INSTRUCTION MANUAL

12-Volt Maintenance Charger

with Full-Time Desulfator

Model 2012

BatteryMINDer

®

Volts

Amps

BATTERY

CONNECTION

TESTING

LOAD

TEMPERATURE

COMPENSATION

DESULFATING

BAD CELL

BATTERY

WEAK

POWER

BatteryMINDer

®

2000 Series

Charger / Maintainer / Desulfator

VDC Electronics, Inc.

147D Woodbury Rd.

Huntington, NY 11743

www.BatteryMINDers.com

techsupport@vdcelectronics.com

READ AND SAVE THESE

Rev. C-091911 P/N VDC2000-MNL

INSTRUCTIONS

INCLUDES:

2’ Fused Ring Terminal Cord

•

Set with Quick Connector

2’ Battery Clip Cord Set with

•

Quick Connector

Ambient Temperature Sensor

•

BatteryMINDer

®

2000 Series

TABLE OF CONTENTS

Safety Instructions ...................................................................... 3 - 7

Warning - Risk of Explosive Gases ................................................. 4

Personal Precautions ................................................................. 4

Preparing to Charge ................................................................... 5

Charger Location ...................................................................... 5

DC Connection Precautions .......................................................... 6

Reduce Risk of a Spark Near Battery ............................................ 6, 7

Operation Instructions .................................................................8 - 14

Indicator Light Table ............................................................... 8, 9

Quick Connect Instructions ........................................................... 9

Charging Stages ....................................................................... 9

Indicator Light Details ...............................................................10

Temperature Compensation ........................................................11

Voltage Table ......................................................................... 12

Specifications Table .................................................................12

Maintaining Multiple Batteries ..................................................... 13

Battery Configurations ...............................................................13

Charging Profile ......................................................................14

Repair or Replacement ................................................................... 15

Warranty and Registration ................................................................ 16

Rev. C-091911 Page 2 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

Underwriters Laboratories (UL)

REQUIRED IMPORTANT SAFETY INSTRUCTIONS for

the BATTERYMINDER 2000 SERIES

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSON, OBSERVE THE

FOLLOWING:

1. SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions

for BatteryMINDer 2000 Series.

2. Do not expose charger to rain or snow.

3. Use of an attachment not recommended or sold by VDC Electronics

may result in a risk of fire, electric shock, or injury to persons.

4. To reduce risk of damage to electric plug and cord, pull by plug

rather than cord when disconnecting charger.

5. An extension cord should not be used unless absolutely necessary.

Use of improper extension cord could result in a risk of fire and

electric shock. If an extension cord must be used, make sure:

a) That pins on plug of extension cord are the same number, size,

and shape as those of plug on charger;

b) That extension cord is properly wired and in good electrical

condition; and

c) That wire size is large enough for ac ampere rating of charger

as specified in Table below.

Recommended minimum AWG size for

extension cords for battery chargers

AC Input Rating,

amperes

Equal To

or

Greater

Than

0 2 18 18 18 16

a

If the input rating of a charger is given in watts rather than in amperes, the

corresponding ampere rating is to be determined by dividing the wattage rating by

the voltage rating - for example: 1250 watts/125 volts = 10 amperes

Rev. C-091911 Page 3 P/N VDC2000-MNL

a

But Less

Than

25

(7.6)

AWG Size of Cord

Length of Cord, feet (m)

50

(15.2)

100

(30.5)

150

(45.6)

BatteryMINDer

®

2000 Series

6. Do not operate charger with damaged cord or plug – replace the

cord or plug immediately.

7. Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; call VDC Electronics

Tech Support Dept. 800.379.5579 x206 (ET) for advice.

8. Do not disassemble charger; call VDC Electronics Tech Support

Dept. 800.379.5579 x206 (ET) for advice when service or repair

is required. Incorrect reassembly may result in a risk of electric

shock or fire.

9. To reduce risk of electric shock, unplug charger from outlet before

attempting any maintenance or cleaning. Turning off controls will

not reduce this risk.

10. WARNING – RISK OF EXPLOSIVE GASES

a) WORKING IN VICINITY OF A LEAD-ACID BATTERY IS

DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES

DURING NORMAL BATTERY OPERATION. FOR THIS REASON,

IT IS OF UTMOST IMPORTANCE THAT YOU FOLLOW THE

INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

b) To reduce risk of battery explosion, follow these instructions

and those published by manufacturer of any equipment you intend

to use in vicinity of battery. Review cautionary marking on these

products and on engine.

11. PERSONAL PRECAUTIONS

a) Consider having someone close enough by to come to your aid

when you work near a lead-acid battery.

b) Have plenty of fresh water and soap nearby in case battery acid

contacts skin, clothing, or eyes.

c) Wear complete eye protection and clothing protection. Avoid

touching eyes while working near battery.

d) If battery acid contacts skin or clothing, wash immediately

with soap and water. If acid enters eye, immediately flood eye

with running cold water for at least 10 minutes and get medical

attention immediately.

e) NEVER smoke or allow a spark or flame in vicinity of battery or

engine.

f) Be extra cautious to reduce risk of dropping a metal tool onto

battery. It might spark or short-circuit battery or other electrical

Rev. C-091911 Page 4 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

part that may cause explosion.

g) Remove personal metal items such as rings, bracelets,

necklaces, and watches when working with a lead-acid battery. A

lead-acid battery can produce a short-circuit current high enough

to weld a ring or the like to metal, causing a severe burn.

h) Use charger for charging a LEAD-ACID battery only. It is not

intended to supply power to a low voltage electrical system other

than in a starter-motor application. Do not use battery charger

for charging dry-cell batteries that are commonly used with home

appliances. These batteries may burst and cause injury to persons

and damage to property.

i) NEVER charge a frozen battery or a battery at a temperature

above 123° F.

12. PREPARING TO CHARGE

a) If necessary to remove battery from vehicle to charge, always

remove grounded terminal from battery first. Make sure all

accessories in the vehicle are off, so as not to cause an arc.

b) Be sure area around battery is well ventilated while battery is

being charged.

c) Clean battery terminals. Be careful to keep corrosion from

coming in contact with eyes.

d) Add distilled water in each cell until battery acid reaches level

specified by battery manufacturer. Do not overfill. For a battery

without removable cell caps, such as valve regulated lead acid

batteries, carefully follow manufacturer’s recharging instructions.

e) Study all battery manufacturer’s specific precautions while

charging and recommended rates of charge.

f) Determine voltage of battery by referring to car owner’s manual

and make sure it matches output rating of battery charger.

13. CHARGER LOCATION

a) Locate charger as far away from battery as DC cables permit.

b) Never place charger directly above battery being charged;

gases from battery will corrode and damage charger.

c) Never allow battery acid to drip on charger when reading

electrolyte specific gravity or filling battery.

d) Do not operate charger in a closed-in area or restrict ventilation

in any way.

Rev. C-091911 Page 5 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

e) Do not set a battery on top of charger.

14. DC CONNECTION PRECAUTIONS

a) Connect and disconnect dc output clips only after setting any

charger switches to “off” position and removing ac cord from

electric outlet. Never allow clips to touch each other.

b) Attach clips to battery and chassis as indicated in 15(e), 15(f),

and 16(b) through 16(d).

15. FOLLOW THESE STEPS WHEN BATTERY IS INSTALLED IN

VEHICLE. A SPARK NEAR BATTERY MAY CAUSE BATTERY

EXPLOSION.

TO REDUCE RISK OF A SPARK NEAR BATTERY:

a) Position ac and dc cords to reduce risk of damage by hood,

door, or moving engine part.

b) Stay clear of fan blades, belts, pulleys, and other parts that can

cause injury to persons.

c) Check polarity of battery posts. POSITIVE (POS, P, +) battery

post usually has larger diameter than NEGATIVE (NEG, N,–)

post.

d) Determine which post of battery is grounded (connected) to

the chassis. If negative post is grounded to chassis (as in most

vehicles), see (e). If positive post is grounded to the chassis, see

(f).

e) For negative-grounded vehicle, connect POSITIVE (RED) clip

from battery charger to POSITIVE (POS, P, +) ungrounded post

of battery. Connect NEGATIVE ( ) clip to vehicle chassis or

engine block away from battery. Do not connect clip to carburetor,

fuel lines, or sheet-metal body parts. Connect to a heavy gage

metal part of the frame or engine block.

f) For positive-grounded vehicle, connect NEGATIVE ( ) clip

from battery charger to NEGATIVE (NEG, N, –) ungrounded post

of battery. Connect POSITIVE (RED) clip to vehicle chassis or

engine block away from battery. Do not connect clip to carburetor,

fuel lines, or sheet-metal body parts. Connect to a heavy gage

metal part of the frame or engine block.

g) When disconnecting charger, turn switches to off, disconnect

AC cord, remove clip from vehicle chassis, and then remove clip

from battery terminal.

Rev. C-091911 Page 6 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

h) See operating instructions for length of charge information.

16. FOLLOW THESE STEPS WHEN BATTERY IS OUTSIDE

VEHICLE. A SPARK NEAR THE BATTERY MAY CAUSE

BATTERY EXPLOSION.

TO REDUCE RISK OF A SPARK NEAR BATTERY:

a) Check polarity of battery posts. POSITIVE (POS, P, +) battery

post usually has a larger diameter than NEGATIVE (NEG, N, –)

post.

b) Attach at least a 24-inch-long 6-gauge (AWG) insulated battery

cable to NEGATIVE (NEG, N, –) battery post.

c) Connect POSITIVE (RED) charger clip to POSITIVE (POS, P,

+) post of battery.

d) Position yourself and free end of cable as far away from battery

as possible – then connect NEGATIVE ( ) charger clip to

free end of cable.

e) Do not face battery when making final connection.

f) When disconnecting charger, always do so in reverse sequence

of connecting procedure and break first connection while as far

away from battery as practical.

g) A marine (boat) battery must be removed and charged on shore.

To charge it on board requires equipment specially designed for

marine use.

Rev. C-091911 Page 7 P/N VDC2000-MNL

BatteryMINDer

BatteryMINDer 2000 Series Label

Power A/C Power Connected

•

®

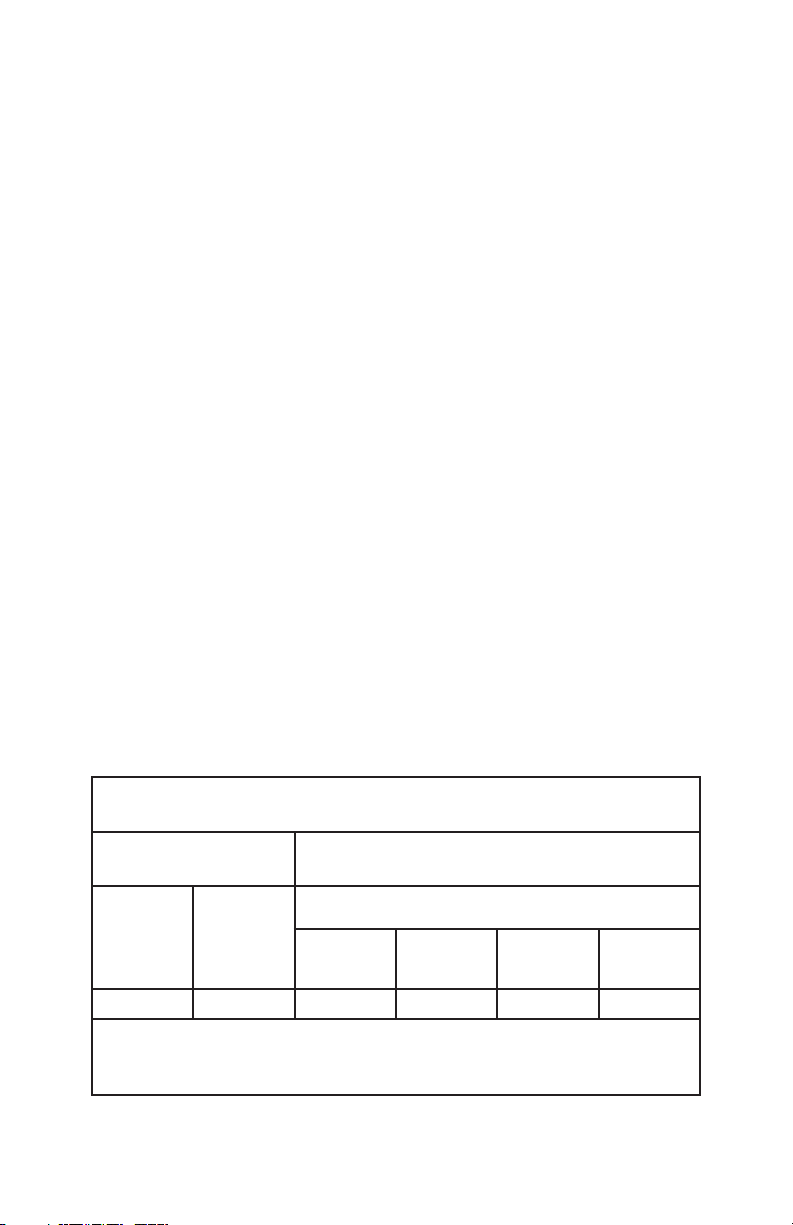

Indicator Light Table

2000 Series

Battery Connection Battery Connected Correctly

•

Battery Connection Battery Connection Reversed

•

Battery Weak

•

Load

•

Bad Cell

•

Testing Battery is being Tested

•

Desulfating Battery is being Desulfated

•

Temperature

•

Compensation

Temperature

•

Compensation

Rev. C-091911 Page 8 P/N VDC2000-MNL

• Battery Required Soft Start

• Battery Tests Under 12.5V

Battery under load and cannot

maintain FV* (See Voltage Table)

Battery under 11.5V after Battery

Test

Temperature Over 27°C/80°F

Temperature Under 21°C/70°F

BatteryMINDer

®

2000 Series

Load Light Off

Soft Start

Constant

Current

Constant

Voltage

Float (Charge

Complete)

Quick Connect Instructions

Place the Positive (RED) clip on the positive battery terminal.

1.

Place the Negative (Black) clip on the negative battery terminal.

2.

Plug in the BatteryMINDer.

3.

Power and Battery Connection light should be GREEN. Indicator

4.

will come on showing state of battery charge and present charging

stage.

• Soft Start is used if a battery’s voltage is under 10.5V when

charging begins. It uses a low constant current to slowly bring

up voltage. This prepares a weak or neglected battery for the

Constant Current stage.

0.5 A

2.0 A

CV* (See

Voltage Table)

FV* (See

Voltage Table)

Charging Stages

Load Light

Float

(Battery < 11V)

Float

(Battery < 12V)

Float

(Battery < 13V)

Float

(Battery > 13V)

•

2.0 A

2.0 A

2.0 A

2.0 A

• Constant Current (sometimes called Bulk) is the main charging

stage. The charger puts out a constant current of 2A, its full power.

Battery voltage rises until the battery reaches the optimal charging

voltage CV* (See Voltage Table).

• Constant Voltage (sometimes called Absorption) is the second

charging stage. The charger regulates the current given to the

battery to maintain a constant voltage CV* (See Voltage Table).

As the battery nears a full charge, the current needed to maintain

this voltage decreases. Once the current falls below 0.5A (0.1A for

2012-AGM) the stage is complete.

• Battery Test is administered by reading your battery voltage

while resting the battery for 10 minutes. A voltage of under 12.5V

indicates a weak battery, under 11.5V indicates a shorted cell. The

battery is tested at completion of the Constant Voltage stage, and

every 12 hours while in Float

Rev. C-091911 Page 9 P/N VDC2000-MNL

BatteryMINDer

• Float (sometimes called Maintenance) is the charger’s long term

stage. The charger can and should be left connected indefinitely.

This will keep the battery fully charged ensuring no sulfate can

form. The charger maintains float voltage FV* (See Voltage Table)

using very little power as it actively monitors the battery and adjusts

its output several times a second.

• Power light is GREEN anytime the charger is plugged into AC

Power.

• Battery Connection light is GREEN when the unit it is correctly

connected to a battery. If the Battery Connection light is RED

the polarity is reversed and the positive and negative terminals

need to be switched. If the light remains RED after switching the

connections, there is a short circuit.

• Battery Weak light is AMBER if the Soft Start mode is used or

the battery fails a Battery Test. The indicator will stay on until the

battery passes a Battery Test.

A neglected battery can take over 2 weeks of desulfation to

correct. If after 2 weeks it still reads as a Weak Battery, there is

likely internal physical damage.

®

Indicator Light Details

2000 Series

• Load light is AMBER if the charger is in Float and outputting 2A.

This indicates a drain on the battery or a large battery that was not

charged within the time limits. If possible remove any loads. When

this light is on, the battery charge level lights correspond only to

battery voltage, not charging stages (see Load Light

Page 9).

• Bad Cell light flashes RED if the charger has not completed the

Constant Current stage in 20 hours and battery voltage is under

11.5V ( Flashing), or if the battery is under 11.5V after a Battery

Test ( Flashing).

The charger shuts off output to avoid any damage to your battery.

Loads or banks of batteries may trigger this mode if they are too

large for this charger. Remove any loads and charge batteries

individually.

• Testing light flashes BLUE when the unit is performing a Battery

Test (see Charging Stages).

Rev. C-091911 Page 10 P/N VDC2000-MNL

•

Table,

BatteryMINDer

®

2000 Series

• Desulfation light flashes BLUE any time the unit is desulfating.

The BatteryMINDer desulfates any time it is outputting current.

Temperature Compensation light is GREEN if the temperature

•

is over 27°C/80°F, BLUE if the temperature is under 21°C/70°F.

BatteryMINDer Model 2012 includes an ambient temperature

sensor which allows it to vary the output voltage as necessary to

properly charge your battery (-0.025 V/°C). Batteries charged at

higher temperatures without compensation will overcharge and

may outgas. Batteries charged at lower temperatures without

compensation will undercharge allowing sulfation to build, possibly

leading to the battery freezing. By using temperature compensation,

the BatteryMINDer ensures your battery will never over or under

charge, even in extreme conditions.

Temperature Compensation

50°C / 122°F -0.625 V

45°C / 113°F -0.500 V

40°C / 104°F -0.375 V

35°C / 95°F -0.250 V

30°C / 86°F -0.125 V

25°C / 77°F 0.000 V

20°C / 68°F +0.125 V

15°C / 59°F +0.250 V

10°C / 50°F +0.375 V

5°C / 41°F +0.500 V

0°C / 32°F +0.625 V

-5°C / 23°F +0.750 V

-10°C / 14°F +1.000 V

-15°C / 5°F +1.125 V

-20°C / -4°F +1.250 V

Consider using accessory ABS-248 “At the Battery Sensor” for more

accurate temperature compensation. It is highly recommended if your

battery is located in a different environment or compartment than your

charger.

Rev. C-091911 Page 11 P/N VDC2000-MNL

BatteryMINDer

®

Voltage Table

*CV : Voltage during the Constant Voltage stage

*FV : Voltage during the Float stage.

Model Battery Types *CV *FV

2000 Series

2012

2012-GEL Gel 14.1V 13.05V

2012-AGM AGM 14.7V 13.6V

2012-CAL Calcium 15.16V 13.5V

Standard

(Flooded)

14.4V 13.4V

Specifications Table

Input 100-240 VAC, 50/60 Hz, 0.65A

Output 2ADC ± 0.2A

Float Current 1mA - 2000mA

Size 5.69” L x 4.06” W x 2.13” H

Weight 1.56 lbs.

Operating Temperature -20°C / -4°F to 40°C / 104°F

Water Resistance IP65

Rev. C-091911 Page 12 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

MAINTAINING MULTIPLE BATTERIES

To properly charge or maintain multiple batteries they should all be the

same type (gel, flooded or AGM) and condition. It is OK to mix deep

cycle and starter. Charge each battery individually before connecting

together. Never connect batteries at different states of charge. The

charged battery will rapidly transfer energy to the discharged battery

possibly causing catastrophic failure. Once the batteries are charged,

use 18 gauge or greater wire to connect the batteries.

If connecting multiple batteries of the same voltage, wire them in parallel

(BatteryMINDer positive to positive A to positive B, BatteryMINDer

negative to negative A to negative B). This is the same type of

connection you would use when jumping a car (in fact, jumper cables

are great for this).

If connecting 2 batteries of half your unit’s voltage (example: 6V batteries

on a 12V unit), wire them in series (BatteryMINDer positive to positive

A, negative A to positive B, negative B to BatteryMINDer negative).

When wired in series they act as one large system at the combined

voltage (example: 6V + 6V = 12V). You can connect these systems in

a series parallel configuration in order to charge or maintain 4 or more

batteries in groups of 2.

As long as your batteries stay wired together they act as one large

battery allowing you to charge and discharge them as a group

Battery Configurations

Model 2012 12 Volt @ 2A

+

12V

_

+

TO CHARGER

+

12V

_

+

12 VOLT PARALLEL

_

TO CHARGER

_

+

TO CHARGER

+

_

+

12 VOLT SERIES

Using 6 Volt Batteries

+

Rev. C-091911 Page 13 P/N VDC2000-MNL

_

TO CHARGER

_

6V6V

_

+

6V6V

_

+

TO CHARGER

+

6V

+

12 VOLT (SERIES-PARALLEL)

Using 6 Volt Batteries

_

+

6V

_

_

+

_

TO CHARGER

_

BatteryMINDer

®

2000 Series

Rev. C-091911 Page 14 P/N VDC2000-MNL

BatteryMINDer

FOR REPAIR OR REPLACEMENT

All returns must be authorized by VDC Electronics.

In the event that you believe your product may be defective, you MUST

speak to a VDC Electronics technician at 1-800-379-5579 x206 (ET) before

proceeding further.

NOTES

®

2000 Series

MODEL BatteryMINDer 20

SERIAL NUMBER _____________________________

PLACE OF PURCHASE _____________________________

DATE OF PURCHASE _____________________________

Rev. C-091911 Page 15 P/N VDC2000-MNL

BatteryMINDer

®

2000 Series

ALL returns must be authorized by VDC Electronics after

speaking to a VDC Electronics technician at 800-379-5579

x206 (ET). Please see our “Repair or Replacement” section of

this manual for additional information.

BatteryMINDer One-Year 100% Unconditional

Money-Back Guarantee

This BatteryMINDer product is guaranteed to perform as claimed or

WE will refund your full purchase price, including all taxes, shipping or

handling cost applicable to the purchase.

Unit must be returned freight prepaid together with Proof of Purchase

directly to VDC Electronics, Inc., NOT TO THE DEALER FROM WHICH

IT WAS PURCHASED.

BatteryMINDer Five-Year Limited Warranty

VDC Electronics, Inc. warrants this product for FIVE years from date of

purchase at retail against defective material or workmanship and will be

repaired or replaced at no charge. We make no warranty other than this

limited warranty and expressly exclude any implied warranty including

any warranty for consequential damages. This limited warranty is not

transferable.

Unit must be returned freight prepaid together with Proof of Purchase

directly to VDC Electronics, Inc., NOT TO THE DEALER FROM WHICH

IT WAS PURCHASED.

IMPORTANT NOTICE

BatteryMINDer® Five-Year Warranty Registration Reminder

Online Registration:

http://www.batteryminders.com/register

Please register your unit online within 10 days of purchase. Due to

the ever-changing technology associated with this BatteryMINDer®

unit, we may be unable to keep you apprised of significant upgrades,

changes, etc. without your registration. The information you provide

upon registration will be used to keep a record of your purchase and

will assist in providing support should you ever need to contact our

Technical Service department:

techsupport@vdcelectronics.com; 800-379-5579 x206 (ET).

Rev. C-091911 Page 16 P/N VDC2000-MNL

Loading...

Loading...