WEH1500

109901

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten

Germany

Phone: +49 5258 971-0

Fax: +49 5258 971-120

Service hotline: +49 5258 971-197

www.bartscher.com

Version: 1.0

Date of preparation: 2023-12-01

EN

2

Original instruction manual

1 Safety ............................................................................................................ 2

1.1 Explanation of Signal Words .................................................................... 2

1.2 Safety instructions.................................................................................... 3

1.3 Intended Use ........................................................................................... 5

1.4 Unintended Use ....................................................................................... 5

2 General information ....................................................................................... 6

2.1 Liability and Warranty .............................................................................. 6

2.2 Copyright Protection ................................................................................ 6

2.3 Declaration of Conformity ........................................................................ 6

3 Transport, Packaging and Storage ................................................................ 7

3.1 Delivery Check ......................................................................................... 7

3.2 Packaging ................................................................................................ 7

3.3 Storage .................................................................................................... 7

4 Technical Data ............................................................................................... 8

4.1 Technical Specifications .......................................................................... 8

4.2 List of Components of the Appliance ....................................................... 9

4.3 Functions of the Appliance ..................................................................... 10

5 Installation and operation ............................................................................ 15

5.1 Installation .............................................................................................. 15

5.2 Electrical Connection ................................ ............................................. 20

5.3 Operation ............................................................................................... 20

5.4 Settings ................................................................ ................................ .. 23

6 Cleaning and Maintenance .......................................................................... 28

7 Possible Malfunctions .................................................................................. 28

8 Disposal ....................................................................................................... 30

109901 1 / 30

Safety

EN

Read this instruction manual before using and keep it available

at all times!

DANGER!

The signal word DANGER warns against hazards that lead to severe

injuries or death if the hazards are not avoided.

WARNING!

The signal word WARNING warns against hazards that may lead to

moderate or severe injuries or death if the hazards are not avoided.

Diese Bedienungsanleitung beschreibt di e Installation, Bedienung und Wartung d es Geräts und gilt als wichtige Infor mationsquelle und Nachschlagewer k. Die Kenntnis aller enthaltenen Sicherh eitshinweise und Handlungsanweisunge n schafft die Voraussetzung f ür das sichere und sachgerechte Ar beiten mit dem Gerät. Darüber hinaus müssen die für den Einsatzbereich d es Geräts geltenden örtlichen Unfall verhütungsvorschriften und allgemeine n Sicherheitsbestimmungen eingehalten werden. Diese Bedienungsanleitung is t Bestandteil des Produkts und muss in unmittelbarer Nähe des Ger äts für das In¬stallations-, Bedienu ngs-, Wartungs- und Reinigungspers onal jederzeit zugänglich auf¬bewahrt werd en. Wenn das Gerät an eine dritt e Person

weitergegeben wird, muss die Bedienung sanleitung mit ausgehändigt werden.

This instruction manual contains information about installation, operation and

maintenance of the appliance and constitutes an important source of information

and reference guide. The knowledge of all operational and safety instructions

included in this manual is a prerequisite for safe and proper handling of the

appliance. Additionally, accident prevention, occupational health and safety, and

legal regulations in force in the area the appliance is used apply.

Before you start using the appliance, especially before turning it on, read this

instruction manual in order to avoid personal injuries and property damages.

Improper use may cause damage.

This instruction manual forms and integral part of the product and must be stored in

an immediate vicinity of the appliance and be available at all times. The instruction

manual should be transferred together with the appliance.

1 Safety

This appliance has been manufactured in accordance with technical standards

currently in force. However, the appliance may be a source of hazards if used

improperly or contrary to its intended purpose. All persons using the appliance must

consider information included in this instruction manual and observe safety

instructions.

1.1 Explanation of Signal Words

Important safety instructions and warning information are indicated in this

instruction manual with appropriate signal words. You must strictly follow the

instructions, to prevent accidents, personal injuries and property damages.

2 / 30 109901

Safety

EN

CAUTION!

The signal word CAUTION warns against hazards that may lead to

light or moderate injuries if the hazards are not avoided.

IMPORTANT!

The signal word IMPORTANT indicates possible property damages,

which may occur if safety instructions are not observed.

NOTE!

The symbol NOTE indicates subsequent information and guidelines

for the user on usage of the appliance.

, die

1.2 Safety instructions

Electrical Current

• Too high a mains voltage or incorrect installation may cause electric shock.

• The appliance may be connected only if data on the rating plate correspond with

the mains voltage.

• To avoid short-circuit, the appliance should be kept dry.

• If there are malfunctions during operation, disconnect the appliance from the

power supply.

• Do not touch the appliance’s plug with wet hands.

• Never take hold of the appliance if it has fallen into water. Immediately

disconnect the appliance from the power supply.

• Any repairs or housing opening may be carried out by professionals and

relevant workshops only.

• Do not transport the appliance, holding it by the power cord.

• Do not allow the power cord to come into contact with heat sources or sharp

edges.

• Do not bend, pinch nor knot the power cord.

• Always completely unwind the power cord.

• Never place the appliance or other objects on the power cord.

• Always take hold of the plug to disconnect the appliance from the power supply.

109901 3 / 30

Safety

EN

• Check the power cord regularly for damage. Do not use the appliance if the

power cord is damaged. If this cable is damaged, it must be replaced by

customer service or a qualified electrician in order to avoid dangers.

Operating Personnel

• The appliance may only be operated by qualified personnel and trained

specialist personnel.

• This appliance may not be operated by persons (including children) with limited

physical, sensory or mental capabilities, nor by persons with limited experience

and/or limited knowledge.

• Children should be supervised to ensure that they are not playing with or

switching on the appliance.

Improper Use

• Unintended or prohibited use may cause damage to the appliance.

• The appliance may only be used when its technical condition is flawless and

allows for safe operation.

• The appliance may only be used when all connections are executed according

to rules of law in force.

• The appliance may only be used when it is clean.

• Use only original spare parts. Never attempt to repair the appliance on your own.

• Do not introduce any changes in the appliance nor modify it.

4 / 30 109901

Safety

EN

1.3 Intended Use

As described below, every use of the appliance for a purpose differing and/or

diverging from its intended standard use, is prohibited and considered to be an

unintended use.

The following is an intended use:

– Reduces limescale build-up in an appliance and on washed items by

reducing water hardness.

1.4 Unintended Use

An unintended use may lead to personal injuries or property damages caused by

hazardous voltage, fire or high temperature. The appliance may only be used to

perform tasks described in this instruction manual.

109901 5 / 30

General information

EN

2 General information

2.1 Liability and Warranty

All information and instructions in this instruction manual account for legal

regulations in force, current level of technical engineering knowledge as well as our

expertise and experience, developed over the years. If special models or additional

options are ordered, or state-of-the-art technical solutions were implemented, the

actual scope of delivery of the appliance may, in some circumstances, differ from

descriptions and numerous drawings in this instruction manual.

The manufacturer is not liable for any damages nor faults stemming from:

– failure to observe instructions,

– unintended use,

– technical alterations introduced by the user,

– usage of unapproved spare parts.

We reserve the right to introduce technical modifications to the product, intended for

improvement of the appliance and its performance.

2.2 Copyright Protection

This instruction manual, and texts, drawings and images included in it, as well as its

other components are copyright protected. It is prohibited to reproduce this

instruction manual (including its excerpts), in any form and by any means, and to

use and/or transfer its content to third parties without manufacturer’s written

permission. Violation of the above results in obligation to pay compensation. We

reserve the right to claim further damages.

2.3 Declaration of Conformity

The appliance meets the currently applicable standards and guidelines of the

European Union. We confirm the above in the EC Declaration of Conformity. We

may provide relevant Declaration of Conformity upon request.

6 / 30 109901

Transport, Packaging and Storage

EN

3 Transport, Packaging and Storage

3.1 Delivery Check

Immediately upon reception, check the delivery for completeness and possible

shipping damage. In the case of visible transport damage refuse to accept the

appliance or accept it conditionally. Mark and note the scope of damage in shipping

documents/consignment list of the shipping company and lodge a complaint.

Concealed damage must be reported immediately upon its discovery, as

compensation claims may only be filed within applicable time limits.

If you find that parts or accessories missing, please contact our Customer Service

Department.

3.2 Packaging

Do not dispose of the appliance cardboard box. It may be used to store the

appliance when relocating or when shipping the appliance to our service point in the

case of any damages.

The packaging and its elements are made of recyclable materials. Particularly,

these are: plastic films and bags, cardboard box.

When disposing of the packaging, observe applicable domestic regulations.

Recyclable packaging materials should be recycled.

3.3 Storage

Leave the packaging closed until installation of the appliance; observe external

indications concerning method of placing and storage. Store the packaging in the

following conditions only:

– in closed rooms;

– in dry and dust-free surrounding;

– away from aggressive agents;

– in a location protected against sunlight;

– in a location protected against mechanical shocks.

In the case of extended storage (over three months), make sure you check the

condition of the packaging and the parts regularly. If needed, replace the packaging

with a new one.

109901 7 / 30

Technical Data

EN

Name:

Water softening system

WEH1500

Art. No.:

109901

Material:

plastic

Output capacity:

1.500 litres/day at 10° dH (total

hardness)

Water connection:

3/4“

Water temperature at inlet, in °C:

1 - 30

Connection capacity, appliances:

1

Return value per cartridge:

0

Operating pressure:

2 - 6

Salt stock in brine tank, in kg:

20

Salt consumption, in kg / regeneration:

0,7

Regeneration duration, in min:

45

Dimensions (W x D x H), in mm:

238 x 465 x 478

Weight, in kg:

9,2

4 Technical Data

4.1 Technical Specifications

We reserve the right to implement technical modifications.

Version / Characteristics

• Designed for: industrial dishwashers

• Digital display

• Setting options:

– interval

– hour

– day of the week

– water hardness

– regeneration

• Regeneration: flow rate or period

8 / 30 109901

Technical Data

EN

Fig. 1

1. Control valve with digital display

2. Filter cartridge

3. Brine tank cover

4. Brine tank

5. Housing

6. Connections

4.2 List of Components of the Appliance

109901 9 / 30

Technical Data

EN

4.3 Functions of the Appliance

How the Appliance Works

Hard water contains a combination of calcium (Ca), magnesium (Mg) and iron (Fe).

Softening is used to remove positively charged ions using an ion exchange resin.

When the ion exchange resin loses its effectiveness, it is activated through a

regeneration process.

Regeneration

Regeneration is carried out by rinsing the sludge with a salt solution and flushing

the absorbed calcium and magnesium ions into the wastewater.

Regeneration is carried out automatically in an intelligent, logical way: based on the

water consumption of the previous 7 days, the system itself selects the day of

regeneration at the set time. During regeneration (60 min), unsoftened water is

available.

The regeneration process consists of 4 cycles:

1. Regenerating agent replenishment

2. Rinsing with the regenerating agent solution

3. Backwashing

4. Quick rinsing

Water Softening System Structure

The system is configured for 0.7 kg of regenerating agent per regeneration. The

amount of water softened between regenerations is calculated with the formula:

Z = 1350x10 / Y

Z — means the amount of softened water between regenerations,

Y — means the hardness of the tested water based on dH (German degrees of

hardness).

Example of calculation of the amount of softened water between regeneration

processes:

The tested water hardness is 15°dH.

The amount of water Z between regeneration processes is calculated as follows:

Z = 1350 x 10/15 = 900 litres.

With a water hardness of 15°dH, 900 litres of softened water will be obtained.

10 / 30 109901

Technical Data

EN

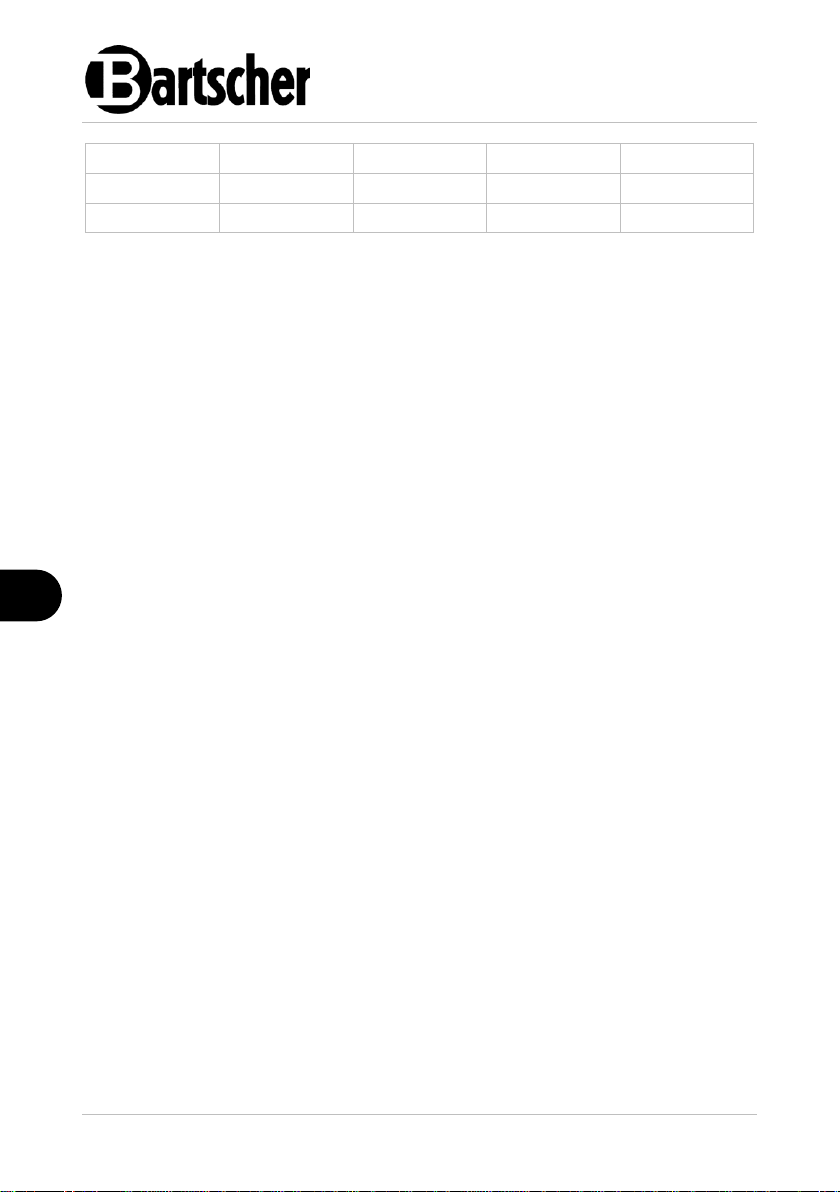

Degree of hardness

Softened

water (L)

English

hardness

French

hardness

PPM

German

hardness

12,5

18,0

178,6

10

1500

13,8

19,8

196,5

11

1364

15,0

21,6

214,3

12

1250

16,3

23,4

232,2

13

1154

17,5

25,2

250,0

14

1071

18,8

27,0

267,9

15

1000

20,0

28,8

285,8

16

938

21,3

30,6

303,6

17

882

22,5

32,4

321,5

18

833

23,8

34,2

339,3

19

789

25,0

36,0

357,2

20

750

26,3

37,8

375,1

21

714

27,5

39,6

392,9

22

682

28,8

41,4

410,8

23

652

30,0

43,2

428,6

24

625

31,3

45,0

446,5

25

600

32,5

46,8

464,4

26

577

33,8

48,6

482,2

27

556

35,0

50,4

5001

28

536

36,3

52,2

517,9

29

517

37,5

54,0

535,8

30

500

38,8

55,8

553,7

31

484

40,0

57,6

571,5

32

469

41,3

59,4

589,4

33

455

42,5

61,2

607,2

34

441

43,8

63,0

625,1

35

429

45,0

64,8

643,0

36

417

46,3

66,6

660,8

37

405

Water Hardness Performance Table (°)

109901 11 / 30

Technical Data

EN

47,5

68,4

678,7

38

395

48,8

70,2

696,5

39

385

50,0

72,0

714,4

40

375

Tab. 1

Standards, Rules and Regulations

• The water used to supply the appliance must be of drinking water quality and

conform to the requirements of the regulations for the use of water of the public

utility at a site.

• All parts in contact with the treated water must be made of waterproof material.

• Ensure that a soil drainage is installed at the water treatment site. The

purchaser is responsible for the drainage.

• The maximum temperature of the supplied water should not exceed 30°C.

• Do not remove the water softening system during use.

• Do not open the water softening system, otherwise the warranty will be voided.

12 / 30 109901

Technical Data

EN

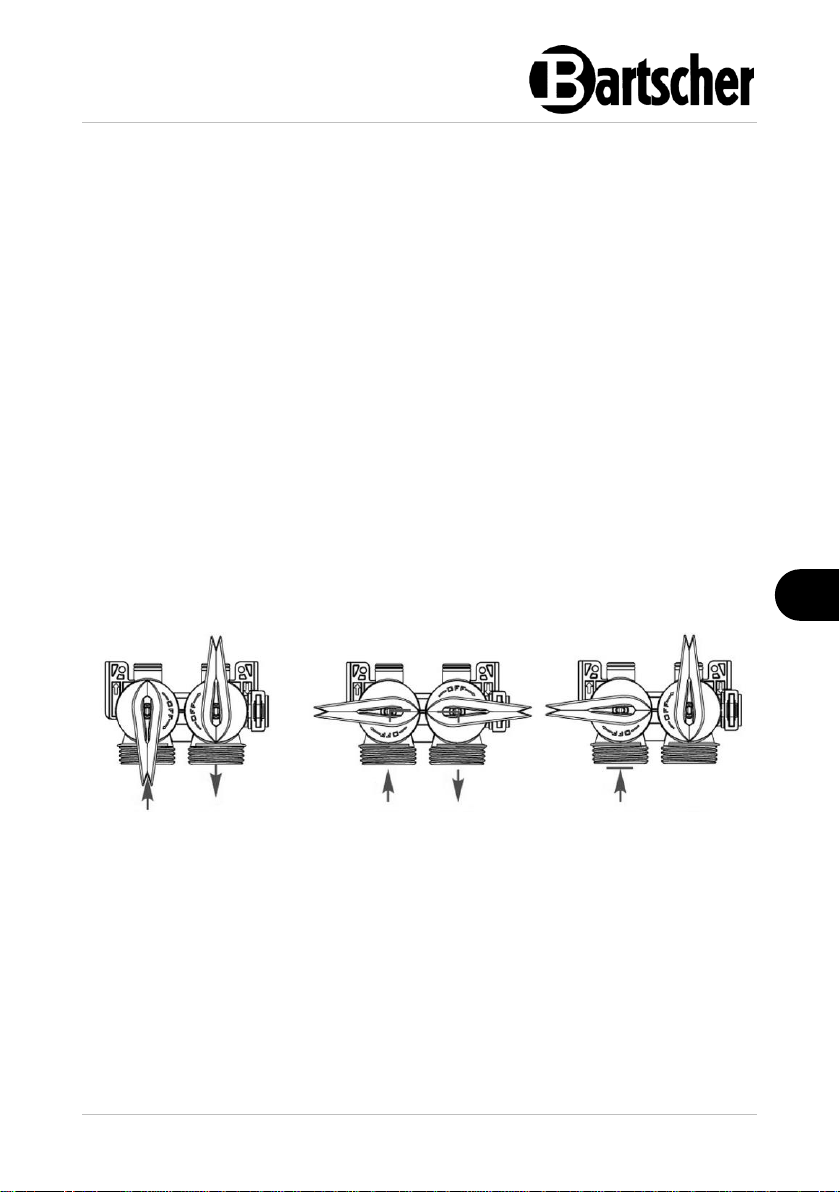

Service position

Bypass position

Shut-off position

Inlet

Discharge

Inlet

Discharge

Inlet

Discharge

Fig. 2

Control Function

Control Valve

Before starting, set the current time and water hardness in degrees.

The valve is set by default to regenerate at 2:00 AM at 20 German degrees.

Salt Replenishment Reminder

The system automatically detects the salt level in the brine tank each time after

regeneration. If the salt level is below normal, the low salt sensor will relay this to

the intelligent control system, and a "SALT" alarm will be displayed in the screen.

The buzzer will sound daily from 7:30 PM to 10:30 PM to remind the user to

replenish the salt.

Salt should be replenished on time to avoid using unsoftened water. When the

display shows the "SALT" alarm, the salt in the brine tank can be used for 2 or 3

more regenerations.

Bypass

The bypass connection allows for convenient installation and maintenance. There

are three different types of states when the bypass handle is rotated.

DRY Brine Tank

The system fills the brine tank each time just a few hours before regeneration to

keep the brine tank largely dry, preventing salt from accumulating above the tank or

leaking out.

INTELLIGENT Control

• The water softening system is equipped with the latest intelligent control valve,

described below.

109901 13 / 30

Technical Data

EN

Upflow regeneration system. Unlike downflow systems, a water softening

system with the upflow system directs the water flow upward. Water flows from

the bottom of the brine tank in an upward swirling motion through the resin. The

upflow system is a high-efficiency system. Thanks to regeneration with the water

stream directed upward, the system can use 30% less salt.

Proportional regeneration. The system regenerates the used resin only

according to the water consumption condition. This saves salt and keeps the

resin fresh.

Holiday mode When the system is not going to be used for a long time, the

holiday mode can keep the resin fresh. Holiday mode can be activated by

pressing and holding the button in softening mode until HOLIDAY appears

in the display. To switch the holiday mode off, press the button until the

HOLIDAY message is no longer displayed.

• If the control valve does not detect water consumption greater than 6 LPM (litres

per minute) or 85 LPD (litres per day) in the next 4 days, the control valve will

initiate 100% regeneration at the set time of the 4th day, and then remain in

standby mode in the operating position.

• If the control valve does not detect water consumption greater than 6 LPM (litres

per minute) or 85 LPD (litres per day) in the next 4 days, the controller will only

perform a 5-minute backwash and quick rinse at the programmed time on the

2nd and 4th day, respectively.

• If the control valve detects water consumption greater than 6 LPM (litres per

minute) or 85 LPD (litres per day), the holiday mode is discontinued and the

control valve switches to normal mode based on previous conditions. The

amount of water consumed is added via the control valve to the records.

14 / 30 109901

Installation and operation

EN

CAUTION!

Incorrect installation, positioning, operation, maintenance or misuse of

the appliance may lead to personal injury or property damage.

Positioning and installation, as well as repairs may be performed by

authorised technical service only and in compliance with the applicable

national law.

NOTE!

The manufacturer disclaims all liability and provides no warranty for

damages, which may be attributed to non-observance of regulations or

incorrect installation.

5 Installation and operation

5.1 Installation

Information for Installer

• All installation and maintenance work on the water softening system must be

performed only by trained and authorized specialized personnel.

• Unpack the appliance and discard the entire packing material. Never remove the

rating plate or any warning signs from the appliance.

• Before installing the water softening system, the appliance working with it

(dishwasher) must be free of lime and gypsum deposits.

• Do not install the appliance in the vicinity of heat sources and open flames.

Protect the appliance from sunlight.

• Protect the appliance from mechanical damage.

• If the water pressure in the water supply line exceeds 6 bar, it is necessary to

install a pressure reducer to the appliance.

• Accessories for the water softening system in contact with water must be made

of material suitable for this purpose.

• All parts must be installed in accordance with the country's guidelines for the

installation of drinking water systems.

• The ambient temperature at the installation site must be at least 10°C.

• Protect the appliance from frost.

109901 15 / 30

Installation and operation

EN

• The installation site of the appliance must be protected from damage caused by

water (e.g., by an existing floor drain). The manufacturer is not responsible for

damage caused by water.

ATTENTION!

After storage and transportation at temperatures below 0°C, the appliance

must be kept in its open original packaging for at least 24 hours before it is

put into operation at the specified ambient temperature.

Preparation for Installation

The user must make the following preparations at the installation site

1. Water supply line with 3/4" connection and shut-off valve.

2. Water discharge line (sewer) with a maximum height of 100 mm,

DN50 connection.

3. Socket 230 V / 50 Hz, 16 A.

4. Floor drain in the installation room.

5. Mechanical fine filter must be installed upstream of the system.

16 / 30 109901

Installation and operation

EN

Fig. 3

1. Water supply line with 3/4"

connection and shut-off valve

2. Cold water supply

3. Mechanical cleaning filter

4. Electrical socket

5. Control valve

6. Brine tank

7. Overflow drain elbow

8. Flexible regeneration hose

9. Air gap

10. Sewage network

11. Floor drain

12. Softened water

Installation Diagram

109901 17 / 30

Installation and operation

EN

Fig. 4

Water Softening System Installation

1. After preparation for installation, place the appliance in the designated room

according to the installation plan.

2. Connect all supply and drain lines. The appliance's connections are shown in

the following figure:

– Connect the water supply line (2) and drain pipe (1) to the appliance.

– Connect the flexible sewage pipe (1/2") to the connection pipe (5) and to

the drain or sewage system.

ATTENTION!

The sewage pipe must be large enough to allow 5 l/m of rinse water to

drain. The drain pipe must be rigid enough not to break and lead to

blockages and overflowing of the brine tank, as well as to the malfunction

of the regeneration process.

– A mechanical fine filter should be installed in front of the water softening

system to protect the appliance from mechanical damage caused by

sediment from water pipes.

– Fill the brine tank of the water softening system with salt tablets.

– Then add 3 litres of water.

– Check all connections to the appliance and tighten them if necessary.

– Connect the water softening system to a single grounded outlet.

18 / 30 109901

Installation and operation

EN

Disassembly and Disposal

At the end of its life, the appliance will be disassembled (for final destruction or

scrapping).

Disassembly should be done in reverse order.

ATTENTION!

First, thoroughly clean the system with clean drinking water and

completely empty the tanks and hoses!

Observe health and safety regulations when doing so!

Preferred Settings

The appliance is pre-set at the factory. Precise adjustment is done by user on site.

1. Program the control valve (section 5.4).

2. Before commissioning, set the current time and water hardness in German

degrees of hardness.

3. Check the water hardness and enter the correct value.

Based on this, the system will calculate the capacity after which regeneration

should begin. The control valve is set by default so that regeneration takes place at

2:00 AM at 20 degrees of water hardness according to the German scale.

4. Open the water supply to the water softening system.

The water pressure must be at least 2.0 bar and a maximum of 6.0 bar.

5. Vent the system, starting the regeneration process. Start the regeneration by

pressing the (EXIT) button for 5 seconds.

There will be an audible buzzing of the electric motor, indicating that regeneration is

in progress. During the regeneration process, the system is ventilated and the brine

tank is filled with water. Immediately after regeneration is complete, the appliance is

ready for operation again. Hard water is available during regeneration.

109901 19 / 30

Installation and operation

EN

Fig. 5

5.2 Electrical Connection

• Verify if the technical specification of the appliance (see the rating plate)

corresponds to the characteristics of the local electric mains grid.

• Connect the appliance to a single, properly grounded mains socket with a

protective contact. Do not connect the appliance to a multi-socket.

• The power cord should be laid in a way preventing anyone from threading on it

or tripping against it.

5.3 Operation

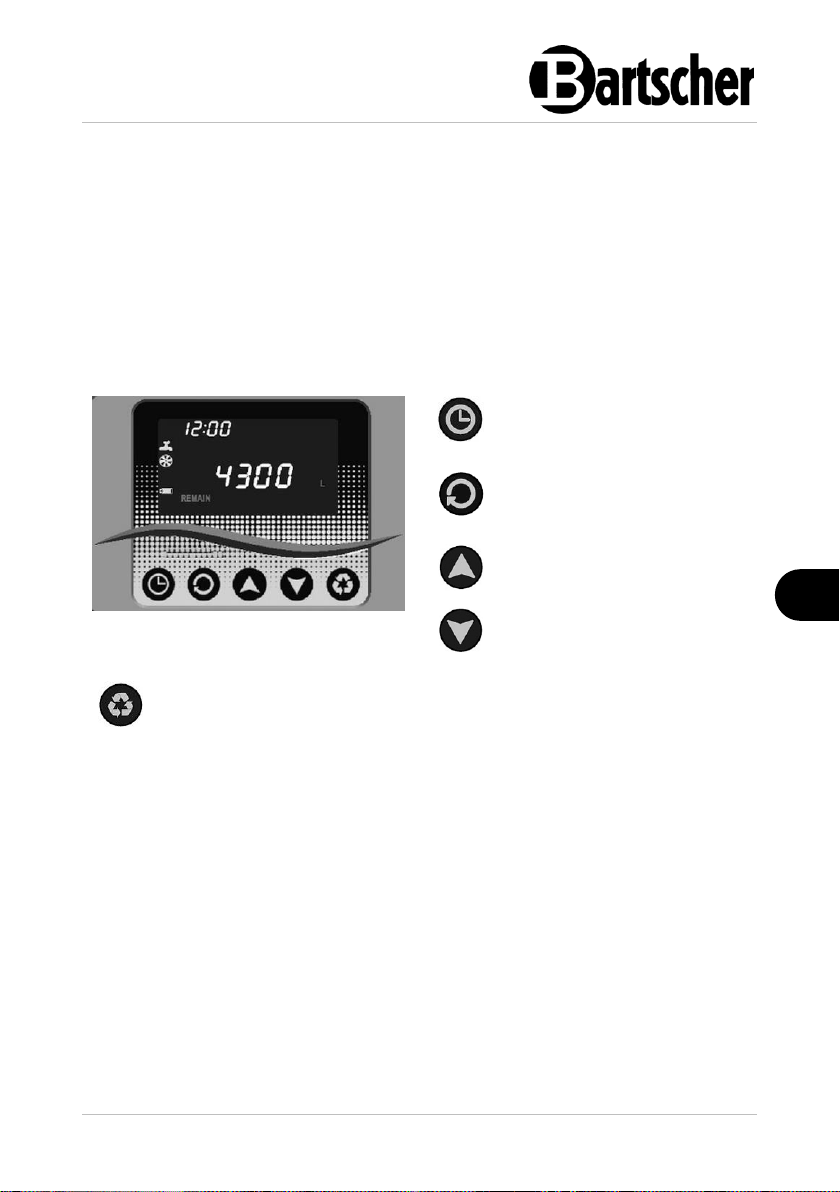

Display Messages

a – current time

b – information about the day of the week

c – appliance: M3 – flow rate; PPM, dH, FH – water hardness unit, dH – German

hardness, FH – French hardness, Kg – total resin replacement capacity.

d – cycle stage: When this message flashes, it means that the control is moving to

the current cycle stage.

e – wireless control: When this message appears, it means that the wireless unit

can control the valve.

f – backup battery: The battery is installed. When this message flashes, it means

that the battery level is low.

20 / 30 109901

Installation and operation

EN

Fig. 6

Time programming menu

Short press – enter user

settings

Entering

Approval and saving of

current settings

Increase button

Increase setting value

Decrease button

Decrease the value of the

settings

Exit

1. Short press in programming mode – return to previous setting step

2. Long press (5 sec) – regeneration starts immediately

3. Short press in softening mode – forces regeneration to start at the

programmed time.

g – queue regeneration: The initiation of queue regeneration means that the

controller is currently in the process of regeneration.

h – flow meter: When the flow meter is installed and flashing, it means that the flow

is going through the meter.

i – appliance is running: If flashing, it means that the controller is moving to the

operating position.

j – setting mode: At the controls in the data settings.

k – valve type: SOFT – softening valve, FILTE – filter valve.

Control Keys

109901 21 / 30

Installation and operation

EN

Fig. 7

Backup battery – connection and functions

NOTE!

The backup battery is not included in the scope of supply.

A 9 V 6LR61 block battery is required for the appliance.

To extend the life of the battery, connect the battery only when the control

valve is properly set.

1. Remove the cover from the battery socket.

2. Slide the battery terminal onto the battery.

3. Then place the battery in the battery socket.

Functions:

• When the power is switched off in the operating position, the control valve

remains in the same position, even after reaching regeneration. The battery,

processor and flow meter operate normally. The skipped regeneration will be

made up as soon as the power supply is restored.

• When there is a power failure during the regeneration stage, the control valve

battery remains on, and the control valve completes the current stage and

moves it back to the operating position, where it waits for electrical power to be

restored. It then returns to the operating position to continue and complete the

remaining regeneration stages to be executed.

22 / 30 109901

Installation and operation

EN

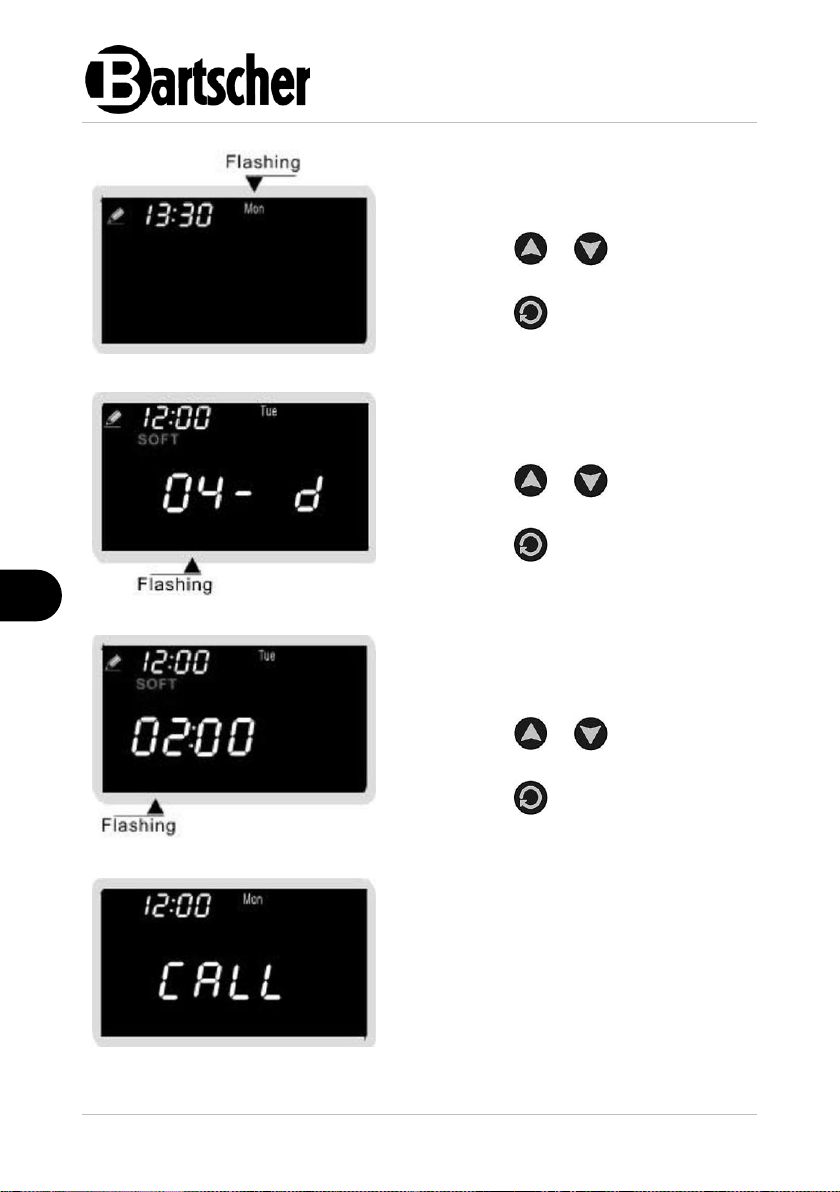

1. To enter the setting mode, press the

button.

2. In the home screen, press the

button to set the time.

Fig. 8

The hours indicator starts flashing.

3. Press the or button to set the

hours.

4. Press the button to save the

setting.

Fig. 9

The minutes indicator starts flashing.

5. Press the or button to set the

minutes.

6. Press the button to save the

setting.

Fig. 10

5.4 Settings

Settings

The appliance is pre-set at the factory. The default language is German.

To set other options, follow the setting steps in the table below or contact the

service department.

109901 23 / 30

Installation and operation

EN

The day of the week indicator starts

flashing.

7. Press the or button to set the

day of the week.

8. Press the button to save the

setting.

Fig. 11

The overrun day indicator starts flashing.

9. Press the or button to set the

overrun day.

10. Press the button to save the

setting.

Fig. 12

The regeneration time indicator starts

flashing.

11. Press the or button to set the

regeneration time.

12. Press the button to save the

setting.

Fig. 13

When the maintenance time arrives, the

informal indicator and alarm will alternate

in the screen.

Fig. 14

24 / 30 109901

Installation and operation

EN

13. Press the button to abort the

alarm and return to the home screen.

Fig. 15

The water hardness indicator starts

flashing.

14. Set the degree of water hardness (dH)

on the inlet by pressing the or

button.

15. Press the button to save the

setting.

Fig. 16

The electric power indicator flashes.

16. Press the button to switch the

acoustic signal off when connected to

the electric power supply.

Fig. 17

109901 25 / 30

Installation and operation

EN

17. In the home screen, press the

button for 3 seconds to activate the

holiday mode.

A message appears in the display as

shown on the left.

18. Press the button again to switch

the message off.

Fig. 18

Manual regeneration initiation

19. Press the button in the home

screen for 5 seconds.

The control valve initiates regeneration

immediately.

Press the button again to proceed to

the next stage of the cycle.

Fig. 19

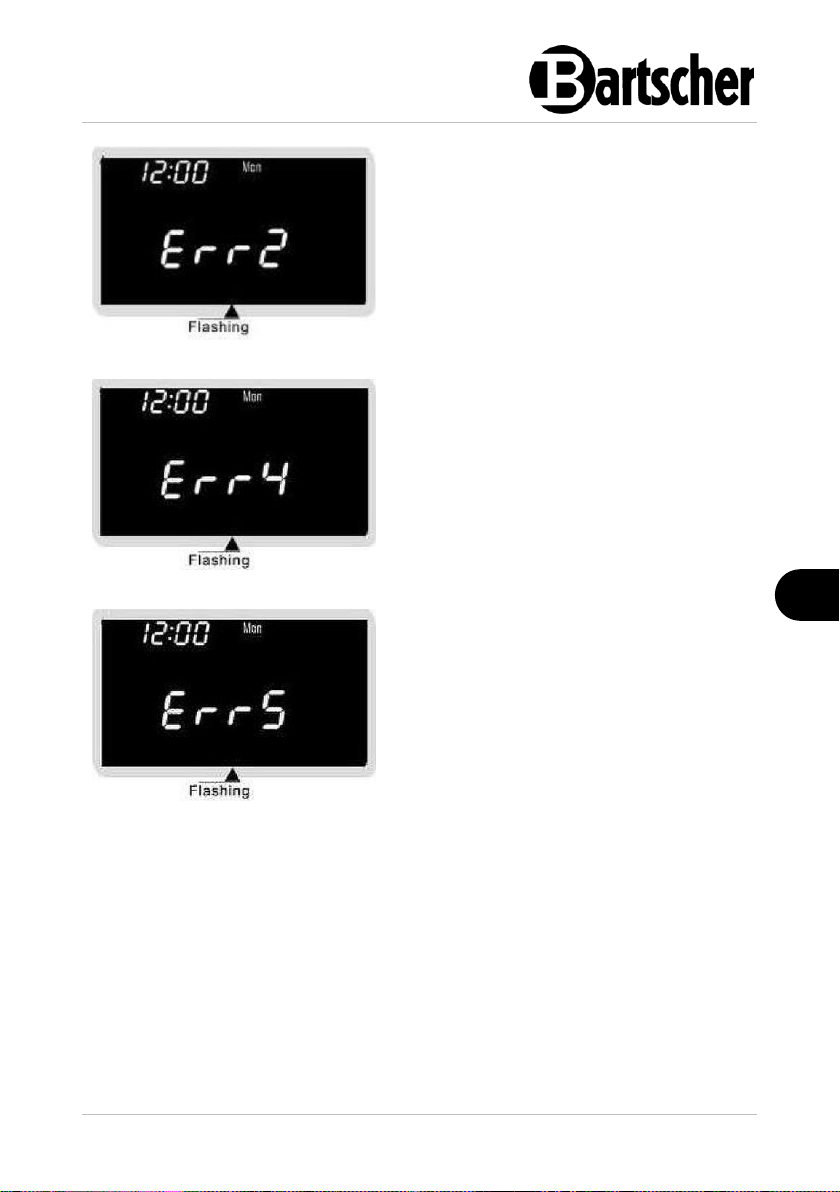

Output position cannot be located

Fig. 20

Automatically Detect and Store System Errors

The control valve automatically displays all detected system errors and warns the

user via the display. The details are as follows:

26 / 30 109901

Installation and operation

EN

The optical sensor does not receive a

signal

Fig. 21

The electric motor is blocked or locking

the wrong starting position

Fig. 22

Digital display is not well connected to the

control valve (cable and radio)

Fig. 23

109901 27 / 30

Cleaning and Maintenance

EN

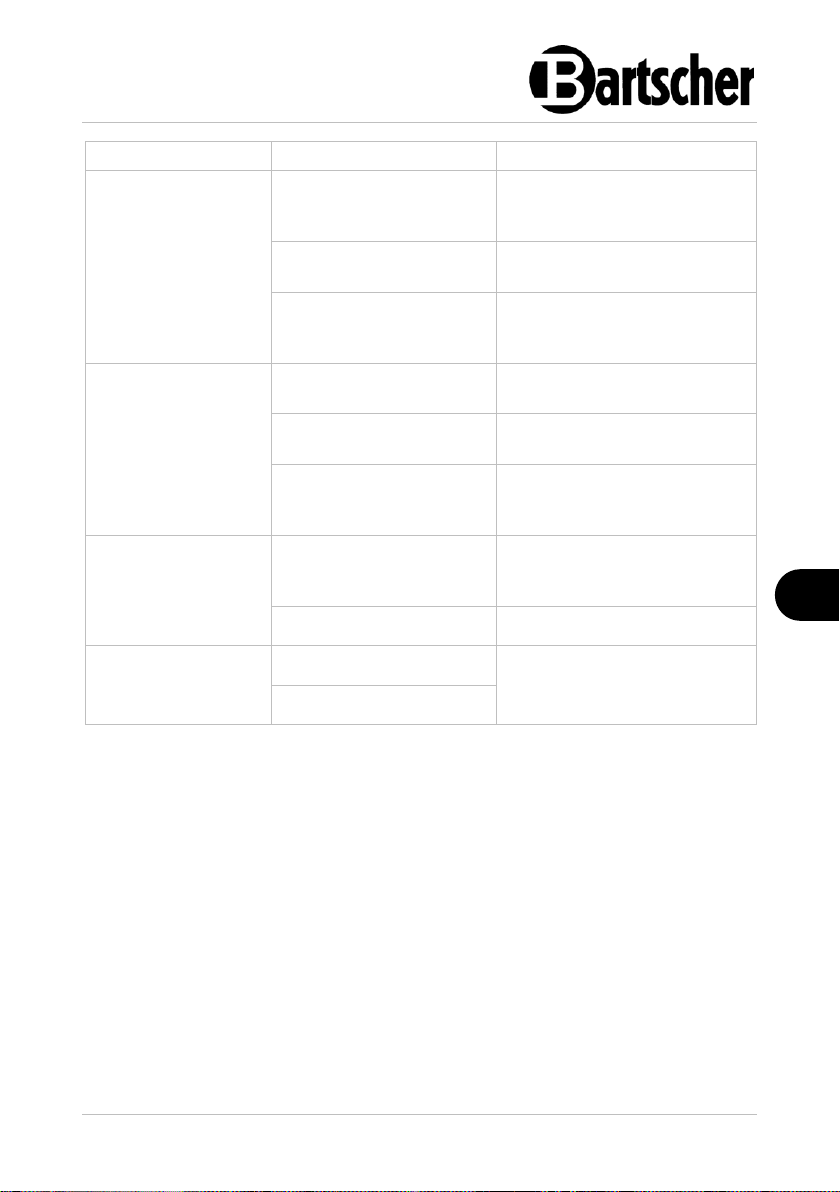

Malfunction

Possible Cause

Solution

The controller does

not automatically

perform regeneration

Disconnect the meter

cable

Reattach the meter cable

Damaged transformer

Replace the transformer

Damaged controller or

sensor

Contact the service company

Replace or repair the parts

Hardness of treated

water is higher than

the setting

Bypass valve is not in

operating position

Move the bypass valve to the

operating position

Incorrectly installed water

supply line and/or drain

line

Correctly install water supply

line and/or drain line

6 Cleaning and Maintenance

1. Check the water treatment device regularly.

2. Check the tightness of the connections. If the connections or seals are leaking,

remove them, and if necessary, replace them.

3. Check hoses for kinks; kinked hoses should be replaced.

4. Hoses should be replaced regularly after a maximum of 5 years, or sooner if

leaking.

5. Do not use caustic chemicals, cleaning solutions or detergents for cleaning.

6. Have the controls maintained and the entire appliance serviced by a qualified

specialist every 3 years.

7 Possible Malfunctions

Mögliche

The table below contains descriptions of possible causes and solutions to

malfunctions or errors during operation of the appliance. When malfunction cannot

be removed, contact the technical service.

In such a case, provide article number, model name and serial number. These data

may be found in the rating plate.

28 / 30 109901

Possible Malfunctions

EN

Malfunction

Possible Cause

Solution

Hardness of treated

water is higher than

the setting

The hardness of the inlet

water is higher than the

setting

Reset the water hardness at

the water inlet

Resin is contaminated

and unsuitable

Contact service and have the

resin replaced

Insufficient salt

concentration or amount

Keep the brine tank filled with

salt at all times. Clean

annually.

The appliance does

not take salt solution

Clogged drain line or flow

regulator

Clean the drain line and flow

regulator

Clogged injector

Clean injector, replace injector

housing

No water in the brine tank

Check that the flow regulator

is not clogged. Make sure the

safety float is not blocked

Salty taste of treated

water

Low pressure in the water

supply line

Install a pressure booster

pump to increase the pressure

in the water supply line

The drain line is blocked

Remove the blockage

Constant flow into

the drain

Internal control leak

Clean valve, reinstall

Contact the service company

Pin stuck in brine

109901 29 / 30

Disposal

EN

Electric appliances are marked with this symbol. Electrical

appliances must be disposed of and recycled in a correct

and environmentally friendly manner. You must not dispose

of electric appliances with household waste. Disconnect the

appliance from the power supply and remove power cord

from the appliance.

8 Disposal

Electrical Appliance

Electrical appliances should be returned to designated collection points.

30 / 30 109901

Loading...

Loading...