Page 1

Installation Instructions BGH

Issue Date October 4, 2010

BGH2UNCNTRLHT-01 Universal

Hot Surface Ignition Control

Application

The BASO Gas Products BGH2UNCNTRLHT-01

Universal Series Hot Surface Ignition (HSI) control is

microprocessor based with timed ignition and suited

for replacement or new applications. Applications for

hot surface ignition modules include agricultural

equipment, space heaters, furnaces,

residential/commercial boilers, water heaters, pool

and spa heaters, and a variety of other commercial

cooking equipment.

This control includes a 5 position DIP switch allowing

up to 32 programmable pre-defined timing selections

to retrofit other Hot Surface Ignitions with flame

sensing rectification, such as: Johnson Controls,

Honeywell, White Rodgers, Fenwal, and

Robertshaw.

The BGH2UNCNTRLHT-01 works with single-rod or

dual-rod sensing to prove a flame. The control has a

continuous and precise monitoring of the HSI

element, wiring, and gas valve, shutting down in the

event of a failure. For a complete listing of

specifications, refer to the Technical Specifications

section.

Installation

IMPORTANT: Only qualified personnel

should install or service BASO Gas Products®.

These instructions are a guide for such personnel.

Carefully follow all instructions for the appliance.

IMPORTANT: Make all gas installations in

accordance with applicable local, national, and

regional regulations.

!

WARNING: Risk of Explosion or Fire.

Do not install the control in an area that is exposed

to water (for example, dripping, spraying, rain). Do

not use the control if it has been exposed to water.

Exposure to water may cause malfunction and can

lead to an explosion or fire and may result in

severe personal injury or death.

© 2010 BASO Gas Products 1

Part No. BASO-INS-BGH, Rev. - www.baso.com

Page 2

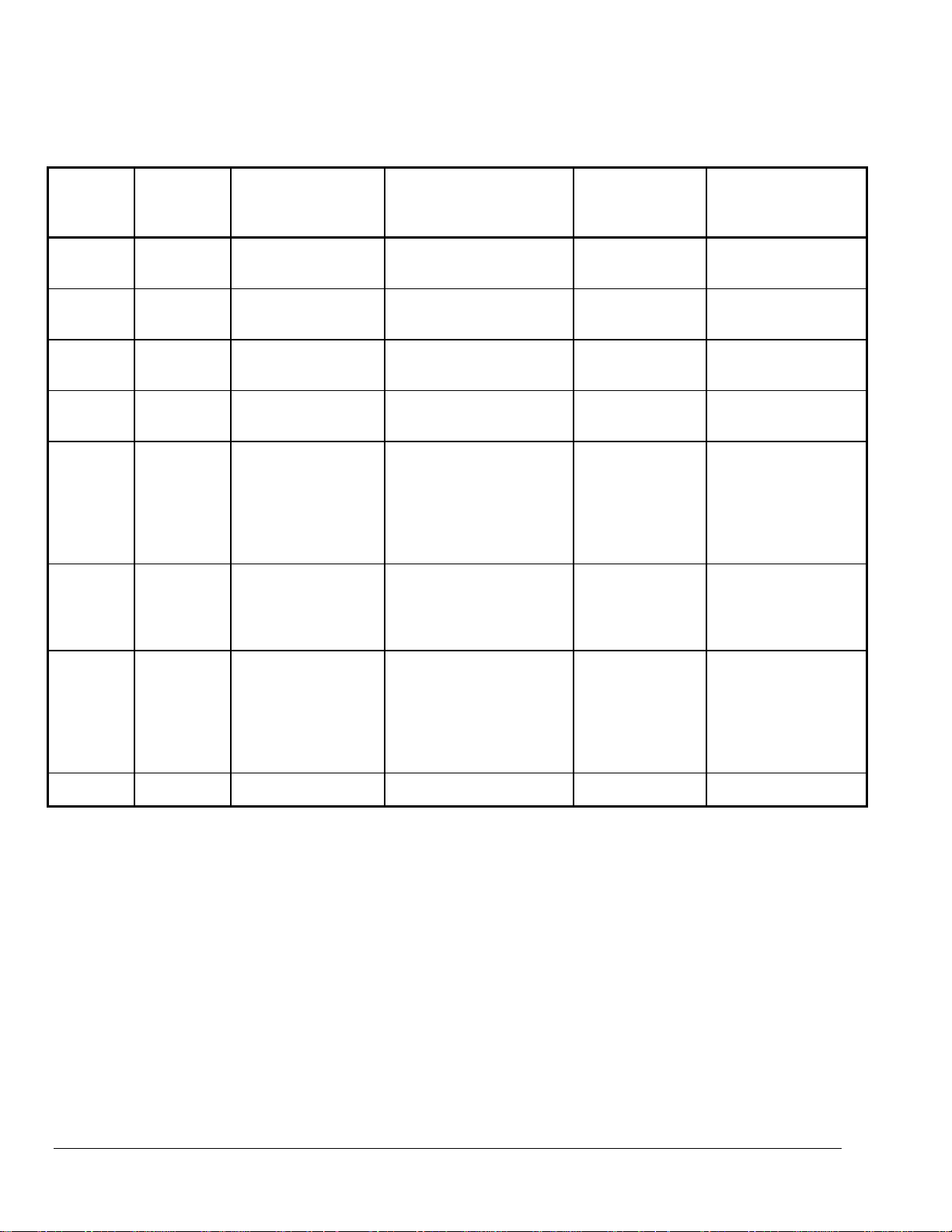

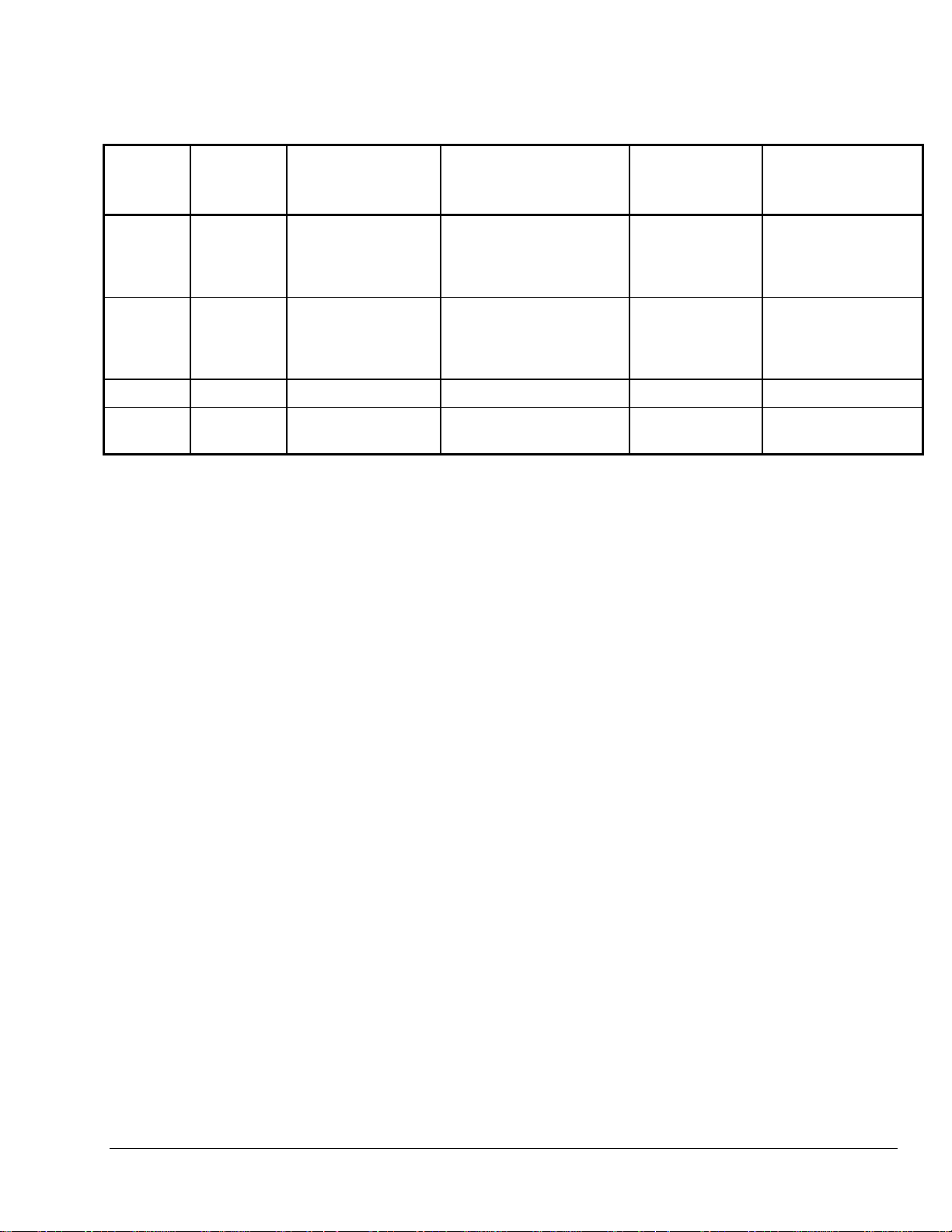

Table 1: BGH2UNCNTRLHT-01 Universal Cross Reference

Switch

Positions

ON

Switch

Positions

OFF

none 1,2,3,4,5

5 1,2,3,4

4 1,2,3,5

4,5 1,2,3

3 1,2,4,5

3,5 1,2,4,

White-Rodgers Robershaw Honeywell Fenwal

50E47-150 to 159

50E47-350 to 359

50E47-140 to 149

50E47-340 to 349

50F47-150 to 159

50F47-350 to 359

50F47-140 to 149

50F47-340 to 349

50E47-170 to 179

50E47-370 to 379

50F47-170 to 179

50F47-370 to 379

50E47-160 to 169

50E47-360 to 369

50F47-160 to 169

50F47-360 to 369

HS780-34NL-306A(a,c)

HS780-34NL-308A(a,c)

HS780-34NL-312A(c,d)

HS780-34NR-306A(a,c)

HS780-34NR-308A(a,c)

HS780-34NR-312A(c,d)

HS780-17NR-306A(a,b)

HS780-17NR-308A(a,b)

HS780-17NL-308A(a,b)

― ― ―

― ― ―

― ― ―

― ―

05-356265-153(d,g)

05-356265-154(d,g)

S89H1011(a,c)

S89G1013(a,c)

S89G1021(c,d)

―

S89H1029(c,d)

S89G1047(a,c)

05-356265-053(c,d)

―

05-356265-054(c,d)

05-356265-055(c,d)

S8910U

S890H1010(a,f)

3,4 1,2,5 ― ―

S890G1011(a,f)

S890H1028(d,f)

―

S890G1029(d,f)

S890G1037(a,f)

3,4,5 1,2 ― ― ― ―

Note: For timing parameters see Table 2.

(a) The BGH2UNCNTRLHT-01 Universal and the referenced control ignition trial times are different; however, the

ignition trial time is within the design tolerance of the referenced control.

(b) The BGH2UNCNTRLHT-01 Universal between trial purge time is longer than that of the referenced control.

(c) The BGH2UNCNTRLHT-01 Universal between trial purge and igniter warmup times is longer than those of the

referenced control.

(d) The BGH2UNCNTRLHT-01 Universal ignition trial time is shorter than that of the referenced control. Be sure

to observe appliance operation to assure reliable performance.

(e) The BGH2UNCNTRLHT-01 Universal pre-purge time is longer than that of the referenced control

(f) The BGH2UNCNTRLHT-01 Universal pre-purge and between trial purge times are longer than those of the

referenced control.

(g) The BGH2UNCNTRLHT-01 Universal pre-purge, between trial purge, and igniter warmup times are longer

than those of the referenced control.

2 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 3

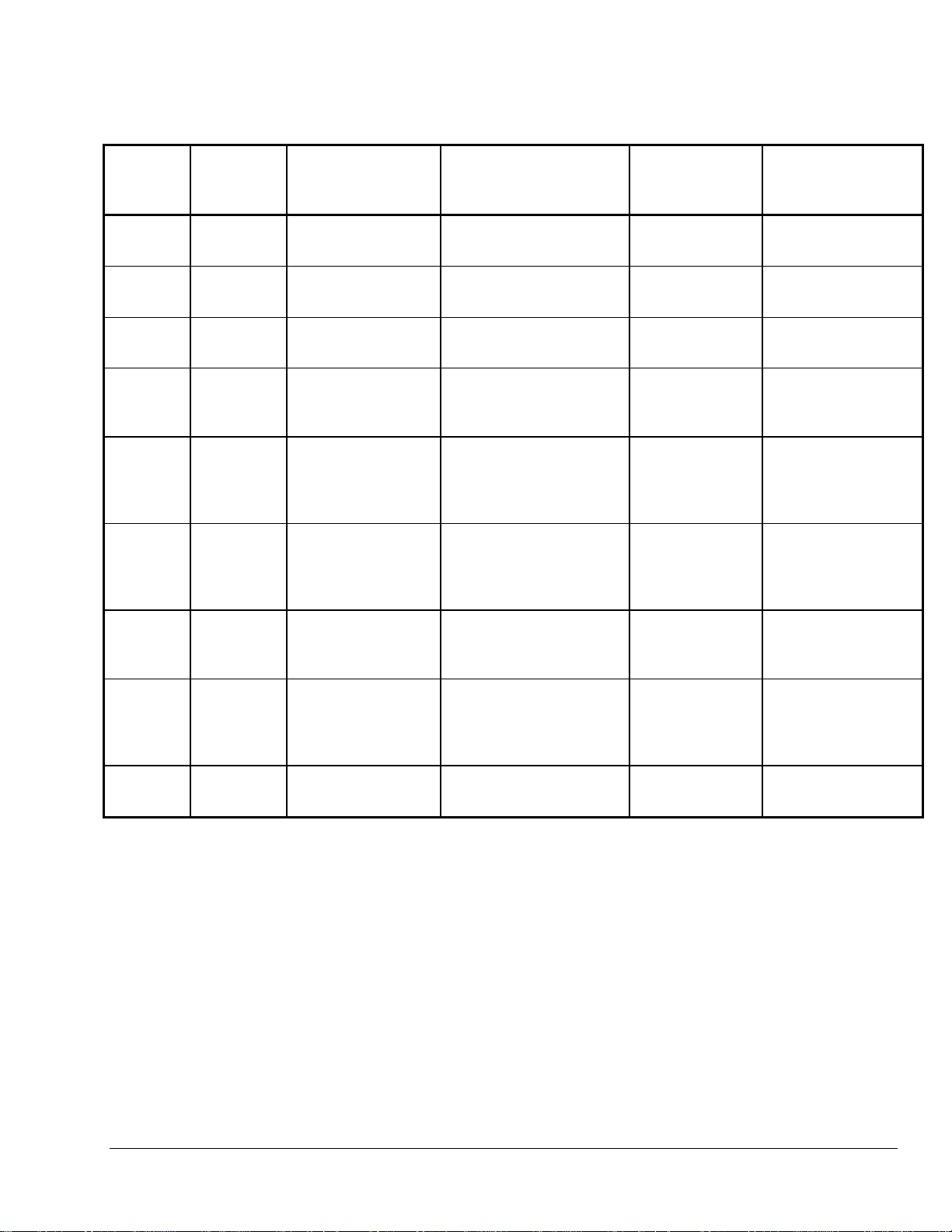

Table 1: BGH2UNCNTRLHT-01 Universal Cross Reference

Switch

Positions

ON

Switch

Positions

OFF

2 1,3,4,5

2,5 1,3,4

2,4 1,3,5

2,4,5 1,3

2,3 1,4,5

2,3,5 1,4

White-Rodgers Robershaw Honeywell Fenwal

50E47-130 to 139

50E47-330 t 339

50E47-120 to 129

50E47-320 to 329

50F47-130 to 139

50F47-330 to 339

50F47-120 to 129

50F47-320 to 329

― ― ―

― ― ―

― ― ―

05-356225-153(d,g)

― ―

05-356225-154(d,g)

05-356225-155(d,g)

50E47-110 to 119

50E47-310 to 319

50F47-110 to 119

― ― ―

50F47-310 to 319

50E47-101 to 109

50E47-301 to 309

50F47-101 to 109

50F47-301 to 309

HS780-17NL-108A(a) ―

05-356225-053(c,d)

05-356225-054(c,d)

05-356225-055(c,d)

8910U

2,3,4 1,5 ― ―

S890D1006(a,e)

―

S890C1007(a,e)

S89D1002(a)

2,3,4,5 1 ― HS780-34NL-108A(a)

S89C1004(a)

S89J1008(a)

―

S89C1012(a)

1 2,3,4,5

50E47-50 to 59

50E47-250 to 259

― ― ―

Note: For timing parameters see Table 2.

(a) The BGH2UNCNTRLHT-01 Universal and the referenced control ignition trial times are different; however, the

ignition trial time is within the design tolerance of the referenced control.

(b) The BGH2UNCNTRLHT-01 Universal between trial purge time is longer than that of the referenced control.

(c) The BGH2UNCNTRLHT-01 Universal between trial purge and igniter warmup times is longer than those of the

referenced control.

(d) The BGH2UNCNTRLHT-01 Universal ignition trial time is shorter than that of the referenced control. Be sure

to observe appliance operation to assure reliable performance.

(e) The BGH2UNCNTRLHT-01 Universal pre-purge time is longer than that of the referenced control

(f) The BGH2UNCNTRLHT-01 Universal pre-purge and between trial purge times are longer than those of the

referenced control.

(g) The BGH2UNCNTRLHT-01 Universal pre-purge, between trial purge, and igniter warmup times are longer

than those of the referenced control.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 3

Page 4

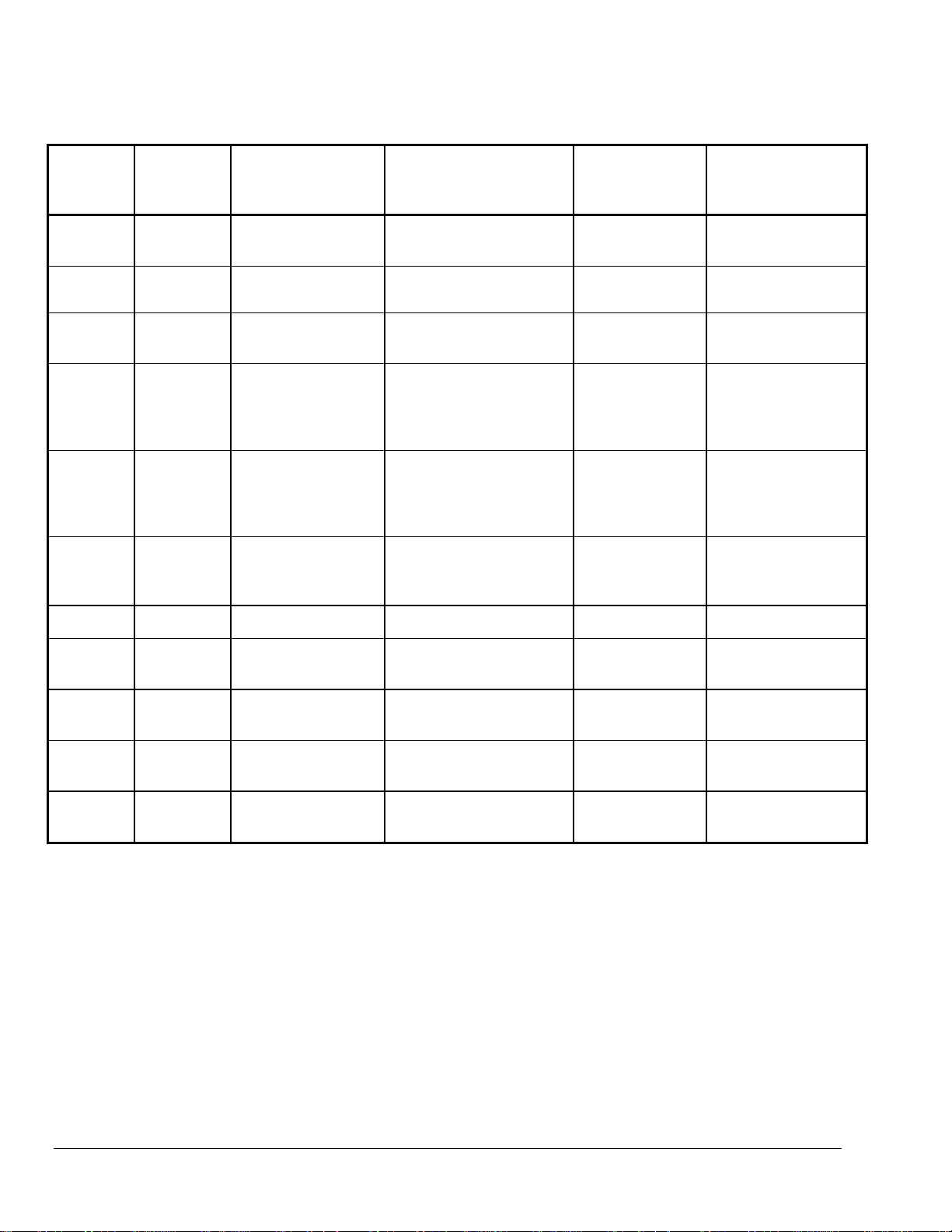

Table 1: BGH2UNCNTRLHT-01 Universal Cross Reference

Switch

Positions

ON

1,5 2,3,4

Switch

Positions

OFF

White-Rodgers Robershaw Honeywell Fenwal

50E47-40 to 49

50E47-240 to 249

50F47-50 to 59

1,4 2,3,5

1,4,5 2,3

50F47-250 to 259

50F47-40 to 49

50F47-240 to 249

50E47-70 to 79

1,3 2,4,5

50E47-270 to 279

50F47-70 to 79

HS780-34NL-304A(c)

50F47-270 to 279

50E47-60 to 69

1,3,5 2,4

50E47-260 to 269

50F47-60 to 69

HS780-17NL-304A(b) ―

50F47-260 to 269

1,3,4 2,5 ― ―

― ― ―

― ― ―

― ―

S89H1003(c)

S89G1005(c)

05-356265-151(a,g)

05-356265-152(a,g)

―

05-356265-051(a,c)

05-356265-052(a,c)

S8910U

S890G1003(f)

S890H1002(f)

1,3,4,5 2 ― ― ― ―

1,2 3,4,5

1,2,5 3,4

1,2,4 3,5

1,2,4,5 3

50E47-30 to 39

50E47-230 to 239

50E47-20 to 29

50E47-220 to 229

50F47-30 to 39

50F47-230 to 239

50F47-20 to 29

50F47-220 to 229

― ― ―

― ― ―

― ― ―

― ―

05-356225-151(a,g)

05-356225-152(a,g)

Note: For timing parameters see Table 2.

(a) The BGH2UNCNTRLHT-01 Universal and the referenced control ignition trial times are different; however, the

ignition trial time is within the design tolerance of the referenced control.

(b) The BGH2UNCNTRLHT-01 Universal between trial purge time is longer than that of the referenced control.

(c) The BGH2UNCNTRLHT-01 Universal between trial purge and igniter warmup times is longer than those of the

referenced control.

(d) The BGH2UNCNTRLHT-01 Universal ignition trial time is shorter than that of the referenced control. Be sure

to observe appliance operation to assure reliable performance.

(e) The BGH2UNCNTRLHT-01 Universal pre-purge time is longer than that of the referenced control

(f) The BGH2UNCNTRLHT-01 Universal pre-purge and between trial purge times are longer than those of the

referenced control.

(g) The BGH2UNCNTRLHT-01 Universal pre-purge, between trial purge, and igniter warmup times are longer

than those of the referenced control.

4 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 5

Table 1: BGH2UNCNTRLHT-01 Universal Cross Reference

Switch

Positions

ON

Switch

Positions

OFF

White-Rodgers Robershaw Honeywell Fenwal

50E47-10 to 19

1,2,3 4,5

50E47-210 to 219

50F47-10 to 19

― ― ―

50F47-210 to 219

50E47-1 to 9

1,2,3,5 4

50E47-201 to 209

50F47-1 to 9

HS780-17NL-104A

HS780-17NR-104A

―

05-356225-051(a,c)

05-356225-052(a,c)

50F47-201 to 209

1,2,3,4 5 ― ― S8910U ―

1,2,3,4,5 none ― HS780-34NR-104A

S89C1046

S89C1103

―

Note: For timing parameters see Table 2.

(a) The BGH2UNCNTRLHT-01 Universal and the referenced control ignition trial times are different; however,

the ignition trial time is within the design tolerance of the referenced control.

(b) The BGH2UNCNTRLHT-01 Universal between trial purge time is longer than that of the referenced control.

(c) The BGH2UNCNTRLHT-01 Universal between trial purge and igniter warmup times is longer than those of

the referenced control.

(d) The BGH2UNCNTRLHT-01 Universal ignition trial time is shorter than that of the referenced control. Be

sure to observe appliance operation to assure reliable performance.

(e) The BGH2UNCNTRLHT-01 Universal pre-purge time is longer than that of the referenced control

(f) The BGH2UNCNTRLHT-01 Universal pre-purge and between trial purge times are longer than those of the

referenced control.

(g) The BGH2UNCNTRLHT-01 Universal pre-purge, between trial purge, and igniter warmup times are longer

than those of the referenced control.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 5

Page 6

Replacing the Existing Ignition Control

7. Mount the new control with #6 sheet metal or

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making electrical

connections to avoid electric shock.

!

WARNING: Risk of Explosion or Fire.

Shut off the gas supply at the main manual shutoff

valve before installing or servicing the control.

Failure to shut off the gas supply can result in the

release of gas during installation or servicing, which

can lead to an explosion or fire, and may result in

severe personal injury or death.

!

WARNING: Risk of Explosion, Fire, or

Electric Shock. Label all wires before they are

disconnected when replacing or servicing the

control. Wiring errors can cause improper or

dangerous operation and may result in an explosion,

fire, or electric shock leading to severe personal

injury or death.

To remove the existing ignition control:

1. Shut off power to the appliance.

2. Turn off the gas at the main manual shutoff valve

adjacent to the appliance. (If the manual shutoff

valve services more than one appliance, be sure

to light the other pilots before leaving the

installation.)

3. Label each wire with the correct terminal

designation prior to disconnection.

machine screws through the mounting holes in

the enclosure.

8. Refer to the Wiring section for electrical

connections and wiring diagrams. Perform the

Checkout section before leaving the installation.

9. Check all wiring for proper connections and make

sure your system is properly grounded.

Wiring

!

WARNING: Risk of Explosion or Fire.

Locate all safety, limit, and operating controls in

series with the thermostat terminal (TH) on the

ignition control. Improper installation may cause gas

leaks, which can lead to an explosion or fire and

may result in severe personal injury or death.

Refer to Figure 1 and Figure 2 for wiring diagrams. All

wiring should be in accordance with the National

Electrical Code (NEC) and all other local codes and

regulations.

Check the voltage rating marked on the control and

make sure it is suited to the application. Use a Class 2

transformer capable of providing 24 VAC under

maximum load, including valves. A transformer having

excessive primary impedance due to poor coupling

affects the ignition potential.

The control is supplied with a jumper wire between

Sense (terminal 10) and 120/240V Hot HSI

(terminal 7). With the jumper in, flame is sensed

through the high voltage HSI (Hot Surface Igniter)

wire. The jumper must be removed for external flame

sense and the sense electrode wired to the Sense

terminal.

4. Disconnect the wires from the existing control.

5. Remove the screws holding the ignition control to

the valve (if direct valve-mount model) or remove

the screws holding the control to the appliance

chassis (if foot-mount model).

6. Remove the old ignition control and discard.

IMPORTANT: Do not mount the control where

it can be exposed to direct infrared radiation from the

main burner or to temperatures in excess of the

maximum product temperature rating.

6 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

!

WARNING: Risk of Electric Shock.

Before applying power to the control, connect all

wires properly to the controller. Verify the controller

is properly grounded. Failure to follow this procedure

can cause electric shock and may result in severe

personal injury or death.

Page 7

Chassis or

Frame Ground

GND

GND

(24V)

(BURNER)

12

GND

3

120/240V

NEUTRAL

(VALVE)

L2

4

HSI

5

120/240V

HOT

L1

6

HSI

UNIVERSAL

ONLY

24V

(TH)

7

MARK

POS

VALVE

ON

1

89

2

3

4

5

Wire

Nut

Thermostat

SENSE

(REMOTE)

10

4

Burner

Ground

5

HSI

(Hot Surface Igniter)

Combination

3

Gas Valve

24V

Class 2

2

Transformer

L1 (Hot)

High Temp

Limit

1

Power Supply. Provides disconnect means and overload protection as required.

The controls 24V circuit must not be in the ground leg to the transformer.

2

3

Alternate location for limit to the controller.

4

For Internal Flame Sense circuits, check that the jumper wire is connected between HSI HOT

L2 (Neutral)

1

(terminal 7) and SENSE REMOTE (terminal 10).

5

Ensure the burner ground is in the pilot flame (3/8” [9mm] to 1/2” [12.7mm]) for proper sensing signal.

Figure 1: Typical Wiring for BGH2UNCNTRLHT-01 with Internal Flame Sense

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 7

Page 8

Universal

1

8

2

3

4

5

Only

MARK

POS

ON

Thermostat

VALVE

9

SENSE

(REMOTE)

10

Burner

Ground

5

HSI

(Hot Surface Igniter)

Flame

Sensor

4

GND

1

Chassis or

Frame Ground

(BURNER)

GND

(24V)

2

120/240V

NEUTRAL

GND

(VALVE)

L2

34

HSI

5

120/240V

HOT

L1

HSI

67

24V

(TH)

Combination

3

Gas Valve

24V

Class 2

2

Transformer

L1 (Hot)

High Temp

Limit

1

Power Supply. Provides disconnect means and overload protection as required.

2

The controls 24V circuit must not be in the ground leg to the transformer.

3

Alternate location for limit to the controller.

4

Check for the sensor tip of the Remote Flame Sensor is 3/8” (9 mm) to 1/2” (12.7 mm)

L2 (Neutral)

1

in the flame for proper sensing signal.

5

Ensure the burner ground i s in the pil ot flame (3/8” [9mm] to 1/2” [12.7mm]) for proper sensing si gnal.

Figure 2: Typical Wiring for BGH2UNCNTRLHT-01 with Remote Flame Sense.

8 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 9

Setup and Adjustments

Select Dip Switch Positions

A 5 position dip switch is provided on the controller to

allow for field programming of 1 to 32 possible predefined sets of timing sequences. Select a predefined

timing sequence from Table 1 and then set the dip

switches on the control.

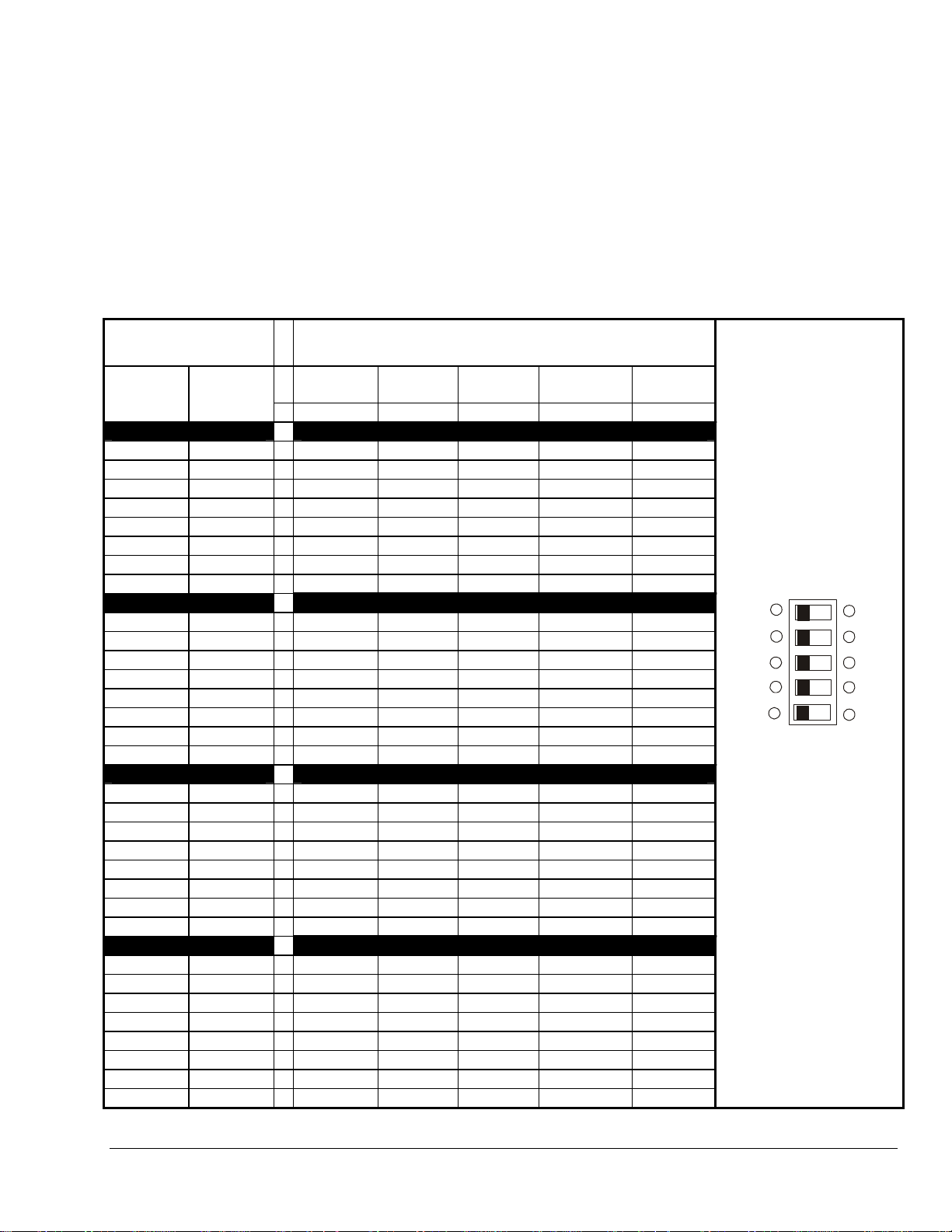

Table 2: BGHUNCNTRLHT-01 Universal HSIC

Parameters/Dip Switch Positions

5 Position Dip

Switch Settings

HSIC Parameters

To change the settings, remove power from the circuit

board, change settings and re-apply power to the

circuit board.

The dip switches remain active until 10 consecutive

power cycles occur without a change in any dip switch

setting. Once this occurs, dip switches become

inactive and cannot further be used to change timing

specifications.

ON OFF

None 1,2,3,4,5 45 30 90 7 3

5 1,2,3,4 17 30 90 7 3

4 1,2,3,5 45 17 77 7 3

4,5 1,2,3 17 17 77 7 3

3 1,2,4,5 45 None 60 7 3

3,5 1,2,4 17 None 60 7 3

3,4 1,2,5 34 32 96 7 3

3,4,5 1,2 34 None None 7 3

2 1,3,4,5 45 30 None 7 1

2,5 1,3,4 17 30 None 7 1

2,4 1,3,5 45 17 None 7 1

2,4,5 1,3 17 17 None 7 1

2,3 1,4,5 45 None None 7 1

2,3,5 1,4 17 None None 7 1

2,3,4 1,5 34 32 None 7 1

2,3,4,5 1 34 None None 7 1

1 2,3,4,5 45 30 90 4 3

1,5 2,3,4 17 30 90 4 3

1,4 2,3,5 45 17 77 4 3

1,4,5 2,3 17 17 77 4 3

1,3 2,4,5 45 0 60 4 3

1,3,5 2,4 17 0 60 4 3

1,3,4 2,5 34 32 96 4 3

1,3,4,5 2 34 0 0 4 3

1,2 3,4,5 45 30 None 4 1

1,2,5 3,4 17 30 0 4 1

1,2,4 3,5 45 17 0 4 1

1,2,4,5 3 17 17 0 4 1

1,2,3 4,5 45 0 0 4 1

1,2,3,5 4 17 0 0 4 1

1,2,3,4 5 34 32 0 4 1

1,2,3,4,5 None 34 0 0 4 1

*Warmup time is timed ignition.

*Warmup

(Sec.) (Sec.) (Sec.) (Sec.) #

Pre-

Purge

Between

Purge

Ignition

Trial Time

No. of

Trials

OFF

ON

1

2

3

4

5

Figure 3: 5 Position

Dip Switch

Switch settings shown

with all 5 switches in the

OFF positions.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 9

Page 10

Checkout

!

WARNING: Risk of Explosion or Fire.

Verify that there are no gas leaks by testing with

appropriate equipment. Never use a match or lighter

to test for the presence of gas. Failure to test

properly can lead to an explosion or fire and may

result in severe personal injury or death.

Make sure all components function properly by

performing the following checks.

1. Before starting the appliance, perform a safety

inspection of piping, burners and venting. Check

for gas leaks, etc. Check all wiring for proper

connections. Be sure the system is properly

grounded, including ground connection to the

burner ground (Terminal 1).

2. With the gas and thermostat off, turn on power to

the appliance.

3. Turn the thermostat to a high setting and verify

that the control goes through the operating

sequence to a shutoff condition.

Note: The burner does not light because the

gas is off.

4. Turn off the thermostat.

5. Turn on the gas and purge gas lines of all air.

6. Check for gas leaks on all pipe joints upstream of

the gas valve with a soap solution.

7. Turn the thermostat to the highest setting and

verify successful ignition and a normal run

condition for at least 5 minutes. If the appliance

fails to run, see the Troubleshooting section.

8. Check for gas leaks on all pipe joints

downstream of the gas valve with a soap

solution.

9. Turn the thermostat down for at least 30 seconds

and then back up again. Verify successful

ignition at least five times.

Operation

Operating Mode Definitions

The following definitions describe the operating

conditions.

• Pre-Purge: Initial time delay between the

thermostat contact closure (Call for Heat) and the

HSI (Hot Surface Igniter) and pilot valve are

activated. The controls “LED” will flash green

“ON” and “OFF” at 0.5 s rate.

• Igniter Warmup (Timed Ignition): The time

allowed for the hot surface igniter to heat up

before the Trial-For-Ignition sequence is

activated. The controls “LED” will flash green

“ON” and “OFF” at 0.5 s rate.

• Trial-For-Ignition (TFI): This is the total time the

pilot valve and hot surface igniter are “ON”

(energized), and flame sense sequence is

activated in an attempt to light the pilot. The

control attempts to prove flame within the TrialFor-Ignition time. The “LED” will flash green at

0.5 second “ON” and 0.5 second “OFF”.

• Flame Sensed: With a flame present, a current

path is connected between the “Igniter” and “Main

Burner” ground on “Internal Flame Sense”

Models, or between a “Flame Sense Rod” and

“Main Burner” ground on “Remote Flame Sense”

Models. The “Main Burner” and gas valve remain

on as long as a flame is present. When the

thermostat opens (Call for Heat ends) the control

turns “OFF” (de-energizes) the gas valve, there by

extinguishing the flame.

• 100% Shutoff (Flame Not Sensed) With 1

Ignition Trial (Bad Flame/No Flame): If the

control does not prove the presence of pilot

burner flame within the “Trial-For-Ignition” time,

then both gas valve relays are turned “OFF”

(de-energized) and the control goes into Lockout

mode. See Troubleshooting Guide for possible

faults.

10. Return the thermostat to a normal temperature

setting before leaving the installation.

!

WARNING:

The control module can not be serviced by user. If

any faults are detected, the control module must be

replaced. If control module has been opened or any

attempts to repair are done, the warranty is void.

10 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 11

• 100% Shutoff (Flame Not Sensed) With 3

Ignition Trials (Bad Flame/No Flame):

If the control does not prove the presence of

igniter flame within the “Trial-For-Ignition” time,

then the relay gas valve is turned “OFF” (deenergized) and the control initiates a time delay of

“Between-Trial-Purge” time, and then followed by

another ignition sequence. If flame is not sensed,

an ignition sequence is repeated until the total

number of Trials-for-Ignition are completed. If

flame is still not sensed then all relays are turned

“OFF” (de-energized) and the control goes into

lockout mode. See Troubleshooting Guide for

possible faults.

• Number of Ignition Trials: If 100% shutoff

occurs and the control was set up for 3 ignition

trials, the control will delay for the “Between-TrialPurge” time and begin another Trial-For-Ignition

sequence.

• Run (Operation): Once an igniter flame is proven

then the hot surface igniter is turned “OFF”

(de-energized) and the gas valve is turned “ON”

(energized). The gas valve remains “ON”

(energized) until the thermostat is satisfied (Call

for Heat).

• Flameout (Flame Lost): After a flame is

established, and a loss of proven flame occurs

during burner operation the gas valve is turned

“OFF” (de-energized) and the control will delay for

the Between-Trial-Purge time before it begins

another ignition sequence.

• Lockout: An internal or external fault has caused

the control to de-energize the hot surface igniter

circuit and valve relays. The thermostat contacts

must be opened for a minimum of 30 seconds and

then closed to begin another ignition sequence.

Sequence of Operation

The heating cycle begins when a call for heat from the

thermostat supplies 24VAC to the 24V (TH) terminal 8

on the Control which starts an ignition sequence. After

a 1 second maximum diagnostic period, the prepurge

cycle starts.

During the Pre-Purge cycle the gas valve relays and

HSI (Hot Surface Igniter) remain “OFF” (deenergized). The controls “LED” will flash green “ON”

and “OFF” at 0.5 s rate. At the end of the Prepurge

time, the control begins the igniter warmup cycle.

Igniter Warmup (Timed Ignition) cycle turns “ON”

(energizes) both HSI relays and remains on for a set

time. The controls “LED” will flash green “ON” and

“OFF” at 0.5 s rate. At the end of the Igniter Warmup

time, the control begins the Trial-For-Ignition cycle.

Trial-For-Ignition cycle turns “ON” (energizes) the

gas valve relay and the hot surface igniter remains

“ON” (energized) to allow a flame to be established.

The control attempts to prove flame within the TrialFor-Ignition time. The “LED” will flash green at 0.5 s

“ON” and 0.5 s “OFF”.

Once, a flame is detected a current path is connected

between the “Igniter” and “Main Burner” ground on

“Internal Flame Sense” Models, or between a “Flame

Sense Rod” and “Main Burner” ground on “Remote

Flame Sense” Models and the hot surface igniter is

turned “OFF” (de-energized) while the gas valve

remains “ON” (energized) as long as a flame is

present. The control will remain in this state until the

igniter flame is lost or the call for heat ends.

If igniter flame is not detected or flame lost, the gas

valve is turned “OFF” (de-energized) and the controls

go into 100% lockout for models having only 1 ignition

trial or will restart the Ignition Sequence for Models

having 3 ignition trials. The control will wait for the

“Between-Purge” time while blinking the “LED” at the

end of each 15 seconds during the Between-Purge

cycle. When the “Between-Purge” time cycle is

completed a new Ignition sequence will begin.

When the “Call for Heat” ends, the thermostat opens

and the control turns “OFF” (de-energizes) the gas

valve, there by extinguishing the flame.

Table 2: LED Indications during Normal Operation

Green Flash Code Flash Code Indication

Flame detected,

Steady On

Good flame,

Main burner on

0.5 Second On

0.5 Second Off

2 Continuous

Quick Flashes

Pre-purge,

Between trial purge,

Igniter warmup

Flame detected,

Weak flame,

Main burner on

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 11

Page 12

Power On

Initialize software,

test ROM, RAM and E2

get voltage and

frequency

OK

Check for flame

sense stuck on

OK

Do pre-purge delay

blink LED .5 sec. on/off

continuously check

gas valve feedback to

assure valve is off

OK

Perform hot surface

igniter short test, turn

on hot surface igniter

OK

Continuously check

gas valve feedback and

HSI current

OK

After required delay

turn on gas valve

Error

Error

Error

Error

LockoutLockout

Error

LockoutLockout

LockoutLockout

LockoutLockout

LockoutLockout

Note:

If the thermostat opens,

the control will turn off valves

and returns to the idle state.

Test ROM, RAM, E2, and line.

Test gas valve relay

feedback voltage.

Good flame LED on solid.

Weak flame LED 2 blink.

Flame

detected?

Wait 0.1 second

Flame bad

7 readings

OK

No

Ye s

LockoutLockout

Ye s

No

FLAME LOST, TURN

OFF GAS VALV E AND

TRY TO RELIGHT

Continuously check

gas valve feed back and

HSI current

HSI

timeout?

Gas valve

No

timeout?

Check flame, read

flame detect circuit

7X @ 100 MSEC apart

Flame

detected?

Turn off all relays.

Do between trial purge

blink LED .5 sec. On/off.

Continuously check

gas valve feedback to

assure valve off.

Ye s

No

Ye s

No

Ye s

Turn off HSI

RELIGHT

Note:

If the controller is flashing an error code, the control

will be in l ockout. The contr oller will stay in lockout and continue

flashing an error code until power is cycled. If an error code repeats,

then see Table 3 Troubleshooting Guide to determine

the problem.

Error Codes

Flame Error

Gas Valve Error

Line Voltage/Frequency Error

Processor Errors

Red Flash Code

1 Blink

3 Blinks

4 Blinks

5 Blinks

Error Type

Lockout

Lockout

Stand By

Lockout

Figure 4: Sequence of Operation Flow Chart

12 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 13

Troubleshooting

!

WARNING: Risk of Personal Injury.

Do not place face, hands, or other parts of the body

in or near the burner area when the LED is flashing

(recycle mode). When the LED is flashing, the

control may at any time (while in the recycle mode)

re-energize the burner control system and ignite the

burner which may result in electric shock from

contact with the electrode or severe burn injury from

firing of the burner.

If the system does not function properly, determine

the cause using the procedures in this section.

Before proceeding with troubleshooting the system,

check the following.

Preliminary Checks

Are all mechanical and electrical connections tight?

Is the system wired and ground correctly?

Is gas inlet pressure per manufacturer’s

specifications?

Is the system powered?

Is the thermostat calling for heat?

LED Error Indications

If the control module internal diagnostics detect a

fault it will go to lockout. The hot surface igniter and

gas valve will be turned off. The LED will flash an

error code 0.25 seconds “on” and 0.25 seconds “off"

for each count of the error code with 1 second off

between codes. The control will remain in this

condition until power is removed by turning off the call

for heat. The flashing LED error code indicates a

problem with wiring, or a component not working, or

the control module is faulty. Try to recycle the power

on the control. If the error repeats then see Table 3

Troubleshooting Guide to determine the problem.

Table 3: BGH2UNCNTRLHT-01 Universal Series HSI Control Troubleshooting Guide

RED

LED

Flash

Code

No LED

“ON”

1

3

4

5

NOTE: If Troubleshooting Guide has been used, and the Control Module is flashing a RED LED FLASH ERROR CODE, then

the Control Module may be faulty. Replace the Control Module.

ERROR

Indication

No Power

Flame Sense

Circuit

GAS Valve

Circuit

Line Voltage

/Freq. Circuit

Internal

Control

Troubleshooting Guide

1. Check for 24 volts on terminal 8 (24V TH) and terminal 2 (24V GND).

2. Check for “OPEN” limits wired between terminal 8 (24V TH) and the 24 volt secondary

coil winding of the controls transformer.

3. Check for 24 volts on the secondary coil winding of the controls transformer.

1. Check if gas is turned “ON”.

2. Check incoming power (NEUTRAL) wiring to terminal 4 (L2 NEUTRAL).

3. Check Igniter wiring to terminal 7 (HSI HOT) and terminal 5 (HSI NEUTRAL).

4. Check Flame Sensor tip is in the flame. For proper sensing the rod tip must be 3/8”

(10mm) to 1/2” (13mm) in the flame.

5. Check the Burner Ground is in the pilot flame. For proper sensing, the burner ground

must be 3/8” (10 mm) to 1/2” (13 mm) in the flame and is connected to terminal 1

(BURNER GND).

6. For Internal Flame Sense circuits, check “JUMPER WIRE” is on

terminal 10 (SENSE REMOTE) and terminal 7 (HSI HOT).

7. For a Remote Flame Sense circuit; check that the Jumper Wire is removed from Terminal

10 (SENSE REMOTE) and Terminal 7 (HSI HOT). Also, check wiring of the Remote

Flame Sensor to Terminal 10 (SENSE REMOTE).

1. Check “GAS VALVE” wiring to terminal 9 (VALVE) and terminal 3 (VALVE GND).

2. Check for 24 volts at the coil of the “GAS VALVE”.

1. Check Burner Ground wiring to terminal 1 (BURNER GND).

2. Check incoming power Line 1 (HOT) (120 or 240 VAC) wiring to terminal 6(L1 HOT).

1. Review all ground connections.

2. Software error – Restart control module.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 13

Page 14

Turn on power

and gas.

Close thermostat

contacts.

Module LED

did not light?

No

Module LED

blinks green?

Ye s

Igniter didn’t turn

on during igniter

warmup mode?

No

Ye s

No

Ye s

LED blinks

1, 3, or 5 quick red

flashes, then

pause?

Ye s

Replace

module.

120 VAC

between HSI (HOT)

and L2 (NEUT)

during igniter

warmup?

No

Replace

module.

24V between

24V and 24V(GND)

terminals?

Ye s

Replace

module.

No

LED blinks

2 quick red

flashes, then

pause?

Ye s

Check wiring to igniter.

Check igniter for short

or malfunction and

replace if necessary.

Ye s

Check wiring to igniter.

Check igniter and replace

if necessary.

No

No

Check transformer,

thermostat and wiring.

Repair or replace as needed.

LED blinks

4 quick red

No

flashes, then

pause?

Ye s

Check line

voltage.

Check shutoff valves are on.

Check wiring to main valve.

Check tubing is clear.

If all OK, replace main valve.

Replace

module.

24 VAC

Main burner

failed to light

during trial for

ignition?

No

After burner

is lit, does valve

turn off and start

new cycle?

No

Control is

operating

Ye s

Ye s

Main flame

in contact with

Adjust main flame size

or igniter position.

LED blinks

3 quick red

flashes, then

pause?

Ye s

Replace

module.

igniter?

No

No

Ye s

grounded to GND

Assure main burner

is properly grounded.

between VALVE

and VALVE (GND)

terminals during trial

for ignition?

Replace

module.

Main burner

(BURNER)?

No

No

Ye s

size or position, adjust

Ye s

Remote

flame sense?

Check wiring to

REMOTE (SENSE) terminal.

If OK, replace module.

Gas at

main burner?

Adjust burner flame

igniter position, or

replace main burner.

Ye s

normally.

Figure 5: BGH Universal Series HSI (Hot Surface Ignition) Control Troubleshooting Flowchart

14 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Ye s

No

No

Replace

module.

Page 15

Maintenance Requirements in Severe

Environments

Regular preventive maintenance is important in any

application, but especially so in commercial cooking,

agricultural, and industrial applications because:

• In many such applications, particularly

commercial cooking, the equipment operates

100,000 to 200,000 cycles per year. Such heavy

cycling can wear out the gas control in one to

two years. A normal forced air furnace, for which

the controls were originally intended, typically

operates less than 20,000 cycles per year.

• Exposure to water, dirt, chemicals, and heat can

damage the ignition control module or the gas

control and shut down the control system. A

NEMA 4 enclosure can reduce exposure to

environmental contaminants.

!

WARNING: Risk of Explosion or Fire. Do

not attempt to take the ignition control module apart

or to clean it. Improper reassembly and cleaning

may cause unreliable operation, which can lead to

an explosion or fire, and may result in severe injury,

property damage or death.

Maintenance frequency must be determined

individually for each application. Some considerations

are:

Repairs and Replacement

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making electrical

connections to avoid electric shock.

!

WARNING: Risk of Explosion or Fire.

Shut off the gas supply at the main manual shutoff

valve before installing or servicing the control.

Failure to shut off the gas supply can result in the

release of gas during installation or servicing, which

can lead to an explosion or fire, and may result in

severe injury or death.

!

WARNING: Risk of Explosion, Fire, or

Electric Shock. Label all wires before they are

disconnected when replacing or servicing the

BGH2UNCNTRLHT-01. Wiring errors can cause

improper or dangerous operation and may result in

an explosion, fire, or electric shock leading to severe

personal injury or death.

• Cycling Frequency – Appliances that may cycle

more than 20,000 times annually should be

checked monthly.

• Intermittent Use – Appliances that are used

seasonally should be checked before shutdown

and again before the next use.

• Consequence of Unexpected Shutdown –

Where the cost of an unexpected shutdown

would be high, the system should be checked

more often.

• Dust, Wet, or Corrosive Environment – Since

these environments can cause the controls to

deteriorate more rapidly, the system should be

checked more often.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 15

Field repairs must not be made to the control. Any

attempt to repair this assembly voids the

manufacturer’s warranty. For a replacement control,

contact the original equipment manufacturer or the

nearest BASO Gas Products distributor.

All other accessories, such as flame sensors,

electrode assemblies, pilot assemblies, and leads can

be obtained through the original equipment

manufacturer or a BASO Gas Products distributor.

Page 16

Cut out and leave near control.

Green LED Indications During Normal Operation

Steady On Flame detected, Good flame, Main burner on

0.5 Second On, 0.5 Second Off Pre-purge, Between trial purge, Igniter warmup

2 Continuous Quick Flashes Flame detected, Weak flame, Main burner on

Red LED Indications During Error Operation

1 Flash, then pause Flame Error Lockout

3 Flashes, then pause Gas Valve Error Lockout

4 Flashes, then pause Line Voltage/Frequency Error Standby

5 Flashes, then pause Internal Control Error Lockout

16 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 17

Notes

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 17

Page 18

Notes

18 BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions

Page 19

Technical Specification

Product

Ignition Type

Ignition Source

Flame Sense Cable Maximum Length

Flame Detection Means

Flame Detection Type

Flame Failure Response Time

Warmup Time (Timed Ignition)

Pre-Purge Time

Between Trial Purge Time

Ignition-Trial-Time (Before Lockout)

Number of Trials (Before 100% Shutoff)

Power Requirements

Gas Valve Relay Contact Rating

Hot Surface Ignition Relay Contact Rating

Wiring Connections

Maximum Firing Rate

Ambient Operating and Storage

Temperature

Humidity

Type of Gas

Packaging

Bulk Pack Quantity

Pack Weight

Agency Listing

Specifications Standards

The performance specifications are nominal and conform to acceptable industry standards. All agency certification of BASO products is

performed under dry and controlled indoor environmental conditions. Use of BASO products beyond these conditions is not recommended and

may void the warranty. If the product is exposed to water (dripping, spraying, rain, etc.) or other harsh environments, it must be protected. The

original equipment manufacturer or end user is responsible for the correct application of BASO products. For questionable applications, please

consult BASO Gas Products LLC. BASO Gas Products LLC shall not be liable for damages or product malfunctions resulting from

misapplication or misuse of its products.

BGH2UNCNTRLHT-01 Universal Hot Surface Ignition Control

Hot Surface Ignition (HSI)

High voltage (120/240VAC) HSI (Hot Surface Igniter)

48 in. (1,220 mm)

Flame Rectification

Internal or Remote

2.0 seconds maximum

17, 34, or 45 seconds

None, 17, 30, or 32 seconds

None, 60,77,90 or 96 seconds

4 or 7 seconds

1 or 3

Control:

Operating Current:

24 VAC (+/- 20%), 50/60 Hz.

0.2 A nominal + valves

2 A maximum @ 24 VAC

3 A maximum @ 240 VAC

6 A maximum @ 120 VAC

1/4 in. (6.35 mm) male spade

400,000 Btu/hr (117 kW)

-40 to 175°F (-40 to 79°C)

95% RH non-condensing

Natural, Liquefied Petroleum (LP), Manufactured, Mixed or LP Gas-Air

Mixture

Bulk pack supplied to original equipment manufacturer (individual pack

[-1AAC] or individual overpack [-1AAE, 20 per box] optional)

25

Bulk pack (-1AAD) 14 lb (6.36 kg)

Individual pack (-1AAC) 1 lb (.454 kg)

Individual overpack (-1AAE) 18 lb (8.17 kg)

CSA Certificate Number 246569-2213607

ANSI Standard Z21.20

CAN/CSA-C22.2 No. 199

1007 South 12th Street

PO Box 170

Watertown, WI 53094 www.baso.gas

1-877-227-6427 (1-877-BASOGAS) Published in U.S.A.

BGH2UNCTRLHT-01 Universal Hot Surface Ignition Control Installation Instructions 19

Loading...

Loading...