BatteryMINDer Models OBD12-24-36-48

INSTRUCTIONS

BatteryMINDer

®

Models OBD-12, -24, -36 & -48

OnBoard Battery Restorer-Conditioners

With Battery and Charging System Indicator

VDC Electronics, Inc.

147D Woodbury Rd.

Huntington, NY 11743

www.batteryminders.com

techsupport@vdcelectronics.com

Rev. H-041409 Page 1 ` P/N VDC OBD12-24-36-48-MNL

Rev. H-041409 P/N VDC OBD12-24-36-48-MNLRev. H-041409 P/N VDC OBD12-24-36-48-MNL

READ AND SAVE THESE INSTRUCTIONS

BatteryMINDer Models OBD12-24-36-48

Table of Contents

General ..................................................................................................................................................................... 3

Qualifying Your Battery ............................................................................................................................................ 4

Components & Descriptions .................................................................................................................................... 8

Auxiliary charger connector.................................................................................................................................... 9

Installing the Restorer-Conditioner ....................................................................................................................... 10

Battery Setup Configurations ................................................................................................................................. 11

Operating the Restorer-Conditioner ....................................................................................................................... 12

Troubleshooting ...................................................................................................................................................... 12

Battery and Charging System Tester ..................................................................................................................... 13

Operation .......................................................................................................................................................... 13

To Test Battery .................................................................................................................................................. 13

To Test Alternator / Charging System .............................................................................................................. 14

Spike Surge Protector ...................................................................................................................................... 14

LED Battery & Alternator Voltage Test Indications ................................................................................................ 15

Specifications ......................................................................................................................................................... 16

Our Guarantee and Warranty Conditions ............................................................................................................... 17

For Repair or Replacement..................................................................................................................................... 18

Rev. H-041409 Page 2 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

General

The BatteryMINDer® OnBoard Battery RestorerConditioners are designed to desulfate your batteries

while you are operating your vehicle. The units utilize

patented technology to produce a wide range of

high frequency pulses known as RFP™ (Random

Frequency Pulsation) designed to dissolve both

old and newly formed sulfate. RFP™ technology,

sweeps the entire frequency range known to

cause sulfation crystals to resonate and then safely

dissolve them. Sulfuric acid, the main component

in the sulfate crystals, safely returns to the battery’s

electrolyte. The Specic Gravity (S.G.) of the

electrolyte is now higher and able to generate more

electrical energy-storage capacity than the previously

sulfated batteries.

Additional advantages of using sulfation-free batteries

include extended alternator and belt life, as the

vehicle’s charging system no longer needs to work

as hard trying to charge batteries that will not accept

high alternator output current due to sulfation build-

up. Better fuel economy can also be expected, as

much lower output current is now demanded from

the alternator to keep clean, sulfate-free batteries fully

charged. Lower alternator output current translates

to lower engine level.

Each of the BatteryMINDer On-Board RFP™ Battery

Restorer-Conditioners can serve up to six batteries at

a time. Thus, even large commercial vehicles, boats

and commercial equipment require only one unit per

system. Units are effective on all brands / types of

batteries, including Maintenance-free, Gel, AGM,

Deep Cycle, Sealed, and Free-electrolyte. Installation

is a simple two wire hook-up to just one (1) battery

or two (2) if using 6-volt batteries in series. The

units stop working shortly after you turn your engine

off. They do not use any power while your vehicle is

turned off and very little when vehicle is running. ■

Rev. H-041409 Page 3 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

QUALIFYING YOUR BATTERY:

Preliminary Requirements

To conrm your battery’s condition before using your

Battery Restorer-Conditioner (in order to prove the

effect of the Battery Restorer-Conditioner) please

take the following suggestions. The time it will

take will be very worthwhile. If you experience any

problems, or are not sure of how to properly use

or connect your BatteryMINDer, please e-mail our

technical support at: techsupport@vdcelectronics.

com or call our toll-free technical support line 800379-5579 x206 (Eastern Time). Be certain to leave

your phone number with the area code, time zone

and the best time to call.

To gain the best result from your new Battery

Restorer-Conditioner and to maximize the life

and performance of your batteries we strongly

recommend you qualify (test) your batteries before

attempting to either charge-maintain or desulfate

them. Remember, even if you just purchased

a “new” battery it may have been subjected to

conditions that have caused “sulfation” such as high

temperature (>=80°) and/or allowed to self-discharge

to 2.06 Volts/Cell or lower.

NOTE: If your battery is new and you are certain it

was not subject to conditions that could have caused

sulfation, even before you purchased it, then you

can disregard our recommendations for qualifying /

testing your battery, before using the BatteryMINDer.

Testing a Filler Cap or Manifold-type Lead Acid

Battery

1. Carefully remove all caps or manifold-type

covers from your battery.

2. Check the water-liquid electrolyte level. If

the level is low or has ever been below top of

plates, severe lead plate sulfation has taken place.

Signicant recharge/reconditioning time is needed to

restore these plates to a condition where the battery

can be expected to function normally.

3. Rell each cell with distilled water only to the

liquid level indicator found in each cell.

Rev. H-041409 Page 4 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

4. Recharge the battery to ensure that it is

completely charged as possible before you determine

its condition. Allow battery to “rest”* overnight

for a minimum of 12 hours before testing with a

temperature compensated hydrometer and/or digital

type voltmeter only.

* “RESTED” = a battery that has been as fully

charged as possible, using a 3 stage charger or your

alternator and left disconnected from charger or any

type load for a minimum of 12 hours before testing.

5. If the BatteryMINDer battery condition LED lights

YELLOW (single battery) or no balls oat in one or

more cells, your battery may be too far gone to be

fully desulfated. Use a hot/cold calibrated hydrometer

tester for the most accurate results** (see next page)

if you see an increase in the Specic Gravity (SG) or

voltage indicating that there is an improvement in

the battery’s condition, continue desulfating for an

additional 72 hours and retest the battery. Continue

this process until the SG or voltage readings no

longer increase.

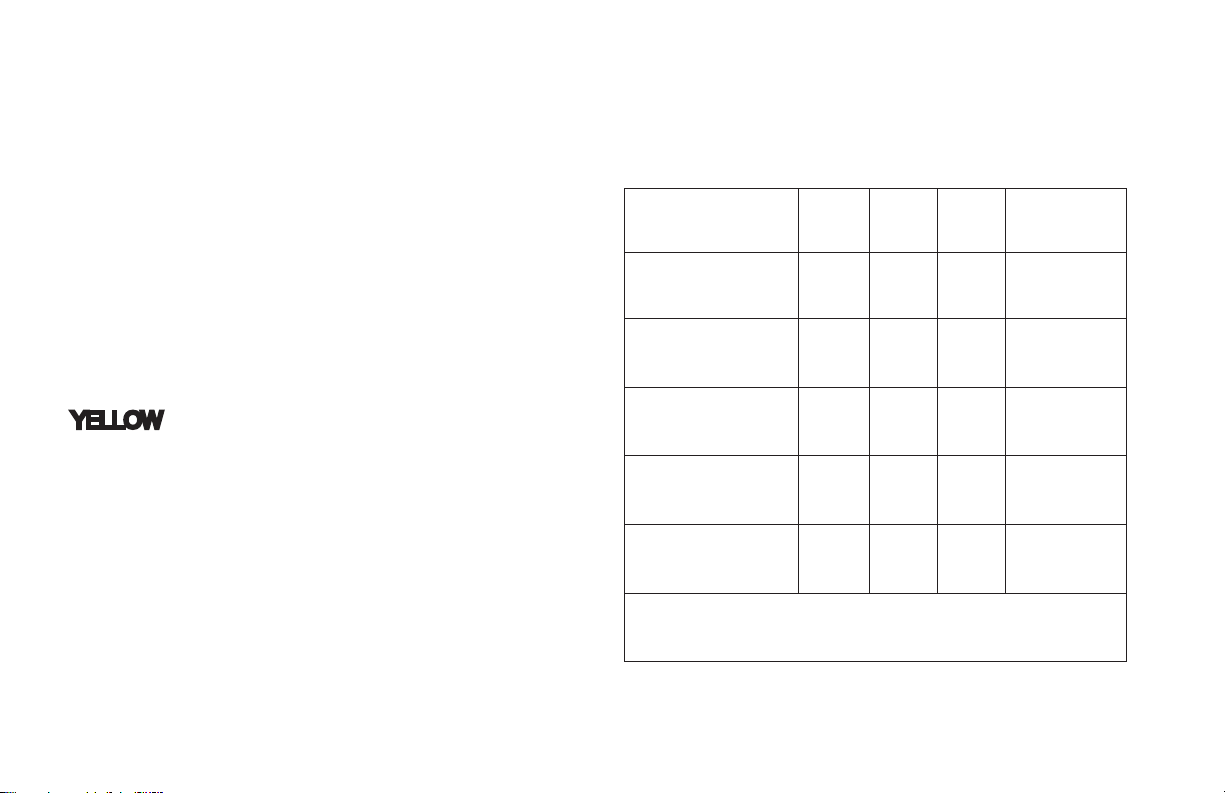

OCV = Open Circuit No Load VoltageOCV = Open Circuit No Load Voltage

Temp. Compensated

Hydrometer - meter

or 4 ball type

1.270 (4 Balls

floating)

1.250 (3 Balls

floating)

1.190 (2 Balls

floating)

1.150 (1 Balls

floating)

1.120 (0 Balls

floating)

1

May denote shorted cell or battery that has been severely

discharged and may not be recoverable

6-V

3

cells

6.3V 8.4V 12.6V 100%

6.18 8.26 12.4 75%

6.09 8.13 12.2 50%

6.0 8.0 12.0 25%

5.8817.84111.81 0%

8-V

4

cells

12-V

6

cells

Full Capacity

Percentage

Rev. H-041409 Page 5 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

**Testing with a Hot/Cold Calibrated

Hydrometer Tester

Read the tester instructions carefully for most

accurate readings.

1. When using the tester the rst time or after a

long period of non-use, ll the tester with the battery

uid and let it sit for 1/2 hour or longer. This will soak

the balls in order to give you more accurate readings.

Failure to do so will give you false readings indicating

a battery that may not be in as good a condition as

you may have thought.

2. After inserting the tester in a cell, gently tap

the tester several times against the inside wall of

each cell to dislodge air bubbles that will cause more

balls to oat than should. Failure to do so will yield

false readings that indicate a battery that is not fully

desulfated or does not qualify for desulfation.

3. If no balls oat in any cell, the cell is shorted.

This means your battery is beyond the point of being

properly recharged or reconditioned-desulfated.

Properly dispose of the battery.

If each cell oats two (2) or more balls (or 1190

on gauge-type), your battery can be desulfated-

reconditioned.

4. Always rinse the tester with fresh water after

every use. Failure to do so will cause false readings.

Testing a Sealed, AGM or Gelled-type Lead Acid

Battery

These batteries have no ller caps or manifold-

type covers. Because you cannot gain access to

the interior of your battery you cannot test it with a

hydrometer.

USE A DIGITAL VOLTMETER ONLY:

1. Recharge the battery with the BatteryMINDer

to ensure it is as completely charged as possible,

before you determine its condition. Allow battery to

“rest” (see pg. 13) for a minimum of 12 hours before

testing with a digital voltmeter only.

Failure to test a “rested” (see pg. 13) battery will

cause false readings.

Rev. H-041409 Page 6 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

2. Measure battery’s voltage, without any load

attached. If the voltage represents less than 50% of

full charge, the battery may be too heavily sulfated

to be fully recoverable. If voltage represents greater

than 50% of the full charge, full recovery can be

expected, given sufcient time (average 1-2 weeks

for batteries that are heavily sulfated).

3. Charge battery to its maximum level. Allow

battery to remain for a minimum of 72 hours before

retesting. If improvement is seen, continue until

battery voltage reaches full capacity level or no

further increase is seen.

OCV -“Rested” Voltage

Gel (volts) & AGM (volts) @ 26°C

6-V

3 Cells

6.42 8.56 12.85 100%

6.33 8.43 12.65 75%

6.18 8.23 12.35 50%

6.00 8.00 12.00 25%

5.90* 7.86* 11.80* 0%

8-V

4 Cells

12-V

6 Cells

Full Capacity

Percentage

*May denote shorted cell or battery that has been

severely discharged and may not be recoverable

Note: OPTIMA brand “Yellow Top” starter/deep

cycle batteries have a fully charged “resting” voltage

of 13.1 (OCV). Increase-Decrease above values

accordingly. ■

Rev. H-041409 Page 7 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Components & Descriptions

1

6

2

7

4

3

5

6

9

(back)

8

Rev. H-041409 Page 8 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

1. LED (Light Emitting Diodes) Indicators (pgs. 11 - 13)

2. Push To Test Button (pg. 12)

3. Positive Lead w/Ring Terminal (pg. 10, 11)

4. Negative Lead w/Ring Terminal (pg. 10, 11)

5. Replaceable Fuse (10 Amps) (pg. 10)

6. Mounting Tabs (2) (pg. 10)

7. Auxiliary Charger Input Cord & Plug (pg. 9, 10)

8. Plug Cover (pg. 9, 10)

9. Velcro loop-lock adhesives (pg. 10)

Auxiliary charger connector

All OBD Model units are equipped with an auxiliary connector plug (charger input cord and plug) designed to

allow a battery charger/maintainer to easily be attached to each unit, providing the voltage, polarity and plug

type of the particular charger is the same*. It must never be used for any other purpose as the polarity of the

connector may be different from the product you are plugging in. This could cause a short circuit or damage

the unit, voiding the guarantee and warranty. Note: RED LED Fault Indicator will light if a device with incorrect

polarity or fault is plugged into the Auxiliary charger connector.

*Model OBD-12 is designed to be attached to one of VDC Electronics’ maintenance type chargers, such as

the BatteryKeeper model 12612 or BatteryMINDer Models 12248, 12112, 12117.

Model OBD-24 is also designed to be attached to a VDC Electronics’ maintenance type charger, namely the

BatteryMINDer Model 24041. ■

Rev. H-041409 Page 9 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Installing the Battery Restorer-Conditioner

Before you install the OnBoard Battery Restorer-

Conditioner, turn the engine off. Mount the unit

in a convenient place close to or directly on the

battery. You can either mount the unit using screws

(not supplied) or the Velcro loop-lock adhesives

(supplied).

Do not use screws of any kind if mounting

the unit directly on the battery. When using screws

to mount unit on other surfaces be very careful of the

length of the screws to avoid puncturing hidden wires

or other sensitive components.

1. Find a safe and convenient place to attach

the unit. Drill the holes for the screws (not supplied)

or clean surface for Velcro fasteners.

2. Attach ring terminal on RED wire to the posi-

tive (+) clamp, threaded studs or side posts of your

battery (depending on type of battery).

3. Attach the ring terminal on the black wire to

the negative (-) clamp, threaded studs or side posts

depending on your battery type.

Note: Your OBD is equipped with a replaceable Ten

(10) Amp at type automotive fuse. Never replace

with a higher rated fuse or a hazardous condition

may exist. ■

Rev. H-041409 Page 10 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

MODEL OBD-24 24-V

MODEL

OBD-36 36-V

MODEL OBD-48 48-V

MODEL OBD-12 12-V

Rev. H-041409 Page 11 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Operating the Battery Restorer-Conditioner

After you have installed the Battery RestorerConditioner start your vehicle and allow it to

idle for 2-3 minutes. The GREEN LED marked

DESULFATING (blinking) will then begin blinking.

Your battery is now being desulfated continuously, as

long as your engine is running and your alternator is

putting current into your battery. When you shut off

your engine, the unit continues operating until your

battery’s voltage returns to standard voltage levels.

It will then shut off with no LED Indicators remaining

on.

Troubleshooting

If the GREEN LED Indicator does not start blinking

within 2 minutes of turning the engine on, check the

polarity of the wires. The RED wire connects to the

positive clamp on the battery and the black wire to

the negative clamp. ■

Rev. H-041409 Page 12 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Battery and Charging System Tester

Although very simple, this tester can accurately

detect the condition of your battery as well as

indicating whether your alternator or charging system

is functioning sufciently to recharge your battery.

However,

to ensure you will get accurate readings.

you must adhere to the instructions below

■

Operation

Note: For the most accurate readings always allow

your battery to “Rest”* for a minimum of 12 hours,

i.e. without charging or discharging or running your

engine. Further test battery only with engine and all

accessories and lights turned off. Test alternator /

charging system only when engine is running and

without lighting/accessories turned on.

*”RESTED” = a battery that has been as fully charged as possible,

using your vehicle’s alternator or a 3-stage charger. When using a

charger be sure to disconnect unit from the charger and any type

load for a minimum of 12 hours before testing.

To Test Battery

(Engine and ALL power using lighting or accessories

must be off for accurate readings

• Press the PUSH to TEST button and hold down

while viewing the LED indicators

NO LEDs are lit = Battery has LESS THAN

VOLTAGE (may be dead, shorted or severely

discharged) Have battery load tested or recharge and

retest.

RED LED lit = POOR = Volts = Battery may be,

shorted, or deeply discharged. If in doubt replace.

YELLOW = FAIR = Volts (Both RED & YELLOW

LED’s will light) = Battery may be shorted or

discharged and unable to start your vehicle. Also

check charging system

GREEN = GOOD = Volts (All 3 LED’s will light) =

Battery is “healthy”

Represents Voltage specific to your OBD model.

See Table for each model on page 15. ■

Rev. H-041409 Page 13 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

To Test Alternator / Charging System

(Engine MUST be Running):

• Press the PUSH to TEST button and hold down

while viewing the LED indicators

• GREEN LED marked Alternator should be lit. ALL

four LEDs should light. If it does not show GREEN,

Alternator / charging system is faulty and must

be checked / repaired. Note: All four (4) test LED

Indicators will light if Alternator is OK. ■

Spike Surge Protector

Many times when using battery “Jumper Cables” a

voltage surge (spike) is created when attaching the

cables to your battery or the second battery system

involved.

Your OBD unit is equipped with a voltage spike

protector designed to shield sensitive engine

computer system components from the harmful

affects of these surges. In addition, it will also

protect plug-in 12-volt accessories such as your

radar detector, cellular phone, personal computer,

etc., from momentary voltage surges during “jump

starting” or external battery charging.

As there are many different component, accessories

and systems and the amount of voltage surges

cannot be fully determined, we cannot guarantee

total 100% protection in all installations. Therefore,

always be very careful to follow the jumper cable

manufacturer’s safety and installation – connection

instructions. ■

Rev. H-041409 Page 14 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

LED Battery & Alternator Voltage Test Indications

POOR FAIR GOOD GOOD-ALT

LED COLORS

OBD-12 11.2 – 12.3 11.8 – 12.3 12.3 – 12.8 13.2 – 14.2 <11.2*

OBD-24 22.4 – 23.6 23.6 – 24.6 24.6 – 25.6 26.4 – 28.4 <22.4**

OBD-36 33.6 – 36.9 35.4 – 36.9 36.9 – 38.4 36.6 – 42.6 <33.6***

OBD-48 44.8 – 49.2 47.2 – 49.2 49.2 – 51.2 52.8 – 56.8 <44.8****

*NO LEDs are lit = Battery has LESS THAN 11.2 VOLTS (see page 13)

**NO LEDs are lit = Battery has LESS THAN 22.4 VOLTS (see page 13)

***NO LEDs are lit = Battery has LESS THAN 33.6 VOLTS (see page 13)

****NO LEDs are lit = Battery has LESS THAN 44.8 VOLTS (see page 13)

All (4) LEDs are lit, if alternator output is high enough to charge battery, when required.

VOLTAGE

Rev. H-041409 Page 15 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Specifications

For 12-V, 24-V, 36-V & 48-V (depending on model)

battery systems only. Draws no current when

Meets watertight specications JIS IP66

Weight : 8 oz.

Size: 5.7” L x 2.25” W x 1.25“ H ■

engine-system is shut off.

A M P L I T U D E

F R E Q U E N C Y

Desulfation Waveform (typical)

Full Time Desulfation output pulse peak current control lp-p....8 ±3 Adc

Full Time Desulfation output PWM frequency...........................50 ±5 Hz

Full Time Desulfation duty........................................................0.2%

Rev. H-041409 Page 16 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Our Guarantee and Warranty Conditions

ONE (1) YEAR 100% UNCONDITIONAL

MONEY BACK GUARANTEE:

BatteryMINDer OnBoard Battery Restorer-

Conditioners are guaranteed to perform as claimed,

or we will refund your full purchase price including

all taxes, shipping or handling cost applicable to

the purchase. Unit must be returned with Proof of

Purchase directly to VDC Electronics, Inc., not to

the dealer from which it was purchased. Physical

damage to the unit will limit this guarantee.

5-YEAR LIMITED WARRANTY

VDC Electronics, Inc. warrantees this product

for FIVE (5) years from date of purchase at retail

against defective materials or workmanship. It will

be repaired or replaced at no charge providing it is

returned to VDC Electronics, Inc., freight prepaid

together with Proof of Purchase. We make no

warranty other than this limited warranty and

expressly exclude any implied warranty including any

warranty for consequential damages. (This limited

warranty is not transferable.)

Return unit to:

VDC Electronics, Inc.,

147 D Woodbury Road

Huntington, NY 11743

Allow up to ten (10) business days for repair or

replacement plus shipping time. ■

Rev. H-041409 Page 17 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

For Repair or Replacement

In the event that you believe your product may be

defective, you MUST speak to a

VDC Electronics technician at 1-800-379-5579 x206

(ET) before proceeding further.

If after speaking with our tech support personnel it is

necessary to return the unit, you MUST request an

VDC Electronics, Inc.

Returns Department

Attn: RMA # (Enter Your RMA# Here)

147D Woodbury Rd.

Huntington, NY 11743

All returns must be authorized by VDC Electronics.

RMA number.

Items must be returned within 10 days after receiving

your Return Merchandise Authorization number

and must be packed in the original packaging with

manual and all connectors included.

Your Return Merchandise Authorization number must

be shown on the return shipping label as follows:

Rev. H-041409 Page 18 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Rev. H-041409 Page 19 ` P/N VDC OBD12-24-36-48-MNL

BatteryMINDer Models OBD12-24-36-48

Rev. H-041409 Page 20 ` P/N VDC OBD12-24-36-48-MNL

Loading...

Loading...