Page 1

Installation Instructions

Issue Date November 3, 2011

BGQ15HAA-1 Retrofit Spark Ignition System

Installation

Parts Included

The retrofit package includes:

• (1) BGD278JBE-20BCGD gas valve

• (1) BG1600M10EK-1AA spark ignition control

• (1) Rajah adapter

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making electrical

connections to avoid electric shock.

• (4) 1/4 inch female quick connects

• (1) Sensing probe cable

• (1) 1/8 inch NPT to 1/4 cc elbow fitting

• (1) Reducer bushing (3/4” to 1/2” NPT)

• (1) Compression fitting (1/4” tube)

• (1) Y75RJ-1 retrofit sensor probe kit

• (1) Sensor probe extension and (1) bushing

• (2) Spacers and (1) cone shaped nut

• retrofit package installation diagram and a

pressure sensitive lighting Caution sticker

Special Tools Needed

The following tools may be needed.

• manometer

• DC microammeter and AC voltmeter

• assorted pipe nipples and fittings

• On/Off toggle switch with wire leads and clips

Remove the Existing Gas Valve

IMPORTANT: Only qualified personnel should

install or service BASO Gas Products. These

instructions are a guide for such personnel. Carefully

follow all instructions in this document and all

instructions for the appliance.

IMPORTANT: Make all gas installations in

accordance with applicable local, national, and

regional regulations.

!

WARNING: Risk of Explosion or Fire.

Shut off the gas supply at the main manual shutoff

valve before installing or servicing the

BGQ15HAA-1. Failure to shut off the gas supply can

result in the release of gas during installation or

servicing, which can lead to an explosion or fire, and

may result in severe personal injury or death.

!

WARNING: Risk of Explosion, Fire, or

Electric Shock. Label all wires before they are

disconnected when replacing or servicing the

BGQ15HAA-1. Wiring errors can cause improper or

dangerous operation and may result in an explosion,

fire, or electric shock leading to severe personal

injury or death.

All installations must comply with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1, and the National Electrical Code

(NEC), ANSI/NFPA 70.

To remove the existing gas valve.

1. Set the thermostat at its lowest setting.

2. Turn off the power to the appliance.

3. Turn off the gas at the main manual shutoff valve.

4. Remove the thermocouple from the gas valve.

5. Disconnect the pilot tubing from the gas valve

Disconnect all wires from the existing gas valve.

6. Carefully remove the old gas valve from the

manifold.

© 2011 BASO Gas Products 1

Part No. BASO-INS-BGQ15, Rev. — www.baso.com

Page 2

Install the Sensing Probe and Cable

To install the sensing probe and cable:

1. Remove the thermocouple from the existing pilot

burner. The pilot burner should be left on its

mounting bracket if you can conveniently reach it.

If not, it may be necessary to partially pull out the

manifold for easy access. In some extreme

cases, it may be necessary to remove the pilot. If

it becomes necessary to replace the pilot burner,

it must be replaced with an identical model and

positioned using the original mounting.

2. Place the threaded end of the sensing probe

assembly into the thermocouple hole in the pilot.

3. Check the position of the spark gap. The spark

gap should be 0.1 in. (2.5 mm) nominal.

Note: Position the spark gap in the pilot gas

stream. Raise or lower the spark gap by adding

or removing the spacers provided between the

pilot and sensing probe assembly.

4. Screw the cone shaped nut onto the probe. The

small end fits into the threaded thermocouple

hole to center the sensing probe and secure it in

place.

5. Depending upon the appliance, the flame sensing

probe may be mounted in a number of positions.

Select the position providing the most clearance

from metal surfaces and the main burner flame.

2. When installing the ignition system on the

manifold, ensure that the gas flows through the

valve body in the direction indicated by the arrow

on the valve body. If the ignition system is

installed with the gas flow in the opposite

direction of the arrow, leakage can occur.

IMPORTANT: Do not use a wrench on any

surface other than the casting flats provided at the

inlet and outlet ends of the valve body. The

BGQ15HAA-1 may be damaged in the mounting

process if a wrench is used on any other surface.

Using a wrench incorrectly may void the warranty.

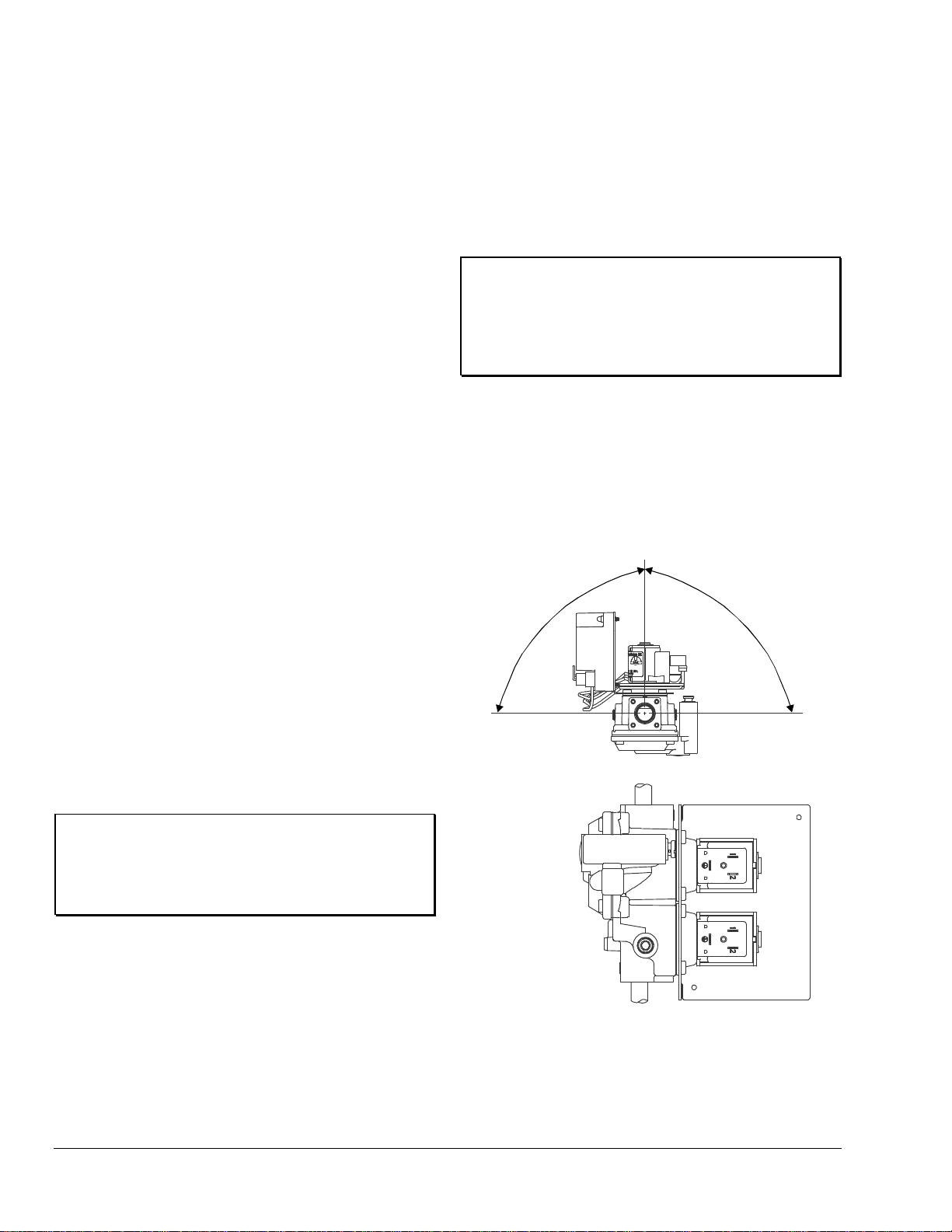

3. Mount the BGQ15HAA-1 ignition system on a

horizontal manifold with the ignition control

pointed up (vertical) or in a position not

exceeding 90° from vertical manifold in any

position around its axis (Figure 1).

Note: Additional piping may be required if

face-to-face dimensions are not the same.

90° Maximum

from Vertic al

90° Maximum

from Vertic al

6. Install the sensing probe cable onto the spade

connector of the sensor.

7. If the pilot burner was removed, reinstall the pilot

on its bracket in the furnace using the original

mounting.

Mounting

IMPORTANT: Verify that the valve is installed

only in applications where the specified maximum

ambient (surface) temperature and maximum

operating pressures do not exceed the limits in the

Technical Specifications section.

To install the BGQ15HAA-1 ignition system:

1. Compare the voltage on the valve with the power

source voltage to ensure the correct unit is being

installed. For valves with 25 volt coils, use an

NEC, Class 2 transformer.

Note: The transformer must be mounted to a

grounded metal enclosure.

Vertical mo unting may

be 360º ar ound its axis

with the gas flow either

up or dow n, but always in

the direction of the arrow.

Figure 1: BGQ15HAA-1 Mounting Positions

2 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 3

4. Mount the ignition system to the pipework. Use

an approved pipe joint sealing compound on the

male threads before assembling. Remove excess

compound after mounting the ignition system to

the pipework. Threads of the pipe and nipples

must be smooth and free of tears and burrs.

Steam clean all piping to remove foreign

substances such as cutting oil or thread chips. A

sediment trap must be installed in accordance

with the National Fuel Gas Code (ANS Z223.1).

See Figure 2.

5. Connect the pilot tubing to the valve assembly

with the 1/8 in. NPT to 1/4 in. cc elbow fitting, if

needed

!

WARNING: Risk of Explosion or Fire.

Verify that there are no gas leaks by testing with

appropriate equipment. Never use a match or lighter

to test for the presence of gas. Failure to test

properly can lead to an explosion or fire and may

result in severe personal injury or death.

6. Check for leakage.

a. Shut off the gas at the main manual shutoff

valve and open the pressure connection

between the manual shutoff valve and the

BGQ15HAA-1 valve.

b. Connect air tubing with a maximum pressure

of 1-1/2 times the valve’s maximum operating

pressure (as indicated on the valve) to the

opened pressure connection.

c. Paint all valve body connections with a rich

soap and water solution.

If bubbles occur, this indicates a leak. To stop

a leak, tighten joints and connections. Replace

the part if the leak cannot be stopped.

If bubbles do not occur, remove the air tubing

and close the pressure connection.

7. Perform the Checkout section before leaving the

installation.

Gas Flow

Manual Shutoff

Sediment

Trap

Valve

"X"

3 in. (76.2 mm)

Minimum

BGQ15 Ignition

System

“X” in dicate s po ssible

locations f or ot her contr ol s.

"X”

Burner

Figure 2: Typical Installation of a BGQ15HAA-1

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 3

Page 4

Wiring

!

WARNING: Risk of Explosion or Fire.

Locate all safety, limit, and operating controls in

series with the thermostat terminal (TH) on the

ignition control. Improper installation may cause gas

leaks, which can lead to an explosion or fire and

may result in severe personal injury or death.

Refer to Figure 3 or Figure 4 for wiring diagrams. All

wiring should be in accordance with the National

Electrical Code (NEC) and all other local codes and

regulations.

Check the voltage rating marked on the control and

make sure it is suited to the application. Use a Class 2

transformer capable of providing 24 VAC under

maximum load, including valves. A transformer having

excessive primary impedance due to poor coupling

affects the ignition potential.

The high-voltage spark transformer cable is noise

suppression (resistive) type rated for at least 15 kV

and must not be in continuous contact with a metal

surface. Use standoff insulators. Ensure that the flame

sensor wire and high voltage spark transformer cable

are separated from one another by a minimum of

1/4 in. (6.35 mm) and are not wrapped around any

pipe, other wiring, or accessories.

Note: A shorting plug that jumpers pins 2 and 3 of the

damper connector is supplied with the control. The

shorting plug must be used if a vent damper is not

used. When a vent damper has been connected and

power turned on, an internal fuse in the control will

blow and the control will only operate with a vent

damper connected. Now you cannot disconnect the

vent damper plug and put back the shorting plug. The

ignition control will not work.

!

WARNING: Risk of Electric Shock.

Before applying power to the control, connect the

high voltage cable to the spark transformer terminal

and spark electrode (pilot burner assembly). Verify

the ground wire is attached to the pilot burner and

the control ground terminal strip. Failure to follow

this procedure can cause electric shock and may

result in severe personal injury or death.

The BGQ15HAA-1 replaces existing intermittent pilot

ignition controls with the following specifications:

• flame detection using flame rectification

technology (ability of a flame to conduct and

rectify current)

• trial for ignition 1 trial

• dual rod (remote sense) flame sensing

• no retry

• infinite trial time

• prepurge period of none

• inter-purge period of 5 seconds

• main burner 400,000 Btu/hr maximum

• pilot burners with flow rates of 1,500 Btu/hr or

less

• with or without automatic vent damper

• must be used with redundant gas valves and

not subjected to temperatures below

-40˚F (-40˚C) or above 170˚F (77˚C)

4 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 5

MV/PV

(COM)

2

PV

3

MV

1

GND

456

24V

GND

BURNER

Use jumper

plug s u pp li ed

with control.

SENSE

TH

7

8

SPARK

INTERNAL

9

10

Thermostat

5

3

High

Temp

Limit

Pilot

Burner/Ignitor

1

Power Supply. Provides disconnect means and overload protection as required.

Maximum cable length 48 in ches (1,220 mm). (Resisti ve wire reco m mended.)

2

3

Alternate location for limit controller.

4

Controls in 24V circuit must not be in ground leg to transformer.

5

Maximum cable length 48 inches (1,22 0 mm) .

Sensor rod must be 3/8” (9.53 mm) to 1/2” (12.7 mm) of the sensor tip should

6

be in the flame for proper sensing signal.

6

Flame

Sensor

4

24VAC

Class 2

Transformer

Chassis or Frame

Ground

1

L1 (Hot)

L2 (Neu)

2

Figure 3: Wiring for 2 Rod Flame Sense with Vent Damper Jumper Plug

Discard jumper

plug supplied

MV/PV

MV

(COM)

2

1

PV

3

GND

45

GND

BURNER

with the control.

24V TH

67

SENSE

89

INTERNAL

DAMPER

PLUG

SPARK

10

Wiring

Harness

Thermostat

24VAC

Class 2

Transformer

Chassis or Frame

3

4

Ground

Combination

Gas Valve

Pilot

Burner/Ignitor

1

Power Supply. Provides disconnect means and overload protection as required.

Maximum cable length 48 in ches (1, 220 mm). (Resisti ve wire rec om m ended.)

2

3

Alternate location for limit controller.

4

Controls in 24V circuit must not be in ground leg to transformer.

Maximum cable length 48 inches (1,220 mm).

5

Sensor rod must be 3/8” (9.53 mm) to 1/2” (12.7 mm) of the sensor tip should

6

be in the fla me f or pr oper sensin g s i gnal.

6

Flame

Sensor

High

Temp

Limit

5

L1 (Hot)

L2 (Neu)

Vent

1

Damper

2

Figure 4: Wiring for 2 Rod Flame Sense with Vent Damper

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 5

Note:

If a damper i s not used

(see Figure 3), use

pin 2-3 jumper plug

supplied with the control

and omit 24V connection.

Page 6

/

j

Setup and Adjustments

Electrical and Mechanical Checkout Procedure

After the BGQ15HAA-1 installation is complete, perform

the following procedures to ensure the installation is

correct. While performing the following procedure, keep

the high voltage cable and the sensing probe cable away

from hot surfaces.

1. Measure the output current in the probe circuit using

a DC microammeter. Connect the microammeter

leads between the sensing probe cable and Terminal

8 on the ignition control. Connect the positive lead to

Terminal 8 and the negative lead to the sensing

probe cable (Figure 5).

MV

1

MV

(COM) P V

2

PV

3

456

GND

BURNER

GND 24V SENSE

TH

7

8

910

INTERNAL

SPARK

Use

plugsupplied

with contr ol.

umper

Flame

Sensor

Digital Multi mete r

Positive

Lead

Flame

Sensor

Cable

Note: Once the pilot flame is lit, the microammeter

shows a reading from the flame sensing probe. The

current reading should be at least 0.15 microampere.

If the reading is less than 0.15 microampere, turn off

the electrical power and adjust the pilot assembly by

adding spacers between the pilot bracket and the

sensing probe assembly. No more than 1/2 in. of the

flame sensor tip should be in the pilot flame. If this

does not correct the current reading, it may be

necessary to increase the pilot burner orifice size.

Recheck until the reading is satisfactory.

6. Flip the toggle switch to the Off or open position.

7. Reconnect the main valve lead to Terminal 1 on the

ignition control.

8. Flip the toggle switch to the On or closed position.

The pilot should light and immediately thereafter, the

main burner should light.

9. Check the outlet pressure reading by removing the

pressure tap plug and connecting a manometer.

Compare it with the furnace or boiler specifications. It

may be necessary to adjust the pressure regulator to

the rating indicated (see the Regulator Adjustment

section).

Negative

Lead

Figure 5: Wiring Diagram for Flame Sensing Current

Measurement

2. Remove the main valve lead from Terminal 1 on the

ignition control. Attach the on/off toggle switch

between the ungrounded post of the transformer and

Terminal 7 on the ignition control. The toggle switch

serves as the thermostat for testing procedures.

Make sure the thermostat contacts are open.

3. Open the main manual shutoff valve to turn on the

gas supply.

4. Restore power to the furnace or boiler and flip the

toggle switch to the On or closed position. The pilot

valve opens and a spark jumps the spark gap at the

pilot.

5. Test for leaks at the pilot tubing connections with a

soap solution. In a few seconds, the spark lights the

pilot after the air is bled from the pilot gas line.

Turndown Test Procedure

With the toggle switch still connected, perform the

following turndown test to assure main burner ignition

under conditions that permits the main valve to open.

1. Slowly close the manual shutoff valve until the pilot

flame is just sufficient to maintain operation of the

main burner.

2. Cycle the main burner off and on with the toggle

switch. Perform this test with the furnace or boiler

burner cold and hot.

3. If the furnace or boiler cycles without igniting the

main burner in four seconds, ensure the pilot is

properly located and correct for the application.

4. Completely open the main manual shutoff valve.

5. If unstable burner lighting occurs, causing the ignition

control to chatter on and off during startup, install the

flame rectification extension as follows.

a. Place the sensor probe extension and bushing

onto the flame sensing probe.

b. Position the extension over the main burner so it

extends into the flame.

c. Secure the extension in place by tightening the

extension probe into the bushing.

Note: The sensor probe extension detects the main

burner flame and the BG1600M ignition control

allows continued operation until a stabilized pilot is

maintained.

6 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 7

6. Ensure the thermostat contacts are open and remove

the toggle switch.

7. Remove the microammeter and reconnect the sensor

probe lead to Terminal 8 on the ignition control.

8. Shut off the gas supply at the main manual shutoff

valve, disconnect the manometer, and replace the

pressure tap plug.

Note: The thermostat heat anticipator setting

should be set for 0.4 ampere (current draw of the

BGQ15HAA-1 gas valve). When using an automatic

vent damper, add the current draw of the vent

damper to the 0.4 ampere of the gas valve. The

transformer should be checked to make sure it has

sufficient capacity to operate the additional load.

9. Reopen the main manual shutoff valve.

10. Perform the Checkout section before leaving the

installation.

Thermostat Heat Anticipator Settings

The anticipator setting is normally equal to the ignition

system current, plus that of the pilot and main valve.

Due to variations in appliance wiring and valves, it is

advisable to measure the actual current draw of the

heating system at the thermostat location. Measuring this

current can be accomplished by opening the thermostat

contacts (lowering the setpoint) and installing an AC

ammeter across the terminals, or by using a clamp-on

ammeter with a 10-turn multiplier attached to the terminals

(Figure 6).

To

Heating

System

To

Heating

System

R

W

R

AC Ammeter Low

Scale Setting

W

Ten Turns

Clamp- on Amme ter

(Divide reading by ten.)

Figure 6: Measuring the Thermostat Current

Regulator Adjustment

!

WARNING: Risk of Explosion or Fire. Do not

adjust the minimum flow rate of the valve below the

minimum safe working rate of the appliance. This may

cause gas leaks, which can lead to an explosion or fire,

and may result in severe personal injury or death.

!

WARNING: Risk of Personal Injury. Do not

take a current draw measurement unless the appliance

is in the run condition. Measuring the current with an

ammeter will energize the system. This may cause the

appliance to proceed to the run condition unexpectedly,

and may result in severe personal injury or death.

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 7

IMPORTANT: Refer to and follow any specific

instructions issued by the appliance manufacturer with

regards to servicing their equipment.

The pressure regulator is adjustable and has been factory

set at 3.5 in. W.C. (8.75 mbar). If a different setting is

desired, follow these instructions.

1. Shut off all gas to the appliance.

2. Turn the thermostat to the lowest setting or Off

position.

3. Remove the pressure tap plug at the valve outlet or

in the manifold pipe downstream of the valve.

4. Install a manometer or pressure gauge suitable for

measuring the desired orifice pressure.

Page 8

5. Remove the seal screw at the end of the regulator

stack.

6. Turn the gas on and place the thermostat at the

highest setting to cycle the ignition system.

7. Allow the system to stabilize. Adjust the screw in the

regulator stack to the desired reading on the

manometer. (Turn clockwise to increase the outlet

pressure and counterclockwise to reduce the outlet

pressure.)

8. Reinstall the seal screw, which incorporates the

proper size hole for venting to the atmosphere. (It

may be necessary to cycle the valve several times to

verify the desired outlet pressure.)

9. Turn off the gas supply and place the thermostat at

the lowest setting.

10. Remove the manometer and reinstall the pressure

tap plug.

11. Turn the gas on and check for leaks at the pressure

tap plug with a soap solution.

12. Set the thermostat to the desired setting before

leaving the site.

3. Turn the thermostat to a high setting and verify that

the control goes through the operating sequence to a

shutoff condition.

Note: The burner does not light because the gas is

off.

4. Turn off the thermostat.

5. Turn on the gas and purge gas lines of all air.

6. Check for gas leaks on all pipe joints upstream of the

gas valve with a soap solution.

7. Turn the thermostat to the highest setting and verify

successful ignition and a normal run condition for at

least 5 minutes. If the appliance fails to run, see the

Troubleshooting section.

8. Check for gas leaks on all pipe joints downstream of

the gas valve with a soap solution.

9. Turn the thermostat down for at least 30 seconds

and then back up again. Verify successful ignition at

least five times.

10. Return the thermostat to a normal temperature

setting before leaving the installation.

Checkout

!

WARNING: Risk of Explosion or Fire. Follow

this or an equivalent checkout procedure after

installation. Before leaving the installation, verify that the

BGQ15HAA-1 functions properly and that the system

has no gas leaks. Gas leaks can lead to an explosion or

fire, and may result in severe personal injury or death.

!

WARNING: Risk of Explosion or Fire. Verify

that there are no gas leaks by testing with appropriate

equipment. Never use a match or lighter to test for the

presence of gas. Failure to test properly can lead to an

explosion or fire and may result in severe personal injury

or death.

Make sure all components function properly by performing

the following test.

1. Before starting the appliance, perform a safety

inspection of piping, burners and venting. Check for

water leaks, etc. Check all wiring for proper

connections. Be sure the system is properly

grounded, including ground connection to the pilot

burner.

!

WARNING:

The control module can not be serviced by user. If any

faults are detected, the control module must be

replaced. If control module has been opened or any

attempts to repair are done, the warranty is void.

Operation

Operating Mode Definitions

The following definitions describe the BG1600M operating

conditions.

• Prepurge: Initial time delay between thermostat

contact closure and activation of the spark circuit and

pilot valve.

• Trial for Ignition: Total time the pilot valve is

energized and spark/sense sequence is activated in

an attempt to light the pilot. The control attempts to

prove flame within the trial-for-ignition time.

• 100% Shutoff: If the control does not prove the

presence of pilot burner flame within the trial for

ignition, the spark circuit and pilot valve are

de-energized.

• Recycle: If 100% shutoff occurs, the control delays

for a specific recycle delay period before beginning

another trial for ignition (models with recycle only).

2. With the gas and thermostat off, turn on power to the

appliance.

8 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 9

• Run: Main valve is energized and spark turns off after

pilot flame is proven. The main valve remains

energized until the thermostat is satisfied.

• Flameout: Loss of proven flame. Should a flameout

occur, the main valve de-energizes and spark recurs

within 2.0 seconds.

• Lockout: An internal or external fault has caused the

control to de-energize the spark circuit and valve

relays. The thermostat contacts must be opened for

30 seconds and then closed to begin another trial for

ignition.

• Inter-Purge: Period between trials for ignition when

both the gas valve and spark are de-activated to allow

unburned gas to escape before the next trial.

Sequence of Operation

The heating cycle start when a call for heat from the

thermostat supplies 24VAC to the TH terminal. The

automatic vent damper (if used) is energized and when

fully open, turns on the power to the ignition control. After

a 1 second maximum diagnostic period, the spark will

start and the pilot valve will turn on, starting with the trial

for ignition period.

During the trial for ignition period, the control sparks for 4

seconds while rapidly flashing LED. It then turns off the

spark and LED for 1 second while checking pilot flame

sense. This cycle will repeat until pilot flame is detected or

trial time is over.

When pilot flame is detected, the spark will stop, main

valve will turn on and the LED will stay on continuously.

The control will remain in this state until the pilot flame is

lost or the call for heat ends. If pilot flame is lost, LED,

main and pilot valves are turned off for 0.5 seconds and a

new trial for ignition sequence will star t.

Troubleshooting

If the system does not function properly, determine the

cause using the procedures in this section.

Before proceeding with troubleshooting the system, check

the following.

Preliminary Checks

Are you using resistive wire between the module

spark (10) and the pilot connection?

Are all mechanical and electrical connections tight?

Is the system wired and ground correctly?

Is gas inlet pressure per manufacturer’s

specifications?

Is the system powered?

Is the thermostat calling for heat?

!

WARNING: Risk of Personal Injury.

Do not place face, hands, or other parts of the body in

or near the burner area when the LED is flashing

(recycle mode). When the LED is flashing, the control

may at any time (while in the recycle mode) re-energize

the burner control system and ignite the burner which

may result in electric shock from contact with the

electrode or severe burn injury from firing of the burner.

If pilot flame is not detected during the trial for ignition

period, the pilot valve will be shut off. Lockout will occur if

your model has no retry. Otherwise, after 5 minutes or 60

minutes (for recycle units only) the control will delay for

the specific recycle delay period before beginning another

trial for ignition.

Table 1: LED Indications During Normal Operation

Flash Code Flash Code Indication

Steady On Flame detected, main burner on

.1 Second On

.1 Second Off

1.0 Second On

Trial time spark on trying to light

pilot burner

2 minute recycle delay time

4.0 Second Off

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 9

Page 10

LED Error Indications

If the control module’s internal diagnostics detect a fault it

will go into lockout. Spark and both valves will be turned

off. The LED will flash an error code .25 seconds on and

.25 seconds off for each count of the error code with

1 second off between codes. The control will remain in

this condition until power is removed by turning off the call

for heat. A flashing LED error code indicates either a

problem with wiring, or a component not working, or the

control module is faulty. Try to cycle the control again. If

the error repeats then see Table 2 for troubleshooting.

Table 2: LED Error Indications

Flash

Code

Flash Code

Description

Troubleshooting Guide

1. Check Controller for a Molex connection;

1.1. Controller w/MOLEX connector and the Vent Damper jumper plug installed, check for

No

LED“

ON”

No Power

24 volts on terminal 7 (TH) and terminal 5 (GND). If using a Vent Damper, make sure it is

connected and the damper is working, check for 24 volts on terminal 6 (24V) and

terminal 7 (TH) to terminal 5 (GND).

1.2. Controller w/o MOLEX connector, check for 24 volts on terminal 6 (24V) and terminal

5 (GND).

2. Check for 24 volts on the secondary coil of the incomi ng transformer.

1. Check if the gas is turned “ON”.

2. Check Controller for a Molex connection;

2.1. Controller w/MOLEX connector and the Vent Damper jumper plug installed, check for

24 volts on terminal 7 (TH) and terminal 5 (GND). If using a Vent Damper, make sure it is

connected and the damper is working, check for 24 volts on terminal 6 (24V) and

1

No flame in

trial time

terminal 7 (TH) to terminal 5 (GND).

2.2. Controller w/o MOLEX connector, check for 24 volts on terminal 6 (24V) and terminal

5 (GND).

3. If no spark, check spark wire and connection to terminal 10 (SPARK) and spark ground

to terminal 4 (GND BURNER).

4. Check if PV is wired to terminal 3 (PV) and common is wired to terminal 2 (MV/PV COM).

5. Check for 24 volts at the PV coil.

1. Check Flame Sensor tip is in the flame. For proper sensing the rod tip must be 3/8”

(10mm) to 1/2” (13 mm) in the flame.

2

Flame

sense circuit

error

2. Check Flame Sensor Circuits;

2.1 For 1 Rod Flame Sense circuit, check Spark/Flame S ensor is wired to terminal

10 (SPARK) and terminal 4 (GND BURNER).

2.2 For 2 Rod Flame Sense circuit, check Flame Sensor is wired to terminal 8 (SENSE) and

terminal 4 (GND BURNER).

3

4

5

6 to 9

PV

(Pilot Valve)

circuit error

MV

(Main Valve)

circuit error

Internal

Control error

Internal

Control error

1. Check for 24 volts on terminal 3 (PV) and terminal 2 (MV/PV COM).

2. Check for 24 volts at the PV coil.

3. Check if PV is wired to terminal 3 (PV) and common is wired to terminal 2 (MV/PV COM).

1. Check for 24 volts on terminal 1 (MV) and terminal 2 (MV/PV COM).

2. Check for 24 volts at the MV coil.

3. Check MV is wired to terminal 1 (MV) and common is wired to terminal 2 (MV/PV COM).

1. Review all ground connections.

2. Check if using fiber core resistive wire for Spark Wire.

1. Software error – Restart control module.

NOTE: If Troubleshooting Guide has been used, and the Control Module is flashing an ERROR CODE, then the

Control Module may be faulty. Replace the Control Module.

10 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 11

Idle State

Call for heat

from the thermostat

If damper connected

wait for it to open

POWER TO CONTROL

One second for

diagnos t ic routine s

Note:

If the thermostat opens,

the control will turn off valves

and returns to the idle state.

Wait 0.1 se cond

checking memory and

relay driver circuits

Flame

on?

OK

No

Yes

FLAME ON

LOOP

If pre-pu r ge wait

flashing LED once a

second unt il ove r

Turn on spark and

pilot gas valve

start trial timer

Spark on 4 seconds

blinking LED rapidly

spark of f 1 second

Flame

on?

No

TRIAL

TIME

LOOP

Trial

No

TIME

Tur n pilot gas

over?

Yes

valve off

Retry

option?

Yes

TRIAL

OVER

Yes

Wait 0.5 se cond

Flame

No

on?

Yes

Tur n on m a in

gas valve and LED

reset try count

0.7 second?

RE-IGNITION

Yes

Turn main gas

valve off, start s park

and t rial timer

Turn pil ot and main

gas valves off

wait 0.7 second

inter - purge bl i nk ing

LED once a second

RELIGHT

Flame off

Yes

Re-Ignition

No

RECYCLE

No

FLAME LOST

Lock out on t imeout or fa ult detected,

Note:

turn off re lays and spark loop bl inking

error code unti l power off.

Error Codes

No flame in trial time.

Flame se nse stuck on .

Pilot relay driver fault.

Main relay driver fault.

Processor errors.

1 Blink

2 Blinks

3 Blinks

4 Blinks

5 to 9 Blinks

Trie s over

Wait 5 or 60 minutes,

blink LED ev er y 15 seconds

Lockout

RESTART

Figure 7: Sequence of Operation

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 11

Page 12

Turn on power

and gas.

Close thermostat

contacts.

Module LED

did not light and

no spark?

No

Module LED

blinks slowly?

No

Module LED

blinks rapidly but

no spark?

No

Pilot flame

does not

light?

No

Yes

Yes

Yes

Yes

Diagnostic error

see next page .

Replace module.

Spark wire

and electrode

OK?

No

Replace spark wire

or electrode.

24V between

PV and GND

terminals?

No

Replace

module.

Yes

Replace

module.

Yes

Gas at pilot

Adjust or replace spark

electro de and /or pilot

24V between

TH and GND

Connect pin 2-3

shor ting plug to

burner?

Yes

burner.

terminals?

Yes

Damper

used?

No

Shorting

plug in?

No

damper.

No

No

Check transformer,

thermostat and wiring.

Repair or replace as needed.

Yes

24V between

damper pin 2 & 4?

Yes

Yes

Check orfice and tubing are clear.

Replace

module.

Check shutoff valves are on.

Check wiring to pilot valve.

If all OK replace pilot valve.

No

Check and repair

damper, and/or

damper wiri ng.

Pilot lights

but keeps

sparking?

No

Pilot is lit

continued

on next page

Pilot flame in contact

with spark or sense

electrode?

Yes

Two rod

flame sense?

Yes

Check wiring electrode

to SENSE terminal.

If OK replace module.

NoYes

No

Check burner orifice.

Adjust pilot flame size or

electro de position.

Replace

module.

Figure 8: Troubleshooting Flow Chart (1 of 2)

12 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 13

Continued

from p revious page

Pilot is lit

Main burner

failed to turn

on?

No

After main is

lit, do valves turn off

and star t new

cycle?

No

Control is

operating

normally.

Yes

Yes

Yes

24V between

MV and MV/PV

terminals?

No

Replace

module.

Pilot flame in

contact with spark or

sense el ectrode?

Yes

Two rod

flame sense ?

Yes

Yes

No

No

Gas at main

burner?

Adjust pilot flame size

and posit ion, or replace

pilot burn er or m ain burner.

Adjust pilot flame size or

Replace

module.

No

Yes

electrode position.

Check that shutoff valves are on.

Check wiring to main valve.

Check tubing is clear.

If all OK replace main valve.

Check wiring electrode

to SENSE terminal.

If OK replace module.

Figure 9: Troubleshooting Flow Chart (2 of 2)

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 13

Page 14

Maintenance Requirements in Severe

Environments

Regular preventive maintenance is important in any

application, but especially so in commercial cooking,

agricultural, and industrial applications because:

• In many such applications, particularly

commercial cooking, the equipment operates

100,000 to 200,000 cycles per year. Such heavy

cycling can wear out the gas control in one to

two years. A normal forced air furnace, for which

the controls were originally intended, typically

operates less than 20,000 cycles per year.

• Exposure to water, dirt, chemicals, and heat can

damage the ignition control module or the gas

control and shut down the control system. A

NEMA 4 enclosure can reduce exposure to

environmental contaminants.

!

WARNING: Risk of Explosion or Fire. Do

not attempt to take the ignition control module apart

or to clean it. Improper reassembly and cleaning

may cause unreliable operation, which can lead to

an explosion or fire, and may result in severe injury,

property damage or death.

Maintenance frequency must be determined

individually for each application. Some considerations

are:

• Cycling Frequency – Appliances that may cycle

more than 20,000 times annually should be

checked monthly.

• Intermittent Use – Appliances that are used

seasonally should be checked before shutdown

and again before the next use.

• Consequence of Unexpected Shutdown –

Where the cost of an unexpected shutdown

would be high, the system should be checked

more often.

Repairs and Replacement

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making electrical

connections to avoid electric shock.

!

WARNING: Risk of Explosion or Fire.

Shut off the gas supply at the main manual shutoff

valve before installing or servicing the control.

Failure to shut off the gas supply can result in the

release of gas during installation or servicing, which

can lead to an explosion or fire, and may result in

severe injury or death.

!

WARNING: Risk of Explosion, Fire, or

Electric Shock. Label all wires before they are

disconnected when replacing or servicing the

BGQ15HAA-1. Wiring errors can cause improper or

dangerous operation and may result in an explosion,

fire, or electric shock leading to severe personal

injury or death.

Field repairs must not be made to the BGQ15HAA-1

control. Any attempt to repair this assembly voids the

manufacturer’s warranty. For a replacement control,

contact the original equipment manufacturer or the

nearest BASO Gas Products distributor.

All other accessories, such as flame sensors,

electrode assembles, pilot assemblies, and leads can

be obtained through the original equipment

manufacturer or a BASO Gas Products distributor.

• Dust, Wet, or Corrosive Environment – Since

these environments can cause the controls to

deteriorate more rapidly, the system should be

checked more often.

14 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 15

Ignition Control Accessories

Table 3: Ignition Control Accessories

Part Number Description

RAA1600A-601D Rajah to 1/4” Spade Adapter (box of 50)

RAA1600A-601H Rajah to 1/4” Spade Adapter (bag of 10)

WHA40A-600D 18” Resistive Wire Harness with (2) 1/4” Terminals (box of 25)

WHA40A-600H 18” Resistive Wire Harness with (2) 1/4” Terminals (bag of 1)

WHA40A-601D 18” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (box of 25)

WHA40A-601H 18” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (bag of 1)

WHA40A-602D 24” Resistive Wire Harness with (2) 1/4” Terminals (box of 25)

WHA40A-602H 24” Resistive Wire Harness with (2) 1/4” Terminals (bag of 1)

WHA40A-603D 24” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (box of 25)

WHA40A-603H 24” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (bag of 1)

WHA40A-604D 36” Resistive Wire Harness with (2) 1/4” Terminals (box of 25)

WHA40A-604H 36” Resistive Wire Harness with (2) 1/4” Terminals (bag of 1)

WHA40A-605D 36” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (box of 25)

WHA40A-605H 36” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (bag of 1)

WHA40A-606D 48” Resistive Wire Harness with (2) 1/4” Terminals (box of 25)

WHA40A-606H 48” Resistive Wire Harness with (2) 1/4” Terminals (bag of 1)

WHA40A-607D 48” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (box of 25)

WHA40A-607H 48” Resistive Wire Harness with (1) 1/4” Terminal and 1 Rajah Terminal (bag of 1)

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 15

Page 16

Technical Specification

Product

Ignition Type

Ignition Source

High Voltage Cable

Maximum Length

Flame Sense Cable

Maximum Length

Flame Detection Means

Flame Detection Type

Minimum Flame Current

Flame Failure Response

Time

Maximum Spark Gap

Number of Trials Before

100% Shutoff

Trial-for-Ignition Time

Prepurge Time

Inter-Purge Time

Automatic Recycle Delay

Period

Power Requirements

Contact Rating

Wiring Connections

Maximum Firing Rate

Ambient Operating and

Storage Temperature

Humidity

Type of Gas

Packaging

Pack Weight

Agency Listing

Specifications Standards

The performance specifications are nominal and conform to acceptable industry standards. All agency certification of BASO products is

performed under dry and controlled indoor environmental conditions. Use of BASO products beyond these conditions is not recommended and

may void the warranty. If the product is exposed to water (dripping, spraying, rain, etc.) or other harsh environments, it must be protected. The

original equipment manufacturer or end user is responsible for the correct application of BASO products. For questionable applications, please

consult BASO Gas Products LLC. BASO Gas Products LLC shall not be liable for damages or product malfunctions resulting from

misapplication or misuse of its products.

BG1600M10EK-1AA Intermittent Pilot Ignition Control

Indirect

High voltage spark, capacitive discharge

48 in. (1,220 mm) (Resistive wire recommended, rated for at least 15kV.)

48 in. (1,220 mm)

Flame Rectification

Remote

0.15 microamperes

2 seconds maximum

0.2 in. (5.1 mm)

One

Infinite

None

5 seconds

None

Control:

Operation Current:

Main Valve:

Pilot Valve:

1/4 in. (6.35 mm) male spade

400,000 Btu/hr (117 kW)

-40 to 170°F (-40 to 77°C)

95% RH noncondensing

Natural, Liquefied Petroleum (LP), Manufactured, Mixed or LP Gas-Air Mixture

Bulk pack supplied to original equipment manufacturer (25 per box)

Individual pack (1 per box)

Individual overpack (20 per box)

Bulk pack 14 lb (6.36 kg)

Individual pack 1 lb (.454 kg)

Individual overpack 18 lb (8.17 kg)

CSA Certificate Number 246569-2161442

ANSI Standard Z21.20

CAN/CSA-C22.2 No. 199

24 VAC (+/- 20%), 50/60 Hz

0.2 A nominal + valves

2 A maximum

1 A maximum

16 BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions

Page 17

Technical Specifications

Product

Maximum Operating

Pressure

Permissible Ambient

(Surface) Temperature

Valve Body

Electrical Rating

Electrical Connection

Regulator Adjustment

Range

Inlet Pipe Size

Outlet Pipe Size

Wiring Connections

Coil Insulation Class

Type of Gas

Agency Listing

Specification Standard

Performance specifications are nominal and conform to acceptable industry standards. All agency certification of BASO products is performed

under dry and controlled indoor environmental conditions. Use of BASO products beyond these conditions is not recommended and may void

the warranty. Product must be protected if exposed to water (dripping, spraying, rain, etc.) or other harsh environments. The original

equipment manufacturer or end user is responsible for the correct application of BASO products. Consult BASO Gas Products LLC for

questionable applications. BASO Gas Products LLC shall not be liable for damages or product malfunctions resulting from misapplication or

misuse of its products.

BGD278JBE-20BCGD Gas Valve

0.5 psi (35 mbar)

-20 to 175°F (-29 to 79°C)

Aluminum

25 VAC, 60 Hz, 0.42A, 10.5 VA per coil

3-Tab Solenoid Coil: 2 x 1/4 in. (6.35 mm) + 1/4 in. (6.35 mm) Earth Ground

3 to 6 in. W.C. (7.5 to 15 mbar)

1/2 in. NPT

3/4 in. NPT

Wire Harness Pre-Wired

Class F

Natural

CSA (AGA/CGA) Certification Number 229521-1656041

ANSI Z21.78, CSA 6.20

1007 South 12th Street

PO Box 170

Watertown, WI 53094 www.baso.com

1-877-227-6427 (1-877-BASOGAS) Published in U.S.A.

BGQ15HAA-1 Retrofit Spark Ignition System Installation Instructions 17

Loading...

Loading...