Page 1

Technical Bulletin VLV

Issue Date 0100

VLV49A Series Universal Replacement Gas Valve

Application

To Terminal 5

or Ground

Black

Grommet

Screw B

Pilot Tap

Connection

To Terminal 1

Screw A

Valve

Inlet

To Terminal 3

Blue

Red

Figure 1: Universal Replacement Gas Valve

The VLV49A Series Universal Replacement Gas Valve is for the

replacement of the valve assembly of an electronic proven pilot spark

ignition control with a valve (i.e., G60 and Q15). They are combination

redundant valves, available with or without a pressure regulator.

These valves can be used on appliances burning natural gas, Liquefied

Petroleum (LP) gas, manufactured gas, mixed gas or LP gas-air mixtures,

including sulfur bearing gases (depending on the regulator selection) at

pressures up to 35 mbar (0.5 psi).

© 2004 BASO Gas Products 1

Part No. 24-8711-455, Rev. ⎯ www.baso.com

Page 2

Table 1: Specifications

Product

Maximum Operating

Pressure

Ambient Temperature

Electrical Rating

Regulator Adjustment

Range

Inlet Pipe Size

Outlet Pipe Size

Pilot Outlet

Wiring Connections

Types of Gas

Accessories

Agency Listings

The performance specifications are nominal and conform to acceptable industry standards.

For application at conditions beyond these specifications, consult BASO Gas Products.

BASO Gas Products shall not be liable for damages resulting from misapplication or misuse

of its products.

VLV49A Series Universal Replacement Gas Valves

35 mbar (0.5 psi)

-40 to 80°C (-40 to 175°F)

24 VAC, 60 Hz, 0.3 ampere draw

7.5 to 15 mbar (3 to 6 in. W.C.)

1/2 in. NPT

3/4 in. NPT

1/8 in.-27 NPT left and right

216 mm (8.5 in.) lead wires

Natural, Liquefied Petroleum (LP), manufactured, mixed,

and LP gas-air mixtures

Conversion Kits

Natural gas to LP gas: lever-acting regulator Y71GF-4

direct-acting regulator Y71GF-3

None

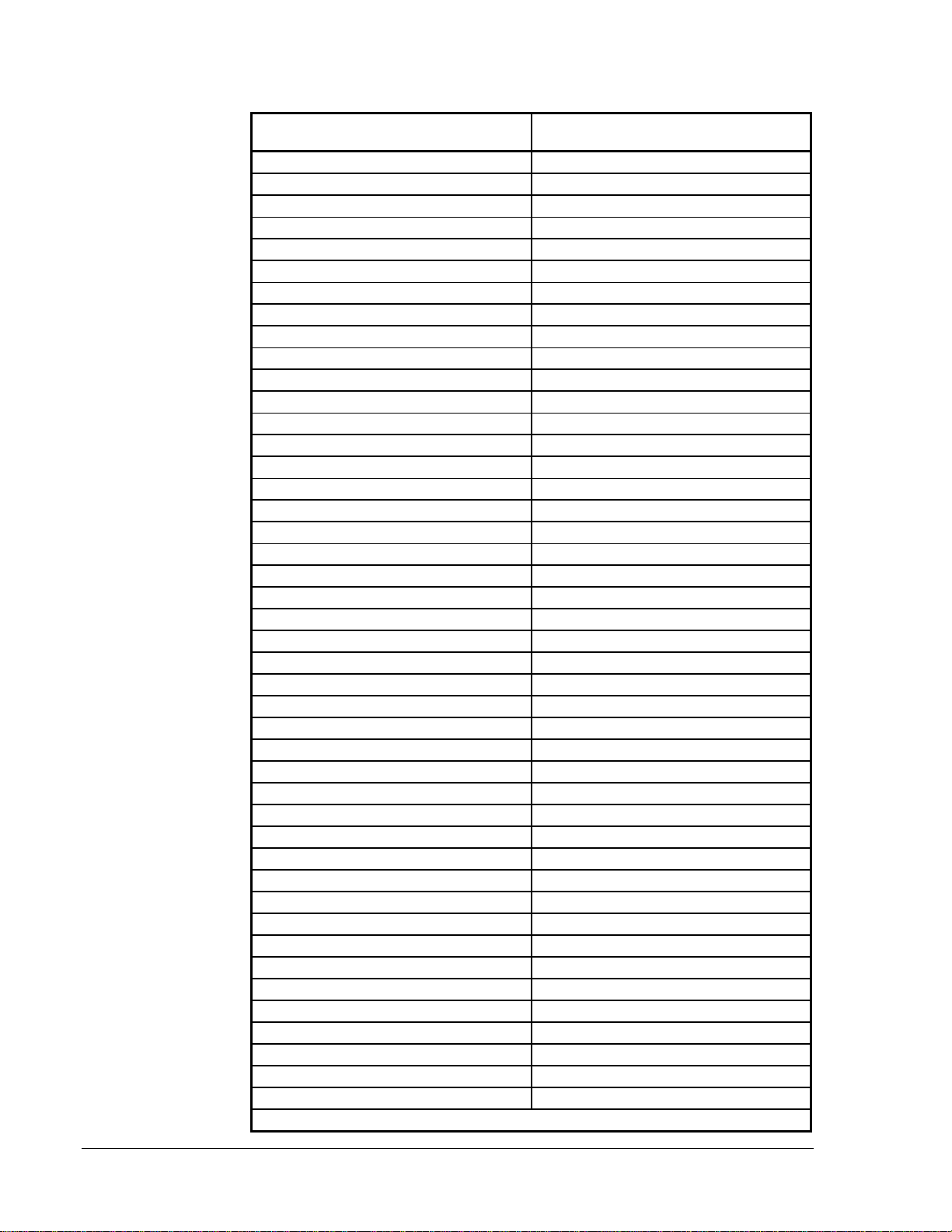

Table 2: Universal Replacement Gas Valve Chart

Valve Part Number Regulator Type

VLV49A-600R

VLV49A-601R

VLV49A-602R

Direct-acting regulator

Lever-acting regulator

No regulator

2 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Page 3

Table 3: Replacement Valve Selection Chart

Original Valve/Ignition Part Number Replacement Valve Part Number

G60CAA-1, 3

G60CAG-1, 2, 3, 4, 6, 7, 8

G60CAG-9

G60CBA-1, 3

G60CBG-1, 3, 4, 9, 10, 11, 14, 16, 17

G60CCA-1

G60CCG-1

G60CPG-1

G60DBG-1

G60DCG-1, 2, 4

G60QAG-1, 2, 3

G60QAG-1

G60QAK-1

G60QBG-1, 2, 3, 4, 5, 6, 7, 8, 9

G60QBH-1

G60QBK-1

G60QBK-3

G60QBL-1

G60QCG-1

G60QCL-1

G60QCJ-1

G60QDG-1

G60QFL-1

G60QHL-1, 2

G60QJL-1

G60QLG-1

G60QPL-1

G60QRH-1

G60QRL-1, 2, 3

G60QSL-1

G60QTH-1

G60QTL-1

G60QUL-1

G60RAG-1

G60RBG-1, 2

G60RBG-3

G60RBK-1, 2

G60RCG-2

G60RCJ-1

G60RDG-1

G60RDK-1

G60RGL-1

G60RHL-1

Continued on next page . . .

VLV49A-602R*

VLV49A-602R

VLV49A-602R*

VLV49A-601R*

VLV49A-601R

VLV49A-600R*

VLV49A-600R

VLV49A-601R plus Y71GF-4

VLV49A-601R

VLV49A-600R

VLV49A-602R

VLV49A-602R

VLV49A-602R

VLV49A-601R

VLV49A-601R

VLV49A-601R

VLV49A-601R

VLV49A-601R

VLV49A-600R

VLV49A-600R

VLV49A-600R

No Replacement Available

VLV49A-602R

VLV49A-600R

No Replacement Available

VLV49A-601R

VLV49A-601R plus Y71GF-4

VLV49A-601R plus Y71GF-4

VLV49A-601R plus Y71GF-4

VLV49A-600R plus Y71GF-3

VLV49A-601R

VLV49A-601R

VLV49A-601R

VLV49A-602R

VLV49A-601R

VLV34A-648R

VLV49A-601R

VLV49A-600R

VLV49A-600R

No Replacement Available

No Replacement Available

VLV49A-601R

VLV49A-600R

VLV49A Series Universal Replacement Gas Valve Technical Bulletin 3

Page 4

Original Valve/Ignition Part Number

(Cont.)

G60RHP-1

G60RPL-1

G60RSL-1

VLV34A-605

VLV34A-608

VLV34A-609

VLV34A-610

VLV34A-613

VLV34A-614

VLV34A-617

VLV34A-621

VLV34A-623

VLV34A-624

VLV34A-625

VLV34A-626

VLV34A-628

VLV34A-633

VLV34A-636

VLV34A-637

VLV34A-638

VLV34A-639

VLV34A-640

VLV34A-641

VLV34A-642

VLV34A-643

VLV34A-644

VLV34A-645

VLV34A-648

VLV37A-602

VLV37A-603

VLV41A-600

VLV41A-601

VLV41A-602

VLV41A-605

VLV43A-600

VLV43A-601

VLV43A-602

VLV43A-603

VLV43A-604

VLV43A-605

VLV43A-606

VLV43A-607

VLV43A-608

VLV43A-612

Continued on next page . . .

Replacement Valve Part Number

VLV49A-600R

VLV49A-601R plus Y71GF-4

VLV49A-600R plus Y71GF-3

VLV49A-601R

VLV49A-602R

VLV49A-601R

VLV49A-602R

VLV49A-602R

VLV49A-601R

VLV49A-600R

VLV49A-600R

VLV49A-601R

VLV49A-602R

VLV49A-601R

VLV49A-600R

VLV49A-600R

VLV49A-601R

VLV49A-601R

VLV49A-600R

VLV49A-602R

VLV49A-601R

VLV49A-602R

VLV49A-602R

VLV49A-601R

VLV49A-600R

VLV49A-600R

VLV49A-601R

VLV34A-648R

No Replacement Available

No Replacement Available

VLV49A-602R

VLV49A-601R

VLV49A-600R

VLV49A-601R

VLV49A-601R

VLV49A-602R

VLV49A-601R

VLV49A-600R

VLV49A-600R

VLV49A-601R

VLV49A-601R

VLV49A-602R

VLV49A-601R

VLV49A-600R

4 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Page 5

Original Valve/Ignition Part Number

Replacement Valve Part Number

(Cont.)

VLV43A-609

VLV43A-610

VLV43A-615

VLV43A-616

VLV44A-600

VLV44A-601

VLV49A-604R

VLV49A-605R

VLV49A-606R

G96JGA-3 (Q15HAA-1)

* 24 VAC replacement gas valve for original 120 VAC valve. A 24 VAC transformer is

required.

Note: All replacement valves come set up for use with natural gas. If used on an LP

system, the appropriate Y71 conversion kit must be installed.

• Y71GF-3 Natural to LP for direct-acting regulators

• Y71GF-4 Natural to LP for lever-acting regulators

VLV49A-601R

VLV49A-601R

VLV49A-601R

VLV49A-600R

No Replacement Available

No Replacement Available

VLV49A-600R plus Y71GF-3

VLV49A-601R plus Y71GF-4

VLV49A-601R

VLV49A-601R

VLV49A Series Universal Replacement Gas Valve Technical Bulletin 5

Page 6

Installation

IMPORTANT: This technical bulletin is intended as a guide for

authorized service personnel installing or servicing

BASO Gas products. Carefully follow all

instructions in this bulletin and all instructions on

the appliance. Limit repairs, adjustments, and

servicing to the operations listed in this bulletin or

on the appliance.

!

WARNING: Fire or Explosion Hazard. The system must meet

all applicable codes. Improper installation may

cause gas leaks, explosions, property damage, and

injuries.

!

WARNING: Fire or Explosion Hazard. To prevent leakage of

upstream gas, shut off the gas supply at the main

manual shutoff valve before installing or servicing

the VLV valve.

!

CAUTION: Equipment Damage Hazard. To prevent damage

to the valve when mounting to the manifold, do not

use a wrench on any surface other than the casting

flats provided at the inlet and outlet ends of the

valve body.

!

CAUTION: Equipment Damage Hazard. Label all wires prior

to disconnection when replacing the valve. Wiring

errors can cause improper and dangerous operation.

Verify proper operation after servicing.

Perform the following procedure to install the replacement VLV49A

valve.

1. Turn off power to the appliance.

2. Turn off the gas at the manual shutoff valve adjacent to the appliance.

(If the manual shutoff valve services more than one appliance, be sure

to light the other pilots before leaving.)

3. With the gas and power to the appliance turned off, disconnect the

power supply (transformer) and the thermostat lead wire at the

ignition control.

6 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Page 7

4. Disconnect the sensing probe lead from Terminal 4 on the ignition

control.

5. Disconnect the high voltage cable from the spark transformer.

6. Disconnect the Pilot Valve 1 and Main Valve 3 leads from the

terminal board or end plug-in Heyco terminals (see Figures 2 and 3).

Termin al Board

Connections

Ground

Terminals

Figure 2: Terminal Board Ignition Control

with Mounting Plate

Ground

Terminals

Heyco Terminal

Connections

Figure 3: Plug-in Heyco Ignition Control

VLV49A Series Universal Replacement Gas Valve Technical Bulletin 7

Page 8

7. Remove Screws A and B holding the ignition control assembly to the

valve and plate assembly (see Figure 1). These two screws are located

on the bottom surface of the ignition control assembly.

8. Remove the ignition control.

9. Disconnect the pilot burner tubing from the pilot tap connection on

the gas valve (see Figure 1).

10. Verify (when looking on the inlet of the valve) that the location of the

grommet and wire leads on the old valve and new replacement valve

are on the same side.

If they are not on the same side, remove the grommet of the new

replacement valve and insert it into the other side of the mounting

plate (see Figure 4). This allows the placement of the ignition control

spark transformer over the outlet of the valve instead of the inlet.

Remove grommet

and wires f r om here.

Remova bl e Portion

of Moun ting Plate

Remova bl e Portion

of Moun ting Plate

Replace grommet

and wires here.

Figure 4: Grommet Locations

11. Remove the old valve from the manifold and install the new

replacement valve. Ensure the gas flows through the valve body in the

direction indicated by the arrow on the valve body. If the valve is

installed with the gas flow opposite the arrow, leakage can occur.

A thread lubricant has been factory applied to the first two or

three threads of the valve inlet and outlet to avoid galling. Use an

approved pipe-joint sealing compound on male threads before

assembling. Take care that excess compound does not work into the

valve and get onto the valve seats. Threads of pipe and nipples must

be smooth and free of tears and burrs.

12. Reconnect the pilot burner tubing at the pilot tap connection.

13. Fasten the ignition control assembly to the valve and plate assembly

with the screws provided with the replacement valve.

14. Break off the portion of the plate that protrudes if it interferes with

surrounding surfaces (see Figure 4).

8 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Page 9

15. Reconnect the thermostat leads, the sensing probe lead, and the high

voltage cable according to the labels on the wires. Do not connect

the electrical supply at this time.

a. On grounded versions (part numbers ending with the

letters H, L, G, or J [e.g., G60QBG or G60QBJ]), connect the

black lead wire to one of the ground terminals on the ignition

control. Four ground spade terminals are located just below the

terminal board on terminal board models (see Figure 2) or in a

square arrangement on the end of the plug-in Heyco models

(see Figure 3).

On ungrounded versions (part numbers ending with a K

[e.g., G60QBK]), connect the black lead wire to Terminal 5 on

the ignition control.

On systems using G600 ignition controls, connect the black lead

wire to a ground terminal on the ignition control.

b. Connect the blue lead wire to Terminal 1 on the ignition control.

IMPORTANT: To permit verification of pilot operation, do not connect

the red lead wire to any terminal at this time.

16. Check for leakage.

a. Open the pressure connection between the manual shutoff valve

and the VLV valve.

b. Connect air tubing with a maximum pressure of 1-1/2 times the

valve’s maximum operating pressure (as indicated on the valve)

to the opened pressure connection.

c. Paint all valve body connections with a rich soap and water

solution.

If bubbles occur, this is an indication of a leak. To stop a leak,

tighten joints and connections. Replace the part if the leak

cannot be stopped.

If bubbles do not occur, remove the air tubing and close the

pressure connection.

VLV49A Series Universal Replacement Gas Valve Technical Bulletin 9

Page 10

17. After installation of the replacement valve is complete, except for the

attachment of the red lead wire, turn on the gas at the manual

shutoff valve.

a. Reconnect the power supply lead wire to the ignition control and

turn the power On.

b. Set the thermostat to the highest setting. The pilot valve will

open, spark will be energized, and the pilot will light.

c. Test for gas leaks in the pilot line with a soap solution.

d. After the check is complete, turn off the power and connect the

red lead wire to Terminal 3 on the ignition control.

18. Turn on the power and set the thermostat to the desired setting.

10 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Page 11

Regulator

Adjustment

IMPORTANT: All adjustments must be made in conjunction with

the gas appliance and in accordance with the

appliance manufacturer’s instruction. Only

authorized personnel should make adjustments.

!

WARNING: Explosion Hazard. The minimum flow rate of the

valve must not be adjusted below the minimum safe

working rate of the appliance.

The pressure regulator is adjustable and has been factory set. If a different

setting is desired, follow these instructions.

1. Shut off all gas to the appliance.

2. Turn the thermostat to the lowest setting or Off position.

3. Remove the pressure tap plug at the valve outlet or in the manifold

pipe downstream of the valve.

4. Install a manometer or pressure gauge suitable for measuring the

desired orifice pressure.

5. Remove the seal screw at the end of the regulator stack.

6. Turn the gas on and place the thermostat at the highest setting to

cycle the ignition system.

7. Allow the system to stabilize. Adjust the screw in the regulator stack

to the desired reading on the manometer. (Turn clockwise to increase

the outlet pressure and counterclockwise to reduce the outlet

pressure.)

8. Reinstall the seal screw, which incorporates the proper size hole for

venting to the atmosphere. (It may be necessary to cycle the valve

several times to verify the desired outlet pressure.)

9. Turn off the gas supply and place the thermostat at the lowest setting.

10. Remove the pressure manometer and reinstall the pressure tap plug.

11. Turn the gas on and set the thermostat to the desired setting.

12. Check for leaks at the pressure tap plug with a soap solution before

leaving the site.

VLV49A Series Universal Replacement Gas Valve Technical Bulletin 11

Page 12

Checkout

Procedure

!

WARNING: Fire or Explosion Hazard. Avoid personal injury

or property damage by making sure the valve

functions properly and there are no gas leaks.

Follow this checkout procedure before leaving the

installation.

Make sure all components are functioning properly by performing the

following test:

1. Test for leaks on all pipe joints and connections upstream of the gas

valve with a soap solution.

2. Turn the thermostat to a low setting.

3. Turn on the gas and purge the gas lines of all air.

4. Turn the thermostat to a high setting. The appliance should operate in

accordance with the manufacturer’s specified sequence of operation.

5. Test for leaks on all pipe joints and connections downstream of the

gas valve with a soap solution.

Repairs and

Replacement

6. Turn the thermostat down for at least 30 seconds and then back up

again. Verify successful ignition at least three times before leaving

the installation.

The VLV49A replacement valves are not field repairable. Do not

attempt field repairs. For a replacement valve, contact the nearest

BASO Gas Products distributor.

1007 South 12th Street

PO Box 170

Watertown, WI 53094 www.baso.com

1-877-227-6427 (1-877-BASOGAS) Printed in U.S.A.

12 VLV49A Series Universal Replacement Gas Valve Technical Bulletin

Loading...

Loading...