baseclick ClickTech Oligo Link Kit, Size S, S (Amount Range of Oligonucleotide per Reaction: From 70 pmol to 22 nmol) User guide

Version 1.1

User Manual

ClickTech Oligo Link Kit

ClickTech Oligo Link Kit

2

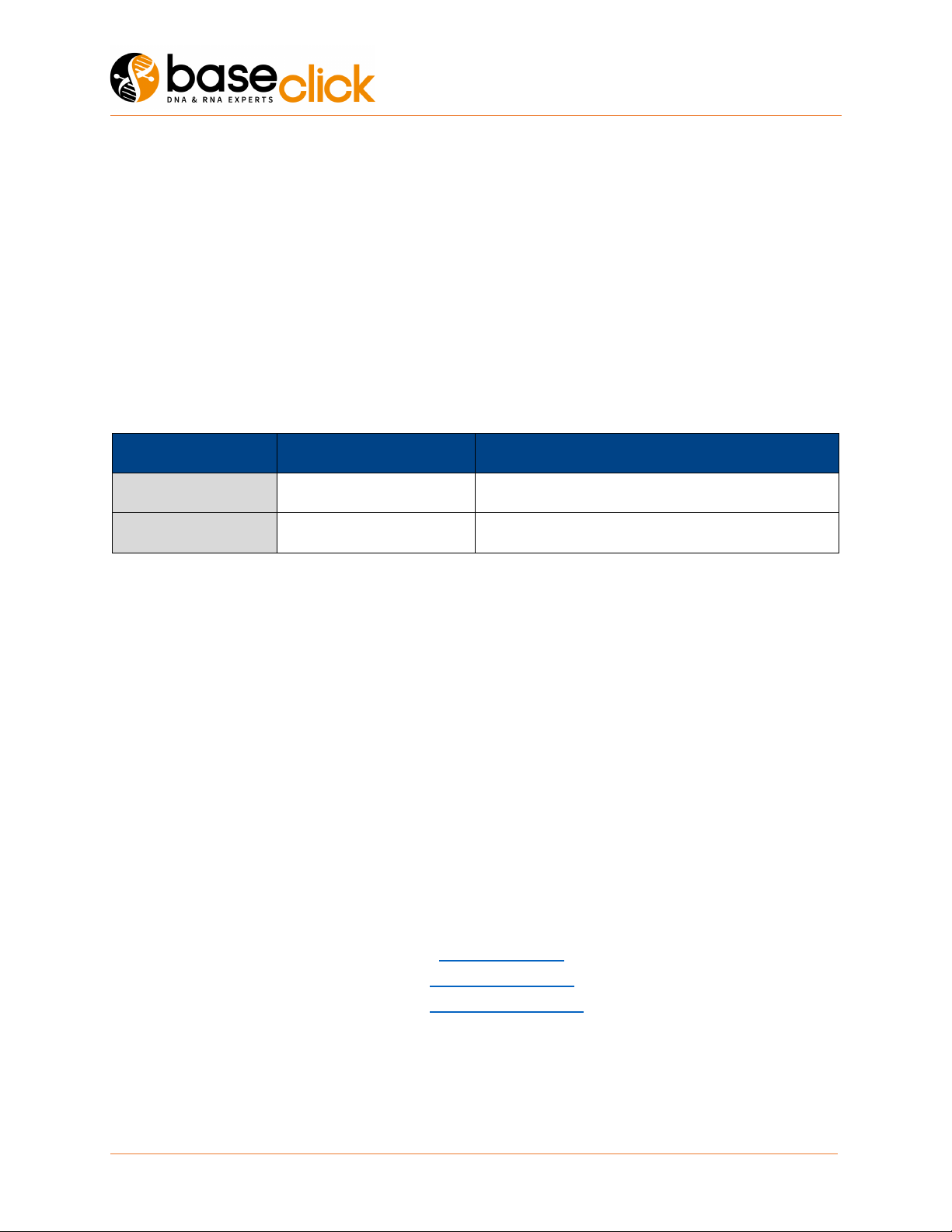

Ordering information

(for detailed kit content see Table 1)

ClickTech Oligo Link Kit:

Product Number

Product Name

Amount Range of Oligonucleotide per Reaction

1

BCK-OL-S

ClickTech Oligo Link Kit S

From 70 pmol to 22 nmol

BCK-OL-L

ClickTech Oligo Link Kit L

From 1 nmol to 90 nmol

1 = These are the minimal and maximal amounts of reacted oligonucleotide that can be achieved using the

kits. The actual feasible amounts are also dependent on the available concentrations of the reaction

partners.

For References, FAQs and ordering please see online or contact us:

online: www.baseclick.eu

orders: orders@baseclick.eu

support: support@baseclick.eu

phone: +49 89 9699 3401

fax: +49 89 9699 4696

ClickTech Oligo Link Kit

3

ClickTech Oligo Link Kit

For click chemistry with 70 pmol to 90 nmol of modified oligonucleotide

Introduction and product description:

This kit was especially optimized to link an oligonucleotide containing a terminal alkyne to an azidemodified oligonucleotide without the need for splint oligos. Labeling of alkyne- or azide-modified

oligonucleotides using label-azides or label-alkynes, respectively, is also possible using this kit.

For research use only.

Information in this document is subject to change without notice. baseclick GmbH assumes no

responsibility for any errors that may appear in this document.

baseclick GmbH disclaims all warranties with respect to this document, expressed or implied, including but

not limited to those of merchantability or fitness for a particular purpose. In no event shall baseclick GmbH

be liable, whether in contract, tort, warranty, or under any statute or on any other basis for special,

incidental, indirect, punitive, multiple or consequential damages in connection with or arising from this

document, including but not limited to the use thereof.

Please read the material safety data sheets (MSDS) provided for each product/component available online

at www.baseclick.eu.

Literature Citation: When describing a procedure for publication using this product, please refer to it as

baseclick ClickTech Oligo Link Kit.

1. Materials and Storage Conditions

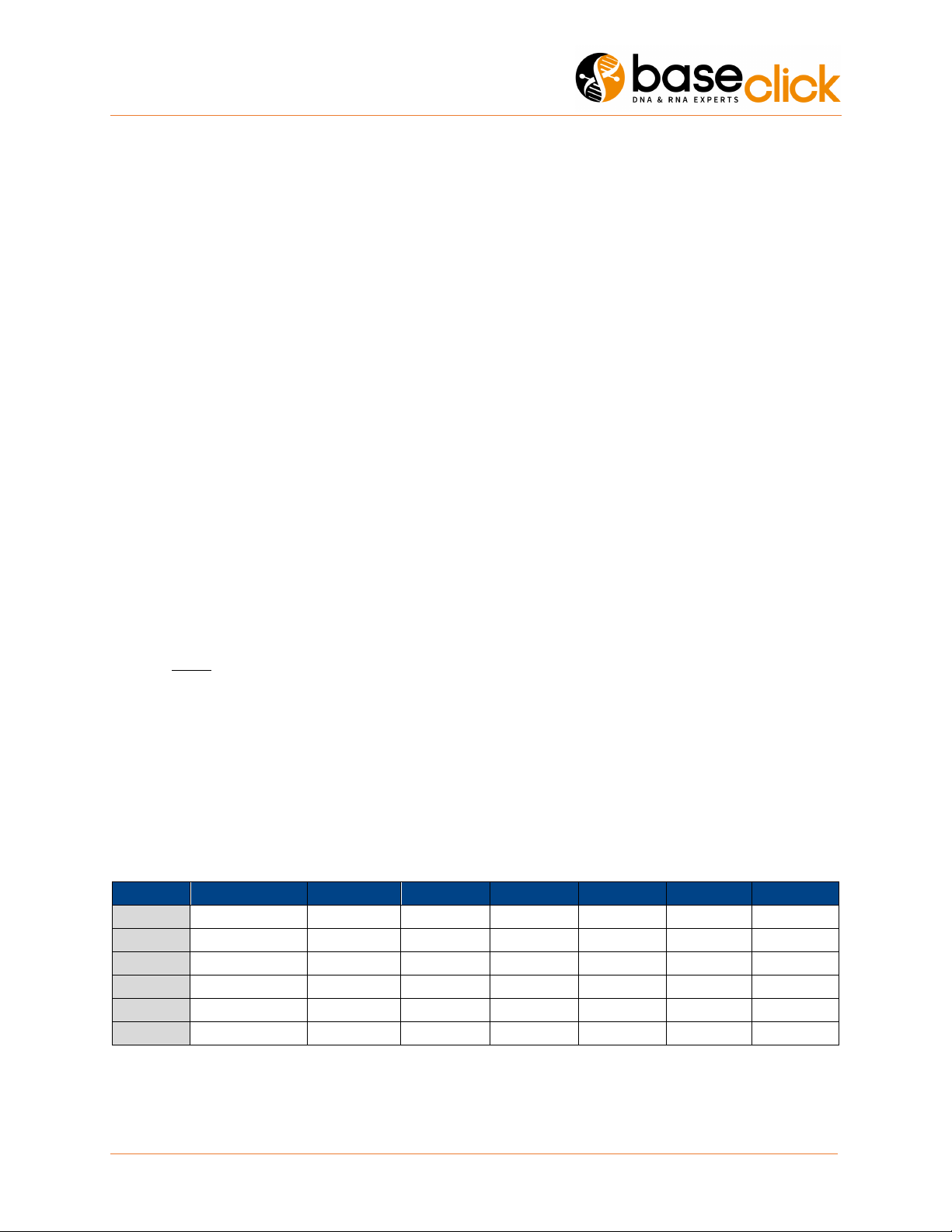

Table 1: Contents of the ClickTech Oligo Link Kits and storage conditions.

Color code

Quantity

Component

Storage

yellow

50 µL (Kit S)

----------------------150 µL (Kit L)

10x Activator²

RT °C

green

10x

Reactor 25 (Kit S)

-----------------------------

Reactor 100 (Kit L)

RT

blue

1 mL

DMSO (solvent)

RT

ClickTech Oligo Link Kit

4

2. Required Material and Equipment – not provided with this kit

• Alkyne-modified oligonucleotide and azide-modified oligonucleotide from enzymatic or

commercial source, preferably dissolved in water (read also section 3 and 11).

• In case of labeling reactions: label-azides or label-alkynes (depending on oligonucleotide

functionality)

• baseclick will be glad to provide you with high quality oligonucleotides as well as labels; please

check our website or inquire via email at quotes@baseclick.eu for an official quote.

• Microcentrifuge tubes

• Thermomixer, thermocycler or water bath

• Polyacrylamide or agarose gel electrophoresis

• PCR or gel purification kit (optional, e.g. from Qiagen)

• HPLC/IEC system for analyses (optional)

3. General Considerations

• The “Reactor” contains a stable heterogeneous catalyst, which won’t be dissolved during the

reaction.

• The DMSO component is not needed for the standard protocol, but is included in the kit to dissolve

label azides/alkynes or as additive (see section 11).

• The click reaction can be performed with 10-100 µM DNA oligonucleotide solutions using the basic

click protocol. For more concentrated samples a “preparative click” protocol might be needed. For

RNA oligonucleotides check extra section.

• The click reaction is optimized for 1 h at 45 °C. For low concentrations (up to 20 µM) DNA

decomposition in this reaction environment can start after 2 h at 45 °C. For optimal results it might

be necessary to adjust the incubation time.

• Low reaction temperatures (e.g. 20 °C) can be applied as well in combination with longer reaction

time.

• Only terminal alkynes can react with azides using the kit reaction conditions.

• It is not feasible to use azide and alkyne functional groups within the same molecule when reaction

to a second reaction partner is desired.

• Read section 11 (Troubleshooting) before getting started.

ClickTech Oligo Link Kit

5

4. Basic Label-Oligo Click Protocol

4.1. Dissolve/Dilute your label azide/label alkyne in DMSO or water to 0.2 - 10 mM to use it as a stock

solution.

4.2. Add the appropriate amount of 10x Activator2 to the Reactor, e.g. 2.5 µL 10x Activator2 are added

to Reactor 25 to be used at a total reaction volume of 25 µL. Depending on Reactor amount and

final volume, this needs to be adjusted (see Table 2).

4.3. Add the alkyne/azide modified DNA oligonucleotide to the vial to a final concentration of

10 - 100 µM.

Note: For reactions of more concentrated solutions, see Preparative Label-Oligo Click Protocol on

page 7.

4.4. Add 2 equivalents of label azide/alkyne per equivalent of alkyne/azide in the oligonucleotide. For

example, a 10 µM solution of a singly alkyne-modified oligonucleotide is mixed with 20 µM of a

label azide for the click reaction.

4.5. Close the vial and incubate the mixture at 45 °C, 600 rpm for 1 h in a thermomixer. Alternatively,

a water bath can be used. When using fluorophores, protect the vial from light. Make sure that

the Reactor is within the reaction solution during the reaction. Spin down the solution if needed.

4.6. Spin down the Reactor. Transfer the supernatant with the clicked oligonucleotide to a new vial.

Note: For long-term storage, reacted samples (without Reactor) should be kept at – 20 °C.

4.7. Analyze the reaction mixture by gel electrophoresis, HPLC or ion exchange chromatography (IEC).

Purifications using column-based kits for oligonucleotide purification (e.g. PCR purification kit

from Qiagen) give good results. Make sure the length of the oligonucleotide is compatible with

the purification kit. Alternatively, purification can be done by HPLC, IEC or ethanol precipitation

(product loss likely).

Exemplary Label-Oligo Click

This guide will help you decide which stock solution concentration of the label azide/alkyne should be

prepared. All concentrations within the table refer to the stock solution concentrations for exemplary

setups using two equivalents of label azide/alkyne for a singly modified oligonucleotide alkyne/azide.

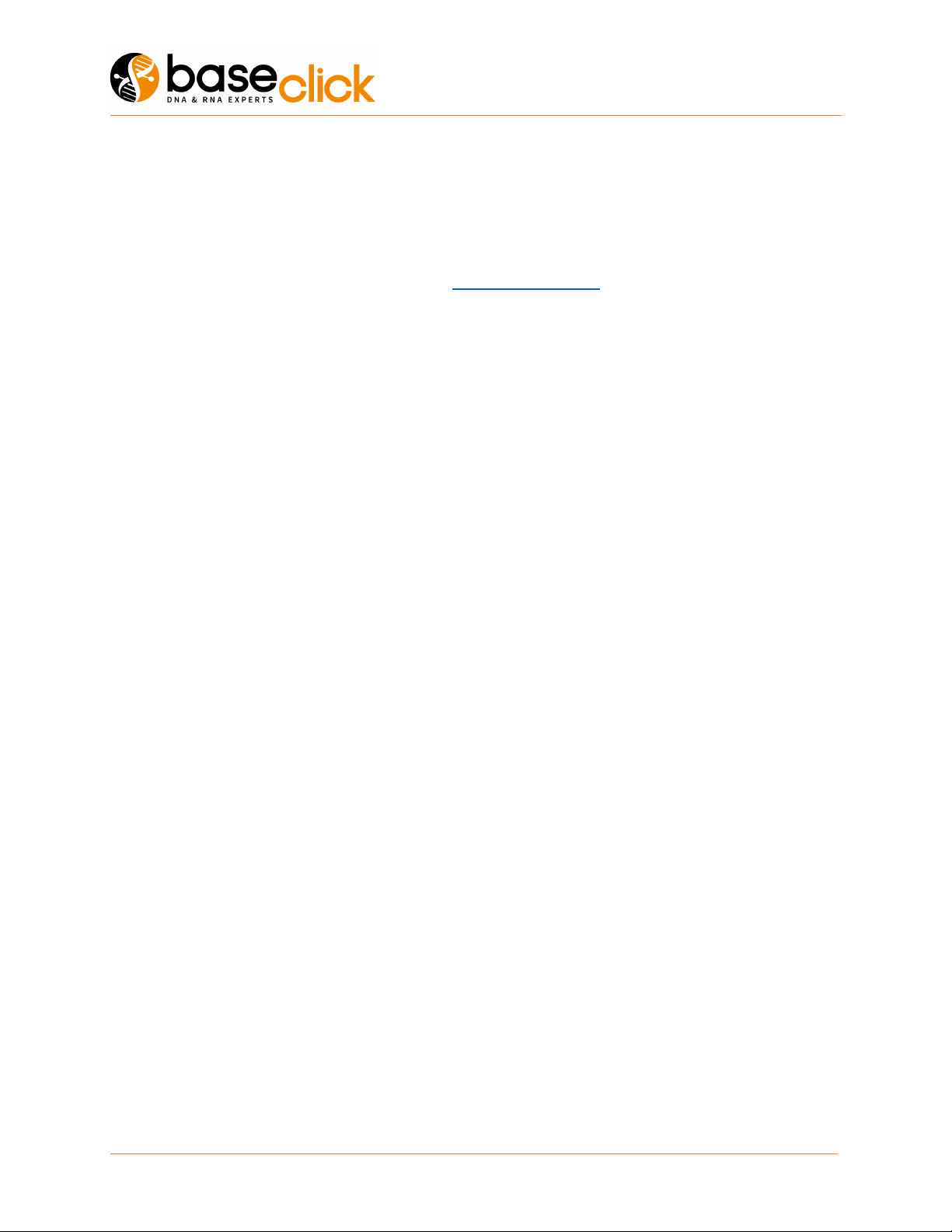

Table 2: Exemplary volumes needed for reaction setups of “basic” label-oligonucleotide click reactions.

Reactor

V (Activator²)

c (Oligo)

V (Oligo)

c (Label)

V (Label)

V (H2O)

Oligo (n)

25

2.5 µL

10 µM

20.0 µL

200 µM

2.0 µL

0.5 µL

200 pmol

25

2.5 µL

50 µM

20.0 µL

1 mM

2.0 µL

0.5 µL

1.0 nmol

25

2.5 µL

100 µM

20.0 µL

2 mM

2.0 µL

0.5 µL

2.0 nmol

100

10.0 µL

10 µM

80.0 µL

1 mM

1.6 µL

8.4 µL

0.8 nmol

100

10.0 µL

50 µM

80.0 µL

2 mM

4.0 µL

6.0 µL

4.0 nmol

100

10.0 µL

100 µM

80.0 µL

10 mM

1.6 µL

8.4 µL

8.0 nmol

ClickTech Oligo Link Kit

6

5. Basic Oligo Link Click Protocol (Oligo – Oligo Connection)

5.1. Add the appropriate amount of 10x Activator² to the Reactor, e.g. 2.5 µL Activator are added to

Reactor 25 to be used with at a total reaction volume of 25 µL. Depending on Reactor and final

volume, this needs to be adjusted (see Table 3).

5.2. Add an equimolar mixture of singly modified alkyne- and azide-modified oligonucleotide (same

final concentration of each oligo) to dilute the Activator to a final 1x concentration.

Note: To achieve optimal reaction progress, do not increase or decrease the final activator

amount. Oligo concentrations of 100 µM will give best yields; down to 10 µM good yields are

achieved. For reaction of more concentrated solutions see “preparative clicks” on page 8.

5.3. Close the vial and incubate the mixture at 45 °C, 600 rpm for 1 h in a thermomixer. Alternatively,

a water bath can be used. Make sure that the Reactor is within the reaction solution during the

reaction. Spin down the solution if needed.

5.4. Spin down the Reactor. Transfer the supernatant with the product to a new vial.

Note: For long-term storage, reacted samples (without Reactor) should be kept at – 20 °C.

5.5. Analyze the reaction mixture by gel electrophoresis, HPLC or ion exchange chromatography (IEC).

Purifications using column-based kits for oligonucleotide purification (e.g. PCR purification kit

from Qiagen) give good results. Make sure the length of the oligonucleotide is compatible with

the purification kit. Alternatively, purification can be done by HPLC, IEC or ethanol precipitation

(product loss likely).

Reaction Volumes and Amounts

This guide will help you to choose the Reactor and calculate the amounts needed.

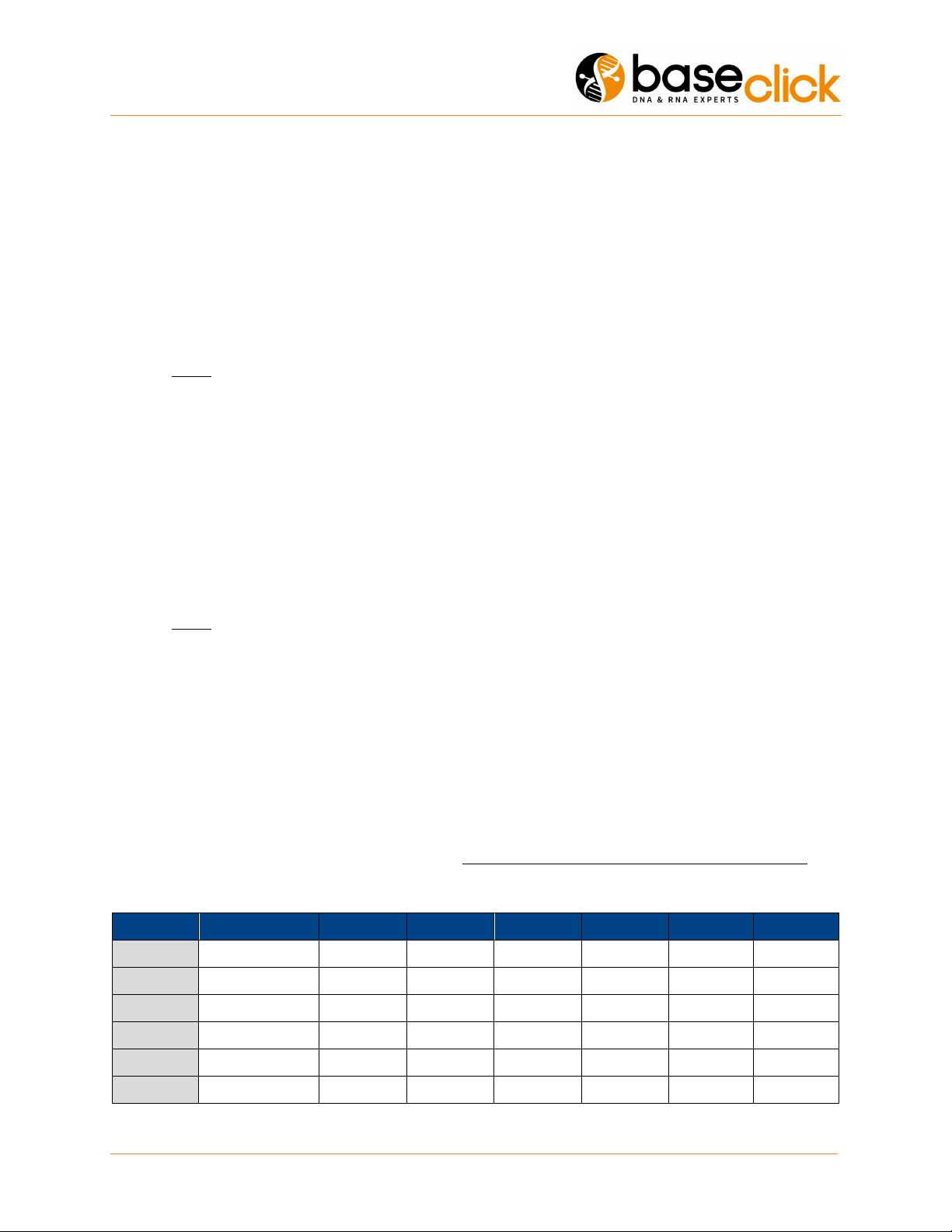

Table 3: Reaction volumes, final concentrations and molar amounts in “basic” click reactions between oligonucleotides.

Reactor

10x Activator²

Oligo solution1 V

Total V

Final oligo (c)

Oligo (n)

25

2.5 µL

22.5 µL

25 µL

10 - 100* µM

0.25 - 2.5 nmol

100

10.0 µL

90.0 µL

100 µL

10 - 100* µM

1.0 - 10 nmol

1

Note: this “oligo solution” volume is referring to the final volume of the equimolar mixture of the singly-

labeled azide and alkyne oligonucleotide to be used in the reaction.

* Note: In order to achieve a final oligo concentration of 100 µM, at least a 220 µM stock solution of each

oligo is needed; for 10 µM, 22 µM is required.

ClickTech Oligo Link Kit

7

6. Preparative Label-Oligo Click Protocol

For click reactions using more concentrated oligo stock solutions (>100 µM final concentration) the

protocol needs some adaption.

6.1. Dissolve/Dilute your label azide/label alkyne in DMSO or water to 10 - 50 mM to use it as a stock

solution.

6.2. Add the appropriate amount of 10x Activator2 to the Reactor, e.g. 10 µL Activator² are added to

Reactor 100 to be used with a total reaction volume of 100 µL. Depending on Reactor and final

volume, this needs to be adjusted (see Table 4).

6.3. Add the alkyne/azide modified oligonucleotide to the vial to a final concentration of 100 - 700 µM.

6.4. Add 2 - 4 equivalents of label azide/alkyne per equivalent of alkyne/azide in the oligonucleotide.

For example a 200 µM solution of a singly alkyne-modified oligonucleotide is mixed with

400 - 800 µM of a label azide for the click reaction.

6.5. Incubate the mixture at 45 °C, 600 rpm for 2 h in a thermomixer. Alternatively, a water bath can

be used. Make sure that the Reactor is within the reaction solution during the reaction. Spin down

the solution if needed.

6.6. Spin down the Reactor. Transfer the supernatant with the product to a new vial. Wash the

remaining pellet with half the reaction volume of H2O to get all reaction mix to the new vial.

Note: For long-term storage, reacted samples (without Reactor) should be kept at – 20 °C.

6.7. Analyze the reaction mixture by gel electrophoresis, HPLC or ion exchange chromatography (IEC).

Purifications using column-based kits for oligonucleotide purification (e.g. PCR purification kit

from Qiagen) give good results. Make sure the length of the oligonucleotide is compatible with

the purification kit. Alternatively, purification can be done by HPLC, IEC or ethanol precipitation

(product loss likely).

Exemplary Preparative Label-Oligo Click Setups

Table 4: Exemplary volumes needed for reaction setups of “preparative” label-oligonucleotide clicks.

Reactor

V (Activator²)

C1 (Oligo)

V(Oligo)

C (Label)

V2 (Label)

V (H2O)

Oligo (n)

25

2.5 µL

200 µM

20 µL

10 mM

1.2 µL

1.3 µL

4.0 nmol

25

2.5 µL

500 µM

20 µL

20 mM

1.5 µL

1.0 µL

10 nmol

25

2.5 µL

1.0 mM

20 µL

50 mM

1.2 µL

1.3 µL

20 nmol

100

10 µL

200 µM

80 µL

10 mM

4.8 µL

5.2 µL

16 nmol

100

10 µL

500 µM

80 µL

20 mM

6.0 µL

4.0 µL

40 nmol

100

10 µL

1.0 mM

80 µL

50 mM

4.8 µL

5.2 µL

80 nmol

1

Concentration of the oligonucleotide stock solution.

2

Note: The volume of label azide/alkyne in the table has been calculated using 3 equivalents for the

reaction.

ClickTech Oligo Link Kit

8

7. Preparative Oligo Link Click Protocol (Oligo – Oligo Connection)

For click reactions between a singly modified alkyne oligonucleotide and a singly modified azide

oligonucleotide, using more concentrated oligo stock solutions (>200 µM stock, >100 µM final

concentration) the protocol needs some adaption compared to the basic protocol described on page 6.

7.1. Dissolve/Dilute your oligonucleotide azide/alkyne in water to 200 µM - 2.0 mM to use it as a stock

solution. The same stock solution concentration of each alkyne and azide oligo is recommended

to allow convenient reaction setup.

Note: The very common TE buffer, which is commonly used for DNA, is not suitable for click

reactions involving this kit, since the EDTA content will interfere with reaction catalysis (see also

section 11).

7.2. Add the appropriate amount of 10x Activator² to the Reactor, e.g. 10 µL Activator² are added to

Reactor 100 to be used with a total reaction volume of 100 µL. Depending on Reactor and final

volume, this needs to be adjusted (see Table 5).

7.3. Add the alkyne/azide modified oligonucleotide to the vial to a final concentration of 100 - 900 µM.

Equimolar amounts of each reaction partner are recommended, i.e. singly modified

oligonucleotides with a stock solution of the same concentration will be applied at same volumes

(see Table 5 for examples). 90% of the total reaction volume can be used for the reaction

partners, dH2O can be used to reach the total volume if necessary. Do not exceed or decrease the

total reaction volume to obtain good reaction progress.

7.4. Incubate the mixture at 45 °C, 600 rpm for 2 h in a thermomixer. Alternatively, a water bath can

be used. Make sure that the Reactor is within the reaction solution during the reaction. Spin down

the solution if needed.

7.5. Spin down the Reactor. Transfer the supernatant to a new vial. Wash the remaining pellet with

half the reaction volume of H2O to get all reaction mix to the new vial.

Note: For long-term storage, reacted samples (without Reactor) should be kept at – 20 °C.

7.6. Analyze the reaction mixture by gel electrophoresis, HPLC or ion exchange chromatography (IEC).

Purifications using column-based kits for oligonucleotide purification (e.g. PCR purification kit

from Qiagen) give good results. Make sure the length of the oligonucleotide is compatible with

the purification kit. Alternatively, purification can be done by HPLC, IEC or ethanol precipitation

(product loss likely).

ClickTech Oligo Link Kit

9

Exemplary Preparative Oligo Link Click Setups

Table 5: Exemplary volumes needed for reaction setups of “preparative” oligonucleotide-oligonucleotide clicks.

Reactor

V (Activator²)

c (Oligo1)

V (Oligo1)

c (Oligo2)

V (Oligo2)

c (final)

Oligo (n)

25

2.5 µL

500 µM

11.2 µL

500 µM

11.2 µL

224 µM

5.6 nmol

25

2.5 µL

1.0 mM

11.2 µL

1.0 mM

11.2 µL

448 µM

11 nmol

25

2.5 µL

2.0 mM

11.2 µL

2.0 mM

11.2 µL

896 µM

22 nmol

100

10 µL

500 µM

45 µL

500 µM

45 µL

225 µM

23 nmol

100

10 µL

1.0 mM

45 µL

1.0 mM

45 µL

450 µM

45 nmol

100

10 µL

2.0 mM

45 µL

2.0 mM

45 µL

900 µM

90 nmol

oligo1 = e.g. singly alkyne modified oligonucleotide

oligo2 = e.g. singly azide modified oligonucleotide.

8. Special Protocols

8.1. Smallest Possible Click Reaction

In order to minimize the amounts needed for a single click reaction, it is possible to adjust the click protocol

for smallest scale reactions. When e.g. using 100 µM final oligonucleotide concentrations, only 700 pmol

oligonucleotide is needed for a single click. Down to 70 pmol oligonucleotide per reaction can be used

without a major decrease in yield.

8.1.1. A single Reactor pellet (0.6 - 0.8 mm diameter) is transferred to a 200 µL vial.

8.1.2. Add 0.7 µL of 10x Activator² to the Reactor pellet.

8.1.3. A volume of 6.3 µL can be used for the reaction partner mix, e.g. alkyne containing

oligonucleotide and fluorophore azide.

8.1.4. Briefly spin down the reaction mix and control if the Reactor pellet is in solution.

8.1.5. Incubate the reaction mix at 45 °C for 45 min without shaking. Spin down the Reactor.

Transfer the supernatant to a new vial.

Note: For long-term storage, reacted samples (without Reactor) should be kept at – 20 °C.

8.1.6. Analyze the reaction mixture by gel electrophoresis, HPLC or ion exchange chromatography

(IEC). Purifications using column-based kits for oligonucleotide purification (e.g. PCR

purification kit from Qiagen) give good results. Make sure the length of the oligonucleotide

is compatible with the purification kit. Alternatively, purification can be done by HPLC, IEC

or ethanol precipitation (product loss likely).

ClickTech Oligo Link Kit

10

8.2. RNA Oligonucleotide Click Reactions

Click reactions involving alkyne and azide modified RNA oligonucleotides have been performed

successfully using this ClickTech Oligo Link Kit protocol. RNA is more prone to chemical and enzymatic

degradation than DNA, please handle with precautions. We recommend to use RNase free components

for the reactions and to keep the RNA on ice apart from the reaction incubation step. The provided

reagents in this kit are not tested to be RNase free.

8.3. Small Molecule Click Reactions

The ClickTech Oligo Link Kit S protocol has been successfully used to join azide modified molecules with

terminal alkyne containing small molecules. For example, 1.1 mM of an amino alkyne linker (BCL-091) was

clicked to 1.1 mM 6-FAM azide (BCFA-001) in 2 hours at 45 °C. Complete conversion of the 6-FAM azide

was observed by analytical HPLC. Using the same click conditions, reactions of amino alkyne linker with 3Azido-7-hydroxycoumarin (BCFA-047), Eterneon-Red 645 Azide (BCFA-201) and 5/6-Sulforhodamine 101

PEG3-Azide (BCFA-044) proceeded with at least 91% conversion yield.

Please note that these reaction examples are no guarantee that every reactant combination between azide

and alkyne containing small molecules will perform well using the ClickTech Oligo Link Kit. It might be a

possible option for reaction catalysis. Experimental optimization of reaction time and temperature for

each system should be considered.

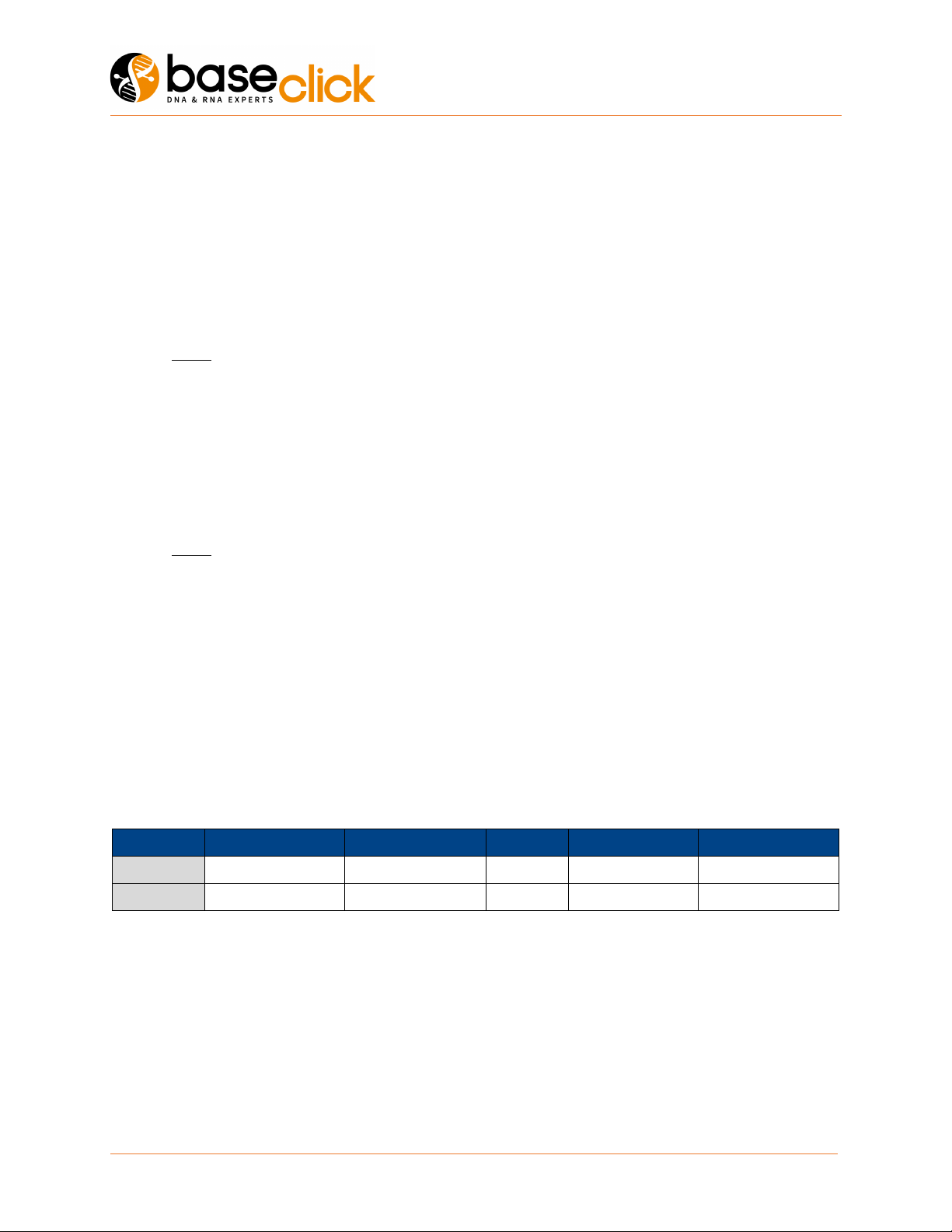

9. Alternative Reaction Temperatures

In case that 45 °C incubation is not possible, alternative reaction temperatures can be used. This will

require adjustment of the incubation time. Here are our recommendations for some alternative reaction

temperatures and the standard condition in the basic protocol (10 - 100 µM oligo) for standard click

ligation reactions described herein. If more complex (bio)molecules should be clicked to oligonucleotides

tests on finding the optimal conditions need to be performed using these recommendations as a starting

point.

Temperature

Duration

20 °C

4 - 5 h

30 °C

90 min

45 °C

60 min

60 °C

50 min

ClickTech Oligo Link Kit

11

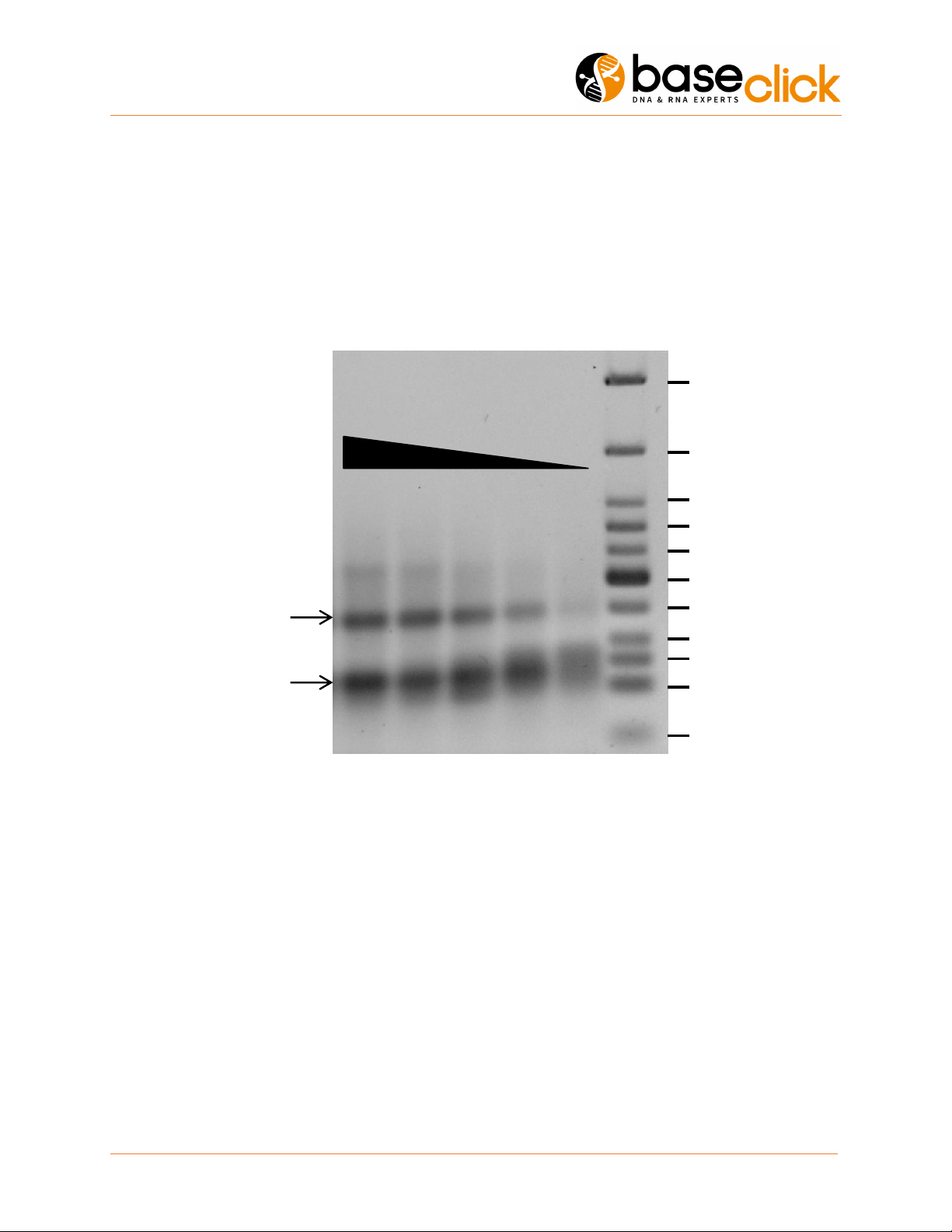

10. Exemplary Gel Image from Oligo link Clicks

Here is an example where the kit has been used to click ligate a 5’-azide oligo (59 mer) to a 5’-alkyne oligo

(59 mer) using varying oligonucleotide amounts. Very low oligonucleotide amounts were studied in order

to determine the lower working range for the kit. No splint oligonucleotides were used for preorganization

of the strands.

Figure 1. Ethidium bromide stained 3% agarose gel from oligo-oligo click reactions using different oligo amounts. For the

analysis the same amount of oligonucleotide was loaded onto each lane of the gel. The sample volumes were adjusted

accordingly. Yield means the densidometric ratio between product band and the sum of all bands in the corresponding lane.

oligo amount in pmol

350 175 87 43 25

product

25

50

75

100

150

200

766

500

350

250

300

27 30 24 18 11 Myield [%]

starting

material

ClickTech Oligo Link Kit

12

11. Trouble Shooting

Some standard commercial buffer components can decrease the click reaction efficiency or even impair

reaction process. For example, TE buffer contains EDTA, which can chelate CuII ions and decrease the

reaction rate. Thiol groups from reducing agents like β-mercaptoethanol or dithiothreitol (DTT) can stop

the click reaction.

Oligonucleotides (DNA and RNA) can have folded structures, which hinder accessibility of the functional

groups that are needed for the reaction. By adding some DMSO (5 - 10% (v/v) final) these folded structures

are destabilized and improved reaction progress can be observed.

Some (dye) labels show low solubility in the final reaction mixture, when used at higher concentrations

and amounts, especially in the preparative label-oligo click protocol. This can impair reaction progress and

decrease the yield. Try to use additional or alternative co-solvents like methanol or tetrahydrofuran if

possible.

When slow reaction progress is observed, increasing the reaction temperature, e.g. to 60 °C might help to

improve the reaction (see 9) and solubility of the reaction partners.

Dissolved oxygen from air in stock solutions can change the reaction kinetic. Much oxygen decreases, less

oxygen increases the reaction progress. As cold solutions can keep more dissolved gas, cold stock solutions

contribute the most oxygen. A main source for the change of dissolved oxygen are freezing and thawing

cycles. By freshly dissolving dry components in degassed or room temperature stored water the reaction

progress can increase. Saturation of solutions with inert gas (e.g. N2 or argon) can also increase the reaction

progress, if available. Be aware that this will not only decrease the reaction time, but might also decrease

the time from which oligonucleotide degradation starts.

Loading...

Loading...