GS E350 LPR - GS E400 LPR K

110350 - 110400

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten

Germany

Phone: +49 5258 971-0

Fax: +49 5258 971-120

Technical Support Hotline: +49 5258 971-197

www.bartscher.com

Version: 1.0

Date of preparation: 2023-01-30

Original operation manual

110350

110400

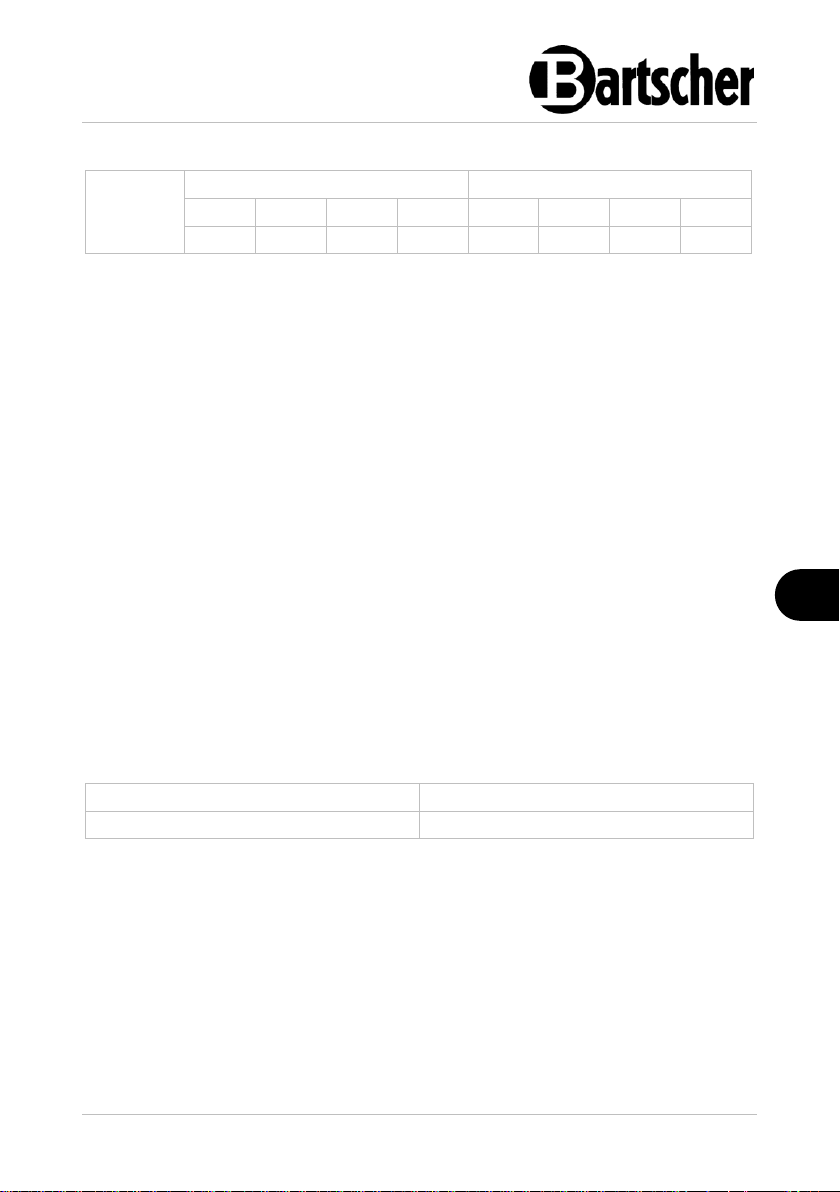

Fig. 1

A B C E F G R

Water

connec-

tion

Hose

Water

outlet

Cable

hose

Rinsing

agent

inlet

Washing

agent inlet

Potential

equaliza-

tion

Connection strip

Beschreibung

Dimensions / supply lines (mm)

Fig. 2

Fig. 3

Fig. 4

Fig. 5

EN

4

1 Safety ............................................................................................................ 2

1.1 Explanation of Signal Words .................................................................... 2

1.2 Safety instructions.................................................................................... 3

1.3 Intended Use ........................................................................................... 5

1.4 Unintended Use ....................................................................................... 5

2 General information ....................................................................................... 6

2.1 Liability and Warranty .............................................................................. 6

2.2 Copyright Protection ................................................................................ 6

2.3 Declaration of Conformity ........................................................................ 6

3 Transport, Packaging and Storage ................................................................ 7

3.1 Delivery Check ......................................................................................... 7

3.2 Packaging ................................................................................................ 7

3.3 Storage .................................................................................................... 7

4 Technical Data ............................................................................................... 8

4.1 List of Components of the Appliance ....................................................... 8

4.2 Technical Specifications .......................................................................... 9

4.3 Functions of the Appliance ..................................................................... 11

5 Installation Instructions ................................................................................ 12

5.1 Unpacking .............................................................................................. 12

5.2 Positioning ............................................................................................. 13

5.3 Electrical Connection ................................ ............................................. 13

5.4 Water Connection .................................................................................. 14

5.5 Discharge Pump .................................................................................... 16

5.6 Cleaning Agent Dosing Pump ................................................................ 16

5.7 Rinsing Agent Dosing Pump .................................................................. 16

6 Operation and Maintenance Instructions ..................................................... 17

6.1 Operation ............................................................................................... 17

6.2 Cleaning and Maintenance .................................................................... 21

6.3 Indications and Tips ............................................................................... 23

7 Possible Malfunctions .................................................................................. 24

8 Disposal ....................................................................................................... 28

110350 1 / 28

Safety

EN

Read this instruction manual before using and keep it available

at all times!

DANGER!

The signal word DANGER warns against hazards that lead to severe

injuries or death if the hazards are not avoided.

Diese Bedienungsanleitung beschreibt di e Installation, Bedienung und Wartu ng des Geräts und gilt als wichtige Infor mationsquelle und Nachschlagewer k. Die Kenntnis aller enthaltenen Sich erheitshinweise und Handlungsanweisu ngen schafft die Voraussetzung für d as sichere und sachgerechte Arbeit en mit dem Gerät. Darüber hinaus müssen die für den Einsatzbereich des Geräts geltenden örtlichen Unfallverh ütungsvorschriften und allgemeine n Sicherheitsbestimmungen eingehalt en werden. Diese Bedienungsanleitung is t Bestandteil des Produkts und m uss in unmittelbarer Nähe des Ger äts für das In¬stallations-, Bedienu ngs-, Wartungs- und Reinigungspers onal jederzeit zugänglich auf¬bewahrt werd en. Wenn das Gerät an eine dritt e Person

weitergegeben wird, muss die Bedienungsa nleitung mit ausgehändigt werden.

This instruction manual contains information about installation, operation and

maintenance of the appliance and constitutes an important source of information

and reference guide. The knowledge of all operational and safety instructions

included in this manual is a prerequisite for safe and proper handling of the

appliance. Additionally, accident prevention, occupational health and safety, and

legal regulations in force in the area the appliance is used apply.

Before you start using the appliance, especially before turning it on, read this

instruction manual in order to avoid personal injuries and property damages.

Improper use may cause damage.

This instruction manual forms and integral part of the product and must be stored in

an immediate vicinity of the appliance and be available at all times. The instruction

manual should be transferred together with the appliance.

1 Safety

This appliance has been manufactured in accordance with technical standards

currently in force. However, the appliance may be a source of hazards if used

improperly or contrary to its intended purpose. All persons using the appliance must

consider information included in this instruction manual and observe safety

instructions.

1.1 Explanation of Signal Words

Important safety instructions and warning information are indicated in this

instruction manual with appropriate signal words. You must strictly follow the

instructions, to prevent accidents, personal injuries and property damages.

2 / 28 110350

Safety

EN

WARNING!

The signal word WARNING warns against hazards that may lead to

moderate or severe injuries or death if the hazards are not avoided.

CAUTION!

The signal word CAUTION warns against hazards that may lead to

light or moderate injuries if the hazards are not avoided.

IMPORTANT!

The signal word IMPORTANT indicates possible property damages,

which may occur if safety instructions are not observed.

NOTE!

The symbol NOTE indicates subsequent information and guidelines

for the user on usage of the appliance.

, die

1.2 Safety instructions

Electrical Current

• Too high a mains voltage or incorrect installation may cause electric shock.

• The appliance may be connected only if data on the rating plate correspond with

the mains voltage.

• To avoid short-circuit, the appliance should be kept dry.

• If there are malfunctions during operation, disconnect the appliance from the

power supply.

• Do not touch the appliance’s plug with wet hands.

• Never take hold of the appliance if it has fallen into water. Immediately

disconnect the appliance from the power supply.

• Any repairs or housing opening may be carried out by professionals and

relevant workshops only.

• Do not transport the appliance, holding it by the power cord.

• Do not allow the power cord to come into contact with heat sources or sharp

edges.

• Do not bend, pinch nor knot the power cord.

110350 3 / 28

Safety

EN

• Always completely unwind the power cord.

• Never place the appliance or other objects on the power cord.

• Always take hold of the plug to disconnect the appliance from the power supply.

• Check the power cord regularly for damage. Do not use the appliance if the

power cord is damaged. If this cable is damaged, it must be replaced by

customer service or a qualified electrician in order to avoid dangers.

Operating Personnel

• The appliance may only be operated by a qualified personnel and trained

specialist personnel.

Improper Use

• Unintended or prohibited use may cause damage to the appliance.

• The appliance may only be used when its technical condition is flawless and

allows for safe operation.

• The appliance may only be used when all connections are executed according

to rules of law in force.

• The appliance may only be used when it is clean.

• Use only original spare parts. Never attempt to repair the appliance on your own.

• Do not introduce any changes in the appliance nor modify it.

4 / 28 110350

Safety

EN

1.3 Intended Use

As described below, every use of the appliance for a purpose differing and/or

diverging from its intended standard use, is prohibited and considered to be an

unintended use.

The following is an intended use:

– Washing dishes, glasses, pots, pans, etc.

The appliance is intended for professional use only.

1.4 Unintended Use

An unintended use may lead to personal injuries or property damages caused by

hazardous voltage, fire or high temperature. The appliance may only be used to

perform tasks described in this instruction manual.

The following is an unintended use:

– Washing other unsuitable objects.

110350 5 / 28

General information

EN

2 General information

2.1 Liability and Warranty

All information and instructions in this instruction manual account for legal

regulations in force, current level of technical engineering knowledge as well as our

expertise and experience, developed over the years. If special models or additional

options are ordered, or state-of-the-art technical solutions were implemented, the

actual scope of delivery of the appliance may, in some circumstances, differ from

descriptions and numerous drawings in this instruction manual.

The manufacturer is not liable for any damages nor faults stemming from:

– failure to observe instructions,

– unintended use,

– technical alterations introduced by the user,

– usage of unapproved spare parts.

We reserve the right to introduce technical modifications to the product, intended for

improvement of the appliance and its performance.

2.2 Copyright Protection

This instruction manual, and texts, drawings and images included in it, as well as its

other components are copyright protected. It is prohibited to reproduce this

instruction manual (including its excerpts), in any form and by any means, and to

use and/or transfer its content to third parties without manufacturer’s written

permission. Violation of the above results in obligation to pay compensation. We

reserve the right to claim further damages.

2.3 Declaration of Conformity

The appliance meets the currently applicable standards and guidelines of the

European Union. We confirm the above in the EC Declaration of Conformity. We

may provide relevant Declaration of Conformity upon request.

6 / 28 110350

Transport, Packaging and Storage

EN

3 Transport, Packaging and Storage

3.1 Delivery Check

Immediately upon reception, check the delivery for completeness and possible

shipping damage. In the case of visible transport damage refuse to accept the

appliance or accept it conditionally. Mark and note the scope of damage in shipping

documents/consignment list of the shipping company and lodge a complaint.

Concealed damage must be reported immediately upon its discovery, as

compensation claims may only be filed within applicable time limits.

If you find that parts or accessories missing, please contact our Customer Service

Department.

3.2 Packaging

Do not dispose of the appliance cardboard box. It may be used to store the

appliance when relocating or when shipping the appliance to our service point in the

case of any damages.

The packaging and its elements are made of recyclable materials. Particularly,

these are: plastic films and bags, cardboard box.

When disposing of the packaging, observe applicable domestic regulations.

Recyclable packaging materials should be recycled.

3.3 Storage

Leave the packaging closed until installation of the appliance; observe external

indications concerning method of placing and storage. Store the packaging in the

following conditions only:

– in closed rooms;

– in dry and dust-free surrounding;

– away from aggressive agents;

– in a location protected against sunlight;

– in a location protected against mechanical shocks.

In the case of extended storage (over three months), make sure you check the

condition of the packaging and the parts regularly. If needed, replace the packaging

with a new one.

110350 7 / 28

Technical Data

EN

Fig. 6

1. Control panel

2. Wash tank

3. Wash-basket

4. Handle

5. Housing

6. Height-adjustable feet (4x)

7. Appliance door

8. Heating elements

9. Bottom wash arms

10. Filter

11. Wash basket guide rails

12. Drain trap

13. Check valve

14. Top wash arms

4 Technical Data

4.1 List of Components of the Appliance

110350-110400

8 / 28 110350

Technical Data

EN

Name:

Dishwasher GS E350 LPR

Art. No.:

110350

Material:

Stainless steel

Basket dimensions (W x D x H), in mm:

350 x 350

Max. glass height, in mm:

220

Run time, in seconds:

120

Max. output / hour, baskets:

30

Number of wash programs:

1

Tank volume, in litres:

11

Water consumption at 2 bar, in litres:

2,0

Water pressure, in bar:

2 - 4

Water supply:

G 3/4

Water outlet, ø in mm:

20

Tank heating, in kW:

2,0

Boiler heating, in kW:

2,4

Connected load:

3.4 kW / 230 V / 250 Hz

Dimensions (W x D x H), in mm:

430 x 535 x 675

Weight, in kg:

30,2

4.2 Technical Specifications

GS E350 LPR

We reserve the right to implement technical modifications.

110350 9 / 28

Technical Data

EN

Name:

Dishwasher GS E400 LPR K

Art. No.:

110400

Material:

Stainless steel

Basket dimensions (W x D x H), in mm:

400 x 400

Max. glass height, in mm:

280

Run time, in seconds:

120

Max. output / hour, baskets:

30

Number of wash programs:

1

Tank volume, in litres:

15

Water consumption at 2 bar, in litres:

2,5

Water pressure, in bar:

2 - 4

Water supply:

G 3/4

Water outlet, ø in mm:

20

Tank heating, in kW:

2,0

Boiler heating, in kW:

2,8

Connected load:

3.4 kW / 230 V / 250 Hz

Dimensions (W x D x H), in mm:

420 x 580 x 725

Weight, in kg:

34,0

GS E400 LPR K

We reserve the right to implement technical modifications.

10 / 28 110350

Technical Data

EN

Version / Design

• Discharge pump

• Washing agent dosing pump

• Rinsing agent dosing pump

• Double-walled door

• Dry-run protection

• Safety thermostat

• Door contact switch

• Can be flush-mounted

• Appliance connection: ready to plug in

• ON/OFF switch

• Indicator light: ON/OFF

• Max. water intake temperature: 60°C

• The set includes: 2 universal baskets, 1 cutlery basket, Ø20 mm drain hose, 1

¾" water supply hose

4.3 Functions of the Appliance

The dishwasher is intended for washing suitable dishes, kitchen pots, pans, cutlery,

etc.

110350 11 / 28

Installation Instructions

EN

CAUTION!

Incorrect installation, positioning, operation, maintenance or misuse of

the appliance may lead to personal injury or property damage.

Positioning and installation, as well as repairs or fitting may be performed

by authorised technical service only and in compliance with the applicable

national law.

CAUTION!

Choking hazard!

Prevent children from accessing packaging materials, for instance: plastic

bags and EPS.

5 Installation Instructions

5.1 Unpacking

• The appliance may be moved with the use of a fork lift or similar equipment only

to avoid damaging the appliance's structure. First, deliver the appliance to the

final installation location and unpack it there.

• Unpack the appliance, remove all external and internal packaging elements and

shipment safeguards.

• If the appliance is covered with a protective film, remove it. Remove the film

slowly, so no glue residues are left. Remove any glue residues with the use of a

suitable solvent.

• Be careful not to damage the rating plate and warning labels affixed to the

appliance.

12 / 28 110350

Installation Instructions

EN

ATTENTION!

Before the appliance’s installation, carefully check the conditions of

the location in which the appliance is to be set to exclude any

subsequent damages which may appear during operation.

• The appliance is equipped with heightadjustable feet.

• To level the appliance, screw the feet out to

the required height.

• Correct levelling is necessary to ensure

optimum performance of the appliance.

Fig. 7

5.2 Positioning

• Never place the appliance in humid or wet environment.

• Place the appliance in a way making the connections easily accessible, so that

they may be quickly disconnected if such a need arises.

• The appliance should be placed on surfaces that are:

– even, with sufficient bearing capacity, resistant to water, dry and resistant

to high temperatures;

– sufficiently large, and thus enabling usage of the appliance with no

problems;

– easily accessible;

– well ventilated.

• The appliance should be installed only in a room, in which ambient temperature

falls in the range of 5°C – 40°C.

5.3 Electrical Connection

• Verify if the technical specification of the appliance (see the rating plate)

correspond to the local electricity grid.

• Connect the appliance to a single, properly grounded mains socket with

protective contact. Do not connect the appliance to a multi-socket.

• The power cord should be laid in a way preventing anyone from threading on it

or tripping against it.

• The appliance is ready for installation and equipped with a power cord of 1.3 m

in length with a plug.

110350 13 / 28

Installation Instructions

EN

Water

temperature (T):

max. 60 °C

Total water

hardness

5 °fH (French hardness

degree scale)

pH value:

6.5–7.5

7 °eH (English hardness

degree scale)

Physical

contamination:

Ø < 0.08 mm

9 °dH (German hardness

degree scale)

Chlorides:

max. 150 mg/l

Conductivity:

400 μS/cm

CI:

0.2–0.5 mg/l

• A multipolar switch with at least 3 mm opening should be connected near the

device, and should be easily accessible. This device is designed for switching

the appliance off in the case of installation, repair, cleaning or maintenance work

conducted on the appliance. This switch must be equipped with fuses adjusted

for the rated voltage of the appliance. A properly selected magnetic thermal

switch may be an alternative to the above mentioned switch.

• The appliance must be properly connected to the equipotent bonding circuit; see

F, Fig. 1.

The manufacturer accepts no liability for any possible bodily injuries nor

property damages relating to the appliance that stem from non-compliance

with instructions and incorrect installation.

5.4 Water Connection

Use only hoses supplied with the appliance (never use second-hand hoses).

Before connecting the appliance to the water supply system, the analysis of water

quality should be performed. Manufacturer recommends the following parameters of

water quality:

If the water hardness exceeds 9 °dH (German hardness degree scale), the use of

water softener is required.

Furthermore, when checking the water quality, the pressure of water supply system

must be taken into account. This parameter determines the correct operation of the

appliance.

14 / 28 110350

Installation Instructions

EN

Water

pressure

MIN.

MAX.

bar

kPa

kg/cm2

psi

bar

kPa

kg/cm2

psi

2

200

2.03

29 4 400

4.07

58.01

S

Shut-off valve

H

Water hose

E

Solenoid valve

B

Booster pump

F

Filter

Cold water

Hot water

5°C – 25°C / 41°F – 95°F

40°C – 60°C / 122°F – 140°F

Water pressure should correspond to the following values:

If the water pressure is above the recommended value, it is required to install the

reducing valve between the water supply system and the water connection of the

appliance (Fig. 2 at the beginning of the operation manual).

Fig. 2. Direct connection of the hose to the water supply installation.

If the water pressure is below the recommended value, it is required to install a

booster pump between the water supply system and the water connection of the

appliance (Fig. 3).

Fig. 3 Connection of the booster pump

The appliance is equipped with the booster pump.

To properly install the appliance, please follow the instructions below:

– water connection must be equipped with a shut-off valve to block the

water supply;

– pressure in the water supply system must be within the range of

recommended values;

– to optimise operation, the recommended water intake temperature

should fall within the range of values given in table below:

– when using warm water, the water temperature may not exceed the

– the appliance must be equipped with a threaded connection (¾").

110350 15 / 28

values of 60°C / 140°F;

Installation Instructions

EN

5.5 Discharge Pump

The appliance is equipped with the discharge pump that, when properly set,

provides for discharging water after washing.

In such a case, the height of 680 mm cannot be exceeded (Fig. 1, Fig. 4).

Fig. 4 Setting of the drain height through the drain pump.

5.6 Cleaning Agent Dosing Pump

The appliance is equipped with the cleaning agent dosing pump. Thanks to this

dosing device the appropriate quantity of cleaning agent is added to the wash-tank

each time.

Located at the rear of the appliance, the hose with marking for cleaning agent (D,

Fig. 1) should be introduced to the tank with cleaning agent.

Operation: the cleaning agent dosing pump is activated when the appliance

collects water during washing or filling process.

Setting: the quantity of cleaning agent should be set during the installation at the

cleaning agent dosing pump, so that the user may use all washing features in an

optimum way from the very beginning.

The hose in the cleaning agent dosing pump must be replaced annually.

ATTENTION!

Use ONLY liquid leaning agent, designed for professional use, which is

suitable for using in high temperatures and shows little foaming

properties.

KlarsKl

5.7 Rinsing Agent Dosing Pump

The appliance is equipped with the rinsing agent dosing pump. Thanks to this

dosing device, the appropriate quantity of rinsing agent is added to the wash-tank

each time.

Located at the rear of the appliance, the hose with marking for rinsing agent (C, Fig.

1) should be introduced to the tank with rinsing agent.

The hoses are transparent, thus the introduced chemical compounds are always

visible.

Operation: Thanks to this dosing device, the liquid rinsing agent is supplied

whenever a drop in pressure is detected during rinsing. This happens when the

filling valve is closed. As an outcome, underpressure is generated, which causes

the liquid to be sucked by the rinsing agent dosing device.

Setting: this dosing device should be set up during the installation, because only

this way the user may use all washing features in an optimum way from the very

16 / 28 110350

Operation and Maintenance Instructions

EN

CAUTION!

The dishwasher can only be used by individuals who have been

instructed in the proper use of the appliance and dangers that may arise

during operation.

A

Selector switch (0, 120, drain)

C

Temperature indicator light

B

Operation indicator light

D

Cycle starting control key

beginning. The setting must be properly adjusted depending on the selected rinsing

agent and hardness of the available water.

NOTE:

A selection of the rinsing agent and setting of the rinsing agent dosing

pump should be ordered with a qualified technician who has experience

with chemical products, to achieve the most efficient washing effects.

6 Operation and Maintenance Instructions

6.1 Operation

• Prior to first operation, clean the appliance and its equipment, observing instructi ons in section 6 'Cleaning'. Make sure no water enters electric installatio n and connection box. Then thoroughl y dry the appliance and the entire eq uipment.

• Insert the bottom cover into the appliance. The cover acts as a spacer between t he heating element and left-over f ood tray.

• Carefully insert the connection box with th e heating element at the back edge of t he appliance. A pin in the bottom part o f the connection box must enter a hole in the main appliance. This wa y the connection box is properly mounte d.

Appliance Preparation

1. Before use, clean the appliance, observing instructions in section 6 6

'Cleaning'.

2. Dry the appliance thoroughly.

Functions of Operating Elements / Indicators (Fig. 5)

110350 17 / 28

Operation and Maintenance Instructions

EN

Switching the Appliance ON

Before switching the appliance on make sure that the following conditions are met:

– the main switch is off;

– water shut-off valve is open;

– water supply is ensured;

– all filters are installed in their respective locations;

– overflow is in the right location;

– appliance door is closed;

– selector switch (A) is rotated to 120 position.

Filling and Heating Process

Filling process begins after starting the appliance. First the rinsing boiler is filled in,

and then the wash tank. Filling process may take up to a few minutes. As soon as

the wash tank is filled in, the heating process of boiler starts. When the boiler is

heated up, the heating process of wash tank starts. Although it would be now

possible to start the washing process, the manufacturer does not recommend this,

because the water inside the appliance has not reached the optimum temperature

yet.

As soon as the appliance reaches temperature ideal for correct washing of

tableware, the temperature indicator light is lit.

The appliance must reach proper temperatures: 82°C – 90°C in boiler, and 55 °C –

62°C in tank, respectively.

18 / 28 110350

Operation and Maintenance Instructions

EN

It is recommended that the water in the appliance should be changed every 40/50

washing cycles or twice a day.

NOTE: To start the filling process, the appliance door must be fully closed.

Due to safety reasons, the appliance cannot be filled with door open.

The appliance is equipped with a safety thermostat inside the boiler and another

safety thermostat inside the wash tank. In the case of a failure of any of the main

thermostats, the heating process is stopped.

Tableware Preparation

1. Tableware to be washed must be prepared the following way:

– Before placing tableware in the basket, remove larger food left-overs

from tableware.

– Wash glasses first.

– Always place glasses face down.

– Put the cutlery in the cutlery basket with handles facing down. Cutlery of

various sizes and types should be mixed.

– Insert the cutlery baskets to universal dishwasher baskets.

2. When filling the dishwasher baskets pay attention to the following:

max. glass height — 200 mm

Washing Process Selection

1. Before starting the washing process, slide the appropriate basket with tableware

into the appliance.

2. Close the device door.

3. Select the washing cycle by rotating the control key (120).

4. Press the cycle starting control key

– Washing cycle starts.

110350 19 / 28

Operation and Maintenance Instructions

EN

Interrupting and Finishing the Washing Process

The washing process may be interrupted in one of the following two ways:

– the appliance is switched off → the washing process is completely

interrupted.

– the appliance door is opened → then the door is closed again during the

cycle.

After finishing the washing process, the basket with tableware may be removed.

Tableware is dried by evaporation. Remove tableware from the basket only with

clean hands. Makes sure not to scald your hands, because tableware is still hot.

Draining the Appliance with Discharge Pump

With this method, the drain hose must always be connected to a drain trap to

prevent foul scents.

Proceed the following way:

– Remove the overflow valve.

– Rotate the selector switch (A) to Drain.

– Close the appliance door.

– Press the cycle starting control key (D).

– The drain cycle starts automatically.

– When the process is finished (duration of approx. 160 seconds), you may

switch the appliance off.

Switching the appliance OFF

Set the selector switch (A) to 0 position, to switch the dishwasher off.

The manufacturer does not recommend to switch the appliance off during the

washing process, because the tableware inside the dishwasher will not be washed

properly.

20 / 28 110350

Operation and Maintenance Instructions

EN

6.2 Cleaning and Maintenance

• Before cleaning, disconnect the appliance from the power supply.

• Do not use any sharp or pointed, nor metal implements (knife, fork, etc.). Sharp

or pointed implements may damage the appliance, and when in contact with live

parts, they may cause electric shock.

• For cleaning, do not use any scouring agents that contain solvents nor corrosive

cleaning agents. They may damage the surface.

Daily Cleaning and Maintenance

At the end of the working day, thoroughly clean filters, wash arms, rinse arms, as

well as other accessories. Thorough cleaning is the most important condition for

maintaining long service life of the appliance. Proper cleaning and disinfection of

the appliance is the prerequisite for effective washing of dishes.

NOTE: To ensure that the draining process proceeds correctly with the

use of the discharge pump, the drain hose must be located at the

appropriate height (not higher than 680 mm).

The following should be performed regularly:

– At the end of the working day, remove all food left-overs from the

appliance.

– Never use abrasive, corrosive or caustic cleaning agents, or solvents and

cleaning agents based on chlorine or petrol derivatives.

– Do not use pressurized water for washing the appliance.

– Check the wash/rinse arms to make sure they rotate correctly.

Before starting the washing process, always check the filling levels of rinsing

agent and washing agent.

110350 21 / 28

Operation and Maintenance Instructions

EN

Technical Service Maintenance

Twice a year, a technical service should carry out the following inspections:

– water filters cleaning;

– descaling of heating resistors;

– checking the condition of gaskets;

– checking the condition of all other components;

– setting of dosing devices;

– checking of electrical connectors;

– checking of power cord.

ATTENTION!

To prevent hazards, a defective power cord may be replaced only by the

qualified electrician while observing all safety measures.

Descaling

To take advantage of all the features offered by the dishwasher, carefully read the

following indications and tips on descaling and follow them.

– add appropriate quantity of the descaling agent to the wash-tank (per 25

litres of water) and run 1–2 washing cycles;

– drain the device (section 6.1);

– refill the wash-tank with water, and then run 2–3 washing cycles without

any dishes;

– finally, pump out all the water to remove all residues of the descaling

agent.

22 / 28 110350

Operation and Maintenance Instructions

EN

6.3 Indications and Tips

Dishwasher Cleaning Agent and Rinsing Agent

ATTENTION!

Usage of incorrect dishwasher cleaning agent and rinsing agent may

damage the appliance.

Use only special cleaning agents designed for dishwashers intended for

professional use.

Do not use any foaming dishwasher cleaning agents.

Do not use any dishwasher washing agents, which are indented for household

use only.

We recommend Bartscher F12kg dishwasher washing agent (art. No. 173070) or

F12kgXTRA dishwasher washing agent (art. No. 173071) and Bartscher F10kg

rinsing agent (art. No. 173072).

When the type of rinsing or washing agent it is necessary to introduce new settings.

The settings may only be introduced by qualified technical personnel.

CAUTION!

When in contact with chemical substances, follow suitable safety

instructions.

When in contact with chemical substances always wear safety clothing,

safety gloves and safety glasses.

Do not mix cleaning agents with one another.

Hygiene Regulations

• Do not touch clean dishes with dirty or greasy hands to avoid soiling dishes.

• For final drying of dishes use clean, sterile towels.

• We recommend using the appliance always after reaching the optimum

temperature to ensure that washing also produces optimum results.

• Drain the wash-tank at least twice a day or every 40/50 washing cycles.

110350 23 / 28

Possible Malfunctions

EN

Malfunction

Possible Cause

Solution

The appliance

cannot be switched

on.

No voltage in the mains.

Check the thermal

magnetic switch for

disconnection.

Melted fuses.

Contact technical service

to determine the cause.

The appliance is not

switched on through the

main switch.

Close the main switch.

Optimum Results

To obtain optimum results during washing dishes, we recommend to proceed the

following way:

– Wash dishes only when the appliance is ready for work.

– Dosing devices must always be properly set.

– Always keep the dishwasher properly clean.

Periods of Non-Operation

If the appliance is not used for a longer period (holidays, interruptions at work etc.),

follow the instructions below:

– Fully drain the appliance, including the boiler.

– Thoroughly clean the appliance.

– Leave the dishwasher door open.

– Close the water supply valve.

– Switch the main power switch off.

– If there is a risk of frost, order the protection of the appliance against frost

to proper technical service.

7 Possible Malfunctions

Mögliche

The table below contains descriptions of possible causes and solutions to

malfunctions or errors during operation of the appliance. When malfunction cannot

be removed, contact the technical service.

24 / 28 110350

Possible Malfunctions

EN

Malfunction

Possible Cause

Solution

The appliance does

not collect water.

Water supply valve closed.

Open the water supply

valve.

Rinse arm nozzles clogged.

Clean the nozzles and

check the rinse arms for

limestone.

Solenoid valve filter clogged.

Contact technical service

to order cleaning.

Rinse pump failure.

Contact technical service

to order replacement.

Pressure switch error.

Contact technical service

to order replacement.

Incorrectly closed appliance

door.

Close the appliance door

correctly.

Washing results are

not satisfactory.

Wash arms are clogged.

Thoroughly clean the wash

arms.

Not enough washing agent

added.

Contact technical service

to request setting of the

rinsing agent dosing pump.

Filters are dirty.

Thoroughly clean the

filters.

Foaming.

Inappropriate cleaning

agent. Contact technical

service to select correct

cleaning agent.

Too much rinsing agent.

Contact technical service

to request change of

setting of the rinsing agent

dosing pump.

110350 25 / 28

Possible Malfunctions

EN

Malfunction

Possible Cause

Solution

Washing results are

not satisfactory.

Temperature in the washtank is below 50°C/122°F.

Thermostat failure or

thermostat is not set

correctly. Contact technical

service to order repair.

Washing cycle is too short for

the heavily soiled dishes.

Select a longer washing

cycle.

Washing water is very dirty.

Drain the wash-tank and fill

in with clean water.

Dishes, pots, pans,

etc. are not properly

dried.

No rinsing agent.

Add the liquid rinsing agent

to the tank.

Not enough liquid rinsing

agent.

Contact technical service

to order new setting of

dosing devices.

Dishes, pots, pans,

etc. are not properly

dried.

Dishes remained too long in

the dishwasher.

Remove the dishes right

after the cleaning cycle and

remain to dry in open air.

Temperature of the rinsing

agent is below 80°C/176°F.

Contact technical service

to fix the problem.

Streaks and spots on

dishes.

Too much rinsing agent.

Contact technical service

to repair the rinsing agent

dosing pump.

Water too hard.

Check water hardness

degree.

26 / 28 110350

Possible Malfunctions

EN

Malfunction

Possible Cause

Solution

Streaks and spots on

dishes.

Salt container is almost

empty.

Fill up the salt container (if

it is installed).

Salt left-overs remain in the

wash-tank.

Be carful when filling the

salt container, not to spill

salt in the wash-tank.

The appliance stops

during the washing

and starts refilling

water.

Clogged pressure switch.

Drain and thoroughly clean

the wash-tank.

Pressure switch malfunction.

Drain and thoroughly clean

the wash-tank.

Overflow incorrectly installed.

Install the overflow

correctly.

The washing cycle

does not start.

Incorrectly closed appliance

door.

Close the appliance door

correctly. If the appliance

door cannot be closed,

contact technical service to

order setting of tensioning

devices.

Door micro switch

malfunction.

Contact technical service

to order replacement.

Draining process is

not successfully

completed.

The appliance is not set

correctly.

Set the appliance correctly.

Pressure switch malfunction.

Contact technical service

to order replacement.

110350 27 / 28

EN

Error

Message

Description

E1

The LED indicator light of the

ON/OFF button lights up for 0.5 sec.,

and then goes off for 2 seconds. The

entire process is repeated numerous

times.

Device door is open.

E2

The LED indicator light of the

ON/OFF button lights up twice for 0.5

sec., and then goes off for 2 seconds.

The entire process is repeated

numerous times.

The water level is wrong.

Time-out of the estimated

filling time.

E3

The LED indicator light of the

ON/OFF button lights up thrice for 0.5

sec., and then goes off for 2 seconds.

The entire process is repeated

numerous times.

The appliance was drained

incorrectly. Time-out of the

estimated draining time.

E4

The LED indicator light of the

ON/OFF button lights up four times

for 0.5 sec., and then goes off for 2

seconds. The entire process is

repeated numerous times.

The temperature in the

boiler is not OK. Time-out of

the estimated boiler heating

time.

E5

The LED indicator light of the

ON/OFF button lights up five times for

0.5 sec., and then goes off for 2

seconds. The entire process is

repeated numerous times.

The temperature in the tank

is not OK. Time-out of the

estimated tank heating time.

Electric appliances are marked with this symbol. Electrical

appliances must be disposed of and recycled in a correct

and environmentally friendly manner. You must not dispose

of electric appliances with household waste. Disconnect the

appliance from the power supply and remove power cord

from the appliance.

Error Codes

Disposal

8 Disposal

Electrical Appliance

Electrical appliances should be returned to designated collection points.

28 / 28 110350

Loading...

Loading...