Q 26 - Q 46

104304 - 104306

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten

Germany

Phone: +49 5258 971-0

Fax: +49 5258 971-120

Technical Support Hotline: +49 5258 971-197

www.bartscher.com

Version: 3.0

Date of preparation: 2024-07-12

Beschreibung

Quick Start Guide

TOUCH

Operation status

LED indicator

status

Standby

every 30”

Storage container full

every 10”

Production cycle start

every 0.5”

Ice production

ON

Alarm blackout

ON 5” + OFF

Cleaning cycle

ON 3” + OFF

ATTENTION! Should subsequent alarms appear, contact the service

company.

Setting

Storage container probe

Standby

phase

3 TIMES

TOUCH

WHITE

RED

Touch

to change settings

After 60” the setting is saved

EN

5

104304 1 / 27

Original instruction manual

1 Safety ............................................................................................................ 2

1.1 Explanation of Signal Words .................................................................... 2

1.2 Safety instructions.................................................................................... 3

1.3 Intended Use ........................................................................................... 5

1.4 Unintended Use ....................................................................................... 5

2 General information ....................................................................................... 6

2.1 Liability and Warranty .............................................................................. 6

2.2 Copyright Protection ................................................................................ 6

2.3 Declaration of Conformity ........................................................................ 6

3 Transport, Packaging and Storage ................................................................ 7

3.1 Delivery Check ......................................................................................... 7

3.2 Packaging ................................................................................................ 7

3.3 Storage .................................................................................................... 7

4 Technical Data ............................................................................................... 8

4.1 Technical Specifications .......................................................................... 8

4.2 List of Components of the Appliance ..................................................... 10

4.3 Operation ............................................................................................... 11

5 Installation and operation ............................................................................ 12

5.1 Installation .............................................................................................. 12

5.2 Operation ............................................................................................... 16

6 Cleaning ...................................................................................................... 20

6.1 Safety Instructions for Cleaning ............................................................. 20

6.2 Cleaning ................................................................................................. 20

7 Possible Malfunctions .................................................................................. 23

8 Disposal ....................................................................................................... 26

Safety

2 / 27 104304

EN

Diese Bedienungsanleitung beschreibt di e Installation, Bedienung und Wartung d es Geräts und gilt als wichtige Inform ationsquelle und Nachschlagewerk. Di e Kenntnis aller enthaltenen Sicherh eitshinweise und Handlungsanweisunge n schafft die Voraussetzung f ür das sichere und sachgerechte Ar beiten mit dem Gerät. Darüber hinaus müs sen die für den Einsatzbereich des Geräts geltenden örtlichen Unfallv erhütungsvorschriften und allgemeine n Sicherheitsbestimmungen eingehalt en werden. Diese Bedienungsanleitung is t Bestandteil des Produkts und muss in unmittelbarer Nähe des Ger äts für das In¬stallations-, Bedienu ngs-, Wartungs- und Reinigungspers onal jederzeit zugänglich auf¬bewahrt werd en. Wenn das Gerät an eine dritt e Person

weitergegeben wird, muss die Bedienungsa nleitung mit ausgehändigt werden.

Read this instruction manual before using and keep it available

at all times!

This instruction manual contains information about installation, operation and

maintenance of the appliance and constitutes an important source of information

and reference guide. The knowledge of all operational and safety instructions

included in this manual is a prerequisite for safe and proper handling of the

appliance. Additionally, accident prevention, occupational health and safety, and

legal regulations in force in the area the appliance is used apply.

Before you start using the appliance, especially before turning it on, read this

instruction manual in order to avoid personal injuries and property damages.

Improper use may cause damage.

This instruction manual forms and integral part of the product and must be stored in

an immediate vicinity of the appliance and be available at all times. The instruction

manual should be transferred together with the appliance.

1 Safety

This appliance has been manufactured in accordance with technical standards

currently in force. However, the appliance may be a source of hazards if used

improperly or contrary to its intended purpose. All persons using the appliance must

consider information included in this instruction manual and observe safety

instructions.

1.1 Explanation of Signal Words

Important safety instructions and warning information are indicated in this

instruction manual with appropriate signal words. You must strictly follow the

instructions, to prevent accidents, personal injuries and property damages.

DANGER!

The signal word DANGER warns against hazards that lead to severe

injuries or death if the hazards are not avoided.

Safety

104304 3 / 27

EN

WARNING!

The signal word WARNING warns against hazards that may lead to

moderate or severe injuries or death if the hazards are not avoided.

CAUTION!

The signal word CAUTION warns against hazards that may lead to

light or moderate injuries if the hazards are not avoided.

, die

IMPORTANT!

The signal word IMPORTANT indicates possible property damages,

which may occur if safety instructions are not observed.

NOTE!

The symbol NOTE indicates subsequent information and guidelines

for the user on usage of the appliance.

1.2 Safety instructions

Electrical Current

• Too high a mains voltage or incorrect installation may cause electric shock.

• The appliance may be connected only if data on the rating plate correspond with

the mains voltage.

• To avoid short-circuit, the appliance should be kept dry.

• If there are malfunctions during operation, disconnect the appliance from the

power supply.

• Do not touch the appliance’s plug with wet hands.

• Never take hold of the appliance if it has fallen into water. Immediately

disconnect the appliance from the power supply.

• Any repairs or housing opening may be carried out by professionals and

relevant workshops only.

• Do not transport the appliance, holding it by the power cord.

• Do not allow the power cord to come into contact with heat sources or sharp

edges.

• Do not bend, pinch nor knot the power cord.

Safety

4 / 27 104304

EN

• Always completely unwind the power cord.

• Never place the appliance or other objects on the power cord.

• Always take hold of the plug to disconnect the appliance from the power supply.

• Check the power cord regularly for damage. Do not use the appliance if the

power cord is damaged. If this cable is damaged, it must be replaced by

customer service or a qualified electrician in order to avoid dangers.

Incorrect operation of the appliance m ay cause fire or explosion hazard due to igniti on of its content.

Fire hazard / flammable materials hazard / explosion hazard!

• Do not use any electric devices in the appliance.

• Do not store nor use petrol or other flammable liquids and gases in the vicinity of

this or any other appliance. Those gases may cause fire or explosion hazard.

• Do not put into the appliance any explosive materials, like sprays filled with

flammable propellants. Contents of containers filled with flammable gases and

liquids may leak in low temperatures, and the contents may catch fire from

sparks generated by an electric appliance. Explosion hazard!

• In the case of coolant leakage, pull the plug from the socket. Remove all

sources of ignition in the vicinity, ventilate room and contact technical service.

Avoid coolant getting in contact with eyes, as it may cause serious eye damage.

• Never use any flammable liquids for cleaning the appliance or its parts. Gases

released may cause fire or explosion hazard.

• In the case of fire, disconnect the appliance from the power supply before

attempting adequate fire-extinguishing actions.

• Never attempt to extinguish fire with water if the appliance is connected to the

power supply. Following extinction of fire, ensure sufficient fresh air inflow.

• Defrosting process may not be sped up with mechanical means or heat energy

sources (candles or heaters) nor with any other means. Vapour produced may

cause short-circuit and too high temperatures may damage the appliance.

• All ventilation slots should not be obstructed during operation.

• Never attempt to damage cooling installation of the appliance.

Safety

104304 5 / 27

EN

Operating personnel

• This appliance is not intended to be used by persons (including children) with

limited physical, sensory or mental capabilities, nor by persons with limited

experience and/or limited knowledge.

• Children should be supervised to ensure that they are not playing with or

switching the appliance on.

Improper Use

• Unintended or prohibited use may cause damage to the appliance.

• The appliance may only be used when its technical condition is flawless and

allows for safe operation.

• The appliance may only be used when all connections are executed according

to rules of law in force.

• The appliance may only be used when it is clean.

• Use only original spare parts. Never attempt to repair the appliance on your own.

• Do not introduce any changes in the appliance nor modify it.

1.3 Intended Use

As described below, every use of the appliance for a purpose differing and/or

diverging from its intended standard use, is prohibited and considered to be an

unintended use.

The following is an intended use:

– Ice cubes preparation.

1.4 Unintended Use

An unintended use may lead to personal injuries or property damages caused by

hazardous voltage, fire or high temperature. The appliance may only be used to

perform tasks described in this instruction manual.

General information

6 / 27 104304

EN

2 General information

2.1 Liability and Warranty

All information and instructions in this instruction manual account for legal

regulations in force, current level of technical engineering knowledge as well as our

expertise and experience, developed over the years. If special models or additional

options are ordered, or state-of-the-art technical solutions were implemented, the

actual scope of delivery of the appliance may, in some circumstances, differ from

descriptions and numerous drawings in this instruction manual.

The manufacturer is not liable for any damages nor faults stemming from:

– failure to observe instructions,

– unintended use,

– technical alterations introduced by the user,

– usage of unapproved spare parts.

We reserve the right to introduce technical modifications to the product, intended for

improvement of the appliance and its performance.

2.2 Copyright Protection

This instruction manual, and texts, drawings and images included in it, as well as its

other components are copyright protected. It is prohibited to reproduce this

instruction manual (including its excerpts), in any form and by any means, and to

use and/or transfer its content to third parties without manufacturer’s written

permission. Violation of the above results in obligation to pay compensation. We

reserve the right to claim further damages.

2.3 Declaration of Conformity

The appliance meets the currently applicable standards and guidelines of the

European Union. We confirm the above in the EC Declaration of Conformity. We

may provide relevant Declaration of Conformity upon request.

Transport, Packaging and Storage

104304 7 / 27

EN

3 Transport, Packaging and Storage

3.1 Delivery Check

Immediately upon reception, check the delivery for completeness and possible

shipping damage. In the case of visible transport damage refuse to accept the

appliance or accept it conditionally. Mark and note the scope of damage in shipping

documents/consignment list of the shipping company and lodge a complaint.

Concealed damage must be reported immediately upon its discovery, as

compensation claims may only be filed within applicable time limits.

If you find that parts or accessories missing, please contact our Customer Service

Department.

3.2 Packaging

Do not dispose of the appliance cardboard box. It may be used to store the

appliance when relocating or when shipping the appliance to our service point in the

case of any damages.

The packaging and its elements are made of recyclable materials. Particularly,

these are: plastic films and bags, cardboard box.

When disposing of the packaging, observe applicable domestic regulations.

Recyclable packaging materials should be recycled.

3.3 Storage

Leave the packaging closed until installation of the appliance; observe external

indications concerning method of placing and storage. Store the packaging in the

following conditions only:

– in closed rooms;

– in dry and dust-free surrounding;

– away from aggressive agents;

– in a location protected against sunlight;

– in a location protected against mechanical shocks.

In the case of extended storage (over three months), make sure you check the

condition of the packaging and the parts regularly. If needed, replace the packaging

with a new one.

Technical Data

8 / 27 104304

EN

4 Technical Data

4.1 Technical Specifications

Name:

Ice-cube maker Q 26

Art. No.:

104304

Material:

CNS 18/10

Ice cube design:

tapered form (hollow taper)

Number of ice cube sizes:

1

Ice cube size (W x D x H), in mm:

32,5 x 29 x 41

Ice cube weight, in g:

21

Ice cubes output / work cycle:

15

Max. output, in kg / h:

25 / 24

Storage container capacity, in kg / in ice

cubes, pcs:

10 / 588

Coolant, amount in kg:

R290 / 0,070

Climate class:

SN

Water connection:

3/4"

Water outlet, Ø in mm:

20

Connected load:

0,265 kW | 220-240 V | 50 Hz

Dimensions (W x D x H), in mm:

400 x 545 x 690

Weight, in kg:

30,9

Technical Data

104304 9 / 27

EN

Name:

Ice-cube maker Q 46

Art. No.:

104306

Material:

CNS 18/10

Ice cube design:

tapered form (hollow taper)

Number of ice cube sizes:

1

Ice cube size (W x D x H), in mm:

32,5 x 29 x 41

Ice cube weight, in g:

21

Ice cubes output / work cycle:

35

Max. output, in kg / h:

45 / 24

Storage container capacity, in kg / in ice

cubes, pcs:

16 / 941

Coolant, amount in kg:

R290 / 0,080

Climate class:

SN

Water connection:

3/4"

Water outlet, Ø in mm:

20

Connected load:

0,36 kW | 220-240 V | 50 Hz

Dimensions (W x D x H), in mm:

500 x 600 x 690

Weight, in kg:

38,8

Version / Characteristics

• Cooling: air-cooled

• Fill level sensor

• Production by means of paddle system

• Control: electronic

• ON/OFF switch / control key

• Indicator light

• Can be integrated

• The set includes: 1 ice shovel

We reserve the right to implement technical modifications.

Technical Data

10 / 27 104304

EN

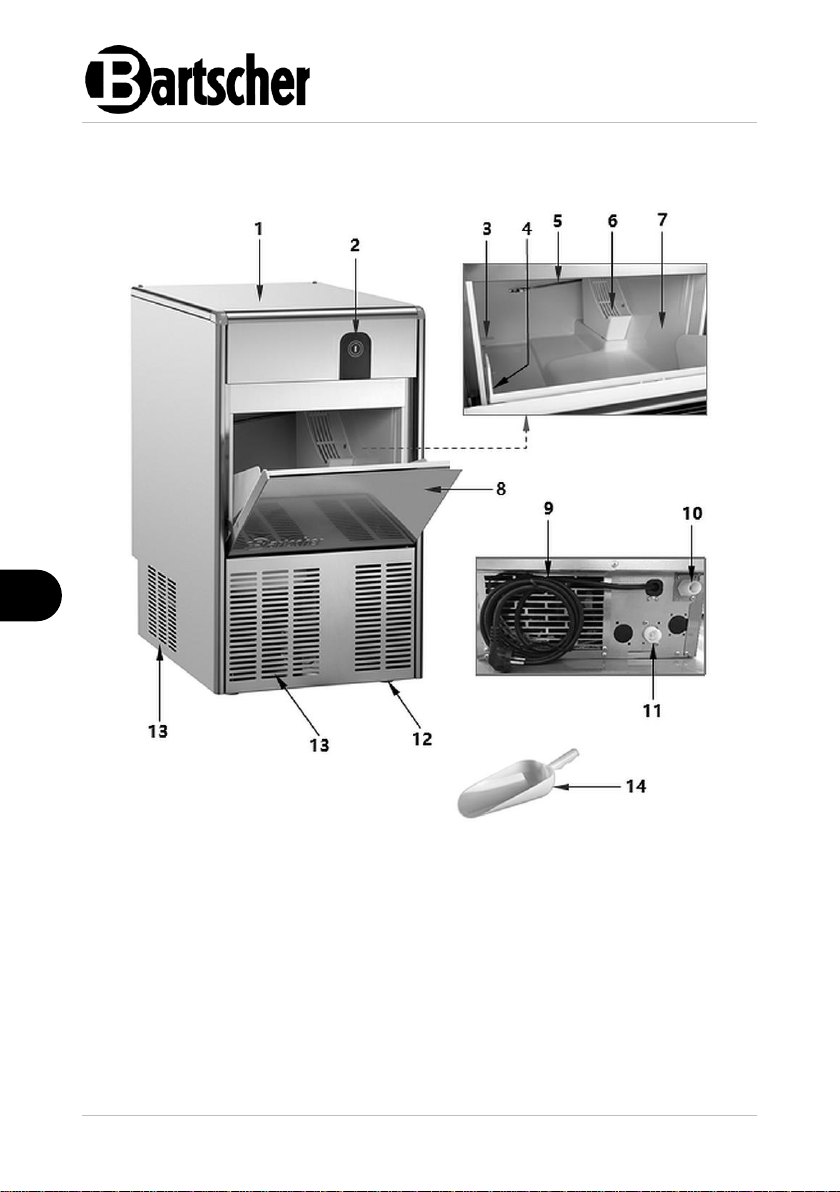

4.2 List of Components of the Appliance

1. Housing

2. Control key

3. Ice shovel holder

4. Water drain opening

5. Temperature probe

6. Water pan

7. Storage container

8. Storage container door

9. Power cord with mains plug

10. Water connection

11. Drain port

12. Feet (4 pcs)

13. Ventilation openings

14. Ice shovel

Technical Data

104304 11 / 27

EN

4.3 Operation

• The production of ice takes place at the terminations (fingers) of the evaporator,

which are plunged in the tank filled with water. Water is constantly stirred by

rotating paddles.

• Water level may be regulated by rotating the micro-float or water sensor through

the designated crevice, located on the right bracket, following screwing the fixing

screw 1 off (Fig. 12). This regulation must be performed with power supply

disconnected.

• When ice cubes reach the expected size, they come into contact wit paddles,

and this spurs vibration of an adequate gear-motor, which powers the microswitch that, in turn, through a relay performs the following actions:

– sending hot gas to the evaporator through the solenoid valve; this makes

ice cubes separate gradually from evaporator's fingers.

– tilting the water tank, which is connected with the gear-motor by means

of a lever.

• After separation ice cubes move to a tilted grate inside the tank and then they

are transported to the storage container's shelf below.

• Water remaining in the pan is collected in a shelf that is located deeper in the

storage container and removed towards the drain.

• After approximately a minute the tank returns automatically to horizontal position

and fills with water to the pre-marked level. In the meantime, hot gas valve

closes again and the production cycle of ice cubes continues regularly. The

entire production cycle, depending on the water and ambient temperature, lasts

for 15–25 minutes.

• The number of ice cubes in the storage container is controlled by electronic

probe, which is located in the storage container. When ice cubes pile and reach

the probe, the appliance automatically stops production of ice cubes. When ice

cubes are removed, the production of ice is continued.

NOTE!

To speed up subsequent production of ice cubes, clear the probe off of

possible ice residue.

Installation and operation

12 / 27 104304

EN

5 Installation and operation

5.1 Installation

CAUTION!

Incorrect installation, positioning, operation, maintenance or misuse of

the appliance may lead to personal injury or property damage.

Positioning and installation, as well as repairs may be performed by

authorised technical service only and in compliance with the applicable

national law.

NOTE!

The manufacturer disclaims all liability and provides no warranty for

damages, which may be attributed to non-observance of regulations or

incorrect installation.

Unpacking / Positioning

• Unpack the appliance, remove all external and internal packaging elements and

shipment safeguards.

CAUTION!

Choking hazard!

Prevent children from accessing package materials, for instance: plastic

bags and EPS.

• If the appliance is covered with a protective film, remove it. Remove the film

slowly, so no glue residues are left. Remove any glue residues with the use of a

suitable solvent.

• Be careful not to damage the rating plate and warning labels fixed on the

appliance.

• Never place the appliance in humid or wet environment.

• Place the appliance in a way making the connections easily accessible, so that

they may be quickly disconnected if such a need arises.

• The appliance should be placed on surfaces that are:

– even, with sufficient bearing capacity, resistant to water, dry and resistant

to high temperatures;

Installation and operation

104304 13 / 27

EN

– sufficiently large, and thus enabling usage of the appliance with no

problems;

– easily accessible;

– well ventilated.

• The appliance may be loaded and unloaded with a forklift truck or a pallet truck,

with the length of over half of the length of the appliance.

• The lifting equipment must be selected according to dimensions of the packed

appliance/components and the weight of the appliance.

• During operation follow all the necessary precautions in order not to damage the

appliance.

• Remove cardboard packaging from the wooden base, on which the appliance is

standing.

• Then lift the appliance with a suitable lifting equipment (lift truck or the like) and

remove he wooden base.

• Place the appliance in a suitable location.

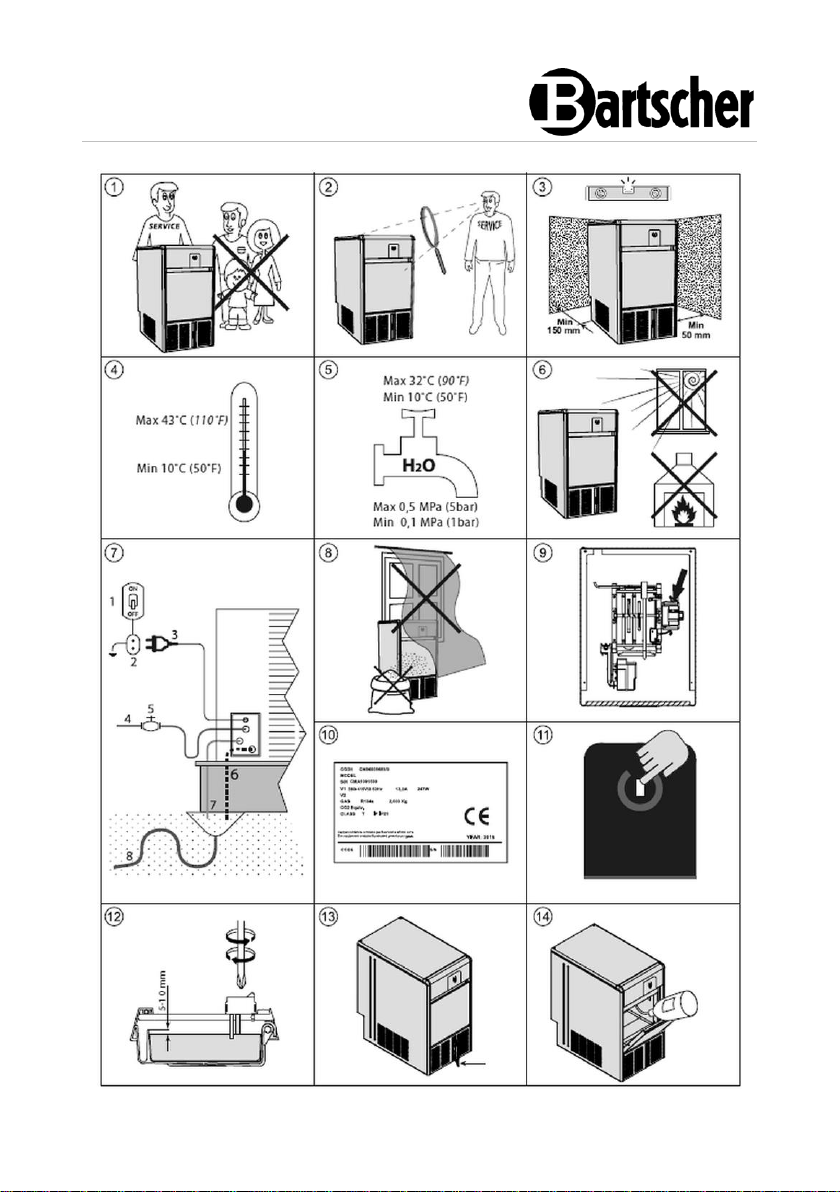

Requirements for Place of Installation

When selecting the place of installation, provide for the following conditions:

– ambient temperature may not drop below 10°C (50°F) and rise above

43°C (110°F);

– water temperature may not be below 10°C (50°F) nor above 32°C (90°F)

(Fig. 4 at the beginning of the operating instructions);

– water supply pressure may not be below 0.1 MPa (1 bar) nor above

0.5 MPa (5 bar). If the pressure exceeds 0.5 MPa, install a pressure

reducer between water supply and the appliance (Fig. 5);

– there may be no heat sources in the vicinity,

– the appliance may not be subject to direct sunlight (Fig. 6);

– the location must be free of dust, as the condenser of the cooling unit

may clog rapidly (Fig. 8);

– the fan of the cooling unit may not be covered (Fig. 8),

– the appliance may not be installed in plunged areas, as in the case of

possible leakages, the coolant will be sinking down (Fig. 15),

– there may be no fuels, flammable nor explosive materials within the

radius of 3 m, and there must be sufficient air circulation provided for

(Fig. 19).

• Maintain minimum clearance from walls and other objects: 150 mm at the rear,

and 50 mm at both sides (Fig. 3).

Installation and operation

14 / 27 104304

EN

• Level the appliance (Fig. 3). If the appliance is not levelled, it may negatively

affect its functionality, as well as water supply.

Remove Transport Safeguards

1. Remove screws fixing the upper cover.

2. Remove the upper cover.

3. Remove transport safeguards of the paddle system motor. Observe indications

on the affixed sticker (Fig. 9).

4. Screw the top cover to the appliance.

Water Connection

1. Install the appliance near a water connection.

ATTENTION!

Connect the appliance only to a supply connection of potable water.

Otherwise install a water purification appliance.

2. Execute water connections before you execute electric connections.

3. Connect the enclosed 3/4” water drain tube to the water connection.

4. Connect the other end of the tube to the water connection at the back of the

appliance.

NOTE!

Due to practical and safety reasons we suggest to integrate a shut-off

valve, which is not a part of the delivery (Fig. 7):

1. ON/OFF switch; 2. Socket; 3. Plug; 4. Water connection; 5. Shut-off valve;

6. Water drain from condenser: water cooling version;

7. Water drain from storage container; 8. Water drain to open water trap.

Water Drain

1. Connect the enclosed water drain tube to the drain connection at the rear of the

appliance.

2. The other end of the water drain tube introduce into the open water trap (Fig. 7).

NOTE!

To provide for perfect water drain, the water drain tube must be routed at

the inclination of at least 3%; at the same time make sure it is not tangled

nor bent.

Installation and operation

104304 15 / 27

EN

Power supply connection

• Verify if technical data of the appliance (see rating plate) correspond with the

local electric power grid specification.

• Connect the appliance to a single, properly grounded mains socket with

protective contact. Do not connect the appliance to a multi-socket.

• The power cord should be laid in a way preventing anyone from threading on it

or tripping against it.

• The maximum allowable tolerance for voltage difference is ±10% of rated value.

• The electric circuit between the appliance and the power supply connection

should be equipped with a suitable multi-polar disconnecting device (Fig. 7),

which is capable of providing distance of contact opening rendering full

separation possible in the conditions of overvoltage category III.

• If in winter the appliance is brought from the outside to a room, leave it for a few

hours to heat up and reach the room temperature before switching it on.

• Before connecting the appliance to the power supply, wait 1 hour for the coolant

to stabilize.

• After a power failure or when the plug is removed from the socket, reconnect the

appliance to the power supply after 5 minutes at the earliest.

• The electric socket should be easily accessi ble so it is possible to quickly discon nect the power cord when necessary. The electric socket should be easily accessi ble so it is possible to quickly discon nect the power cord when necessary. The electric socket should be easily accessi ble so it is possible to quickly discon nect the power cord when necessary.

Installation and operation

16 / 27 104304

EN

5.2 Operation

Preparation of Appliance

1. Remove all accessories from the storage container (water supply tube, water

drain tube, ice shovel, documentation).

2. Before use, clean the appliance observing instructions in section 6 'Cleaning'.

3. Dry the appliance thoroughly.

Indications for User

• If the appliance is installed in an area, where potable water features high salt

content, follow the instruction to avoid possible malfunctions.

• For the ice not to take up unpleasant scent nor taste, do not store food, bottles

nor anything else in the storage container.

• Do not leave the storage container lid open during normal operation.

Switching-On

1. Before switching on, check if water and power connections are executed

correctly.

2. Check if bands, screws, studs and clamps are securely tightened and did not

come loose during transportation to prevent water leaks or other malfunctions

during operation.

3. Open the water connection tap and the shut-off valve.

4. Plug the appliance into a single grounded socket.

The appliance is now in standby. The control key blinks every 30 seconds.

5. To leave the Standby mode and switch the appliance on, press the control key

for at least 3 seconds, and wait for a long acoustic signal, confirming the

appliance is on (Fig. 11).

NOTE!

We recommend not to use ice cubes from the first 5 production cycles to chill

beverages nor foods.

Never disconnect the water supply when the appliance operates; do not cover

nor clog the air outlet openings.

Check if water is supplied to the tank, if the sensor and/or float stop water flow

and prevent overflowing, and if there are no leakages in installations and water

pipes. Normal water level in the tank is approx. 5–10 mm, counted from top

edges (Fig. 12).

Installation and operation

104304 17 / 27

EN

Water level may be regulated by rotating the micro-float or water sensor through

the designated crevice, located on the right bracket, following screwing the fixing

screw 1 off (Fig. 12). This regulation must be performed with power supply

disconnected.

6. Make sure there are no strange vibrations generated by loose screws.

7. If an interference is required due to water leak, tightening of screws, etc., always

switch the appliance off first.

8. Check the ice production cycle by verifying whether ice cubes are unload to the

storage container.

9. Check the storage container probe for operation: place an ice cube on a cooled

probe inside the storage container; the appliance should stop within 1 minute

and automatically re-start shortly after the ice cube is removed.

10. Re-fix the cover removed beforehand.

Setting Probe in Storage Container

With time, due to the change in ambient temperature, the set value for temperature

probe in the storage container may appear to be insufficient. To set this value,

proceed the following way:

1. In Standby mode, press the control key 3 times over a 2-second period

(Fig. 11).

The control key lights up in white or red.

2. To increase the set temperature, press the control key (Fig. 11) repeatedly and

try to change the key colour to red.

3. To reduce the temperature, press the control key repeatedly until it changes its

colour to white.

If the control key is not pressed during 5 seconds, the entered setting will be saved

and the appliance will leave the change phase.

Installation and operation

18 / 27 104304

EN

Operation Status / Alarm Status Indicators

Indicator / Alarm

RED

WHITE

Too long a cooling cycle alarm

blinks 1x

ON 3"

Pump alarm

blinks 1x

blinks 1x

Change in duration of alarm between

two production cycles

blinks 2x

ON 3"

Deposit probe damage alarm

blinks 3x

ON 3"

IR probe alarm

blinks 3x

ON 3"

Discharge/charge parameters –

HACCP

blinks 3x

blinks 3x

Condenser probe damage alarm

blinks 4x

ON 3"

Evaporator probe damage alarm

blinks 5x

ON 3"

Inverted evaporator–deposit probe

alarm

blinks 5x

blinks 2x

Too long a defrosting process alarm

blinks 6x

ON 3"

Condenser cleaning alarm

blinks 7x

ON 3"

Start phase

OFF

2 Hz lamp

Ice production

OFF

ON

Ice dumping

OFF

ON

Storage container full

OFF

blinks 10 s

Standby

OFF

blinks 30 s

Washing cycle phase alarm (optionally)

OFF

ON 3"

Ozone cycle phase alarm (optionally)

OFF

ON 1"

Power supply malfunction alarm or no

electric supply

OFF x 1"

ON 5"

Condenser high temperature alarm

ON

OFF

High pressure alarm

ON

OFF

Gas charge phase signal

ON 1"

ON 1"

No water alarm

ON 3"

blinks 1x

Periodic maintenance alarm

ON 3"

ON 3"

Capacitive sensor alarm

ON 3"

blinks 3x

Installation and operation

104304 19 / 27

EN

Evaporator high temperature alarm

ON 3"

blinks 2x

Evaporator low temperature alarm

ON 3"

blinks 4x

OFF: LED indicator / colour always off

ON: LED indicator / colour always on

Blinking: LED indicator / colour on for 0.2 s and off for 0.3 s

Malfunctions

ATTENTION!

In the case of incorrect operation, disconnect the appliance from power

and water supply. Contact an authorised service, check the appliance and

have it repaired.

• Check if the water supply tap is open.

• Check if the appliance is powered electrically: if the plug is properly connected,

and the disconnecting device is switched on.

• Make sure there are no strange vibrations generated by loose screws.

• If you must perform tasks connected with water loss, screw tightening, etc.,

always switch the appliance off first, and check whether clogged drains are not

the reason for leaks.

• If the appliance produces too little ice, check the condenser for cleanliness and

the coolant for leaks.

Cleaning

20 / 27 104304

EN

6 Cleaning

6.1 Safety Instructions for Cleaning

• Before cleaning, disconnect the appliance from the power supply.

• Leave the appliance to cool down completely.

• Make sure water does not enter the appliance. Do not immerse the appliance in

water or other liquids during cleaning. Do not clean the appliance with a

pressurized water jet.

• Do not use any sharp or pointed, nor metal implements (knife, fork, etc.). Sharp

or pointed implements may damage the appliance, and when in contact with live

parts, they may cause electric shock.

• For cleaning, do not use any scouring agents that contain solvents nor corrosive

cleaning agents. They may damage the surface.

6.2 Cleaning

User Cleaning

1. At the end of each working day, as well as after a long period without operating

the appliance, clean the appliance thoroughly.

2. Clean the housing with a soft cloth, moistened with a chlorine-free stainless

steel cleaning agent.

3. Clean the internal chamber with a sponge and cloth moistened in lukewarm

water and a minute amount of sodium bicarbonate.

4. Rinse in fresh water.

5. Dry the internal chamber thoroughly.

If the appliance is not to be used for a long time:

– switch the appliance off and disconnect it from power and water supply;

– remove the produced ice from the storage container;

– drain the entire water;

– perform thorough cleaning;

– leave the door (lid) of the storage container slightly open.

Cleaning

104304 21 / 27

EN

Descaling and Disinfection

To avoid problems caused by water hardness and the formation of contaminants on

parts or components in contact with water, the appliance is equipped with "Self

Cleaning" function.

This function keeps the appliance clean, free of limescale and deposits, thanks to

the cleaning action of a special descaling agent. Follow instructions of the agent's

manufacturer.

ATTENTION!

To ensure the cleanliness of the appliance, we recommend carrying out a

descaling cycle 3–4 times a year, depending on the hardness of tap water.

Carrying out Cleaning and Disinfection Cycle

CAUTION

When preparing the descaling solution (water + citric acid), take necessary

precautions when handling citric acid and wear gloves and protective

goggles.

1. Switch the appliance to stand-by mode.

2. Remove all ice from the storage container.

3. Pour at least 500 ml of descaling solution into the internal compartment of the

appliance (Fig. 14).

4. Hold down the Stand-by key for at least 9 seconds to start the descaling cycle.

During the descaling cycle, the key blinks as follows: off for 1 second, and on for 3

seconds (white). When the descaling cycle is complete, the appliance switches to

stand-by mode.

The descaling cycle lasts approximately 2 hours and 15 minutes.

Once the function protecting against limescale build up is activated, the descaling

cycle can no longer be interrupted. In the event of a power failure, the appliance

continues from the point at which the interruption occurred.

NOTE!

If the appliance has not been used for a long period of time, it is advisable

to carry out the descaling cycle before starting ice production.

Cleaning

22 / 27 104304

EN

Service Cleaning

Air Filter and Condenser

In order to maintain performance and extend the life of the appliance, clean the air

filter and condenser regularly; the components are located under the front cover of

the appliance (Fig. 13):

– remove the air filter;

– clean the air filter under running water and dry completely;

– screw off and remove the front cover;

– clean the condenser with a soft brush or a vacuum cleaner;

– fix the front cover with screws;

– fit the air filter.

ATTENTION!

In order to avoid malfunction, never use the appliance without air filter.

Water Inlet Filter

The water inlet filter must be regularly cleaned, observing the blow indications:

– close the water shut-off valve;

– unscrew water supply tube;

– use tweezers to pull the water inlet filter from the socket at the inlet of the

solenoid valve;

– clean the water inlet filter under running water;

– fit the water inlet filter;

– fit water supply tube.

Possible Malfunctions

104304 23 / 27

EN

7 Possible Malfunctions

Mögliche

ATTENTION!

The table below contains descriptions of possible causes and solutions to

malfunctions or errors during operation of the appliance. These

malfunctions may be cleared by a qualified refrigeration technician.

In such a case, provide article number, model name and serial number. These data

may be found in the rating plate.

Malfunction

Alarm

Appliance Condition

Solution

Too long a cooling

cycle alarm

Check condenser for ventilation

Check the cooling circuit for loss

of coolant

Change in duration

of alarm between

two production

cycles

Duration of alarm

between two production

cycles changed

Check condenser for cleanliness

and ventilation

Check condenser's fan

Check the circulation for loss of

the coolant

No water alarm

Appliance stops or waits

for another attempt of

automatic start-up

Check water supply

Check water circulation for water

leaks

Check water inlet valve for

operation, clean if necessary

Check sensor position

Deposit probe

damage alarm

Appliance stops

Check probe connection to PCB

Check probe integrity

Replace the damaged probe

Periodic

maintenance

alarm

Appliance continues

operation

Contact the service company

(Reset the alarm by touching the

control key for 10 seconds)

Possible Malfunctions

24 / 27 104304

EN

Malfunction

Alarm

Appliance Condition

Solution

Condenser high

temperature alarm

The appliance stops; the

condenser's fan remains

on in order to reduce the

condenser's temperature

Check condenser for cleanliness

and ventilation

Check fan for operation

Evaporator probe

damage alarm

Appliance stops

Check evaporator probe

connection to PCB

Replace the damaged probe

High pressure

alarm

The appliance stops; the

condenser's fan remains

on in order to reduce the

condenser's temperature

Check condenser for cleanliness

and ventilation

Check if condenser fan rotates

Power supply

malfunction alarm

or no electric

supply

Appliance stops

Check electric connections and

power supply

Disconnection of alarm signal:

– touch the control key once to

silence the buzzer

– touch the control key once to

silence the buzzer if it is the

first minute of operation

– only two touches of the control

key if the first minute has

elapsed

Possible Malfunctions

104304 25 / 27

EN

Malfunction

Alarm

Appliance Condition

Solution

Discharge pump

alarm

Clogged discharge

opening

Check the appliance for obstacles

in discharge route

Discharge pump

damaged

Replace the discharge pump

Too long a

defrosting process

alarm

Defrosting process takes

too long

Check filling with coolant

Capacitive sensor

alarm

Check electric power connection

Condenser cleaning

alarm

Appliance continues

operation

Clean air filter and condenser

Inverted

evaporator–deposit

probe alarm

Appliance stops

Check wiring on the sensor's

PCB; replace the sensor's PCB if

needed

IR probe alarm

The appliance stops, IR

probe damaged

Check probe connection to PCB

Replace the damaged probe

Evaporator high

temperature alarm

Appliance stops

Check evaporator probe location

and insulation

Check the appliance for loss of

the coolant

Evaporator low

temperature alarm

Appliance stops

Check the appliance for loss of

the coolant

Check evaporator probe location

Disposal

26 / 27 104304

EN

8 Disposal

Electrical Appliance

Electric appliances are marked with this symbol. Electrical

appliances must be disposed of and recycled in a correct

and environmentally friendly manner. You must not dispose

of electric appliances with household waste. Disconnect the

appliance from the power supply and remove power cord

from the appliance.

Electrical appliances should be returned to designated collection points.

Coolant

The propellant used in the appliance is flammable. It should be utilised pursuant to

national regulations in force.

Loading...

Loading...