Operating Manual

UNIROB R8 – UNILOG B2

Read before using the robot and

keep it near the robot for reference purposes.

Robot - Type R8 / B2 6-10-20

Controller type UNILOG B2

Robot No.: 26358

Model: 2003

Version R82GBV00 04/03

Injection moulding

R82GBD1A.PMD

Scherl 10 • D-58527 Meinerzhagen

Battenfeld GmbH

Tel. ++49 2354/72-0 • Fax ++49 2354/72-234

Battenfeld Kunststoffmaschinen Ges.m.b.H.

Wr.Neustädter Straße 81• A - 2542 Kottingbrunn

Tel. ++43 2252/404-0 • Fax ++43 2252/404-261

www.battenfeld.com

DIN EN ISO 9001

Index

Chapter 1 General information

Chapter 2 Safety

Chapter 3 Technical Data

Chapter 4 Transport - Installation

Chapter 5 Structure and function

Chapter 6 Comissioning

Chapter 7 Maintenance

Chapter 8 Spares / Plans

Chapter 9 Customer service

?

0

Chapter 10 Extra chapter for special modules

A:PB2GBI1A.P65

B: PB2DEI1A.P65

E: 180202 / Ruder

G: 190202 / G. Krajnik

Section - IN1

Page - 1

Index

Section - IN1

Page - 2

A:PB2GBI1A.P65

B: PB2DEI1A.P65

E: 180202 / Ruder

G: 190202 / G. Krajnik

Table of contents

1.0 General

1.1 Introduction

1.2 Use

1.3 Symbols

1.4 Copyright

1.5 Confirmation of receipt

1.6 Declaration of Conformity

2.0 Safety

2.1 Safety regulations

2.1.1 General

2.1.2 Installation

2.1.3 Operation and maintenance

2.1.4 Safety - Personnel

2.1.5 Safety regulations –

Pneumatic systems

2.1.6 Safety regulations –

Electrical systems

3.2 Robot axles

3.2.1 Linear axles

3.2.2 Auxiliary axes

3.3 Performance data /

Mechanical interfaces /

Technical features

3.3.1 Linear axes (main axes)

Main axis paths – Axis

lengths

3.3.2 Drives / Repeat accuracy

3.3.3 Maximum speeds of main

and linear axes

3.3.4 Maximum speeds of rotating

and auxiliary axes

3.4 Pneumatic system

3.4.1 Compressed air connection

3.4.2 Creating a vacuum

3.4.3 Pneumatic valves

3.4.4 Pressure monitoring

3.4.5 Central configuration

3.0 Specifications

3.1 Machine description

UNIROB B2 industrial robot

3.1.1 Kinematics

3.1.2 Handling loads

3.1.3 Mechanical interface

3.1.4 Delivery side selection

3.5 Guideways on main axes

3.6 Motors / Gearing

3.6.1 Maintenance-free servo

three-phase a.c. motors for

main linear axes

3.6.2 Planetary gearing for the X

(Z) and Y and Z axis drive

A: R82GBI2A.PDM

B: R82DEI2A.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section - TC

Page 1

Table of contents

3.7 Drive elements on main axes

3.7.1 X + Z-axis

3.7.2 Y-axis immersion pipe

3.8 Mechanical interface

3.8.1 Gripper interfaces

3.8.2 Manual gripper quick change

3.9 R8/B2 robot options

3.10 EUROMAP 12

3.10.1 Robot / Injection moulding

machine interface

3.10.2 Injection moulding machine

signals

3.10.3 Handling device signals

4 Transport - Installation

4.1 General

4.1.1 Storage

4.1.2 Unloading

4.1.3 Securing devices

4.1.4 Crane transportation

4.1.5 Transport weight

4.1.6 Injection moulding machine

assembly

?

4.1.7 Installation layout

4.1.8 External stand

4.1.9 Removing protective

coatings

4.2 Connecting to the power

supply

4.3 Commissioning

4.3.1 Connecting to the power

supply

4.3.2 Harting connector

4.3.3 Lubrication points

4.3.4 Compressed air supply

4.3.5 Activating the main switch

4.3.6 EMERGENCY STOP test

4.3.7 Power ON

5 Assembly and Operation

5.1 Modules

5.2 Pneumatic system

5.2.1 Directional control valves

5.2.2 Vacuum suction nozzle

5.2.3 Cleaner

5.3 Electrical systems

Section - TC

Page 2

5.3.1 Electric motors

5.3.2 Control cabinet

5.3.3 Terminal box 1

5.3.4 Terminal box 2

A: R82GBI2A.PDM

B: R82DEI2A.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Table of contents

5.4 Unirob B2 controller

5.4.1 Manual Control Device

(MCD)

5.4.2 PCS General

5.4.3 CP476 status display

5.4.4 CAN CP476 node number

switch

5.4.5 Digital inputs and outputs

5.5 B2 Control System

Handbook

5.5.1 Manual Control Device

(MCD) – Key functions

5.5.2 Start-up display

5.5.3 Status pages

5.5.4 Teach, Edit, Save, Load,

Delete, Print programs

5.5.5 Creating token programs

5.5.5.3 Token commands for additional devices

5.5.5.4 Palletising program

5.5.6 Examples of programs

5.5.7 Lock areas

5.5.8 Error messages

6 Operation

0

6.1 Start-up

6.2 Referencing

6.3 Manual operation

6.4 Single step mode

6.5 Automatic operation

6.6 Stopping the program

6.7 Automatic mode STOP

6.8 EMERGENCY STOP

5.5.5.1 Token commands: Gripper

(GRP), Robot (ROB),

Injection Moulding Device

(IMD)

5.5.5.2 PCS token commands

A: R82GBI2A.PDM

B: R82DEI2A.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section - TC

Page 3

Table of contents

7 Maintenance

7.1 General

7.2 Transport, Storage and

Waste Disposal

7.2.1 Lubricants

7.2.2 Electrical components

7.3 Electrical systems

7.3.1 Electromechanical limit

switch

7.3.2 Proximity switches

7.3.3 Indicator lights

7.3.4 Control cabinet

7.3.5 Battery change

7.4 Pneumatic system

7.4.1 Compressed air servicing

unit

7.4.2 Pneumatic connections

7.5.1 X, Y and Z axis greasing

points

7.6 Drive units

7.6.1 Belt

7.6.1.1 Belt tension - X, Y, Z axes

7.6.1.2 X and Z axis belt drive

7.6.1.3 Toothed belt replacement

7.6.1.4 Noise

7.6.2 Gears

7.7 Power guide chains

7.8 Maintenance catalogue

8 Spare parts / Diagrams

9 Customer Services

7.4.3 Pneumatic C-axes

7.4.3.1 Settings C – axis (tilting)

7.4.4 Pneumatic B-axes

7.4.4.1 Settings: B - axis (swivel)

7.4.5 Pneumatic installation

components

7.4.6 Sound absorbers

7.5 Linear axis guideways

10 Additional section for

special models

Section - TC

Page 4

A: R82GBI2A.PDM

B: R82DEI2A.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Attention! Attention! Attention! Attention!

Important notes for initial operation!

A factory password is required for robot operation.

It enables the user to switch to Password level 1.

PASSWORD: 2002

Further details of the various password levels can be found in Section 5.5.2

Start-up display.

R82GBPAA.PMD

General

General

1.1 Introduction

All persons involved in the operation of the

Battenfeld robot system must read and pay

close attention to each section of this manual.

The complete manual should always be kept

near the robot system for use by machine

operators and service engineers.

The manual should be read thoroughly, paying

special attention to the Section on ”Safety”, in

order to avoid any faults occurring and ensure

smooth operation of the robot system. It is

therefore essential that the manual is available

to all persons who are responsible for operation

of the system. The manual must be studied

before start-up. We cannot accept responsibility

for any damage or stoppages which are due to

failure to read the manual.

Should you encounter any problems in operating

the robot system, please get in touch with our

Service section or one of our agents (Addresses

can be found in the ”Servicing” section).

This operating manual only applies to operation

of the robot system depicted on the title page.

Diagrams and specifications contained in this

manual are subject to change where these are

deemed necessary in improving and developing

the robot system.

1.2 Use

The Battenfeld robot system is generally used in

conjunction with other injection moulding

equipment.

The robot is not designed for any other purpose.

We cannot be held responsible for damage

resulting from improper use. Any risks incurred

in such use shall be borne by the user.

We offer operator training courses in our

company. In-house courses can also be

arranged Contact our Training Department for

further details.

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 1

Page 1

1.3 Symbols

The safety symbol can be found in all the work

safety regulations in this operating manual

where operators and service technicians are

exposed to the risk of physical and fatal injuries.

Follow these instructions and take extreme care

in such situations. Ensure that all other users

are familiar with the work safety instructions.

Apart from the instructions found in this

operating manual, it is also important to be

aware of general safety and accident prevention

rules.

The following safety symbols and prohibiting

signs are used on the robot system. They are

intended to warn operators and service

engineers of any dangers which may result in

physical and fatal injuries.

General

”Danger of crushing” indicates there is a risk of

being crushed.

or jammed etc.

A ”Do not enter” sign warns that a surface or

area must not be used / entered.

Attention

”Attention” is used throughout this operating

manual where it is especially important that

guidelines, rules, instructions and proper work

procedures and processes are adhered to. It is

also intended to ensure that measures are taken

to prevent the robot system from being

damaged or destroyed.

Areas labelled ”Hot surface” indicate there is a

risk of burning. Operators and service engineers

must wear suitable protective clothing (refer to

DIN EN 407).

The high voltage symbol is used in sections of

the operating manual which describe where

operators and service engineers may come into

contact with electrical components and

operating materials. It is important to ensure that

local electrical safety regulations are adhered to.

Section 1

Page 2

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

General

The symbol indicating environmental hazards

indicates that there is a risk of environmental

pollution when disposing of various materials.

Local laws and regulations must be observed

when carrying out any necessary repairs or

maintenance.

1.4 Copyright

The copyrights to this operating manual are the

property of Battenfeld GmbH. The operating

manual is intended for assembly, operating and

monitoring staff. It contains regulations and

diagrams which may not be copied, distributed

or used for competitive purposes – in part or

whole - without prior authorisation, or revealed to

third parties.

1.6 Declaration of Conformity

The Declaration of Conformity can be found at

the end of this section.

1.5 Confirmation of receipt

The confirmation of receipt supplied with this

operating manual serves to verify that the

manual has been received and is complete.

Please sign the Confirmation of receipt to

confirm that you have received the complete

manual and return it to the ”Documentation”

department.

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 1

Page 3

General

Section 1

Page 4

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Fax transmission

General

To: BKU Documentation Department ++43/2252 404 - 3002

Confirmation of receipt

to confirm that the technical documentation has been received

by the customer

1) Robot - Type _______________________________________ Robot No.: ________________

2) Customer’s address ___________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

3) The robot specified under Item 1 was acquired by our company. Upon receipt of the robot

we were supplied with ___________________________________ (quantity)

operating manual (s) in __________________________ supplied.

_________________________ ___________________________________________

Date Customer’s signature

4) Supplied: _____ ___________________________________________

5) Signature of dealer or importer:

Company stamp / signature

6) The robot was supplied to the customer in accordance with the

manufacturer’s guidelines:

_______________________________

Date Signature of service engineer

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Signature if different to 5

Section 1

Page 5

General

Section 1

Page 6

A: R82GB0AA.PDM

B: R82DE0AA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Safety

2 Safety

2.1 Safety rules

2.1.1 General

The injection moulding machine and the robot

are fitted with numerous safety devices to

provide safe operation and to prevent accidents

occurring. The user is responsible for ensuring

that the safety devices are functioning properly.

The robot system has been designed and built

in accordance with currently valid safety

specifications (EN 201) and is an operationally

reliable machine. The system can, however, be

dangerous if it is operated by untrained persons

in an improper manner or not used for the

intended purpose.

Safe operation can only be guaranteed provided

the control program is not modified. Any

unauthorised changes made to the program

shall invalidate any guarantee claims.

The robot system must always be operated in

accordance with current environmental, safety

and accident prevention rules and the specified

operating procedures.

The user may not make any modifications or

changes which may affect the operating safety

of the system.

Intended use of the system shall include

adherence to the assembly, dismantling, startup, operation and maintenance procedures

specified by the manufacturer.

The responsible persons and the work

procedures involved in assembly, dismantling,

start-up, operation, conversion and maintenance

of the system must be recorded in the form of

general instructions.

Any modifications and changes which affect

safe operation of the system as well as all

maintenance work must be recorded in an

inspection book and kept for at least 10 years.

It is important to be familiar with the safety

regulations specified in the ”Injection Moulding

Machine” operating manual before using the

SGM with a robot system.

Before using the robot system in conjunction

with an attached peripheral device (e.g.

materials transport device) it is important to be

familiar with the safety regulations in the relevant

operating manual.

Peripheral devices may only be installed and

connected by authorised specialists.

The user is responsible for making sure that the

system is operated as specified in the operating

manual, i.e. in a safe manner in view of the

potential risks involved.

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Section 2

Page 1

Safety

Tool cranes may only be erected by authorised

persons. Cranes may only be used for the

purpose of mounting and removing tools. Do not

stand under suspended loads! The maximum

load is indicated on a sign on the crane.

The robot system must be disconnected from

all power supply sources whenever it is moved

to another location or moved only slightly.

Reconnect all the power supply points as

specified in the manual before restarting the

system.

If the robot system is transferred to a third party

or company it must be supplied with the

operating manual. We recommend you request

this be confirmed in writing.

2.1.2 Installation

Individual components, modules and the entire

robot system must be securely attached to the

lifting gear whenever any assembly,

disassembly, conversion, adjustment or

maintenance is work carried out in order to

guard against any potential hazards.

Only use suitable lifting gear which is in perfect

working order and has sufficient load capacity.

Do not stand or work under suspended loads.

Loads may only be attached, secured and

transported by experienced authorised

specialists.

The robot system may only be transported using

the eyebolts and elements specified in the

Section entitled ”Transport – Installation”.

The safety measures specified in DIN EN 292-2,

Item 6.1.2 must be taken into account before the

IMM is installed.

It is necessary to ensure that all the IMM power

sources are deactivated (electrical system) or

not in operation (pneumatic system) before

mounting the ”self-supporting protective grating”.

The safety devices must be tested after fitting or

carrying out repairs on electrical systems.

Potential risks may be created if untrained

persons are allowed to make adjustments to the

robot system in an improper manner and

without due regard to its intended use.

Adjustments may therefore only be made by

trained set-up engineers.

Set-up engineers are persons who, based upon

their specialist raining and experience, have a

wide knowledge of the materials, tools and

control systems used in robot systems and who

are also familiar with the relevant national work

protection and accident prevention regulations,

as well as guidelines and generally accepted

technical specifications, such as DIN norms.

Section 2

Page 2

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Safety

2.1.3 Operation and maintenance

Servicing may only be carried out when the

robot system is not in operation. Here, it is

important to follow the corresponding shut down

procedures.

Before carrying out any work on the robot

system make sure that the drives and auxiliary

devices are secured against accidental start-up,

e.g. by attaching a padlock to the main switch.

The safety devices must always be tested

before the robot system is restarted.

Make sure that all the safety devices are

properly attached before you restart the robot

system after carrying out maintenance work.

Check the gap between the IMM and the ”selfsupporting protective grating”. The gap must be

small enough to prevent anyone from reaching

inside. If it is too large, the grating must be

repositioned by the user.

Replacement parts must at least meet with the

technical requirements specified by the

manufacturers.

The user must ensure that electrical

components, motors etc. do not come into

contact with liquids.

Before carrying out any repairs, clean the

surrounding area thoroughly, especially the

connections and screw fittings.

Cleaning agents are toxic, inflammable liquids.

Follow the manufacturer’s instructions. Do not

use any aggressive cleaning agents. Use nonliming cleaning cloths.

Observe the relevant product safety regulations

when handling oil, grease and other chemical

substances.

The user must ensure that process materials

are disposed of in a safe, environmentally

friendly manner.

Safety devices may only be removed when the

IMM and the robot system have been shut down

and secured.

When operating the ejector mechanisms or the

core pullers with the safety door open, it is

necessary to ensure that there are no crushing

or shearing marks on the tool.

Always tighten any screw fittings which have

been slackened off during maintenance and

repair work. Check for leaking pipes, loose

screw fittings, signs of wear and damage.

Remedy any defects immediately.

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Section 2

Page 3

Safety

2.1.4 Safety - Personnel

Every person concerned with the IMM and the

robot system at the user’s plant must have read

and understood the relevant operating manual,

especially the section entitled ”Safety”. This

applies to all persons involved in assembly/

disassembly work, commissioning, operation

and repair activities (servicing, maintenance and

repairs). Users are recommended to require

this be confirmed in writing by each of the

persons concerned.

The IMM and the robot system may only be

operated, serviced and repaired by authorised,

qualified persons who have received special

training on how to deal with potential hazards.

Persons who are to be trained and instructed or

who are participating in general training courses

may only work on the IMM and the robot system

provided they are constantly supervised by

authorised, qualified persons.

When carrying out any form of assembly/

disassembly, conversion and maintenance

activities the IMM and the robot system must be

deactivated at the main switch and secured

against accidental start-up, e.g. by padlocking

the main switch.

During any work involving assembly/

disassembly, conversion, operation and

maintenance activities, inflammable liquids must

not be allowed to come into contact with

components which may create a fire hazard or

explode as a result of high temperatures.

The following systems must be allowed to cool

down to a safe temperature before carrying out

any work involving assembly/disassembly,

conversion or maintenance activities:

• Heating elements and guards.

• Temperature stabilisers, including

fittings, feeder/return pipes and

mountings.

Operators must not have long hair, wear loosefitting clothing or wear any form of jewellery or

rings. Here there is the risk of injury, e.g. getting

caught in moving parts.

Responsibility for assembly/disassembly,

commissioning. operation and maintenance

activities must be clearly defined and adhered to

in order to avoid any potential

misunderstandings with regard to safety.

• Water/heat transfer oil-filled surface

cooling on the worm cylinder (optional)

and/or worm feed zone (optional),

including all fittings, feeder/return pipes

and mountings.

• Water/heat transfer oil internal cooling on

the worm (optional), including all fittings,

feeder/return pipes and mountings.

Section 2

Page 4

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Safety

Operators must wear suitable protective

clothing to guard against burns caused by

contact with heating elements, temperature

stabilisers and their protective coverings,

fittings, feeder/return pipes and mountings as

well as electric motor housing sections (refer to

DIN EN 407).

The IMM and the robot system may only be

operated with the safety covers and doors

closed.

No work must be allowed to affect safe

operation of the IMM or the robot system.

Operators must ensure that no unauthorised

persons are allowed to work on the IMM or the

robot system.

The operator and any other persons may only

stand in front of the IMM on the operating side

whilst the machine is in operation.

Do not enter the IMM or the robot system

operating area or reach into the injection

moulding unit during operation.

Operators must always follow the shutting-down

procedures specified in the operating manual

when carrying out any work on the IMM and the

robot system.

The operator must immediately report any

changes which will affect the safety of the IMM

and the robot system. The robot system must

always be stopped immediately using the

emergency stop button and by deactivating the

main switch.

The IMM and the robot system may only be

operated when they are in perfect condition.

Users must issue the appropriate instructions

and carry out the corresponding checks to

ensure that the IMM and the robot system are

kept clean and tidy.

The operator must observe all safety

instructions and warning signs on the IMM and

the robot system. These must all be kept in a

legible condition.

Safety ladders and platforms must be used

when assembling/disassembling, converting,

operating or servicing overhead sections of the

IMM and robot system, in accordance with legal

rules and regulations. Do not climb onto any

parts of the IMM or robot system. Safety

harnesses must be worn when working at

heights.

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Section 2

Page 5

Safety

2.1.5 Safety regulations – Pneumatic

system

Compressed air pipes for the pneumatic system

must be properly routed and fitted. The fittings,

length and cross section must meet with the

requirements.

Carry out regular checks on all pipes, hoses,

and screw connections to determine any leaks

and recognisable exterior damage. Any damage

must be repaired immediately.

2.1.6 Safety regulations – Electrical system

The IMM and robot electrical system, which

have been designed and built according to

currently valid DIN EN 60204-1 and IEC 801-2

norms, are operationally reliable. Hazards may

however be created in the IMM robot’s electrical

system if it is improperly operated by untrained

persons or used for purposes other than its

intended use. All assembly/disassembly,

conversion and maintenance work may

therefore only be carried out by electricians

(according to DIN VDE 0105 or DIN EN 60204-

1).

The electrical system may only be connected to

a power supply of a current type, voltage and

frequency which corresponds to the

specifications on the robot system rating plate.

Electrical feeder cables must meet with the

specified requirements.

Shut down the robot system at the main switch

before carrying out any assembly/disassembly,

conversion or maintenance work. Make sure

that the electrical system is de-energised,

earthed and short-circuited.

The electrical system must be checked

regularly. Any defects such as loose

connections or burned cables must be

remedied immediately.

For safety reasons, the operator must log off the

control system after completing the set-up

operation in order to prevent unauthorised

persons from specifying any other values.

Legal rules and regulations must be observed

when carrying out any assembly/disassembly,

conversion or maintenance work.

Section 2

Page 6

A: R82GB0BA.PMD

B: R82DE0BA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Specifications

3 Specifications

The ”Specifications” section contains all the

required technical data which are usually

required for installation, start-up and operation of

the UNIROB B2 industrial robot.

3.1 UNIROB B2 Industrial robot

The UNIROB B2 industrial robot was developed

for automation of injection moulding machines

with medium clamping forces of up to 3500 kN

(385 sh tn).

3.1.1 Kinematics

The kinematic structure of the UNIROB B2

comprises a portal robot whose main axes

consist of two horizontally aligned unsupported

linear axes (X/Y) and a vertically aligned linear

axis (Y). It has a maximum of two (B/C)

auxiliary axes.

3.1.2 Handling loads

The rated and maximum load (operating

load) is 8 kg (18lb) for the component and

gripper.

3.1.3 Mechanical interface

The robot is supported by a torsion-free base

which is mounted on the IMM injector plate. The

mechanical interface can be attached to the

Battenfeld injection moulding machine and to

machines with Euromap drilling patterns.

3.1.4 Delivery side selection

Component delivery is at the rear of the IMM.

The linear axes (main axes) are driven by

electric motors whilst the B and C auxiliary axes

are pneumatically driven.

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 3

Page 1

Specifications

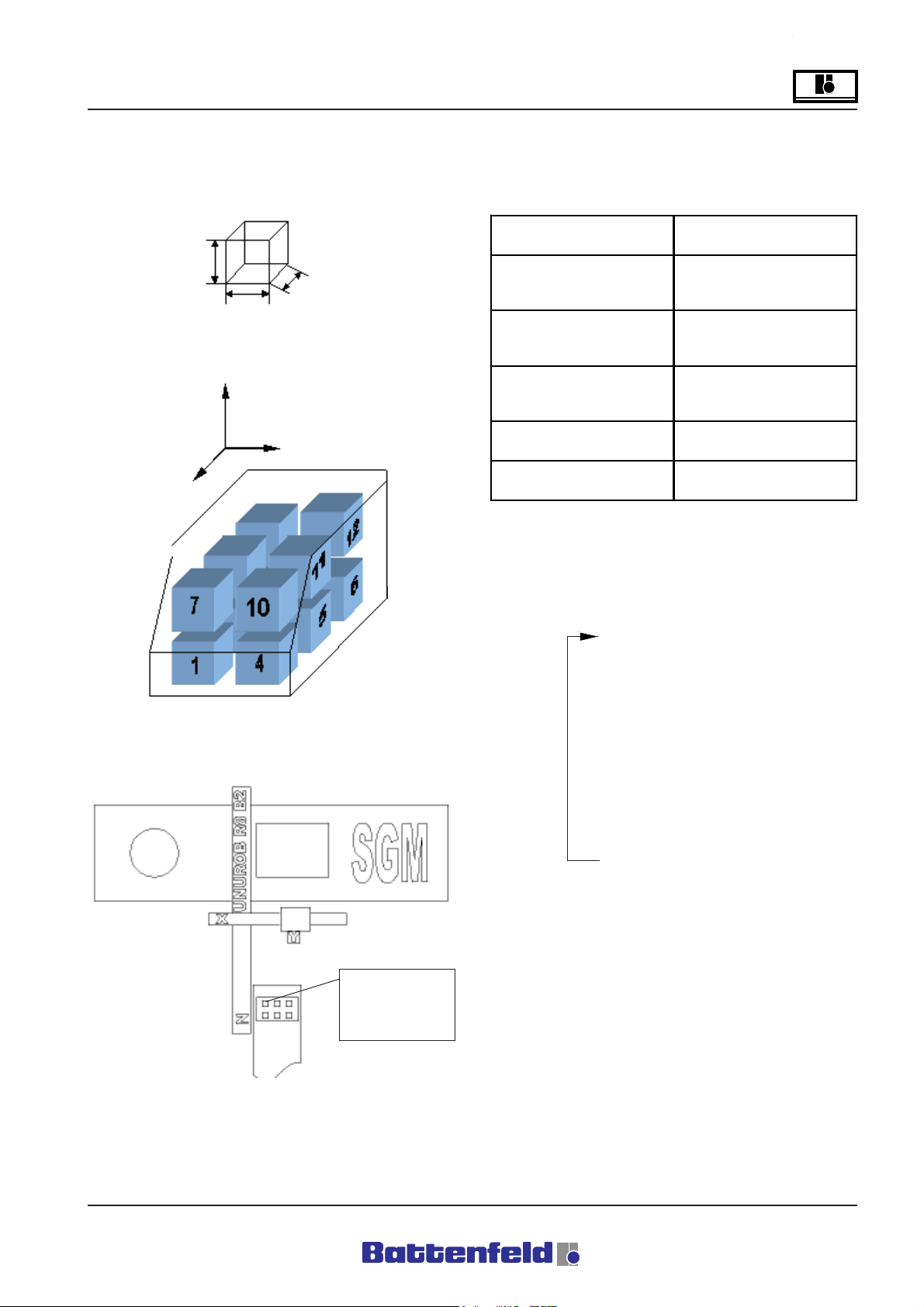

3.2 Robot axis definitions

The axes are defined according to a fixed

cartesian co-ordinate system made up of the

horizontal X and Z axes and the vertical Y axis.

Industrial robots are, in a broader sense,

numerically controlled machines. The axes are

therefore defined as in DIN 66 217.

Extensive use of DIN 66 025 creates a uniform

addressing system for the purpose of controlling

the axes.

3.2.1 Linear axes

The following linear and main axes are driven by

electric motors:

X main horizontal linear axis parallel to the

first axis of the reference co-ordinate

system (IMM longitudinal direction)

3.2.2 Auxiliary axes

The following rotating and auxiliary axes are

pneumatically driven:

B auxiliary axis parallel to the Y-axis or

other main rotating axis

C auxiliary axis parallel to the Z-axis

The most common axes are shown in the ”Axis

definition” diagram below.

Z main horizontal linear axis parallel to the

second axis of the reference co-ordinate

system (IMM transverse direction)

Y main vertical linear axis parallel to the

third axis of the reference co-ordinate

system

R8B2_001.JPG

The axis letter symbols are positioned at

suitable, clearly visible points to indicate the type

and direction of movement of each axis.

Section 3

Page 2

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Specifications

p

(Op

p

3.3 Performance data /

Mechanical interfaces /

Technical features

3.3.1 Linear axes (main axes) Main axis

paths – Axis lengths

R8 / B2

Robot

B2 4-8-15

B2 6-10-20

B2 6-12-25

mm

mm

mm

inch

inch

inch

3.3.2 Drives / Repeat accuracy

The main axes (X/Y/Z) are driven by a servo

three-phase a.c. motor.

Travel: Axis sequencing of the main and linear

axes.

The Y-axis is fitted with an immersion pipe.

400

600

600

X-axis Y-axis Z-axisUnits

15,7

23,6

23,6

800

1000

1200

31,5

39,4

47,2

1500

2000

2500

R8B2_GB002.XLS

59,1

78,7

98,4

3.3.3 Maximum speeds of main and linear

axes

Units X-axis Y-axis Z-axis

m/s

inch/s

118,1

3

157,5

4

126

3

R8B2_GB003.XLS

Position detection:

ACOPOS servo-assisted (B&R drive

mechanism)

refer to 5.3.1"Electric motors“.

3.3.4 Maximum speeds of rotating and

auxiliary axes

Axis

Turning

angle

C90° 90 °/s

B

tion)0° - 90° 90 °/s

max.

speed

Drive

neumatic

neumatic

R8B2_GB004.XLS

The performance data apply at a minimum

operating pressure of 6 bar (87 psi).

The repeat accuracy of +/- 0.1 mm (+/- 0.004

inches) is based upon the centre of the gripper

mounting.

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 3

Page 3

Specifications

3.4 Pneumatic system

3.4.1 Compressed air connection

The compressed air servicing unit for non-oil

compressed air is fitted with a pressure

regulator valve and a gauge which keeps the

operating pressure constant virtually all the time.

The minimum operating pressure is 6 bar (87

psi). Pressure losses and fluctuations make it

necessary to set the supply pressure at the

control valve to 6 bar (87 psi). ( refer to Section

7 Maintenance/Repairs).

The available initial pressure must not be

allowed to fall below 7 bar (102 psi) and or

exceed 12 bar (174 psi).

The pressure control valve is not designed to be

able to deenergise the system pneumatically.

This is done by activating the electrical main

switch via the main valve which then vents the

system.

3.4.2 Creating a vacuum

3.4.3 Pneumatic valves

The system uses pneumatic 5/2-way valves

with multiple mounting plates. The integrated

vacuum nozzle in the valve block means that it

can only be used with oil-free air.

The vacuum valve air consumption is 27 l/min

(7.13 US gallons).

3.4.4 Pressure monitoring

The standard pneumatic system is fitted with a

pressure switch which acts as a pneumaticelectronic converter (closer). If the pressure falls

below the 3 bar (44 psi) setting the robot sends

out a fault signal.

This is indicated in the display. The pneumatic

axis and gripper functions cannot operate safely

if the supply pressure drops below the specified

setting. The user shall be liable for any

consequential damage.

3.4.5 Central configuration

All the pneumatic elements are located on the

Z(X) slide except for the servicing unit.

The vacuum which is required to operate the

gripper is created using a vacuum injector

(Venturi principle). A blow out function is used to

place the components in the correct position.

Section 3

Page 4

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Specifications

3.5 Guideways on main axes

All the main linear axes have guiderails and S

(standard) precision circulating ball steering,

with a max. 0.01 mm (0.0004 inch) play and no

pretensioning.

Each of the guide units running along the ground

guiderails with hardened tracks has 4 rows of

balls.

The guiderails and guide units can be replaced

separately. The reversing flaps on the guide

units have an integrated sealing lip and a forcefeed lubrication nipple or a connector for the

central lubrication circuit.

3.6 Motors / Gearing

3.6.1 Maintenance-free servo three-phase

a.c motors for main linear axes

The servo drives produce a constant sustained

torque over the entire speed range up to a

maximum ambient temperature of 45°C (113°F).

This produces a motor temperature of 60°C

(140°F) depending upon the thermal motor time

constant.

3.6.2 Planetary gearing for the X (Z) and Y

and Z axis drive.

• single stage

• Circumferential backlash < 8 angular

minutes

• Max. input speed of 4500 rpm.

• 94-97% efficiency at a max. operating

temperature of 100°C (212°F)

• Shaft linked to motor by a clamping hub

(sleeve shaft)

• Smooth drive shaft with clamping hub

link

The servo controlled axle drives are fitted with

integrated motor brakes which are activated at

the end position.

Standard high quality bearings permit speeds

ranging from approx. 1 revolution per day up to a

maximum of 4000 rpm (depending upon the

gearing).

• Maintenance-free synthetic oil (refer to

Section 7).

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 3

Page 5

Specifications

3.7 Drive elements on main axes

3.7.1 X and Z axis

The power transmission and conversion from

rotary to linear movement is produced by means

of a toothed belt which is clamped to the slide, a

pinion attached to the gearing drive shaft and a

bearing-mounted deflection roller at the end of

the axis.

3.7.2 Y-axis immersion pipe

The power transmission and conversion from

rotary to linear movement is produced by means

of a toothed belt clamped to the immersion pipe

and a pinion attached to the gear shaft.

3.8 Mechanical interface

3.8.1 Gripper interface

The gripper flange measures 80 x 80 mm (3.15

x 3.15 inches) with a centred M6 – 40 x 20 (1.57

x 0.79 inches) drilling pattern and 60 x 25mm

(2.36 x 0.98 inches) spacing.

The quick-fitting coupling for the vacuum action

and the gripper compressed air connectors are

located on the pneumatic connecting block.

3.8.2 Manual gripper quick change

A optional manual quick change gripper device

is available for frequent gripper changes.

It is possible to change the gripper in approx. 1

minute by pushing it into the dovetail guideway

and then securing it with clamping elements.

Two mounting plates are supplied with the

gripper.

Section 3

Page 6

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Specifications

3.9 R8/B2 robot options

Description of options

RA B02 B-axis, pneumatic 0° - 90°

RM C03

RG M01 Gripper quick change100x100

RP D02 Additional clamp circuit

RP D02 Additional vacuum circuit

RE L01 Equipped acc. NFPA

Quick change flange, C-axis

(manual fasr change flange, ds/ss)

R8B2_GB005.XLS

3.10 EUROMAP 12

3.10.1 Robot / Injection moulding machine

interface

The 32-pin HAN 32A plug connector is used to

provide a secure link between the injection

moulding machine (IMM) and the handling

device (HD). HD contacts and contacts inside

the IMM are all floating and can be used with

maximum loads of 64V/200mA.

3.10.2 Injection moulding machine signals

01/09 EMERGENCY STOP (IMM)

The contact must be opened by the

EMERGENCY STOP switch on the IMM.

02/16 Start handling procedure

(IMM)

Start HD approach. The signal from the IMM

indicates that the contact is closed when the

minimum width for forward movement has been

reached. It must not be possible to accidentally

adjust the opening to a narrower setting than the

minimum required tool width.

The signal must be indicated while the tool is

open. It must not be interrupted if the machine is

switched to a different mode or when the guard

door is opened. Damage may occur if the signal

is indicated too early (incorrect or accidental

adjustment of the limit switch or position

encoder signal).

The pin assignment of the plug connector

between the injection moulding machine and the

handling device is as in EUROMAP 12.

03/11 Guard doors closed

(IMM)

Forward/Backward movement of the HD is

prevented. The contact is closed when the IMM

guard doors are closed (and the anti-slip device

is not activated).

04/16 Ejector retracted (from IMM)

The IMM signals that the ejector has been

retracted regardless of the position of the

moveable mounting plate.

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 3

Page 7

Specifications

05/16 Ejector forward (from IMM)

IMM signals that the ejector is forward.

06/16 Core pullers released, HD can move

in (IMM)

The IMM signals to the HD that the core pullers

are in position to allow the removal device to

enter (regardless of the position of the mounting

plate).

07/16 Core pullers in removal position

(IMM)

The IMM signals to the HD that the core pullers

are in position to remove the casting.

08/16 Defective casting (from IMM)

The IMM signals to the HD that the removed

casting is defective. The signal must be

triggered by ”Tool open” and can be reset by

”Close tool”.

10/16 IMM Fully automatic mode (from IMM)

The IMM signals to the HD that the operating

mode selector is set to ”Fully automatic”.

3.10.3 Handling device signals

17/32 Start Tool close sequence (by HD)

Activate Tool close: The contact is closed when

the HD has been extended to the point where

the tool can be closed and when other HD

control devices activate the Tool close

sequence.

This contact is only bypassed automatically

when the IMM is operated without the HD.

It must not be possible to activate the Tool close

action when closing the guard door, in manual

operation or by using the ”OR” function button.

The signal is activated during the closing

sequence. If the signal is cancelled, the closing

movement must be interrupted.

18/26 Tool area monitoring free (HD)

Open/close tool monitoring: The contact is

made by the limit switch on the positioning slide.

The limit switch is activated when the

positioning slide leaves its starting position in the

IMM area (before it enters the tool area). If the

link is open, the IMM can neither be opened or

closed. The contact can also be made without

the HD.

12/16 Tool closed (IMM)

The IMM signals to the HD that the closing

sequence has been completed. The ”Start

closing” signal is then cancelled.

Section 3

Page 8

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Specifications

19/27 EMERGENCY STOP (HD)

The IMM control system is deactivated when the

contact is opened. The contact must be in

series with the IMM EMERGENCY STOP.

20/32 Handling device operation (HD)

Operating mode switch: Opened contact signals

to IMM: Operation with HD (Position 1).

Closed contact signals to IMM: Operation

without HD (Position 0).

21/32 Ejector retracted (from HD)

The closing contact returns the tool ejector.

22/32 Ejector forward (from HD)

The closing contact moves the tool ejector

forward.

23/32 Core pullers in removal position

(from HD)

Move core pullers into position to remove the

moulded component.

24/32 Core pullers retracted (from HD)

Move core pullers into position to move in the

HD.

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Section 3

Page 9

Specifications

Section 3

Page 10

A: R82GB0CA.PDM

B: R82DE0CA.PDM

E: 080403 / T. Wenger

G: 020403 / TCS

Transport - Installation

4 Transport - Installation

4.1 General

Upon delivery, the handling device (hereafter

referred to as the ”robot”) it must be checked

immediately for any damage and for

completeness.

The scope of delivery also includes:

• Operating Manual

• Data carriers with the required

software

• Dummy plugs for bypassing

EMERGENCY STOP

(refer to 4.3 Commissioning)

All keys, e.g. for the switch cabinet, enclosures

etc. can be found at the main switch.

We recommend you arrange for the robot to be

assembled by Battenfeld engineers. We cannot

accept liability for any damage resulting from

improper assembly.

4.1.1 Storage

All robots are adequately packaged in order to

prevent any damage occurring in transit. The

robot must be put into operation immediately

after it has been delivered by the transport

company.

Contact our Customer Services department if

the robot is to be stored for a prolonged period

of time.

4.1.2 Unloading

We cannot guarantee the robot will function

perfectly or accept any guarantee claims

unless it has been unloaded in the proper

manner.

The robots may only be transported and

lifted horizontally on the special transport

and loading elements The lifting gear must

be secured to prevent it from slipping.

The crane carrying capacity and the lifting

gear must be at least the same weight as the

robot. (refer to Installation layout– Section

3.0 Specifications)

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Do not stand inside the danger area around

suspended loads!

Section 4

Page 1

Transport - Installation

4.1.3 Securing devices

All forms of securing devices (ropes, cable

ties, adhesive tape etc.) must be removed

before commissioning. They must always be

reattached before the machine is

transported again.

4.1.4 Crane transportation

4.1.6 Injection moulding machine assembly

Safety ladders and platforms must be used

when assembling/disassembling,

converting, operating or servicing overhead

components belonging to the robot in

accordance with legal regulations and

specifications. Do not climb onto any of the

robot components. Safety harnesses must

be worn when working at heights.

If the robot is mounted on the injection moulding

machine, it is important to ensure that the

machine is aligned to within 0.1 mm (0.004

inches). (refer to the IMM Operating Manual –

Section 4: Transport - Installation).

4.1.7 Installation layout

The precise space requirements are specified in

the ”Installation layout” diagram at the end of this

section.

4.1.5 Transport weight

Model S Length Width Height

R8 4-8-15 B2

R8 6-10-20 B2

R8 6-12-25 B2

Control cabinet B2

Section 4

Page 2

400 kg 2700 mm 1600 mm 1800 mm

882 lbs 106.3 inch 63 inch 70.9 inch

430 kg 3200 mm 1800 mm 2000 mm

984 lbs 126 inch 70.9 inch 78.7 inch

460 kg 3700 mm 1800 mm 2200 mm

1014 lbs 145.7 inch 70.9 inch 86.6 inch

30 kg 700 mm 600 mm 300 mm

66 lbs 27.6 inch 23.6 inch 11.8 inch

R8B2_164.PDF

R8B2GB_165.XLS

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Transport - Installation

4.1.8 External stand

If external stands are used, make sure that the

robot can be positioned horizontally on the

stands.

Smooth operation cannot be guaranteed unless

the robot is mounted in a horizontal position.

4.1.9 Removing protective coatings

Remove the rust protection agent from all

polished, moving parts and guideways, as well

as all non-coated and non-galvanised bolts. Use

cleaning cloths soaked in degreasing solvents,

benzine, petrol or similar agents.

These cleaning agents are toxic,

inflammable liquids. Pay attention to the

manufacturer’s instructions!

4.2 Connecting to the power

supply

The robot may only be connected up to power

supplies which conform with the current type,

voltage and frequency specified on the rating

plate (control cabinet).

It is important that users comply with

national regulations relating to earthing and

protective measures (overcurrent and

residual-current protection devices) in TN, IT

and TT systems. External and neutral

conductors (IT systems) and must be

protected against short-circuiting as

specified on the rating plate.

Conventional protective multiple earthing

(PEN conductors) may not be used. PE

conductors and N conductors (if required)

must always be connected separately.

It is also important to observe local

regulations relating to the disposal of such

liquids and impregnated cleaning cloths!

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Section 4

Page 3

Transport - Installation

Attach the outer conductors to the terminals

inside the control cabinet.

Attachment type:

Feeder + neutral conductor

L1a

L2a L3a N

5(L1, L2, L3, N, PE)

R8B2_006.BMP

Main incoming supply. Refer to the circuit

diagram on Sheet B1. No.: 10

X1

4.3. Commissioning

Before you start the commissioning

procedure, it is important to read and make

sure that you have understood all the items

contained in the ”General” and ”Safety”

sections.

This section deals with the key points to be

observed when activating the electrical systems

for the first time. It is important to adhere to each

of these points in order to ensure that the

machine runs properly.

4.3.1 Connecting to the power supply

Connect up the power supply to terminal row X1

using a 5 x 6 mm2 cable as described in 4.2..

4.3.2 Harting connector

The Harting connector point is located on the

side of the control cabinet.

18X0 HAN6 - Hand control

12X2 HAN10 - 3 x 400 V power supply

Servo booster

21X0 HAN16 - 24V DC power supply

CAN

100X1 HAN24 - Interface

Service door

80X1 HAN32 - IMM interface

Sections of the control cabinet are shown in the

circuit diagram on Sheet 71 and in Section 5

Assembly and Operation, 5.3.2 Switch cabinet.

Section 4

Page 4

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Transport - Installation

If no peripheral device is used or if there is

no service door, it is important that the

supplied dummy plugs for bypassing the

EMERGENCY STOP are connected.

The plugs can be clearly identified by the

coded sockets and pins.

4.3.3 Lubrication points

Check all lubrication points.

4.3.4 Compressed air supply

Connect the compressed air supply to the robot

service unit and adjust to 6 bar (87 psi). Refer to

Section 2.0 Safety, 2.1.5 Safety regulations –

Pneumatic systems.

4.3.5 Activate main switch

Activate the main switch on the control cabinet

to start the control system. The motors are

initially interrupted by the main fuse (40 K1).

4.3.6 EMERGENCY STOP test

To test the EMERGENCY STOP

(hardware and software) on the

manual control device, press and

release the button. Also check that

all the other EMERGENCY STOP

devices (IMM, Periphery) are

released. This procedure must be repeated

each time the main switch is activated/

deactivated.

4.3.7 Power ON

After checking the EMERGENCY

STOP line and activating the slam

button, press the START button

together with the TOTMANN button

on the MCD and observe the robot

(visual check).

Once all the initial start-up steps have been

carried out, the main contactor (40 K1) activates

the power supply at the ACOPOS servo booster.

The motor holding brakes remain activated. The

three servo axes are not controlled. (Axis

sequencing)

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Section 4

Page 5

Transport - Installation

Section 4

Page 6

A: R82GB0DA.PMD

B: R82DE0DA.PMD

E: 080403 / T. Wenger

G: 020403 / TCS

Assembly and Operation

5 Assembly and

Operation

5.1 Modules

1 Pneumatic system (refer to 5.2)

2 Electric motors (refer to 5.3.1)

3 Terminal box 1 (refer to 5.3.3)

4 Terminal box 2 (refer to 5.3.4)

?

4

2

3

1

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 1

?

Assembly and Operation

5.2. Pneumatic system

The pneumatics are a key component of the

robot system. They provide a ”source of energy”

for the auxiliary axes and the gripper clamping /

vacuum circuits.

5.2.1 Directional control valves

These valves shut off, release and divert the

compressed air channels.

Electromagnetic valve

These valves adjust the auxiliary axes (basic

and end positions) and set/reset the clamping

circuits.

Solenoid valve

R8B2_010.PDF

Principle:

Electrically activated 5/2 monostable directional

control valve Once it has been set, the valve

only remains in position while the adjusting

signal is activated. A mechanical spring resets

the valve when the signal is deactivated.

5.2.2 Vacuum suction nozzle

R8B2_009.PDF

Principle:

Electrical, indirectly activated 5/2 bistable,

directional valve. The valve remains in position

after it has been adjusted until it is reset by a

counter signal.

R8B2_011.PDF

A vacuum is created inside the vacuum

generator by the compressed air passing

through it (Venturi principle). The vacuum

generator is switched on/off by an input signal.

The housing has an integrated filter to keep out

any dirt.

Section - 5

Page - 2

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Assembly and Operation

?

5.2.3 Maintenance unit

1

2

3

1 - Pressure control valve

adjusting knob

2 - Condensate drain

3 - Pressure gauge

4 - Condensate tank

5 - Drain plug

4

5

R8B2_133.PDF

The cleaner removes any liquids and solid

materials in the compressed air flow and

regulates the air pressure.

The cleaner may only be used with properly

processed compressed air which does not

contain any aggressive agents.

A filter and a water separator remove any solid

particles and water from the compressed air.

This protects the downstream pneumatic

elements from premature wear.

5.3. Electrical systems

5.3.1 Electric motors

R8B2_013.PDF

General:

The three linear axes on the 3-axis handling

device are driven by three motors which are

controlled by a digital servo booster. (B&R/

Type:8V1090.00-2)

Axis change-over:

The motors are activated together with the required

digital inputs/outputs. (e.g. HW limit switch)

The drive is not controlled when it is not moving.

The holding brake keeps the axis in position when

the servo booster is not activated.

Attention!

The robot system pneumatics may only be

operated using oil-free air!

The booster communicates with the CP276

controller via CAN. (refer to Section 5.4.2 PCS)

Connections are specified in Section 4.2 Transport

and Installation – Electrical connections.

Electrical components may only be serviced

by qualified electricians!

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 3

?

5.3.2 Control cabinet

The control cabinet is located near the robot

system. It must be mounted in an easily

accessible position.

Assembly and Operation

1 Socket

2 Printer interface or floppy disc

DSUB9

3 Main switch

4 Conveyor belt cable gland

5 Peripheral cable gland

6 Power supply (3x400V) cable gland

7 HAN_E plug, power supply connection

3x400V ACOPOS servo booster

Section - 5

Page - 4

R8B2_014.PDF

8 HAN24 operating door interface

9 Injection moulding machine interface

EUROMAP12 HAN32

10 HAN16_E plug, 24 V DC power supply

for Terminals 1, 2 and CAN

11 HAN6 manual control panel with 24-pin

contact unit

Attention!

Refer to the circuit diagram for details of the

individual plugs!

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Assembly and Operation

?

5.3.3 Terminal box 1

Terminal box 1 is located at the end of the main

axis support. It contains the servo booster as

well as the motors and sensor analysis changeover.

Do not alter change the shielding on the

motor cables!

The fan inside the terminal box must be

switched on in order to prevent the ACOPOS

servo booster from overheating.

Basic design of the B&R 8V1090.00-2 servo

booster:

The LED is illuminated when the ACOPOS

servo booster is connected to the 24 V DC

power supply.

LED Description Colour

1 Ready green

2 Run orange

3Errorred

R8B2_GB016.XLS

After switching off the devices the intermediate

circuit requires a discharge time of at least 5

minutes. Use a suitable measuring device to

check that the current intermediate circuit

voltage is below 24 V DC to ensure that the

system is safe before carrying out any work. If

the LED indicator is extinguished this does not

necessary mean that the device has been

deenergised!

Signal LED

Ready green

R8B2_GB130.XLS

R8B2_015.PDF

Description:

Illuminated when the ACOPOS servo booster is

ready for operation and the power stage can be

activated. (Operating system available and

booted up, no permanent or temporary faults

detected).

3

Signal LED

2

1

Run orange

R8B2_GB131.XLS

Description:

Lights up when the ACOPOS servo booster

power stage is activated.

4

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 5

?

Assembly and Operation

Signal LED

Error red

R8B2_GB132.XLS

Description:

Lights up when there is a fault at the ACOPOS

servo booster. The LED is extinguished

automatically once the fault has been remedied.

t

Permanent faults include:

Motor feedback interrupted or not

connected

Low level at Enable input

Motor temperature sensor not connected

Internal fault

Temporary faults include:

24 V DC voltage supply or intermediate

circuit voltage is outside of the tolerance

range

Internal 15 V DC voltage supply is

outside of the tolerance range

Motor overheated

Servo booster overheated

LED indicators:

Red LED: Power is switched off. Green LED:

POWER ON and system stationary.

During adjustment, i.e. when an axis is moving,

the green and orange LEDs are illuminated.

The servo booster has four card sockets. All

four sockets are used in this application:

1. Socket AC110:

CAN interface

2.3.4 Socket AC112:

3 Resolver cards

5.3.4 Terminal box 2

Terminal box 2 is located on the main slide and

contains the following Beckhoff components:

LS5100 CAN coupler

KL1104 input terminals.

KL2134 output terminals.

The input and output terminals are read in and

triggered by the CP476 controller via CAN.

Braking resistance overheated, CAN or

powerlink network fault.

Section - 5

Page - 6

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Assembly and Operation

?

LS5100 transceiver

24 V DC power supply

(See circuit diagram for details of connections)

The two K bus LEDs indicate the operating

statuses of the bus terminals and the

connections to them.

Green LED illuminated: In operation, no faults.

Red LED flashing. Fault signal. Two different

frequencies.

Address

selector

Configuration

interface

left: Field bus LED

right: C bus LED

K bus

left: CAN-H

right: CAN-L

V+

Transceiver

supply

Faults are coded as follows:

Fast flashing Error code start

1st. slow sequence Error code

2nd. slow sequence Error cause

R8B2_GB018.XLS

Error code Error cause

1 pulse 0 1 2

R8B2_GB154.XLS

Description:

0 EEPROM check sum fault

1 Inline Code Buffer overrun

2 Unknown data type

Error code Error cause

2 pulse 0 n(n>0)

R8B2_GB155.XLS

Description:

Programmed configuration

Incorrect table entry / bus coupler Table

comparison (Terminal ”n”) incorrect

V-

Shield

Power contacts

R8B2_017.PDF

Error code Error cause

3 pulse 0

R8B2_GB156.XLS

Description:

Terminal bus command fault

Error code Error cause

4 pulse 0 n

R8B2_GB157.XLS

Description:

Terminal bus data error: Breakage behind

Terminal ”n” (0: coupler)

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 7

?

Assembly and Operation

Error code Error cause

5 pulse n

R8B2_GB158.XLS

Description:

Terminal bus fault in signal communication with

terminals

Error code Error cause

7 pulse n

R8B2_GB159.XLS

Description:

Non-supported terminal at ”n”.

KL1104 input terminals

Signal – LED 1

Signal – LED 3

E1

A

B

1

C

D

5

E2

KL2134 output terminals

Signal – LED 1

Signal – LED 3 Signal – LED 4

A1

Power-

contacts

A3 A4

A

CD

1

2

3

4

Top view

B

Signal – LED 2

5

A2

6

+24 V

7

0 V

8

R8B2_020.PDF

2

Power-

contacts

E3 E4

3

4

Top view

6

7

8

R8B2_019.PDF

Section - 5

Page - 8

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Assembly and Operation

?

5.4. Unirob B2 controller

The Unirob B2 is straightforward and easy to

operate.

The main axes and auxiliary axes are regulated

by a sophisticated control system.

The sequential programming process (hereafter

referred to as token programming) is structured

in a simple format which is easy to understand.

This program also facilitates universal usage.

The current token program can be saved to a

floppy disc via an RS232 interface or printed out.

5.4.1 Manual Control Device (MCD)

The MCD consists of:

• LCD (approx. 2.76") with 8 x 21

character lines.

• Green START button and a red

EMERGENCY STOP slam button.

• Four function keys (F1 to F4) for

selecting the various functions.

• Two cursor keys on either side of the

display, ON/OFF (right) and START/

STOP (left).

• A ”Num.” key for switching the numeric

pad (0-9) on/off.

• Four positioning keys for controlling the

movement and speed of the axes.

• Seven object selection keys (e.g.

gripper, IMM etc.) for use in Manual

mode and token programming.

R8B2_021.JPG

The MCD key configuration and functions are

explained in Section 5.5 Handbook.

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 9

?

Assembly and Operation

5.4.2 PCS General

The CP476 B&R SYSTEMS 2003 comprises a

sophisticated central component of the robot

system.

Features:

750 kByte User SRAM

1.5 mByte User FlashPROM

CP interface with four module slots

Two node number switches

The CP476 central unit has a system bus for

additional expansion units. Two CAN node

number switches eliminate the need for offset

adjustments. The actual node number always

corresponds to the switch position.

5.4.3 CP476 status display

R8B2_021.JPG

LED Colour Decription

CAN orange Data flow from/to CAN controller

RS232 orange

ERR red

RUN green

RDY green Lights up in Service mode

MODE green

1, 2, 3, 4 orange

Indicates whether data are

received/sent

Lights up in Service mode and if a

fault occurs

Lights up in RUN and in Service

mode

Lights up during FlashPROM

programming

LEDs indicate operating status of

each adapter module.

R8B2_GB023.XLS

Section - 5

Page - 10

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Assembly and Operation

?

RS 232 interface

Interface

User interface RS232

9-pin 7 RTS

DSUB plug 8 CTS

1NC

2RXD

3TXD

4 + 5 VCD/max. 500 ma

5GND

6NC

9NC

Connection configuration

RS232

Receive Signal

Transmit Signal

Panelboard power

Request To Send

Clear To Send

Reserved

Ground

Reserved

Reserved

R8B2_GB028.XLS

The non-isolated RS232 interface is used for

programming the central unit or the signal is

transferred to the disc drive and the printer

interface at the control cabinet.

5.4.4 CAN CP476 node number switch

R8B2_029.JPG

The CAN node number is adjusted using the two

HEX switches.

The switch positions can be determined at any

time with the aid of the user program. The

switch position is only registered by the

operating system at start-up.

Positions 00, FD, FE and FF are reserved for

special software programming functions. (not

required for standard operation)

5.4.5 Digital Input/Output module

DI439.7 Digital input module – 16 inputs, 24 V

DC

R8B2_030.JPG

Features:

16 digital inputs

24 V DC input voltage

1 ms input delay

PCS control-to-load isolation

All inputs can be sink or source-connected.

The UNIRON-B2 system uses a sink RC circuit

(refer to circuit diagram on page 14).

UNIROB-B2 switch position for Node number 1

• RIGHT ”0”

• LEFT ”1”

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 11

?

Assembly and Operation

DM435 Digital hybrid module – 8 x 24 V DC

outputs, 8 x 24 V DC inputs

R8B2_031.JPG R8B2_032.JPG

Features:

8 digital inputs

24 V DC input voltage

1 ms input delay

8 digital outputs

24 V DC switching voltage

Max. continuous current: 0.5 A per output

Short circuit and overload proof

DO722 Digital output module – 8 240 VAC /

24 V DC isolated relay outputs

Features:

8 isolated relay outputs, make contact elements

Switching voltage

240 VAC/24 V DC

2.5 A continuous current

Section - 5

Page - 12

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Handbook

UNIROB R8 – UNILOG B2

Read before using the controller and

keep it near the controller for reference purposes.

Version R82GBV00 04/03

Injection moulding

R82GBD2A.PMD

Scherl 10 • D-58527 Meinerzhagen

Battenfeld GmbH

Tel. ++49 2354/72-0 • Fax ++49 2354/72-234

Battenfeld Kunststoffmaschinen Ges.m.b.H.

Wr.Neustädter Straße 81• A - 2542 Kottingbrunn

Tel. ++43 2252/404-0 • Fax ++43 2252/404-261

www.battenfeld.com

DIN EN ISO 9001

Operation and Control System

5.5 B2 Handbook

5.5.1 Manual Control Device (MCD) – Key

functions

?

1

2

3

4

5

6

7

8

9

10

11

R8B2_033.JPG

17

16

15

14

13

12

1 – ON/OFF and START/STOP buttons

Press one of the two buttons to start/stop

the automatic program. The START

button is also used to move the servo

axes in Manual mode after entering a

numerical value. Press STOP to interrupt

the movement. The red LED in the

STOP button lights up when the power is

deactivated or when the robot has been stopped

in Automatic mode.

A: R82GB0FA.PMD

B: R82DE0FA.P65

E: 080403 / T. Weiß

G: 200103 / TCS

2 - PROG button

Press the PROG to switch to the

Programming menu and then

Programming mode in User level 1. The

orange LED indicates that Programming mode

is activated. This button is not activated in

Automatic mode.

3 - ERROR button

Press this button to switch to the Error

list. The red LED lights up if an error is

detected.

Section 5.5

Page 1

?

Operation and Control System

4 - AUTO/SINGLE button

Press this button to switch from Manual

(MAN) to Automatic (AUTO) or Single

(SINGLE) mode. The left orange LED

indicates Single mode and the right LED

indicates Fully Automatic mode.

5 - PCS button

Press this button to switch to the User

variables status page. If this button is

pressed in Programming mode, the

system switches to the PCS commands menu.

The orange LED belonging to this button lights

up on this side.

6 - REF/MAN button

Press this button to switch between

Manual mode (MAN) and Reference

(REF). It automatically switches to MAN

mode when the system is switched ON/OFF.

The right orange LED lights up in MAN mode

and the left orange LED in REF.

7 - ROB button

This button is used to carry out various

display change functions in any User

level or mode. In Manual and Automatic

mode it switches to the Axis status page. Press

the ROB button twice in User level 2 to switch to

the Service page. In Program mode it switches

to the Axis selection page The orange LED

belonging to this button lights up when one of

these pages is selected.

8 - PERIPHERY button

Press this button in Manual mode to

switch to the Periphery and Conveyor

pages. Press PERIPHERY in

Programming mode to select Periphery and

Conveyor commands. The orange LED

belonging to this button lights up when one of

these pages is selected.

9 - Move buttons

These four buttons are

used for moving the

servo and auxiliary

axes. The two outer buttons (snail, hare) adjust

the servo axis overrides. The orange snail LED

lights up at 5% override and the orange hare

LED at 100%.

The arrow buttons are used for moving the main

and the auxiliary axes. These buttons have

different functions on some of the other pages.

The LEDs light up wherever the arrow buttons

are in use.

10 - PAL button

Press the PAL button to switch to the

Palletising program status page in

Manual and Automatic mode. In

Programming mode the system switches to the

Palletising command pages. The orange LED

belonging to this button lights up when one of

these two pages is selected.

Section 5.5

Page 2

A: R82GB0FA.PMD

B: R82DE0FA.P65

E: 080403 / T. Weiß

G: 020304 / TCS

Operation and Control System

?

11 - Gripper button

Press this button to switch to the Gripper

status page in Manual and Automatic

mode. In Programming mode it switches

to the Gripper command selection page. The

orange LED belonging to the Gripper button

lights up when one of these two pages is

selected.

12 - ENTER button

Select ENTER to confirm a numerical

entry.

13 - NUM button

Press the NUM button to activate the

numerical pad and ”,” and ”+/-” on the

MCD. The orange LED belonging to this

button lights up when the numerical pad is

activated.

15 - C button

The C (CLEAR) button is activated when

the numerical keypad is on. Press to

delete the last entered number on the

numerical keypad. If this button is pressed in

the Programming page this deletes the selected

program line after an option box has been

confirmed.

16 - IMM button

Press the IMM button to display the IMM

interface status page in Manual mode. or

the IMM commands in Programming

mode. The orange LED for this button lights up

when one of these two pages is selected.

17 - Cursor buttons

The Cursor buttons are used to move the

screen cursor up and down.

14 - ESC

Press the ESC button to switch to the

Start-up display, or, in Programming

mode, to move back one level to the

program.

A: R82GB0FA.PMD

B: R82DE0FA.P65

E: 080403 / T. Weiß

G: 200103 / TCS

Section 5.5

Page 3

?

Operation and Control System

Green START BUTTON on MCD

Press the START BUTTON to

activate the power supply (main

contactor).

EMERGENCY STOP BUTTON on MCD

The red Emergency Stop button is

intend to protect both the machine

and the machine operators.

TOTMANN BUTTON

The TOTMANN button must

be pressed for every

movement.

5.5.2 Start-up display

1

R8B2_GB052.JPG

2

These details appear in the MCD display when

the controller is activated.

Top line:

1 ”err” flashes if an error has been

detected.

2 The current operating mode is shown

here, i.e. MAN (Manual mode), REF

(Reference), AUTO (Automatic), SINGLE

(Single Step mode) or HOME after

referencing.

Enter the password in the box. Set to the

required language.

Password level:

0 The axes can be moved manually and

the Automatic program stopped/started.

1 As in Level 0, users can write, load and

delete token programmes.

2 Service level (only to be used by

Battenfeld service engineers).

Section 5.5

Page 4

A: R82GB0FA.PMD

B: R82DE0FA.P65

E: 080403 / T. Weiß

G: 020304 / TCS

Operation and Control System

?

5.5.3 Status pages

Axis status page (ROB button)

Press ROB button.

Use the arrow buttons to move the

selected axes.

In Automatic mode it is possible to stop the

current program by pressing F1. Select F4 to

switch to the Program status page to monitor

the current program.

R8B2_GB054.JPG

R8B2_GB053.JPG

Press F4 button.

The ”Snail” and ”Hare” buttons are

used to adjust the override.

The current axis positions (Actual values) are

shown on the Axis status page in both Manual

and Automatic mode.

In Manual mode the axis moves next to the

cursor.

At Password level 1 or 2, select F1 to display

”Sdata” (Service data) and F3 for ”L.Area” (Lock

area). For further details, refer to Section 5.5.7

Lock areas.

R8B2_GB055.JPG

A: R82GB0FA.PMD

B: R82DE0FA.P65

E: 080403 / T. Weiß

G: 200103 / TCS

Section 5.5

Page 5

?

Operation and Control System

Gripper status page (Gripper button)

Press Gripper button.

R8B2_GB056.JPG

This display shows the current clamping and

vacuum circuit statuses in Manual and

Automatic mode. The clamping circuits can be

set and reset in Manual mode.

IMM status page (IMM button)

Press IMM button.

R8B2_GB057.JPG

R8B2_GB058.JPG

This display shows all signals sent from the

robot system to the IMM (digital outputs) and all

signals sent from the IMM to the robot system

(digital inputs) in Manual and Automatic mode.

The digital outputs can be set and reset in

Manual mode.

Section 5.5

Page 6

A: R82GB0FA.PMD