Page 1

Installation Instructions

Issue Date June 12, 2014

E Series CE/AGA Approved

Intermittent Pilot Ignition Control

Application

The E Series CE/AGA Approved Intermittent Pilot

Ignition Control is a safety control designed for indirect

burner ignition and supervision, for use with all gases

and applicable to gas-fired appliances.

The E Series is a microprocessor based ignition

control. The microprocessor provides reliable software

control of all timings and operates a diagnostic

Light-Emitting Diode (LED). It provides ignition

sequence, flame monitoring, and safety shutoff for

boilers, furnaces and other gas-fired heating

appliances.

Installation

IMPORTANT: Only qualified personnel should

install or service BASO Gas Products®. These

instructions are a guide for such personnel. Carefully

follow all instructions for the appliance.

IMPORTANT: Make all gas installations in

accordance with applicable local, national, and

regional regulations.

Instructions for installing the pilot burner/igniter-sensor

are typically provided by the appliance manufacturer. It

is important to follow those instructions. If such

information is not included, refer to the Mounting

section.

Mounting

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making electrical

connections to avoid electric shock.

!

WARNING: Risk of Explosion or Fire.

Shut off the gas supply at the main manual shutoff

valve before installing or servicing the control.

Failure to shut off the gas supply can result in the

release of gas during installation or servicing, which

can lead to an explosion or fire, and may result in

severe personal injury or death.

!

WARNING: Risk of Explosion or Fire.

Do not install the control in an area that is exposed

to water (for example, dripping, spraying, rain). Do

not use the control if it has been exposed to water.

Exposure to water may cause malfunction and can

lead to an explosion or fire and may result in severe

personal injury or death.

IMPORTANT: This control is approved for use

with noise suppression (resistive) spark wires. If the

application has copper wire, it must be replaced.

© 2014 BASO Gas Products. 1

Part No. BASO-INS-ECA, Rev. A www.baso.com

IMPORTANT: Do not mount the control where

it can be exposed to direct infrared radiation from the

main burner or to temperatures in excess of the

maximum product temperature rating.

Replacement Instructions

Mark wires to existing control. Disconnect the wires

and remove the existing control.

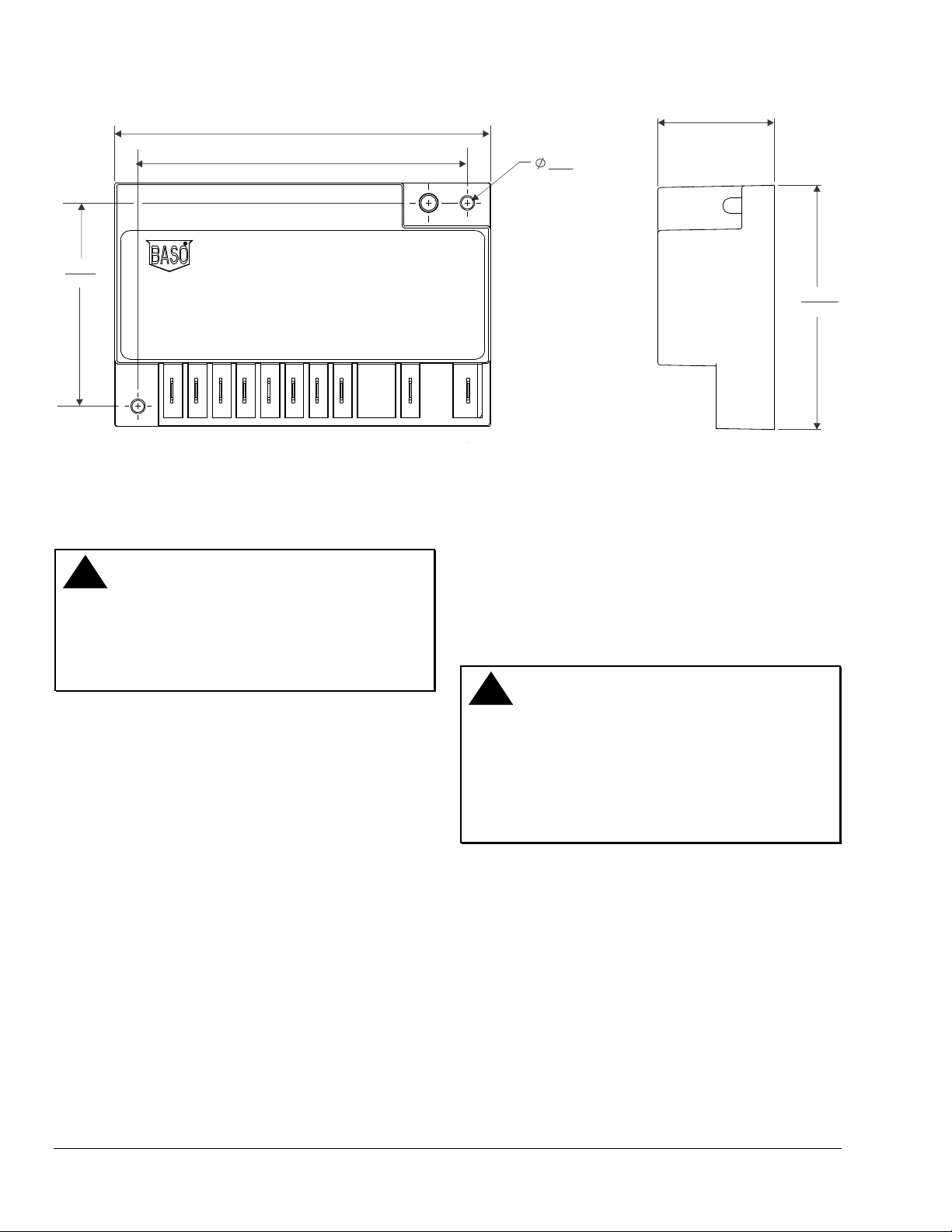

The control is not position sensitive. It may be

mounted horizontally or vertically with two #6 sheet

metal or machine screws.

Page 2

123.19

4.850

107.95

66.68

2.625

4.250

LED

Figure 1: Dimensions (mm/in.)

Wiring

!

WARNING: Risk of Explosion or Fire.

Locate all safety, limit, and operating controls in

series with the thermostat terminal (TH) on the

ignition control. Improper installation may cause gas

leaks, which can lead to an explosion or fire and

may result in severe personal injury or death.

Refer to Figure 2 and 3 for wiring diagrams. All wiring

should be in accordance with the National Electrical

Code (NEC) and all other local codes and regulations.

Check the voltage rating marked on the control and

make sure it is suited to the application. Use a Class 2

transformer capable of providing 24 VAC under

maximum load, including valves. A transformer having

excessive primary impedance due to poor coupling

affects the ignition potential.

38.10

1.500

3.96

.156

HOLE THRU

(2 HOLES)

LED

80.01

3.150

Spark Cable

The cable must be noise suppression (resistive) type

rated for at least 15kV and must not be in continuous

contact with a metal surface. If a separate flame sense

probe is used, the sense wire should be separated

from the high voltage wire by a minimum of

6.35 mm (1/4 in.).

!

WARNING: Risk of Electric Shock.

Before applying power to the control, connect the

high voltage cable to the spark transformer terminal

and spark electrode (pilot burner assembly). Verify

the ground wire is attached to the pilot burner and

the control ground terminal strip. Failure to follow

this procedure can cause electric shock and may

result in severe personal injury or death.

Controls with universal flame sense are supplied with

a jumper wire between SENSE and INTERN terminals

and is ready for internal (one rod) flame sense. With

the jumper in, flame is sensed through the high voltage

spark wire. For external (two rod) flame sense, the

jumper must be removed and discarded and the sense

electrode is wired to the SENSE terminal.

2 E Series EC/AGA Approved Intermittent Pilot Ignition Control Installation Instructions

Page 3

123

MAIN

GND

VALVE

PILOT

456

24V

GND

GND

BURNER

78 11

ALARM

SENSE

ALARM

9

RESET

10

INTERN

RESET*

THERMOSTAT

HIGH

TEMP

LIMIT

L1 (HOT)

L2 (NEU)

PILOT BURNER

COMBINATION

GAS VALVE

24 VAC

CLASS 2

TRANSFORMER

CHASSIS OR FRAME

GROUND

RESISTIVE NOISE SUPPRESSION WIRE

*RESET SWITCH ONLY FOR NON-VOLATILE LOCKOUT UNITS

Figure 2: Wiring for 1 Rod Flame Sense used for Internal Sense

SPARK

JUMPER WIRE

SUPPLIED WITH

THE CONTROL

REMOVE

JUMPER

11

SPARK

PILOT BURNER

2

1

GND

(VALVE)

MAIN

COMBINATION

GAS VALVE

*RESET SWITCH ONL Y FOR NON-VOLATILE LOCKOUT UNITS

3

PILOT

FLAME

SENSOR

45

GND

BURNER

6

7

ALARM

24V

GND

ALARM

THERMOSTAT

HIGH

TEMP

LIMIT

24 VAC

CLASS 2

TRANSFORMER

CHASSIS OR FRAME

GROUND

RESISTIVE NOISE SUPPRESSION WIRE

9

8

SENSE

RESET

RESET*

L1 (HOT)

L2 (NEU)

10

INTERN

Figure 3: Wiring for 2 Rod Flame Sense used for External Sense

E Series CE/AGA Approved Intermittent Pilot Ignition Control Installation Instructions 3

Page 4

Setup and Adjustments

Checkout

!

WARNING: Risk of Explosion or Fire. Verify

that there are no gas leaks by testing with appropriate

equipment. Never use a match or lighter to test for the

presence of gas. Failure to test properly can lead to an

explosion or fire and may result in severe personal injury

or death.

Make sure all components function properly by performing

the following test.

1. Before starting the appliance, perform a safety

inspection of piping, burners and venting. Check for

water leaks, etc. Check all wiring for proper

connections. Be sure the system is properly

grounded, including ground connection to the pilot

burner.

2. With the gas and thermostat off, turn on power to the

appliance.

3. Turn the thermostat to a high setting and verify that

the control goes through the operating sequence to a

shutoff condition.

Note: The burner does not light because the gas is

off.

4. Turn off the thermostat.

5. Turn on the gas and purge gas lines of all air.

6. Check for gas leaks on all pipe joints upstream of the

gas valve with a soap solution.

7. Turn the thermostat to the highest setting and verify

successful ignition and a normal run condition for at

least 5 minutes. If the appliance fails to run, see the

Troubleshooting section.

8. Check for gas leaks on all pipe joints downstream of

the gas valve with a soap solution.

9. Turn the thermostat down for at least 30 seconds

and then back up again. Verify successful ignition at

least five times.

10. Return the thermostat to a normal temperature

setting before leaving the installation.

!

WARNING:

The control module can not be serviced by user. If any

faults are detected, the control module must be

replaced. If control module has been opened or any

attempts to repair are done, the warranty is void.

Operation

Operating Mode Definitions

The following definitions describe the E Series operating

conditions.

• Waiting Time (Prepurge): The initial delay between

the start signal and the safety time to allow ventilation

of the combustion chamber and flue passages to

displace any unburned gas and/or products of

combustion.

• Safety Time (Trial for Ignition): The time between

energizing the pilot gas valve and de-energizing the

pilot gas valve if the flame signal is not detected.

• 100% Shutoff: Pilot gas did not ignite within the

safety time (trial-for ignition time) or the amount of

trials. The control de-energizes the spark circuit and

gas valve, and enters into lockout.

• Retrial: Failing an ignition attempt, the control enters

the inter-waiting time (retry) and then starts another

safety time (models with optional retrials).

• Running Position (Run): The main valve and pilot

valve remain energized and the spark is de-energized.

The appliance is in normal operation under the

supervision of the ignition control and its flame

detector device.

• Flame Loss Response (Inter-Purge): The loss of

proven flame. The main and pilot valves are turned off

(de-energized) and the control waits the recycle

(Inter-Purge) time before another spark sequence is

started. For controls without recycle (Inter-Purge) time

the main valve is turned off (de-energized) and pilot is

turned on (energized) and a spark sequence recurs

within 2.0 seconds.

• Volatile Lockout (Lockout): The safety shutdown of

the system where a startup sequence can only begin

after the thermostat contacts or main power is cycled

(off, then on) to reset lockout.

• Non-Volatile Lockout (Lockout): The safety

shutdown of the system where a startup sequence

can only begin after the operation of the external reset

switch to reset lockout.

• Recycle (Inter-Purge): If shutoff occurs, the control

delays for a specific recycle delay period before

beginning another trial for ignition (models with

recycle only).

• Inter-Waiting Time (Retry): Period between trials for

ignition when both the gas valve and spark is

deactivated to allow unburned gas to escape before

the next trial. Inter-Waiting (Retry) occurs between

unsuccessful trials on a multi-trial control.

• Alarm Output: The alarm output uses the normally

closed contact on the safety relay. It will turn on if

flame fails to light in the safety time or a fault is

detected in the control. The output will also be on for a

half second on power up until the safety relay turns

on.

4 E Series EC/AGA Approved Intermittent Pilot Ignition Control Installation Instructions

Page 5

Troubleshooting

If the system does not function properly, determine the

cause using the procedures in this section.

Before proceeding with troubleshooting the system, check

the following.

Preliminary Checks

Are you using resistive wire between the module

spark (11) and the pilot connection?

Are all mechanical and electrical connections tight?

Is the system wired and grounded correctly?

Is gas inlet pressure per manufacturer’s

specifications?

Is the thermostat calling for heat?

Is the system powered?

Table 1: LED Error Indications

LED Indications During Normal Operation

Orange once a second Waiting Time (Prepurge)

Red rapid flashing Safety Time Spark On (Trial for Ignition)

Steady green Running Position Flame On (Run)

Orange once every 5 seconds Inter-Waiting Time Between Cycles (Retry)

Orange once a second Flame Loss Waiting Time (Inter-Purge)

LED Error Indications

Red Green Error

1 0 Flame did not light in safety time (Trial for Ignition)

1 1 Flame sense circuit stuck on

1 2 Internal fault

1 3 Line frequency or micro clock error

2 1 Pilot valve fault

2 2 Pilot valve relay contact fault

2 3 Main relay fault

2 4 Main valve relay contact fault

Note: More than 2 red blinks indicate micro-memory or software fault.

E Series CE/AGA Approved Intermittent Pilot Ignition Control Installation Instructions 5

Page 6

Technical Specification

Product

Ignition Type

Ignition Source

High Voltage Cable

Maximum Length

Flame Sense Cable

Maximum Length

Flame Detection Means

Flame Detection Type

Minimum Flame Current

Flame Failure Response

Time

Maximum Spark Gap

Power Requirements

Contact Rating

Wiring Connections

Burner Rating

Ambient Operating and

Storage Temperature

Humidity

Type of Gas

Packaging

Bulk Pack Quantity

Pack Weight

Agency Listing

Specifications Standards

The performance specifications are nominal and conform to acceptable industry standards. All agency

certification of BASO products is performed under dry and controlled indoor environmental conditions. Use of

BASO products beyond these conditions is not recommended and may void the warranty. If the product is

exposed to water (dripping, spraying, rain, etc.) or other harsh environments, it must be protected. The original

equipment manufacturer or end user is responsible for the correct application of BASO products. For questionable

applications, please consult BASO Gas Products LLC. BASO Gas Products LLC shall not be liable for damages

or product malfunctions resulting from misapplication or misuse of its products

EC/AGA Universal Intermittent Pilot Ignition Control

Indirect

High voltage spark, capacitive discharge

1,220 mm (48 in.) (Resistive wire recommended, rated for at least 15Kv.)

1,220 mm (48 in.)

Flame Rectification

Local or Remote

0.15 microamperes

2 seconds maximum

5.1 mm (0.2 in.)

Control:

Operation Current:

Main Valve:

Pilot Valve:

Alarm Output

6.35 mm (1/4 in.) male spade

117 kW (400,000 Btu/hr)

-40 to 77°C (-40 to 176°F)

95% RH noncondensing

Natural, Liquefied Petroleum (LP), Manufactured, Mixed or LP Gas-Air Mixture

Bulk pack supplied to original equipment manufacturer (individual pack [-1AAC] or overpack

25

Bulk pack (-1AAD) 6.36 kg (14 lb)

Individual pack (-1AAC) .454 kg (1 lb.)

EC Certification Number EC-86/10/147

AGA Certification Number 7811

ANSI Standard Z21.20

CAN/CSA-C22.2 No. 199

24 VAC (+/- 20%), 50/60 Hz

0.2 A nominal + valves

2 A maximum

2 A maximum

1 A maximum

1007 South 12th Street

PO Box 170

Watertown, WI 53094 www.baso.com

1-877-227-6527 (1-877-BASOGAS Published in U.S.A.

6 E Series EC/AGA Approved Intermittent Pilot Ignition Control Installation Instructions

Loading...

Loading...