PF15E - PF25E - PF40E

PF15E PF25E PF40E

101902

ISTRUZIONI PER L'USO E LA MANUTENZIONE

Istruzioni originali

OPERATION AND MAINTENANCE MANUAL

Translation of the original instructions

IT

EN

MANUEL D’UTILISATION ET D’ENTRETIEN

Traduction des instructions originales

FR

BEDIENUNGS-UND WARTUNGSANLEITUNG

Übersetzung der Original-Bedienungsanleitung

DE

MANUAL DE OPERACIÓN Y MANTENIMIENTO

Traducción de las instrucciones originales

ES

MANUAL DE OPERAÇÃO E MANUTENÇÃO

Tradução das instruções originais

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ И ТЕХНИЧЕСКОМУ ОБСЛУЖИВАНИЮ

Перевод оригинальных инструкций

Cod. EM1081BCV0 - 01/2023

PT

RU

AR

MEANING OF SYMBOLS

Meaning of the danger and hazard symbols used in this

manual

Each of the symbols used in this manual correspond to a specic given meaning.

IT

EN

FR

l

a

f

d

WARNING

To indicate particularly important and sensitive operations

which, if not correctly performed, could damage the equipment and/or materials used by it.

CAUTION! HAZARD

To indicate operations which may cause injury of a generic nature, or which may cause malfunctions or damage to the equip-

ment and/or materials used by it, if not carried out correctly;

they therefore require due attention and adequate preparation.

CAUTION! ELECTRICAL HAZARD

To indicate operations which may cause injury from electri-

cal accidents, or which may cause malfunctions or damage to

the equipment and/or materials used by it, if not carried out

correctly; they therefore require due attention and adequate

preparation.

IT IS PROHIBITED TO

To indicate operations which MUST NOT be performed.

DE

Compliance

The equipment complies with the necessary directives for proper placing on the market. The full text of the declarations of conformity is provided with the documentation

ES

supplied with the equipment.

PT

RU

AR

28

INDEX

Table of contents

1 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

1.1 Important safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.1.2 Prohibitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.2 Symbols on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 Equipment presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.2 Working environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3 Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.1 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3 Using the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 Product receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2 Transport and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.3 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3.1 Preliminary cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.3.2 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.3.3 Water connection (PF40E models only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.4 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.1 Description of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.2 Extruder die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.3 Electric knife (optional for PF25E - standard for PF40E) . . . . . . . . . . . . . . . . . . . . . . 45

3.4.4 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Cleaning the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Cleaning at the end of the process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.1 Removing components for easier cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.2 Cleaning the electric knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2 Long periods of inactivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5 Equipment maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1 Scheduled maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1.1 Scheduled maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2 Extraordinary maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3 Possible operating faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

IT

EN

FR

DE

ES

PT

29

RU

AR

SAFETY

1 SAFETY

1.1 Important safety information

1.1.1 General warnings

IT

EN

FR

DE

ES

PT

RU

l

WARNING

– This manual is the property of the equipment manufacturer;

the reproduction or transmission of its contents to third par-

ties is prohibited. All rights reserved. It is an integral part of

the product; make sure it is always supplied with the equipment, even if sold/transferred to another owner, so that it

can be consulted by the user or by authorised personnel for

maintenance and repairs. Photographs and drawings are

provided as examples. The manufacturer may make changes

without prior notice as part of its policy of ongoing product

development and updating.

– Read this manual carefully before using the equipment

to ensure safe operation.

– The product is delivered in a single package. Ensure the sup-

ply is intact and contact the local distributor that sold you the

equipment if anything is damaged or missing.

– If the packaging is damaged, inform the carrier and the sup-

plier promptly of the issue.

– The equipment is designed to knead and extrude dough in

dierent formats. Any contractual and extra-contractual liability of the manufacturer for damage caused to people, an-

imals or property by adjustment or maintenance errors or

improper use is excluded.

– This equipment is not designed for mass or industrial-scale

food production.

– The equipment is not designed to be used in locations ex-

posed to atmospheric agents.

– For proper equipment use, place it in a stable position on a

strong, stable, level surface that can be cleaned and sanitised

to avoid the risk of dirt build-up and contamination from

foodstus.

AR

30

SAFETY

– In case of doubt as to the conditions and/or functionalities of

the equipment and its parts, please contact the local distributor for further information.

– The conditions required for proper equipment operation are:

– Ambient temperature no lower than 5°C.

– Relative humidity between 50% (detected at 40°C) and 90% (de-

tected at 20°C).

– Remove any utensils from the equipment before the initial

start-up.

– Place unused utensils on the shelf out of reach of children

and unauthorised people.

– Always stay at a safe distance from the moving parts.

– Following the initial start-up, notify the product supplier of

any faults or malfunctions encountered.

– Provide adequate workplace lighting. Proper lighting is im-

portant to ensure suitably safe working conditions.

– Check the power cable, plug and socket at regular intervals. If

the power cable is damaged, it must only be replaced by the

manufacturer or the local distributor who sold you the equip-

ment, or by personnel authorised to carry out maintenance

and repairs.

– Carry out the following as a minimum if the equipment is un-

used for a long period:

– set the main equipment switch to “OFF”

– remove the power plug from the socket. If the plug is not eas-

ily accessible, disconnect the omnipolar switch relating to the

socket to which the equipment is connected

– empty it completely and clean it.

– Only use original spare parts or those approved by the man-

ufacturer to prevent causing any damage to the product.

– If a qualied person detects or suspects a fault that could

compromise safe use, the equipment must be stopped immediately and may only be used again after repairs are car-

ried out.

IT

EN

FR

DE

ES

PT

RU

31

AR

1.1.2 Prohibitions

SAFETY

IT

EN

FR

DE

ES

PT

RU

AR

d

IT IS PROHIBITED TO

– DO NOT make changes to and/or attempt to repair the prod-

uct. Making changes will void the equipment Declaration of

Conformity. The user alone is liable for any damage arising

from improper use. Any repairs must be carried out by a

qualied technician.

– DO NOT leave the equipment exposed to atmospheric agents.

– DO NOT obstruct the equipment vents.

– DO NOT touch the equipment with bare feet or parts of the

body which are wet/damp. If current dispersion is detected

on contact with metal parts of the equipment, turn o the

switch, unplug the equipment and contact an authorised

dealer.

– DO NOT allow children or persons with reduced abilities or

who do not have the required experience or knowledge to

use the equipment, unless they are supervised by a qualied

person responsible for their safety.

– DO NOT allow children to play with the equipment.

– DO NOT leave the packaging material in the environment or

within reach of children as it may be a potential source of

hazard. Dispose of it as required by current legislation.

– DO NOT remove any entangled material from the equipment

when it is running, or introduce foreign material during the

work cycle.

– DO NOT use the equipment if its electrical connections are

damaged. This may cause a dangerous short-circuit.

– DO NOT use the equipment if its safety guards are not cor-

rectly positioned or in perfect condition.

– DO NOT place anything on the equipment when it is in oper-

ation or in standby.

– DO NOT use the equipment in an improper way.

– NEVER consume alcoholic beverages or medication which

could cause tiredness and/or drowsiness before and during

work.

– DO NOT force the equipment while it is running. Always use

it under suitable operating conditions.

32

SAFETY

– DO NOT remove or damage any nameplate or safety sign on

the equipment.

– NEVER pull, disconnect or twist electrical wiring which pro-

trudes from the appliance, even if the latter is isolated from

the electrical power supply.

1.2 Symbols on the equipment

Safety pictograms are applied to the equipment at points where RESIDUAL RISKS exist.

The pictograms and their meanings are listed below.

Electrical hazard: indicates that the mains power supply must be cut (or

the plug removed) before carrying out any cleaning or maintenance.

IT

33

EN

FR

DE

ES

PT

RU

AR

EQUIPMENT PRESENTATION

2 Equipment presentation

2.1 Identication

The equipment is tted with a nameplate stating the product data. Ensure the nameplate is tted. If not, inform the manufacturer and/or dealer immediately. Equipment

without a nameplate must not be used, or the manufacturer will forfeit all liability.

1

6

2

3

5

4

1 Manufacturer identication

2 CE marking of conformity

IT

3 Year of manufacture

4 Technical data

5 Serial number

EN

6 Equipment model

FR

l

WARNING

Products without a nameplate are to be considered anonymous and potentially hazardous.

DE

2.2 Working environment

The equipment can operate in locations with the following environmental conditions:

ES

– ambient temperature: from +4°C to +40°C

– humidity: max 90%

– lighting: the location must be suciently lit (see the applicable technical standards

PT

RU

in the country of use)

– altitude: max 2000 m above sea level (contact the manufacturer for use above this

altitude).

AR

34

EQUIPMENT PRESENTATION

2.3 Technical data and dimensions

Description PF15E PF25E P40E U/M

Power 0,25 (0,33) 0,37 (0,5) 0,75 (1) kW (Hp)

Electrical power supply 230/1/50Hz 230-400V/3/50Hz V/Ph/Hz

Tank capacity 1,5 2,5 4 kg

Maximum hourly output (*) 5 8 13 kg/h

Extruder die diameter Ø 50 Ø 57 mm

Equipment dimensions (LxDxH)

Net weight 16 35 48 kg

Type of installation Worktop installation

Noise level < 70 dB (A)

(*) Rough estimate, output depends on type of extrusion and our used.

253 x 472.5 x

316-450

2.4 Description

“Fresh pasta machines” are designed and manufactured to knead and extrude dough

in dierent formats for human consumption.

The equipment is for professional use and is to be installed in commercial settings

(bars, pizzerias, restaurants, etc.). No special training is required, but knowledge and

skills specic to the hospitality sector are necessary.

285 x 540 x

420-540

305 x 600 x

525-625

mm

l

WARNING

Any use other than that indicated by the manufacturer is to be

considered IMPROPER USE.

The equipment is made from selected construction materials suitable for guaranteeing maximum hygiene, oxidation resistance, considerable energy saving and safe operation.

All food contact parts are made from suitable materials.

35

IT

EN

FR

DE

ES

PT

RU

AR

EQUIPMENT PRESENTATION

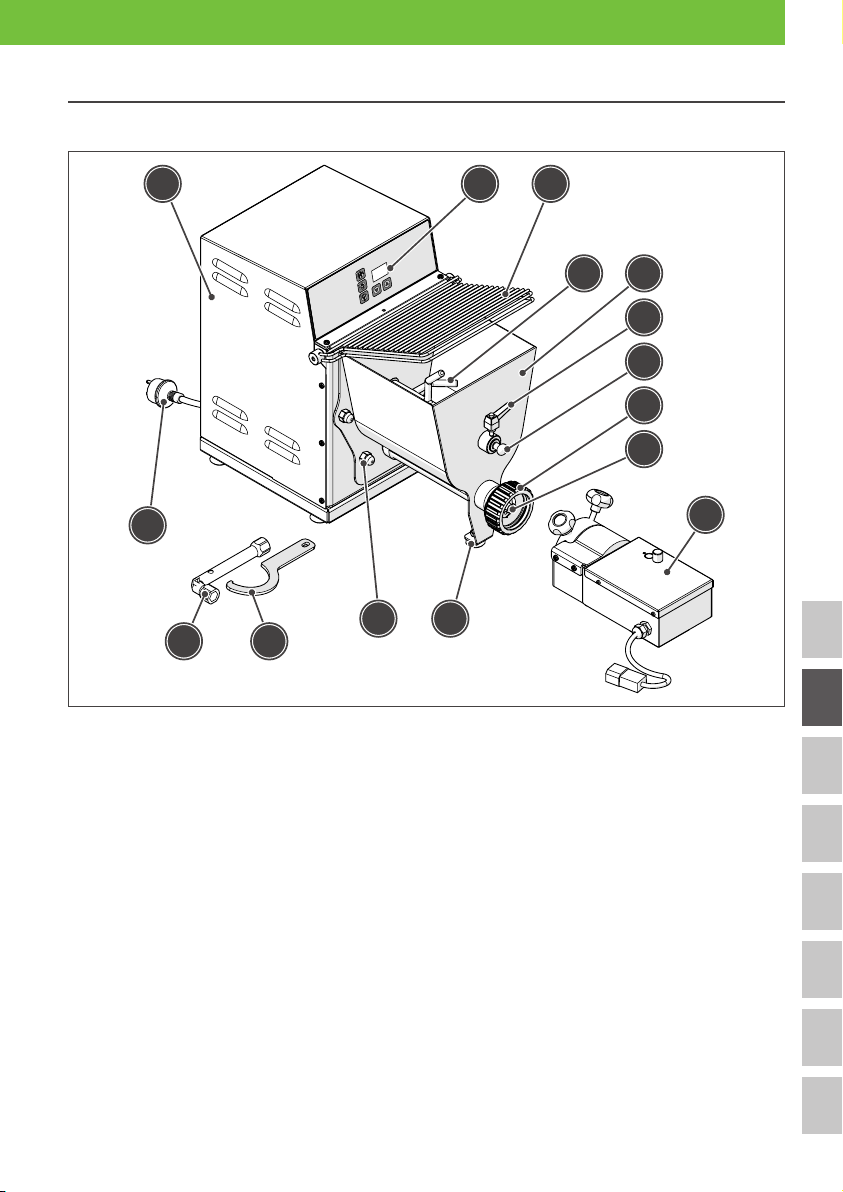

2.4.1 Main components

PF15E

1 2

3 4

5

14

IT

1213

1011

EN

1 Guard covering electrical parts

2 Tank cover tted with safety device that stops the equipment when opened

FR

3 Dough kneader

4 Tank for containing the food to be kneaded

5 Kneader locking pin

DE

6 Kneader alignment shaft

7 Ring nut for locking die

8 Food propeller

ES

9 Adjustable feet for levelling the equipment on the worktop

10 Release nuts for removing the tank

11 Function selector (knead - STOP/START cycle - extrude)

PT

12 Spanner for loosening the ring nut

13 Socket wrench for loosening the tank nuts

14 Power plug

RU

6

7

8

9

AR

36

PF25E

EQUIPMENT PRESENTATION

1 3

2

4 5

6

7

8

9

15

10

1112

1314

1 Guard covering electrical parts

2 Function selector (knead - STOP/START cycle - extrude)

3 Tank cover tted with safety device that stops the equipment when opened

4 Dough kneader

5 Tank for containing the food to be kneaded

6 Kneader locking pin

7 Kneader alignment shaft

8 Ring nut for locking die

9 Food propeller

10 Electric knife for cutting the pasta (optional)

11 Adjustable feet for levelling the equipment on the worktop

12 Release nuts for removing the tank

13 Spanner for loosening the ring nut

14 Socket wrench for loosening the tank nuts

15 Power plug

IT

EN

FR

DE

ES

PT

RU

37

AR

PF40E

EQUIPMENT PRESENTATION

1 3

2

17

IT

12141516

13

EN

1 Guard covering electrical parts

2 Function selector (knead - STOP/START cycle - extrude)

3 Tank cover tted with safety device that stops the equipment when opened

FR

4 Dough kneader

5 Tank for containing the food to be kneaded

6 Kneader locking pin

DE

7 Kneader alignment shaft

8 Ring nut for locking die

9 Food propeller

ES

10 Electric knife for cutting the pasta (optional)

11 Water circuit for cooling the extruder

12 Adjustable feet for levelling the equipment on the worktop

13 Release nuts for removing the tank

PT

14 Spanner for loosening the ring nut

15 Socket wrench for loosening the tank nuts

16 Pipes for water circuit connection

RU

17 Power plug

11

4 5

6

7

8

9

10

AR

38

USING THE EQUIPMENT

3 Using the equipment

3.1 Product receiving

The equipment is delivered in a single package, protected by a cardboard box and

stabilised with impact-resistant material to ensure it stays intact.

The package may be fastened to a pallet depending on the equipment characteristics

and to make it easier to handle.

The following material is contained in a plastic bag inside the package:

– Spanner for loosening the ring nut

– Socket wrench for loosening the tank nuts

– Pipes for water circuit connection (PF40E models only)

– Electric knife for cutting the pasta (standard for PF40E models, optional for PF25E

models).

l

The equipment is provided with the instructions and documentation summarised in

chapter “6 Attachments” on page 53.

l

WARNING

On receiving the equipment, check all components are intact.

If any parts are damaged or missing, contact your local dealer

to agree on how to proceed.

WARNING

All documentation provided with the equipment must be carefully read and stored.

3.2 Transport and handling

a

CAUTION! HAZARD

– The equipment must be transported by professionally quali-

ed personnel, taking care to avoid causing any damage to its

parts by impact or stresses caused by incorrect lifting.

– The warranty does not cover damage to the equipment

caused during transport and handling.

– Repairs or replacements of damaged parts are to be paid

for by the customer and must be carried out by personnel

authorised by the manufacturer using solely original spare

parts.

IT

EN

FR

DE

ES

PT

RU

39

AR

USING THE EQUIPMENT

– The packed product must be handled according to its charac-

teristics (weight, dimensions, etc.). If the weight and dimensions are small, the product can be handled manually. Otherwise, suitable lifting gear must be used.

– Manual lifting must be carried out by at least two people.

Once the packing is removed, the equipment must be handled following the loading

and unloading instructions stated on the packing.

d

IT IS PROHIBITED TO

leave the packaging material in the environment or within

reach of children as it may be a potential source of hazard.

Dispose of it as required by current legislation.

3.3 Initial start-up

l

IT

EN

FR

DE

ES

PT

WARNING

– The initial start-up must be carried out by authorised, ex-

pert personnel who must ensure in advance that the power

supply line complies with current laws, standards and spec-

ications in force in the country of use. Checks must be run

to ensure the electrical installation is properly earthed and

the line voltage and frequency match the data stated on the

nameplate.

– Before starting the equipment, check that the chosen loca-

tion meets the requirements stated in section “2.2 Working

environment” on page 34.

– Check that the work surface is able to withstand the

weight and characteristics of the equipment, that it is

stable, level, and can be easily cleaned to avoid the risk

of dirt build-up and contamination from foodstus. Use

the adjustable feet to level the equipment.

– Failure to follow these instructions exposes the user to the

risk of equipment failure and accidents arising from direct or

indirect contact.

RU

AR

40

USING THE EQUIPMENT

f

3.3.1 Preliminary cleaning

Clean and sanitise the equipment before use.

f

l

CAUTION! ELECTRICAL HAZARD

– Harm to property, animals and people caused by the ab-

sence of an earth plate is not covered by the warranty and all

liability will fall entirely on the operator who failed to check

the presence of the earth plate and a correctly installed and

calibrated dierential safety switch.

– If an adapter is used for the electric socket, its characteristics

must be checked to ensure they are not below those of the

equipment.

– Never use multiple sockets.

CAUTION! ELECTRICAL HAZARD

Before carrying out any cleaning, always make sure the equipment is disconnected from the power supply.

WARNING

Only use suitable cleaning products. Never use corrosive or

ammable cleaning products or products containing substances harmful to human health. Do not use substances designed

for cleaning and polishing silver, brass or other unapproved

products.

IT

EN

3.3.2 Electrical connection

f

CAUTION! ELECTRICAL HAZARD

The machine’s mains electrical connection and related preliminary test must be carried out solely by a specialised installer

with proper training and tools.

FR

DE

ES

PT

RU

AR

41

USING THE EQUIPMENT

21

To connect the equipment to the mains, simply insert the plug (1) into the prepared

socket (2).

3.3.3 Water connection (PF40E models only)

PF40E models are equipped with a liquid cooling system that prevents the union and

ring nut from overheating while extruding the pasta. This cooling system prevents the

dough inside the union from overheating and losing the right consistency.

IT

EN

OUT

IN

1

2

FR

To connect to the water supply:

– connect the water inlet pipe (1) provided to the water supply at one end and to the

DE

ES

PT

“IN” quick-t coupling on the back of the equipment

– connect the water outlet pipe (2) provided to a drain at one end and to the “OUT”

quick-t coupling on the back of the equipment

– open the tap slowly to check there are no leaks.

To connect the pipes to the quick ts, simply push the pipe all the way into the hole and

then pull it towards you to check it is secure.

To remove the pipes, simply push the movable part around the quick t all the way in

and then pull the pipe out towards you.

RU

AR

42

USING THE EQUIPMENT

l

WARNING

Install a stopcock upstream of the water inlet.

3.4 Use

a

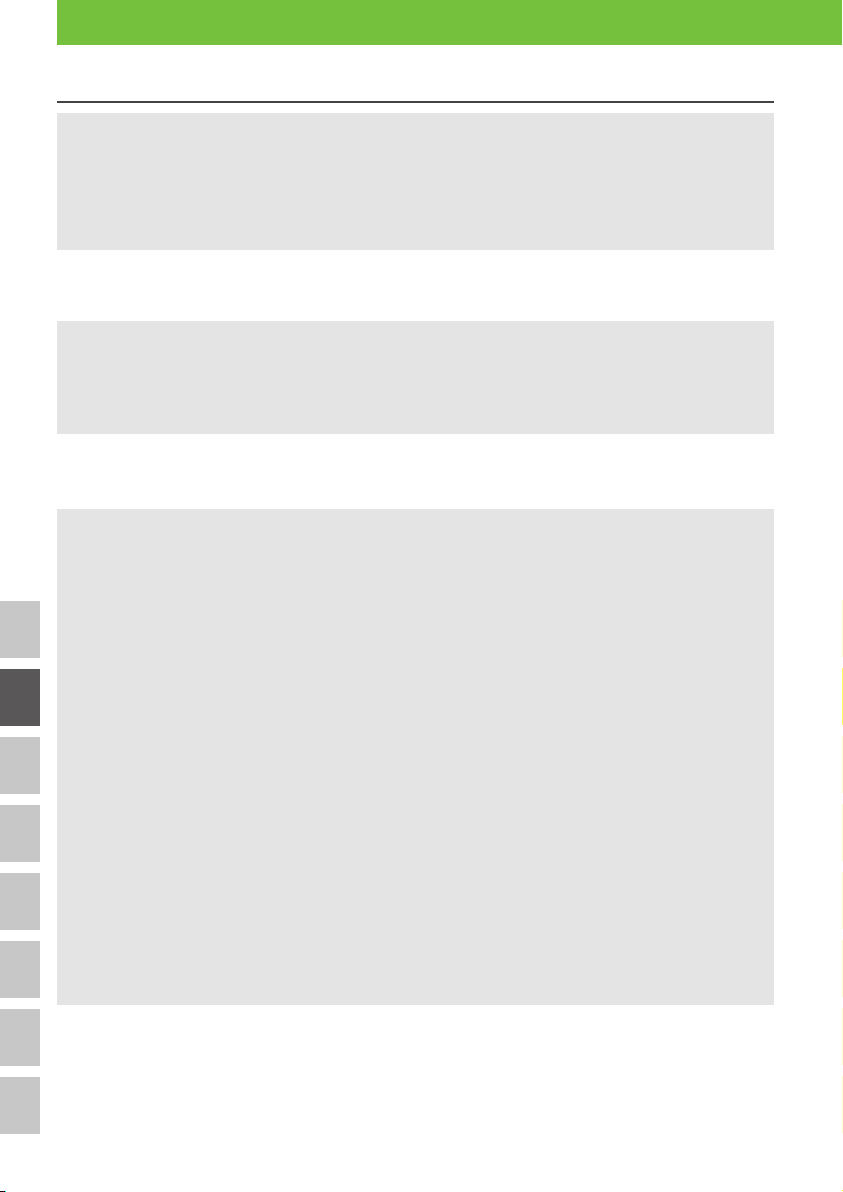

3.4.1 Description of controls

PF15E

CAUTION! HAZARD

– Before using the equipment, ensure that the top guards are

intact and the interlock is ecient. Do not attempt to remove

the interlock or tamper with it.

– Never run the equipment when it is empty.

– Do not smoke or use open ame appliances in the proximity

of the equipment.

1

2

IT

EN

3

1 Kneading cycle selector (press repeatedly to set the kneading cycle timer)

2 Start/stop cycle selector: starts or stops the kneading cycle

3 Extrusion cycle selector.

The LED at the side of selectors (1) and (3) indicates the function currently active. The

LED at the side of selector (2) indicates the power supply is on.

43

FR

DE

ES

PT

RU

AR

USING THE EQUIPMENT

PF25E - PF40E

1 524 3

1 Extrusion cycle selector

2 Start/stop cycle selector: starts or stops the kneading cycle

3 Display: displays the time during the kneading cycle

4 Kneading cycle selector

5 Set timer duration buttons.

The LED at the side of selectors (1) and (4) indicates the function currently active. The

LED at the side of selector (2) indicates the power supply is on.

IT

l

WARNING

The EXTRUSION cycle only activates after at least one minute

of kneading.

EN

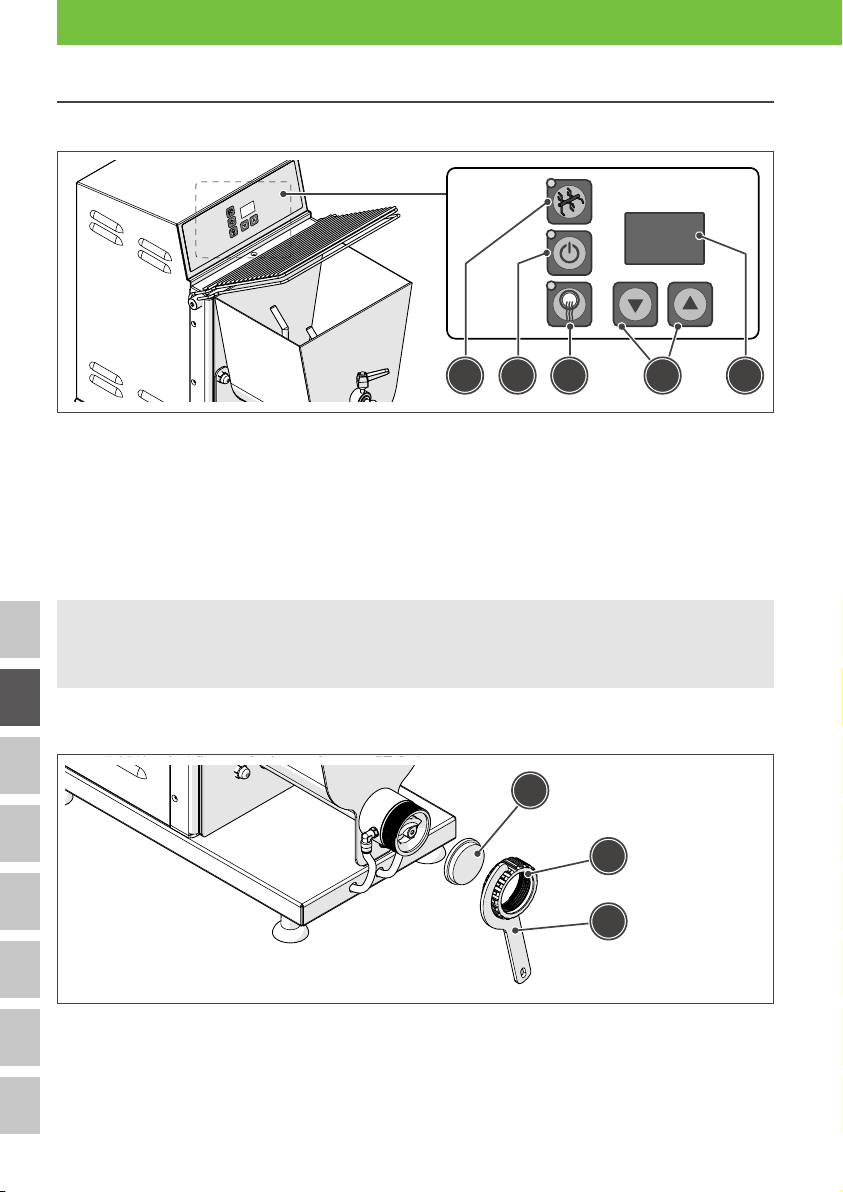

3.4.2 Extruder die

FR

3

DE

ES

PT

To install or replace the extruder die:

RU

– unscrew ring nut (1) using the spanner (2) provided

– replace the extruder die (3) with the one suitable for the selected process

– reposition and tighten ring nut (1).

AR

44

1

2

USING THE EQUIPMENT

3.4.3 Electric knife (optional for PF25E - standard for PF40E)

1

3

2

67

To install the electric knife:

– check that the ring nut (2) is properly tightened

– position the knife group (1) on the ring nut (2) and secure it by tightening the two

knobs (3)

– plug the knife’s power connector (4) into the socket (5).

To activate the knife:

– check that the equipment is on and the tank cover is closed

– press the button (6)

– turn the regulator (7) to change the cutting speed (depending on the selected pro-

cess)

– press the button (6) again to stop the knife.

l

WARNING

5 4

– The knife stops whenever the equipment stops.

– If the knife is to be used for the rst time, before installing it

remove the protective lm and clean it thoroughly using suitable cleaning products. Never use corrosive or ammable

cleaning products or products containing substances harmful to human health.

IT

EN

FR

DE

ES

3.4.4 Use

The main phases for normal equipment use are listed below.

– Fit the utensils for the chosen process (for extruding see section “3.4.2 Extruder die”

on page 44, to use the knife see section “3.4.3 Electric knife (optional for PF25E - standard for PF40E)” on page 45).

– Lift the tank cover

– Add the our and then the liquid (do not add the liquid rst as it may leak out of the

extrusion holes)

– Close the tank cover

45

PT

RU

AR

USING THE EQUIPMENT

KNEADING CYCLE

– Select the kneading cycle using the selector

– For models with a DISPLAY: a ashing number shows on the display indicating the

duration of the kneading cycle in minutes. The time can be set using the designated

buttons

– Start the kneading cycle using the START CYCLE selector

– For models with a DISPLAY: the minutes remaining until the end of the cycle are

shown

– During the kneading cycle, the equipment can be stopped by using the STOP CYCLE

selector or lifting the tank cover. This can be done to correct the dough consistency

(if necessary) by adding our or liquid to obtain the granular dough needed for ex-

trusion. The kneading cycle lasts roughly 8-10 minutes. The equipment only resumes

the work cycle if the cover is lowered and the START CYCLE selector is used. Continue

until the dough reaches the right consistency

– Stop the kneading cycle using the STOP CYCLE selector

EXTRUSION CYCLE

– Select the extrusion cycle by pressing and holding the designated selector for 3 sec-

onds

– For models with a DISPLAY: two dashes (- -) appear on the display as this is a man-

ual function

– Start the extrusion cycle using the START CYCLE selector and check the desired type

of pasta exits the extrusion holes

– For models with a DISPLAY: the number of minutes since the motor started are

IT

shown on the display

– At the end of the process, stop the extrusion cycle using the STOP CYCLE selector.

EN

l

FR

WARNING

The EXTRUSION cycle only activates after at least one minute

of kneading.

DE

ES

PT

RU

AR

46

CLEANING THE EQUIPMENT

4 Cleaning the equipment

f

l

CAUTION! ELECTRICAL HAZARD

Before carrying out any cleaning, always make sure the equipment is disconnected from the power supply.

WARNING

– All cleaning operations must be carried out by qualied per-

sonnel who have read this manual and been trained in the

equipment’s operation.

– Only use suitable cleaning products. Never use corrosive or

ammable cleaning products or products containing substances harmful to human health. Do not use substances

designed for cleaning and polishing silver, brass or other unapproved products.

– Do not wash the equipment using a pressurised, spray or im-

mersion device.

– Do not use steam utensils to clean the equipment.

– Do not use sponges, abrasive pads or utensils previously

used to clean metals or metal alloys.

– Ensure the equipment is completely empty before cleaning.

– How often the equipment is cleaned depends on the use en-

vironment and the type of foodstu processed.

– Never leave the equipment dirty between processes.

IT

EN

FR

4.1 Cleaning at the end of the process

At the end of each process the equipment must be properly cleaned to remove any

food residue from its surfaces.

Cleaning can be carried out by hand or using a dishwasher.

The outer surfaces can be wiped with a soft damp cloth or sponge.

Clean the work surface and all surrounding areas thoroughly.

47

DE

ES

PT

RU

AR

CLEANING THE EQUIPMENT

4.1.1 Removing components for easier cleaning

Some components can be removed for easier cleaning.

1

4

2

3

7 6 5

IT

8 9

EN

To do this:

– lift the tank protection (1)

– loosen clamp (2) and remove shaft (3)

FR

– take out kneader (4)

– loosen and remove ring nut (5)

– remove die (6) and take out propeller (7)

– remove nuts (8) and remove tank (9).

DE

WARNING

The dies are not dishwasher safe and must be washed by hand.

ES

l

After being used, they must be soaked in hot water to prevent

the formation of dried dough.

PT

After washing the removed components by hand, they can be placed in a dishwasher

(with the exception of the dies which must only be washed by hand). If cleaning by

hand, the components can be soaked in hot water to make it easier to remove dough

RU

residue.

After cleaning, check that all components are perfectly clean and dry, then ret them

in the reverse order in which they were removed.

AR

48

CLEANING THE EQUIPMENT

l

4.1.2 Cleaning the electric knife

The electric knife can be wiped with a soft damp cloth or sponge.

f

d

WARNING

Pay attention to the top cover after removing the tank. After

removing the tank, the lid must be in the fully open and NOT

closed position.

Comply with the following warnings:

– DO NOT close the lid without the tank;

– DO NOT force or lean on the lid when closing in the absence

of the tank;

– DO NOT place anything on the lid without the tank to prevent

damage to the safety micro-switch.

– After removing the tank, check that the lid is properly opened

until the end of the stroke.

CAUTION! ELECTRICAL HAZARD

Do not put the electric knife under a direct ow of water as its

electrical parts could be damaged.

IT IS PROHIBITED TO

wash the electric knife in the dishwasher.

IT

EN

4.2 Long periods of inactivity

If the equipment is unused for a long period:

– disconnect it from the power supply

– carry out a general cleaning of the equipment

– cover the equipment with a sheet to protect it from dust and dirt.

FR

DE

ES

PT

RU

AR

49

EQUIPMENT MAINTENANCE

5 Equipment maintenance

f

CAUTION! ELECTRICAL HAZARD

Before carrying out any maintenance, always make sure the

equipment is disconnected from the power supply.

5.1 Scheduled maintenance

Regular maintenance is essential for maintaining equipment performance and guaranteeing its safe operation over time.

5.1.1 Scheduled maintenance table

Description Inspection Frequency Action

Check the working area Visual check Daily - Follow the instructions

Clean the machine Visual check Daily

Visual check

Check the safety devices

Daily, before

operation

IT

Functional

check

Daily, before

operation

EN

FR

Check the nameplates and

safety pictograms are intact

Visual check Weekly

DE

on cleaning the equipment and working area

- Carry out a visual

inspection to check the

safety and protective

devices are intact

- Run a functional check

of the safety devices,

interlock and start and

stop elements

- Carry out a visual

inspection to check the

nameplates and safety

pictograms are intact.

If they are illegible or

have come o, request

copies from the manufacturer

ES

PT

RU

AR

a

50

CAUTION! HAZARD

If the safety devices malfunction, are damaged or fail to trip,

disconnect the equipment from the power supply immediately, do not use it and contact the manufacturer.

EQUIPMENT MAINTENANCE

5.2 Extraordinary maintenance

a

CAUTION! HAZARD

– Extraordinary maintenance operations require specic skills

and must be carried out by the manufacturer, who declines

all liability in the event of failure to comply with this instruction.

– Any operations requiring the removal of mechanical parts,

protective devices, safety devices, or access to the electrical

installation or electronic boards must be carried out solely by

the manufacturer.

5.3 Possible operating faults

This section contains solutions to problems that may arise during equipment use.

a

CAUTION! HAZARD

It is important to intervene solely after having read this manual

in detail.

Fault Cause Possible solution

- Check that line voltage reaches the

workplace and that the socket works

- Check that the equipment is correctly

connected to the power supply

- Check that the power supply to the sock-

et is correct and its specications match

those stated on the product nameplate

- Check that the interlock system is closed

and operational

- Check the cover is closed correctly

- Contact the manufacturer

- Switch o and unplug the equipment

immediately. Contact the manufacturer

- If liquid accidentally spills on the electrical parts, DISCONNECT THE EQUIPMENT

FROM THE SOCKET IMMEDIATELY and

contact the manufacturer

The equipment does not start

Unusual noise during operation

Accidental spillage of water or

other liquids on electrical parts

No electrical

power supply

The tank cover

is not closed

correctly

The electric

motor or electronic board is

faulty

Malfunctioning

belt or mechanical parts

Exposure to or

contact with

liquids

IT

EN

FR

DE

ES

PT

RU

AR

51

EQUIPMENT MAINTENANCE

Fault Cause Possible solution

- Check the status of the protective devices (no cracks or deformation caused

by the fall). If the protective devices are

damaged, DO NOT USE THE EQUIPMENT

and contact the manufacturer

Violent impact Accidental fall

- Check the operation of the safety devic-

es. If the safety devices are damaged or

do not work, DO NOT USE THE EQUIP-

MENT and contact the manufacturer

- Check there are no unusual noises or

faults. In the event of unusual noise, DO

NOT USE THE EQUIPMENT and contact

the manufacturer

l

WARNING

If the equipment still does not start after implementing the

suggested solutions, contact the manufacturer.

5.4 Disposal

As with the initial start-up and maintenance operations, equipment disposal at the end

of its lifespan must also be carried out by qualied personnel.

This product is made up of various types of material: some can be recycled; others

IT

must be disposed of. Find out about the recycling or disposal systems provided by the

regulations in your area for this category of product.

EN

a

CAUTION! HAZARD

– Some product parts may contain polluting or hazardous sub-

FR

stances that, if released into the environment, could harm

the environment and human health.

DE

ES

l

– Current local regulations may impose heavy penalties in the

event of improper disposal of this product.

WARNING

As indicated by the adjacent symbol, this product

must not be disposed of with domestic waste. It

PT

must be recycled in accordance with local regulations or returned to the vendor when purchasing a

new equivalent product.

RU

AR

52

ATTACHMENTS

6 Attachments

The following attached documentation is provided with the equipment:

– Usage and maintenance instructions

– Declarations of conformity

– Any other documents for safe equipment use.

l

WARNING

All documentation provided with the equipment must be carefully read and stored.

IT

EN

FR

DE

53

ES

PT

RU

AR

Loading...

Loading...