Page 1

N E T A F I M U S A

Hydrometers

OPERATION AND

MAINTENANCE MANUAL

NETAFIM USA

5470 E. Home Ave. • Fresno, CA 93727

888.638.2346 • 559.453.6800

FAX 800.695.4753

www.netamusa.com

Page 2

This manual is intended for use by the users of this equipment. The information

contained herein is the property of Netam USA and may not be copied, used, or

disclosed to others without the manufacturer’s prior written approval.

Users are cautioned that the material contained herein is subject to change by the

manufacturer at any time and without prior notice. The material in this manual is

intended for informational purposes only.

Page 3

Table of Contents

INTRODUCTION

General Description ............................................................ 4

Water Meter/Registers .........................................................4

Hydraulic Valve (Flow Sensor) ...........................................4

Specications and Dimensions ........................................... 5

Netam USA Hydrometers with Electrical Output ............ 7

Electrical Output Specications (Reed Switch Reg.) ......... 7

Transducer Type ................................................................ 10

Hydrometer Internal Components .....................................12

MAINTENANCE PREPARATION

Preliminary Steps ..............................................................23

Tools .................................................................................. 23

MAINTENANCE 1 ½” – 8” HYDROMETERS

Hydrometer Removal From Pipeline ................................24

Finger Strainer Cleaning and Replacement ......................25

Register Assembly Removal and Replacement ................25

INSTALLATION

A. Installation Requirements .............................................13

B. Unpacking ....................................................................13

C. Pipeline Installation ...................................................... 13

D. Preliminary Steps .........................................................13

E. Installing 1 ½” and 2” Models ......................................13

F. Installing 3” – 8” Models ..............................................13

CONTROL SYSTEM

A. Solenoid Connection ....................................................14

B. Electrical Output ..........................................................14

DRAINAGE VALVE .......................................................15

OPERATIONAL TESTING

A. To test water ow and manual operation .....................16

B. To test automatic and remote operation .......................16

OPERATIONS

A. Manual Operation ........................................................17

B. Automatic Operation ....................................................17

C. Solenoid Operation .......................................................17

TYPICAL APPLICATIONS

Pressure Sustaining ...........................................................18

Pressure Reducing .............................................................19

TROUBLESHOOTING

A. Leakage from Hydrometer Connection to Pipeline .....20

B. No Electrical Output Signal from Hydrometer ............ 20

C. Controller Indicates Water Not Flowing as Instructed .20

D. No Indication of Flow on Meter Dial ...........................20

E. Controller Indicates Valve Opening Failure .................21

F. Controller Indicates Valve Closure Failure ...................21

G. Leakage from Valves or Connectors ............................21

H. Constant Drainage from Pilot Valve ............................21

I. Excess or Insufcient Output Pressure .......................... 22

J. Excess or Insufcient Input Pressure ............................22

K. Excess or Insufcient Flow Rate .................................22

MAINTENANCE 1 ½” & 2” HYDROMETERS

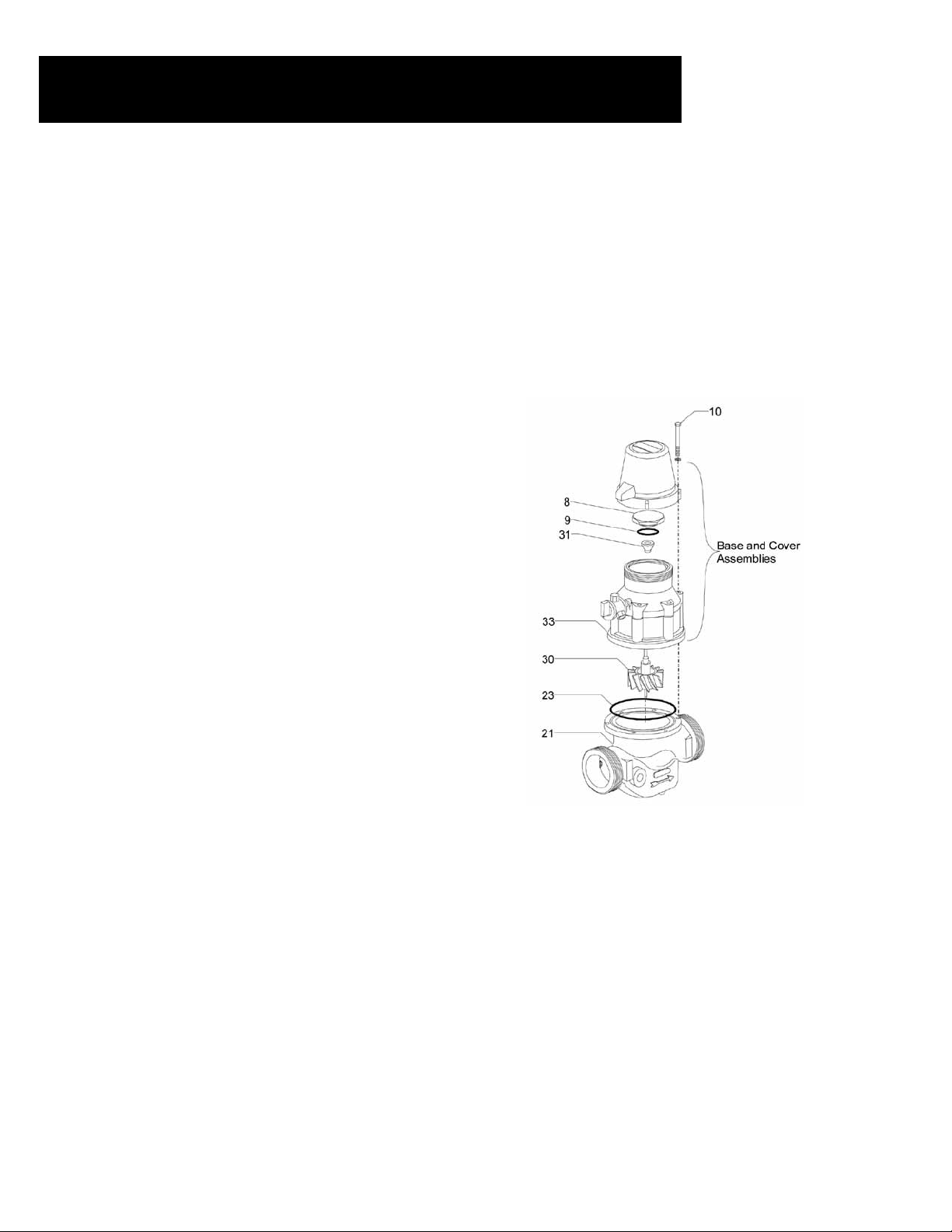

Hydrometer Cover and Base Assemblies ..........................26

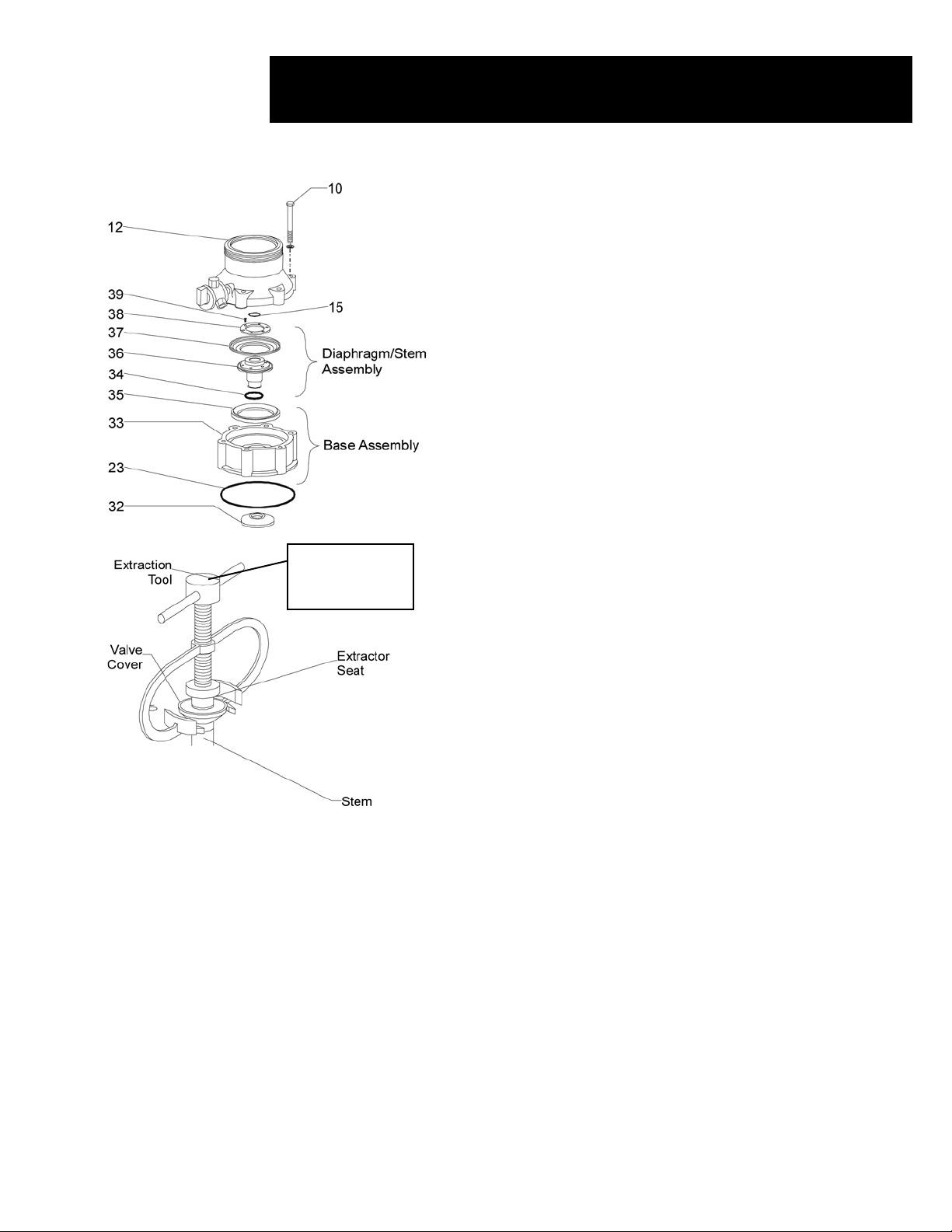

Diaphragm/Stem Dis-Assembly .......................................27

Base and Stem Dis-Assembly ........................................... 27

Inlet Spider and Strainer ...................................................28

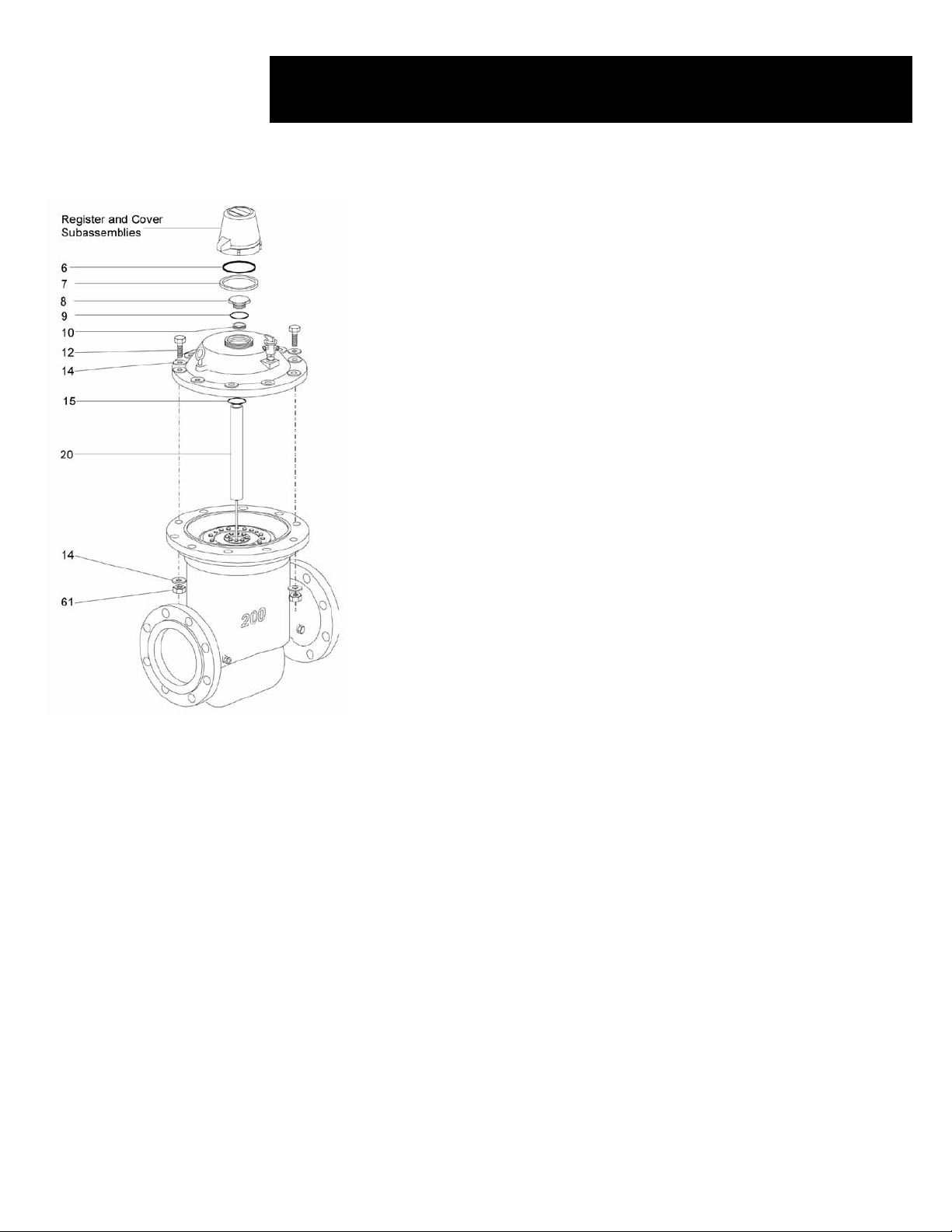

MAINTENANCE 3” & 4” HYDROMETERS

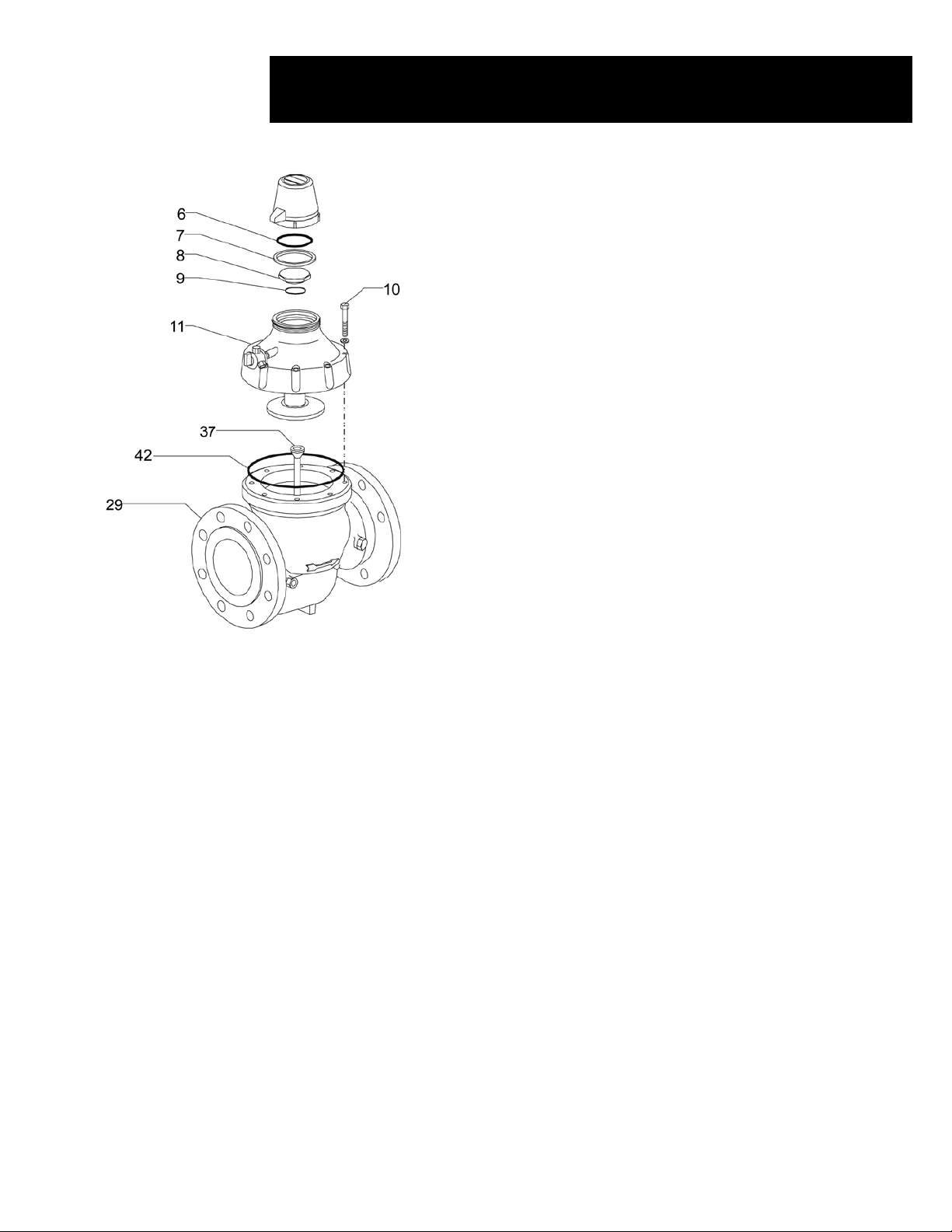

Hydrometer Dis-Assembly and Re-Assembly ................... 29

Hydrometer Cover and Base Sub-Assemblies .................. 29

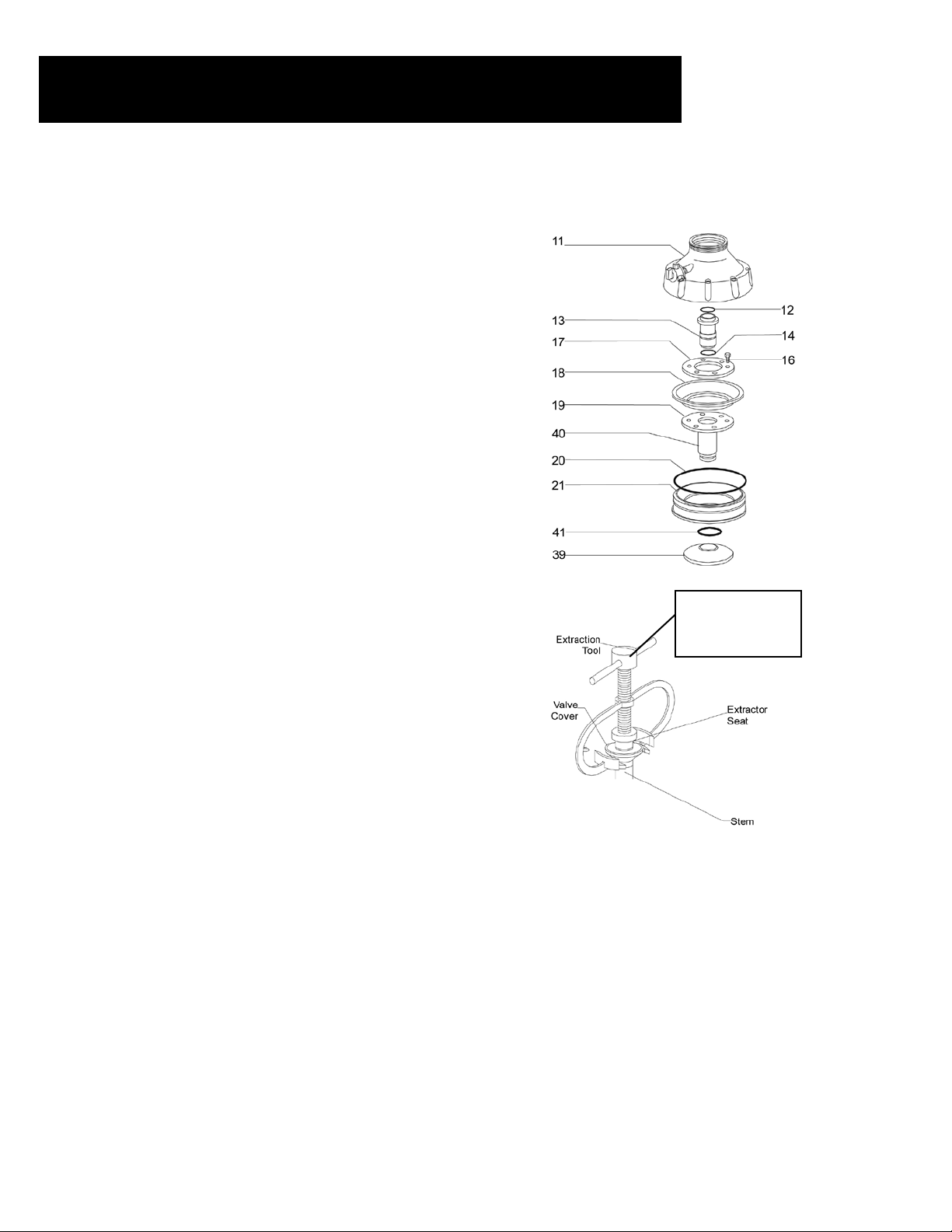

Diaphragm/Stem Assembly and Base Assembly ..............30

Inlet Spider and Strainer ...................................................31

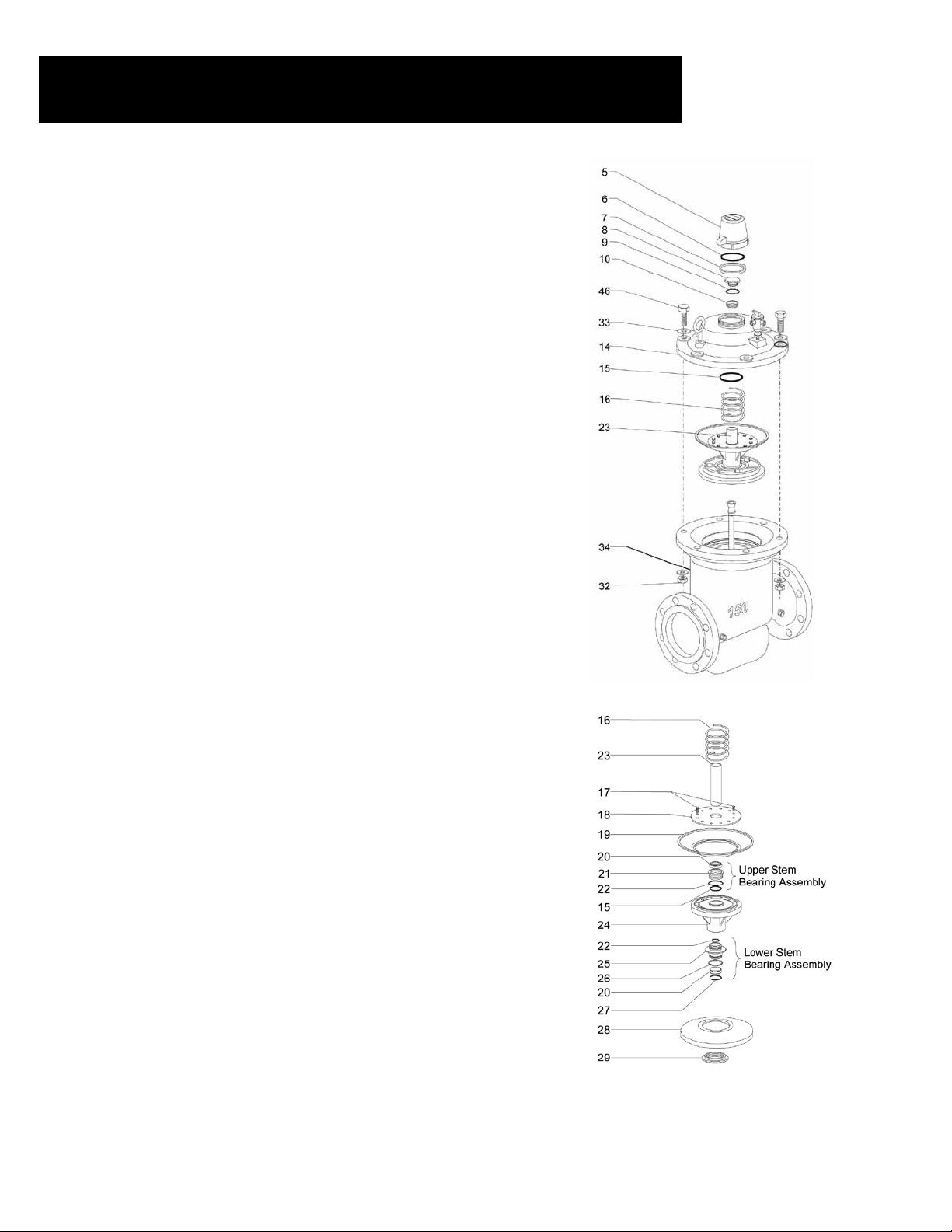

MAINTENANCE 6” HYDROMETERS

Hydrometer Dis-Assembly and Reinstallation .................32

Register ............................................................................. 32

Hydrometer Cover ............................................................32

Diaphragm and Upper Stem Bearing ................................ 33

Lower Stem Bearing and Valve Cover ..............................33

Impeller and Flow Tube Sub-Assemblies ......................... 34

Inlet Spider ........................................................................ 34

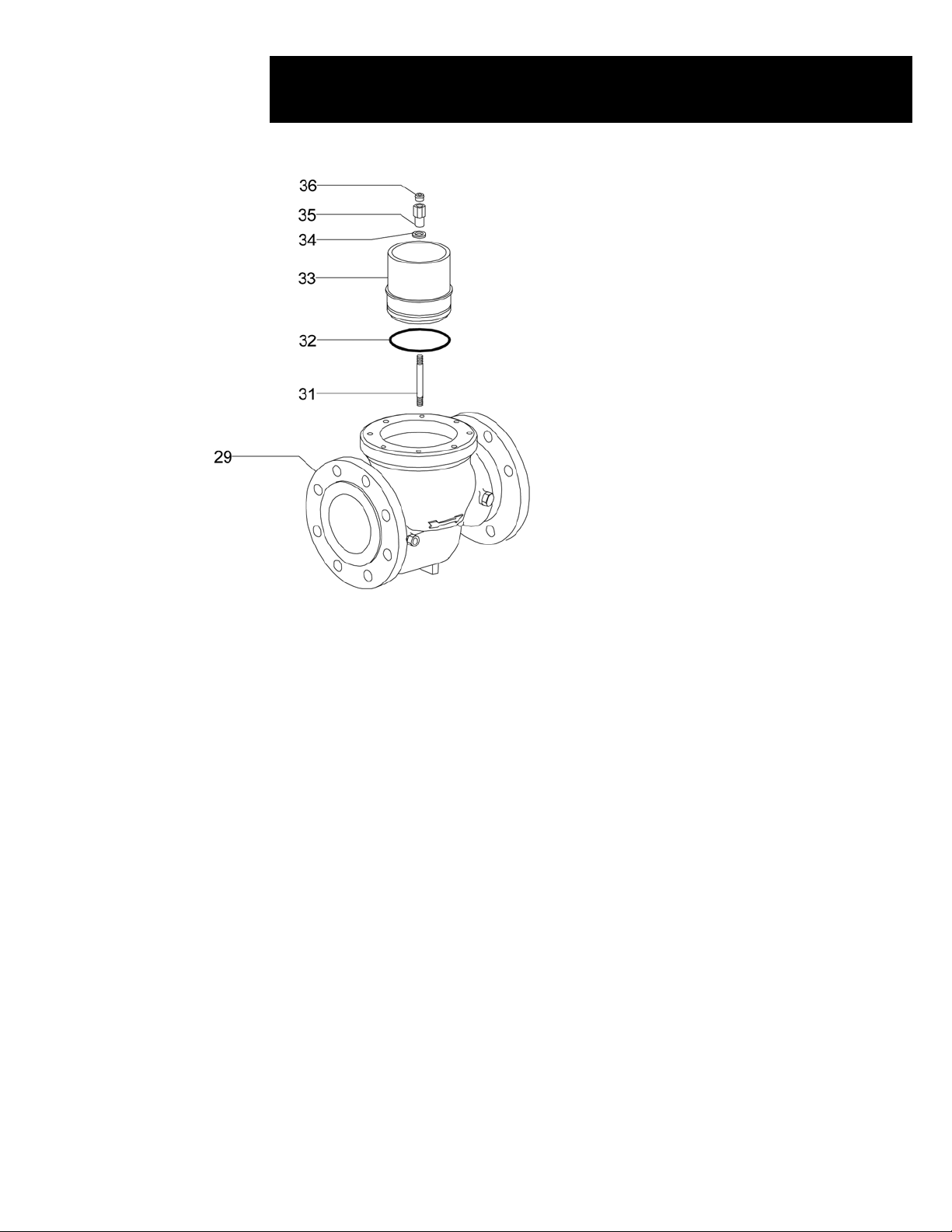

MAINTENANCE 8” HYDROMETER

Hydrometer Dis-Assembly and Re-Assembly ................... 35

Register ............................................................................. 35

Hydrometer Cover ............................................................35

Diaphragm Sub-Assembly ................................................35

Diaphragm Sub-Assembly and Dis-Assembly .................36

Lower Chamber Disc Sub-Assembly ................................36

Stem Sub-Assembly and Valve Cover ..............................37

Impellar and Flow Tube Assemblies ................................. 38

Inlet Spider ........................................................................ 38

SCHEMATICS ................................................................39

Page 4

Introduction

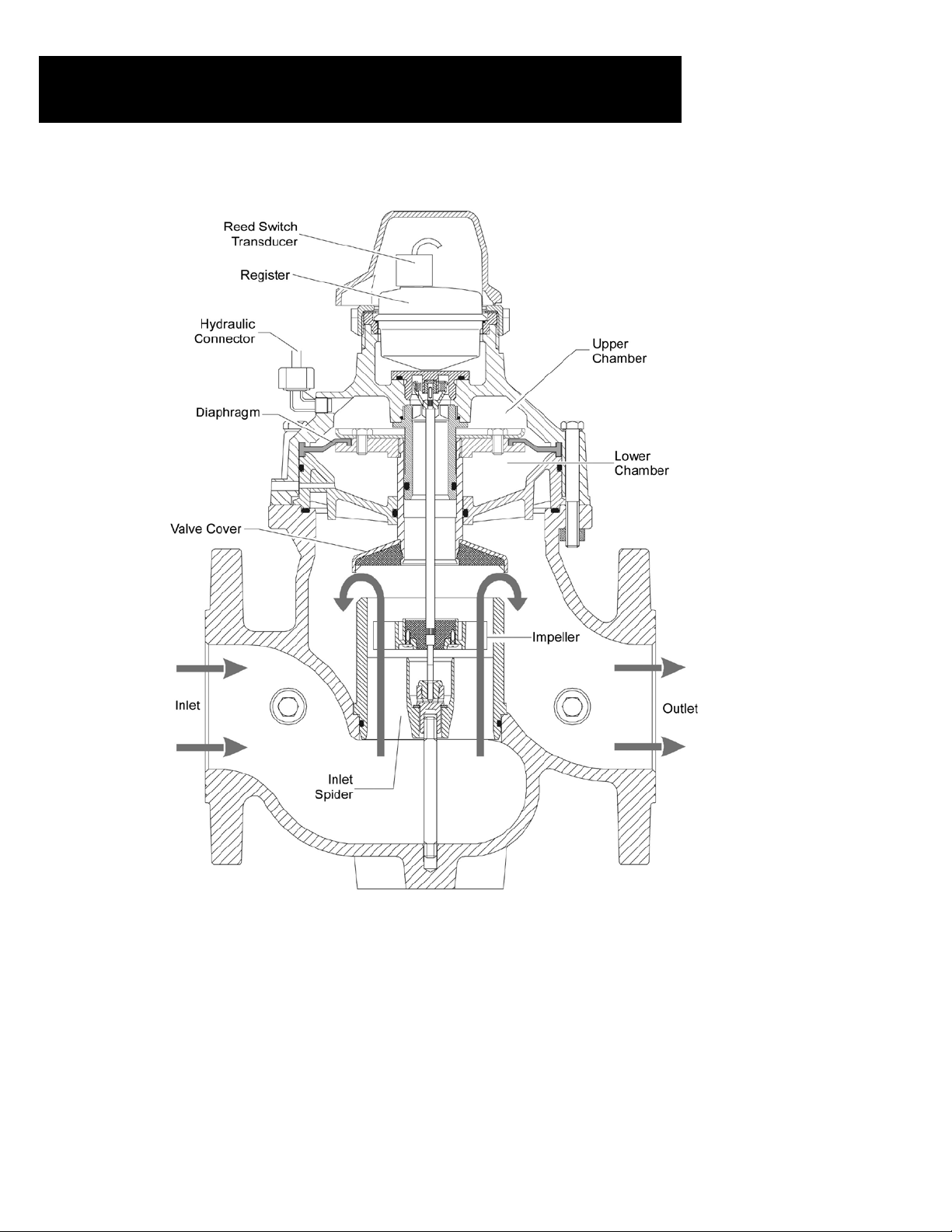

GENERAL DESCRIPTION

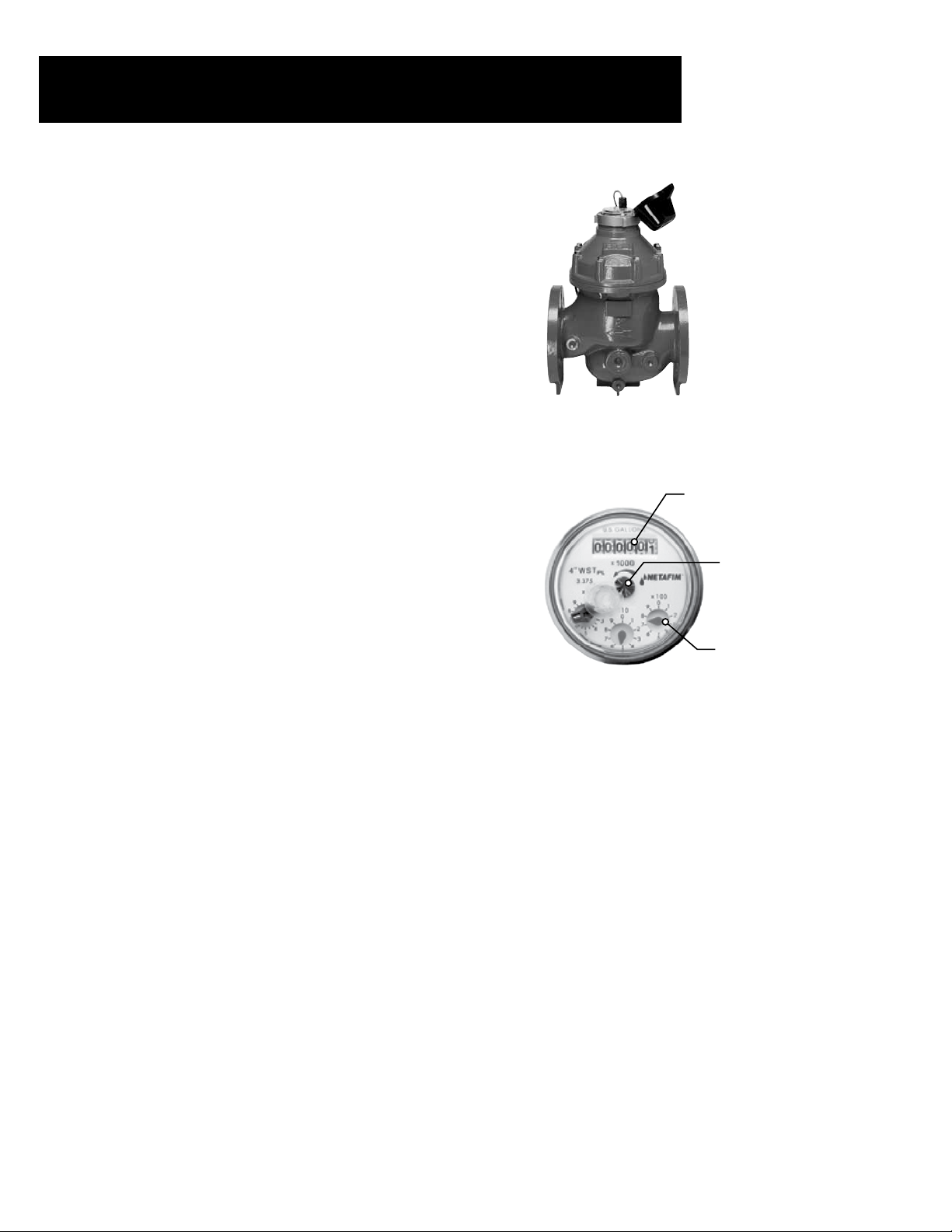

A hydrometer combines a hydraulic master valve, water meter and a

ow sensor in a single unit. Netam USA’s Hydrometer is designed

for high pressure, remote control irrigation and industrial applications.

Body: Horizontal

Available Sizes: 1½”, 2”, 3”, 4”, 6” and 8”

Operation: For automatic and remote operation in a variety

of applications. Remote operation is possible via

an external solenoid valve activated by a remote

controller or control center. Flow rate and volume

data are electronically transmitted to the remote

controller by means of a transducer inserted into

the register dial.

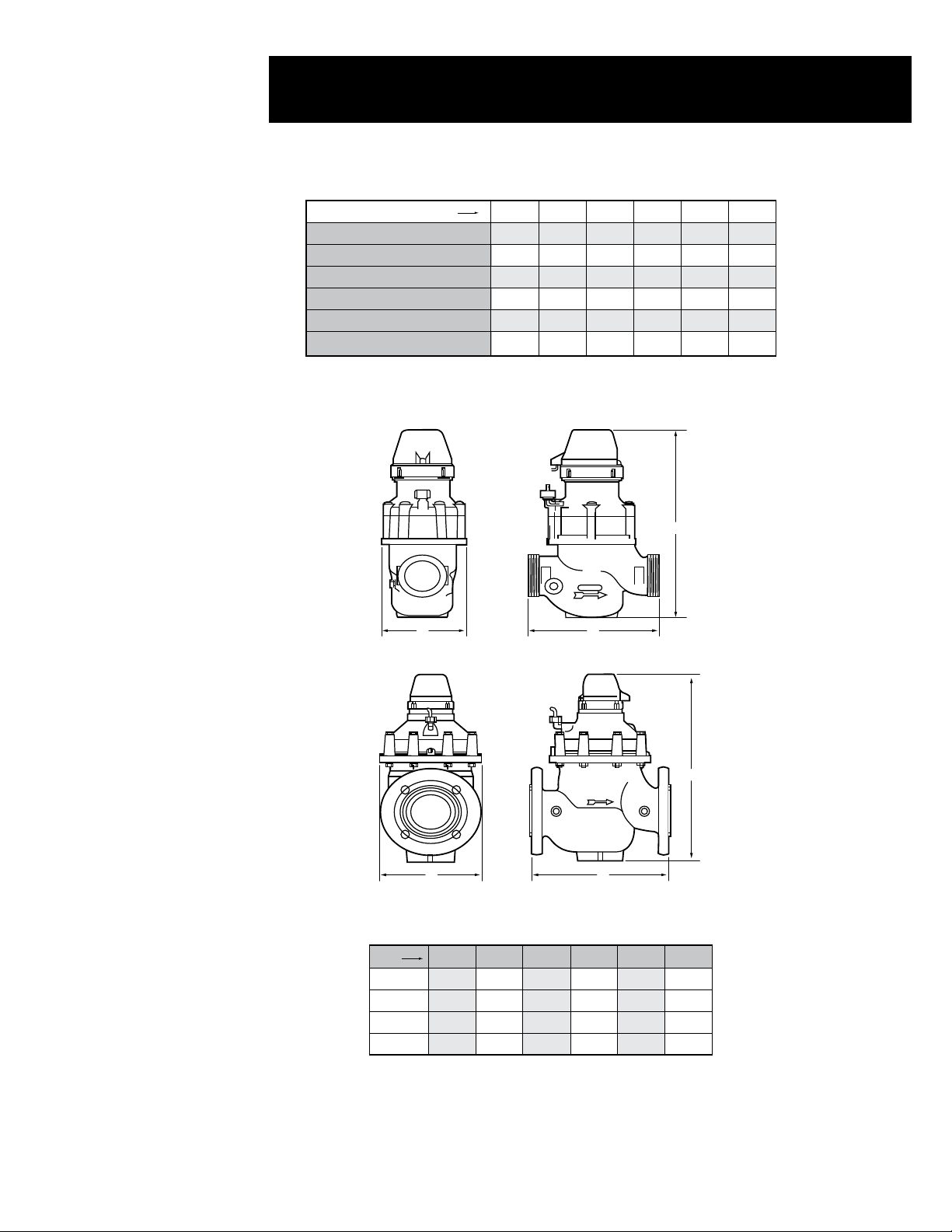

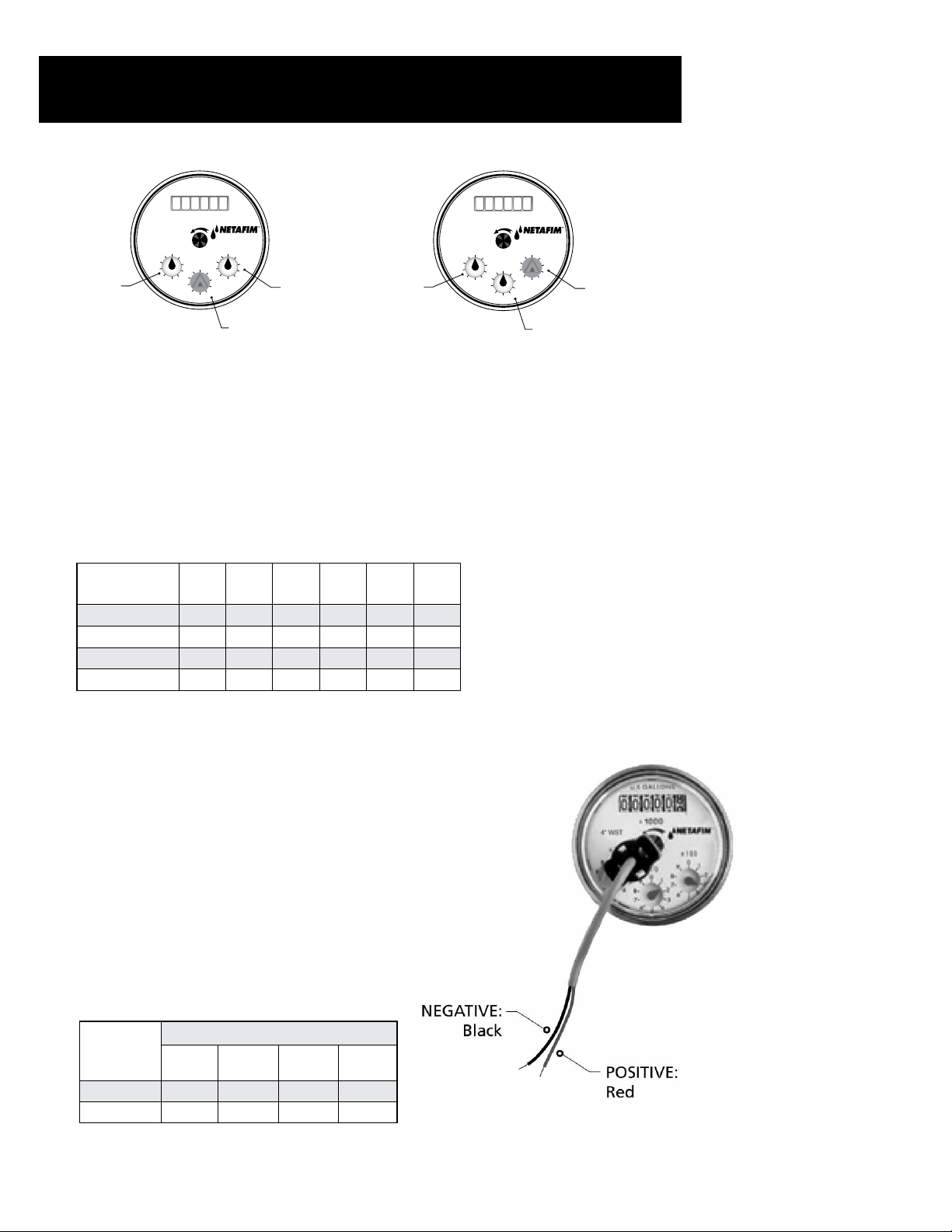

WATER METER/REGISTERS

The hydrometer contains both a dry contact (reed switch) type

magnetic drive and a higher frequency output photo-diode register

transmission water meter, the impeller is the only moving part in

contact with the water. The meter may be calibrated to measure either

gallons or cubic meters. A hermetically sealed register contains the

dial face and all mechanical meter components.

The dial face contains:

• Totalizer

• Three (3) analog pointers

• Rotating ow indicator or leak detector

A magnetic pointer, located over one of the analog pointers, measures

the ow rate and transmits the data to the reed switch transducer in

the register cover.

HYDRAULIC VALVE (FLOW SENSOR)

The hydrometer contains a hydraulic master valve operated either

manually or by remote control. The valve normally remains closed

until a command is received to open it. Hydraulic commands

are transmitted to the valve via an external solenoid valve. The

hydrometer can also be ordered in a Normally Open conguration.

In this case the valve is opened until a command is received and the

valve closes.

Standard Register

Gallon Totalizer

Totalizer

Analog Pointers

Rotating Flow

Indicator or

Leak Detector

4 • Hydrometers Operation and Maintenance Manual

Page 5

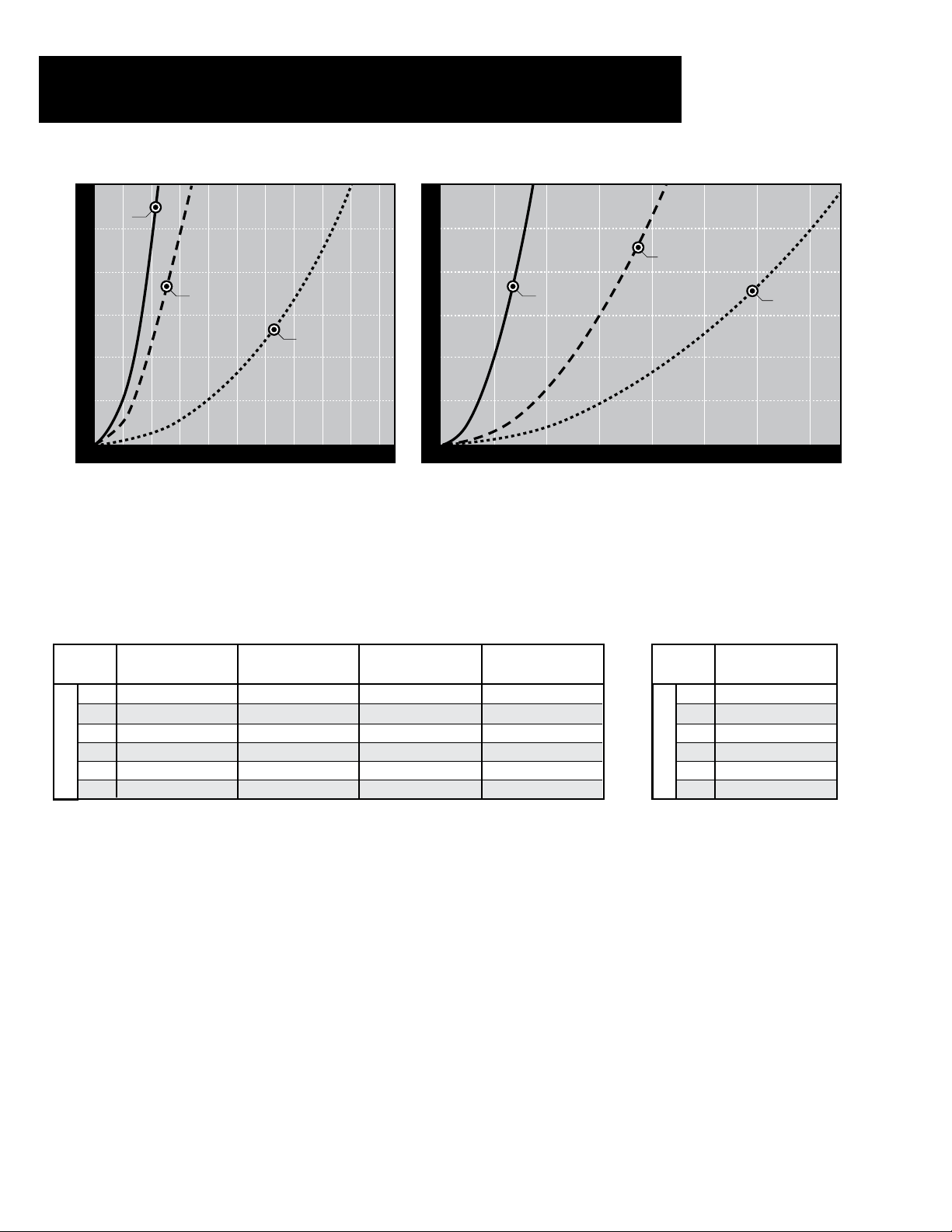

Specications and Dimensions

W L

H

SPECIFICATIONS

Size 1 ½”

Maximum Working Pressure (psi) 230 230 230 230 230 230

Minimum Working Pressure (psi) 14 14 14 14 14 14

Regulated Pressure Ratio 1:3 1:3 1:3 1:3 1:3 1:3

Maximum Flow Rate (GPM) 55 95 220 380 860 1500

Minimum Flow Rate (GPM) 4.4 20 53 79 198 357

Accuracy ±2% ±2% ±2% ±2% ±2% ±2%

2”

3” 4” 6” 8”

H

W

W L

L

H

Hydrometer Dimensions

Size 1 ½”

Length (L) 6 5/16” 6 1/4” 9 9/16” 10 15/16” 19 1/2” 20 11/16”

Width (W) 4 3/4” 4 3/4” 8 1/4” 9 1/16” 14 7/8” 17 3/4”

Height (H) 10 5/16” 13 13/16” 16 15/16” 17 3/4” 25 7/16” 25 5/8”

Weight 4 lbs. 7 lbs. 52 lbs. 65 lbs. 245 lbs. 309 lbs.

2”

3” 4” 6” 8”

Hydrometers Operation and Maintenance Manual • 5

Page 6

Headloss Charts

1 ½”

5.0

Specications, Cont.

5.0

4.0

2”

3.0

3”

Headloss (psi)

2.0

1.0

0

Pressure loss in psi = (gpm/Cv)

50

100 150 200 250

^2

Example: 2” Hydrometer, design ow @ 97 gpm

(55 gpm/35 gpm)

^2

= 2.5 psi headloss

Performance Data

Size

within ± 5% Accuracy

1 ½”

2”

3”

4”

6”

8”

Lowest Flow

1.8 GPM 4.4 GPM 44 GPM 55 GPM

5.3 GPM 20 GPM 66 GPM 95 GPM

14 GPM 53 GPM 176 GPM 220 GPM

21 GPM 79 GPM 264 GPM 380 GPM

53 GPM 198 GPM 660 GPM 860 GPM

97 GPM 357 GPM 1,189 GPM 1,500 GPM

Lowest Flow

within ± 2% Accuracy

4.0

3.0

Headloss (psi)

2.0

1.0

0

Nominal Flow

within ± 2% Accuracy

4”

200

within ± 2% Accuracy

400 600 800 1000 1200 1400

Maximum Flow

6”

8”

Flow Rate (gpm)Flow Rate (gpm)

Cv Values

Cv (Flow Rate at

1.0 psi of Headloss)

Size

1 ½”

2”

3”

4”

6”

8”

23 GPM

35 GPM

92 GPM

139 GPM

347 GPM

624 GPM

6 • Hydrometers Operation and Maintenance Manual

Page 7

Specications, Cont.

NETAFIM USA HYDROMETERS WITH ELECTRICAL OUTPUT

Netam USA Hydrometers are equipped with electrical output devices that combine the high reliability

of hermetically sealed, magnetically driven registers with a wide variety of electrical output options.

Hydrometers (measuring instruments) provide electrical output information about the ow of water.

When more than just the traditional register is needed, they also provide the solution for automation and

communication with controllers, electronic devices and other water delivery systems.

Netam USA has three types of transducer outputs available which provide three levels of resolution:

• Reed Switch (RS) Register - low frequency pulse output for functions related

primarily to recording volume.

• Photo Diode (PD) Register - standard frequency pulse output (open collector) for

functions such as rate of ow and recording total volume.

• Photo Diode (PDH) Register - high frequency pulse (open collector) for functions

such as rate of ow and recording total volume.

Recommended Register

Transducer Outputs

Manufacturer

Baseline Basestation PDH

Hunter ACC 2-Wire PDH

Rain Bird MDC & Maxi RS

Signature All Models RS

Sentinel PDH

Toro

TDC 2-Wire PDH

Rainmaster All Models

PD (6”, 8”)

Flowmaster

Tucor

& RK Series

Motorola All Models RS

Controller

Model

Recommended

Register Type

RS (1” to 4”)

PDH

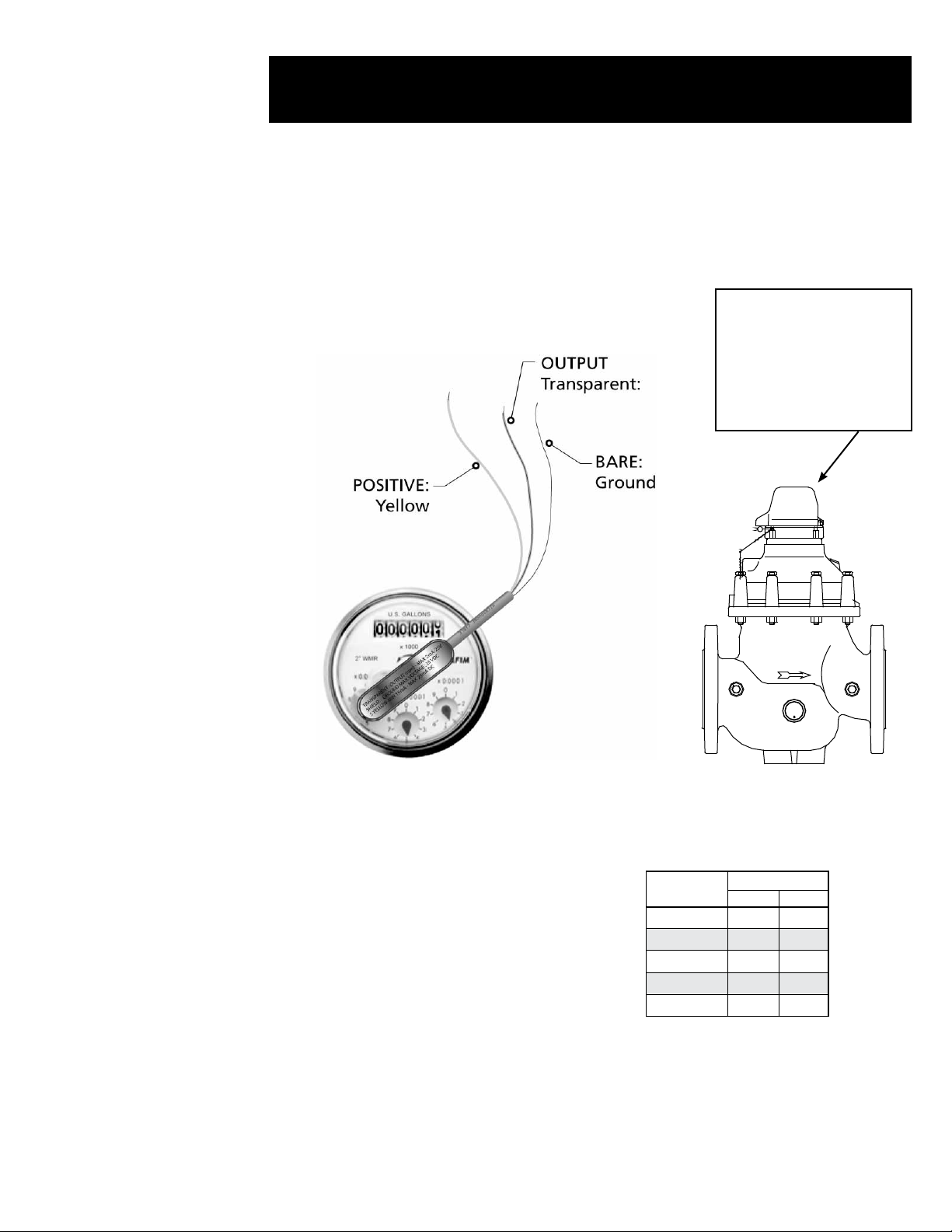

ELECTRICAL OUTPUT SPECIFICATIONS

REED SWITCH (RS) REGISTER

The ow rate is transmitted as periodic electrical pulses are measured by the magnetic pointer in

the dial face. The hydrometer is congured to transmit a pulse according to a pre-dened volume

interval. The following summarizes the available volume intervals for various hydrometer sizes in

either gallons or cubic meters.

• A three pointer register, with a magnet installed on one of the pointers.

• Output denition: Volume Output

• Output type: RS – Reed Switch and PD – Photo Diode

The sensor is installed in a transparent plastic cover that can be mounted on the register in one of

three positions with the pointer facing the magnet. Three values of electrical output are available

in 1:10:100 ratios.

Hydrometers Operation and Maintenance Manual • 7

Page 8

Specications, Cont.

U.S. GALLONS

0 0 0 0 0 0

BM

0

9

1

8

2

0

7

9

3

1

6

8

4

5

Pulse per

1 USG

EXAMPLE for sizes 1½”, 2”, 3”, 4”

(standard pulse = 1 g/p)

7

6

4

5

9

8

7

6

2

3

0

1

2

3

4

5

Pulse per

10 USG

Pulse per

100 USG

Pulse per

10 USG

U.S. GALLONS

0 0 0 0 0 0

x 1000

BM

0

9

1

8

7

6

4

5

EXAMPLE for sizes 6”, 8”

(standard pulse = 10 g/p)

0

9

1

8

2

9

3

8

7

6

2

0

7

3

1

6

4

2

5

3

4

5

Pulse per

100 USG

Pulse per

1000 USG

For sizes 1½”, 2”, 3”, 4”: If the pointer with the magnet is set in the middle position as shown

in the drawing the magnet will make one contact of the reed switch for every 360° rotation - the

result is an output of 1 pulse per 10 USG.

For sizes 6”, 8”: If the pointer with the magnet is set in the right position as shown in the drawing

the magnet will make one contact of the reed switch for every 360° rotation - the result is an

output of 1 pulse per 1000 USG.

Available Impulse Sequences

Available Outputs

(U.S. gallons/pulse)

1

10

100

1000

1 ½”

3” 4” 6” 8”

2”

Reed Switch (RS) Register

Specifications

• Magnet activated.

• Acts as a “dry contact”, uses very little

electric power.

• For “Volume” related functions such as

data recorders or simple counters.

Electrical Specifications

Maximum Contact Current: 50 mA

Maximum Contact Voltage: 28 VDC

Reed Switch (RS)

Low Frequency Pulse Outputs

Reed Switch (RS)

Hydrometer

Size

1½”, 2”, 3”, 4” 1 1 60.00 0

6”, 8” 10 0.1 600.00 0

Gallons/

Pulse

Pulse/

Gallon K Factor Offset

Circuit Diagram

Register with Reed Switch

Output, Two Wires

8 • Hydrometers Operation and Maintenance Manual

Page 9

Specications, Cont.

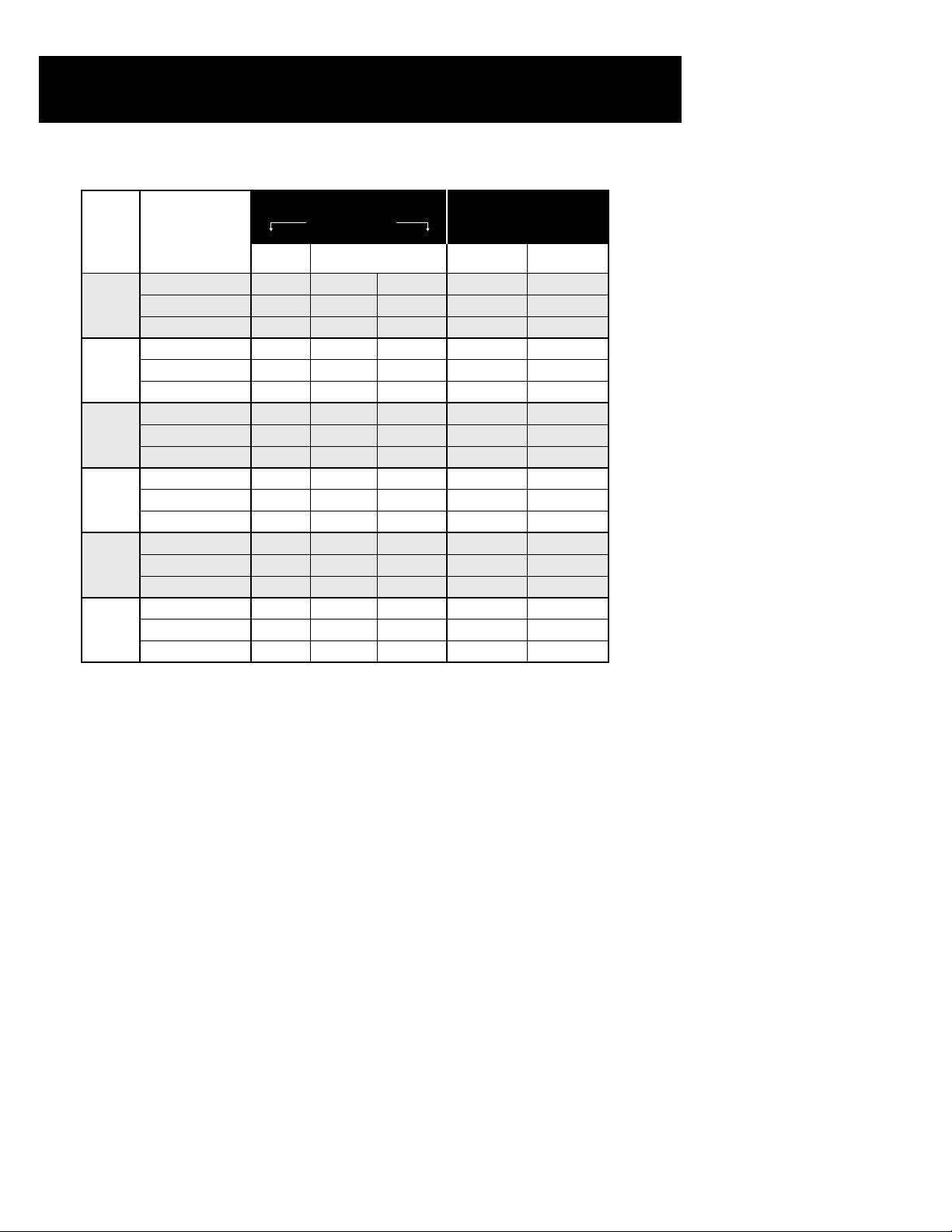

Photo-Diode (PD & PDH) Register

• SensorcombinesanIRlightsourceandalightsensitive

diode in one package.

• Signalsarecreatedwhenthelightbeamcreatedbythe

IRlightisinterruptedbyarotatingelement.

• RequiresaconstantsupplyofDCpower.

Circuit Diagram

Register with Photo Diode

Output and Wire Leads

Note:Sunlightwillinterfere

withtheIRlightandmay

corruptorinterferewiththe

signal—keepdustcapclosed

during operation to ensure

propersignaloutput.

Photo-Diode Electrical

Specifications

POSITIVE powers the IR light

(yellow wire)

Current Min: 15 mA to a maximum of 25 mA DC

through a resistor

•MaximumVoltage:28VDC

OUTPUT (clear wire)

Output–Opencollector

Recommended

Resistor Valves

Voltage (V+)

Ω W

5 180 0.25

6 220 0.25

9 330 0.25

12 470 0.50

24 1000 1.00

Resistor Values

(Max. Load – 2 mA)

GROUND (bare wire)

NOTE: Correct polarity of the leads should be

checked carefully to prevent damage to

the sensor.

Hydrometers Operation and Maintenance Manual • 9

Page 10

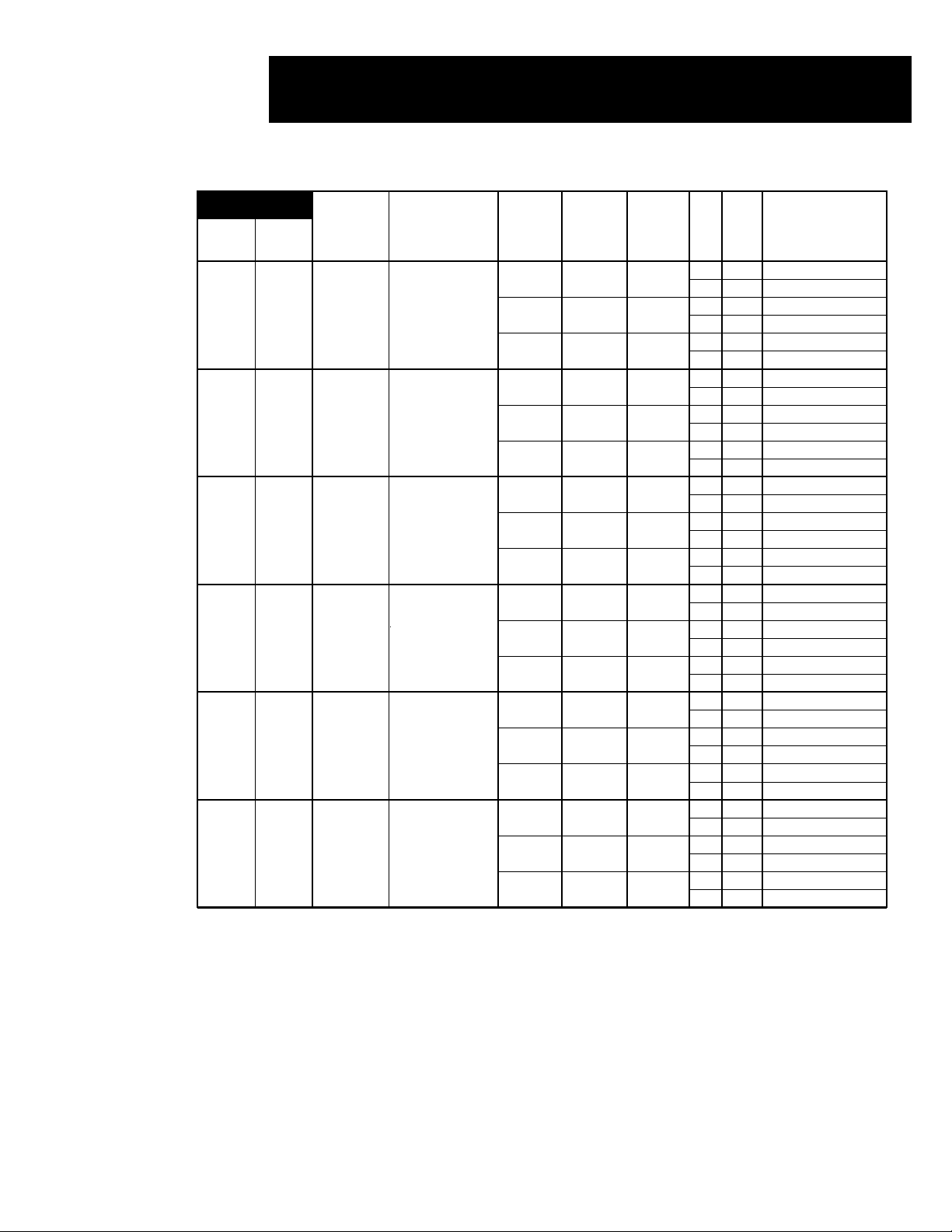

Transducer Type

Transducer Type: Reed Switch and Photo Diode K Factors

Photo Diode (PD) and

Photo Diode High Frequency

Meter

Size

1½”

2”

3”

4”

6”

8”

Reed Switch (RS)

Standard

Output

Gallons per pulse 1 10 100 0.1 0.0053

Pulse per gallon 1 0.1 0.01 10 187.900

K factor 10.00 60.00 600.00 6000.00 6.00 0.319

Gallons per pulse 1 10 100 0.1 0.0085

Pulse per gallon 1 0.1 0.01 10 117.000

K factor 10.00 60.00 600.00 6000.00 6.00 0.5100

Gallons per pulse 1 10 100 0.1 0.0205

Pulse per gallon 1 0.1 0.01 10 48.710

K factor 10.00 60.00 600.00 6000.00 6.00 1.232

Gallons per pulse 1 10 100 1 0.0556

Pulse per gallon 1 0.1 0.01 10 17.993

K factor 10.00 60.00 600.00 6000.00 6.00 3.335

Gallons per pulse 10 100 1000 1 0.1741

Pulse per gallon 0.1 0.01 0.001 1 5.747

K factor 10.00 600.00 6000.00 60000.00 60.00 10.437

Gallons per pulse 10 100 1000 1 0.317

Pulse per gallon 0.1 0.01 0.001 1 3.152

K factor 10.00 600.00 6000.00 60000.00 60.00 19.036

Optional Output PD PDH

Pulse (PDH)

Note: Offset = 0 in all Netafim USA Water Meters

When entering K factors in controllers and/or data recorders please refer to the manufacturer’s

recommendations—some will require the number of gallons per pulse and others will require

the number of pulses per gallon. Some manufacturers will require a “K” and “offset” (for all

Netam USA Water Meters the offset = 0) where the K and offset are calculated using he following equation:

Freq = (GPM/K) – offset

Where:

Freq = pulse/second

GPM = gallons per minute

K = unit less constant specic to each hydrometer pulse output

Offset = correction factor (All Netam USA water meters have an offset = 0)

or:

K = 60/(pulse/gallon)

10 • Hydrometers Operation and Maintenance Manual

Page 11

Specications, Cont.

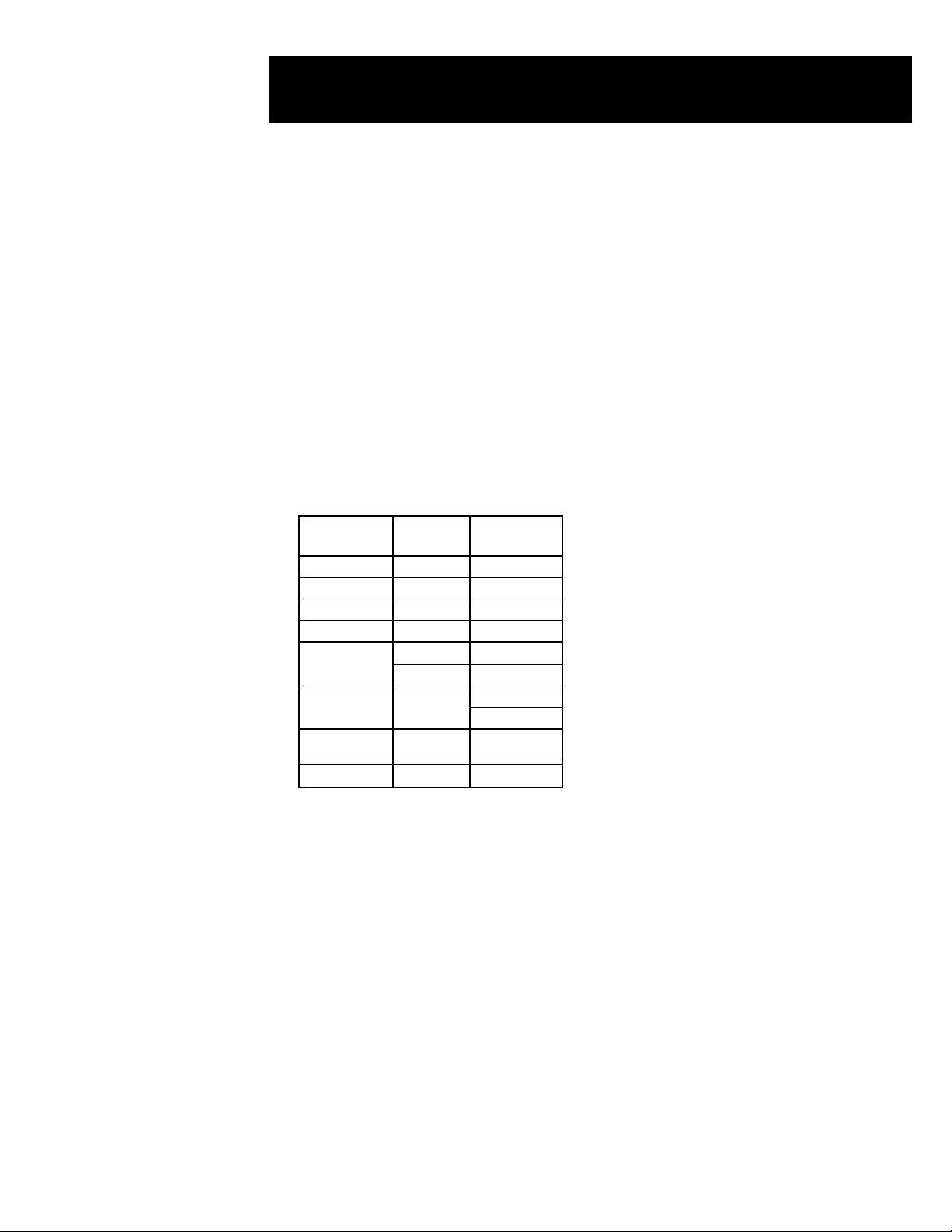

Ordering Information

FLOW RANGE

Min GPM

PD 10 0.1

1.8 55 1½” Male Pipe Thread PDH 187.900 0.0053

RS 1 1

PD 10 0.1

5.3 95 2” Female Pipe Thread PDH 117.000 0.0085

RS 1 1

PD 10 0.1

14 220 3” Flanged PDH 48.710 0.0205

RS 1 1

PD 10 0.1

21 380 4” Flanged PDH 17.933 0.0556

RS 1 1

PD 1 1

53 860 6” Flanged PDH 5.747 0.1741

RS 0.1 10

PD 1 1

97 1,500 8” Flanged PDH 3.152 0.317

RS 0.1 10

± 5%

Max GPM

± 2%

Meter

Size

Connection

Register

Output

Type

Pulse per

Galon

Gallons

per Pulse

Electric

• LHM15TG01-MEL

• • LHM15TG01-PRMEL

• LHM15TG0053-MEL

• • LHM15TG0053-PRMEL

• LHM15TG1-MEL

• • LHM15TG1-PRMEL

• LHM2TG01-MEL

• • LHM2TG01-PRMEL

• LHM2TG0085-MEL

• • LHM2TG0085-PRMEL

• LHM2TG1-MEL

• • LHM2TG1-PRMEL

• LHM3FG01-MEL

• • LHM3FG01-PRMEL

• LHM3FG0205-MEL

• • LHM3FG0205-PRMEL

• LHM3FG1-MEL

• • LHM3FG1-PRMEL

• LHM4FG01-MEL

• • LHM4FG01-PRMEL

• LHM4FG0556-MEL

• • LHM4FG0556-PRMEL

• LHM4FG1-MEL

• • LHM4FG1-PRMEL

• LHM6FG1-MEL

• • LHM6FG1-PRMEL

• LHM6FG1739-MEL

• • LHM6FG1739-PRMEL

• LHM6FG10-MEL

• • LHM6FG10-PRMEL

• LHM8FG1-MEL

• • LHM8FG1-PRMEL

• LHM8FG317-MEL

• • LHM8FG317-PRMEL

• LHM8FG10-MEL

• • LHM8FG10-PRMEL

Model Number

Pressure

Regulating

Hydrometers Operation and Maintenance Manual • 11

Page 12

Hydrometer Internal Components

Hydrometer Internal Components

(DoubleChamberNotAvailablein6”)

12 • Hydrometers Operation and Maintenance Manual

Page 13

Installation

A. Installation Requirements

• Globe conguration hydrometers

require no straight pipe installation

requirements. Do not install valves

that will cause a restriction directly

upstream or downstream of the

hydrometer.

• Connections to the hydrometer

should be the same size as the meter.

Example: if a 3” hydrometer is

installed, 3” pipe and ttings should

Globe Configuration

Straight Pipe Installation Requirement

0 x D and 0 x D

Upstream

Size

1 ½” 0” 0” 6 5/16” 6 5/16”

2” 0” 0” 8 5/8” 8 5/8”

3” 0” 0” 11 1/2” 11 1/2”

4” 0“ 0” 14 1/8“ 14 1/8“

6” 0“ 0” 19 1/2“ 19 1/2“

8” 0” 0” 23 5/8“ 23 5/8“

Distance

Downstream

Distance

Meter

Length

Total

Requirement

be connected to the hydrometer.

• Prior to installation of the meter, the

pipeline should be thoroughly ushed.

• Recommendation: Air Vents of proper size and type, Continuous

acting and large acting, be installed to eliminate air.

B. Unpacking

The hydrometer comes fully assembled according to the customer’s specications. The 1½” model

is shipped with the appropriate couplings and gaskets. For larger diameter models installation

hardware is not included for larger diameter models. Pilot valves and other accessories are factory

installed and calibrated according to the customer’s specications.

C. Pipeline Installation

The following tools are required to perform these procedures:

• Flat blade and Phillips head screwdrivers in various sizes

• Open end or box wrenches in various sizes

• Large pipe wrenches

• Pliers

• Dies or pipe threading tools compatible with the pipeline diameter

• Teon tape or similar pipe sealing material

D. Preliminary Steps

1. Before beginning the installation, the line should be thoroughly ushed to remove any

foreign matter.

2. Close the inlet valve in order to shut off the water ow to the pipeline.

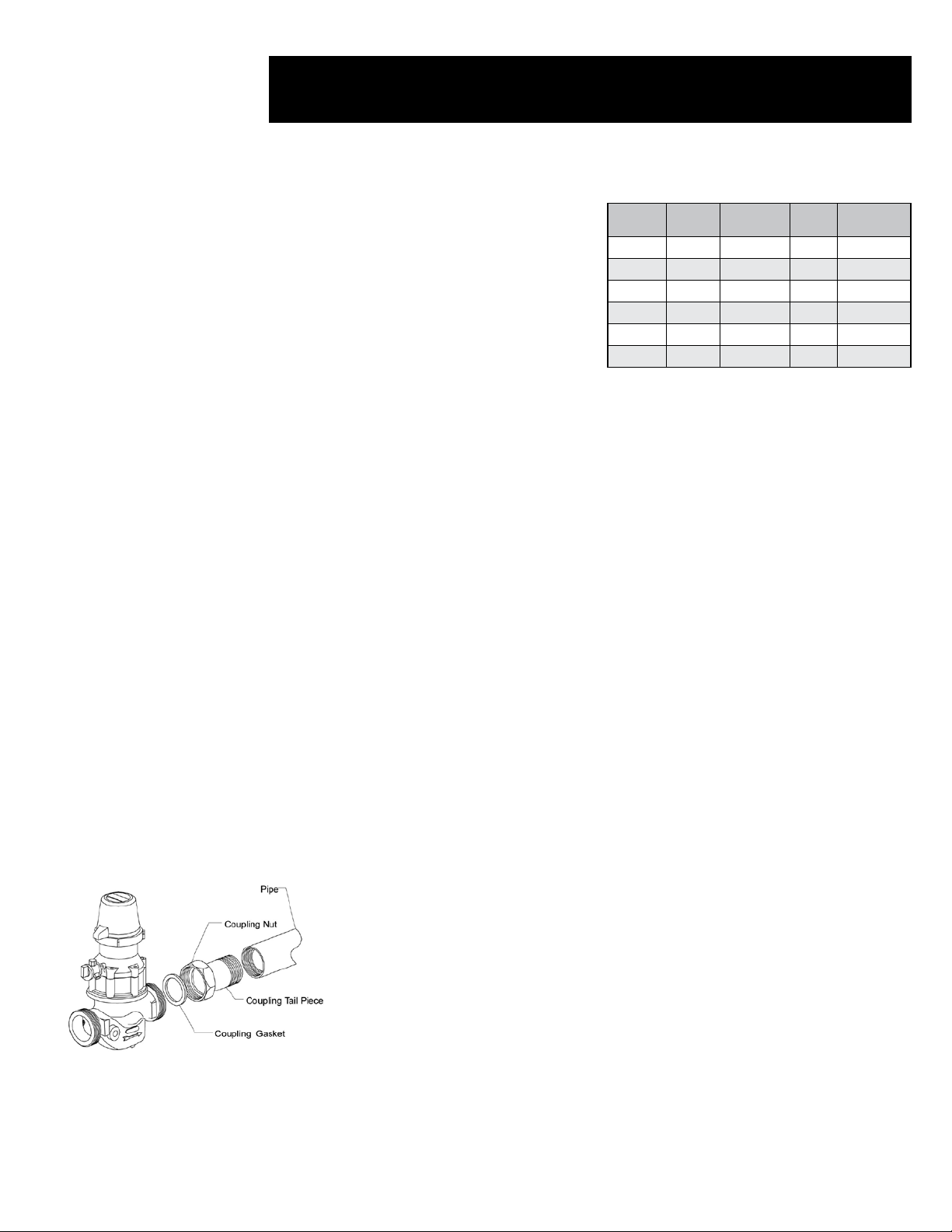

E. Installing 1½” and 2” Models

The 2” hydrometer can be attached directly to a male threaded pipeline or to a female threaded

pipeline using a coupling. The 1½” model can only be attached using a coupling.

Coupling Connection

• Create a female threaded connection on both pipe sections.

• Apply Teon tape or similar material to seal the connections.

• Insert the male coupling connections into the pipeline sections and tighten securely.

• Place a coupling gasket over each male threaded hydrometer connection and

securely tighten the coupling nuts.

Direct Connection

• Create a male threaded connection on both pipe sections that are to be attached.

• Apply Teon tape or similar material to seal the connections.

• Insert the male threaded pipe connection into the hydrometer and tighten securely.

F. Installing 3” – 8” Models

The end user is expected to supply the appropriate gaskets

and bolts according to the diameter of the pipeline.

• Place the appropriate gasket onto each ange.

• Insert the bolts, nuts and washers and tighten securely.

Hydrometers Operation and Maintenance Manual • 13

Page 14

Installation, Cont.

CONTROL SYSTEM

A. Solenoid Connection

The hydrometer receives commands from the controller or control center via an external solenoid

valve. The hydrometer may be ordered with a factory installed solenoid valve or connected to an

solenoid valve supplied by the user.

To connect to a factory installed solenoid:

1. Connect the electric cable from controller to the attached solenoid valve. Position

the three-way selector in the “Auto” position - in this position the hydrometer will be

controlled by the solenoid.

B. Electrical Output

The hydrometer supplies volume and ow rate data to a controller or to an external measuring

device via an electrical connection. A reed switch transducer is factory installed in the register

dial. The cable attached to the reed switch transducer attaches to the controller or measuring

device.

To connect the hydrometer to the controller or measuring device:

1. Install an appropriate connector onto the bare end of the cable exiting from the reed

switch. Refer to the user manual of the controller or measuring device for details

regarding the specic connector type.

2. Connect the cable to the input port of the controller or measuring device.

(See pages 7-10 for more details)

14 • Hydrometers Operation and Maintenance Manual

Page 15

Drainage Valve

DRAINAGE VALVE

At the beginning of the winter it is necessary to drain the water from the pipeline in order to

prevent the pipes from bursting. (Please refer to the drawing below)

• Before draining, it is very important to ensure that there is no pressure in the line.

• Dissassemble plug (1)

• Assemble the drainage ball valve (2)

• Assemble elbow (3)

CAUTION: Do not use compressed air to blow out hydrometer.

Hydrometers Operation and Maintenance Manual • 15

Page 16

Operational Testing

INSTALLATION

Before the hydrometer is placed into service, you should perform the following tests to verify that

it is operating properly:

A. To test water ow and manual operation:

• Set 3-Way Selector to the “Open position”.

• Turn on the water ow to the hydrometer.

• Visually verify that water is owing downstream from the hydrometer in appropriate

quantities.

• Verify that the leak detector, pointers and the totalizer are functioning properly.

• Check all hoses, connections, pilot valves, etc. for leakage and repair as necessary.

• Set 3-Way Selector to the “Close position”.

• Verify that the water ow downstream has stopped.

B. To test automatic and remote operation:

• Set 3-Way Selector to the “Auto” position.

• Turn on the water ow to hydrometer.

• Verify that the hydrometer output is correctly received by the controller or control center.

• Use the controller or control center to close the hydrometer. Verify that the water ow

downstream has stopped.

• Use the controller software to test operation of the hydrometer under various applications

and conditions such as pressure reducing, pressure sustaining and ow regulation.

• Your hydrometer is now ready for routine use.

16 • Hydrometers Operation and Maintenance Manual

Page 17

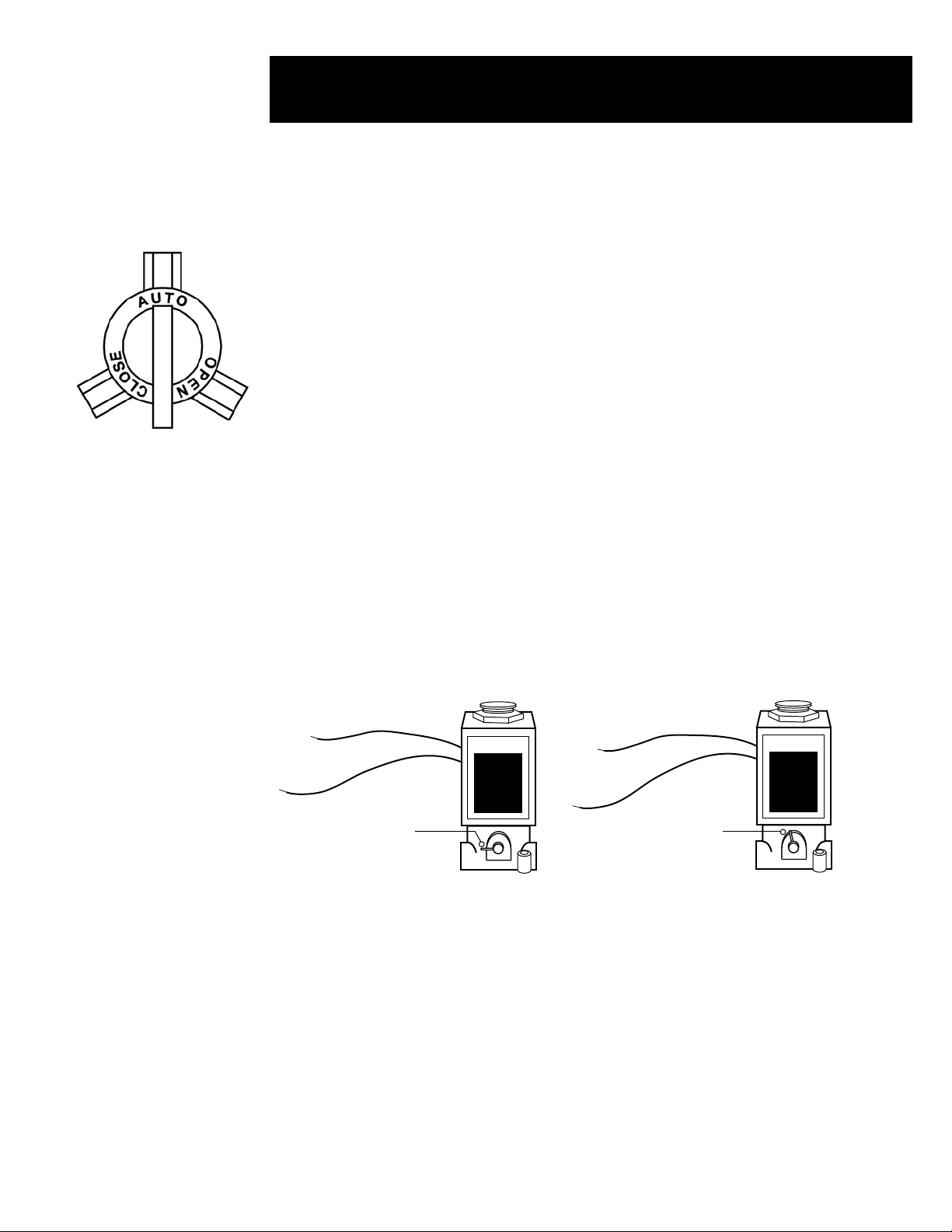

3-Way Selector

SOLENOID

Operations

The hydrometer is designed to operate in a variety of automatic and remote control applications.

The hydrometer valve is also capable of manual operation and the register dial may be read as an

ordinary water meter.

A. Manual Operation

The hydrometer may be manually operated using the 3-Way Selector:

• To manually open the valve: Rotate the 3-Way Selector to the “Open” position.

• To manually close the valve: Rotate the 3-Way Selector to the “Close” position.

B. Automatic Operation

Automatic operation is made possible by direct hydraulic control from a remote controller or

control center. Volume and/or ow data is electronically transmitted to the remote controller

by means of a reed switch transducer. The command to open or close the hydrometer valve is

transmitted from the controller to a solenoid, which, in turn, transmits a hydraulic command to the

hydrometer.

Automatic operation may also be based on a pre-set pressure or ow rate by the use of one or

more Pilot Valves. To enable automatic and/or remote operation, rotate the 3-Way Selector to the

“Auto” position.

C. Solenoid Operation

The hydrometer is always controlled via an external solenoid valve. A “normally open” (NO),

high pressure, 3-Way solenoid valve is required for this purpose resulting in a normally closed

hydrometer. When a normally closed solenoid is used it will result in a normally open hydrometer.

An electric cable connects the controller and the solenoid valve. 8 mm polyethylene tubing runs

from the solenoid valve to the “Auto” connection on the 3-Way Selector.

SOLENOID

Open

Manual Override

Automatic

Position

SOLENOID

Open

Position

Automatic Position

Operated by the Controller

Electric Solenoid Specications

• Operation:

– Solenoid: 24vac 5.5 watts,

0.23 amps inrush

– Manual Override

• Construction: Brass

• Connections: In/Out NPT Threaded

Hydrometers Operation and Maintenance Manual • 17

Page 18

Typical Applications

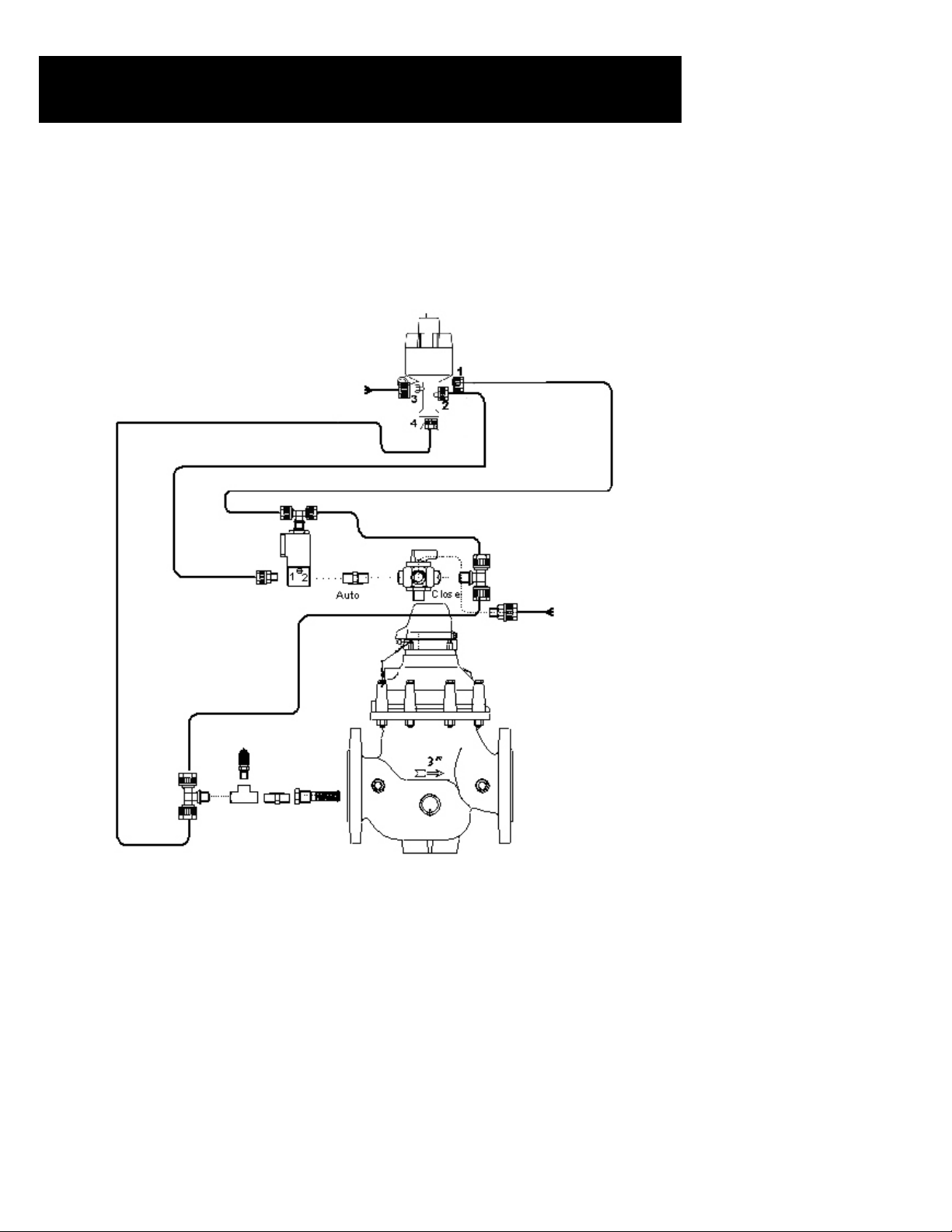

PRESSURE SUSTAINING

The pressure sustaining operation prevents the input pressure from falling below a predetermined

value. This application requires a Netam Pressure Regulating Pilot Valve, or comparable valve.

Rotate the adjusting screw atop the pilot valve counterclockwise to increase the desired input

pressure and clockwise to reduce the desired input pressure.

Connection Information

The sensor connection runs from the input connector on the hydrometer to the controlled input

connector (1) on the pilot valve. The sensor connection also branches off to the “Close” connector

on the 3-Way Selector and to the vent connector (4) on the pilot valve.

The command connection runs from solenoid to the “Auto” connector on the 3-Way Selector

(via the shuttle valve) and continues on to the pressure controlled input connector (2) on the pilot

valve.

The supply connector (3) on the pilot valve serves as a vent. The output connector on the

hydrometer is not used.

18 • Hydrometers Operation and Maintenance Manual

Page 19

Typical Applications, Cont.

PRESSURE REDUCING

The pressure reducing operation prevents the output pressure from increasing above a

predetermined value. This application requires a PC Pressure Regulating Pilot Valve, or

comparable valve. Rotate the adjusting screw on top of the pilot valve counterclockwise to

increase the desired output pressure and clockwise to reduce the desired output pressure.

Connection Information

The sensor connection runs from the output connector on the hydrometer to the pilot valve

controlled input connector (1).

The pressure supply connection runs from the hydrometer input connection to the pilot valve

supply connector (3). This connection branches off to the “Close” connection on the 3-Way

Selector.

The command connection runs from solenoid to the “Auto” connector on the 3-Way Selector and

continues on to the pressure controlled input connector (2) on the pilot valve.

The vent connector (4) on the pilot valve serves as a vent.

Hydrometers Operation and Maintenance Manual • 19

Page 20

Troubleshooting

This chapter provides detailed troubleshooting procedures and solutions for a variety of

common problems. The procedures described below are general in nature and are presented in

a “Quick Reference” style outline format.

We recommend that you perform the steps in order until the specic problem is solved. It may

not be necessary to complete all of the steps in a given procedure.

A. Leakage from Hydrometer Connection to Pipeline

• Inspect and tighten the couplings or ange bolts. Replace the coupling, bolts and nuts

as necessary.

• Apply Teon tape, or other similar material, to seal the connection.

• Inspect and replace gaskets as necessary.

• Inspect and clean the orice and associated gaskets (ow control applications only).

Replace as necessary.

B. No Electrical Output Signal From Hydrometer

• Inspect all cables and electrical connections. Repair or replace cables as necessary.

• Verify that the reed switch transducer is properly inserted into the register dial.

• Verify that the controller is functioning properly. If not, restart the controller and make

certain that your software is properly congured.

• Replace the reed switch transducer.

• Verify that the ow indicator on the meter dial is rotating.

C. The Controller Indicates Water is Not Flowing as Instructed

• Verify that the controller is functioning properly. If not, restart the controller and verify

that your software is properly congured.

• Move the 3-Way Selector to the “Open” position. Check to see if the controller shows

water ow. If so, this indicates that the solenoid is not functioning properly. Repair or

replace as necessary.

• Verify that the reed switch transducer is properly inserted into the register dial.

• Check all electrical connections. Replace cables as necessary.

• Verify that the ow indicator on the meter dial is rotating.

D. No Indication of Flow on Meter Dial

• Remove the register assembly as described on page 25. Place a small magnet on the

bottom of the register assembly and move it in a circular motion. This should cause the

ow indicator to rotate freely. If it does not, replace the register.

• Disassemble the hydrometer as described in Chapter 5.

• Clean or replace the strainer (1½” and 2” models only).

• Verify that the impeller rotates freely. If it does not, inspect the impeller, impeller shaft

and other related components. Replace as necessary.

• Inspect the diaphragm and o-rings. Replace as necessary.

20 • Hydrometers Operation and Maintenance Manual

Page 21

Troubleshooting, Cont.

E. Controller Indicates Valve Opening Failure

• Verify that the 3-Way Selector is in the “Auto” position. If it is not, turn the switch to the

“Auto” position and then check to see if the controller indicates that the valve is open.

• Verify that the controller and your software are functioning properly. If not, restart the

controller and make certain that your software is properly congured.

• Verify if there is water ow downstream from the hydrometer. If there is not, this indicates

that the valve is indeed closed.

• Check the electrical connections as described on page 8.

• Check the register as described in the rst step on page 5.

• Remove the 3-Way Selector. Clean or replace as necessary.

• Verify solenoid operation. Repair or replace as necessary.

• Disassemble the hydrometer as described in the Maintenance section, pages 23-38.

• Clean or replace the strainer (1½” and 2” models only).

• Inspect the diaphragm and o-rings. Replace as necessary.

F. Controller Indicates Valve Closure Failure

• Verify that the 3-Way Selector is in the “Auto” position. If it is not, turn the switch to the

“Auto” position and then check to see if the controller indicates that the valve is open.

• Verify that the controller and your software are functioning properly. If not, restart the

controller and make certain that your software is properly congured.

• Move the 3-Way Selector to the “Close” position. Check to see if the controller indicates

that the valve is closed. If so, this indicates that the solenoid is not functioning properly.

Repair or replace as necessary.

• Verify if there is water ow downstream from the hydrometer. If there is, this indicates that

the valve is indeed open.

• Check the electrical connections as described on page 7.

• Check the register as described in the rst step on page 4.

• Remove the 3-Way Selector. Clean or replace as necessary.

• Remove and clean the nger strainer. Replace if necessary.

• Disassemble the hydrometer as described in the Maintenance section, pages 22-37.

• Inspect the diaphragm, valve cover and o-rings. Replace as necessary.

G. Leakage from Valves or Connectors

• Inspect the control hoses, connectors, shuttle valves and adapters. Tighten and replace as

necessary.

H. Constant Drainage from Pilot Valve

• Repair or replace the pilot valve.

Hydrometers Operation and Maintenance Manual • 21

Page 22

Troubleshooting, Cont.

I. Excess or Insufcient Output Pressure

• Inspect the control hoses, connectors, shuttle valves and

adapters. Replace as necessary.

• Rotate the adjustment screw atop of the pilot valve. Rotate

clockwise to increase pressure or counterclockwise to reduce

pressure as necessary.

• Remove and clean the nger strainer. Replace if necessary.

• If this fails to balance the pressure, try the following procedure:

- Unscrew and remove the throttle housing (12) at the

bottom of the pilot valve.

- Remove the throttle pin (14) from inside the housing.

- Wrap the throttle pin (14) with Teon tape and re-insert

it into the housing.

- Re-insert and tighten the throttle housing into the pilot

• Replace the pilot valve.

J. Excess or Insufcient Input Pressure

• Inspect the control hoses, connectors, shuttle valves and adapters. Tighten and replace as

necessary.

• Remove and clean the nger strainer. Replace if necessary.

• Repair or replace the pilot valve.

K. Excess or Insufcient Flow Rate

• Inspect the control hoses, connectors, shuttle valves and

adapters.

• Tighten and replace as necessary.

• Rotate the adjustment screw on the top of the pilot valve.

Rotate clockwise to increase ow rate or counterclockwise

to reduce the ow rate as necessary.

• Clean and check the orice and gaskets. Replace as

necessary.

• Remove and clean the nger strainer. Replace if necessary.

• If this fails to balance the pressure, try the following

procedure:

- Unscrew and remove the throttle housing (12) at the

bottom of the pilot valve.

- Remove the throttle pin (14) from inside the

housing.

- Wrap the throttle pin (14) with Teon tape and

re-insert it into the pilot valve.

• Replace the pilot valve.

22 • Hydrometers Operation and Maintenance Manual

Page 23

Maintenance Preparation

The hydrometer requires no routine periodic maintenance. In the unlikely event that the

hydrometer fails to operate as expected, please follow the troubleshooting procedures as outlined

on pages 20-22. If and when the troubleshooting procedures necessitate the inspection

or replacement of internal parts, use the procedures contained in this chapter to perform the

required action.

This chapter contains step-by-step instructions for the dis-assembly of the hydrometer as well as

the inspection, cleaning and replacement of its component parts.

PRELIMINARY STEPS

The following steps should be undertaken before attempting to remove the hydrometer from the

pipeline or performing any repairs:

1. Flush the pipeline to remove impurities and foreign matter.

2. Close the inlet valve in order to shut off the water ow to the pipeline.

3. Drain all water from the hydrometer.

4. Remove the reed switch from the register dial. Gently turn and pull the switch mechanism

up to release it.

5. Disconnect all control hoses from the inlet and outlet connectors.

6. Disconnect all control hoses and shuttle valves from the 3-Way Selector.

TOOLS

The following tools are required to perform these procedures:

• Flat blade and Phillips head screwdrivers in various sizes

• Socket and open end wrenches in various sizes

• Hammer

• Large pipe wrench

• Special box wrench for removal of the upper spindle bolt – Model Number: 00360-000071

• Special extractor tool for removal of the valve cover – Model Number: 00360-000072

• Teon tape or similar sealing material

• Grease for sealing gaskets and o-rings

IMPORTANT NOTE:

Use plumbing grease. DO NOT USE petroleum base grease, it will degrade the o-rings.

Hydrometers Operation and Maintenance Manual • 23

Page 24

Maintenance 1½” - 8” Hydrometers

HYDROMETER REMOVAL FROM PIPELINE

The hydrometer is designed for easy site repairs. Removal from the pipeline is not required for

dis-assembly and most repairs. The following removal instructions are included

in the unlikely event that the hydrometer needs to be disassembled and repaired in the shop.

1½” and 2” Models

The 1½” model may only be attached, using a coupling, to a male threaded pipeline.

Coupling Connection

• Unscrew the coupling nuts on both sides of the hydrometer counterclockwise.

• Slide the coupling nuts away from the hydrometer and remove the hydrometer from the

pipeline. Retain the coupling gaskets.

Direct Connection

• If the hydrometer is attached directly to the pipeline, unscrew the pipeline on both sides of the

hydrometer.

• Remove the hydrometer from the pipeline.

3” - 8” Models

• Unscrew and remove the bolts from the anged connections on both sides of the hydrometer.

• Remove the hydrometer from the pipeline.

• Inspect the gaskets and replace as necessary.

24 • Hydrometers Operation and Maintenance Manual

Page 25

Maintenance 1½” - 8” Hydrometers, Cont.

FINGER STRAINER CLEANING AND REPLACEMENT

It is not necessary to remove the hydrometer from the pipeline or to disassemble it in order to

perform this procedure.

To Remove the Finger Strainer:

• Locate the inlet connection on the hydrometer body.

• Remove the angle nipples and other connection devices.

• Turn the nut counter-clockwise to loosen the nger strainer.

• Gently pull the nger strainer out.

• Clean or replace as necessary.

To Replace the Finger Strainer:

• Insert the nger strainer into the inlet connection and turn clockwise to tighten.

• Apply Teon tape or similar material to seal the connections.

• Re-install the angle nipples and other connection devices.

REGISTER ASSEMBLY REMOVAL

AND REPLACEMENT

It is not necessary to disassemble the hydrometer to perform this procedure.

Removal:

• Remove the reed switch transducer (4) from

the register dial.

Gently turn and pull the switch (4) upward to

release it.

• Close the register cover (1).

• Using a large pipe wrench, turn the register

cover assembly (1, 2) counterclockwise until

you can remove it from the hydrometer cover

(12).

• Remove and set aside the sliding ring (3).

• Lift the register assembly (5) out of the

hydrometer body.

• Remove the register o-ring (6) and the adapter

ring (7) from

the register.

• Inspect and replace as necessary.

Replacement:

• Close the register cover (1).

• Place the register o-ring (6) around the register assembly. Insert the register assembly into

the adapter ring (7) and place them inside the hydrometer cover (12).

• Replace the sliding ring (3) over the register assembly.

• Replace the register cover assembly (1, 2) over the register. Turn it clockwise to tighten.

• Insert the reed switch (4) into its hole in the register dial. Gently turn the reed switch until

it is fully seated.

Hydrometers Operation and Maintenance Manual • 25

Page 26

Maintenance 1½” and 2” Models

1½” and 2” Hydrometers

The dis-assembly of the hydrometer is divided into the following assemblies:

• Cover Assembly

• Diaphragm/Stem and Base Assemblies

• Inlet Spider/Strainer Assembly

Perform only those procedures necessary to inspect and replace parts as directed by the

troubleshooting procedures. It is recommended to replace the various o-rings and gaskets

during dis-assembly as well as to inspect certain other parts. All gaskets and o-rings must

be covered with grease prior to installation.

HYDROMETER COVER AND BASE ASSEMBLIES

Removal

• Remove the register assembly as described on page 25.

• Loosen and remove the upper bearing bolt (8) using the specially

sized box wrench. Model number: 03640-000071

• Remove the upper bearing bolt o-ring (9) from the groove in the

underside of the bolt. Inspect and replace as necessary.

• Loosen and remove the six cover screws (10), with the washers.

• Lift the base and cover assemblies off of the hydrometer body (21).

• Be especially careful not to damage the impeller.

• Place the two assemblies upside down. Pull the impeller (30) up

and out.

• Some force may be required to free the impeller.

• Remove the magnet housing (31) from inside the cover assembly.

The magnet housing was freed from the impeller shaft during the

previous step.

• Inspect the impeller and its components for signs of excessive wear

or damage.

• Verify that the impeller shaft is straight. Replace as necessary.

Re-assembly

• Carefully place the base and cover assemblies over the impeller shaft

(30).

• Push the magnet housing (31) down over the top of the impeller shaft (which extends

through the hole in the cover). Tap the magnet housing with a hammer to ensure that it

is properly secured to

the shaft.

• Place the base and cover assemblies onto the hydrometer body (21).

• Replace and tighten the six cover screws (10).

• Place the upper bearing bolt o-ring (9) into the groove on the underside of the bolt (8).

• Screw in the upper bearing bolt “O” (8) using the specially sized

box wrench.

• Replace the register assembly and cover as described on page 25.

26 • Hydrometers Operation and Maintenance Manual

Page 27

Maintenance 1½” and 2” Models, Cont.

DIAPHRAGM/STEM DIS-ASSEMBLY

• Separate the base assembly from the cover (12).

• Visually inspect the diaphragm (37), valve cover (32) and stem

assembly (36) for damage or excessive wear. If replacement is

needed, continue with the following steps.

• Remove the six screws (39) from the diaphragm retaining ring (38).

• Lift the ring off of the diaphragm (37).

• Lift the diaphragm (37) off of the stem (36).

BASE AND STEM DIS-ASSEMBLY

• Place the base and stem assemblies upside down on a at surface.

• Use the extraction tool to remove the valve cover (32) as follows:

- Slide the lower prongs of the extraction tool under the cover.

- Turn the bolt on the extraction tool clockwise until the

extractor seat ts securely into the stem.

- Continue turning the bolt until the valve cover slides off

of the stem (36).

• Invert the base and pull the stem (36) out of the base (33).

• Remove the base o-ring (23) from the underside of the base. Inspect

and replace as necessary.

Extraction Tool

Model Number:

00360-000072

• Remove the stem o-ring (34) from the groove in the hole in the

center of the base. Inspect and replace as necessary.

• Remove the diaphragm support ring (35) from the base (33).

• Inspect the base (33) for cracks or excessive wear. Replace as

necessary.

WARNING

You must use the extraction tool to remove the valve cover. Use

of any other tool may damage the valve cover and the stem.

Re-assembly

• Insert the diaphragm (37) into the grooves on the top of the stem

(36).

• Place the diaphragm retaining ring (38) over the diaphragm. Secure

the ring with the six screws (39). Apply Loctite 270 or similar glue

to the screws.

• Set the lower diaphragm support ring (35) inside the base (33).

• Insert the re-assembled diaphragm and stem assembly into the base.

• Push the valve cover (32) up onto the bottom of the diaphragm/stem

subassembly. It should easily snap into place.

• Remove and replace the central bushing o-ring (15) at the bottom of

the central bushing (14 not shown), located in the underside of the

cover (12).

• Set the cover (12) onto the re-assembled base subassembly. These

subassemblies are now ready for reinstallation onto the hydrometer

body.

Hydrometers Operation and Maintenance Manual • 27

Page 28

Maintenance 1½” and 2” Models, Cont.

INLET SPIDER AND STRAINER

Dis-assembly

• Loosen the impeller bushing (29) located atop the inlet

spider screw (24) and bushing (28). Pull the entire inlet

spider screw assembly up and out.

• Pull the inlet spider (27) upward and remove it from the

hydrometer body (21). Inspect for cracks or excessive

wear and replace as necessary.

• Remove and replace the body o-ring (26).

• Remove the strainer (25). Clean and inspect for damage or

excessive wear.

• Replace as necessary.

Re-assembly

• Place the body o-ring (26) in the small ange inside the

hydrometer base.

• Place the strainer (25) into the hydrometer base.

• Insert the inlet spider into the body so that the end rests on

the top of the strainer and the ange rests over the body

o-ring (26).

• Place the inlet spider screw assembly through the holes

in the input spider (27) and strainer (25). Use a socket

wrench to tighten the impeller bushing (29) atop the

assembly.

28 • Hydrometers Operation and Maintenance Manual

Page 29

Maintenance 3” and 4” Models

HYDROMETER DIS-ASSEMBLY AND REASSEMBLY

Dis-assembly of the 3” and 4” hydrometer is divided into the following

assemblies:

• Cover Assembly

• Diaphragm/Stem and Base Assemblies

• Inlet Spider/Strainer Assembly

Perform only those steps necessary to inspect and replace parts as directed

by the troubleshooting procedures. It is recommended to replace the

various

o-rings and gaskets during dis-assembly as well as to inspect certain

other parts. All gaskets and o-rings must be covered with grease prior to

installation.

HYDROMETER COVER AND BASE SUBASSEMBLIES

Removal

• Remove the register subassembly as described on page 24.

• Loosen and remove the cover screws (10) along with the washers.

• Lift the cover off of the hydrometer body (29). Be especially careful

not to damage the impeller.

• Carefully remove the impeller assembly (37) from the hydrometer

body.

• Inspect the impeller and its components for signs of excessive wear

or damage. Verify that the impeller shaft is straight. Replace as

necessary.

• Inspect the base o-ring (42) for excessive wear or damage. Replace as

necessary.

Re-assembly

• Insert the impeller (37) into the inlet spider (located inside the

hydrometer base).

• Insert the base “O” ring (42) into the groove on the upper body ange.

• Carefully place the cover over the impeller shaft (37) and onto the

hydrometer body (29).

• Replace and tighten the cover screws (10).

• Replace the register subassembly as described on page 24.

Hydrometers Operation and Maintenance Manual • 29

Page 30

Maintenance 3” and 4” Models, Cont.

DIAPHRAGM/STEM ASSEMBLY

AND BASE ASSEMBLY

Diaphragm/Stem Dis-assembly

• Pull the diaphragm and stem assemblies up and out from the

hydrometer cover (11). The central bushing (13) remains attached

to the cover.

• Unscrew and remove the central bushing (13) from the cover (11).

• Inspect the upper and lower central bushing o-rings (12,14).

Replace as necessary.

• Visually inspect the diaphragm (18), valve cover (39) and stem

(40) for damage or excessive wear. If repair or replacement is

required, continue with the following steps.

Diaphragm and Base Dis-assembly

• Remove the six screws (16) from the upper diaphragm ring (17).

Lift the upper diaphragm ring off of the diaphragm (18).

• Lift the diaphragm off of the lower diaphragm support ring (19)

and the stem (40). The stem remains attached to lower diaphragm

support ring.

• Place the stem subassembly upside down on a at surface.

• Use the extraction tool to remove the valve cover (32) as follows:

- Slide the lower prongs of the extraction tool under the

valve cover.

- Turn the bolt on the extraction tool clockwise until the

extractor seat ts securely into the stem.

- Continue turning the bolt until the valve cover slides

off of the stem.

• Visually inspect the base o-ring (20) and replace as necessary.

• Visually inspect the stem o-ring (41), located in the groove in the

hole in the center of the base. Replace as necessary.

• Inspect the base (21) for cracks or excessive wear. If replacement

is necessary, pull the base off of the stem. Push the replacement

base onto the stem as far as it can go.

Extraction Tool

Model Number:

00360-000072

WARNING

You must use the extraction tool to remove the valve cover

(39). Use of any other tool may damage the valve cover and

the stem assembly.

Re-assembly

• Insert the diaphragm (18) into the grooves on lower diaphragm support ring (19).

• Place the upper diaphragm ring (17) over the diaphragm. Secure it to the lower diaphragm ring (19)

with the six screws (16). Apply Loctite 270 or similar glue to the screws.

• Push the base up onto the stem as far as it will go.

• Push the valve cover (39) up onto the bottom of the stem. It should easily snap into place.

• Insert the re-assembled diaphragm, stem base assemblies into the cover (11).

• Replace the impeller assembly into the inlet spider, located inside the hydrometer body.

30 • Hydrometers Operation and Maintenance Manual

Page 31

Maintenance 3” and 4” Models, Cont.

INLET SPIDER AND STRAINER

Dis-assembly

• Loosen and remove the impeller bushing (36), the inlet

spider bearing nut (35) and the inlet spider bearing

washer (34).

• Remove the inlet spider tube (33).

• Inspect the inlet spider o-ring (32) and replace as

necessary.

Re-assembly

• Replace the inlet spider tube (33)

• Replace the inlet spider bearing washer (34) and nut

(35) onto the inlet spider shaft (31) and tighten.

• Replace the impeller bushing (36) into the inlet spider

nut (35).

Hydrometers Operation and Maintenance Manual • 31

Page 32

Maintenance 6” Models

HYDROMETER DIS-ASSEMBLY AND REINSTALLATION

The dis-assembly of the 6” hydrometer is divided into the following

subassemblies:

• Register

• Hydrometer Cover

• Diaphragm and Stem Assemblies

• Stem and Valve Seal Assemblies

• Impeller and Flow Tube Assemblies

• Inlet Spider Assembly

Perform only those procedures necessary to inspect and replace parts as

directed by the troubleshooting procedures. It is recommended to replace the

various o-rings and gaskets during dis-assembly as well as to inspect certain

other parts. All gaskets and o-rings must be covered with grease prior to

installation.

REGISTER

Dis-assembly

• Remove the register assembly as detailed on page 24.

• Using a large box wrench, unscrew and remove the upper bearing bolt (8).

Use spacing tool, Model number 00360-000072.

• Inspect the upper bearing o-ring (9). Replace as necessary.

• Using a screwdriver or a special key, loosen the guide tube nut (10). It is

not necessary to remove the nut.

Re-assembly

• Tighten the guide tube nut (10). Use spacing tool, Model number

00360-000072.

• Screw the upper bearing bolt (8) back into the cover.

• Replace the register assembly.

HYDROMETER COVER

Disassembly

• Loosen and remove the six cover hex bolts (46) along with their nuts (32)

and washers (33).

• Remove the spring (16).

• Lift out the guide tube (23).

• Inspect and replace as necessary.

• Pull the diaphragm/stem assembly out of the hydrometer body. Be careful

not to damage the impeller during removal.

Re-assembly

• Carefully replace the diaphragm/stem assembly over the impeller shaft and

into the hydrometer body. Be careful not to damage the impeller.

• Place the guide tube (23) over the impeller shaft.

• Place the spring (16) over the guide tube (23).

• Replace the hex cover bolts (46) together with their washers and nuts.

32 • Hydrometers Operation and Maintenance Manual

Page 33

Maintenance 6” Models, Cont.

DIAPHRAGM AND UPPER STEM BEARING

Dis-assembly

• Unscrew and remove the 12 screws (17) and remove the upper

diaphragm ring (18).

• Remove the diaphragm (19).

• Inspect for cracks or excessive wear and replace as necessary.

• Inspect the upper stem wiper (20) and replace as necessary.

• Remove the upper stem bearing (21) from inside the stem

(24). Inspect the upper stem bearing (21) along with the upper

stem bearing o-ring (22) and the stem o-ring (15). Replace as

necessary.

Re-assembly

• Replace the upper stem wiper (20) onto the upper stem bearing

(21)

• Replace the upper stem bearing (21) into the stem (24).

• Place the diaphragm (19) into the grooves on the stem (24).

• Place the upper diaphragm ring (18) over the diaphragm and

screw the 12 stem screws (17) into place.

LOWER STEM BEARING AND VALVE COVER

Dis-assembly

• Unscrew and remove the stem lock nut (29).

• Pull the valve cover (28) from the stem. Inspect the rubber for

cracks or excessive wear. Replace as necessary.

• Inspect the lower valve cover o-ring (26) and replace as

necessary. It is located in a groove inside the valve cover

opening.

• Using a screwdriver, remove the lock ring (27) from inside the

bottom of the stem (24).

• Inspect the lower stem bearing wiper (20) and the lower stem

bearing o-ring (22) and replace as necessary.

• Inspect and replace the lower stem bearing (25) as necessary.

Use a pipe wrench to remove it from the stem (24).

• Apply Loctite 270 or similar glue to the threads of the lower

stem bearing (25).

• Screw it back into the stem (24).

Re-assembly

• Replace the lower stem wiper (20) into the bottom of the stem

(24).

• Snap the wiper locking ring (27) into the stem (24).

• Push the valve cover (28) onto the lower stem bearing (25).

• Apply Loctite 270 or similar glue to the threads of the stem

lock nut (29).

• Screw the stem lock nut (29) into the stem (24). Do not over

tighten. Make sure that the valve cover is free to move up and

down slightly.

Hydrometers Operation and Maintenance Manual • 33

Page 34

Maintenance 6” Models, Cont.

IMPELLAR AND FLOW TUBE SUB-ASSEMBLIES

Dis-assembly

• Remove valve seat base (45) from atop the ow tube (41). Be careful not

to damage the impeller shaft. Inspect for excessive wear and replace as

necessary.

• Remove the impeller assembly (43). Inspect for cracks or excessive

wear and check that the impeller shaft is perfectly straight. Replace if

necessary.

• Remove the ow tube (41).

• Inspect and replace as necessary.

• Inspect the upper and lower ow tube o-rings (40) and replace as

necessary.

• Remove the inlet spider assembly (38). Inspect and repair as necessary.

Re-assembly

• Replace the inlet spider assembly (38) into the hydrometer body.

• Place the lower ow tube o-ring (40) onto the ow tube (41).

• Place the upper ow tube o-ring into the valve seat base (45).

• Replace the ow tube (41) atop the inlet spider assembly (38) in the

hydrometer body.

• Replace the impeller assembly (43) into the ow tube (41) so that the

impeller shaft rests in the lower bearing bushing (39).

• Place the valve seat base (45) over the impeller shaft so that it rests atop

the ow tube (41).

INLET SPIDER

Dis-assembly

• Unscrew and remove the cap (35). Inspect and replace as necessary.

• Remove the lock nut (36).

• Unscrew and remove the lower bearing screw (37) from the inlet spider

(38). Inspect and replace as necessary.

• Inspect the inlet spider (38) and the lower bearing bushing (39) and

replace as necessary.

Re-assembly

• Screw the lower bearing bushing (37) back into the inlet spider (38).

• Replace the lower bearing screw (37) into bottom of the inlet spider.

Tighten approximately eight turns.

• Replace the lock nut (36) and the spider cap (35).

34 • Hydrometers Operation and Maintenance Manual

Page 35

Maintenance 8” Models

HYDROMETER DIS-ASSEMBLY AND RE-ASSEMBLY

The dis-assembly of the 8” hydrometer is divided into the following logical assemblies:

• Register

• Hydrometer Cover

• Diaphragm Sub-assembly

• Lower Chamber Disc Sub-assembly

• Stem and Valve Cover Sub-assemblies

• Impeller and Flow Tube Assemblies

• Inlet Spider Assembly

Perform only those procedures necessary to inspect and replace parts as directed by the

troubleshooting procedures. It is recommended to replace the various o-rings and gaskets

during dis-assembly as well as to inspect certain other parts. All gaskets and o-rings must be

covered with grease prior to installation.

REGISTER

Dis-assembly

• Remove the register assembly as detailed on page 24.

• Using a large box wrench, loosen and remove the upper bearing bolt (8).

• Remove upper bearing o-ring (9). Inspect and replace as necessary.

• Using a screwdriver or a special key, loosen the guide tube nut (10). It is not necessary to

remove the nut.

Re-assembly

• Re-tighten the guide tube nut (10).

• Replace the upper bearing o-ring (9).

• Replace and tighten the upper bearing bolt (8).

• Replace the register assembly.

HYDROMETER COVER

Disassembly

• Loosen and remove the cover hex bolts (12) along with their nuts (61) and washers (14).

• Attach a hoist cable or chain to the rings on the hydrometer cover (14). Use the hoist to

lift the cover off of the hydrometer body. Be careful not to damage the impeller shaft.

• Lift out the guide tube (20).

• Inspect and replace as necessary.

• Inspect the cover o-ring (15) and replace as necessary. The o-ring is located on the

underside of the cover in the upper opening.

Re-assembly

• Replace the guide tube (20) over the impeller shaft.

• Replace the hydrometer cover (24) onto the body.

• Replace the cover hex bolts (12) along with their washers (14) and nuts (61).

• Tighten the nuts.

DIAPHRAGM SUB-ASSEMBLY

Removal of Diaphragm Assembly

• Remove all eight screws from the inner circle of screws on the lower diaphragm disc

(25). Four of the screws are ½” length (21) and four are 7∕8” length (24).

• Insert the four 7∕8” screws (24) into the holes from which you removed the four ½”

(21) screws and tighten. This will lift the entire diaphragm subassembly off of the stem

subassembly.

• Pull the diaphragm subassembly up and remove it from the hydrometer body.

• Inspect the diaphragm (23) for cracks or excessive wear. Continue with the following

steps to replace the diaphragm only if necessary.

Hydrometers Operation and Maintenance Manual • 35

Page 36

Maintenance 8” Model, Cont.

DIAPHRAGM SUB-ASSEMBLY DIS-ASSEMBLY

Dis-assembly and Re-assembly

• Remove the sixteen ½” screws (21) from the upper diaphragm ring (22).

• Lift the upper diaphragm ring (22) off of the diaphragm (23).

• Lift the diaphragm (23) off of the lower diaphragm disc (25).

• Place the replacement diaphragm (23) onto the lower diaphragm disc (25).

• Place the upper diaphragm ring (22) over the diaphragm.

• Replace and tighten the ½” screws (21) into the upper diaphragm ring.

Replacement in the Body

Perform the preceding steps in the reverse order to reassemble the diaphragm

assembly.

1. Replace and tighten the four ½” screws (21) and the four 7∕8” screws (24)

into the lower diaphragm disc (25).

2. Place the diaphragm assembly over the impeller shaft onto the lower

chamber disc and stem assemblies.

LOWER CHAMBER DISC SUB-ASSEMBLY

Dis-assembly

The following steps are performed following removal of the diaphragm

sub-assembly as described on page 24.

• Remove the six 6 mm screws (33) from the top of the lower chamber disc (27).

• Remove the two lower chamber disc locking rings (26).

• Temporarily replace the diaphragm subassembly onto the lower chamber

disc (27).

• Insert and tighten the four 7∕8” screws (24) into the lower diaphragm disc

(innermost ring) on the diaphragm subassembly, temporarily re-attaching

it to the stem.

• Pull upward and lift to remove the diaphragm subassembly, together with

the lower chamber disc and stem subassemblies, from the hydrometer body.

• Remove, once again, the four 7∕8” screws (24) and pull the diaphragm

subassembly up from the stem.

• Lift the lower chamber disc (27) off of the stem (41).

• Inspect the two lower chamber o-rings (28) and (29) on outside of the

lower chamber disc (27). Replace as necessary.

• Remove the four ½” screws (21) that fasten the lower chamber ring (35)

to bottom of the lower chamber disc (27) and remove the lower chamber

ring.

• Inspect the lower chamber bearing wiper (32). Replace as necessary.

• Remove the lower chamber bearing (30) from inside the lower chamber

disc (27). Inspect and replace as necessary.

• Inspect the lower chamber bearing o-rings (31 and 34). Replace as

necessary.

Re-assembly

• Replace the lower chamber bearing (30) into the lower chamber disc.

• Replace the lower chamber bearing ring (35) onto the lower chamber

disc.

• Insert and tighten the four ½” screws (21).

• Perform the rest of the above steps in the reverse order.

36 • Hydrometers Operation and Maintenance Manual

Page 37

Maintenance 8” Model, Cont.

STEM SUB-ASSEMBLY AND VALVE COVER

Follow this procedure only if it is necessary to replace the stem

bearings or the valve cover. Otherwise, skip this section:

Dis-assembly and Re-assembly

• Inspect the upper stem bearing wiper (36). Replace as necessary.

• Remove the upper stem bearing (37) from the stem (41).

• Inspect the upper stem bearing o-rings (38,39). Replace as

necessary.

• Unscrew and remove the stem locking nut (48), located at the

bottom of the stem subassembly.

• Remove the valve cover (47) from the stem. Inspect the rubber for

cracks and excessive wear. Replace as necessary.

• Inspect the valve cover o-ring (43) and replace as necessary.

• Remove the retaining ring (46) that holds the lower stem bearing

wiper (45) in place. Inspect the lower stem bearing wiper (45) and

replace as necessary.

• Inspect the lower stem bearing o-ring (44) and replace as

necessary.

• Inspect the lower stem bearing (42) for scratches or wear. Replace

as necessary.

• Apply Loctite 270 or similar glue to the threads of the lower stem

bearing and screw it into the stem assembly (41).

• Replace the valve cover (47) onto the stem assembly.

• Apply Loctite 270 or similar glue to the threads of the stem

locking nut (48) and screw into the stem assembly.

• Push the upper stem bearing (37) onto the stem assembly.

Hydrometers Operation and Maintenance Manual • 37

Page 38

Maintenance 8” Models, Cont.

IMPELLAR AND FLOW TUBE ASSEMBLIES

Dis-assembly

• Remove valve seat base (49) from atop the ow tube (55). Be careful not

to damage the impeller shaft. Inspect the valve seat base for excessive

wear and replace as necessary.

• Remove the impeller (50).

• Inspect for cracks or excessive wear and check that the impeller shaft is

perfectly straight. Replace if necessary.

• Remove the ow tube (55).

• Inspect and replace as necessary.

• Inspect the upper and lower ow tube o-rings (54) and replace as

necessary.

• Remove the inlet spider (57) assembly. Inspect and repair as necessary.

Re-assembly

• Replace the inlet spider assembly (57) into the hydrometer body.

• Place the two lower ow tube o-rings (54) onto the ow tube (55).

• Place the upper ow tube o-ring (54) into the valve seat base (49).

• Replace the ow tube (55) atop the inlet spider assembly (57) in the

hydrometer body.

• Replace the impeller assembly (51) into the ow tube (55) - the impeller

shaft should rest in the lower bearing bushing (56).

• Place the valve seat base (49) over the impeller shaft so that it rests atop

the ow tube (55).

INLET SPIDER

Dis-assembly

• Unscrew and remove the cap (60). Inspect and replace as necessary.

• Remove the lock nut (59).

• Unscrew and remove the lower bearing screw (58) from the inlet spider

(57). Inspect and replace as necessary

• Inspect the inlet spider (57) and the lower bearing bushing (56) and

replace as necessary.

Re-assembly

• Screw the upper bearing bushing (56) back into the top of the inlet

spider (57).

• Replace the lower bearing screw (58) into bottom of the inlet spider.

Tighten approximately eight turns.

• Replace the lock nut (59) and the cap (60).

38 • Hydrometers Operation and Maintenance Manual

Page 39

Schematics

SCHEMATICS TABLE OF CONTENTS

Manual Electric

1½”, 2” Hydrometer, Manual Electric Normally Closed, 8mm Tubing .................................. 40

1½”, 2” Hydrometer, Manual Electric Normally Open, 8mm Tubing ..................................... 41

3”, 4” Hydrometer, Manual Electric Normally Closed, 8mm Tubing ..................................... 42

3”, 4” Hydrometer, Manual Electric Normally Open, 8mm Tubing ........................................ 43

6”, 8” Hydrometer, Manual Electric Normally Closed, 8mm Tubing ..................................... 44

6”, 8” Hydrometer, Manual Electric Normally Open, 8mm Tubing ....................................... 45

Pressure Reducing, Manual Electric

1½”, 2” Hydrometer, Pressure Reducing Manual Electric Normally Closed, 8mm Tubing ... 46

1½”, 2” Hydrometer, Pressure Reducing Manual Electric Normally Open, 8mm Tubing ...... 47

3”, 4” Hydrometer, Pressure Reducing Manual Electric Normally Closed, 8mm Tubing ...... 48

3”, 4” Hydrometer, Pressure Reducing Manual Electric Normally Open, 8mm Tubing ......... 49

6”, 8” Hydrometer, Pressure Reducing Manual Electric Normally Closed, 8mm Tubing ...... 50

6”, 8” Hydrometer, Pressure Reducing Manual Electric Normally Open, 8mm Tubing ......... 51

Hydrometers Operation and Maintenance Manual • 39

Page 40

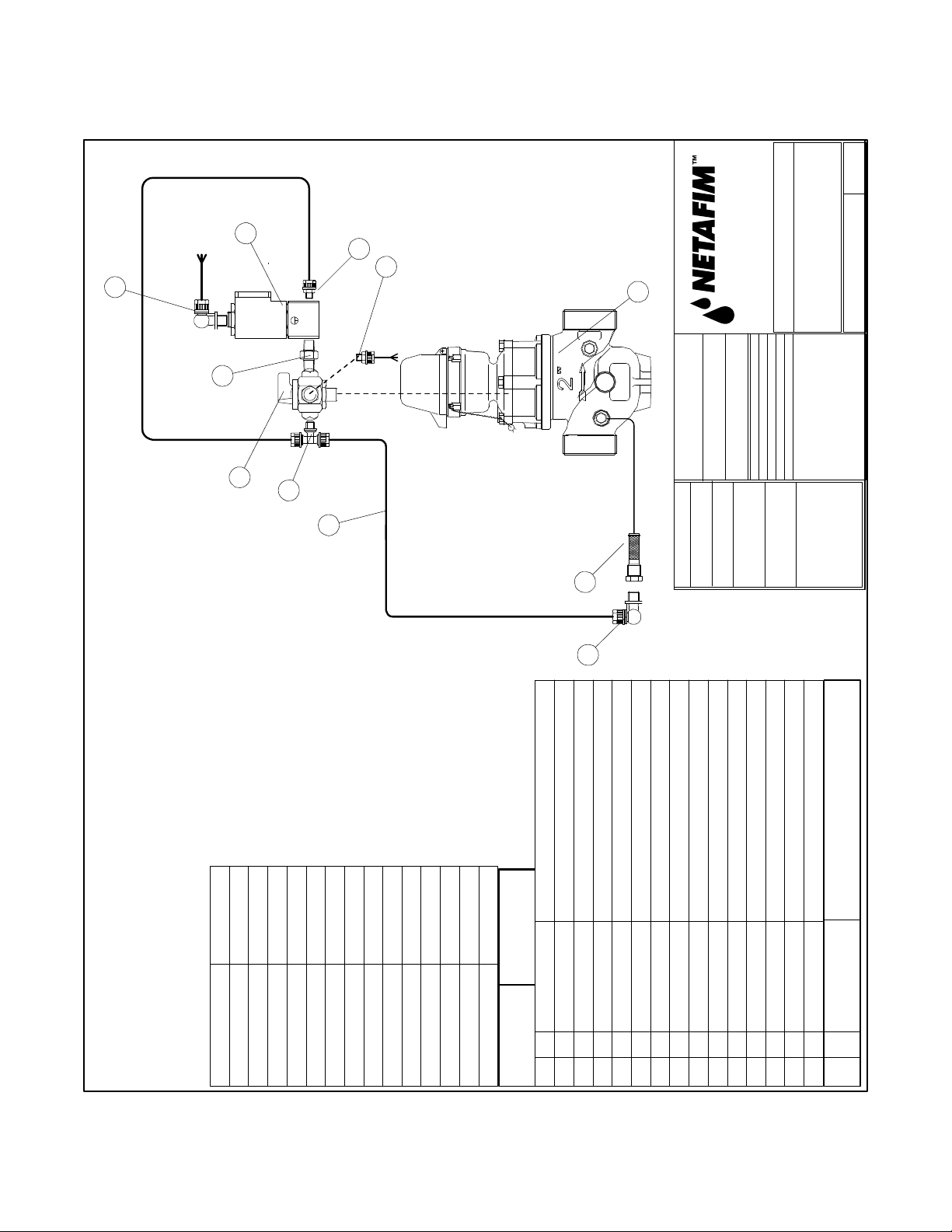

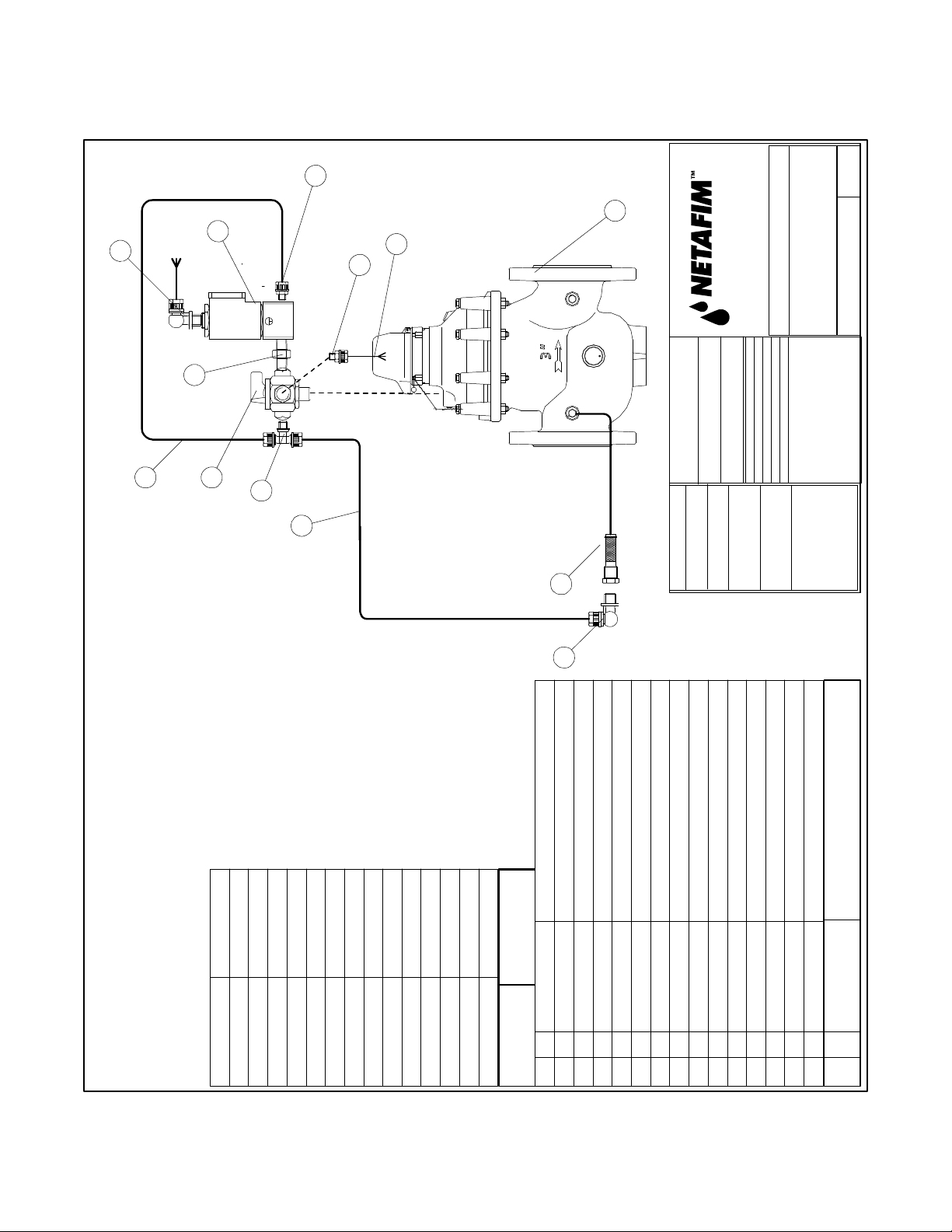

1½”, 2” HYDROMETER, MANUAL ELECTRIC, NORMALLY CLOSED, 8MM TUBING

0

rev

3

5

2 1

2

AUTO

CLOSED

7

7

1

5470 E Home Ave.

Fresno, CA 93727

T (888) 638-2346

F (800) 695-4753

N

E

P

O

Approved: P C

8MM PE TUB ING

1.5", 2" Hydrometer

MANUAL ELECTRIC NC

Part Number: LHMxxTG- MEL-NC

4

6

Material: ASTM 102 0

prepared by PC

Date: 9-6-08

8

9

Scale: 1=1

Units: English [metri c]

Quantity: 1

Surface Finish: N/A

Heat Treatment: N /A

Tolerances:

5

LHM1.5TG-MEL-NC

LHM2TG-MEL-NC

40 • Hydrometers Operation and Maintenance Manual

Basic Hydrometer 1.5 and 2 "

BRASS HEX NIPPLE 1/8"

SOLENOID 3-WAY 24VAC N.O.

LHMxxTG

55B216P2

1111212

Part No. Part No.

Variable Finished Goods

1234567

noitpircseDtnenopmoCYTQmetI

3-WAY VALVE 1/8" X 1/ 8"

Plastic male 90-Elbow 8mm x 1 /8" npt

Plastic male branch tee 8mm x 1 /8" npt

Plastic male connector 8mm x 1 /8" npt

PE TUBING 8MM

BRASS FINGER FILTER 1/4" X 1/8 "

Part No.

36SOLNO-024

62SV21/8M

55P4694802

55P4724802

55P4684802

15CONT-8-I

61SF25SB

2

1

8

9

1011121314

15

Page 41

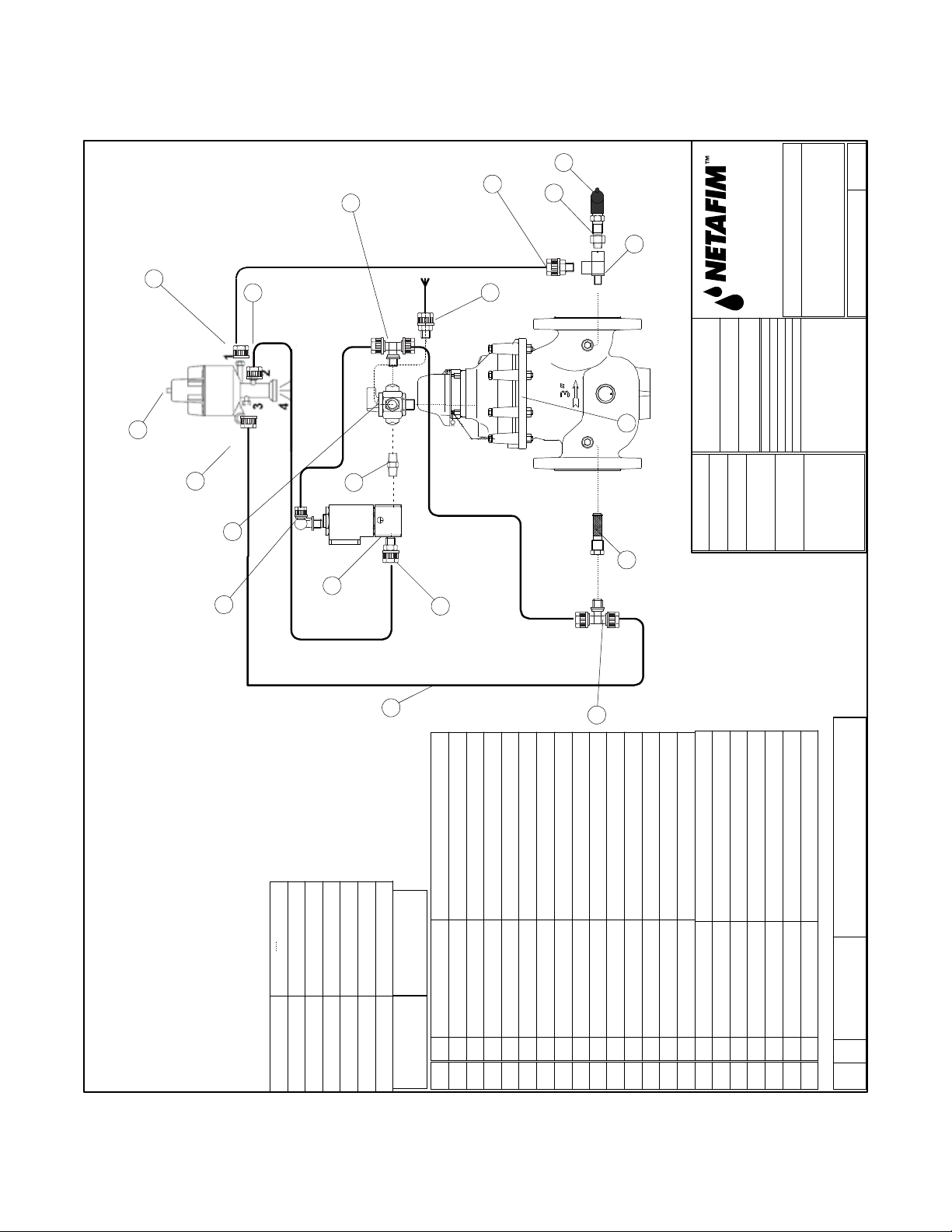

1½”, 2” HYDROMETER, MANUAL ELECTRIC, NORMALLY OPEN, 8MM TUBING

0

rev

3

7

7

5470 E Home Ave.

Fresno, CA 93727

T (888) 638-2346

5

1

2 1

N

E

P

O

2

AUTO

CLOSED

Material: ASTM 102 0

4

prepared by PC

F (800) 695-4753

Approved: P C

Date: 9-6-08

8MM PE TUB ING

1.5", 2" Hydrometer

MANUAL ELECTRIC NO

Part Number: LHMxxTG -MEL-N O

6

8

Scale: 1=1

Units: English [metri c]

Quantity: 1

Surface Finish: N/A

Heat Treatment: N /A

9

Tolerances:

5

noitpircseDtnenopmoCYTQmetI

Basic Hydrometer 1.5 and 2 "

BRASS HEX NIPPLE 1/8"

SOLENOID 3-WAY 24VAC N.C.

3-WAY VALVE 1/8" X 1/ 8"

Plastic male 90-Elbow 8mm x 1 /8" npt

Plastic male branch tee 8mm x 1 /8" npt

Plastic male connector 8mm x 1 /8" npt

PE TUBING 8MM

BRASS FINGER FILTER 1/4" X 1/8 "

Part No.

LHMxxTG

55B216P2

36SOLNC-024

62SV21/8M

55P4694802

55P4724802

55P4684802

15CONT-8-I

61SF25SB

111

Part No. Part No.

Variable Finished Goods

LHM1.5TG-MEL-N O

LHM2TG-MEL-N O

123

12122

45678

1

9

1011121314

15

Hydrometers Operation and Maintenance Manual • 41

Page 42

3”, 4” HYDROMETER, MANUAL ELECTRIC, NORMALLY CLOSED, 8MM TUBING

7

0

rev

1

3

5

2 1

N

E

P

O

2

8

AUTO

CLOSED

4

6

8

7

5470 E Home Ave.

Fresno, CA 93727

T (888) 638-2346

F (800) 695-4753

Material: ASTM 102 0

Date: 9-6-08

prepared by PC

8mm tubin g

3",4" Hydrometer

MANUAL ELECTRIC NC

Approved: Perry Contine nte

Part Number: LHMxFG- MEL-NC

8

9

Scale: 1=1

Units: English [metri c]

Quantity: 1

Surface Finish: N/A

Heat Treatment: N /A

Tolerances:

5

noitpircseDtnenopmoCYTQmetI

SOLENOID 3-WAY 24VAC N.O.

Basic Hydrometer 3",4"

LHMxFG

111121221

Part No. Part No.

Variable Finished Goods

LHM3FG-MEL-NC

LHM4FG-MEL-NC

123456789

3-WAY VALVE 1/8" X 1/8" MAL E

BRASS HEX NIPPLE 1/8"

PLASTIC MALE 90-ELBOW 8MM X 1/8"

PLASTIC MALE BRANCH-TEE 8MM X 1/8"

PLASTIC MALE CONNECTOR 8MM X 1/8"

PE TUBING 8MM

BRASS FINGER FILTER 1/4" X 1/8 "

Part No.

36SOLNO-024

55B216P2

62SV21/8M

55P4684802

55P4714802

55P4684802

15CONT-8-I

61SF25SB

1011121314

15

42 • Hydrometers Operation and Maintenance Manual

Page 43

3”, 4” HYDROMETER, MANUAL ELECTRIC, NORMALLY OPEN, 8MM TUBING

7

0

rev

1

3

5

2 1

N

E

P

O

2

8

4

AUTO

CLOSED

8

7

5470 E Home Ave.

Fresno, CA 93727

T (888) 638-2346

F (800) 695-4753

Material: ASTM 102 0

prepared by PC

Date: 9-6-08

8mm tubin g

3",4" Hydrometer

MANUAL ELECTRIC NO

Approved: Perry Contine nte

Part Number: LHMxFG -MEL-NO

6

8

Scale: 1=1

Units: English [metri c]

Quantity: 1

Surface Finish: N/A

Heat Treatment: N /A

9

Tolerances:

5

noitpircseDtnenopmoCYTQmetI

Basic Hydrometer 3",4"

BRASS HEX NIPPLE 1/8"

SOLENOID 3-WAY 24VAC N.C.

3-WAY VALVE 1/8" X 1/8" MAL E

PLASTIC MALE 90-ELBOW 8MM X 1/8"

PLASTIC MALE BRANCH-TEE 8MM X 1/8"

PLASTIC MALE CONNECTOR 8MM X 1/8"

PE TUBING 8MM

BRASS FINGER FILTER 1/4" X 1/8 "

Part No.

LHMxFG

55B216P2

36SOLNC-024

62SV21/8M

55P4684802

55P4714802

55P4684802

15CONT-8-I

61SF25SB

111

Part No. Part No.

Variable Finished Goods

LHM3FG-MEL-N O

LHM4FG-MEL-N O

123

12122

45678

1

9

1011121314

15

Hydrometers Operation and Maintenance Manual • 43

Page 44

6”, 8” HYDROMETER, MANUAL ELECTRIC, NORMALLY CLOSED, 8MM TUBING

7

16

3

0

rev

15

12

8

PC

2 1

5470 E Home Ave.

Fresno, CA 93727

T (888) 638-2346

N

E

P

11

O

AUTO

F (800) 695-4753

8MM PE TUB ING

6", 8" Hydrometer MEL - NC

Approved:

Part Number: LHMxFG- MEL-NC

6

11

CLOSED

13

5

14

Engr:

Date: 09/20/08