Rev. A-021210 Page 1 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

INSTRUCTION MANUAL

Rev. A-021210 P/N VDC E12248AA-S2-MNL

VDC Electronics, Inc.

147 D Woodbury Rd.

Huntington, NY 11743 U.S.A.

www.batteryminders.com

techsupport@vdcelectronics.com

*For use with Aviation Type 12-V Batteries ONLY. Requires proper

installation of Battery Temperature Sensor (ABS-248 - supplied). Not

for use with Gill LT Series or Odyssey Aircraft Batteries.

READ AND SAVE THESE

INSTRUCTIONS

BatteryMINDer

®

Model

E

12248-AA-S2*

Aviation Charger /

Maintainer /

Desulfator-Conditioner

See Page 13 for Simplied Operating Instructions

Rev. A-021210 Page 2 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

TABLE OF CONTENTS

Safety Instructions............................................................3

Preparing To Charge...........................................................5

Charger Location...............................................................5

DC Connection Precautions..................................................6

Qualifying Your Battery: ......................................................8

Testing A Filler Cap Or Manifold-type Lead Acid Battery................8

Testing With A Hot/Cold Calibrated Hydrometer Tester.................10

Testing A Sealed, AGM Or Flooded (wet-cell) Lead Acid Battery ....10

Unit With Call-outs ..........................................................12

Simplified Operating Instructions .........................................13

LED Indicator Functions ...............................................14, 15

Detailed Operation Instructions ...........................................16

Temperature Sensor ABS-248 (At-the-Battery Sensor).......17, 21 - 24

Maintaining Multiple Batteries.............................................25

Battery Configurations .....................................................26

Troubleshooting - Model E12248-AA-S2..................................27

Detailed Specifications - VDC Model No. E12248-AA-S2.........29 - 33

Charging Profile..............................................................34

For Repair Or Replacement..................................................35

Warranty........................................................................36

Rev. A-021210 Page 3 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

REQUIRED SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSON, OBSERVE THE FOLLOWING:

1. Do not expose charger to rain or snow. It is designed to operate ONLY INDOORS.

2. USE of any attachment not specifically recommended by the

battery charger manufacturer for use with this exact model of

charger may result in risk of fire & electric shock or injury to person. 3. An extension cord should not be used, unless absolutely

necessary. Use of an improper extension cord could result in fire

or electric shock. If extension cord must be used be sure:

a. Pins on plug of extension cord are the same number, size, &

shape of plug on charger

b. Extension cord is properly wired and in good condition.

c. Wire size is enough for AC ampere of charger as specified

below: Length of cord, feet (meters) 25 (7.6), 60 (15.2), 100

(30.5), 150 (45.6) AWG Size #18.

4. Do not use charger if it received a sharp blow, been dropped,

or damaged.

5. Charger contains no serviceable parts. If it fails for any reason,

return to the address shown within for a free replacement under

warranty.

6. To reduce risk of electric shock, unplug charger from outlet

before attempting any cleaning.

7. WARNING - RISK OF EXPLOSIVE GASES.WHENEVER

YOU WORK NEAR A LEAD ACID BATTERY IT IS

DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES

DURING NORMAL BATTERY OPERATION. FOR THIS

REASON, IT IS OF UTMOST IMPORTANCE THAT EACH

TIME BEFORE USING YOUR CHARGER, YOU MUST

READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS

EXACTLY.

Rev. A-021210 Page 4 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

To reduce risk of battery explosion, follow these instructions and

those published by the battery manufacturer and the manufacturer of any equipment you plan to use in the vicinity of the battery.

Review cautionary markings on the products and the engine.

8. PERSONAL PRECAUTIONS when working with or near a lead

acid battery.

a. Someone should be able to hear your voice or close enough

to aid you when working near a lead acid battery.

b. Have fresh water and soap nearby case battery acid contact

skin, clothing, or eyes. Wear complete eye protection and clothing

protection. Avoid touching eyes while working near battery.

c. If battery acid does contact skin or clothing, wash immediately

with soap and water. If acid entered the eye, immediately ood

the eye with running water for at least 10 minutes and get help

immediately.

d. NEVER smoke or allow a spark of ame near battery or en

gine.

e. Be extra cautious to reduce risk of dropping a metal tool onto

battery. It might spark or short circuit battery or other electrical

part that may cause an explosion.

f. Remove personal metal items such as rings, bracelets, neck

laces, and watches when working with a lead acid battery. A lead

acid battery can produce a short circuit current high enough to

weld a ring or the like to metal, causing a severe burn.

g. Charger is designed to be used for recharging lead acid bat

teries ONLY. Never use it to power a low voltage electrical system,

or for attempting to recharge dry cell batteries that are commonly

used in house holds. These batteries may explode and cause

injury to persons and damage property

Rev. A-021210 Page 5 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

NEVER CHARGE A FROZEN BATTERY OR ONE AT A

TEMPERATURE ABOVE 123° F.

PREPARING TO CHARGE

a. Turn off all accessories in the aircraft, so as not to cause an

arc. If battery manufacturer requires battery to be removed from

aircraft before charging, always remove ground wire rst.

b. Be sure area around battery is well ventilated while battery is

being charged. Force gas vapors away by using a piece of nonmetallic material as a fan.

c. Clean battery terminals. Be careful to keep corrosion from

contacting eyes.

d. Add distilled water to each cell until battery acid reaches level

specied by the manufacturer. This helps purge excessive gas

from cells. Do not overll. For a battery without caps, follow manufacturer’s recharging instructions.

e. Study all battery manufacturer’s specic instructions such as

removing cell caps while charging and recommended charge

rates.

f. Determine condition of battery, by referring to instructions

herein, before ever attempting to charge or desulfate any / all

batteries.

CHARGER LOCATION

a. Make sure charger is as far away from battery as output

cables permit.

b. Never place charger directly above battery being charged;

gases from battery will corrode and damage charger.

c. Never allow battery acid to drip on charger when reading spe-

cic gravity or lling.

d. Do not operate charger in a closed-in area or restrict ventilation in any way.

e. Do not set battery on top of charger.

Rev. A-021210 Page 6 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

DC CONNECTION PRECAUTIONS

Note: Steps to be done in a well-ventilated area away from

aircraft.

a. Connect and disconnect DC output clips from battery only

after removing charger power cord from outlet.

b. Attach clips to battery posts and twist or rock back and forth

several times to make good contact. This tends to keep clips

from slipping off terminals and reduces risk of sparking.

Rev. A-021210 Page 7 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

A SPARK NEAR THE BATTERY MAY CAUSE BATTERY

EXPLOSION. TO REDUCE RISK OF A SPARK NEAR

BATTERY:

a. Check polarity of battery posts. POSITIVE (POS,P,+) usually

has a large diameter than NEGATIVE (NEG, N, -) battery post.

b. Connect (RED) charger clip to (POS+) post of battery.

c. Position yourself and free end of cable as far away from battery as possible, then connect NEGATIVE (BLACK) charger clip

to free end of cable.

d. Do not face battery when making final connections.

e. When disconnecting charger, always do so in reverse

sequence of connecting procedure and break first connection

while as far away from battery as practical. Do not attempt

to permanently install charger not specifically designedapproved for permanent installation, especially in a wet

high moisture environment.

Rev. A-021210 Page 8 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

QUALIFYING YOUR BATTERY:

Preliminary Requirements

NOTE: The BatteryMINDer has no electrical output

unless it is connected to a healthy battery. Testing the

BatteryMINDer with a volt or an Amp meter without the unit

being connected across a good battery will result in a false reading. If you experience any problems, or are not sure of how to

properly use or connect your BatteryMINDer, please e-mail our

technical support at: techsupport@vdcelectronics.com.

To gain the best result from your new charger and to maximize

the life and performance of your batteries we strongly recommend you qualify (test) your batteries before attempting to either

charge-maintain or desulfate them. Remember, even if you just

purchased a “new” battery it may have been subjected to conditions that have caused “sulfation” such as high temperature

(>=80°).

NOTE: If your battery is new and you are certain it was not

subject to conditions that could have caused sulfation*,

even before you purchased it, then you can disregard our

recommendations for qualifying / testing your battery,

before using the BatteryMINDer.

* Such as high temperature storage (=/> 80°F) and/or allowed to

self-discharge to 12.4 Volts or lower.

Testing a Filler Cap Lead Acid Battery

1. Carefully remove all filler caps from your battery.

2. Check the water-liquid electrolyte level. If the level is low or

has ever been below top of plates, severe lead plate sulfation has

taken place. Significant recharge/reconditioning time is needed

to restore these plates to a condition where the battery can be

expected to function normally.

Rev. A-021210 Page 9 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

3. Refill each cell with distilled water only to the liquid level

indicator found in each cell. Before proceeding further you

must be thoroughly familiar with the safety and operating

instructions.

4. Recharge the battery with the BatteryMINDer to ensure that

it is slowly and completely charged before you determine its

condition. Allow battery to “rest”* overnight or momentarily apply

a small load to remove the “surface” charge which creates false

voltage readings.

* “RESTED” = a battery that has been as fully charged as

possible, using a 3 stage charger (model E12248-AA-S2)

and left disconnected from charger or any type load for a

minimum of 12 hours.

5. If the BatteryMINDer battery condition LED lights (YELLOW)

within 72 hours (single battery) or no balls float in one or more

cells, your battery may be too far gone to be fully desulfated.

Reconnect battery to your BatteryMINDer. Allow battery to

remain in maintenance mode for a minimum of 72 hours, before

re-test. Use a hot/cold calibrated hydrometer tester for the

most accurate results (see Table 1) if you see an increase in

the Specific Gravity (SG) or voltage indicating that there is an

improvement in the battery’s condition, continue desulfating

for an additional 72 hours and retest the battery. Continue this

process until the SG or voltage readings no longer increase.

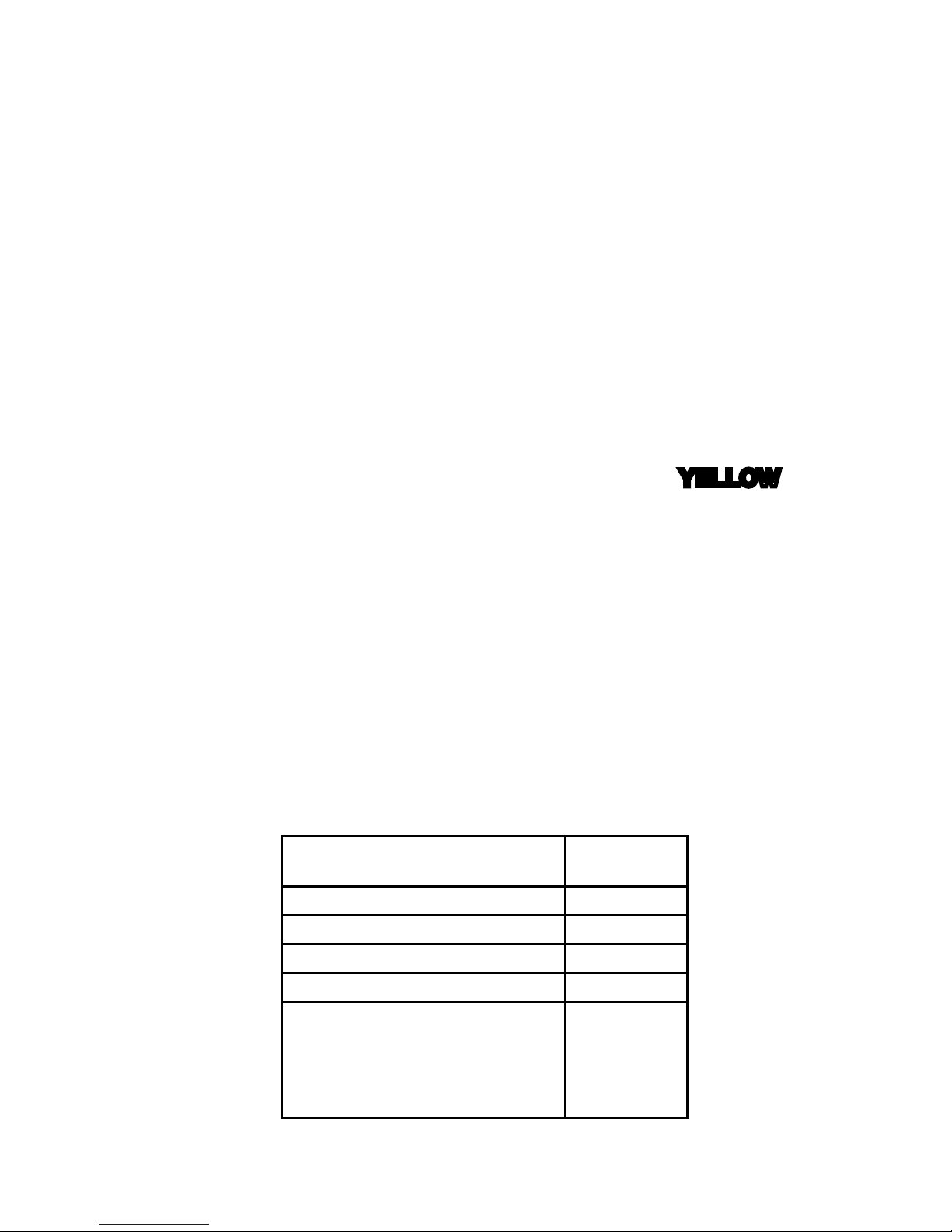

TABLE 1

Temp. Compensated Hydrometer

or 4 ball type

Full Capacity

Percentage

1.270 (4 Balls oating) 100%

1.250 (3 Balls oating) 75%

1.190 (2 Balls oating) 50%

1.150 (1 Balls oating) 25%

1.120 (0 Balls oating)

May denote shorted cell or battery

that has been severely discharged

and may not be recoverable

0%

Specific Gravity – Capacity

Rev. A-021210 Page 10 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

Testing with a Hot/Cold Calibrated Hydrometer Tester

Read the tester instructions carefully for most accurate readings.

1. When using the tester the first time or after a long period

of non-use, fill the tester with the battery fluid and let it sit for 1/2

hour or longer. This will soak the balls in order to give you more

accurate readings. Failure to do so will give you false readings

indicating a battery that may not be in as good a condition as

you may have thought.

2. After inserting the tester in a cell, gently tap the tester

several times against the inside wall of each cell to dislodge air

bubbles that will cause more balls to float than should. Failure to

do so will yield false readings that indicate a battery that is not

fully desulfated or does not qualify for desulfation.

3. If no balls float in any cell, the cell is shorted. This means

your battery is beyond the point of being properly recharged or

reconditioned-desulfated. Dispose of the battery.

If each cell floats three (3) or more balls (or 1250 on gauge-type),

your battery can be desulfated-reconditioned.

4. Always rinse the tester with fresh water after every use.

Failure to do so will cause false readings.

Testing a Sealed, AGM or Flooded (wet-cell)

Lead Acid Battery

These batteries have no filler caps or manifold-type covers.

Because you cannot gain access to the interior of your battery

you cannot test it with a hydrometer.

USE A DIGITAL VOLTMETER ONLY:

1. Recharge the battery with the BatteryMINDer to ensure it

is as completely charged as possible, before you determine its

condition. Allow battery to “rest” (see pg. 9) overnight for a minimum of 12 hours before testing with a digital voltmeter only.

Rev. A-021210 Page 11 P/N VDC E12248-S2-MNL

BatteryMINDer

®

E12248-AA-S2

Failure to test a “rested” (see pg. 9) battery will cause false readings. Be certain to read and understand all safety related instructions (pages 3 to 7) before proceeding further.

2. Measure battery’s voltage, without any load attached. If

the voltage is less than 12.6 volts (Typically 75% of charge) the

battery may be too heavily sulfated to be fully recoverable. If

voltage is 12.6-V or higher full recovery can be expected, given

sufficient time (average 1-2 weeks for batteries that are heavily

sulfated).

3. Connect the BatteryMINDer to the battery.

4. Charge battery to its maximum level. Allow battery to

remain for a minimum of 72 hours before retesting. If improvement is seen, continue until battery voltage reaches full capacity

level or no further increase is seen.

Note: Do not expect to completely eliminate sulfate in a

few days. Long established sulfate will require several

weeks or longer to be fully dissolved. Be patient and you

will be rewarded with a “sulfate-free” battery.

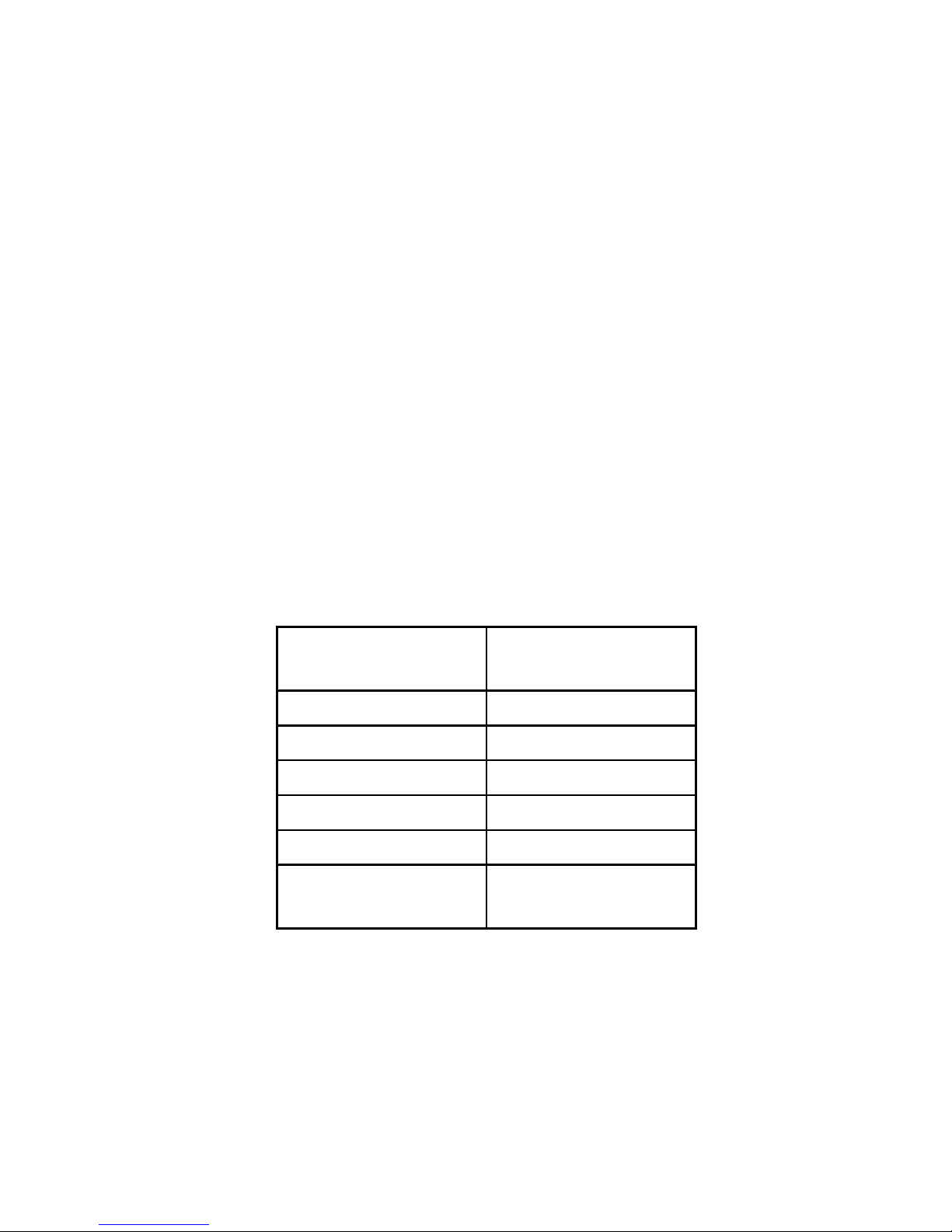

OCV - “Rested”

Voltage

Full Capacity

Percentage

12.9 - 13.1 Volts 100%

12.6 - 12.9 Volts 75%

12.4 - 12.6 Volts 50%

12.2 - 12.4 Volts 25%

12.0 - 12.2 Volts 0%

<11 Volts

= shorted

OCV=Open Circuit No Load Voltage

TABLE 2

Loading...

Loading...