Page 1

BL-PFS100, BL-PFS150, & BL-PFS200

Two-Wire Ready Flow Sensor Installation

Baseline’s BL-PFS100, BL-PFS150, and BL-PFS300 are PVC tee-type, impeller flow sensors that

provide accurate digital output signals proportional to the velocity of the liquid flowing

through the pipe.

Installation Overview

1. Choose the proper location and

orientation.

2. Install the sensor in the pipe.

3. Make the electrical connections.

4. Program the controller.

Operation Notes

Make sure the flow sensor is assembled and the retaining nut is tightened (hand tight)

before pressurizing the system.

Fill the pipeline and eliminate all trapped air.

The flow sensor should begin transmitting flow immediately; however, it may take up to

a minute for the flow readings to display in the appropriate screens on the BaseStation

controllers.

Always wait for flow to stabilize before setting control limits. Stabilization may take

several minutes in large piping systems.

1-866-294-5847 Rev 03262013 www.baselinesystems.com

Page 2

BL-PFS100, BL-PFS150, & BL-PFS200

Two-Wire Ready Flow Sensor Installation

Choosing the Proper Location and Orientation

Because an impeller sensor measures the velocity of the liquid and converts it to a flow

measurement based on area, proper flow measurement depends on the condition of the pipe

interior and the sensor’s location in the piping system. The pipeline must be full, free from trapped

air, floating debris and built-up sediment.

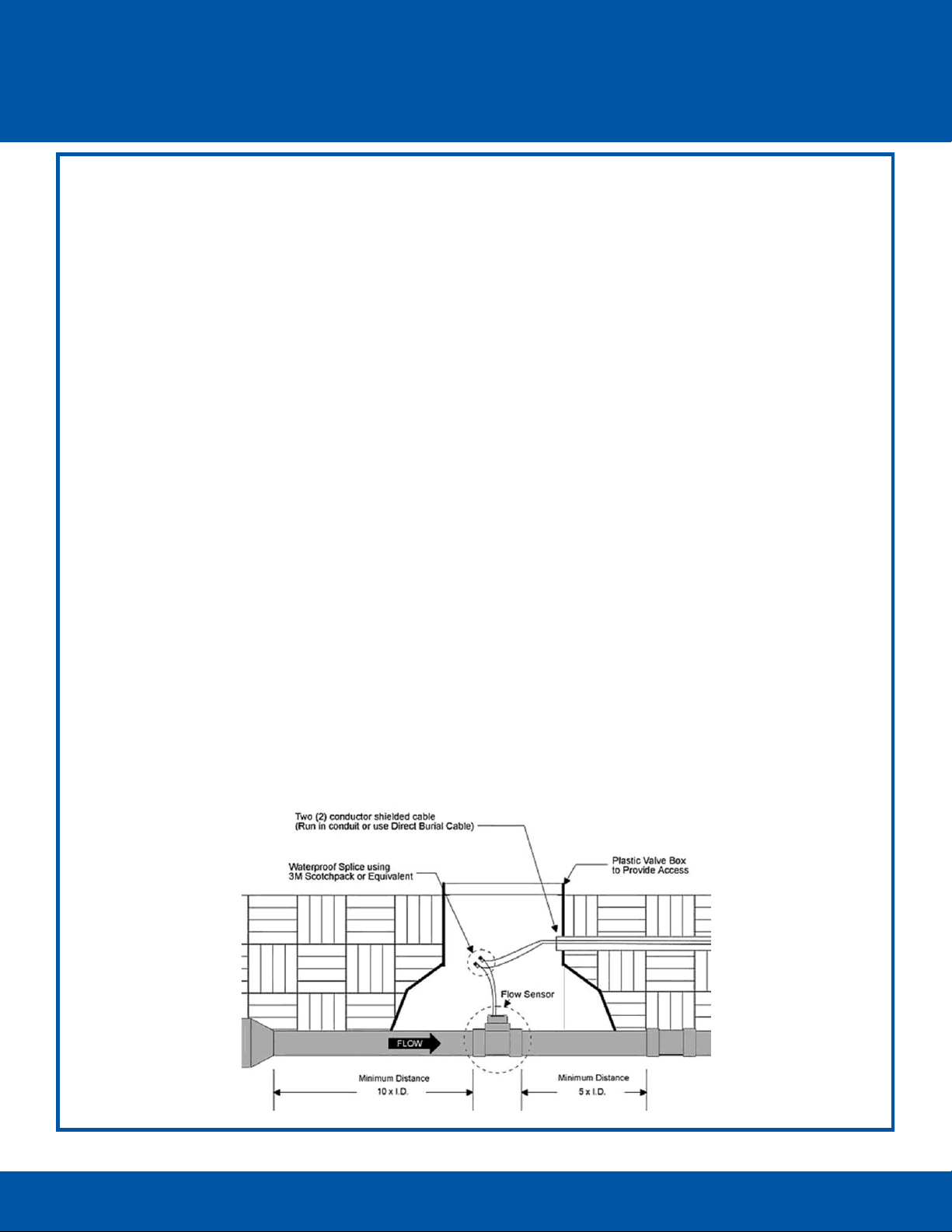

The mounting tee should be installed with a minimum of 10 diameters of straight pipe (15

inches for 1½ inch pipe), upstream and a minimum of 5 diameters of straight pipe (7½ inches

for 1½ inch pipe) downstream to eliminate irregular flow profiles caused by valves, fittings or

pipe bends.

Always install with the flow arrow on the mounting tee pointed downstream.

Allow 3¾” clearance to remove the flow sensor housing from the tee for service. The tee is

usually installed with the housing up in the vertical or 12 o’clock position. However, if

necessary, it may be installed with sensor housing at an angle from vertical to provide

clearance.

Flow sensors may be installed inside a building, outside above grade or underground. If

installed above grade, provide adequate security to prevent damage or disassembly. If

installed below grade, provide access for service.

Flow sensors are most typically installed below grade in a horizontal section of pipe with the

sensor housing up. Do not direct bury the flow sensor. Provide a meter pit or valve box of

adequate size and drainage to service the sensor. Provide a service loop in the wire

connections to allow the sensor housing to be brought above grade.

Flow sensors may be installed on vertical sections of pipe providing that the piping is full and

does not contain trapped air. A vertical pipe with rising flow is preferred over falling flow. The

sensor housing may be oriented in any direction radially around the pipe.

1-866-294-5847 Rev 03262013 www.baselinesystems.com

Page 3

BL-PFS100, BL-PFS150, & BL-PFS200

Two-Wire Ready Flow Sensor Installation

Installing the Sensor in the Pipe

The PVC flow sensor tee features socket ends intended for solvent welding into PVC piping systems. Use

best industry practices to ensure that the sensor is installed in the correct position with strong permanent

joints.

1. Disassemble the flow sensor before joining the tee to the piping system. To

remove the flow sensor housing from the tee turn the retaining nut counter

-clockwise to loosen it, and then pull the housing straight out of the tee.

Do not pull on the wire leads!

3. Use appropriate tools to cut the pipe. Remove all chips, filings, or cuttings

from the pipe.

4. Solvent weld the tee to the pipe using manufacturer’s recommendations.

5. After the joints have set, reattach the sensor housing to the tee. Make sure

the housing and tee are clean and free from dirt or debris. Position the

arrow on the top of the housing in the downstream direction. This aligns

the guide key on the housing with the slot inside the tee. Push straight in so

that the key enters the slot until the o-ring seals the opening.

6. Slide the retaining nut over the wire leads and turn clockwise by hand to

tighten.

Do not use sealant or Teflon tape on the retaining nut

threads!

Making the Electrical Connections

1. Power off the two-wire when installing devices. Leave 24 to 36 inches of slack on the two-wire to allow

the PFS flow sensor housing to be removed from the tee and brought above grade for servicing.

2. Connect the red and black wire from the PFS flow sensor to the corresponding red and black wires on

the two-wire. It is critical that polarity is maintained. Do not connect flow sensor to power or valve

circuits!

3. Use wire nuts for your initial connections. After you verify communications between the BaseStation

and the PFS flow sensor, replace the wire nuts with DBR/Y or equivalent moisture-resistant connectors

for all two-wire path connections.

Programming the Controller

In the BaseStation 1000 User Manual, refer to Setting Up Flow

biCoders. If you want the PFS flow sensor to be associated

with a water source, refer to Assigning a Flow Sensor to a

Water Source.

In the BaseStation 3200 User Manual, refer to Searching for

and Assigning Flow Meters. If you want the PFS flow sensor to

be associated with a water source, refer to Assigning

Devices to Water Sources.

BL-PFS100, BL-PFS150 & BL-PFS200

Calibration Table

Model K Value Offset

PFS100

PFS150

PFS200

0.322

0.650

1.192

0.20

0.75

0.94

1-866-294-5847 Rev 03262013 www.baselinesystems.com

Loading...

Loading...