Page 1

ELECTRONIC MODULAR

FLAKERS

SERVICE MANUAL

104409 F80

104436 F125

71503

135-0-000 service Flakers GB

Page 2

Page 3

GB

3

TABLE OF CONTENTS

S

pecification F 80C pagina 4

Specification F 125C 5

Specification F 120 6

Specification F 200 7

Specification SF 300 8

S

pecification SF 500 9

Specification SFN 1000 10

GENERAL INFORMATION AND INSTALLATION

Introduction 11

Unpacking and Inspection - Ice maker 11

Unpacking and Inspection - Storage bin 11

Location and levelling 12

Electrical connections 13

Water supply and drain connection 13

Final ceck list 13

Installation pratice 14

OPERATING INSTRUCTIONS

Start up 15

Operations checks 17

PRINCIPLE OF OPERATION (how it works)

Water circuit 20

Refrigerant circuit 21

Mechanical system 23

Operating pressures 24

Components description 25

ADJUSTMENT, REMOVAL AND REPLACEMENT PROCEDURES

Adjustment of the evaporator water level 29

Replace of the gear motor magnetic sensor 29

Replace of auger, water seal, bearing and coupling 29

Replacement of the gear motor assy 30

Replacement of freezing cylinder 31

Wiring diagram 32

Service diagnosis 36

MAINTENANCE AND CLEANING INSTRUCTIONS

General 38

Icemakers 38

Cleaning instructions of water system 38

Page 4

GB

4

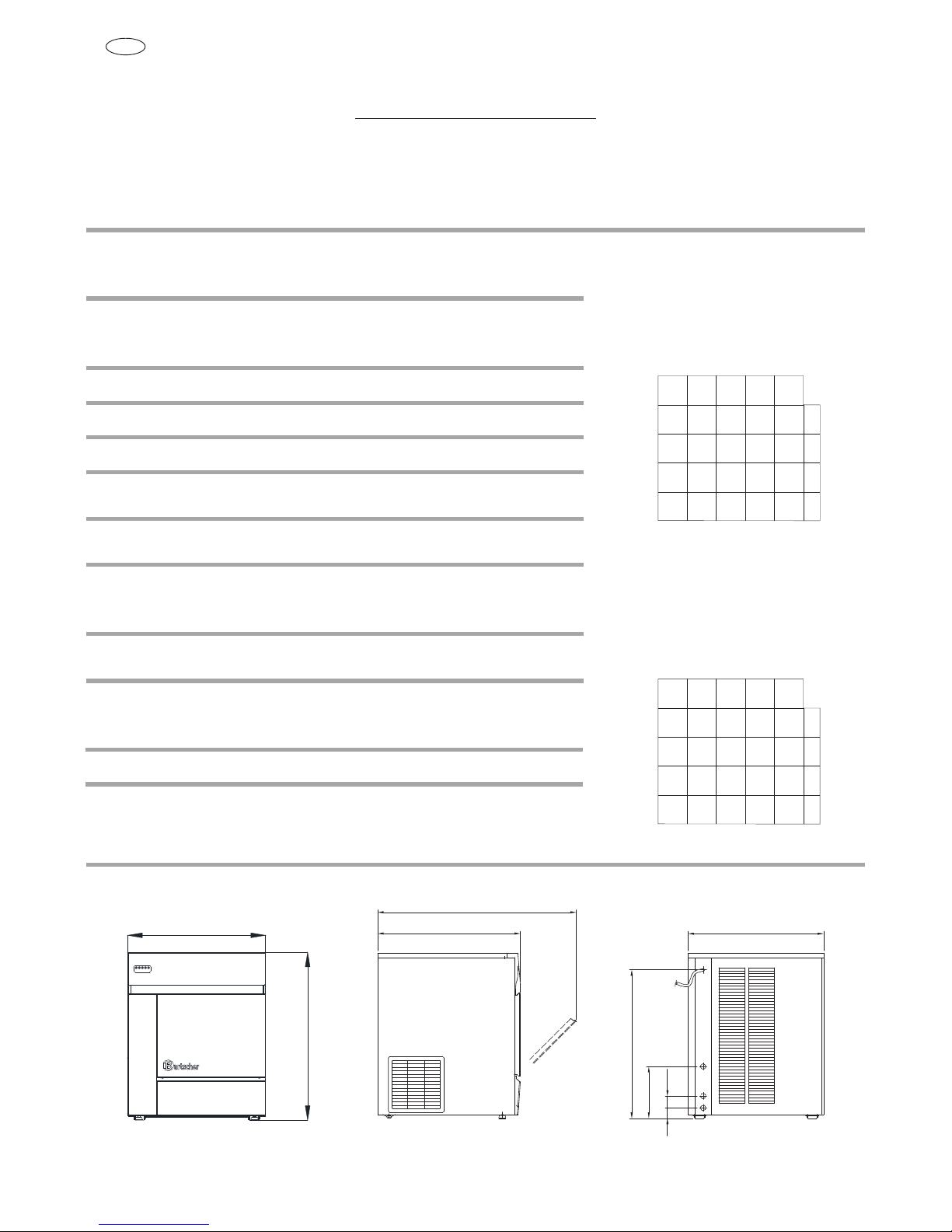

TECHNICAL SPECIFICATION

ELECTRONIC MODULAR

FLAKERS mod. F80 (R 134a)

Produzione di ghiaccio in 24 ore fino a

Ice produced for 24 hours up to

Eisproduktion in 24 Stunden bis zu

Production de glace en 24 h jusqu’à

Produccion de hielo en las 24 horas hasta

Raffreddamento unità condensatrice aria o acqua: consumo n. 20 litri per ora*

Condensing unit cooling air or water: consumption n. 20 litres per hour*

Kondensatoreinheit Luft oder Wasser: Verbrauch n. 20 liter pro Stunde*

Refroidissement de l’unité de condensation air ou eau: consommation n. 20 litres par heure*

Refrigeración de la unidad condensadora aire o agua: consumo n. 20 litros para hora*

Potenza assorbita/Absorbed power/Leistungsaufnahme

Puissance absorbée/Potencia Absorbida

Refrigerante/Refrigerant/Kältemittel

Réfrigérant/Refrigerant

Attacco entrata acqua/Water iniet connection

Anschluss für Wasserzufluss/Prise entrée d’eau/conexión entrada agua

Attacco scarico acqua/Water output connection

Anschluss für Wasserabfluss/Prise écoulement d’eau

Conexión desague

Alimentazione monofase/Single phase input/

Einphasige Spannung/Alimentation monophase

Alimentación monofásica

Alimentazione voltaggi speciali: a richiesta

Extra voltages: on request

Andere Spannungen: Lieferbar auf Wunsch

Alimentation voltages spéciaux: sur demande

Otros voltajes especiales: según pedido

Capacità deposito - Storage bin capacity

Inhalt des Vorrats-Eisbehänders

Capacité de la réserve - Capacidad del deposito

Carrozzeria

External structure

Ausfühnrung inox

Carrosserie

Carroceria

Peso netto/Net weight/Netto Gewcht

Poids net/Peso neto

PRODUZIONE DI GHIACCIO

ICE PRODUCTION

EIS PRODUKTION

PRODUCTION DE GLACE

PRODUCICON DE HIELO

RAFFR. AD ACQUA/WATER COOLED

WASSERGEKÜHLT/REFR. A EAU

REFR. A AGUA

Temperatura acqua/Water temperature

Wassertemperatur/Température eau

Temperatura agua

Prod. ghiaccio in 24 h/Ice prod. per 24 h

Eisprod. in 24 h/Prod. de glace en 24 h

Prod. de hielo en 24 h

RAFFR. AD ARIA/AIR COOLED

LUFTGEKÜHLT/REFR. A AIR

REFR. A AIRE

Temperatura acqua/Water temperature

Wassertemperatur/Température eau

Temperatura agua

Prod. ghiaccio in 24 h/Ice prod. per 24 h

Eisprod. in 24 h/Prod. de glace en 24 h

Prod. de hielo en 24 h

°C 32° 21° 15° 10°

10° 78 84 87 90 kg

21° 72 78 81 84 kg

32° 58 63 66 68 kg

38° 48 52 54 56 kg

°C 32° 21° 15° 10°

10°

76 81 84 86 kg

21° 72 77 80 82 kg

32° 68 74 76 78 kg

38° 64 70 71 72 kg

Temperatura ambiente

Ambient temperature

Raumtemperatur

Température ambiante

Températura ambiente

Temperatura ambiente

Ambient temperature

Raumtemperatur

Température ambiante

Températura ambiente

(*) con temperatura acqua 15 °C

with water temperature 15 °C

mit Wassertemperatur 15 °C

avec température eau 15 °C

con temperatura agua 15 °C

kg. 90

W 400

R 134a

3/4” Gas

mm. Ø 20

220V-240V - 50 Hz

kg. 53

kg. 20

Dimensioni / Dimensions / Masse / Dimensions / Dimensiones

835

600

570

695

624

218

5044

570

Page 5

GB

5

TECHNICAL SPECIFICATION

ELECTRONIC MODULAR

FLAKERS mod. F125 (R 134a)

Produzione di ghiaccio in 24 ore fino a

Ice produced for 24 hours up to

Eisproduktion in 24 Stunden bis zu

Production de glace en 24 h jusqu’à

Produccion de hielo en las 24 horas hasta

Raffreddamento unità condensatrice aria o acqua: consumo n. 24 litri per ora*

Condensing unit cooling air or water: consumption n. 24 litres per hour*

Kondensatoreinheit Luft oder Wasser: Verbrauch n. 24 liter pro Stunde*

Refroidissement de l’unité de condensation air ou eau: consommation n. 24 litres par heure*

Refrigeración de la unidad condensadora aire o agua: consumo n. 24 litros para hora*

Potenza assorbita/Absorbed power/Leistungsaufnahme

Puissance absorbée/Potencia Absorbida

Refrigerante/Refrigerant/Kältemittel

Réfrigérant/Refrigerant

Attacco entrata acqua/Water iniet connection

Anschluss für Wasserzufluss/Prise entrée d’eau/conexión entrada agua

Attacco scarico acqua/Water output connection

Anschluss für Wasserabfluss/Prise écoulement d’eau

Conexión desague

Alimentazione monofase/Single phase input/

Einphasige Spannung/Alimentation monophase

Alimentación monofásica

Alimentazione voltaggi speciali: a richiesta

Extra voltages: on request

Andere Spannungen: Lieferbar auf Wunsch

Alimentation voltages spéciaux: sur demande

Otros voltajes especiales: según pedido

Capacità deposito - Storage bin capacity

Inhalt des Vorrats-Eisbehänders

Capacité de la réserve - Capacidad del deposito

Carrozzeria

External structure

Ausfühnrung inox

Carrosserie

Carroceria

Peso netto/Net weight/Netto Gewcht

Poids net/Peso neto

PRODUZIONE DI GHIACCIO

ICE PRODUCTION

EIS PRODUKTION

PRODUCTION DE GLACE

PRODUCICON DE HIELO

RAFFR. AD ACQUA/WATER COOLED

WASSERGEKÜHLT/REFR. A EAU

REFR. A AGUA

Temperatura acqua/Water temperature

Wassertemperatur/Température eau

Temperatura agua

Prod. ghiaccio in 24 h/Ice prod. per 24 h

Eisprod. in 24 h/Prod. de glace en 24 h

Prod. de hielo en 24 h

RAFFR. AD ARIA/AIR COOLED

LUFTGEKÜHLT/REFR. A AIR

REFR. A AIRE

Temperatura acqua/Water temperature

Wassertemperatur/Température eau

Temperatura agua

Prod. ghiaccio in 24 h/Ice prod. per 24 h

Eisprod. in 24 h/Prod. de glace en 24 h

Prod. de hielo en 24 h

°C 32° 21° 15° 10°

10° 102 111 115 120 kg

21° 95 104 108 110 kg

32° 84 90 94 97 kg

38° 75 81 85 87 kg

°C 32° 21° 15° 10°

10°

97 108 117 120 kg

21° 95 105 115 117 kg

32° 90 100 107 110 kg

38° 87 97 102 105 kg

Temperatura ambiente

Ambient temperature

Raumtemperatur

Température ambiante

Températura ambiente

Temperatura ambiente

Ambient temperature

Raumtemperatur

Température ambiante

Températura ambiente

(*) con temperatura acqua 15 °C

with water temperature 15 °C

mit Wassertemperatur 15 °C

avec température eau 15 °C

con temperatura agua 15 °C

kg. 120

W 480

R 134a

3/4” Gas

mm. Ø 20

220V-240V - 50 Hz

kg. 64

kg. 27

Dimensioni / Dimensions / Masse / Dimensions / Dimensiones

680

90595~

750

510 680

150

90

45

Page 6

GB

6

A INTRODUCTION

the step-by-step procedures for the installation,

start- up and operation, maintenance and

cleaning for the F80 - F125 Modular Icemakers.

The Electronic Flakers and Superflakers are

quality designed, engineered and manufactured. Their ice making systems are thoroughly

tested providing the utmost in flexibility to fit the

needs of a particular user.

B. UNPACKING AND INSPECTION

Icemaker

1 Call you rauthorizedI Distributor or Dealer for

proper installation.

2 Visually inspect the exterior of the packing

and skid. Any severe damage noted should

be reported to the delivering carrier and a

concealed damage claimformfilled in subjet

to inspection of the contents with the carrier’s

representative present.

3 a) Cut and remove the plastic strip securing

the carton box to the skid.

b) Cut open the top of the carton and remove

the polystyre protection sheet.

c) Pull out the polystyre posts from the cor-

ners and then remove the carton.

d) Lift the whole carton and pull it out from

the device.

4 Remove top and sides panels of the unit and

inspect for any concealed damage.

Notify carrier of your claim for the concealed

damage as stated in step 2 above.

5 Remove all internal support packing and

masking tape.

6 Check that refrigerant lines do not rub again-

st or touch other lines or surfaces, and that

the fan blades move freely.

7 Check that the compressor fits snugly onto

all its mounting pads.

8 See data plate on the rear side of the unit and

check that local main voltage corresponds

with the voltage specified on it.

NOTE. To retain the safety and performance

built into this icemaker, it is important that

installation and maintenance be conducted

in the manner outlined in this manual.

GENERAL INFORMATION AND INSTALLATION

Page 7

GB

7

C. LOCATION AND LEVELLING

1 Position the storage bin in the selected per-

manent location. Criteria for selection of location include:

a) Minimum room temperature 10°C (50°F)

and maximum room temperature 40°C

(100°F).

b) Water inlet temperatures: minimum 5°C

(40°F) and maximum 35°C (90°F).

c) Well ventilated location for air cooled

models (clean the air cooled condenser at

frequent intervals).

d) Service access: adequate space must be

left for all service connections through the

rear of the ice maker.

A minimum clearance of 15 cm (6")must be

left at the sides of the unit for routing cooling

air drawn into and exhausted out of the compartment to maintain proper condensing

operation of air cooled models.

2 Level the Storage Bin Assy in both the left to

right and front to rear directions by means of

the adjustable legs.

D. ELECTRICAL CONNECTIONS

See data plate for current requirements to determine wire size to be used for electrical connections. All icemakers require a solid earth

wire.

All ice machines are supplied from the factory

completely pre-wired and require only electrical

power connections to the wire cord provided at

the rear of the unit.

Make sure that the ice machine is connected to

its own circuit and individually fused (see data

plate for fuse size).

The maximum allowable voltage variation

should not exceed -10% and +10% of the data

plate rating. Low voltage can cause faulty

functioning and may be responsible for serious

damage to the overload switch and motor windings.

Check voltage on the line and the ice maker’s

data plate before connecting the unit.

WARNING. This Modular Flaker and

Superflaker is designed for indoor installation only. Extended periods of operation at

temperature exceeding the following limitations will constitute misuse under the terms

of the Manufacturer’s Limited Warranty

resulting in LOSS of warranty coverage.

NOTE: This ice flake maker contains sensiti-

ve and highly precise parts. Knocks and

heavy blows must therefore be avoided.

NOTE. All external wiring should conform to

national, state and local standards and regulations.

Page 8

GB

8

E. WATER SUPPLY AND DRAIN

CONNECTIONS

When choosing thewater supply for the ice flaker

consideration should be given to:

a) Length of run

b) Water clarity and purity

c) Adequate water supply pressure

Since water is the most important single ingredient in producting ice you cannot emphasize

too much the three items listed above.

Low water pressure, below 1 bar may cause

malfunction of the ice maker unit.

Water containing excessive minerals will tend to

produce scale build-up on the interior parts of

the water system while too soft water (with too lo

contents of mineral salts), will produce a very

hard flaker ice.

Dark chlorinated or iron-containing water can be

improved through the active carbon filter

If water contains a high level of impurities, it is advisable to consider the installation of an appropriate

water filter or conditioner.

WATER SUPPLY

Connect the 3/4" GAS male of the water inlet fitting,usingthefoodgradeflexiblehosesupplied to

thecoldwater supply linewith regularplumbing

fitting and a shut-off valve installed in an accessible position between the water supply line and

the unit.

If water contains a high level of impurities, it is

advisable to consider the installation of an

appropriate water filter or conditioner.

WATER SUPPLY - WATER COOLED MODELS

The water cooled versions of Ice Makers require

two separate inletwater supplies, one for the

water making the flaker ice and the other for the

water cooled condenser.

Connect the 3/4" GAS male fitting of the water

inlet, using the flexible hose supplied to the cold

water supply linewith regular plumbing fitting

and a shut-off valve installed in an accessible

position between the water supply line and the

unit.

WATER DRAIN

The recommended drain tube is a plastic or flexible hose with 18mm(3/4") I.D. which runs to an

open trapped and vented drain. When the drain

is a long run, allow 3 cm pitch per meter (1/4"

pitch per foot). Install a vertical open vent on

drain line high point at the unit drain connection

to ensure good draining.

Theidealdrainreceptacleisatrappedandvented

floor drain.

WATER DRAIN - WATER COOLED MODELS

Connect the 3/4" GAS male fitting of the condenser water drain, utilizing a second flexible

hose to the open trapped and vented drain.

This additional drain linemust not interconnect to

any other of the units drains.

F. FINAL CHECK LIST

1 Is the unit in a room where ambient tempera-

tures are within a minimum of 10°C (50°F)

even in winter months?

2 Is there at least a 15 cm (6") clearance

around the unit for proper air circulation?

3 Is the unit level? (IMPORTANT)

NOTE. The water supply and the water drain

must be installed to conform with the local

code. In some case a licensed plumber and/

or a plumbing permit is required.

ATTENTION. The use of fully hardened

water (without or nearly without mineral

salts) with electric cable capability of

under 30 μS blocks the flow of low voltage

electricity between the lowest sensors in

the swimming pool and therefore causes

the device to be switched off or to stop

working

Page 9

GB

9

4 Have all the electrical and plumbing con-

nections been made, and is the water supply

shut-off valve open?

5 Has the voltage been tested and checked

against the data plate rating?

6 Has the water supply pressure been che-

cked to ensure a water pressure of at least 1

bar (14 psi). been checked to ensure that the

compressor is snugly fitted onto the mounting pads?

8 Check all refrigerant lines and conduit lines

to guard against vibrations and possible failure.

9 Have the bin liner and cabinet been wiped

clean?

10 Has the owner/user been given the User

Manual and been instructed on the importance of periodic maintenance checks?

11 Has the Manufacturer’s registration card

been filled in properly?

Check for correct model and serial number

against the serial plate and mail the registration card to the factory.

12 Has the owner been given the name and the-

phone number of the authorized Service

Agency serving him?

G. INSTALLATION PRACTICE

WARNING. This icemaker is not designed for outdoor installation and will not function in

ambient temperatures below 10°C (50°F) or above 40°C (100°F). This icemaker will malfunction with water temperatures below 5°C (40°F) or above 35°C (90°F).

1 Hand shut-off valve

2 Water filter

3 Water supply line

4 3/4" GAS male fitting

5 Power line

6 Main switch

7 Drain fitting

8 Vented drain

9 Vented drain

10 Open trapped vented drain

Page 10

GB

10

OPERATING INSTRUCTIONS

START UP

A

fter having correctly installed the ice maker and

co mple ted the p lumb ing a nd electr ical

connections, perform t he f ollowing “Start-up” procedure.

A. Open the water supply line shutoff valve

and put the unit under electrical power by moving

the main switch, on the power supply line, to the

ON position.

The first LED - GREEN - will glow to signal that

unit is under power.

NOTE. Every t ime t he unit i s put under power,

after being kept for sometime in shut-off

conditions (electrically disconnected) the

RED LED will blink for 3 minutes (60' on MF

66 only) after which the unit will start up with

the immediate operation of the gear motor

assembly and, af ter few seconds, of the

compressor (Fig.1).

B

. Elapsed the stand by period the unit starts

operating with the activation in sequence of the

following assemblies:

GEAR MOTOR/S

COMPRESSOR

FAN MOTOR/S (if unit is an air cooled version)

kept under control by the condenser temperature sensor which has i t s probe within t he condenser

fins (Fig.2).

C. After 2 or 3 minutes from the compressor

start up, observe that flaker ice begins dropping

off the ice spout to fall through the ice chute into

the storage bin.

NOTE. The first ice bits that drop into the ice

storage bin are not so hard as t he e v aporating

temperature has not yet reached the correct

operating value. It is necessary to allow the

ice - just made - to cure itself and wait for

about ten minutes for the evaporating temperature to reach the correct value so to

make more hard bits of ice.

FIG. 1

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

DATA PROCESSOR

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

T>1°C

11

10

9

1

2

L

N

8

7

6

5

4

3

13

12

Page 11

GB

11

FIG. 3

FIG. 2

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

C

ONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

R

ESET

S E N S O R S

W

ATER

LEVEL

GEAR MOTOR ROTATION

C

ONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

T 40÷50°C

DATA PROCESSOR

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

DATA PROCESSOR

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

T>-1°C

11

10

9

1

2

L

N

8

7

6

5

4

3

10

9

1

2

L

N

8

7

6

5

4

3

12

11

13

1

3

12

Page 12

GB

12

NOTE. If, after ten minutes from the

compressor start-up, the evaporating temp

erature has not dropped down to a value

lower than -1

°

C (30°F) the evaporating tem-

perature sensor detects such an abnormal

s

ituation and stops consequently the unit

operation (first the compressor and 3' later

the gear reducer).

I

n t his c ircustanc e , t he 5th w arning YELLOW

LED will blink.

The machine will remain in OFF mode for

one hour then it will restart automatically.

In case the unit trips OFF again in alarm for

3 times in 3 hours, the machine SHUTS OFF

DEFINITIVELY.

After having diagnosed and eliminated the

cause of the too hi evaporating temperature

(insufficient refrigerant in the system or

compressor not running) it is necessary to

unplug and plug in again to restart the

machine. The unit, before resuming the

normal operation, will go through the usual

3 minutes STAND-BY period.

OPERATION CHECKS UPON THE UNIT

START UP

D. Remov e front service panel and, if

necessary, install the refrigerant service gauges

on the corresponding service valves to check

both the HI and LO refrigerant pressures.

NOTE. On air cooled models, the condenser

temperature sensor, which is located within

th e con denser fins, keeps the head

(condensing) pressure between preset

values.

In the event of condenser clogged - such to

prevent the proper flow of the cooling air - or,

in case the fan motor is out of operation, the

condenser temperature rises and when it

reaches 70° C (160°F) for air cooled version -

a

nd 60

°

C (140

°

F

) - for water cooled version -

the condenser temperature sensor shuts-off

t

he ice maker (first the compressor and 3'

later the gear reducer) with the consequent

light-up o f t he R E D W ARNING LIGHT ( F ig.3).

The machine will remain in OFF mode for

one hour then it will restart automatically.

In case the unit trips OFF again in alarm for

3 times in 3 hours, the machine SHUTS OFF

DEFINITIVELY.

After having diagnosed the reason of the

temperature rise and removed its cause, it is

necessary to proceed as per the previous

“NOTE” to start up again the operation of the

ice maker.

E. Check for the correct CUT-OUT and

CUT - I N o f t he water l evel sensor by f irst s hutting

closed the water shutoff valve on the water

supply line.

FIG. 4

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

T>75°C

DATA PROCESSOR

11

10

9

1

2

L

N

8

7

6

5

4

3

13

12

Page 13

GB

13

After 3 minut e s t he unit resumes i ts t o t al operation

w

ith the immediate start-up of the gear motor

and, few seconds later, of the compressor.

F. Check for the correct operation of the

electronic eye (one per each ice chute on model

M

F 66) of the optical ice level control, by closing

t

he bottom opening of the vertical ice chute.

Wait the built up of the ice into the ice chute till it

cuts the light beam of the sensing "eyes".

This interruption will c ause an immediate blinking

of the Bin Full YELLOW LED located on the front

of the P.C. Board and after about 6 seconds

causes the shutoff of the unit (compressor first

and 3' later the gear reducer) with the

simultaneous lighting (steady) of the Same LED

signalling the full bin situation (Fig.5).

Discharge the ice from the ice chute so to resume

the light beam previously interrupted (YELLOW

LED blinking fast) and after about 6 seconds the

flaker will re-start - t hrough t he 3 minutes S TANDBY period - wit h t he e xtinguishing o f t he Y E LLOW

LED.

This will cause a gradual decrease of the water

level in the float reservoir and as soon as the

level gets below the two vertical metal pins, the

flaker stops to operate (compressor first and 3'

later t he gear reducer) and t he YELLOW w arning

LED will glow to signal the shortage of water

(Fig. 4)

NOTE. The water level sensor detects the

presence of water in the float reservoir and

confirms it to the micro processor by

maintaining a low voltage current flow

between the two metal pins using the water

as conductor.

WARNING. The use of de-mineralized

water (water with no salt content) having

an electrical conductivity lower than 30

μS, will cause break with the consequent

CUT-OUT of the flaker and the glowing of

the YELLOW LED of water shortage, even

with water in the reservoir.

Opening the water supply line shutoff valve to fill

up again the float reservoir, the YELLOW LED

goes off while the RED LED starts blinking.

FIG. 5

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

DATA PROCESSOR

11

10

9

1

2

L

N

8

7

6

5

4

3

13

12

Page 14

GB

14

NO TE. The ICE LEVE L CONTROL

(INFRARED SYSTEM) is independent of the

temperature however, the reliability of its

detection can be affected by external light

radiations or by any sort of dirt and scale

sediment which may deposit directly on the

l

ight source and on the receiver.

T

o prev ent any pos sibl e ice ma ker

malfunction, it is advisable to locate the unit

where it can't be reached by any direct light

beam or light radiation and to follow the

instructions for the periodical cleaning of the

l

ight sensor elements as detailed in the

MAINTENANCE AND CLEANING PROCEDURES.

NOTE. In the front of the PC Board is located

a

small I/R Trimmer directly connected with

t

he optical Ice level control. By means of its

screw it is possible to modify the signal

r

eceived from the Ice Level control so to

o

vercame some problem caused by dirt and/

or low power supply.

When adjusted it is very important to check

for its correct operation using ice (NOT

HAND) to break the Infrared Beam. In case

t

he machine doesn't stop it means that the

new setting is too much powerfull and need to

be reduced alway s b y means o f t he I/R T rimmer.

M. If previously installed, remove t he refrigerant

service gauges and re-fit the unit service panels

previously removed.

N. Instruct the owner/user on the general

operation of the ice machine and about the

cleaning and care it requires.

FIG. 6

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

DATA PROCESSOR

REINSERZIONE

8

Page 15

FLOAT TANK

FLOAT VALVE

FREEZER

WATER INLET LINE

FREEZER

WATER

FEED LINE

ICE SPOUT

GB

15

FREEZER WATER

F

EED LINE

FREEZER

F

LOAT VALVE

ICE SPOUT

F

LOAT TANK

FREEZER

FLOAT TANK

F

LOAT VALVE

WATER INLET LINE

WATER INLET LINE

ICE SPOUT

F

REEZER

WATER

FEED LINE

WATER CIRCUIT

The water enter in the machine through the

water inlet fitting which incorporates a strainer located at the rear side of the cabinet - then it

goes to the water reservoir flowing through a

float valve.

The float reservoir is positioned at the side of the

freezing at such an height to be able to maintain

a constant water level. The water flows from the

reservoir into the bottom inlet of the freezer to

sorround the stainless steel auger which is vertically fitted in the center of the freezer.

In the freezer the incomingwater gets chilled into

soft (slush) ice which is moved upward by the

rotating action of the auger. The auger rotates

counter-clockwisewithin the freezer powered by

a direct drive gear motor and carries the ice

upward along the refrigerated freezer innerwalls

andbydoingso theice gets progressively thicker

and harder.

The ice, being costantly lifted up, meet the teeth

of the ice breakerwhich is fitted on the top end of

the auger,where it gets compacted, cracked and

forced to change from vertical into horizontal

motion to be discharged out, through the ice

spout and chute, into the storage bin.

NOTE.

The presence of thewater in the float

reservoir is detected by a system of two sensors which operates in conjunction with the P.C.

Board. The two sensors use the water as a conductor to maintain a low voltage current flow

between them. In case the water used is very

soft (de-mineralized) or the float reservoir gets

empty the current flow between the sensors

become so weak or is no longer maintained

that, as consequence, the P.C. Board shutoff

the flaker operation with the simultaneous

glowing of the

YELLOW LED

signalling

“Shortage of water”.

PRINCIPLE OF OPERATION

Page 16

GB

16

By running the ice maker, i.e. by putting the unit

under power, starts the automatic and conti-

nuous icemaking process which would not stop

until the ice storage bin gets filled-up to the

level of the control “eyes” located on the ice

chute. As the ice level raises to interrupt the

light beam running between the two infrared

leds, the unit stops after six seconds (compressor first and 3' later the gear reducer), with the

simulteneous glowing of the YELLOW LED

signalling the “Full Bin” situation.

As some ice gets scooped out from the storage

bin, the light beam between the two sensors

resumes (fast blinking of YELLOW LED) and six

seconds later the ice machine restarts the ice

making process - going always through the 3'

stand by - and the YELLOW LED goes off.

REFRIGERANT CIRCUIT

The hot gas refrigerant discharged out from the

compressor reaches the condenser where,

being cooled down, condenses into liquid.

Flowing into the liquid line it passes through the

drier filter, then it goes all theway throughthecapillary tubewhere it looses some of its pressure

so that its pressure and temperature are lowered.

Next, the refrigerant enters into the evaporator

coil wrapped around the freezer inner tube.

The water being constantly fed at the interior of

thefreezer inner tube,exchange heat with the

refrigerant circulating into the evaporator coil,

this cause the refrigerant to boil-off and evapora-

te, there by it changes from liquid into vapor.

The vapor refrigerant then passes through the

suction accumulator and through the suction line

where the refrigerant exchanges heatwith the

one flowing into the capillary tube (warmer) beforebeingsuckedinto thecompressor to be recirculated.

The refrigerant head pressure is kept between

two pre-set values (8÷9 bar - 110÷125 psig on

F120) by the condenser temperature sensorwhich has its probe locatedwithin the condenser fins

- in air cooled versions.

This condenser temperature sensor, when senses a rising of the condenser temperature

beyond thepre-fixedlimit,changesits electrical

resistance and send a low voltage power flow to

the

MICROPROCESSOR of the P.C. Board

which energizes,

through a

TRIAC, the Fan Motor in ON-OFF

mode.

On the water cooled versions, the refrigerant

head pressure is kept at the constant value of 8.5

bar (120 psig) on F120 by themetered amount

ofwater passing through the condenserwhich is

regulated by the action of theWater Regulating

Valve that has its capillary

tube connected to the

liquid refrigerant line. As pressure increases,

the water regulating valve opens to increase the

flow of cooling water to the condenser.

NOTE.

The interruption of the light beam

between the two light sensors is immediately

signalled by the blinking of the

BIN FULL

YELLOW LED

located on the front of the

P.C. Board.

After about

6" of steady interruption

of the

light beam the unit stops and the

“Full Bin”

YELLOW LED

glows steady.

The six seconds of delay prevent the unit

from stopping for any undue reason like the

momentarily interruption of the light beam

caused by the flakes that slides along the ice

spout before dropping into the bin.

ACCUMULATOR

C

APILLARY TUBE

DISCHARGE LINE

EVAPORATOR

F

AN MOTOR

COMPRESSOR

CONDENSER

SUCTION LINE

Page 17

GB

17

FIG. 6

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

T<1°C

DATA PROCESSOR

11

10

9

1

2

L

N

8

7

6

5

4

3

13

12

The refrigerant suction or Lo-pressure sets - in

normal ambient conditions - on the value of 0.5

bar (7 psig) on F120 after few minutes from the

unit start-up.

This value can vary of 0.1 or 0.2 bar (1.5÷3

psig) in relation to the water temperture variations influencing the freezer cylinder.

NOTE.

In case the condenser temperature

probe senses that the condenser temperature

has rised to 70°C on air cooled version - or

60°Conwater cooled version - for one of the following abnormal reasons:

CLOGGED CONDENSER

(Air cooled version)

INSUFFICIENT FLOW OF COOLING

WATER

(Water cooled version)

FAN MOTOR OUT OF OPERATION

(Air coo-

led version)

AMBIENT TEMPERATURE HIGHER THEN

43°C (110°F)

it causes the total and immediateSHUT-OFF of

the machine (compressor first and gear motor

3' later) in order to prevent the unit from operating in abnormal and dangerous conditions.

When the ice maker stops on account of this

protective device, there is a simultaneous

glowing of the

RED LED

, warning the user of

the

Hi Temperature

situation.

The machine will remain in OFF mode for one

hour then it will restart automatically.

In case the unit trips OFF again in alarm for 3

times in 3 hours, the machine SHUTS OFF DEFINITIVELY.

After having eliminated the source of the excessive condenser temperature, to restart the icemachine it is necessary to unplug and plug in

again.

The RED LED starts blinking and three minutes

later the flaker unit resume its normal operating

mode. The condenser temperature sensor has a

further safety function which consist in preventing the unit from operating in Lo-ambient conditions i.e. when the condenser temperature equivalent to the ambient temperature - is lower

then 1°C 34°F (Fig.6).

As soon as the ambient temperature rises up to

5 °C the P.C. Board restarts automatically the

machine on the three minutes starting time.

Page 18

GB

18

FIG. 7

2

1

L

N

COMPRESSOR

9

10

11

12

13

3

4

5

6

7

8

CONTACTOR COIL

GEAR MOTOR

FAN MOTOR

ELECTRONIC

CARD

RELAYS

TRIAC

RESET

S E N S O R S

WATER

LEVEL

GEAR MOTOR ROTATION

CONDENSER TEMP.

EVAPORATOR TEMP.

ICE LEVEL CONTROL

TRANSF.

DATA PROCESSOR

11

10

9

1

2

L

N

8

7

6

5

4

3

13

12

MECHANICAL SYSTEM

The mechanical system of the Flaker machines

consists basically of a gear motor assembly

which drives, through a ratched coupling, a

worn shaft or auger placed on its vertical axis

within the freezing cylinder.

The gear motor is made of a single phase electric motor with a permanent capacitor. This

motor is directly fitted in the gear case through

which it drives - in counter clockwise rotation at

a speed of 9.5 r.p.m. - the freezer auger being

linked to it by the ratched coupling.

Too low ambient and water temperature (well

below the limitations of respectively 10°C and

5°C - 50°F and 40°F) or frequent interruptions

of the water supply to the freezing cylinder

(clogging of thewater hose connecting the

float reservoir to the water inlet at the bottom

of the freezer) may cause the ice to get too

hard and compact loosing fluidity and the-

reby seizing the auger.

This situation will put under excessive strain

and load the entire drive system and freezer

bearings.

NOTE

. If, after tenminutes fromthe unit start

up, no ice is made and the evaporating

temperature detected by the evaporator

sensor results to be higher than -1°C (30°F)

the ice maker stops (compressor first and

gear motor 3' later) and the

5th WARNING

YELLOW LED

blinks.

The machine will remain in OFF mode for

one hour then it will restart automatically.

In case the unit trips OFF again in alarm for

3 times in 3 hours, themachine SHUTSOFF

DEFINITIVELY.

ANMERKUNG. Zur Wiederherstellung des

Betriebs nach Behebung der Ursache für die

Abschaltung müssen die oben angegebenen

Schritte, wie bei Drehung in die falsche

Richtung, durchgeführt werden.

Page 19

Refrigerant metering device:

Capillary tube

Gas charge (R 134a)

Air cooled Water cooled

F 80 300 gr 300 gr

F 125 400 gr 300 gr

Working pression

(with 21°C ambient temperature)

Pression

discharge 8÷9 bar 8÷5 bar

Pression

suction 0.5 bar 0.5 bar

Working pression

(with 21°C ambient temperature)

Pression

discharge 17÷18 bar 17 bar

Pression

suction 2.5 bar 2.5 bar

NOTE.

Before charging the refrigerant system

always check thetypeof refrigerantandquantity as specified on the individual ice machine

dataplate. The refrigerant charges indicated

are relatives to averages operating conditions.

GB

19

Page 20

20

GB

A Evaporator temperature sensor

The evaporator sensor probe is inserted into its

tube well, which is welded on the evaporator

outlet line, it detects the temperature of the ref-

rigerant on the way out from the evaporator and

signals it by suppling a low voltage current flow

to the P.C. Board.

According to the current received, the micro-

processor let the ice maker to continue its ope-

rations or not. In case the evaporating temperature, after 10 minutes from the unit start-up,

does not go below -1°C (30°F) the evaporator

sensor signals to stop immediately the unit operation, with the blinking of the 5th Warning

YELLOW LED.

B Water level sensor

This sensor consists of two small stainless steel

rods vertically fitted on the inner face of the

reservoir cover and electrically connected to

the low voltage circuit of the P.C. Board.

When the cover of the reservoir is positioned in

its place the tips of both the rods dip into the

reservoir water transmitting a low power current

throu the same.

C Condenser temperature sensor

The condenser temperature sensor probe, located

within the condenser fins (air cooled version) or in

contact with the tube coil (water cooled version)

detects the condenser temperature variations and

signals them by supplying current, at low voltage,

to the P.C. BOARD.

In case thecondenser temperaturesensordetects

a temperature at the condenser lower than +3°C

(37°F) that means ambient temperature too low for

the correct unit operation, the sensor signals to the

P.C. BOARD to do not start up the unit till the

ambient temperature rises to 10°C.

In the air cooled versions, in relation to the different current transmitted, the micro processor of the

P.C. BOARD supplies, through a TRIAC, the power

at high voltage to the fan motor.

In the event the condenser temperature rises and

reaches 60°C or 70°C according to the setting of

DIP SWITCH number 8 the current arriving to themicro processor is such to cause an immediate

and total stop of the machine operation.

NOTE. In the event of shortage of water in the

reservoir or, in case the water used is too soft (demineralized) to cause greater resistence to the

current flow (electrical conductivity lower than 30

μS) this sensor system causes the shutoff of the

machine, to protect it from running without water

or with an inadequate water quality. In this situation the YELLOW LED will glow to warn of the

machine shutoff and the reason why.

NOTE. Themachinewill remaininOFFmode

for one hour then it will restart automatically.

In case the unit trips OFF again in alarm for

3 times in 3 hours, themachine SHUTSOFF

DEFINITIVELY.

To restart the unit after the shutoff caused by

the hi evaporating temperature, it is necessary

to switch OFF and ON the power line

main disconnect Switch.

NOTE. The machine will remain in OFF mode

for one hour then it will restart automatically.

In case the unit trips OFF again in alarm for 3

times in 3 hours, themachine SHUTSOFF DEFINITIVELY.

To restart the unit after the shutoff caused by

the hi condenser temperature, it is necessary to

switch OFF and ON the power line main

disconnect Switch.

COMPONENTS DESCRIPTION

Page 21

21

GB

D Electromagnetic sensor

This safety device is housed on top of the Drive

Motor and detects - based on Hall Effect principle - the rotating speed and rotating direction of

the drive Motor.

Should the rotating speed drop below1300

r.p.m. the magnitude measured by this device

is such to signal to the microprocessor to stop

the unit and light-up the YELLOW LED. The

same reaction occures when the drive motor

will tend to rotate inthewrongdirection(counterclockwise) or when it doesn't rotate at all.

E Optical ice level control

The electronic optical ice level control, located

into the ice chute has the function to stop the

operation of the ice machine when the light

beam between the light source and the receiver

gets interrupted by the flake ice which accumulates in the chute.

When the light beam is interrupted the Bin Full

YELLOW LED located in the front of the P.C.

BOARD blinks; in case the light beam gets interrupted for as longer as 6 seconds, the ice

machine stops with the glowing-up of the 2nd

YELLOWLEDto monitor thefull ice binsituation.

The 6 seconds of delay prevents that any minimum interruption of the light beam due to the

regular ice chuting through the ice chute may

stop the operation of the unit.

As soon as the ice is scooped out (with the

resumption of the light beam between the two

infrared sensor of ice level control - YELLOW

LED blinks fast) 6 seconds later the ice machine resumes its operation with the simultaneous

extinguishing the 2nd YELLOW LED.

NOTE. The machine will remain in OFF mode

for one hour then itwill restart automatically. In

case the unit trips OFF again in alarm for 3

times in 3 hours, the machine SHUTS OFF

DEFINITIVELY. To restart the unit after the shutoff caused by this safety device, it is necessary first to eliminate the cause that has generated the intervention of the device and then

switch OFF and ON the power line main

disconnect switch.

Characteristics of the optical sensor

for flakes

Infra-red receiver (Photo transistor)

Maximum voltage Vce 35V

Maximum electricity Ic 50 mA

Collector electricity whereby

Ev=1000 1x, Vce=5V between 1 and 2 mA

Operation temperature -55°C ÷ +100°C

Infra-red transmitter (Photo dioxde)

Max. conversion voltage Vr 5V

Maximum electricity If 100 mA

Direct voltage Vr@100mA 25°C = 1.5V

Operation temperature -55°C ÷ +100°C

Resistive values

Evaporatore probe

KTY 10.62

T°C Rmin Rmax

-30 1223 1276

-20 1345 1394

-10 1474 1517

0 1611 1650

10 1757 1788

20 1910 1933

25 1990 2010

30 2067 2092

40 2226 2263

50 2395 2442

60 2569 2629

70 2752 2824

80 2941 3027

Resistive values

Condenser probe

KTY 11.7

T°C Rmin Rmax

-30 1236 1301

-20 1358 1422

-10 1489 1547

0 1628 1683

10 1774 1824

20 1929 1972

25 2010 2050

30 2088 2134

40 2249 2308

50 2420 2490

60 2594 2681

70 2779 2880

80 2970 3087

Page 22

22

GB

YELLOW LED

U

nit shut-off due to a

t

oo lo-water level into

float tank

RED LED

O

N all the time

- Unit shut-off due to a

too hi-condensing

temperature

- Unit shut-off due to a

too lo-ambient temperature

<+1

°C

Blinking

3 minutes start up delay time

YELLOW LED

ON all the time

- Unit shut-off due to the

wrong rotation direction

of gear motor

- Unit shut-off due to the

too lo speed of gear motor

Blinking

- Unit shut-off due to a

too hi-evaporating temp.

>-1°C after 10 min of operation

YELLOW AND

RED LED

- Blinking: Evaporator sensor

out of order

- Steady: Condenser sensor

out of order

infrared sensor of ice level control - YELLOW LED

blinks fast) 6 seconds later the

ice machine resumes

its operation wit h t he simul-taneous e xtinguishing

the 2nd YELLOW LED.

F. P.C. BOARD (Data processor)

The P.C. BOARD, fitted in its plastic box located

in the front of the unit, consists of two separated

printed circuits one at high and the other at low

voltage and protected by fuses. Also it consists of

five aligned LEDS monitoring the operation of the

machine of three jumpers (TEST used only in the

factory, 60/70°C used to set up the PC Board at

proper safety cut out condensing temperature and

3' to by pass the 3 minutes Stand By) and of input

terminals for the leads of the sensor probes as

well as input and output terminals for the leads of

the ice maker electrical wires.

The P.C. BOARD is the brain of the system and

it elaborates, through its micro processor, the

signals received from the sensors in order to

control the operation of the different electrical

components of the ice maker (compressor, gear

motor, etc.).

The five LEDS, placed in a row in the front of the

P.C. BOARD, monitor the following situations:

GREEN LED

Unit under electrical

power

YELLOW LED

- Blinking: I/R beam cut

out

- Steady: unit shut-off at storage

bin full

- Blinking fast: I/R beam resumed

'06/33PJ

C°07/062PJ

TSET

1PJ

NEYS

REMROFSNART

REMROFSNART

TEKCOSROSNESROTAROPAVE

TEKCOSROSNESROTAROPAVE

TEKCOSROSNESRESNEDNOC

TEKCOSROSNESRESNEDNOC

TEKCOSROSNESROTOMEVIRD

TEKCOSROSNESROTOMEVIRD

ROSNESRETAW

TEKCOS

ROSNESRETAW

TEKCOS

LEVELECILACITPO

TEKCOSROSNESLORTNOC

LEVELECILACITPO

TEKCOSROSNESLORTNOC

LANIMRET

DRAOB

LANIMRET

DRAOB

ESUF

ESUF

CAIRT

CAIRT

ROSSERPMOC

YALER

ROSSERPMOC

YALER

ROTOMEVIRD

YALER

ROTOMEVIRD

YALER

MORPE.RPORCIM

MORPE.RPORCIM

ETOMER

TEKCOS

ETOMER

TEKCOS

TUO’06/NI’3

REPMUJYBDNATS

TUO’06/NI’3

REPMUJYBDNATS

REWOP

REWOP

LLUFNIB

LLUFNIB

RETAWON

RETAWON

.DNOCWOL/IHOT

.PMET

DNATS’3

REWOPYB

.DNOCWOL/IHOT

.PMET

DNATS’3

REWOPYB

.PMET.PAVEIHOT

WOLSROGNORW

ROTOMEVIRD

NOITATOR

.PMET.PAVEIHOT

WOLSROGNORW

ROTOMEVIRD

NOITATOR

NIC°07-TUOC°06

REPMUJ

NIC°07-TUOC°06

REPMUJ

ECNATSISER

ECNATSISER

RETSUJDAR/I

RETSUJDAR/I

F P.C. BOARD (Data processor)

The P.C. BOARD, fitted in its plastic box located

in the front of the unit, consists of two separated

printed circuits one at high and the other at low

voltage and protected by fuses. Also it consists

of five aligned LEDS monitoring the operation of

the machine of three jumpers and of input terminals for the leads of the sensor probes as well

as input and output terminals for the leads of

the ice maker electrical wires. The P.C. BOARD

is the brain of the system and it elaborates,

through its micro processor, the signals received from the sensors in order to control the operation of the different electrical components of

the ice maker (compressor, gear motor, etc.).

The five LEDS, placed in a row in the front of the

P.C. BOARD, monitor the following situations:

GREEN LED

Unit under electrical power

YELLOW LED

Blinking: I/R beam cut out

Steady: storage bin full

YELLOW LED

Unit shut-off due to a too lo-water level

into float tank

RED LED

ON all the time

- Unit shut-off due to a too

hi-condensing temperature

- Unit shut-off due to a too

lo-ambient temperature <+1°C

Blinking

3 minutes start up delay time

YELLOW LED

ON all the time

- Unit shut-off due to the wrong

rotation direction of gear motor

- Unit shut-off due to the too lo speed

of gear motor

Blinking

- Unit shut-off due to a too hi-evaporating

temp.

>-1°C after 10 min of operation

YELLOW AND RED LED

– Blinking: Evaporator sensor

out of order

– Steady: Condenser sensor

out of order

Page 23

23

GB

G Jumpers

TheFlakerPCBoardisequipped by threejumpers:

J1 · TEST:

Used in the factory to energise all

theelectrical components duringthe Testing

Mode. Used to by-pass the 3' stand by time

(just jumpthecontactswith PCBoard under

power).

J2 - SYEN / J3 - Pro. El. Ind. - 60/70°C:

Used to set up the CutOut temperature

of the condenser sensor:

• Jump OUT = 60°C

• Jump IN = 70°C

J3 - SYEN / J2 - Pro. El. Ind. - · 3'/60':

Used to set up the start up delai time:

• Jump IN = 3'

• Jump OUT = 60'

H Float reservoir

The float reservoir consist of a plastic water pan

on which is fitted a float valve with its setting

screw. The float valve modulate the incoming

water flow to maintain a constant water level in

the reservoir, level that corresponds to the one

in the freezing cylinder to ensure proper ice formation and fluidity.

On the inner side of the reservoir cover are fitted the twowater level sensor pinswhich detects the presenceor theshortageof water inthereservoir.

I Freezing cylinder or evaporator

The freezing cylinder ismade of a stainless steel

vertical tube onwhich exterior iswrapped around the cooling coil with the evaporating chamber and in its interior is located the auger which

rotates on its vertical axis and it is maintained

aligned by the top and bottom bearings. A

water seal system is located in the bottom part

of the freezer while at the top end is fitted the ice

breaker.

The water constantly flowing into the cylinder

bottompart, freezes into ice when in contact

with the cylinder inner walls. The ice is then lifted up by the rotating auger and compacted

and forced out by the ice breaker.

J Eisbrecher

Der Eisbrecher befindet sich im oberen Teil des

Freezers und wirkt dem an den Zylinderwänden

aufsteigendem Eis entgegen, das auf diese

Weise komprimiert wird, so dass ein Teil des

darin enthaltenen Wassers beseitigt und das

Eis in viele Körnchen gebrochen wird, die in

den Behälter befördert werden.

Im Eisbrecher befindet sich das obere Lager,

das aus zwei Reihen Rollen aus rostfreiem Stahl

besteht, die den von der Schnecke ausgeübten

radialen und axialen Belastungen standhalten

können.

Dieses Lager ist mit einem speziellen, wasserabstoßenden Lebensmittelschmierfett

geschmiert.

NOTE. It is very important tomake sure of the

correct fitting of the cover on the reservoir in

order to enablethesensor to efficiently control

the water situation avoiding undue shutoff interventions.

ANMERKUNG. Es wird empfohlen, alle sechs

Monate den Zustand des Schmiermittels und

des oberen Lagers zu überprüfen.

Page 24

GB

24

K Gear motor

The gearmotor ismade of a single phase elec-

tric motor with permanent capacitor directly fitted on a gear box.

The drive motor rotor is kept aligned on its vertical axis by two ball bearings permanently

lubricated. The gear case contains a train of

three spur gears with the first one in fiber to limit

the noise level. All the three gears are encased

in case roller bearings and are covered by lubricant grease (MOBILPLEX IP 44).

Two seal rings, one fitted on the rotor shaft and

the other on the output shaft keep the gear case

sealed.

The interior can be inspected and serviced by

unbolting the two halves of the aluminium gear

case housing.

L Fan motor (Air cooled version)

The fanmotor is controlled through the TRIAC of

the P.C. BOARD by the condenser temperature

sensor. Normally it operates to draw cooling air

through the condenser fins.

In cold ambient situation, the fan motor can run

at intermittance as the condenser pressuremust

be kept between two corresponding head pressure values.

M Water regulating valve

This valve controls the head pressure in the

refrigerant systemby regulating the flowofwater

going to the condenser.

As pressure increases, the water regulating

valve opens to increase the flow of cooling

water.

N Compressor

The hermetic compressor is the heart of the refrigerant system and it is used to circulate and

retrieve the refrigerant throughout the entire

system.

It compresses the lowpressure refrigerant vapor

causing its temperature to rise and become

high pressurehotvaporwhich isthenreleasedthrough the discharge valve.

Page 25

GB

25

A Adjustementof the evaporator water level

The correct water level in the freezing cylinder is

about 25 mm. below the ice discharge opening.

Low water level causes excessive strain inside

the freezer assembly due to a faster freezing

rate.

When the water level is above or below the correct one, adjustment can be performed by raising or lowering at the measure required, the

water reservoir and its mounting bracket.

1 To Raise or Lower the water level:

a Loosen and remove the screw securing

the mounting bracket of the water reservoir to the unit cabinet and raise the water

reservoir to the correct level.

b Thread the mounting screw in the corre-

sponding hole and tighten it.

2 For the reduction the water level as given

above, and lower the bath, as soon as it is

released from the casing.

B. Replacement of the gearmotor magnetic

sensor

1 On F80, F120 remove the front/top and

side/rear panels top and left side panels.

2. Unloose the three screws securing the plastic cover to the top of the gear motor and

remove it.

3. Unloose the two screws securing the magnetic sensor to the plastic housing and withdraw it from its seat.

4. Trace the gear motor magnetic sensor terminal plug on the rear side of the control box

(red with four terminal pins) and draw it out

from its socket by carefully slackening the

fastening tie.

5. To install the replacement gear motor magnetic sensor follow the above steps in reverse.

WARNING. Be sure the electrical power

supply circuit breaker and the inlet water

supply are OFF, before starting any of the

following Removal and Replacement procedures as a precaution to prevent possible personal injury or damage to the

equipments.

NOTE. Read the instructions throughly befo-

re performing any of the following adjustment

or removal and replacement procedure.

ADJUSTMENT, REMOVAL

AND REPLACEMENT PROCEDURES

Page 26

GB26GB

C Replacement of the auger, water seal, bea-

rings and coupling

1 Remove the panels.

2 Follow the steps at item H to remove the ice

spout.

3 On model F120 unloose and remove two

screws and washers holding tight the spout

bracket to the freezing cylinder.

4 On model F120 grasp the wire cap hook at

the top of the freezer and pull out the auger,

attached cap and icebreaker from the top of

the freezer.

D Replacement of the gear motor assy

1 Remove the front/top and side/rear panels.

2 Remove the three/four bolts and washers

securingthegear reducerbase to theunitchassis, then remove bolts and lockwasherswhich attach the bottom of the aluminium

adaptor to the gear reducer case cover.

3 Follow the steps of item E to remove the gear

motor magnetic sensor.

4 Trace and disconnect the electric wires leads

of the drive motor. Lift and remove the entire

gear motor assembly.

E Change of the water level sensors in the

bath

1 Remove the upper plate

2 Loosen the fastening nuts of the ring cable

lugs of both the rod made of stainless steel –

water sensors -, which are found on the cover

of the swimming pool

3 Search for the terminal of the lowest water

sensor with two red mandrels in the back part

of the switch box and pull them out of their

position by pressing on the fastening strap.

4 Proceed with the installation of the new lowe-

st sensor in the reverse order.

F Change of the control card

1 Remove the front upper plate

2 Search for the terminal of the single sensor

with two red mandrels in the back part of the

switch box and pull them out of their position

through pressing on the fastening strap.

3 Pull off the terminals for the electrical con-

nections of the back part of the control card

and then remove the whole control card by

loosening the four screws, with which it is

fastened in the electrical switch box made of

plastic

4 Proceed with the installation of the new lowe-

st sensor in the reverse order

G Change of the ice discharge opening

1 Loosen the screws and remove the upper

plate.

2 Remove the wing nuts and the take the ope-

ning from the ice removal canal. Work on the

optical reading device, so that these are not

damaged.

3 The two shells, with which the polystyrene

bowls in the upper part of the evaporators

are fastened, and remove both the insulating

bowls.

4 Pull out the opening made of stainless steel

from its upper bronze part with the F 125

models, for the other models loosen both

bolts, with which they are fastened in the icebreaker.

5 For Model F125 loosen both bolts, with which

the bronze opening is fastened to the evaporator and free it.

6 Proceed with the installation of the new ope-

ning in the reverse order.

NOTE. If the auger cannot be pulled out, proceed to steps 10 and 11 of this paragraph, to

gain access to the auger bottom. Then, with a

rowhide mallet or placing a piece of wood on

the bottomend of the auger, tap this bottom to

break loose the auger and be able then to pull

it out as per step 4 above.

NOTE. In F 125 and F 80 models inspect the

rectangular rubber seal of the nozzle and, if

damaged, replace it.

Page 27

GB27GB

H Replacement of the screw, seal ring, bea-

rings and coupling

1 Loosen the screws and remove the front

upper plate.

2 Change the procedure described in Point H

for the removal of the ice discharge opening

3 Loosen and remove both screws, which are

used to fasten the clip of the opening on the

evaporator.

4 Grasp the ring in the upper part of the ice-

breakers of the evaporators and pull

upwards hard to remove the unit icebreaker

5 For the F125 Model, remove the ring which is

used to fasten the cover on the icebreaker, with

the Seeger tongs. For the other models, a

screw driver is used for removing the cover.

6 Loosen and remove the head bolt used to

fasten the unit icebreaker storage on the screw

(augur) and pull out the icebreaker unit from the

screw.

7 Remove the remaining grease from the ice-

breaker unit and examine and change the O R

seal, in case it is not alright.

8 Test the storage in the icebreaker carefully.

Immediately change if there are signs of the

start of wear and tear or lacking grease.

9 Pull the brass rotating ring of the seal system

from the lower part of the screw.

For the F125 Model , pull the brass rotating ring

of the seal system from the lower part of the

screw, the remaining models of the steel ring

must be pulled out with a spring.

10 Loosen and remove the three/four bolts, which

are used to fasten the aluminum container

underneath the evaporator.

11 Lift the evaporator and raise it from its contai-

ner. After that push a wooden or plastic tool

with a suitable knife and length in the upper

part of the evaporator, so that it can be pressed

out from the lower end. It is necessary in case

a wooden hammer is used.

NOTE. Whenever you disassemble the auger

to make a few checks or replacement, take

care not to let dirt inside the evaporator and

especially that these should not be deposited

on the surface in graphite seal ring.

If there were any doubts, proceed without delay

to the complete replacement of the seal ring.

WARNING. The upper bearing works in critical conditions as regards its lubrication

because it will insert within the icebreaker

where you normally form a considerable

condensation. E 'exhaustive use of dietary

fat and water-repellent in order to provide

adequate lubrication to the upper bearing.

NOTE. If you are unable to remove the auger

assembly / icebreaker from above, switch to

perform as described in paragraphs 10 and 11

of this paragraph in order to act on the bottom

of the cochlea. Using a mallet of wood or plastic, beat on the lower end of the auger in order

to loosen and eject it from the top of the evaporator.

Page 28

GB

28

12 Press and remove the Super Flakes Ice Model

with the sheets, from two screws pulled from the

lower edge of the brass rings of the lower storage casing.

13 Pull the components of the drive coupling from

aluminum container out.

14 Control the state of both half couplings.

Immediately exchange if there is wear and tear.

15 Install the lower storage in its bronze casing

and put it in such a way that the white plastic

ring shows on the top.

16 Install the upper storage of the icebreakers.

The flat part starts with the radial part.

The surfaces must be mounted upward.

17 Lubricant (grease) on the upper part.

Then mount the roll cage with the smaller openings at the top, to allow a little movement

between the plastic cage and the flat surfaces

of the lower storage part (see diagram).

18 Grease and then mount the equalizing disc

made of steel

19 After changing the O-Ring seal in the ice-

breaker, install the icebreaker on top of the

screw and fasten it with the upper bolt.

20 Install the screw icebreaker unit in the evapora-

tor. Use the previous points in a reverse order.

I Change of the gear motor

1 For the F125 Model the front/upper and the

side/back plate

2 Loosen the three-four screws, which are

used to fasten the evaporator on the upper

casing.

3 Remove the sensors for the engine rotating

direction according to the instructions in

Point B.

Loosen the screws which are used to fasten

the gear motor on the framework.

4 Interruption of the supply of power of the

motor through the electrical equipment. The

gear motor is now released and can be exreverse

5 To install the new gear motor, use the process

in the reverse order.

J Change of the ventilator

1 For the F125 Model the front/upper and the

side/back plate

2 Loosen the nuts and search and pull out the

yellow/green grounding cable. The mandrel

for the connection of the electrical cable of

the ventilator.

3 For the F 125 Model, loosen the bolts which

are used to fasten and take out the ventilator

unit on the base of the device.

NOTE. Is a good practice to replace both the

ring of the mechanical seal that the bearings,

upper and lower, as well as O-rings each time

it is disassembled the evaporator assembly.

For this purpose there is a kit of these parties

also accompanied by a tube of grease food

and water repellent.

NOTE. When installing a new fan motor check

that the blades do not touch anything and turn

freely.

Page 29

GB

29

K Change of the driers

1 For the F 125 Model front/upper and the

side/back plate

2 Remove the cooling agent from the system

and let it flow into a particular container,

which can be later recycled after a corresponding cleaning.

3 The cooling agents guides from both ends

(for the F 125 Model, weld the capillary tube

on a side of the drier).

4 Remove the seals to both ends for the moun-

ting of the new driers and wearing the pipes

of the cooling agent.

5 Carefully rinse the cooling agent circulation

for humidity and remove the non-condensable gases after installing the new driers.

6 Fill the cooling agent circulation with the right

amount of cooling agent (see type) and examine, whether appearances* with the level

smelted* places are available.

7 Mount the previously removed plate again.

L Change of the evaporator

1 Follow the instructions of Point H for the

removal of the ice discharge opening.

2 Remove the *shell of the connection of the

water entry* in the evaporator and draw out

the *pipe. Empty the water found in a container.

3 Pull out the sensor pipe of the evaporator as

in Point B.

4 Remove the cooling agent from the system

and let it run into a particular container, so

that it can be recycled later after a corresponding cleaning.

5 Welding and separate the capillary tube and

the collection/sucking unit from the outflow

pipe of the evaporator.

6 Loosen the three-four bolts, which are used

to fasten the evaporator on the upper casing

of the gear motor.

7 Remove the evaporator of the gear motor

and if necessary, remove the aluminum container* by loosening the three-four bolts of

the evaporator.

8 For the installation of the new evaporator the

process used in a reverse order.

M Change of the air-cooled condenser

5 For the F 125 Model the front/upper and the

side/back plate

2 Remove the sensor pipe from the cooling

bulb of the condensers.

3 Loosen the bolts, which are used to fasten it

on the base/frame.

4 Remove the cooling agent from the system

and let it flow into a particular container, to be

able to recycle it later after the corresponding

cleaning.

5 Weld the cooling agent pipes from both

ends.

6 For the installation of the new condensers,

use the process in a reverse order

NOTE. Replace the dryer filter whenever the

refrigerant circuit is opened. Do not apply the

new filter dehumidifier until all repairs or replacements have been made.

NOTE. Carefully purged the refrigerant circuit

to remove moisture and non-condensable

gases after the replacement of the evaporator.

NOTE. Replace the dryer filter whenever the

refrigerant circuit is opened. Do not apply the

new filter dehumidifier until all repairs or replacements have been made.

NOTE. Carefully purged the refrigerant circuit

to remove moisture and non-condensable

gases after the replacement of the condenser.

Page 30

GB

30

N Change of the water-cooled condensers

1 For the F 125 Model the front/upper and the

side/back plate

2 Remove the sensing probe from the conden-

ser.

3 Loosen and remove the bolts with which it is

fastened on the base.

4 Unscrew the pipe terminal and pull the pla-

stic pipe of the two ends of the condensers.

5 Remove the cooling agent from the system

and let it flow into a particular container, to be

able to recycle it later after the corresponding

cleaning.

6 Welding the cooling agent pipes from the two

ends of the condenser.

7 For the installation of the new condensers

use the process in reverse order.

O Exchange of the regulating valve

(water-cooled equipment)

1 For the F 125 Model the front/upper and the

side/back plate

2 Close the water stop valve and the supply

pipes for the regulating valve from the back

part of the device.

3 Loosen the pipe terminal and remove the pla-

stic pipe from the pipe holder at the exit of

the regulating valve.

4 Loosen the nuts, which are used for fastening

the regulating valve in the frame of the equipment.

5 Remove the cooling agent from the system

and let it flow in a particular container, to be

able to recycle it later after the corresponding

cleaning

6 Try the capillary tube of the regulating valve

and weld it onto the cold circulation. Then

remove it from the device.

7 For the installation of the new condensers

use the process in reverse order.

P Change of the compressor

1 For the F 125 Model the front/upper and the

side/back plate

2 Remove the cover and pull out the electrical

cable from the terminals of the compressor.

3 Remove the cooling agent from the system

and let it flow into a particular container, to be

able to recycle it later after the corresponding

cleaning

4 Weld the conveyor pipe as well as the suc-

tion pipe of the compressor.

5 Loosen the screws, which is used to fasten it

to the base, and remove the compressor

from the socket of the equipment.

6 For the F125 Model, weld the working/filling

pipe, to be able to weld it on the new compressor.

NOTE. Replace the dryer filter whenever the

refrigerant circuit is opened. Do not apply the

new filter dehumidifier until all repairs or replacements have been made.

NOTE. Carefully purged the refrigerant circuit

to remove moisture and non-condensable

gases after the replacement of the condenser.

NOTE. Replace the dryer filter whenever the

refrigerant circuit is opened. Do not apply the

new filter dehumidifier until all repairs or replacements have been made.

NOTE. Carefully purged the refrigerant circuit

to remove moisture and non-condensable

gases after the replacement of the condenser.

NOTE. The water flow passing through the

pressure valve must be adjusted using the

screw in the upper part of its stem until you

have a condensing pressure of 14 bar.

Page 31

GB

31

7 For the installation of the new compressors,

use the process in a reverse order

NOTE. Carefully purged the refrigerant circuit

to remove moisture and non-condensable

gases after the replacement of the condenser.

NOTE. Replace the dryer filter whenever the

refrigerant circuit is opened. Do not apply the

new filter dehumidifier until all repairs or replacements have been made.

Page 32

GB32GB

TECHNISCHE DATEN DES EISFLOCKENBEREITERS

MODELLO

MODEL

MODELL

VOLTS

COMPRESSORE

COMPRESSOR

KOMPRESSOR

REFRIGERANTE

REFRIGERANT

KÄLTEMITTEL

CARICA

REFRIGERANTE

REFR. CHARGE

BEFÜLLUNG MIT

KÄLTEMITTEL

CAPILLARE

CAPILLAR

KAPILLARROHR

POTENZA

ASSORBITA

POWER

AUFGENOMME-

NE LEISTUNG

ASS.

MARCIA

AMPS

AMP.

BETRIEB

ASS.

AVVIAMENTO

START

AMPS

AMP. START

CONSUMO

ELETTRICO

POWER

CONS.

STROMVERBRAUCH

ASSORBIMENTO

MOTORIDUTTORE

AMPS MOTOREDUCT.

AUFNAHME GETRIE-

BEMOTOR

3000mm.

F80 A/W 230/50/1 ELECTROLUX R134a 300/300 gr. D int. 0.90 400W 2.6A 11A 0.200A 9.6 KWH/24 HR

GL90TB R134A D: 2.2mm

2500mm.

F125 A/W 230/50/1 UNITE HERMETIQUE R134A 400/300gr D int. 1.00 480W 3.2A 18A 0.200A 11.5 KWH/24 HR

GP14 TB R134A D: 2.2mm

Page 33

GB33GB

WIRING DIAGRAM F80

AIR AND WATER COOLED

220-240/50/1