Page 1

Original-Gebrauchsanleitung

V1/1118

GMS580

120328

Page 2

GB/UK

ENGLISH

Table of contents

1. Safety ...................................................................................................................... 34

1.1 Key to symbols ................................................................................................... 34

1.2 Safety instructions .............................................................................................. 35

1.3 Proper use ......................................................................................................... 39

1.4 Use against the intended purpose ..................................................................... 39

2. General information .............................................................................................. 40

2.1 Liability and Warrantees .................................................................................... 40

2.2 Copyright protection ........................................................................................... 40

2.3 Declaration of conformity ................................................................................... 40

3. Transport, packaging and storage ....................................................................... 41

3.1 Delivery check .................................................................................................... 41

3.2 Packaging .......................................................................................................... 41

3.3 Storage .............................................................................................................. 41

4. Technical data ........................................................................................................ 42

4.1 Technical specification ....................................................................................... 42

4.2 Overview of parts ............................................................................................... 43

4.3 Protective elements ........................................................................................... 45

5. Installation and operation ..................................................................................... 49

5.1 Installation .......................................................................................................... 49

5.2 Operation ........................................................................................................... 51

5.2.1 Preparation of the appliance ...................................................................... 51

5.2.2 Control panel ............................................................................................. 53

5.2.3 Inspection and control of operation before start-up ................................... 55

5.2.4 Start-up ...................................................................................................... 56

5.2.5 Switching off .............................................................................................. 57

5.2.6 Unlocking after the product jam ................................................................. 57

6. Maintenance, troubleshooting, cleaning ............................................................. 58

6.1 Maintenance ...................................................................................................... 58

6.2 Troubleshooting and unlocking of movable elements ........................................ 59

6.3 Cleaning ............................................................................................................. 61

7. Waste disposal ...................................................................................................... 64

Bartscher GmbH phone: +49 5258 971-0

Franz-Kleine-Str. 28 fax: +49 5258 971-120

33154 Salzkotten Service-Hotline: +49 5258 971-197

Germany www.bartscher.com

- 33 -

Page 3

Read this instruction manual before using and

keep them available at all times!

This instruction manual contains information about the installation, operation and

maintenance of the device and should be consulted as an important source of

information and reference guide.

Awareness of the safety instructions and instructions for use in this manual will ensure

the safe and correct use of the device.

In addition to the information given here, you should comply with any local Health and

safety Controls and generally applicable safety regulations.

The instruction manual forms part of the product and should be kept near the device

and easily accessible for anyone carrying out the installation, servicing, maintenance or

cleaning.

Please keep these instructions and give them to future owners of the device.

1. Safety

This device is designed in accordance with the presently applicable technological

standards. However, the device can pose a danger if handled improperly and

inappropriately.

All persons using the device must follow the recommendations and instructions

in this instruction manual.

1.1 Key to symbols

In this manual, symbols are used to highlight important safety instructions and any

advice relating to the device. The instructions should be followed very carefully to avoid

any risk of accident, personal injury or material damage.

DANGER!

This symbol highlights hazards which could lead to injury.

WARNING!

This symbol highlights dangerous situations which could lead to injury or death.

- 34 -

Page 4

CAUTION!

This symbol highlights dangerous situations which could lead to light

injuries, or damage, malfunction, and/or destruction of the device.

NOTE!

This symbol highlights recommendations and information aimed for effective

and trouble-free device operation.

1.2 Safety instructions

The device is not intended for use by individuals (including

children) with physical or mental disabilities, insufficient

experience, and/or insufficient knowledge unless such persons

are under the care of a person responsible for their safety or

have received instructions regarding appropriate use of the

device.

Children should be observed to ensure that they are not playing

with or starting the device.

Never leave the device unattended when in use.

Only use the device indoors.

The device may be operated only when it is in good working

order and is safe to use. In case of any malfunction, disconnect

the device from the power supply (pull the plug from the socket)

and call the technical service.

Prevent access of children to the package materials like plastic

bags and foamed polystyrene elements. Suffocation hazard!

- 35 -

Page 5

Only a qualified technician and using original spare parts and

accessories should carry out repairs and maintenance of the

device. Do not attempt to repair the device yourself.

Do not use any accessory or spare parts that have not been

recommended by the manufacturer. These can be dangerous

for the user or lead to damages of the device or personal injury,

and further, the warranty expires.

To prevent hazards and to ensure optimum efficiency, no

modifications or alterations to the device that are not explicitly

approved by the manufacturer may be undertaken.

DANGER! Electric shock hazard!

To avoid the hazard results please follow the safety instructions

below.

Never allow the power cable to come into contact with heat

sources or sharp edges. The power cable should not hang over

the side of the working surface. Ensure that no one can step on

or trip over the cable.

The power cable must not be folded, bent or tangled, and must

always remain fully unrolled. Never place the device or other

objects on the power cable.

Do not cover the cable. Keep away the cable from operating

range and do not immerse it into water.

- 36 -

Page 6

Check the power cord regularly for damage. Do not use the

appliance if the power cord is damaged. If this cable is damaged,

it must be replaced by customer service or a qualified electrician

in order to avoid dangers.

The supply cable must be disconnected from the socket

only by pulling the plug.

Never carry or lift the device by the supply cable.

In any case do not open the device housing. In case of

electrical or mechanical modifications the electric shock

hazard will occur.

Do not use any acid agents and make sure no water ingresses

the device.

Never operate the device with moist hands or standing on wet

floor.

Disconnect the device from the electric power supply.

- when the device is not used,

- in case of anomalies during operation,

- before cleaning.

WARNING! Injury hazard!

To avoid the hazard results please follow the safety instructions

below.

Blades of the cutting disks are very sharp! Always wear solid,

soft protective gloves allowing for firm grip of objects during

installation, replacement, and cleaning of cutting disks.

Never press the cut products with hand, always use delivered

plunger!

Never insert any objects or tools into the appliance!

Never put hands or other body parts into the cutting area or

filling hole to remove the cut products.

- 37 -

Page 7

Never put any objects under the appliance or between the

appliance feet and the working surface.

Never open the appliance lid during operation or after filling it

with food products.

Never unscrew the setting screw on the lid during operation or

earlier that 5 seconds after turning off the appliance.

Never use the appliance when the permanent or movable

protective elements are not properly fixed or have been

removed.

Never place the appliance upside down.

Always use the protective gloves during the appliance

operation!

The appliance, working surfaces, and floor around the cutter

must be always dry and free from dust, residuals of cut

products, and foreign bodies in order to avoid the risk of

slipping on wet floor or residuals of vegetables.

- 38 -

Page 8

1.3 Proper use

CAUTION!

The device has been designed and built for commercial use and should

be operated only by qualified personnel in kitchen facilities.

Every use of the device for a different purpose and/or in a way that diverges from the

intended use is not allowed and is assumed as the use against the intended purpose.

Any claims against the manufacturer or their authorized representatives as a consequence

of experiencing damage resulting from the use against the intended purpose are

inadmissible.

The liability for damage occurred during the use of the device against its intended

purpose is borne solely and exclusively by the user.

Safety operation of the device is guaranted only when it is used for its intended purpose

and according to the instructions included in this manual.

The vegetable cutter is designed only for cutting vegetables, fruits, and cheese

with use of appropriate cutting discs.

Use the vegetable cutter only for processing of appropriate food products!

1.4 Use against the intended purpose

Any use other than those mentioned in point “1.3 Use as intended“ is assumed as the

use against the intended purpose and is not allowed.

The use against the intended purpose may lead to severe injury or damage caused by

hazardous voltage, fire or high temperature. It is allowed to use the device to perform

only the work described in the instruction manual. Improper use may cause the device

damage.

Any manipulation with the device, assembly or maintenance work may be performed

exclusively by the authorized service staff.

The vegetable cutter must not be used for cutting deep frozen products, bone-in

meat, or fish.

- 39 -

Page 9

The device complies with the current standards and directives of the EU.

We certify this in the EC declaration of conformity. If required we will be

glad to send you the according declaration of conformity.

2. General information

2.1 Liability and Warrantees

All the information and instructions in this manual take into account standard safety

regulations, current levels of technical engineering as well as the expertise and

experience we have developed over the years.

The instruction manual was translated with all due care and attention. However, we do

not accept liability for any translation errors. The German version of this instruction

manual is definitive.

If the delivery consists of a special model, the actual scope of delivery may differ from

the descriptions and illustrations in this manual. This is also the case for special orders

or when the device has been modified in line with new technology.

CAUTION!

Read this manual carefully and thoroughly before any operation

of the device, and especially before turning it on!

Manufacturer is not liable for any damages or faults caused by:

- violation of advice concerning operation and cleaning;

- use other than designed;

- alterations made by user;

- use of inadequate spare parts.

We reserve the right to make technical changes for purposes of developing and improving

the useful properties.

2.2 Copyright protection

The instruction manual including any texts, drawings, images or other illustrations is

copyright. No part of this publication may be reproduced, transmitted or used in any

form or by any means without permission in writing from the manufacturer. Any person

who commits any unauthorized act in relation to this publication shall be liable to claims

for damages. All rights reserved.

NOTE!

The contents, texts, drawings, pictures and any other illustrations are

copyright and subject to other protection rights. Any person unlawfully

using this publication is liable to criminal prosecution.

2.3 Declaration of conformity

- 40 -

Page 10

If you liked to dispose the packing, consider the regulations applicable

in your country. Supply re-usable packing materials to the recycling.

3. Transport, packaging and storage

3.1 Delivery check

Please check the delivery upon completeness and transport damage immediately

after receipt. In case of visible damage do not accept or accept the delivery with

reservation only.

Note the extent of damage on the carrier’s bill of delivery. Trigger off the complaint.

Hidden damages should be reclaimed immediately after notice, as claims for damages

can only be asserted within the effective period for complaints.

3.2 Packaging

Please do not throw away the covering carton of your device as it might be useful for

storage purposes, when moving or, in case of damages, when the device must be sent

back to a repair center. The outer and inner packing material should be removed

completely from the device before installation.

Please inspect the device upon completeness. In case any part is missing please

contact our customer service center immediately.

3.3 Storage

Keep the package closed until installation and under consideration of the outside

indicated positioning- and storage markings.

Packages should be stored under consideration of the following:

- do not store outdoors,

- keep it dry and dust-free,

- do not expose it to aggressive media,

- do not expose it to direct sunlight,

- avoid mechanical shocks and vibration,

- in case of longer storage (> 3 months) make sure you check the state

of the packaging and the parts regularly, if required refresh or renew.

- 41 -

Page 11

Name

Vegetable cutter GMS580

Code-no.:

120328

Material:

cast aluminium, stainless steel, plastic

Model:

filling funnel:

- W 83 x D 160 x 150 mm

ON/OFF switch

Control lights: in operation, warning light

Features:

- Magnetic switch

- Stainless steel lid, dishwasher safe

- Simple assembly / disassembly of attached parts

Power:

0.58 kW / 230 V 50 Hz

Degree of protection:

IPX3

Dimensions:

W 300 x D 500 x H 535 mm

Equipment

(included in delivery):

1 cutting disc E2-580 for slices, slicing thickness 2 mm

1 eject disc

1 stamper

Weight:

21.0 kg

4. Technical data

4.1 Technical specification

We reserve the right to make technical changes!

- 42 -

Page 12

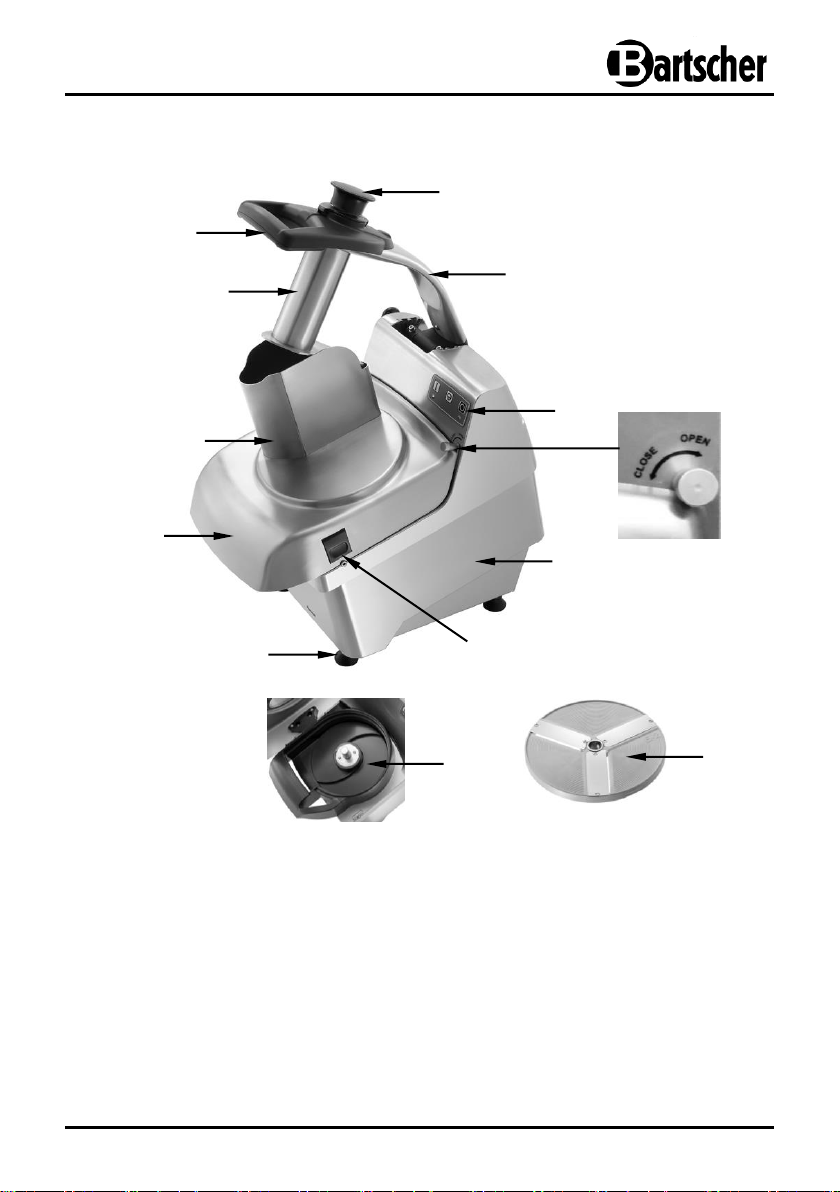

1

Pusher

8

Lid handle

2

Stamper

9

Feet (4x)

3

Oval filling hole

10

Outlet hole

4

Stamper lever

11

Lid with oval filling hole

5

Control panel

12

Eject disc

6

Lid closing setting screw

13

Cutting disc E2-580

7

Body

10

11

2 1 3

7

12

13

Fig. 1

6 4 5

8

9

4.2 Overview of parts

- 43 -

Page 13

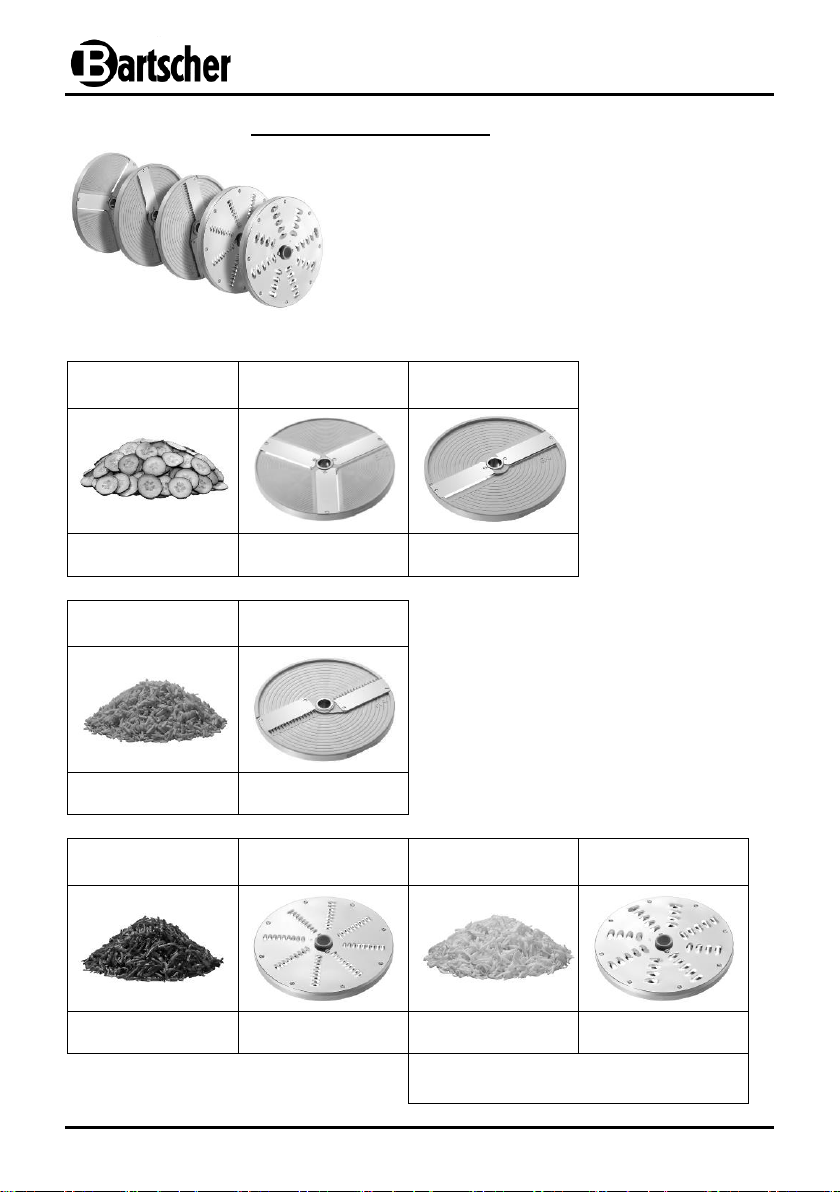

Slicing disc set GSM580

Material: CNS 18/10, plastic

dimensions: W 210 x D 230 x H 240 mm

Weight: 1.8 kg

Code-no. 120354

Slicing discs

for slices

E2-580

E4-580

Cutting

thickness:

2 mm

4 mm

Slicing disc

for sticks

H4-580

Cutting

thickness:

4 mm

Slicing disc

for grating

Z4-580

Slicing disc

for grating

Z7-580

Cutting

thickness:

4 mm

Cutting

thickness:

7 mm

also suitable for grated cheese and soft

cheese

Auxiliary equipment (not included in the delivery!)

Set comprises:

- 44 -

Page 14

4.3 Protective elements

WARNING!

Non-compliance with safety rules and processes may lead to danger

and damage.

Use of the appliance is only permitted if the user complies with the following rules:

1. follows all regulations and/or standards that apply to the installation of the

appliance and the behaviour of persons; especially regarding the fixed

equipment of the appliance used for connection/operation of the appliance;

2. follows all other instructions and warning signs for the use of the appliance,

which are to be regarded as part of the technical/graphic system of the

appliance.

CAUTION!

Do not remove any protective and safety elements from the appliance.

When those elements have to be removed due to exceptional maintenance

works, appropriate steps must be taken immediately to mark the absence of

protective elements and to minimise the resulting danger.

After removing the circumstances which led to the temporary removal of protective

or safety elements, those elements must be reassembled immediately.

All protective elements of the device, both electrical and mechanical, should be kept

in perfect and unchanged condition.

- 45 -

Page 15

Warnings for residual risks

CAUTION!

Under no circumstances may the user attempt to open or remove the fixed or

movable lid or modify the safety elements.

The vegetable cutter GMS580 has electronic and mechanic protective devices

conforming to the standard requirements, either during operation and cleaning and

maintenance.

Nevertheless, there are RESIDUAL RISKS, resulting from removal of fixed or movable

elements or interference with damaged/worn parts of the appliance.

This operating instruction indicates possible residual risks with use of expression:

WARNING.

During refilling, maintenance, replacement of equipment, and cleaning, as well as

during all other manual activities at the appliance, during which hands or other body

parts are introduced into hazardous areas of the appliance, there is a residual risk

mainly consisting of:

1. hitting the elements of the appliance,

2. abrasion on rough parts of the machine,

3. injury on pointed elements,

4. cut wounds from sharp elements.

Moreover, during the filling phase there is a residual risk of hands being introduced into

hazardous areas of the machine when the stamper is lifted, thereby creating a risk of

cutting injuries from sharp elements.

During the cleaning phase and removal of jammed product residues there is also a

residual risk if hands are placed near the cutting discs inside the appliance, which may

result in cut wounds from sharp elements of equipment.

Both the user and the maintenance technician must be trained in all operations carried

out with the open lid. Moreover, they must be trained in range of risk and authorised by

the responsible person.

The user and the service technician must wear suitable personal protective equipment,

e.g. cut-resistant gloves.

All work at the cutting discs must only be carried out when the cutting disc blades are

pointing downwards.

- 46 -

Page 16

Fig. 2

There is a magnetic switch on the stamper

lever group, which stops rotation of the

appliance elements during access through

the filling hole (Fig. 2)

Fig. 3

There is a magnetic switch on lid in the

upper part of the appliance, which stops

rotation of the appliance elements during

access through the filling hole (Fig. 3)

The drive elements of the device are fully shielded by protective elements which

prevent access to the drive elements.

All safety systems, including control pushbuttons, use proven parts and safety

components.

Taking into account the conditions and the purpose of use, the moving parts have been

separated by fixed or movable protective devices or by other protective elements which

are at such distance from the access points of the device as to prevent access to

dangerous places.

Protective devices

The vegetable cutter GMS580 is equipped with the following protective

devices:

A Magnetic switch on the stamper lever group

B Magnetic switch in the lid

- 47 -

Page 17

Fig. 4

The cutting filling hole has appropriate

length: the appliance elements are

located in such distances from the

access points that they are not

reachable (Fig. 4).

C Permanent protective device on the filling hole

In the product ejection area access with hand or its part to the movable elements of

the appliance or other dangerous places is prevented by special design of eject disc and

moving discs.

The vegetable cutter is equipped with self-locking circuit which

protects the appliance from self-activation after the power supply failure.

- 48 -

Page 18

5. Installation and operation

5.1 Installation

CAUTION!

Any installation, connection and maintenance work related to the device must

be performed by the qualified and certified technician in accordance with the

applicable international, national and local regulations.

Positioning

Unpack the device and discard the entire packaging material according to the

regulations valid in the country of installation.

Place the device on an even, stable, dry and waterproof and heat-resistent surface.

Never place the device on an inflammable surface.

Never place the device in wet or damp locations.

Do not place the device near open flame, electric heaters or other heat source.

The working room must be consistent with the requirements of the Directive

89/654/EEC. No foreign objects may be found in the working area. The employer

shall, according to the Directive 89/391/EEC regarding measures to encourage

improvements in health and safety of employees during work, remove or reduce the

residual risks mentioned in the instructions in accordance with law.

Place the appliance on the working table, suitable for use in range of work with food

products, of height of 900 – 1100 mm from the floor level.

During positioning of the cutter take into consideration space required for

positioning, as well as place for container collecting cut vegetables and products to

be cut. Leave sufficient free space around the cutter to assure free movements of

operator and for movement of third persons.

The location of the device must be properly illuminated, illumination must include the

whole work station and must not dazzle the operator.

- 49 -

Page 19

Do not cover or block the device ventilation holes in order to avoid overheating or

injuries and damages.

Place the device so that the plug is easily accessible so as to quickly disconneet the

device if the need arises.

Before the first use, remove the protective foil from the device. Remove the foil slowly

not to leave glue residues. Remove possible glue residues with appropriate solvent.

CAUTION!

Never remove the type plate and warning signs from the device.

Connection

DANGER! Electric shock hazard!

The device can cause injuries due to improper installation!

Before installation and connecting the local power grid specification should

be compared with that of the device (see rating plate). Connect the device only

in case of compliance!

The power supply circuit with the socket must be protected by the fuse of at least 16A.

Connect the device directly to a single grounded socket. Do not use any power bar or

multiple socket.

- 50 -

Page 20

5.2 Operation

CAUTION!

The appliance is designed for operation by one user only. The user should be

properly trained and informed about residual risks, and at the same time

should have the knowledge of the maintenance technician in range of safety.

Standard working area of the user consists of:

1. side area of the appliance near the filling holes in normal operational

conditions, in order to realize all activities aimed for manual filling of food

products and to operate the pusher for pushing the food products into the filling

hole, with closed and fixed permanent and movable protective elements;

2. front area of the appliance near the food products eject area in normal

operational conditions, in order to realize all activities aimed for manual receiving

of food products and to put them in the appropriate containers, with closed and

fixed permanent and movable protective elements.

5.2.1 Preparation of the appliance

The appliance should be thoroughly cleaned before the first use. Follow the

instructions in section 6.3 “Cleaning”.

For products to be grated select the appropriate discs and install them in the

appliance before starting the grating process. Follow the instructions regarding the

cutting discs in section 4.2 “List of appliance subassemblies / Auxiliary

equipment”.

WARNING! Injury hazard!

Blades of the cutting disks are very sharp! Always wear solid, soft protective

gloves allowing for firm grip of objects during the installation, replacement,

and cleaning of cutting discs.

- 51 -

Page 21

- Lift the stamper lever group from

the lid filling hole using the handle.

- Rotate the lid closing setting

screw (1) clockwise to unlock the

appliance lid (2).

- Open the lid (2) using the handle

(3), rotating it to the side.

- First put the eject disc (4) on the

motor shaft. Make sure that the

motor shaft driving pins are

located in the eject disc (4) holes.

- Now install selected cutting

disc (5) on the motor shaft

above the eject disc (4).

Fig. 5

Assemble the appliance before start-up. During the assembly proceed in the

following way (Fig. 5):

NOTE!

It is ALWAYS required to install the eject disc so the cutting discs are

correctly positioned on the motor shaft.

CAUTION!

After installing the cutting disc make sure that it is correctly fixed to the motor

shaft with use of bayonet lock.

- Replace the lid (2) to close the cutting discs area.

- Lock the lid (2) with the setting screw (1), rotating ir counterclockwise.

- The disassembly shall be performed according to the above mentioned description,

but in the reverse order.

- 52 -

Page 22

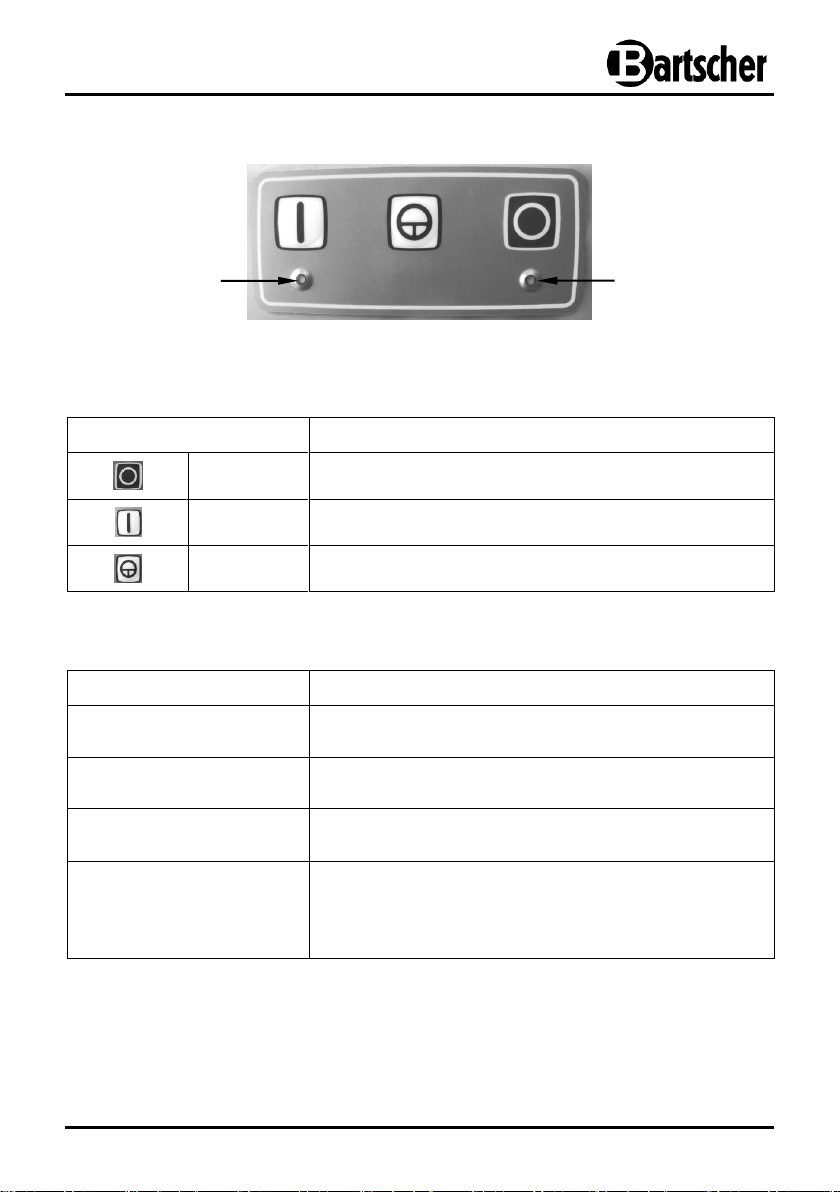

Type/colour

Description

black

STOP button

white

START button

white

PULSE button

Type/colour

Description/meaning

Red LED indicator light

illuminates

The appliance operates with closed lid and stamper

lever pressed down

Red LED indicator light

flashes

The appliance operates with closed lid

Green LED indicator light

illuminates

The appliance operates

Green LED indicator light

flashes

The appliance operates with pressed Pulse-Start

pushbutton and stamper lever lifted;

the device operates while the stamper lever is lifted

(green LED indicator light illuminates)

Red

LED indicator light

Green

LED indicator light

5.2.2 Control panel

Control pushbuttons

Indicator lights

Fig. 6

- 53 -

Page 23

START

The appliance start-up is possible only by intended use of appropriate control

pushbutton: white Start pushbutton should be pressed to start the appliance.

STOP

Press black Stop pushbutton to stop the appliance. In case of temporary or longer

standstill of the device all food products should be removed from inside before

restarting it: Follow the appliance disassembly instructions.

START IN PULSE OPERATION MODE

The appliance start-up in pulse mode is possible only by intended use

of appropriate control pushbutton: white Start pushbutton should be pressed to

start the appliance in pulse mode. The appliance stops after releasing the pushbutton.

NO POWER SUPPLY

In case of power supply failure or when the appliance is disconnected from the power

supply it may be restarted only by repeating the start-up process, after restoring or

reconnecting to the power supply

LIFTING THE STAMPER LEVER GROUP

After lifting the stamper lever group the appliance is immediately stopped due to the

operation of the magnetic switch on the stamper lever. Reactivation of the appliance is

possible only after lowering the stamper to level preventing access of fingers to the

cutting area and after repeating the start-up process.

REMOVING THE LID OF THE DEVICE

After unscrewing the setting screw and removing the lid with use of both hands the

appliance is immediately stopped due to the operation of the magnetic switch on the lid.

Reactivation of the appliance is possible only after replacing the lid and refitting the

setting screw, and after repeating the start-up process.

- 54 -

Page 24

Inspection/control

Procedure and results

Make sure that:

there are no foreign objects

on the appliance and in the

filling and eject holes

there are no foreign objects like tools, towels, etc.,

and food products in the given elements and areas.

Remove such objects if found.

Cleanness control:

internal parts of the appliance

slicing area, discs, internal

side of the lid

eject hole

lever and pusher

external surface of the

appliance

Above areas should be visually checked for

cleanness.

In order to perform the visual inspection of internal

elements in the slicing area it is required to remove

the lid.

When mould or other contaminants are found, those

parts should be cleaned according to instrctions in

Section 6.3 “Cleaning”.

The condition inspection

includes:

permanent covers

lid

filling and eject holes

stamper

housing of the appliance

All permanent covers must fulfil their functions.

Perform the visual inspection of given elements to

make sure they are not externally damaged.

Those elements must be absolutely replaced in

case of the first signs of wear or damage (by the

authorized service company only).

Inspection of operational

ability:

of control elements designed

for assuring safety;

of control systems.

Check all elements to make sure they realize their

functions.

Those elements must be absolutely replaced in

case of the first signs of wear or damage (by the

authorized service company only).

Make sure that:

the appliance does not emit

any strange sounds after

switching on

After noticing any strange sound during inspection

of control elements, indicating e.g. seizure or

mechanical damages, stop the appliance

immediately and call the service company.

5.2.3 Inspection and control of operation before start-up

Any intervention in the appliance or replacement of damaged parts may only be

carried out by the authorised service company. Use only the original spare parts

supplied by the manufacturer!

- 55 -

Page 25

5.2.4 Start-up

Before starting the cutting process make sure that vegetables/fruits are suitable in

range of type, quality, and size. Vegetables/fruits must be properly prepared (peeled,

cut into appropriate pieces, have seds removed, etc.).

Hint: use only hard tomatoes for cutting!

The device must be switched on while observing the following instructions:

1. Positive inspection result in range of preparation;

2. Positive inspection result in range of power supply;

3. Connection of the appliance to the grounded, single socket;

4. Positive inspection result in range of assembly (position of discs, etc.);

5. Positive inspection result before start-up;

6. Positive inspection result in order to assure following all safety regulations;

7. Put on the lid and tighten the setting screw;

8. Place appropriate receiving container under the eject hole in front area of the

appliance;

9. Stand on the left side at the appliance and start it by pressing white Start

pushbutton;

10. Use hand to fill the filling hole with prepared food products: put large pieces into

the lid filling hole, put smaller ones (potatoes, courgette, etc.) into the filling hole

on the stamper lever.

Warning: Never press the cut products with hand, always use delivered

stamper! Danger of injuries!

11. Depending on the processing type the food products should be pressed down,

toward the slicing area, by gradual lowering of the stamper lever or with use of

attached pusher. Apply light pressure force to obtain the optimum results without

causing high load of drive elements.

12. After pressing the stamper or pusher until the end lift it and repeat, until the

required amount of sliced product is prepared. When the stamper is pressed

down again, the device turns on automatically;

13. After finishing the slicing process or when the products are no longer ejected

from the eject hole, stop the device by using

black Stop pushbutton.

Empty the receiving container regularly. Overfilled containers may hinder normal

emptying process, cutting may be irregular, the appliance may become jammed,

or motor may become damaged.

- 56 -

Page 26

5.2.5 Switching off

Disconnect the appliance according to the following sequence:

1. wait until all sliced products exit the eject hole. It is realized by

complete lowering the stamper lever and pusher;

2. stop the appliance by pressing black Stop pushbutton;

3. remove the plug from the socket;

4. perform the cleaning process according to instructions in section

6.3 “Cleaning”.

5.2.6 Unlocking after the product jam

During processing or rotation of the appliance elements it may be stopped due to:

1. using incorrect pieces of food products,

2. using too hard or dry products.

A similar situation may occur in case of power supply failure or when the appliance gets

jammed by products inside it.

In order to restore normal operation first it is necessary to remove the slicing discs.

During disassembly follow the procedure described above.

- 57 -

Page 27

6. Maintenance, troubleshooting, cleaning

6.1 Maintenance

CAUTION!

We recommend to order the maintenance of the appliance in the professional

service company at least once a year. Any works interfering in the appliance

must be performed by the professional and qualified personnel.

WARNING!

Any activities connected with maintenance, cleaning, and replacement of the

individual elements must be absolutely realized with appliance stopped and

disconnected from the power supply.

Requirements for the maintenance personnel

The term “Maintenance” means not only the periodical inspection of correct

operation of the appliance, but also the analysis and resulting interventions

regarding any reasons making the appliance non-operational. For activities including

maintenance, cleaning, replacement of individual parts, and troubleshooting,

realized by the user, those tasks must be assigned to an experienced,

authorized, and qualified person.

Maintenance regulations

Removing covers and/or protective elements

Few interventions described in this section require removing of some permanent

protective elements. They must be removed by the maintenance technician only.

After the intervention those covers must be replaced and fixed in their initial

position in appropriate elements, just like before the repair.

A responsible maintenance technician must completely turn off the device

and disconnect it from the power supply (remove the plug from the socket!)

before removing any permanent cover or replacing any element.

Extraordinary maintenance

Interventions in range of extraordinary maintenance, required due to damages,

overhauls, or mechanical and electrical damages (e.g. tensioning of drive belts,

etc.), must be realized by the authorized service company only.

- 58 -

Page 28

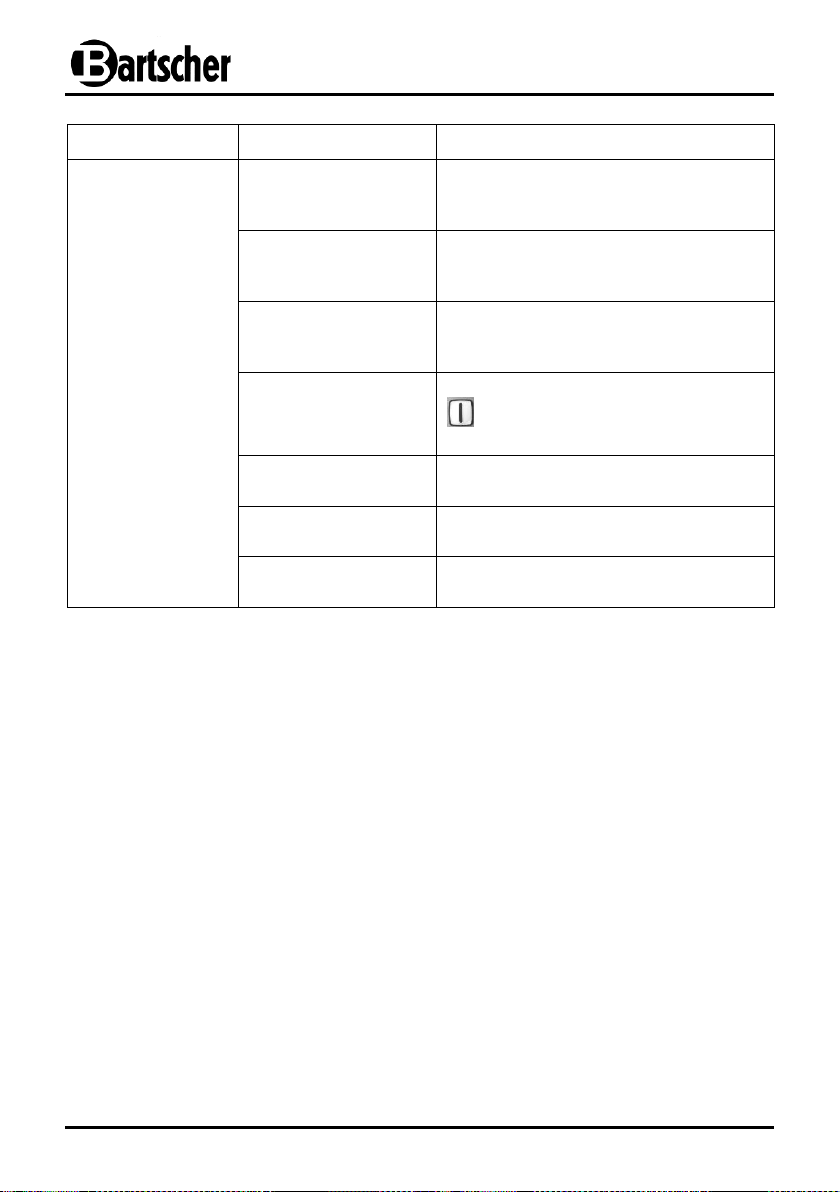

Failure type

Possible reason

Procedure and results

No voltage

No power supply

Contact the electricity company

Fuses or residual

current device tripped

Reset those elements after removing

the reason of their activation. When

such situation persists, call the

electrician.

Interrupted work

Protective element in

the appliance tripped

Call the electrician. Reset those

elements after removing the reason of

their activation.

Lifting the stamper

lever (green LED

indicator light flashes)

After lifting the stamper lever the

appliance is immediately turn off: the

magnetic switch interrupts its operation.

Press the stamper lever group down to

prevent putting fingers into the moving

elements.

Lid removal

(red LED indicator

light flashes)

After removing the lid by unscrewing

the setting screw the appliance is

turned off by the magnetic switch.

Replace the lid and fix it with the setting

screw to restart the appliance.

Reasons impossible

to identify

Contact the service company

6.2 Troubleshooting and unlocking of movable elements

CAUTION!

Troubleshooting and unlocking of movable elements must be realized

by the maintenance technician only.

- 59 -

Page 29

Failure type

Possible reason

Procedure and results

The appliance is

non-operational:

cutting discs do

not rotate or do

not make the

clean cutting.

Complete voltage

loss: all LED lights

are off

Check and restore the power supply

The switchable socket

is set to position “0” (all

LED lights are off)

Set the switchable socket to position "I"

Fuses or residual

current device tripped

Replace fuses, check the residual

current device

Damaged Start

pushbutton

Check operation of Start pushbutton

and contact the service company

when required

Damaged magnetic

switch

Contact the service company

Slicing discs are worn

or damaged

Contact the service company

Drive belt causes

noise or scratching

Contact the service company

- 60 -

Page 30

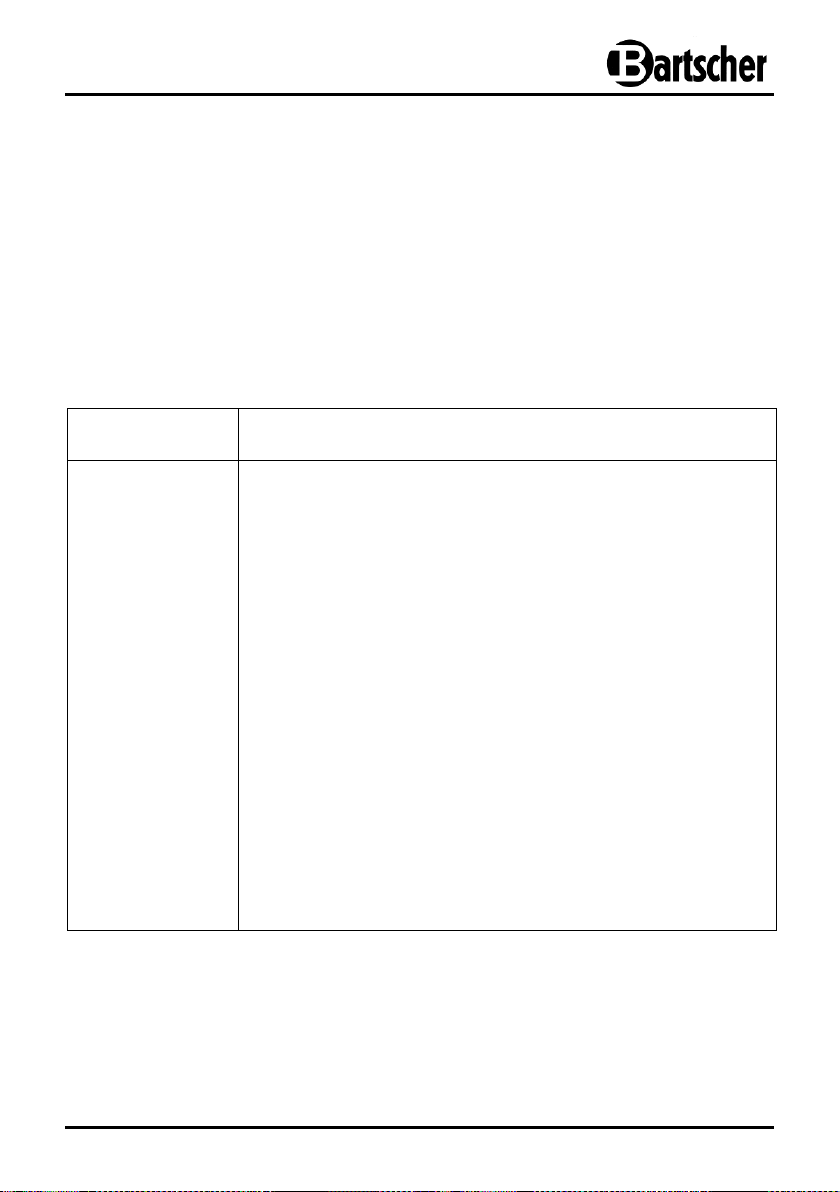

Frequency/

Personnel

Process

After each work

shift and

absolutely

before the daily

use/

Operators

All external surfaces and elements having contact with food or

located in food area (internal surfaces of filling and eject holes,

tamper, pusher, slicing area, cutting discs, lid, permanent

covers) and splash areas (external surfaces of the appliance)

should be cleaned as described below.

Follow the procedure described above to disassemble the

cutting discs.

Remove any food residuals from the external surfaces

(e.g. using the plastic scraper).

Clean all external surfaces in the food and splash areas

with moistened cloth (non-dripping) and detergent diluted

in lukewarm water (also common dishwashing soap); Do not

soak. Use only special liquid and chlorine-free products for

steel (do not use any polishing creams or pastes). It is

allowed to use the denaturised alcohol for degreasing.

Rinse in lukewarm water and wipe all surfaces in the food

and splash areas with soft, lint-free cloth.

All stainless steel elements may be also washed in a

dishwasher.

Reassemble the appliance only before the next use; store

the appliance elements wrapped in soft, lint-free cloth.

6.3 Cleaning

o It is forbidden to clean the movable parts and elements manually.

o All activities connected with cleaning must be realized only when the appliance is

completely empty of food products and disconnected from the power supply.

o Never clean the appliance, electric system, or components with water or jet,

regardless their character or amount.

o Never place the appliance directly to the sink or under the tap.

o The hygienic level for the appliance and its accessories is two (2) for the

intended use: Appliances fulfilling the international requirements upon the risk

analysis connected with hygiene, but requiring the programmed disassembly for

cleaning.

- 61 -

Page 31

Frequency/

Personnel

Process

After each work

shift and

absolutely

before the daily

use/

Operators

Longer operational breaks

In case of longer operational breaks all steel surfaces

(especially made from stainless steel) should be covered with

thick coating of vaseline oil with use of cloth to protect them by

an additional layer.

Before and during cleaning it is forbidden to:

grab the movable elements without making sure that they are

at standstill;

grab the movable elements without making sure that the

appliance has been safely stopped (interrupted power supply,

possibly switched off power supply socket)

Products which should not be used:

Jet of compressed air onto the areas covered with flour and in

general onto the appliance;

Steam cleaning devices;

Cleaning agents containing CHLORINE (also diluted) or its

compounds, like bleaching lyes, hydrochloric acids, pipe

unclogging agents, cleaning agents for marble, general

descaling agents, which may impact steel properties and

cause permanents stains or oxidation. Even the vapours of

listed agents may cause oxidation and damage steel in some

cases.

Metal plates, brushes, or polishing discs from other materials

or alloys (e.g. steel, aluminium, brass, etc.) or tools used

previously for cleaning of other metals or alloys. Those

elements scratch the appliance surface.

Polishing powders for cleaning;

Petrol, solvents, flammable and/or caustic liquids;

Silver cleaning agents.

- 62 -

Page 32

DISASSEMBLY / ASSEMBLY FOR CLEANING

1. Unscrew the lid (1) setting screw and

use both hands and handle (2) to tilt the

lid (3) to the side.

2. Remove the cutting discs and eject disc

(4) from the motor shaft, remove the

cutting dics holder (5).

3. Pull the lid (2) from the motor shaft (1).

4. Use the handle to open the stamper lever

group as far as possible.

5. Pull the protective mandrel (1).

6. Disconnect the stamper lever group from

position (2) by lifting it.

7. Rotate and remove the pusher (3).

- 63 -

Page 33

The electric devices are marked with this symbol. You must not

dispose of electric devices with household waste. When the

device may not be longer used each consumer is obliged to

dispose of the device at the dedicated local collection point,

separately from household waste.

NOTE!

Electric devices should be used and disposed of properly to prevent the impact on

the environment.

Disconnect the device from the power supply and remove the power cord from

the device.

7. Waste disposal

Old devices

Bartscher GmbH phone: +49 5258 971-0

Franz-Kleine-Str. 28 fax: +49 5258 971-120

33154 Salzkotten Service-Hotline: +49 5258 971-197

Germany www.bartscher.com

- 64 -

Loading...

Loading...