Portable Grain Belt Conveyor

Swing Away

Operator’s Manual

This manual applies to:

1500 Series: 1565 SA, 1575 SA, 1585 SA, 1590 SA, 15100 SA

2000 Series: 2065 SA, 2075 SA, 2085 SA, 2095 SA, 20105 SA, 20110 SA, 20120 SA

2400 Series: 2465 SA, 2475 SA, 2485 SA, 2495 SA, 24105 SA, 24110 SA, 24120 SA

Original Instructions

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: P151114 R3

Revised: August 2017

We strongly recommend that all personnel associated with this equipment be trained in the correct operational

and safety procedures required for this product. This product has been designed and constructed according to

general engineering standards, other local regulations may apply and must be followed by the operator. Use the

sign-off sheet below to record initial and periodic reviews of this manual with all such personnel.

Date

Employee Signature Employer Signature

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

CONTENTS

1. Introduction ............................................................................................................................................ 5

1.1. Serial Number Location............................................................................................................ 5

1.2. Intended Use ............................................................................................................................ 5

1.2.1 Misuse ........................................................................................................................ 6

2. Safety....................................................................................................................................................... 7

2.1. Safety Alert Symbol and Signal Words..................................................................................... 7

2.2. General Safety .......................................................................................................................... 7

2.3. Overhead Power Lines ............................................................................................................. 8

2.4. Moving Conveyor Belt Safety................................................................................................... 8

2.5. Upending .................................................................................................................................. 8

2.6. Rotating Parts Safety................................................................................................................ 8

2.7. Work Area Safety ..................................................................................................................... 8

2.8. Guards Safety ........................................................................................................................... 9

2.9. Raising and Lowering the Conveyor....................................................................................... 10

2.10. Hydraulic Winch Safety ........................................................................................................ 10

2.11. Conveyor Stability ................................................................................................................ 10

2.12. Towing the Conveyor ........................................................................................................... 11

2.13. Drives and Lockout Safety.................................................................................................... 11

2.13.1 PTO Driveline Safety............................................................................................... 12

2.13.2 Hydraulic Power Safety .......................................................................................... 13

2.14. Tire Safety............................................................................................................................. 14

2.15. Personal Protective Equipment............................................................................................ 14

2.16. Safety Equipment ................................................................................................................. 15

2.17. Safety Decals ........................................................................................................................ 15

2.17.1 Decal Installation/Replacement............................................................................. 15

2.17.2 Safety Decal Locations and Details ........................................................................ 16

3. Transport............................................................................................................................................... 31

3.1. Transport Safety ..................................................................................................................... 31

3.2. Transport Preparation............................................................................................................ 31

3.3. Connect the Conveyor to the Towing Vehicle ....................................................................... 32

4. Placement ............................................................................................................................................. 33

4.1. Placement Safety.................................................................................................................... 33

4.2. Positioning the Conveyor ....................................................................................................... 33

4.3. Extendable Axle Positioning ................................................................................................... 35

4.4. Raising and Lowering ............................................................................................................. 36

4.5. Hitch Adjustment.................................................................................................................... 37

4.6. Extended Swing Arm .............................................................................................................. 38

4.7. Raising and Lowering the Intake Hopper............................................................................... 39

4.8. Hydraulic Power Swing........................................................................................................... 40

4.9. Electric Power Swing Operation............................................................................................. 41

4.10. Collapsible Hopper Cloth Control......................................................................................... 43

4.11. Conveyor Operating Angles ................................................................................................. 43

5. Operation .............................................................................................................................................. 46

5.1. Operation Safety .................................................................................................................... 46

5.2. Start-up and Break-in ............................................................................................................. 46

5.3. Operation - Swing Away Transfer Hydraulic Motor Drive..................................................... 47

P151114 R3 3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

5.4. Operation - PTO Drive ............................................................................................................ 48

5.5. Loading Area........................................................................................................................... 48

5.6. Conveyor Belt Speed .............................................................................................................. 49

5.7. Emergency Shutdown ............................................................................................................ 49

5.8. Restarting with a Full Tube .................................................................................................... 49

5.9. Shutdown ............................................................................................................................... 49

5.10. Clean Out.............................................................................................................................. 50

5.11. Conveying Fertilizer.............................................................................................................. 50

5.12. Storage.................................................................................................................................. 52

6. Maintenance ......................................................................................................................................... 53

6.1. Maintenance Safety ............................................................................................................... 53

6.2. Maintenance Schedule ........................................................................................................... 53

6.3. Visually Inspect the Equipment.............................................................................................. 54

6.4. Lubricate the Equipment........................................................................................................ 55

6.4.1 PTO Driveline............................................................................................................ 55

6.5. Oil the Chain Coupler ............................................................................................................. 55

6.6. Check the Gearbox Oil............................................................................................................ 56

6.7. Change the Gearbox Oil ......................................................................................................... 56

6.8. Inspect Hydraulic Hoses and Fittings ..................................................................................... 57

6.9. Inspect the Hopper Flashing .................................................................................................. 57

6.10. Check the Roller Bearings .................................................................................................... 57

6.11. Check the Roller Lagging ...................................................................................................... 57

6.12. Tension the Conveyor Belt................................................................................................... 57

6.12.1 S-Drive Pinch Roller................................................................................................ 58

6.13. Align the Conveyor Belt........................................................................................................ 58

6.13.1 Adjust the Rollers ................................................................................................... 59

6.13.2 Adjust the Belt Return Wear Blocks....................................................................... 60

6.14. Inspect Belt Lacing................................................................................................................ 61

6.15. Replace the Belt Lacing ........................................................................................................ 61

6.16. Replace the Conveyor Belt................................................................................................... 61

6.17. Clean and Wash the Equipment .......................................................................................... 63

6.18. Repack the Wheel Bearings with Grease............................................................................. 63

6.19. Check/Adjust the Truss Cables............................................................................................. 64

6.20. Inspect and Service the Hydraulic Winch and Lift Cable..................................................... 66

7. Troubleshooting.................................................................................................................................... 67

8. Specifications ........................................................................................................................................ 70

9. Appendix ............................................................................................................................................... 72

9.1. Power Swing Remote Transmitter Instructions ..................................................................... 72

9.2. Programming Receivers.......................................................................................................... 73

10. Batco Limited Warranty ..................................................................................................................... 75

4 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 1. INTRODUCTION

1. Introduction

Thank you for purchasing a Batco Portable Grain Belt Conveyor. This equipment will allow safe and

efficient operation when you read and follow all of the instructions contained in this manual. With

proper care, your conveyor will provide you with many years of trouble-free operation.

Keep this manual handy for frequent reference and to review with new personnel. A sign-off form is

provided on the inside front cover for your convenience. If any information in this manual is not

understood or if you need additional information, please contact your local distributor or dealer for

assistance.

This manual should be regarded as part of the equipment. Suppliers of both new and second-hand

equipment are advised to retain documentary evidence that this manual was provided with the

equipment.

1.1. Serial Number Location

Always give your dealer the serial number on your conveyor (shown below) when ordering parts or requesting

service or other information. Please record this information in the table below for easy reference.

Model Number

Serial Number

Date Received

1.2. Intended Use

The conveyor is designed solely for use in the intended agricultural use as listed below. Use in any other way is

considered as contrary to the intended use. Compliance with and strict adherence to the conditions of

P151114 R3 5

1. INTRODUCTION PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

operation and maintenance as specified by the manufacturer, also constitute essential elements of the intended

use.

The conveyor should be operated, maintained, serviced, and repaired only by persons who are familiar with its

particular characteristics and who are acquainted with the relevant safety procedures.

Accident prevention regulations and all other generally recognized regulations on safety and occupational

medicine must be observed at all times.

Any modifications made to the conveyor may relieve the manufacturer of liability for any resulting damage or

injury.

Intended use for the conveyor:

• Handling grain, pulse crops, treated seeds, or other similar materials.

• Handling fertilizer when strict operation and cleanout procedures are followed as noted in Operation

section.

Use in any other way is considered as contrary to the intended use and is not covered by the warranty.

1.2.1 Misuse

Do not use the conveyor for:

• transferring material other than dry, free-flowing food-grains.

• conveying canola, or any other oilseeds

• lifting or using as a hoist or crane.

6 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

2. Safety

2.1. Safety Alert Symbol and Signal Words

This safety alert symbol indicates important safety messages in this manual. When you see

this symbol, be alert to the possibility of injury or death, carefully read the message that

follows, and inform others.

Signal Words: Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE with the safety

messages. The appropriate signal word for each message has been selected using the definitions below as a

guideline.

Indicates an imminently hazardous situation that, if not avoided, will result in serious injury or

death.

Indicates a hazardous situation that, if not avoided, could result in serious injury or death.

Indicates a hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation that, if not avoided, may result in property damage.

2.2. General Safety

The safety information in the safety section of this manual applies to all safety practices. Specific safety

information (such as Operation Safety), can be found in the appropriate section.

YOU are responsible for the SAFE use and maintenance of your conveyor. YOU must ensure that you and

anyone else who is going to work around the conveyor understands all procedures and related SAFETY

information contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect you, but also the people around

you. Make these practices a working part of your safety program. All accidents can be avoided.

• It is the conveyor owner, operator, and maintenance personnel's responsibility to

read and understand ALL safety instructions, safety decals, and manuals and follow

them when assembling, operating, or maintaining the equipment.

• Owners must give instructions and review the information initially and annually with all personnel before

allowing them to operate the conveyor. Untrained users/operators expose themselves and bystanders to

possible serious injury or death.

• The conveyor is not intended to be used by children.

• Use the conveyor for its intended purposes only.

• Do not modify the conveyor in any way without written permission from the manufacturer. Unauthorized

modification may impair the function and/or safety, and could affect the life of the conveyor. Any

unauthorized modification of the conveyor will void the warranty.

P151114 R3 7

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

2.3. Overhead Power Lines

• When operating or moving, keep conveyor away from

overhead power lines and devices.

• The conveyor is not insulated.

• Electrocution can occur without direct contact.

2.4. Moving Conveyor Belt Safety

• DO NOT step on or touch moving conveyor belt.

• Shut off and lock out power to adjust, service, or clean.

2.5. Upending

• Anchor intake end and/or support discharge end to prevent

upending.

• Intake end must always have downward weight. Do not

release until attached to tow bar or resting on ground.

• Do not raise intake end above tow bar height.

• Empty the conveyor and fully lower before moving.

2.6. Rotating Parts Safety

• Keep body, hair, and clothing away from rotating pulleys,

belts, chains, and sprockets.

• Do not operate with any guard removed or modified. Keep

guards in good working order.

• Shut off and remove key or lock out power source before

inspecting or servicing machine.

2.7. Work Area Safety

• Have another trained person nearby who can shut down the conveyor in case of accident.

• The work area should be kept clear of bystanders.

• Keep the work area clean and free of debris.

8 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Figure 1. Conveyor Work Area

2.8. Guards Safety

• Keep guards in place and do not operate unless all guards are in place.

• Do not walk on, step on, or damage guards.

• Lock out power before removing a guard.

• Ensure all guards are replaced after performing maintenance.

P151114 R3 9

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

2.9. Raising and Lowering the Conveyor

• Before raising/lowering/moving/adjusting the conveyor, make sure the area around the

conveyor is clear of obstructions and/or untrained personnel. Never allow anyone to stand

on or beneath the conveyor when it is being placed.

• Lower the conveyor to its lowest position when not in use.

• Empty the conveyor before raising or lowering.

• Do not get on or beneath the conveyor when raising or lowering.

• Raise and lower conveyor on reasonably level ground only.

• Never attempt to increase height of the tube by positioning wheels on lumber, blocks, or by

any other means. To do so will result in damage to conveyor and/or serious injury.

2.10. Hydraulic Winch Safety

When Equipped:

• Keep away from rotating cable drum and winch cable. Do not touch or grab cable while

winch is being operated or use hands to guide the cable. Failure to heed could result in

serious injury.

• Inspect cable and cable clamps before installing and using hydraulic winch. Replace cable if

frayed or damaged. Tighten cable clamps if necessary.

• Do not continue to supply power to hydraulic winch after the conveyor has reached full up

position.

• Do not disconnect hydraulic quick couplers when lines are pressurized.

• Make sure lift cable is seated in cable pulley.

• Always keep a minimum of 3 cable wraps on the cable drum.

2.11. Conveyor Stability

• Transport and place equipment on reasonably level ground when raising, lowering,

positioning, or operating.

• Chock wheels and anchor intake end after placement.

10 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

2.12. Towing the Conveyor

• Check with local authorities regarding transport on public roads. Obey all applicable laws

and regulations.

• Always travel at a safe speed, never exceeding 20 mph (32 km/h).

• Reduce speed on rough surfaces.

• Do not transport on slopes greater than 20°.

• Use caution when turning corners or meeting traffic.

• Make sure the SMV (slow moving vehicle) emblem and all the lights and reflectors that are

required by local authorities are in place, are clean, and can be seen by all over-taking and

oncoming traffic.

• Always use hazard-warning flashers on tractor/towing vehicle when transporting unless

prohibited by law.

• Do not allow riders on the conveyor or towing vehicle during transport.

• Attach to towing vehicle with an appropriate pin and retainer. Always attach safety chain(s).

• Place the conveyor in the transport position before moving on roads.

2.13. Drives and Lockout Safety

Inspect the power source(s) before using and know how to shut down in an emergency.

Whenever you service or adjust your equipment, make sure you shut down the power

source and unplug or remove the key (as applicable) to prevent inadvertent start-up and

hazardous energy release. Know the procedure(s) that applies to your equipment from the

following power source(s). Ensure that all personnel are clear before turning on power to

equipment.

P151114 R3 11

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

2.13.1 PTO Driveline Safety

Drive

• Keep body, hair, and clothing away from rotating PTO

driveline.

• Make certain the driveline shields telescope and rotate freely

on driveline before attaching.

• Make certain the driveline is securely attached at both ends.

• Do not operate conveyor unless all driveline, tractor, and

equipment shields are in place and in good working order.

• Do not exceed operating speed of 540 rpm.

• Keep universal joint angles small and equal. Do not exceed

maximum recommended length for PTO driveline.

• Engage tractor park brake and/or chock wheels.

Lockout

• Position all controls in neutral, shut off tractor’s engine, and remove key from tractor.

• If removing key is impossible, remove PTO driveline from tractor.

12 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

2.13.2 Hydraulic Power Safety

Power Source

• Refer to the rules and regulations applicable to the power

source operating your hydraulic drive.

• Do not connect or disconnect hydraulic lines while system is

under pressure.

• Keep all hydraulic lines away from moving parts.

• Escaping hydraulic fluid under pressure will cause serious

injury if it penetrates the skin surface (serious infection or

toxic reaction can develop). See a doctor immediately if

injured.

• Use metal or wood as a backstop when searching for

hydraulic leaks and wear proper hand and eye protection.

• Check all hydraulic components are tight and in good

condition. Replace any worn, cut, abraded, flattened, or

crimped hoses.

• Clean the connections before connecting to equipment.

• Do not attempt any makeshift repairs to the hydraulic fittings

or hoses with tape, clamps, or adhesive. The hydraulic

system operates under extremely high pressure; such repairs

will fail suddenly and create a hazardous and unsafe

condition.

Lockout

• Always place all hydraulic controls in neutral and relieve

system pressure before disconnecting or working on

hydraulic system.

P151114 R3 13

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

2.14. Tire Safety

Failure to follow proper procedures when mounting a tire on a

wheel or rim can produce an explosion that may result in

serious injury or death.

• DO NOT attempt to mount a tire unless you have the proper

equipment and experience to do the job.

• Have a qualified tire dealer or repair service perform

required tire maintenance.

• When replacing worn tires, make sure they meet the original

tire specifications. Never undersize the replacement tire.

• DO NOT weld to the tire rim with the tire mounted on the

rim. This action may cause an explosion which could result in

serious injury or death.

• Inflate tires to the manufacturer’s recommended pressure.

• Tires should not be operated at speeds higher than their

rated speed.

• Keep wheel lug nuts tightened to manufacturer’s

recommendations.

• Never reinflate a tire that has been run flat or seriously

under-inflated without removing the tire from the wheel.

Have the tire and wheel closely inspected for damage before

remounting.

2.15. Personal Protective Equipment

The following Personal Protective Equipment (PPE) should be worn when operating or maintaining the

equipment.

Safety Glasses

• Wear safety glasses at all times to protect eyes from debris.

Coveralls

• Wear coveralls to protect skin.

Hard Hat

• Wear a hard hat to help protect your head.

14 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Steel-Toe Boots

• Wear steel-toe boots to protect feet from falling debris.

Work Gloves

• Wear work gloves to protect your hands from sharp and rough edges.

Dust Mask

• Wear a dust mask to prevent breathing potentially harmful dust.

2.16. Safety Equipment

The following safety equipment should be kept on site:

Fire Extinguisher

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and

accessible place.

First-Aid Kit

• Have a properly-stocked first-aid kit available for use should the need arise, and

know how to use it.

2.17. Safety Decals

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Replacement safety decals are available free of charge from your distributor, dealer, or factory.

2.17.1 Decal Installation/Replacement

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion with the exposed sticky backing

in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign backing paper.

P151114 R3 15

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

2.17.2 Safety Decal Locations and Details

Replicas of the safety decals that are attached to the conveyor and their messages are shown in the figure(s)

that follow. Safe operation and use of the conveyor requires that you familiarize yourself with the various safety

decals and the areas or particular functions that the decals apply to, as well as the safety precautions that must

be taken to avoid serious injury, death, or damage.

Figure 2. Conveyor Safety Decal Locations

16 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Figure 3. Swing Away Safety Decal Locations

P151114 R3 17

P1513022

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Figure 4. S-Drive Safety Decal Locations

Figure 5. PTO Front Drive Safety Decal Locations

18 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Figure 6. Transport Arm Safety Decal Locations

P151114 R3 19

WARNING

ROLLOVER / TRANSPORT

HAZARD

To prevent serious injury or death:

• Fully extend axles before raising tube.

• Retract axles before transporting.

To prevent serious injury or death:

• Fully extend axles before raising tube.

• Retract axles before transporting.

ROLLOVER / TRANSPORT

HAZARD

WARNING

Country of Origin Part Number

CAUTION

To prevent personal injury or

damage to equipment, close valve in

lift cylinder hydraulic line after raising

equipment into position.

To prevent personal injury or

damage to equipment, close valve

in lift cylinder hydraulic line after

raising equipment into position.

CAUTION

Country of Origin Part Number

To prevent serious injury or death:

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

• Keep all components in good repair.

HIGH PRESSURE FLUID HAZARD

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

HIGH PRESSURE FLUID HAZARD

WARNING

Country of Origin Part Number

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1. Safety Decals

Part Number

P1513044

P1513010

P1513035

Description

20 P151114 R3

NOTICE

To prevent damage, wheels must be

free to move when raising or lowering

equipment.

When equipment is positioned, chock

all wheels.

To prevent damage, wheels must be

free to move when raising or lowering

equipment.

When equipment is positioned, chock

all wheels.

NOTICE

Country of Origin Part Number

To prevent death or serious injury:

• When operating or moving, keep equipment away from

overhead power lines and devices.

• Fully lower equipment before moving.

This equipment is not insulated.

Electrocution can occur without direct contact.

ELECTROCUTION HAZARD

DANGER

Country of Origin Part Number

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Table 1 Safety Decals (continued)

Part Number

P1513052

P1513046

Description

P151114 R3 21

CAUTION

NOT A STEP - SLIP HAZARD

To prevent injury or damage to

the equipment, do not use belt

guard as a step.

Country of Origin Part Number

To prevent injury or damage to the

equipment, do not use belt guard as

a step.

NOT A STEP - SLIP HAZARD

CAUTION

WARNING

UPENDING HAZARD

To prevent death or serious injury:

• Anchor intake end and/or support

discharge end to prevent upending.

• Intake end must always have downward

weight. Do not release until attached to

tow bar or resting on ground.

• Do not raise intake end above tow bar

height.

• Empty conveyor and fully lower before

moving.

To prevent death or serious injury:

UPENDING HAZARD

WARNING

• Anchor intake end and/or support

discharge end to prevent upending.

• Intake end must always have downward

weight. Do not release until attached to

tow bar or resting on ground.

• Do not raise intake end above tow bar

height.

• Empty conveyor and fully lower before

moving.

Country of Origin Part Number

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1 Safety Decals (continued)

Part Number

P1513030

Description

P1513042

22 P151114 R3

WARNING

TRANSPORT HAZARD

To prevent serious injury or death:

• Securely attach equipment to vehicle with correct

pin and safety chains.

• Use a tow vehicle to move equipment.

To prevent serious injury or death:

• Securely attach equipment to vehicle with

correct pin and safety chains.

• Use a tow vehicle to move equipment.

TRANSPORT HAZARD

WARNING

Country of Origin Part Number

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Table 1 Safety Decals (continued)

Part Number

P1513037

Description

P151114 R3 23

Country of Origin Part Number

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate,

or maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• Do not modify the equipment. Keep in good

working order.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for

replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect

power before resetting overloads.

WARNING

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1 Safety Decals (continued)

Part Number

P1513001

Description

24 P151114 R3

NOTICE

To prevent belt damage, use correct belt tension and do not attempt to

adjust belt tracking with the take-up roller.

To set correct belt tension:

• While conveyor is running empty, fully tighten nut against the pretensioner

(take-up pipe) so that spring is not visible.

• Ensure take-up roller is tensioned equally by using a tape to measure distance

"X

• After the conveyor belt has been tensioned, check the alignment of all other

s-drive rollers and periodically afterward.

See manual for complete instructions.

TAKE-UP ROLLER

X

PRETENSIONER

NUT

PRETENSIONER

NUT

TAKE-UP ROLLER

X

To prevent belt damage, use correct belt tension and do

not attempt to adjust belt tracking with the take-up roller.

To set correct belt tension:

• While conveyor is running empty, fully tighten nut against the

pretensioner (take-up pipe) so that spring is not visible.

• Ensure take-up roller is tensioned equally by using a tape to

measure distance “X”.

• After the conveyor belt has been tensioned, check the alignment

of all other s-drive rollers and periodically afterward.

See manual for complete instructions.

NOTICE

Country of Origin Part Number

To prevent death or serious injury:

• DO NOT step on or touch moving conveyor belt.

• Shut off and lock out power to adjust, service, or

clean.

OPEN BELT CONVEYOR

WARNING

Country of Origin Part Number

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Table 1 Safety Decals (continued)

Part Number

P1513022

P1513045

Description

P151114 R3 25

To prevent serious injury or death:

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

• Keep all components in good repair.

HIGH PRESSURE FLUID HAZARD

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting or

disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

HIGH PRESSURE FLUID HAZARD

WARNING

Country of Origin Part Number

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1 Safety Decals (continued)

Part Number

P1513035

Description

26 P151114 R3

WARNING

ENTANGLEMENT HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

• Do not operate with any guard removed or

modified. Keep guards in good working order.

• Shut off and remove key or lock out power source

before inspecting or servicing machine.

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

• Do not operate with any guard removed or

modified. Keep guards in good working order.

• Shut off and remove key or lock out power

source before inspecting or servicing machine.

ENTANGLEMENT HAZARD

WARNING

Country of Origin Part Number

WARNING

HIGH PRESSURE FLUID HAZARD

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before disconnecting hydraulic line.

• Wear proper hand and eye protection, and use wood

or cardboard, not hands, when searching for leaks.

HIGH PRESSURE FLUID HAZARD

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve system pressure before repairing, adjusting

or disconnecting.

• Wear proper hand and eye protection when searching

for leaks. Use wood or cardboard instead of hands.

WARNING

Country of Origin Part Number

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Table 1 Safety Decals (continued)

Part Number

P1513002

Description

P1513036

P151114 R3 27

NOTICE

To prevent damage, tighten/snug bolts as shown when

assembling or maintaining the conveyor.

To prevent damage, tighten/snug bolts as shown

when assembling or maintaining the conveyor.

NOTICE

Country of Origin Part Number

NOTICE

This equipment is not intended for transport

on public roads. If it must be moved, check

local regulations.

To avoid damaging the equipment:

• Be careful when turning corners.

• Watch for low overhead objects.

• Retract axles before transporting unit.

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1 Safety Decals (continued)

Part Number

P1513032

Description

P1513041

28 P151114 R3

Country of Origin Part Number

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate,

or maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• Do not modify the equipment. Keep in good

working order.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for

replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect

power before resetting overloads.

WARNING

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 2. SAFETY

Table 1 Safety Decals (continued)

Part Number

P1513001

Description

P151114 R3 29

DANGER

ROTATING PTO DRIVELINE

HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

PTO driveline.

• Do not operate equipment unless all driveline,

tractor, and equipment shields are in place and in

good working order.

• Make certain the driveline shields turn freely on

driveline.

• Make certain the driveline is securely attached at

both ends.

• Do not exceed operating speed of 1000 rpm.

• Keep u-joint angles small and equal. Do not

exceed maximum recommended length for PTO

driveline.

DANGER

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

PTO driveline.

• Do not operate equipment unless all driveline,

tractor, and equipment shields are in place and

in good working order.

• Make certain the driveline shields turn freely on

driveline.

• Make certain the driveline is securely attached

at both ends.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not

exceed maximum recommended length for PTO

driveline.

ROTATING PTO DRIVELINE

HAZARD

Country of Origin Part Number

WARNING

To prevent serious injury or death:

• Keep away from rotating cable drum and winch

cable.

• Inspect lift cable periodically; replace if damaged.

• Inspect cable clamps periodically; tighten if

necessary.

To prevent death or serious injury:

• Keep away from rotating cable drum and winch

cable.

• Inspect lift cable periodically; replace if damaged.

• Inspect cable clamps periodically; tighten if necessary.

WARNING

Country of Origin Part Number

2. SAFETY PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 1 Safety Decals (continued)

Part Number

P1513048

P1513038

Description

30 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 3. TRANSPORT

3. Transport

Before continuing, ensure you have completely read and understood this manual’s

Safety section, in addition to the safety information in the section(s) below.

3.1. Transport Safety

• Check with local authorities regarding transport on public roads. Obey all applicable laws

and regulations.

• Always travel at a safe speed, never exceeding 20 mph (32 km/h). Reduce speed on rough

surfaces. Use caution when turning corners or meeting traffic.

• Yield to other drivers and allow faster traffic to pass.

• Make sure the SMV (slow moving vehicle) emblem and all the lights and reflectors that are

required by local authorities are in place, are clean, and can be seen by all over-taking and

oncoming traffic. Always use hazard-warning flashers on tractor/towing vehicle when

transporting unless prohibited by law.

• Do not transport during times of limited visibility such as fog, snow, or heavy rain. Take extra

precautions at night and at dusk.

• Keep others away from the transport vehicle and conveyor.

• Do not allow riders on the conveyor or towing vehicle during transport.

• Stay away from overhead obstructions and power lines when operating and transporting.

Electrocution can occur without direct contact.

• Fully lower the conveyor before transporting, and only raise when next to storage facility.

• Attach to towing vehicle with a pin and retainer. Always attach safety chain(s).

• Do not raise the intake end above drawbar, upending may occur.

• Empty conveyor of all grain before transporting. Transporting a full conveyor will place

excessive loads on the tube, frame, axle, hitch, and tow vehicle.

• Do not transport on slopes greater than 20°.

• Do not transport with an under-inflated tire(s).

• If the conveyor wheels are partially or fully buried in snow or grain, failure to clear area

around the wheels before transporting may cause damage to the conveyor or result in

serious injury.

3.2. Transport Preparation

1. It is not recommended that the conveyor be transported faster than 20 mph (32 km/h). Table 2 on page 32

references the acceptable transport speed as per the ratio of tractor weight versus conveyor weight. See

Specifications for conveyor weights.

2. Ensure the conveyor will clear any overhead obstructions or electrical wires prior to transporting. Refer to

Specifications for the transport height of your conveyor.

3. Longer conveyors have a large turning radius. Allow ample room for turning as discharge end may swing

dramatically.

P151114 R3 31

3. TRANSPORT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Table 2. Speed versus Weight Ratio

Weight or fully equipped or loaded implement(s)

Road Speed

relative to weight of towing machine

Up to 32 km/h (20 mph)

Up to 16 km/h (10 mph)

Do not tow if More than 2 to 1

1 to 1, or less

2 to 1, or less

3.3. Connect the Conveyor to the Towing Vehicle

Follow all safety precautions when transporting the conveyor and use a proper towing vehicle.

1. Place the conveyor in the full down position. The frame should be in the full down position with slight

tension on the lift cable. Refer to Lowering procedure.

2. Place and secure hitch pin and safety chain. The safety chain should be threaded and form a cradle that will

prevent the conveyor from digging into the road surface or upsetting (should a breakaway occur) before

attaching to the towing vehicle.

3. Replace the safety chain if one or more links or end fittings are stretched, broken, damaged, or deformed.

4. The safety chain should have a load rating at least as high as the conveyor weight, refer to Specifications.

Important

Use a type of hitch pin that will not allow conveyor to separate from towing vehicle.

32 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

4. Placement

Before continuing, ensure you have completely read and understood this manual’s

Safety section, in addition to the safety information in the section(s) below.

4.1. Placement Safety

• The conveyor is not insulated, keep away from overhead power lines. Electrocution can

occur without direct contact.

• Anchor intake end before using.

• Place the conveyor on reasonably level ground before operating. The conveyor could topple

if ground is too uneven.

• Chock the conveyor wheels after placement.

• Empty the conveyor before raising, lowering, or positioning.

• Check that wheels are free to move before raising or lowering the conveyor.

• Never attempt to increase height of the conveyor by positioning wheels on lumber, blocks,

or by any other means.

• Do not permit anyone to stand beneath the conveyor when raising or lowering.

• Move the conveyor into position slowly. Do not unhitch and attempt to move by hand.

• Do not leave tube in raised position when not in use.

4.2. Positioning the Conveyor

Filling Bins

The conveyor is designed to be transported and operated without unhitching unit from tractor.

1. Disconnect PTO driveline from tractor and secure in transport saddle.

Failure to disconnect from the tractor will damage the PTO driveline.

2. Ensure that tractor and conveyor are securely hitched together.

3. Disconnect the safety chain from the intake hopper.

Important

Use a type of hitch pin (see Conveyor / Tractor Hookup section) that will not allow the conveyor to

separate from towing vehicle.

4. Before connecting hose, ensure that the quick-connect coupler on the conveyor and tractor is clean and free

of dirt by wiping with a cloth.

Dirt in the hydraulic system can damage the cylinder o-rings, causing leakage and the

possible failure of the system and personal injury.

5. Connect hydraulic hoses, ensure connections are tight. Check for leaks, binding, flattening, kinks, or wear.

6. Fully extend wheel axles, see Extendable Axle Positioning.

7. Where Equipped: Fully extend wheel axles, see Extendable Axle Positioning.

P151114 R3 33

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

8. Adjust the hitch adjustment to the operating position, refer to Hitch Adjustment.

9. Move the jack into storage position.

10. Raise the main conveyor tube as required, see Raising and Lowering.

The hydraulic cylinders are shipped without oil and must be charged with oil before the

conveyor is put into operation. See the Appendix for charging instructions.

11. Move the conveyor into working position slowly. Do not unhitch and attempt to move the conveyor by

hand.

12. Once the conveyor is in position, chock wheels on both sides and apply the park brake on the tractor (or

chock its wheels as well) to prevent movement during operation.

13. Back the conveyor up to the storage facility while it is in its lowered configuration.

14. Set the park brake on the tractor before dismounting.

15. Raise the conveyor so it clears the storage facility.

16. Slowly back the conveyor up until the outlet is over the opening in the storage facility.

17. Slowly lower the conveyor to the bin.

18. Place chocks in the front and back of each wheel.

19. Lower the intake hopper to the ground, see Raising and Lowering the Intake Hopper.

20. See Operation for correct operating procedures.

34 P151114 R3

Æ

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

Figure 7. Conveyor Placement (Direct PTO Drive)

4.3. Extendable Axle Positioning

When equipped with extendable axles:

Important

Do not raise the conveyor unless the axles are in the extended position. Do not transport the conveyor

unless the axles are in the retracted position.

P151114 R3 35

Æ

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Rollover can occur if axles are not extended before raising the conveyor.

1. Ensure the conveyor is on level ground before attempting to extend or retract the axles. The conveyor must

be attached to tractor at all times.

2. Using the jack supplied, insert it into one of the jack stubs located on one end of the axle. Jack must be

secured to jack stub using pin (attached to jack).

3. Raise one side at a time. Raise until the tire clears the ground.

4. Remove the axle pin from the axle and position the axle as desired until the holes line up. Reinsert the axle

pin and secure with r-clip hairpin. Lower the jack.

5. Repeat the process on the opposite side of the axle.

Figure 8. Typical Extendable Axle

4.4. Raising and Lowering

When equipped with a Hydraulic Lift Cylinder:

Before using the hydraulic lift cylinder:

• The hydraulic cylinders are shipped without oil and must be charged with oil before operating the first time.

• Check that the hydraulic hoses are free from leaks, binding, flattening, kinks, or wear.

Raising

1. Before connecting the hydraulic hose, wipe the hose coupler clean.

Dirt in the hydraulic system can damage the cylinder o-rings and can cause leakage and

failure of the system.

2. Connect the hydraulic hoses, ensure the connections are tight. Visually check for leaks, binding, flattening,

kinks, or wear.

3. Open the ball valve on the hose connected to the cylinder.

4. Start tractor and idle at low rpm.

5. Engage hydraulic lever to power the cylinder.

6. Increase tractor rpm until desired rate of lift is reached.

7. Raise the conveyor to the desired height.

8. Close the hydraulic ball valve when the conveyor is fully raised.

36 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

Failure to close the ball valve will cause the frame to lower, damaging the conveyor.

Lowering:

1. Reconnect the hydraulic hose coupler to tractor, if disconnected. Keep the tractor running while lowering

the conveyor should the need arise to re-lift it.

Some conveyors are equipped with dual acting hydraulic cylinders, for these units the

tractor must be running to pump oil oil to the upper chamber of the hydraulic cylinder(s)

to prevent overfilling of the tractor reservoir.

2. Open the ball valve.

3. Open the tractor valve, feathering the control to prevent too rapid a descent.

Note

Once the valves are opened, the conveyor tube lowers by gravity. As the tube nears the full down

position, the rate of descent will increase. Do not operate with the tractor valve fully open.

4. Turn off the tractor, and lock out the tractor power source.

5. Before disconnecting hydraulic couplers, relieve the hydraulic pressure.

Disconnecting a hydraulic hose under pressure can result in serious injury.

6. Adjust the conveyor in the full down position until there is a slight tension on the lift cable. Do not leave the

cable slack.

4.5. Hitch Adjustment

Before operating the conveyor, confirm that dimensions A, B, and C, are within the limits stated in Figure 9

when the PTO is connected to the tractor.

This does not apply to the 2000 Series Swing Away Conveyor.

Note

The dimensions in Figure 9 are based on the adjustable hitch being in position 2.

P151114 R3 37

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Figure 9. Hitch Adjustment Tolerance

If dimension C is greater than the hitch adjustment tolerance

The PTO driveline will separate causing potential damage to equipment and/or operators.

1. With the conveyor completely lowered, adjust the hitch to position 1.

2. If dimension C is still too large, move the draw bar closer to the tractor until dimensions A and C are within

the bounds given.

If dimension C is less than the hitch adjustment tolerance

The PTO driveline will bottom out causing potential damage to equipment and/or operators.

1. With the conveyor completely lowered, adjust the hitch to position 3.

2. If dimension C is still too small, move the draw bar further from the tractor until dimensions A and C are

within the bounds given.

If dimension B is greater than the hitch adjustment tolerance

The PTO driveline will shorten at a higher rate as the conveyor is raised causing the PTO to bottom out, which

will damage the equipment. The angle between the u-joints in the driveline will also become too large and

damage may occur.

1. Raise the level of the drawbar such that dimension B is within the given parameters.

4.6. Extended Swing Arm

The swing-away conveyor is equipped with an extendable swing transport arm. The purpose of this arm is to

move the transfer in for transporting. With the arm extended, the transfer can be dropped to the ground

without interference at any conveyor elevation. To adjust the transport arm for use on the road:

• Disconnect the safety catch.

• Lower the transfer to ground.

• Remove the pin from the extendable arm and slide the pin into transport position.

38 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

• Lift the transfer using winch and connect the transport safety catch.

Never transport conveyor on roads with transfer attached to swing arm in the extended

position. The extendable swing should be in the extended position for off-road use only.

Figure 10. Extended Swing Arm

4.7. Raising and Lowering the Intake Hopper

1. Position the swing-away transfer under the transport arm.

2. Loosen the lift cable and connect it to the transfer hopper. Lift the swing-away transfer into the transport

position using the hydraulic winch lift.

Figure 11. Swing Away Transfer Lift Winch

3. Connect the swing catch.

4. Attach the winch cable hook to the appropriate hopper lifting point.

5. Reverse the procedure to lower the swing-away transfer.

P151114 R3 39

Æ

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Figure 12. Hopper in Transport Position

4.8. Hydraulic Power Swing

When Equipped with a Hydraulic Power Swing

1. Connect the hydraulic hoses to the power source.

2. Use the valve handle to move the Swing Away Transfer to the desired position.

Note

When adjusting the power swing, it is normal to hear high pitched sounds depending on the power

source. This sound is caused by a safety device which restricts hydraulic oil flow and prevents the

power swing from moving too quickly.

40 P151114 R3

Æ

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

Figure 13. Power Swing Control Valve

4.9. Electric Power Swing Operation

The Electric Power Swing is an optional component for some conveyor models.

Remote transmitters are pre-programmed from the factory — to reprogram your remote (or to add additional

remotes, please see the Appendix.

You can register more than one remote transmitter to a single Power Swing. However, it is not recommended to

register one remote transmitter to multiple Power Swings.

P151114 R3 41

DANGER

1

2 3

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Figure 14. Power Swing Remote Transmitter

1. On the high end of the Power Swing remote receiver box, flip the power switch (Figure 15 on page 42) to

the ON position.

Table 3. Power Swing Receiver Box

Item

1 Receiver Box

2

3

Figure 15. Power Swing Receiver Box

Description

Power Switch

Direction switch

For Receiver Box Operation:

1. Using the direction switch, move the switch in the desired direction of travel (either F1 or F2).

2. Once finished moving the hopper, release the switch to stop operation (it should return to the neutral

position).

42 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

For Remote Transmitter Operation:

1. Push the green button (no symbol) to turn the remote ON (Figure 14 on page 42).

2. Push the yellow directional buttons (marked with arrows) located below the ON/OFF buttons in the

direction you want the hopper to move (Figure 14 on page 42).

3. If this does not work:

a. Push the red button (with an exclamation mark) to turn the remote OFF.

b. Then push the green button (no symbol) to turn the remote back ON.

4. Operate the remote as outlined above, using the two yellow directional buttons (marked with arrows)

located at the bottom of the remote to move the hopper as desired.

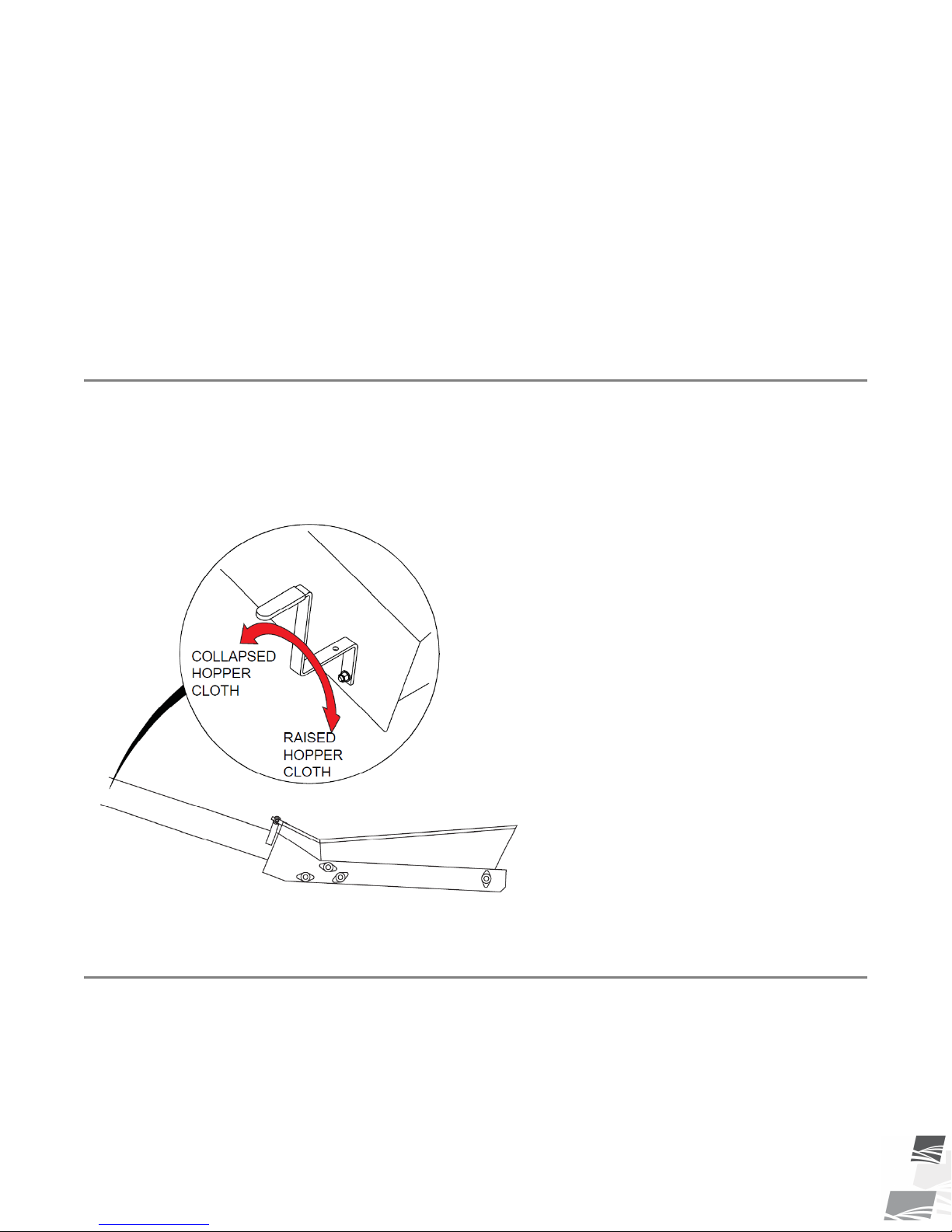

4.10. Collapsible Hopper Cloth Control

The conveyor is designed with a collapsible hopper cloth to allow it to go under low discharge units.

Move the control handle toward the hopper or intake to raise the hopper cloth, and move the handle toward

the outlet or spout end to collapse the hopper cloth, see Figure 16 on page 43.

Figure 16. Collapsible Hopper Handle

4.11. Conveyor Operating Angles

The conveyor lift can set the tube angle up to 30° when operating. Because the belt does not have roll back

barriers, the material will roll back if the angle is too steep. Do not position the conveyor at an angle steeper

than the grain will roll back (angle of repose) of the material to be moved.

Note

The lower the angle, the greater the capacity of the conveyor.

P151114 R3 43

4. PLACEMENT PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

The following table indicates the maximum angle a conveyor can move grain.

To roughly determine conveyor angle, use angle guide on right. Stand the manual (vertically) on conveyor tube

and hold a string with a weight attached to end against the top of this page. Weighted end of string will fall

between degree lines, and from this the approximate angle of the conveyor can be determined.

Figure 17. Conveyor Operating Angles

Table 4. Maximum Conveying Angles for Grains

Grain

Flax

Lentils

Mustard

44 P151114 R3

Maximum Conveyor Operating Angle (degrees)

24

29

26

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 4. PLACEMENT

Table 4 Maximum Conveying Angles for Grains (continued)

Grain

Maximum Conveyor Operating Angle (degrees)

Oats 28

Peas 30

Rice 36

Rye 25

Soybeans

Sunflower

Triticale

Wheat

Alfalfa Pellets

Barley

Canary Seed

28

22

23

26

34

25

26

Chickpeas

30

Corn 26

Shelled Corn (dry)

Shelled Corn (wet)

Cotton Seed

25

28

30-45

Durum 25

P151114 R3 45

5. OPERATION PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

5. Operation

Before continuing, ensure you have completely read and understood this manual’s

Safety section, in addition to the safety information in the section(s) below.

5.1. Operation Safety

• Keep away from rotating and moving parts, including the conveyor belt, drive components,

shafts, and bearings.

• Do not enter the grain bin while the conveyor is operating.

• Always operate with guards, covers, and shields in place.

• Have another trained person nearby who can shut down the equipment in case of accident.

• Keep the work area clear of bystanders.

• Keep the work area clean and free of debris.

• Ensure maintenance has been performed and is up to date.

Refer to your bin operation manual for specific operating and safety information for your bin.

5.2. Start-up and Break-in

Although there are no operational restrictions on the conveyor when used for the first time, it is recommended

that the following items be checked during the first hours of operation.

1. Check that the conveyor intake and discharge areas are free of obstructions.

2. Check conveyor belt alignment to ensure preset alignment does not vary under loaded conditions. See

Maintenance Section for alignment instructions.

3. Check the conveyor belt tension. See Maintenance Section for tension instructions.

4. Check the pinch roller bearings on the s-drive pinch roller are not tight.

5. Visually inspect the conveyor, see Visual Inspection in Maintenance Section.

6. Check tightness of all bolts/nuts, fasteners, and hardware (re-torque if necessary).

7. Ensure adequate power is supplied to operate the conveyor. Refer to the Specifications Section for power

requirements.

8. Start the tractor and idle at low rpm. Slowly engage the PTO drive. Refer to PTO Drive Operation.

9. Start the hydraulic drive on the Swing Away transfer conveyor. Refer to Hydraulic Drive Operation.

10. Gradually begin feeding grain into the hopper, bringing the tractor PTO drive to roughly half speed. Do not

overfeed the hopper on initial loads; keep the feed of grain at about half capacity.

11. Be aware of unusual sounds. If any are heard, determine the source and stop the conveyor. Lock out and

correct the problem before resuming work. If you are unsure of the problem or procedure, contact your

local dealer.

12. After the conveyor runs fairly smoothly, proceed to unload at full PTO speed of 540 rpm. Do not exceed 540

RPM.

46 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 5. OPERATION

13. Do not run the conveyor for long periods of time without material on the conveyor belt because it increases

wear. Try to run only when moving material.

14. Stop the conveyor when it is empty of grain and lockout power, lower fully.

Important

After the initial start-up and inspection, the conveyor should be shut down and visually inspected

(see Maintenance Section) after approximately ten hours of operation.

5.3. Operation - Swing Away Transfer Hydraulic Motor Drive

1. Set the hydraulic valve so that is open as shown in Figure 18 on page 47.

2. Place all tractor controls in neutral.

3. Start the tractor and run at low idle.

4. Engage the tractor hydraulic control lever and increase the engine to desired speed.

Note

The correct operation of a hydraulic system is directly linked to the pump’s ability to supply the

correct oil flow and pressure. If you cannot obtain the correct belt speed, check with the dealer to

ensure the power unit is delivering the correct oil volume and pressure.

5. Run until the belting is empty.

6. Reduce tractor engine speed to low idle.

7. Place hydraulic control lever in neutral.

8. Shut off engine and remove ignition key.

9. Set the hydraulic valve so that it is closed.

Hydraulic Valve

The hydraulic valve can be set to control the flow of oil to the hydraulic motor. This valve should normally be set

fully open to operate or fully closed when not operating. The valve handle can be used to set partial speeds,

however this is not recommended for extended periods.

Figure 18. Hydraulic Drive Valve

P151114 R3 47

5. OPERATION PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

5.4. Operation - PTO Drive

540 RPM PTO Drive

1. Attach the PTO driveline securely to the tractor and confirm the connection to the conveyor shaft is secure.

2. Confirm the PTO driveline rotating shield and other shields/guards are in place and in good working order.

3. Align the tractor axis with the conveyor input shaft to minimize the angles of the universal joints on the PTO

driveline.

Note

Check that the PTO does not exceed the maximum operating angle of 25°.

4. The conveyor-to-tractor PTO hookup distances are set as specified.

5. Ensure the PTO drive on the tractor is in the off position before starting the tractor.

6. Start tractor engine at low idle, slowly engage the PTO with the tractor idling to prevent unneeded stress on

the drive components and shear bolts.

7. If everything is operating normally, start running grain through the conveyor and increase the speed to 540

rpm to produce the required flow.

8. To shut down, reduce the speed to low idle and lock out the PTO.

9. Disconnect PTO driveline from tractor and secure to the PTO transport saddle. Secure it with the safety

chain and keep in transport saddle when transporting.

When raising or lowering the conveyor:

Disconnect the PTO driveline.

When starting under load:

If restarting the conveyor under load (tube is full), engage the PTO with the tractor idling.

Engaging the PTO at high engine speed will result in equipment damage.

Shear Bolts:

If a shear bolt in the PTO driveline fails, shut down and lock out the tractor to replace the shear bolt. Ensure

that the shear point is through the shank of the bolt, not the threads. Refer to Section 8. – Specifications on

page 70 for shear bolt sizes.

5.5. Loading Area

To achieve maximum capacity:

• Feed material onto the belt until the material tube clearance is 1/2”.

• Direct the flow of material into the input hopper in the direction of the belt travel for the best capacity.

Do not flood feed the hopper.

48 P151114 R3

Æ

Æ

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 5. OPERATION

5.6. Conveyor Belt Speed

The best results are obtained when the input drives are set to provide a conveyor belt speed of 500 to 600 ft/

min on the 1300 and 1500 series, and 600 to 650 ft/min on the 1800, 2000, and 2400 Series.

Count the number of belt revolutions per minute to determine belt speed. See Specifications for belt length.

Note

Use the connector splice as a reference when counting belt revolutions.

To calculate, for example, 600ft/minute belt speed for a 47ft belt:

Therefore, 12.76 or approximately 13 belt passes per minute will provide a 600ft/min belt speed.

Contact your dealer or the factory for the appropriate drive components to give the recommended belt speed.

If the belt speed is too low, conveyor may leak around transition area.

5.7. Emergency Shutdown

In an emergency situation:

1. Stop or shut down the power source immediately and lock out all power.

2. Stop the flow of material (if applicable).

3. Ensure the machine components come to a stop before inspecting.

4. Correct the emergency situation before resuming work.

5.8. Restarting with a Full Tube

When the conveyor is shut down inadvertently or due to an emergency, the tube may still be filled with grain.

1. With the power source locked out, remove as much of the grain as possible from the tube and intake using

a shop vacuum or other tool. Do not use your hands.

Starting under load may result in damage to the conveyor if grain is not removed as much

as possible.

2. If guards or covers have been opened or removed, close or replace them before restarting the unit.

3. Electric and Gas Drive Models: It may be necessary to tighten the drive belts slightly to handle the heavier

than normal loads.

4. Gas and PTO Drive Models: Since the start-up torque loads are so much higher than normal when the

conveyor belting is full, restart at low speed. Do not let the conveyor belt drive roller spin on the belt if

conveying belt does not start moving immediately. This will damage the drive roller and conveying belt.

5. Once the conveyor has been started, you may resume normal operation.

5.9. Shutdown

When operation has been completed:

P151114 R3 49

5. OPERATION PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

1. Once the conveyor is clear of grain, lock out the power source.

2. Lower the conveyor fully.

3. Clean out any remaining grain from the conveyor with a vacuum or sweep out.

4. Clean the entire work area.

5. Remove anchors, supports, and chocks.

5.10. Clean Out

After using your conveyor, follow the clean out steps below to ensure longer belt life and trouble free

operation. Failure to clean out the conveyor can cause build up of product on the belt and roller shafts, causing

spillage, roller misalignment, and excess wear/damage to the belt.

Failure to lock out power can cause severe injury.

1. Remove any product remaining in the hopper and spout with a vacuum or sweep out.

2. Remove debris from shafts, sheaves, and drive belts (as equipped).

3. Once the conveyor is empty of all product, check for damage on belt and lacing such as notches or cut outs.

Any damage on belt may result in product getting under it creating a build-up. If belt replacement and relacing is necessary, refer to the Maintenance Section.

Important

Ensure the conveyor is free from all product and debris to prevent build-up. Any build-up on belt

and shaft becomes a source of spillage and can cause belt misalignment with the possibility of belt

edges sustaining damage on the fixed structure. Build-up on the hopper and spout will cause the

belt to wear faster due to drag.

4. Once cleaned out, cover intake to prevent moisture from collecting in hopper.

5.11. Conveying Fertilizer

Fertilizer may be conveyed using the conveyor when strictly operated at a reduced capacity and additional care

is taken to thoroughly clean the conveyor after operation.

Important

Fertilizer weakens the belt lacing and warranty is void on all lacing used with fertilizer. The belt lacing

may need to be replaced more often if you convey fertilizer.

Additional Operating Requirements

To prevent problems that can be caused by conveying fertilizer:

1. Do not allow fertilizer to fill over the edge of the belt. This will allow fertilizer to get under the belt and start

building up.

2. Reduce the flow if the conveyor belt starts to slip. Denser fertilizers will slow the conveyor belt down due to

the weight of the product. Too much material will cause the drive roller to slip and lead to additional wear

on the roller.

3. Do not move fertilizer with your conveyor in humid, wet or rainy conditions. This will cause buildup of

fertilizer under your conveyor belt.

50 P151114 R3

PORTABLE GRAIN BELT CONVEYOR – SWING AWAY 5. OPERATION

Additional Clean-Out Procedures

Proper cleaning will help to ensure longer belt life and prevent excess rust formation.

1. Run conveyor empty at full speed for 5-10 minutes after conveying fertilizer. This will help ensure that any

product that may be under the belt will be cleaned out and prevent build up.

Do not attempt to manually remove build-up while conveyor is running.

2. Next, run the belt at low idle and inspect for damage on the belt and lacing, such as notches or cut outs

caused by mice and normal wear. Any damage on the belt may result in fertilizer getting under the belt

creating a buildup. Consider replacing the conveyor belt if it is in poor condition. If equipped with an electric

motor, inspect on the belt return side with the electric motor not running. Turn on the conveyor to expose

the belt that was previously in the tube. Turn off the conveyor and inspect the belt on the belt return, along

with the lacing.

3. Shutdown and lockout power to the conveyor and vacuum or sweep out any remaining fertilizer from the

hopper.

4. Remove the s-drive bottom cover and remove any buildup from this area and clean cover. Replace the cover

when complete.

5. If buildup is evident on or under the belt, remove the buildup to ensure proper operation of the conveyor.

When necessary remove fertilizer buildup from under the belt by scraping and washing the belt.

Figure 19. Fertilizer Buildup on Rollers

P151114 R3 51

5. OPERATION PORTABLE GRAIN BELT CONVEYOR – SWING AWAY

Figure 20. Fertilizer Buildup at Hopper Transition

5.12. Storage

After the season’s use, the conveyor should be thoroughly inspected and prepared for storage. Repair or replace

any worn or damaged components and perform maintenance as described in the Maintenance Section to

prevent any unnecessary downtime at the start of the next season.

To ensure a long, trouble-free life, this procedure should be followed when preparing the unit for storage.

1. Remove all residual material from the hopper and the tube.

2. Stop the machine with the belt lacing inside the tube. This helps prevent the lacing from rusting.

3. Wash the entire conveyor thoroughly using a water hose or pressure washer to remove all dirt, mud, debris,

or residue.

4. Inspect all moving or rotating parts to see if anything has become entangled in them. Remove any entangled

material.

5. Touch up all paint nicks and scratches to prevent rusting.

6. Check tire pressure and inflate according to tire side-wall recommendations.

7. Inspect the conveyor for cracks, tightness of fittings and fasteners, hydraulic hose cracks (if applicable). Have

required repairs performed to replace worn or damaged components and complete required annual

maintenance.

8. Store in an area that is dry, level, free of debris, and away from human activity. Store inside if possible.

9. Chock wheels.

10. Support intake on blocks to eliminate prolonged contact with the ground.

11. Clean and lightly lubricate the spline on the PTO driveline. Cover the PTO driveline with a plastic bag to