

By dividing the compression work into various stages it results in a lower power requirment. This is visible in the p-- v diagram.

Fig. 2 shows the power requirement with a theoretical 1 stage compression to 200 bar.

Fig. 3 shows the power requirement witha3stagecompressionandthesavedwork.

200 bar

1 bar

Fig. 2 P--V Diagram

P

200 bar

P

3. Stage

Ideal theoretical

isothermal compression

actual polytropic

compression

V

saving of work

P

200 bar

2. Stage

1. Stage

1 bar

V

Fig. 3 Saving of work

By dividing the compression work it not only saves energy, but it also increases the operating safety due to a lower thermical load.

1 bar

V

3

Page 12

1.3. DESIGN AND MODE OF OPERATION

1.3.1. Design

The compressor unit comprises the following major assemblies:

• compressor block

• drive motor

• filter set

• base and frame assembly with instrument/filling panel

• electric control system

• electronic monitoring system

• automatic condensate drain

1.3.2. Mode of operation; air flow diagram

The path of the air through the compressor system is shown in the following air flow diagrams.

a)

a)

a)

Operator’s Manual

a) optional extra according to order

4

Page 13

Operator’s Manual

1.3.3. Air flow diagram 3--stage

Fig. 4 Air flow diagram Purus, Utilus 10 and Junior

1 Telescopic air intake

2 Intake filter

3 Cylinder 1st stage

4 Cylinder 2nd stage

5 Cylinder 3rd stage

6 Inter-- cooler 1st/2nd stage

7 Inter-- cooler 2nd/3rd stage

8 Intermediate separator 2nd/3rd stage

9 After-- cooler

10 Safety valve 1st stage

11 Safety valve 2nd stage

12 Final pressure safety valve

13 Central filter assembly

14 TRIPLEX longlife cartridge

15 Condensate drain valve

16 Pressure maintaining valve

17 Filling hose

18 Filling valve

19 Final pressure gauge

20 Safety valve, final pressure PN 200

21 Change-- over devicea)

a) optional extra

a)

5

Page 14

Operator’s Manual

Fig. 5 Air flow diagram Utilus, Capitano und Mariner

1 Intake filter

2 Cylinder 1st stage

3 Cylinder 2nd stage

4 Cylinder 3rd stage

5 Inter-- cooler 1st/2nd stage

6 Inter-- cooler 2nd/3rd stage

7 After-- cooler

8 Safety valve 1st stage

9 Safety valve 2nd stage

10 Final pressure safety valve

11 Intermediate separator 2nd/3rd stage

12 Central filter assembly

13 TRIPLEX longlife cartridge

14 Condensate drain valve

15 Pressure maintainig valve

16 Filling hose

17 Filling valve

18 Final pressure gauge

19 Change-- over device

20 Safety valve, final pressure PN 200

a

) optional extra

a

)

a)

6

Page 15

Operator’s Manual

1.3.4. Air flow diagram 4--stage

Fig. 6 Air flow diagram K14, K15, K150, K180

1 Intake filter

2 Inter-- cooler 1st/2nd stage

3 Inter-- cooler 2nd/3rd stage

4 Inter-- cooler 3rd/4th stage

5 After-- cooler

6 Intermediate separator 2nd/3rd stage

7 Intermediate separator 3rd/4th stage

8 Oil and water separator

9 Purifier

10 Pressure maitaining valve

11 Non--return valve

12 Filling valve

13 Condensate drain valve (manual)

14 Safety valve, intermediate pressure 2nd stage

15 Safety valve, intermediate pressure 3rd stage

16 Safety valve, intermediate pressure 4th stage

17 Safety valve, final pressure

18 Pressure gauge, final pressure

19 Venting valve with pressure gauge

An additional intermediate separator,1./2. stage is available for operation at high temperatures (e.g.: installation in subtropical countries) and high humidity.

The order number can be obtained through our technical customer service, Tel. 089 --78049 175

7

Page 16

NOTES

Operator’s Manual

8

Page 17

Operator’s Manual

2. SAFETY REGULATIONS

2.1. GENERAL

WARNING

Never open filling or shut--off valves when under pressure and not connected as highly compressed emerging

air can cause serious accidents.

WARNING

Ensure intake air is free from noxious gas, exhaust fumes and solvent vapour. Use an intake hose and ensure

that it is mounted in such a way as to avoid taking in any noxious substances.

WARNING

Filling hoses must be in satisfactory condition and threads undamaged. Pay particular attention to damage on

the interface from hose fitting to hose. If the rubber is scored, hose must be discarded otherwise water can enter

and attack wire gauze causing it to rust and thus endangering pressure tightness.

CAUTION

Always shut down and decompress the complete system prior to carrying out any work on the compressor.

Working on compressor units requires the necessary expert knowledge!

CAUTION

Check the complete system for leakage from time to time by brushing all fittings and couplings with soapy water

or spraying with leak test spray. Repair any leakage.

CAUTION

Always disconnect the system from mains supply prior to carrying out any work on compressor systems with

electric drive motor.

CAUTION

Never repair pressure lines by soldering or welding.

CAUTION

Do not use any toxic substances like gasoline or acetone or similar to clean the compressor unit or any of its

parts.

9

Page 18

Operator’s Manual

2.2. NOTES AND WARNING SIGNS

Notes and warning signs displayed on compressors according

to model, application or equipment.

WARNING

Hot surfaces, do not touch!

Danger of burning by touching cylinders, cylinder heads and pressure lines of individual

compressor stages.

WARNING

High voltage!

Life threatening danger of electric shock.

Maintenancework on electric units or operating equipment may only be carried out by a

qualifiedelectrician or by a person instructed

and supervised by a qualified electrician according to electrical regulations.

WARNING

Automatic compressor control, unit may

start--up without warning

Before carrying out maintenance and repair

work, s witch off at the main switch or disconnect from the mains and ensure unit will not

restart.

!

MANDAT ORY

Instructions must be readby personsoperating the machinery

The instruction manual supplied and all other

applicable instructions,regulations etc. must

be read and understood by operating personnel before using the machine.

!

WARNING

This notice is used with maintenance

work and operatingprocedures and must

be adhered to exactly in order to avoid

endangering personnel.

This notice must be complied with in

order to avoid damageto or destructionof

the machine or its equipment.

NOTICE

2.4. FUNDAMENTAL SAFETY NOTICES

Authorized use

• The machine / unit is built according to state of the art technology and established safety technical regulations. Nevertheless,its use can cause danger tolifeand limb of theoperator or third parties or damage to the machine and other

equipment.

• Operate the machine / unit only in technically perfectcondition in accordance with regulations and safety and danger

notices detailed in the instruction manual! In particular, immediately correct faults (or have them corrected) which can

impair safety!

• The machine / unit is exclusively for the compression ofmediums (air/gas) specified in section A, chapter 1.3. “Technical data”. Any other medium or use outside that specified is

not authorized. The manufacturer / supplier is not liable for

damage resulting from this. The user alone is responsible

for this risk. Authorizationfor use is also under the condition

that the instruction manual is complied with and inspection

and maintenance requirements are enforced.

Organizational measures

MANDAT ORY

Hearing protectors must be worn!

Hearing protectors must beworn when working on a machine which is running.

NOTE

Ensure correct direction of rotation!

When switching on the machine, check the

arrowto ensure correct direction of rotationof

the drive motor.

2.3. IDENTIFYING THE SAFETY NOTICES

Important instructions concerning the endangerment of personnel, technical safety and operating safety will be specially

emphasized by placing the following signs before the instructions.

• Keep the instruction manual to hand near the machine / unit

at all times in the relevant holder.

• In addition to the instruction manual, observe and comply

with universally valid legal and other obligatory regulations

regarding accident prevention and environment protection.

This can involve, for example, contact with hazardous substances or the provision / wearing of personal protective

equipment.

• In addition to theinstruction manual, provide supplementary

instructions for supervision and monitoring duties taking

into consideration exceptional factors e.g. with regard to organization of work, production, personnel employed.

• Personnel engaged to operate the machine must have read

the instruction manual before beginning work, especially

the safety notices chapter. When work is already underway

it is too late. This is particularly relevant for temporary personnel, e.g. maintenance personnel.

• At the very least, supervise temporary personnel’s work in

accordance with the instruction manual, taking intoaccount

safety and danger factors.

• Personnel may not wear long hair loose, loose clothing or

jewellery, including rings. There is a danger of injury

10

Page 19

Operator’s Manual

through, for example, these getting caught or being pulled

into the equipment.

• As far as necessary or according to regulations, use personal protective equipment.

• Observe all safety anddanger notices on the machine / unit.

• Keep all safety and danger notices on the machine / unit

complete and in readable condition.

• If there are any modifications to the machine / unit or operating conditions which may affect safety, stop the machine /

unit immediately and inform the department / person responsible of the fault.

• No modifications may be made to the machine / unit which

could impair safety without first obtaining permission from

the suppliers. This is also thecase withregard to installation

and adjustment of safety devices and valves as well as

welding of piping and reservoirs.

• Spare parts must always comply with the technical requirements specified by the manufacturer. This is always guaranteed with original spare parts.

• Do not carry out programme changes (software) to the programmable control system.

• Piping must be thoroughly checked (pressure and visual inspection) by the operator at appropriate time intervals, even

if no safety related faults have been noticed.

• Intervals stipulated or given in the instruction manual for recurring checks / inspections must be adhered to.

• It is absolutely essential that the workplace is appropriately

equipped for maintenance measures.

• Make sure location and operation of fire extinguishers is

known.

• Pay attention to fire warning and fire fighting procedures.

Qualifications, fundamental duties

• Work on / with the machine / unit may only be c arried out by

reliable personnel. Observe the legal minimum age permissible.

• Only employ trained personnel, clearly establish responsibility of personnel for operation, maintenance and repairwork.

• Ensure that only trained personnel work with the machine.

• Establish the responsibilities of the machine operator and

establish a procedure for him to inform a third person of unfavourable safety conditions.

• People who are being trained or introduced to the job should

only be allowed to work with the machine / unit under constant supervision of an experienced person.

• Work on the electrical equipment of the machine / unit may

only be carried out by a qualified electrician or by an instructed person under the direction and supervision of a

qualified electrician according to electrotechnical regulations.

• Work on gas equipmentmay only be carried out by qualified

personnel.

Safety notices for operation

• Do not carry out any work if safety is questionable.

• Meet all requirements demanding that the machine / unit is

only operated in safe and good working order. Only operate

the machine if all protective and safety equipment, e.g. all

detachable protective equipment, emergency shut--down

devices, soundproofing is provided and in good working

order.

• At least once every day, check the machine / unit externally

for damage and faults. Inform the department / person responsible immediately if anything is not as is should be (including operation). If necessary, shut the machine down immediately and make it safe.

• If there are any malfunctions, shut the machine / unit down

immediately and make it safe. Correct faults immediately (or

have them corrected).

• Observe switching on and off processes and monitoring indications according to the instruction manual.

• Before switching on / starting up the machine / unit, ensure

that no one can be put at risk through running the machine

/ unit.

• Carry out the setting, maintenance and inspection processes at the intervals specified in the instruction manual,

including replacement of parts / equipment. This work may

only be carried out by qualified personnel.

• Bef

ore carrying out any exceptional work or repairwork,op-

erating personnel should be informed. Call the supervisor.

• For all work concerning operation, change in production,

conversion or regulating of the machine / unit and its safety

measures such as inspection, maintenance and repairwork, observe the switching on and off processes in the instruction manual and the notices for maintenance work.

• Clear and make the maintenance area safe as far as

necessary.

• If the machine / unit is completely switched off for maintenance and repairwork, ensure that it is protected from unexpected start-- up. Turn off main control device and remove

the key and / or display a warning sign on the main switch.

• When replacing individual parts and larger assembly

groups, they must be carefully fastened to the lifting device

so that there is no risk of danger. Use only s uitable and

technically perfect lifting devices and equipment with sufficient lifting power and strength. Do not linger or work under

suspended loads.

• Only entrust an experienced person with the fixing of loads

and guiding of crane drivers. The person guiding must remain within sight or in contact with the operator.

• For assembly work above body height, use appropriate

safety approved equipment, e.g. ladders and platforms. Do

not climb on machine parts. For maintenance work at high

levels, wear a safety harness.

• Clean oil,fuel or care products fromthe machine, in particular the connections and screw joints, before carrying out

maintenance / repairwork. Do not use aggressive cleaning

fluid. Use a fibre--free cleaning cloth.

• Before cleaning the machine with water or jet of steam(high

pressure cleaner) or detergent, cover / seal all openings

which for safety and/or operating reasons no water / steam

/ detergent may penetrate. Electric motor and switch cabinets are particularly at risk.

• When cleaning the operating room, ensure that the temperature sensors of the fire alarm and sprinkler system do

not come into contact with hot cleaning fluid, in order to

avoid triggering the sprinkler system.

11

Page 20

Operator’s Manual

• Completely remove all covers / seals after cleaning.

• After cleaning, check all pressure lines for leaks, loose con-

nections, wear and damage. Immediately eliminate any

faults.

• Always retighten any screw connections loosened formaintenance or repairwork.

• If it is necessary to remove safety devices for maintenance

and repairwork, these must be replaced and checked immediately after completion of the maintenance or repairwork.

• Ensure safe and environmentally friendly disposal of consumables and old parts.

Particular areas of danger

• Use only original fuses with specified current rating. If there

is a failure in the electric energy supply, shut the machine /

unit down immediately.

• Work on electric units or operating equipment may only be

carriedout by a qualifiedelectrician or by a personunder the

instruction and supervision of a qualified electrician according to electric technical regulations.

• Machines and unit parts which must undergo inspection,

maintenance and repairwork, must be disconnected from

the mains supply, if specified. Parts which have been disconnected must first be checked for voltage, then earthed

and short--circuited and isolated from live neighbouring

parts.

• The electrical equipment of a machine / unit must be regularly checked. Defects, such as loose screw connections

or burnt wires, must be rectified immediately.

• If work is to be carried out on live parts, work with a second

person who can operate the emergency off switch or the

main switch in the case of an emergency. Close off the work

area with a red and white safety chain and a warning sign.

Only use voltage isolated tools.

• Only carry out welding, burning and grinding work on the

machine / unit when specifically approved. There can, for

example, be a risk of fire or explosion.

• Before carrying out welding, burning or grinding work, clean

the machine / unit and surrounding area fromdust and flammable material and ensure there is adequate ventilation

(danger of explosion!).

• When working in smallrooms, observe any national regulations.

• Only personnel with particular knowledge and experience

with pneumatics may carry out work on pneumatic equipment.

• Check all pressure lines,hoses and screw connections regularly for leaks and visible damage. Immediately repair any

damage. Escaping air or gas under pressure can cause injury and fire.

• Depressurize system and pressure lines before commencing repairwork.

• Pressurized air lines must be laid and mounted by qualified

personnel. Connections must not be mixed up. Fittings,

length and quality of the piping must correspond to requirements.

• Soundproofing equipment on the machine / unit must be in

place and functional during operation.

• The stipulated hearing protectors must be worn.

• With regard to oil, grease and other chemical substances,

observe the relevant safety regulations for the product.

• For loading,only use lifting device and equipment with sufficient lifting power and strength.

• Appoint trained guide personnel for lifting operations.

• Machines may only be lifted with a lifting device and by

trainedpersonnelaccording to instructions in theinstruction

manual (fixing points for fixing equipment etc.).

• Use only suitable transporters with sufficient carrying

power.

Secure the load properly. Use suitable fixing points.

• If necessary, provide machine / unit with transportation

brackets. Display the appropriate notice. Remove transportation brackets in the correct manner before taking into

operation.

• Parts which need to be dismantled for transport purposes

must be carefully replaced and secured before taking into

operation.

• Even when moving the machine / unit only slightly, the machine / unit must be disconnected from all external energy

sources. Before putting into use again, reconnect the machi

ne to the mains according to regulations.

• When taking back into operation, proceed according to the

instruction manual.

Notices of danger regarding pressure vessels

• Never open or loosen pressure vessel lids or pipe connection parts under pressure; always depressurise the vessel

or the unit.

• Never exceed the permissible operating pressure of the

vessels!

• Never heat the vessels or any of their parts above the

stated, maximum operating pressure.

• Always exchange damaged pressure vessels completely.

Individualparts that are subject to pressureloads cannot be

purchased as spare parts, since the vessels are tested as

a complete part and the documentation considers them as

a whole (see pressure vessel documentation, serial-numbers!).

• Always pay attention to the permissible operating mode of

the pressure vessels.

We differentiate:

-- vessels for static load

-- vessels for dynamic load

Vessels for static

These pressure vessels are permanently under virtually

constant operating pressure; the fluctuations of pressure

are very small.

Vessels for this type of load are not marked in a particular

way and may be used as long as the vessel inspections,

carried out regularly, do not uncover any safety--relevant

deficiencies.

We recommend that aluminium vessels should be exchanged after 15 years at the latest.

Vessels for dynamic

load:

load:

12

Page 21

Operator’s Manual

These pressure vessels may also be used under conditions

of changing operating pressure. The pressure may vary between the atmospheric and the maximum admissible operating pressure.

The pressure vessel documentation and the appropriate

notes in the operating manual particularly characterise vessels of this type as being adequate fordynamic loads. In the

technical information for these vessels you will find specifications concerning their permissible operating period.

Due to thevariationofthe operatingpressure,thesevessels

are subject to a so-- called dynamicload, which puts the vessels under great stress. The change between two different

pressures is called a load change or cycle. In the technical

information for these vessels you will find specifications

concerning the permissible number of cycles depending on

the fluctuation of the operating pressure.

Having reached half the permissible number of cycles, the

vessel has to be submitted to an internal check, in which the

critically stressed areas of the vessels are examined by

means of suitable testing methods, in order to ensure the

operating safety.

After having reached the total permissible number of load

cycles, the vessel must be exchanged and scrapped.

Record the number of load cycles in writing if you do not

have an automatic cycle--counter.

We recommend that aluminium vessels should be exchanged after 15 years at the latest.

Please pay attention to and follow these measures, for your

own safety and that of you employees and customers!

In order not to unnecessarily load the pressure vessels additionally, the non-- return valves, that are meant to avoid a

drop in pressure, and also the pressure maintaining valves,

which should reduce big pressure fluctuations as well,

should be checked regularly for internal and external tightness and functionality.

• Check the pressure vessels regularly on the inside and outside for damage from corrosion.

• Be particularly careful with second--hand pressure vessels,

when their previous operating mode is not specifically clarified.

2.5. SAFETY REGULATIONS (EC; partly Germany,

only)

A compressor is identified by German law as being a filling system if pressure cylinders are filled by the system, especially

when these cylinders are made available for third parties. The

start--up and operation of compressorsystems foruse as filling

stations is governed by the following regulations:

a-- Pressure vessel directive (Directive 97/23/EC) of

29.05.1997

b-- Operating safety regulations (BetrSichV) of 27.09.2002

c-- Machine safety law (GSG) as of 11.05.2001

d-- 14th regulation to machine safety law (14. GSGV -- pressure vessel regulation) of 03.10.2002

e-- Technical regulations for pressure gases (TRG 400,401,

402, 730).

If a high pressure compressor is used for filling pressure vessels or for the supply of pneumatic systems, the following regulations apply:

f-- Accident Prevention Regulations (UVV):

• UVV compressors (VBG 16).

Copies of the above regulations are available through the usual

outlets, e.g. in Germany from:

Carl Heymanns Verlag

Luxemburger Str. 449

50939 Köln

Beuth-- Vertrieb GmbH

Burggrafenstr. 4 -- 7

10787 Berlin

The manufacturer has complied with all applicable regulations

and the unit is prepared accordingly. If desired, we offer at our

Munich site a partial acceptance test according to § 14 BetrSichV. Please contact our Technical Service Department with

regard to this. They can also supply our leaflet “IMPORTANT

NOTES FOR CERTIFICATION”.

According to the operation safety regulations (BetrSichV), all

compressor units which will be used as filling stations must undergo an acceptance test by a professional at their location before bringing them into service.If pressure vessels (bottles) are

to be filled by the compressor fora third party then the appropriate permission must be obtained from the responsibleauthority

before the acceptance test. As a rule, this is the factory inspectorate. The procedure for obtaining permission is according to

TRG 730, guidelines for permission to set up and operate filling

stations.The testcertificates and documents delivered with the

compressor are important and may be requested during the

procedure for obtaining permission. In addition, the documents

belonging to theunit are important for recurrent inspections and

should therefore be carefully kept.

Inspections in accordance with the regulations for prevention of

accidents will be carried out by the manufacturerorby a specialist.

No guarantees whatsoever are valid for damage caused or favoured by the non-- consideration of these directions for use.

We strongly emphasize these regulations.

13

Page 22

Operator’s Manual

3. INSTALLATION, OPERATION

3.1. INSTALLATION OF THE COMPRESSOR UNIT

The compressor frame is equipped with anti--vibration mounts and thus a machine base orspecial means ofsecuring thecompressor

are not necessary.

3.1.1. Outdoor location

For installation observe the following:

-- The floor must be capable of taking the load of the system weight.

-- Locate the unit level.

-- On units employing petrol or diesel engine it is mostimportantthat only cleanair be used. Position compressor in direction ofwind

so that exhaust fumes are blown away from the unit. It is good practice to have intake hose of at least 3 m length with pre--filter

and intake filter.Pre-- filterto be located 2 m above ground. See Fig. 7. This arrangement will ensure necessary spacing between

exhaust outlet and air inlet.

-- Turn unit as soon as wind direction changes.

-- On petrol or diesel engines, operation unit must only be located outdoors, never indoors, not even in partially closed rooms however large they may be.

-- Take care that no vehicles with running engines are in direct vicinity.

-- Do notoperate unit in thevicinity ofopen fire (flue gas!). Even cigarette smoke can pollute the breathing air filled in the pressurized

cylinders!

WIND

Fig. 7 Locating air intake hose

EXHAUST

14

Page 23

Operator’s Manual

3.1.2. Indoor location

WARNING

Petrol and Diesel driven units must not be operated indoors!

-- Ensure adequate ventilation.

-- Here too, air must be free from exhaust fumes and hazardous vapours e.g. smoke, solvent vapours, etc.

-- If possible install unit in such a manner that the compressor fan can get fresh air from outside, for instance through an opening

in the wall.

-- Ensure that an adequate exhaust air opening is provided .

3

-- When locating the compressorin rooms of less than 30m

must be taken to provide artificial ventilation.

This also applies when other systems having high radiation are operating in the same room.

3.2. COMPRESSOR ROOM CONDITIONS:

(39.2 cu yd) space where natural ventilation is not ensured, measures

-- The compressor room must be clean, dust--free, dry and as

cool as possible.

-- Avoid direct exposure to sunlight; if possible, choose north

side of building.

-- Additional heat producing units or line systems should not

be installed in the same room or should be well isolated.

-- The floor must be capable of taking the load of the system

weight.

-- Locate the unit level; refer to technical data for max. allowable inclination.

-- Ensure adequate ventilation. Remember: room temperature = cooling air temperature ! Min. = +5 °C, max. = +45 °C.

Fig. 8.

Fig. 8 Room temperature

15

Page 24

3.2.1. Locating the unit

-- If possible install unit in such a manner that the compressor

fan can draw fresh air from outside, for instance through an

opening in the wall as low as possible.

-- Ensure that an adequate exhaust air opening is provided,

as high as possible.

-- Locate compressor as close to the air intake opening as

possible. (Minimum distance approx. 50 cm)

-- Locate unit so as to absolutely avoid intake of warm or hot

cooling air.

-- Observe the minimum distances as listed in the table overleaf (Fig. 11).

Operator’s Manual

3.2.2. Cooling air duct installation

On all Verticus 5 units the cooling air outlet can be installed as

standard in two different ways. By simply removingthe air outlet

cover and grid and mounting them in the desired position, the

air outlet can either be on top or on the back of the unit (Fig. 10).

If the outlet on the top is selected, the unit can be positioned

close to a wall, provided a correct airintake according to the following paragraphs is ensured.

3.2.3. Air baffle control (Option)

See drawing 073733 in section F, if applicable. The air circulating baffles ensure optimal temperature in the compressor room

or at least that the temperature stays within the permissible

range of +5 to +45°C when the outside temperature is low.

The recommendedcontrollerthermostatsetting is +15 to 18°C.

Adjustment takes place at 4°C above or below the set value.

A temperature sensor in thecooling air intake channel transmits

to the control unit the temperature of the air taken in. This activates the actuator of the air circulating baffles. According to requirements, one of the two baffles in the cooling air exhaust

channel is opened. One guides the warm cooling air to the outside, the other recirculates the warm cooling air back into the

room. The procedure is continuous and therefore the amount

of warm air being recirculated is continually being adjusted as

necessary.

The cooling air exhaust channel with baffle unit can be connected to the top or the rear of the VERTICUS 5 unit.

Fig. 9 Locating the unit

Front

side

Fig. 10 Cooling air flow

Cooling air outlet

standard

optional

Cooling air inlet

NOTE

For further information on the installation of air

cooled compressors, see our Installation Manual

which can be obtained from BAUER Customer Services, P.O. 710260, D--81452 Munich

16

Page 25

Operator’s Manual

3.3. NATURAL VENTILATION

Natural ventilation is the most simple and commonly used. It is created by convection and is sufficient if no thermal overload is expected, i.e. for units with small drive motors, for intermittent operation or in moderate climates this is the ideal method of cooling the

compressor unit.

Fig. 11 Installation of the c ompressor unit (natural ventilation)

A Minimum distance from wall, intake side: 0.5 m (may be ignoredif locating the unit in front of an opening).

B Minimum distance from wall, exhaust side: 2 m (may be ignored if locating the unit in front of an opening)

C Intake opening: refer to tab. 1

D Exhaust opening: refer to tab.1

The inlet and outlet air openings are dependent on:

-- the power of the electric motor

-- the height difference between air intake and outlet openings

-- the air volume of the compressor room.

The following table shows some significant values. If the indicated values cannot be obtained, artificial ventilation will be necessary,

seeFig.15toFig.16.

17

Page 26

Operator’s Manual

Power

(kW)

V=50m

3

Room volume / Height difference

Δh=2m

Intake Outlet Intake Outlet Intake Outlet

2.2 0.12 m

3 0.24 m

4 0.30 m

5.5 0.42 m

7.5 0.90 m

11 1.38 m

15 1.92 m

2

2

2

2

2

2

2

0.10 m

0.20 m

0.25 m

0.35 m

0.75 m

1.15 m

1.60 m

2

2

2

2

2

2

2

-- -- -- -- -- -- -- --

0.12 m

0.12 m

0.24 m

0.60 m

0.90 m

1.45 m

Tab. 1 Air intake and outlet openings

Fig. 12 to Fig. 14 show installation examples with natural ventilation:

V = 100 m

Δh=3m

2

2

2

2

2

2

3

0.10 m

0.10 m

0.20 m

0.50 m

0.75 m

1.20 m

V = 200 m

3

Δh=4m

2

2

2

2

2

2

-- -- -- --

-- -- -- --

2

0.12 m

2

0.24 m

2

0.54 m

2

0.90 m

0.10 m

0.20 m

0.45 m

0.75 m

2

2

2

2

Correct: Air intake low, cooling air flows though

unit

Fig. 12 Installation with natural ventilation, example 1

18

Incorrect: Air intake high, cooling air does not

reach unit

Page 27

Operator’s Manual

Correct: Air outlet duct upward

Fig. 13 Installation with natural ventilation, example 2

Incorrect: Warm air is not taken away, but circulates and will be taken in again

Correct: Cooling air led directly to unit

Fig. 14 Installation with natural ventilation, example 3

Incorrect: Cooling air does not reach intake opening,

intake air duct too short

19

Page 28

Operator’s Manual

3.4. ARTIFICIAL VENTILATION

For drive powers above 15 kW natural ventilation is not sufficient. Under certain circumstances this can also apply for smaller power

ratings, e.g.:

-- when locating the compressor in small rooms,

-- if ventilation openings cannot be large enough,

-- when other systems with high heat radiation are operating in the same room or

-- when two or more compressors are operating in the same room.

The principle is: forced ventilation is obligatory if room temperature exceeds the allowed ambient temperature

(45° C)

Cooling air flow

The necessary cooling air flow is calculated to an appoximate value by using the following formula:

3

Required minimum cooling air volume [m

For calculation of the cooling air duct cross section the following formula can be used:

Cooling air duct [m

2

] = cooling air volume [m3/h]

cooling air flow [m/s] x 3600 [s/h]

/h] = 360 x drive power [kW]

The recommended cooling air flow is approx. 3 to 5 m/s, but max. 10 m/s.

Example:

Cooling air volume = 360 x 11 = 3960 m

Cross section =

Verticus III, drive power 11 kW:

3960 m

3

/h

3 m/s x 3600 s/h

=0.36m

3

/h

2

Methods

There are several types of artificial ventilation:

-- free air flow effected by a blower

-- ventilation by means of an air channel with or without additional blower

-- ventilation by means of an air circulating flap with or without additional blower

a)

a)

If installed correctly, the free air flow cooling method should be sufficient for all VERTICUS compressor units.

a) ATTENTION: Ensure that the max. counter--pressure in the intake and outlet channels Δp= 0.5 mbar = 5 mm W.G. (measured at a distance

of 1 m from the compressor unit) is not exceeded.

20

Page 29

Operator’s Manual

Fig. 15 Installation of the compressor unit (artificial ventilation)

A Minimum distance from wall, intake side: 0.5 m (may be ignored if locating the unit in front of an opening)

B Minimum distance from wall, exhaust side: 1 m

C Intake opening

D Exhaust opening

21

Page 30

Fig. 16 and Fig. 17 show installation examples with artificial ventilation:

Operator’s Manual

Correct: Air flows along an imaginary streamline

through the compressor

Fig. 16 Installation with artificial ventilation, example 1

Correct: cooling air led directly to unit

Incorrect: Cooling air does not reach unit

Incorrect: cooling air duct does not reach intake

opening, intake duct too short

Fig. 17 Installation with artificial ventilation, example 2

22

Page 31

Operator’s Manual

3.5. ELECTRICAL INSTALLATION

For installation of electrical equipment observe the following:

-- Observe regulations of local electricity supply company.

-- Arrange for the electrics to be connected by an electrician only.

-- If control devices are delivered by the factory refer to the appropriate wiring diagram.

-- Ensure correct installation of protective conductor.

-- Check conformity of motor and control device tension and frequency with those of electric network.

-- The necessary cables, main fuses and main switch are to be providedby the customer. The fusing should bedone inaccordance

with the regulations of the responsible electricity supply company.

-- Adjust motor protection, thermal overload relay. For start over contactor adjust to motor amperage rating. For start via star--delta

contactor adjust to motor amperage rating x 0.58.

For example: motor amperage rating = 10 Amp.:

Adjust relay to 10 x 0.58 = 5.8 Amp.

-- When connecting the unit to the electrical supply, check direction of rotation for agreement with arrow on unit.

-- Fuse motor correctly (see table below; use slow--blow fuses).

FUSE TABLE

Motor type Voltage V 125 220 240 380 415 440 500 600 660

3--phase, 2.2 kW

(star--delta starting)

3--phase, 2.2 kW

(direct starting)

3--phase, 3 kW

(star--delta starting)

3--phase, 3 kW

(direct starting)

3--phase, 4 kW

(star--delta starting)

3--phase, 4 kW

(direct starting)

3--phase, 5.5 kW

(star--delta starting)

3--phase, 5.5 kW

(direct starting)

3--phase, 7.5 kW

(star--delta starting)

3--phase, 7.5 kW

(direct starting)

3--phase, 11 kW

(star--delta starting)

3--phase, 11 kW

(direct starting)

3--phase, 15 kW

(star--delta starting)

3--phase, 15 kW

(direct starting)

3--phase, 18.5 kW

(star--delta starting)

3--phase, 18.5 kW

(direct starting)

current A 20 10 10 6 6 6 6 4 4

current A 25 16 16 10 10 6 6 6 6

current A 25 16 16 10 10 10 10 6 4

current A 35 20 20 16 16 10 10 6 6

current A 35 20 20 10 -- -- 10 10 10 6

current A 35 25 25 16 -- -- 16 16 10 10

current A 50 25 25 16 16 16 10 10 10

current A 63 35 35 20 20 20 16 16 16

current A 50 35 35 20 16 16 16 16 10

current A 63 35 35 25 25 25 20 16 16

current A -- -- 50 50 25 25 25 20 20 16

current A -- -- 63 50 35 35 35 25 25 25

current A -- -- 63 63 35 35 35 25 25 20

current A -- -- 80 80 50 35 35 35 35 25

current A -- -- 80 63 50 50 35 35 25 25

current A -- -- 100 80 63 50 50 50 35 35

23

Page 32

Operator’s Manual

3.6. TAKING INTO OPERATION

3.6.1. Preparation for operation

CAUTION

All compressor units are tested prior to delivery to the customer, so after correct installation of the unit there

should be no problem putting it into operation, observing the following points:

-- Read Instruction Manual carefully. Make sure that all persons handling the compressor and the filling station are familiar with the

function of all controls and monitors. Observe the WARNINGs in the section filling procedure.

-- Depending on the model range, some compressor units are delivered without oil in the crankcase. Check prior to first operation

and if necessary,fillwithoil.Aftertaking unit into operation after a standstill period of 2 years or more changecompressoroil.When

using a mineral oil change oil after one year.

-- Prior to first operation or operation subsequent to maintenance work, turn the compressor manually using the flywheel to ensure

that all parts are turning freely.

-- Immediatelyafterswitchingon the systemfor the first time check thedirectionof rotationof the motor for compliance with the arrow

on the unit. If motor turns in the wrong direction, the phases are not connected properly. Shut down unit immediately and interchange two of the three phase leads in the switch box. Never change leads at the motor terminal board.

-- Prior to first operation or operation subsequent to repair

work operate unit for at least 10 minutes with open condensate valves (pressureless) to ensure properlubrication ofall

parts before pressure is built up. For units with automatic

condensate drain, loosen screw (3, Fig. 18) on coil (1) and

pull plug (2) from solenoid valve.

1

2

Fig. 18 Solenoid valve plug

Units with petrol or diesel engines, additionally:

-- Check oil level of petrol or diesel motor according to manufacturer’s instruction manual.

-- Check fuel tank. Top up if necessary.

-- Open fuel shut-- off valve.

NOTE

Charge battery with enclosed battery liquid before taking unit into operation!

Battery is dry and charged !

3

24

Page 33

Operator’s Manual

3.6.2. Starting the unit

NOTE

Knocking, audible when starting, is due to last stage floating piston. This knocking disappears as soon as there

is pressure between the stages and the piston is running synchronous with the other pistons. Therefore, this

knocking can be ignored.

Units with electric drive motor:

-- Alternating current: Position 0 --1 control switch on engine to 1.

-- Three-- phase current: Master switch must be ON (to be supplied by customer).

-- Depending on model, either set 0 --I switch at switch box to I, or press the I button on the control and monitoring unit.

-- (Units with electronic monitoring unit):

Start--up of the compressor is indicated by the pilot light illuminating on the Electronic Control which must extinguish once the

specified operating conditions have been attained.

-- Observe the pressure switch shut-- off pressure on units with automatic compressor control.

-- If finalpressure is reached and pressure switch shuts off unit properly, open condensate drain valves and drain condensate. Unit

is then ready for filling operation.

Units with petrol or diesel engine

-- Open condensate drain valves on the filters so that motor starts without load.

-- Set choke on petrol engine to position START. Start engine with recoil starter or crank handle. As soon as motor runs smoothly

return choke to normal operating position.

-- Close condensate drain valves and run unit to final pressure. Check final pressure safety valve and pressure gauge.

-- As soon as final pressure is reached and final pressure safety valve blows off, open condensate drain valves and drain condensate -- unit is ready for filling operation.

25

Page 34

Operator’s Manual

3.7. FILLING PROCEDURE

3.7.1. General

The filling valve connection is of the manual type and permits connection to air tanks without using tools. An O--ring is provided for

self--sealing due to internal overpressure.

Compressed air tank filling valves for a pressure in excess of 200 bar are standardized (DIN 477, sheet 5) and connectors for 200

and 300 bar are different and cannot be mixed up.

To ensure safe air tank removal after filling, the valve has an integral venting bore. Therefore always close tank valve first before

closing filling valve.

During filling procedure bottles will warm up due to recompression. After removing, allow to cool down, bottles may then be reconnected and topped up to the respective maximum filling pressure (max. allowed filling overpressure at 15 °C).

3.7.2. Intake air quality

At routine tests, CO

compressed air is taken from rooms in which one or more persons are working. At insufficient ventilation, the CO

rounding air can increase quite fast because of the exhaling of CO

unusual (MAK--value (max. workroom concentration) is 5,000 ppm

producing approx. 2g CO

technically caused excessive increase of CO

of the reasons stated above and for your own security, the filling of breathing air bottles is not allowed in rooms used as

workrooms.

3.7.3. Scavenging the compressor unit

values beyond the permissible values are noted from time to time. Closer investigations often show that the

2

.CO2values from 1,000 to 5,000 ppmvin workrooms are not

2

). Another additional increase is caused by cigarette smoking,

(¶ 2,000 ppmv) per cigarette. These pollutions add up to the basic pollution of approx. 400 ppmv.The

2

during the filling process and the CO2peak at taking the unit into operation.Because

2

v

value in the sur-

2

is present in the atmosphere with a natural amount of 250 -- 800 ppmV. The molecular sieve used in the purifiers for drying the

CO

2

breathing air is, as well as other capabilities, able to adsorb CO

pressor, adsorbed CO

may be desorbed again due to the partial pressure decrease. The now free CO2then gets washed out of

2

which is accumulated in the cartridge. After shut --down of the com-

2

the cartridge when the compressor is started again.

To avoid increased CO

contents in the compressed breathing air, we recommend scavenging the compressor unit before con-

2

necting and filling the air bottles, i.e. let the compressed air escape into the open air by opening the filling valves for about 1 to 2

minutes. Remove filling hose for this action, or hold the respective filling hose tightly when opening the filling valve, to avoid any uncontrolled whipping of the filling hose. See also chapter filling the bottles.

3.7.4. Switch--over valve

Filling panels for 2 pressure ranges (PN 200 / PN 300) and with a switch--over valve, with which it is possible to s witch between two

pressure ranges, can only be used for one pressure range at a time. The 200 bar side is opened by means of the shut--off valve. The

300 bar filling valves remain pressurized but can only be used up to a pressure of 200 bar. It is impossible to connect 200 bar bottles

to the 300 bar filling connections (right hand side).

CAUTION

Before switching from 300 bar to 200 bar, i.e. to the

lower pressure range, it is essential

venting valve and to reduce the 300 bar line to at

least 200 bar. Otherwise, the pressure gauge could

be damaged or destroyed.

to open the

Open the switch --over valve slowly in order to avoid

a pressure surge! Filling hoses which are not in use

must be hung inthe holderson the bottom of the filling panel, so that should a filling valve be inadvertentlyopened, thepressurized air outstream cannot

WARNING

cause the hose to whip and cause serious injury.

3.7.5. Pressure reducer

Filling panels for 2 pressure ranges (PN 200 / PN 300) and with a pressure reducer, can be used for filling bottles simultaneously

at two pressures, i.e. simultaneous filling of 200 bar and 300 bar bottles is possible!

The pressure reducer used in the filling panel is adjustable to a high precision.

Max. inlet pressure 420 bar

Secondary pressure 0.1 to 280 bar

(range of adjustment)

Temperature range --10 °C to +100 °C

Normal delivery 32 m

3.

A20mm particle filter is installed at the pressure reducer inlet.

26

Page 35

Operator’s Manual

3.7.6. Connecting the bottles

-- Connect air bottle to filling valve (see Fig. 19 and Fig. 20).

NOTE

On models of 300 bar rated filling pressuredo notattach bottles unless rated for this presssure (note

pressure stamped on tank neck).

-- Air bottles with international filling connector c an be connected with filling adaptor (part no. 08487-- 635) to the German filling connector or with filling adapter (part no.

03147--635) directly to the filling hose (see Fig. 21)

Fig. 19 Connecting air bottle

.

NOTE

The international connector is not permitted in the

Federal Republic ofGermany. Inother countries itis

allowed only for pressures up to 200 bar (2,850 psi).

This filling connector cannot be used on 300 bar

(4,350 psi) models due to constructive measures.

Fig. 20 International filling connector

Fig. 21 Connecting air bottle

27

Page 36

3.7.7. Filling the bottles

Operator’s Manual

WARNING

Never open filling valve unless bottle is connected

to filling hose.

Hose whipping due topressurizedairoutstreamcan

cause serious injury!

-- First open filling valve. Fig. 22 and Fig. 23

-- Then open bottle valve -- bottle will be filled. Drain condensate regularly during filling. On units with automatic condensate drain check that condensate is drained regularly.

WARNING

The filling procedure should not be interrupted for

more than 10 minutes, to avoid high C0

the bottle air

values in

2

1.

Fig. 22 Opening of filling valve

1.

Fig. 23 Opening of filling valve

2.

2.

3.7.8. Removing the bottles

-- Upon reachingfinalbottlepressureclose bottle valve first,

then filling valve. Fig. 24 and Fig. 25

-- Remove compressed air bottle.

.

WARNING

After removing the air bottle the filling hose should

be secured back into its provided fitting. Never

leave hoses without securing them.

2.

Fig. 24 Removing air bottle

2.

Fig. 25 Removing air bottle

1.

1.

28

Page 37

Operator’s Manual

3.8. SHUT-- DOWN PROCEDURE

-- Close filling valves.

Units with electric motor:

-- Alternating current: Position 0 --1 control switch on engine to 0.

-- Three-- phase current: Master switch must be OFF (to be supplied by customer).

-- Press control button 0 on the control-- and monitoring unit. Place main switch to position OFF.

-- When servicing the compressor or the electrical control unit switch the master switch (provided by customer) to OFF.

Units with petrol or diesel engines:

-- Shut down petrol engine with stop button, close fuel shut--off valve.

-- Shut down diesel engine with stop lever, close fuel shut --off valve.

-- Open condensate drain valves until no more condensate comes out. Then close all valves again and leave unit with residual

pressure, so that no moisture can penetrate into the unit.

-- Check the oil level in thecompressorand top up,if necessary.Also check whether the compressor needs servicing in accordance

with maintenance schedule -- see next chapter.

29

Page 38

Operator’s Manual

4. MAINTENANCE

4.1. MAINTENANCE RECORD

We recommend that all maintenance work is recorded in a service book, showing the date and details of the work carried out. This

will help to avoid expensive repairwork caused by missed maintenance work.

If it is necessary to claim against the warranty, it will help to prove that regular maintenance work has been carried out by BAUER

KOMPRESSOREN GmbH or a specialist agency authorized by BAUER KOMPRESSOREN München, and that the damage has not

been caused by insufficient maintenance. Please refer to section 23 of our general terms and conditions.

For this purpose, the following maintenance control sheet is provided (copy as required). The grey boxes indicate when the maintenance work isdue. The appropriate box(es) will be signed,dated and stamped by the requested specialistagency to show themaintenance work has been carried out in an expert manner.

4.2. MAINTENANCE INTERVALS

CAUTION

For filter cartridge change intervals refer to respective instruction manual !

CAUTION

Saturated filter cartridges as well as any condensate that accumulates are considered to be special

waste! They have to bedisposed of according tothe

valid federal-- and regional waste laws and the local

waste laws (disposal according to DIN safety data

sheet section 5.5)

WARNING

Maintain motors according to the manufacturers

instructions.

30

Page 39

Operator’s Manual

5. MAINTENANCE SCHEDULE

5.1. MAINTENANCE INTERVALS

CAUTION

For filter cartridge change intervals refer to chap-

ter 5 !

Interval Maintenance work

Daily before taking unit into

operation

1/2 hour after start--up Manual check of valve function 9.

Weekly or as required Check automatic condensate drain; open manual condensate drain

25 operating hours after first

time operation/maintenance

work

250 operating hours Check drive belt(s)

1000 operating hours Dismantle valves, clean, check, and replace if necessary

2000 operating hours Synthetic oil change

Check oil level with dipstick

Operate unit to final pressure and check function of final pressure valve

before opening outlet valve

taps

Tighten drive belt(s), check all accessible screws and nuts are tightly

fitted and if necessary tighten to the stipulated torque.

Service micronic intake filter

Check safety valves

Check all connections for leakage

Mineral oil change

Clean sintered metal filter element(s)

Replace valves

Sec.

2.

7.

10.

12.

12.

3.

7.

-- --

9.

2.

4./5.

2.

9.

3000 operating hours or as required

Annually Mineral oil change, if run for less than 1000 operating hours

Annually or as required Check cycle counter; replace oil and water separator if required 11./5.

Biannually Synthetic oil change, if run for less than 2000 operating hours 2.

Check pistons and piston rings 18.

2.

Check opening pressure of safety valves

7.

31

Page 40

Operator’s Manual

5.2. MAINTENANCE RECORD

We recommend that all maintenance work is recorded in a service book, showing the date and details of the work carried out. This

will help to avoid expensive repairwork caused by missed maintenance work.

If it is necessary to claim against the warranty, it will help to have proof that regular maintenance work has been carried out and that

the damage has not been caused by insufficient maintenance. Please refer again to the explainations made in section 4.1.

For this purpose the following maintenance control sheet is provided (copy as required). The grey boxes indicate the maintenance

work to be carried out. The appropriate box(es) will be signed, dated and stamped by the requested specialist agency to show the

maintenance work has been carried out in an expert manner.

Operating hours

Work to be done

Check drive V--belts

Service micronic intake

filter

Check safety valves

Check connections for

leakage

Dismantle valves, clean,

check

Oil change; mineral oil

Clean sintered metal filter

elements

Oil change; synthetic oil

Replace valves

Check opening pressure

of safety valves

Check pistons and piston

rings

Check cycle counter

a

a

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

3000

Annually

Bi--annually

Date/Signature

Stamp of BAUER

KOMPRESSOREN specialist agency

32

Page 41

Operator’s Manual

6. STORAGE, PRESERVATION

6.1. GENERAL

If the compressor is put out of service for more than six months, the unit should be preserved inaccordance with the followinginstructions:

Make sure the compressor is kept indoors in a dry, dust free room. Only cover the compressor with plastic, if it is certain that no condensation will form under the sheet.Nevertheless, the sheet should be removed from timeto time and the unit cleanedon theoutside.

If this procedure cannot be followed and/or the compressor is going to be taken out of service for more than 2 years, please contact

our Technical Service Department for special instructions.

6.2. PREPARATION

Before preserving the compressor unit, run it warm and when it reaches the specified service pressure, keep it running for approx.

10 minutes.

Then carry out the following:

-- Check all pipes, filters and valves (also safety v alves) for leakage.

-- Tighten all couplings, as required.

-- After 10 minutes, open the filling valves or the outlet valve and run the compressor at the set minimum pressure (is approx. 150

bar for 200-- 300 bar units) for approx. 5 minutes.

-- After these 5 minutes,shut the system down.Drain condensate from separators. Depressurizeunit.Shutfillng valves/outlet valve.

-- Remove intake filter from manifold and all intake lines from valve heads.

-- Let compressor unit cool down.

-- Open filters and grease threads, then close them again.

On units equipped with a filter system please observe the following:

-- Ensure that filter cartridges remain in filters!

This will prevent oil entering filling lines as a result of preservation procedures.

6.3. PRESERVING THE COMPRESSOR

-- Turn the compressor on and spray a small amount (approx. 10 ccm/0.6 cu. in.) of compressor oil into the valve heads inlet ports

while the compressor is running. Do not let the compressor warm up too much, to keep oil sticky.

-- Shut compressor unit off.

-- Close all valves.

-- Remount intake lines and close the inlet port with the dust cap.

6.4. PRESERVING THE MOTOR/ENGINE

Preserve the motor/engine according to the instructions of the motor/engine manufacturer.

6.5. PREVENTIVE MAINTENANCE DURING STORAGE

Run the compressor once every 6 months as described in the following:

-- Remove the dust c ap from the inlet port and insert the intake filter.

-- Open the filling valves or the outlet valve.

-- Turn the unit by hand.

-- Let the unit run for approx. 10 minutes or until the air flows out of the filling valves or the outlet valve. With units with pressure oil

lubrication, make sure it’s working properly (oil in sight glass of oil pressure regulator or oil pressure gauges).

-- Repeat preparation work according to para. 6.2.

-- Carry out preservation procedure again according to para. 6.3.

33

Page 42

Operator’s Manual

6.5.1. Changing the lube oil for preserving

-- After prolonged storage,the oil will age in the compressor and engine. It should be drained after2 yearsat the latestand replaced

with fresh oil.

-- The stated period can only be attained when the crankcase is sealed during the preservation period in accordance with the preservation requirements.

-- After changing the oil, turn the compressor and the engine or run them for the required period. See paras. 6.2. and 6.5

-- Check the lubrication of the compressor when putting the unit into operation once every six months or when turning the compressor.

The oil pump is functioning properly when oil can be seen flowing through the sight glass of the oil pressure regulator and if the oil

pressure gauge indicates the prescribed pressure.

6.6. REACTIVATING THE COMPRESSOR UNIT

-- Remove the dust c ap from the inlet port and insert the intake filter.

-- Check the oil level of the compressor.

-- Check the motor/engine according to the manufacturer’s instructions.

-- Turn the compressor unit a few times by hand.

-- Run the compressor warm with open filling valves or outlet valve for approx. 10 minutes.

-- Check the oil flow through the sight glass or oil pressure on the pressure gauge. If there is any fault, check the lubrication of the

compressor.

-- After 10 minutes, close the filling valves or the outlet valve and run the unit up to final pressure until the final pressure safety valve

blows. To do so, override the pressure switch, if installed on the unit. On units with a built in compressor control put the S3 service

switch on position ON.

-- Check the intermediate--pressure safety valves for leakage.

-- Establish cause of any fault from the trouble--shooting table and remedy.

-- On units, equipped with a filter system, please note:

open purifier and replace filter cartridge.

-- Stop the system when running properly, the compressor is then ready for operation.

34

Page 43

Operator’s Manual

7. REPAIR INSTRUCTIONS

7.1. GENERAL

Preventive maintenance usually involves replacing the valves, gaskets and sealing rings as well as carry--ing out the maintenance

work.

Repair work can be carried out on the compressor block to a certain extent but a certain experience and skill is necessary. It should

be noted, however, that

-- no repair should be carried out on the crankdrive nor on the bearings

-- safety valves are not repaired but always replaced completely.

-- suction and pressure valves of each stage are only to be changed together.

NOTE

For all further repair instructions refer to applicable workshop manual.

35

Page 44

Operator’s Manual

y

pg,

t

i

d

i

l

h

toilt

i

l

8. TROUBLE--SHOOTING

Trouble Cause Remedy

Drive motor (electric)

Motor will not start Electric circuit faulty Before attempting to make any re-

pairs, check all fuses, terminal connections, wire leads, make sure that

motor data complies with mains

supply

Drive motor (petrol or diesel)

Engine will not start

Compressor block

No oil pressure