CL6040-1 / CL6080-1 / CL6080-2 /

CL6080-3

117910 - 117911 - 117912 - 117913

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten

Germany

Phone: +49 5258 971-0

Fax: +49 5258 971-120

Technical Support Hotline: +49 5258 971-197

www.bartscher.com

Version: 2.0

Date of preparation: 2023-04-04

EN

2

Original instruction manual

1 Safety ............................................................................................................ 2

1.1 Explanation of Signal Words .................................................................... 2

1.2 Safety instructions.................................................................................... 3

1.3 Intended Use ........................................................................................... 7

1.4 Unintended Use ....................................................................................... 7

2 General information ....................................................................................... 8

2.1 Liability and Warranty .............................................................................. 8

2.2 Copyright Protection ................................................................................ 8

2.3 Declaration of Conformity ........................................................................ 8

3 Transport, Packaging and Storage ................................................................ 9

3.1 Delivery Check ......................................................................................... 9

3.2 Packaging ................................................................................................ 9

3.3 Storage .................................................................................................... 9

4 Technical Data ............................................................................................. 10

4.1 Technical Specifications ........................................................................ 10

4.2 Functions of the Appliance ..................................................................... 16

4.3 List of Components of the Appliance ..................................................... 17

5 Installation Instructions ................................................................................ 18

5.1 Unpacking and Positioning .................................................................... 18

5.2 Electrical Connection ................................ ............................................. 21

5.3 Water Connection .................................................................................. 23

6 Operating Instruction ................................................................................... 26

6.1 Operation ............................................................................................... 30

7 Cleaning and Maintenance .......................................................................... 65

7.1 Safety Instructions for Cleaning ............................................................. 65

7.2 Cleaning ................................................................................................. 65

7.3 Maintenance .......................................................................................... 67

8 Disposal ....................................................................................................... 68

117910 1 / 68

Safety

EN

Read this instruction manual before using and keep it available

at all times!

DANGER!

The signal word DANGER warns against hazards that lead to severe

injuries or death if the hazards are not avoided.

Diese Bedienungsanleitung beschreibt di e Installation, Bedienung und Wartung d es Geräts und gilt als wichtige Inform ationsquelle und Nachschlagewer k. Die Kenntnis aller enthaltenen Sicherheits hinweise und Handlungsanweisungen sch afft die Voraussetzung für das sich ere und sachgerechte Arbeiten mit d em Gerät. Darüber hinaus müssen die f ür den Einsatzbereich des Geräts gelt enden örtlichen Unfallverhütungsvorsc hriften und allgemeinen Sicherheitsb estimmungen eingehalten werden. Diese Bedienungsanleitung ist Bestandteil d es Produkts und muss in unmittelb arer Nähe des Geräts für das In¬stallations -, Bedienungs-, Wartungs- und R einigungspersonal jederzeit zugängli ch auf¬bewahrt werden. Wenn das Gerät a n eine dritte Person

weitergegeben wird, muss die Bedienung sanleitung mit ausgehändigt werden.

This instruction manual contains information about installation, operation and

maintenance of the appliance and constitutes an important source of information

and reference guide. The knowledge of all operational and safety instructions

included in this manual is a prerequisite for safe and proper handling of the

appliance. Additionally, accident prevention, occupational health and safety, and

legal regulations in force in the area the appliance is used apply.

Before you start using the appliance, especially before turning it on, read this

instruction manual in order to avoid personal injuries and property damages.

Improper use may cause damage.

This instruction manual forms and integral part of the product and must be stored in

an immediate vicinity of the appliance and be available at all times. The instruction

manual should be transferred together with the appliance.

1 Safety

This appliance has been manufactured in accordance with technical standards

currently in force. However, the appliance may be a source of hazards if used

improperly or contrary to its intended purpose. All persons using the appliance must

consider information included in this instruction manual and observe safety

instructions.

1.1 Explanation of Signal Words

Important safety instructions and warning information are indicated in this

instruction manual with appropriate signal words. You must strictly follow the

instructions, to prevent accidents, personal injuries and property damages.

2 / 68 117910

Safety

EN

WARNING!

The signal word WARNING warns against hazards that may lead to

moderate or severe injuries or death if the hazards are not avoided.

CAUTION!

The signal word CAUTION warns against hazards that may lead to

light or moderate injuries if the hazards are not avoided.

IMPORTANT!

The signal word IMPORTANT indicates possible property damages,

which may occur if safety instructions are not observed.

NOTE!

The symbol NOTE indicates subsequent information and guidelines

for the user on usage of the appliance.

, die

1.2 Safety instructions

Electrical Current

• Too high a mains voltage or incorrect installation may cause electric shock.

• The appliance may be connected only if data on the rating plate correspond with

the mains voltage.

• To avoid short-circuit, the appliance should be kept dry.

• If there are malfunctions during operation, disconnect the appliance from the

power supply.

• Do not touch the appliance’s plug with wet hands.

• Never take hold of the appliance if it has fallen into water. Immediately

disconnect the appliance from the power supply.

• Any repairs or housing opening may be carried out by professionals and

relevant workshops only.

• Do not transport the appliance, holding it by the power cord.

• Do not allow the power cord to come into contact with heat sources or sharp

edges.

• Do not bend, pinch nor knot the power cord.

117910 3 / 68

Safety

EN

• Always completely unwind the power cord.

• Never place the appliance or other objects on the power cord.

• Always take hold of the plug to disconnect the appliance from the power supply.

• Check the power cord regularly for damage. Do not use the appliance if the

power cord is damaged. If this cable is damaged, it must be replaced by

customer service or a qualified electrician in order to avoid dangers.

Flammable Materials

• Never subject the appliance to contact with high temperature sources, e.g.:

oven, furnace, open flame, heat generating devices, etc.

• To avoid fire hazard, clean the appliance regularly.

• Do not cover the appliance with, e.g., aluminium foil or cloths.

• Use the appliance only with materials designated to this end and with correct

temperature settings. Materials, groceries and left-overs remaining in the

appliance may catch fire.

• Never use the appliance near flammable or inflammable materials, e.g.: petrol,

spirit, alcohol, etc. High temperature triggers evaporation of these materials,

and, as a result of contact with sources of ignition, an explosion may occur.

• In case of fire, disconnect the appliance from the power supply before

attempting suitable fire-extinguishing actions.

• Never attempt to extinguish fire with water if the appliance is connected to the

power supply. Following extinction of fire, ensure sufficient fresh air inflow.

Hot Surfaces

• Surfaces of the appliance become hot during operation. Burning hazard! High

temperature remains for some time after switching the appliance off.

• Do not touch any hot surfaces of the appliance. Use the provided handling

elements and holders.

• You may transport and clean the appliance after it cools down entirely.

• It is prohibited to sprinkle hot surfaces with cold water or flammable liquids.

Operating Personnel

• The appliance may only be operated by qualified personnel and trained

specialist personnel.

• This appliance may not be operated by persons (including children) with limited

physical, sensory or mental capabilities, nor by persons with limited experience

and/or limited knowledge.

4 / 68 117910

Safety

EN

• Children should be supervised to ensure that they are not playing with or

switching on the appliance.

Supervised Usage only

• Only supervised appliance may be used.

• Always remain in an immediate vicinity of the appliance.

Improper Use

• Unintended or prohibited use may cause damage to the appliance.

• The appliance may only be used when its technical condition is flawless and

allows for safe operation.

• The appliance may only be used when all connections are executed according

to rules of law in force.

• The appliance may only be used when it is clean.

• Use only original spare parts. Never attempt to repair the appliance on your own.

• Do not introduce any changes in the appliance nor modify it.

117910 5 / 68

Safety

EN

DANGEROUS VOLTAGE

Dangerous voltage inside. Contact leads to electric shock or burns.

Before performing maintenance and cleaning works, the system

must be switched off and locked.

Failure to observe these instructions may result in serious injury.

RISK OF BURNS!

This symbol indicates situations where persons must be careful not

to touch any hot external surfaces of the oven during operation.

Failure to observe these instructions may result in serious injury.

RISK OF BURNS — hot water and steam!

This symbol indicates situations in which persons must take care

not to come into contact with hot water on surfaces and steam

which may be generated when the oven is in operation.

Failure to observe these instructions may result in serious injury.

RISK OF BURNS — hot steam!

This symbol indicates situations in which persons must take care

not to come into contact with hot steam which may escape during

the operation of the oven.

Failure to observe these instructions may result in serious injury.

RISK OF BURNS — handling hot sheets with products!

This symbol indicates situations where persons must be careful

when handling hot sheets with hot products and liquids that may fall

or spill on a person during loading or unloading. The sticker is part

of the scope of supply of the appliance and must be placed at a

height of 1.6 m above the installation surface.

Failure to observe these instructions may result in serious injury.

Warning Signs on the Appliance

6 / 68 117910

Safety

EN

1.3 Intended Use

As described below, every use of the appliance for a purpose differing and/or

diverging from its intended standard use, is prohibited and considered to be an

unintended use.

The following is an intended use:

– Baking bread, buns

– Baking cakes

1.4 Unintended Use

An unintended use may lead to personal injuries or property damages caused by

hazardous voltage, fire or high temperature. The appliance may only be used to

perform tasks described in this instruction manual.

The following is an unintended use:

– Processing of unsuitable food products

– Heating of rooms

– Drying clothes

– Storage of flammable objects

– Heating up and warming up of liquids and materials that are flammable,

hazardous to health, volatile, etc.

117910 7 / 68

General information

EN

2 General information

2.1 Liability and Warranty

All information and instructions in this instruction manual account for legal

regulations in force, current level of technical engineering knowledge as well as our

expertise and experience, developed over the years. If special models or additional

options are ordered, or state-of-the-art technical solutions were implemented, the

actual scope of delivery of the appliance may, in some circumstances, differ from

descriptions and numerous drawings in this instruction manual.

The manufacturer is not liable for any damages nor faults stemming from:

– failure to observe instructions,

– unintended use,

– technical alterations introduced by the user,

– usage of unapproved spare parts.

We reserve the right to introduce technical modifications to the product, intended for

improvement of the appliance and its performance.

2.2 Copyright Protection

This instruction manual, and texts, drawings and images included in it, as well as its

other components are copyright protected. It is prohibited to reproduce this

instruction manual (including its excerpts), in any form and by any means, and to

use and/or transfer its content to third parties without manufacturer’s written

permission. Violation of the above results in obligation to pay compensation. We

reserve the right to claim further damages.

2.3 Declaration of Conformity

The appliance meets the currently applicable standards and guidelines of the

European Union. We confirm the above in the EC Declaration of Conformity. We

may provide relevant Declaration of Conformity upon request.

8 / 68 117910

Transport, Packaging and Storage

EN

3 Transport, Packaging and Storage

3.1 Delivery Check

Immediately upon reception, check the delivery for completeness and possible

shipping damage. In the case of visible transport damage refuse to accept the

appliance or accept it conditionally. Mark and note the scope of damage in shipping

documents/consignment list of the shipping company and lodge a complaint.

Concealed damage must be reported immediately upon its discovery, as

compensation claims may only be filed within applicable time limits.

If you find that parts or accessories missing, please contact our Customer Service

Department.

3.2 Packaging

Do not dispose of the appliance cardboard box. It may be used to store the

appliance when relocating or when shipping the appliance to our service point in the

case of any damages.

The packaging and its elements are made of recyclable materials. Particularly,

these are: plastic films and bags, cardboard box.

When disposing of the packaging, observe applicable domestic regulations.

Recyclable packaging materials should be recycled.

3.3 Storage

Leave the packaging closed until installation of the appliance; observe external

indications concerning method of placing and storage. Store the packaging in the

following conditions only:

– in closed rooms;

– in dry and dust-free surrounding;

– away from aggressive agents;

– in a location protected against sunlight;

– in a location protected against mechanical shocks.

In the case of extended storage (over three months), make sure you check the

condition of the packaging and the parts regularly. If needed, replace the packaging

with a new one.

117910 9 / 68

Technical Data

EN

4 Technical Data

4.1 Technical Specifications

Version / Characteristics

• Series: CL

• Equipment connection: 3 NAC

• Heating type: top/bottom heating element

• Independent adjustment of top / bottom heating element

• Steam generator: external Steam-Box

• Steaming:

– set in a program

– manual

• Parameters per baking phase:

– pre-hating

– baking time

– top/bottom heating element

– steaming intensity

– vapour extraction position

• Manual baking time extension

• Automatic switch-on via timer

• Automatic pre-heating

• USB port

• Internal lighting: LED

• Control: touch

• Display:

– 7" LCD display

– program

– timer settings

– date and time

• Features:

– programs with all parameters can be copied within the menu

– programs from other appliances can be imported

10 / 68 117910

Technical Data

EN

Name:

Deck oven CL6040-1

Art. No.:

117910

Material:

stainless steel

Baking chamber material:

stainless steel

Number of baking chambers:

1

Capacity, in mm:

1 x 600 x 400

Baking chamber dimensions (W x D x H),

in mm:

680 x 420 x 160

Loading height, in mm:

140

Temperature range, max., in °C:

300

Temperature control, in °C increments:

1

Heating power output, in kW:

2,4

Steam generator output, in kW:

1,5

Number of programs: pre-installed / for

programming / manually set:

15 / 84 / 1

Number of baking phases:

6

Time setting, from–to, in min.:

1 - 99

Water connection:

R 3/4“

Water supply temperature range, in °C:

10 - 40

Connected load:

4,8 kW | 400 V | 50/60 Hz

Dimensions (W x D x H), in mm:

980 x 900 x 400

Weight, in kg:

98,0

• Important indication:

– installation kit LBO100 is required for the operation of the appliance in

single mode (in the case of installation of the appliance in combination

with other appliances, the appropriate installation kit must be selected)

– connection of a softener at the water inlet is always required

– in the case of water pressure of 3,5 bar and more, a pressure reducer is

required

We reserve the right to implement technical modifications.

117910 11 / 68

Technical Data

EN

Name:

Deck oven CL6080-1

Art. No.:

117911

Material:

stainless steel

Baking chamber material:

stainless steel

Number of baking chambers:

1

Capacity, in mm:

1 x 600 x 800 / 2 x 600 x 400

Baking chamber dimensions (W x D x H),

in mm:

680 x 840 x 160

Loading height, in mm:

140

Temperature range, max., in °C:

300

Temperature control, in °C increments:

1

Heating power output, in kW:

4,8

Steam generator output, in kW:

1,5

Number of programs: pre-installed / for

programming / manually set:

15 / 84 / 1

Number of baking phases:

6

Time setting, from–to, in min.:

1 - 99

Water connection:

R 3/4“

Water supply temperature range, in °C:

10 - 40

Connected load:

6,5 kW | 400 V | 50/60 Hz

Dimensions (W x D x H), in mm:

980 x 1330 x 400

Weight, in kg:

131,0

12 / 68 117910

Technical Data

EN

Name:

Deck oven CL6080-2

Art. No.:

117912

Material:

stainless steel

Baking chamber material:

stainless steel

Number of baking chambers:

2

Capacity, in mm:

2 x 600 x 800 / 4 x 600 x 400

Baking chamber dimensions (W x D x H),

in mm:

680 x 840 x 160

Loading height, in mm:

140

Temperature range, max., in °C:

300

Temperature control, in °C increments:

1

Heating power output, in kW:

9,6

Steam generator output, in kW:

3

Number of programs: pre-installed / for

programming / manually set:

15 / 84 / 1

Number of baking phases:

6

Time setting, from–to, in min.:

1 - 99

Water connection:

R 3/4“

Water supply temperature range, in °C:

10 - 40

Connected load:

13,8 kW | 400 V | 50/60 Hz

Dimensions (W x D x H), in mm:

980 x 1330 x 700

Weight, in kg:

233,0

117910 13 / 68

Technical Data

EN

Name:

Deck oven CL6080-3

Art. No.:

117913

Material:

stainless steel

Baking chamber material:

stainless steel

Number of baking chambers:

3

Capacity, in mm:

3 x 600 x 800 / 6 x 600 x 400

Baking chamber dimensions (W x D x H),

in mm:

680 x 840 x 160

Loading height, in mm:

140

Temperature range, max., in °C:

300

Temperature control, in °C increments:

1

Heating power output, in kW:

14,4

Steam generator output, in kW:

4,5

Number of programs: pre-installed / for

programming / manually set:

15 / 84 / 1

Number of baking phases:

6

Time setting, from–to, in min.:

1 - 99

Water connection:

R 3/4“

Water supply temperature range, in °C:

10 - 40

Connected load:

20,6 kW | 400 V | 50/60 Hz

Dimensions (W x D x H), in mm:

980 x 1330 x 995

Weight, in kg:

329,0

14 / 68 117910

Technical Data

EN

Fig. 1

A

Baking chamber

protection

B

Hood connection

C

Steam generator

protection

D

Water connection

E

Grounding

connection

F

High voltage

G

Internet

connection

H

USB connection

I

Rating plate

Appliance Label Description

There are labels on the appliance with important information about the oven and

hazardous areas, as shown in the following figure.

117910 15 / 68

Technical Data

EN

4.2 Functions of the Appliance

Baked goods from a deck oven are baked on the traditional fireclay brick with

separately adjustable top and bottom heating elements.

The deck oven distinguishes itself with small temperature losses even with the

steaming function. External steam generation system of Steam-Box and fireclay

brick are a guarantee of practically unchanged temperature in the baking chamber.

99 programs, 6 baking phases and 6 parameters ensure that work proceeds quickly

and without complications.

16 / 68 117910

Technical Data

EN

Fig. 2

1. Internal LED lighting

2. Top heating element

3. Thermal processing chamber

ventilation openings

4. Housing

5. Appliance door

6. Door handle

7. Fireclay brick

8. Bottom heating element

9. Control panel

10. USB connection

11. Ventilation openings

4.3 List of Components of the Appliance

117910 17 / 68

Installation Instructions

EN

CAUTION!

Incorrect installation, positioning, operation, maintenance or misuse of

the appliance may lead to personal injury or property damage.

Positioning and installation, as well as repairs may be performed by

authorised technical service only and in compliance with the applicable

national law.

NOTE!

The manufacturer disclaims all liability and provides no warranty for

damages, which may be attributed to non-observance of regulations or

incorrect installation.

5 Installation Instructions

5.1 Unpacking and Positioning

Place of Installation

• The appliance is designed to operate in closed rooms and may not be used in

open air nor subject to unfavourable atmospheric conditions.

• The appliance may be used in properly ventilated room in order to avoid

excessive accumulation of harmful substances in the air.

• In order to evacuate the hot fumes and odours escaping from the baking

chamber, an industrial ventilation hood (or other system ensuring adequate

evacuation of the vapours) must be installed above the appliance.

• To ensure fire safety, a fire extinguisher must be installed near the appliance.

• We recommend installing a fire alarm near the oven.

• The surface under the appliance must feature load-bearing capacity suitable for

the appliance's weight with maximum load.

• Place the appliance on a stable, even, dry surface that features water resistance

and high temperature resistance.

• The installation place must be easily accessible and sufficiently spacious to

allow easy operation of the appliance.

• The room in which the appliance will be installed must be prepared in

accordance with the manufacturer's instructions. The end customer must

provide:

18 / 68 117910

Installation Instructions

EN

CAUTION!

Choking hazard!

Prevent children from accessing packaging materials, for instance: plastic

bags and EPS elements.

– a location with adequate minimum clearance from walls and ceiling

– an electrical connection with appropriate fuses and a main switch located

nearby

– a connection to the equipotential bonding system — separate earth cable

– a connection to cold water supply with softening system with valve and

pipe pressure of 2.5–3.5 bar

– a condensate drain to drain with a trap

– a ventilation system and vapour extraction (condensation hood) above

the appliance.

• The appliance must be transported to the installation location in packaging, on

its dedicated wooden pallet.

• Transportation must be executed with the use of pallet trolley or forklift,

observing all safety precautions, in order to avoid the risk of tipping it over. Also,

following the operation period, the appliance must be transported on a pallet and

manipulate with the highest caution, in order to avoid the risk of tipping it over.

• Remove the external packaging (wooden crate and/or carton box) and utilize it

according to regulations in force in the country of installation.

• Check if the appliance is undamaged.

• Before positioning the appliance, check the dimensions and exact positions of

the electric, water, and extraction connections.

• If the appliance is covered with a protective film, remove it. Remove the film

slowly, so no glue residues are left. Remove any glue residues with the use of a

suitable solvent.

• Be careful not to damage the rating plate and warning labels affixed to the

appliance.

• Remove all accessories, information materials, and plastic bags from the

appliance.

• Check if ventilation openings and fume extractor are not covered nor obstructed

in any way.

• Place the appliance in a way making the connections easily accessible, so that

they may be quickly disconnected if such a need arises.

117910 19 / 68

Installation Instructions

EN

• Never place the appliance directly next to walls, low walls, division walls kitchen

furniture, or other surfaces made of flammable materials. Unconditionally

observe fire-fighting regulations in force.

• Walls and objects in the vicinity of the appliance must be made of noncombustible materials (e.g. ceramic tiles, steel pallets) or be lined with noncombustible thermal insulation material.

• When it is not possible to maintain the recommended clearance, employ

appropriate protective measures (e.g. a film made of a heat-resistant material)

that will ensure keeping the wall temperature within the safe range (up to 60°C).

• Position the appliance vertically — to this end, the height of adjustable feet is set

with a spirit level.

ATTENTION!

Differences in height or tilting may negatively influence the appliance's

functionality.

• Minimum clearances must be maintained from walls and combustible objects, as

shown in the following figure.

20 / 68 117910

Installation Instructions

EN

Fig. 3

5.2 Electrical Connection

• Verify if the technical specification of the appliance (see the rating plate)

corresponds to the characteristics of the local electric mains grid.

• The power cord should be laid in a way preventing anyone from threading on it

or tripping against it.

WARNING!

The electrical connection of the appliance may only be made by

authorised personnel. Safety regulations for the operation of such

appliances and national regulations must be observed during installation

work.

NOTE!

Please refer to the enclosed wiring diagram for details.

117910 21 / 68

Installation Instructions

EN

Fig. 4

• The 5-pin socket must be fixed to the wall close to where the oven is installed

and should be easily accessible.

According to the regulations, the distance between the contacts in the open

position must be at least 3 mm. A standardised connection cable with rubber

insulation, which is supplied with the oven, must be used to connect the

appliance correctly to the 5-pin plug. If the appliance is installed in countries with

a different power supply, the cable cross-section will increase accordingly and

the cable will need to be replaced.

• The appliance must be earthed in accordance with the safety regulations for

electrical equipment.

• Potential equalisation is carried out at the screw marked , which is located

under the cable gland for the electrical connection at the rear of the appliance.

• A separate 5-core cable must be provided for the appliance from the 5-pin

socket in the wall to the facility's control cabinet, and its cross-section must

correspond to the maximum electrical power of the appliance with adequate

protection provided by an automatic circuit breaker.

22 / 68 117910

Installation Instructions

EN

5.3 Water Connection

1. Make sure that the potable water connection is located close to the appliance.

2. Prior to establishing the water connection, flush with enough water to remove all

residues of substances that might be present in tubes, so that they do not enter

solenoid valves.

3. In order to utilise the water connection, consider the following information:

– The water supply connection is located at the rear of the appliance, to

the left-hand side. The connection to the distribution network valve can

be made using the supplied flexible pipe or with a ¾" threaded pipe. The

connection must be made in such a way that it cannot be removed in the

event of a pressure overload. Illustration of water connection and water

drain is shown in the below Fig. 5.

– Before connecting the water supply to the oven, install a pressure

regulator and set it to 2.5–3.5 bar (50–200 kPa). A filter must be installed

before water is delivered to the oven.

– The on-site water supply must be fitted with a shut-off valve that may be

used to shut off the water supply to the appliance.

– Check the hardness of the water on site or ask your local water supply

company.

117910 23 / 68

Installation Instructions

EN

Fig. 5

ATTENTION!

The appliance must be supplied with potable water to ensure correct

operation in order to avoid limescale build-up in the injection lines, baking

chamber and steam generator.

A connection of a softener at the water inlet is always required!

24 / 68 117910

Installation Instructions

EN

Drain of Condensed Water

WARNING!

The temperature of the steam is very high and can cause scalding on

contact with skin or eyes.

Take special care in the area of the vapour extractor and steam generator!

A sufficient amount of water and steam is released from the cooking cabinet during

the baking process.

Draining the condensed liquid from the condensation hood requires the installation

of an additional rubber hose with a diameter of Ø20 mm, which must also be

connected to the tank.

Excess condensation water from the steam generator is drained through additional

pipes that are connected to the tank.

Condensation water from the tank is drained through the drain hose of the

appliance, which is connected to a heat-resistant hose (Ø50 mm) or a drain pipe in

the building floor.

In both cases, a suitable trap is required.

Connection of Condensation Hood

WARNING!

The electrical connection of the condensation hood may only be made by

authorised personnel.

When installing the condensation hood to the appliance, all safety

regulations for the handling and operation of electrical appliances must be

observed!

• The condensation hood is connected by connecting the hood connection cable

(4 x 0.75 mm2) to the cable gland at the back of the appliance. The connection

cable is connected to the marked terminals in the electrical part of the appliance.

The connection cable is supplied with the condensation hood.

• The connection cable must not come into contact with hot surfaces of the oven.

NOTE!

The condensation hood is not included in the delivery of the oven.

117910 25 / 68

Operating Instruction

EN

6 Operating Instruction

Safety Indications for the User

WARNING!

All persons operating the appliance must be properly educated and

trained by authorised personnel and must understand, respect and

observe the safety rules and indications in the manual.

The following safety regulations and precautions must be observed when operating

the appliance:

• The ovens are intended only for the processing of food, i.e. bread, cakes and

other products complying with current food regulations.

• Never use the oven for other products or materials without written permission

from the manufacturer.

• Never use the oven to process volatile or flammable materials and liquids

(alcohol, thinners, etc.) as this may cause a fire or explosion!

• Unauthorised persons are not permitted to operate the oven.

• Use oven mitts when placing products in the oven and when removing them

from the oven.

• Before operating and switching the oven on, make sure that:

– all safety devices are in place;

– no part of the oven is damaged;

– all objects which should not be in or on the oven have been removed;

– the water supply line is open;

– the water valve is open;

– there is a water drain in the thermal processing chamber.

• Do not switch the oven on until you have checked that it is in good working

order, observing the health and safety regulations. Any defects or faults which

may affect the safety of the appliance must be rectified immediately by

authorised personnel or a service company!

• Constant care is required when loading and unloading the oven. Hot products

can fall out of containers and burn the operator. Never place liquid products on

sheets located higher as they may spill over. Baking sheets with liquid products

must not be placed higher than the operator's chest.

• After each baking process:

– remove all products from the appliance,

– clean the inside and outside of the appliance,

26 / 68 117910

Operating Instruction

EN

OSTRZEŻENIE

Risk of burning!

During operation, the housing and appliance door become very hot and

remain hot for a while after switching the appliance off.

Do not touch the appliance during operation nor immediately after

switching it off. Open and close the oven only using the door handle.

To operate the appliance, use handles and elements designed to this end.

Oven sheets heat up considerably during operation.

Use oven mitts or a kitchen cloth when removing baking sheets or

containers with food.

– close the water valve.

• At the end of the working day, disconnect the power supply and close the water

tap.

• Disconnect the oven from the power supply before carrying out maintenance

and service work.

• Maintenance, service and repair work must only be carried out by qualified

personnel in accordance with safety regulations.

• Never use water hoses, high-pressure cleaners, steam cleaners or similar

devices to clean the oven.

• After maintenance or servicing of the oven, it is necessary to follow and recheck all the above instructions.

• Przed pierwszym użyciem wyczyścić urzą dzenie i wypos ażenie zgodnie z e wskazówka mi zawartymi w punkcie 6 „Czyszczenie” . Uważać, a by do instalacji elektrycznej i s krzynki rozdzielcz ej nie dostała się woda. Następ nie dokładnie osusz yć urządz enie i eleme nty wyposażeni a.

• Setzen Sie die Boden-Abdeckung in das Becken ein. Osł ona pełni fu nkcję rozpór ki pomiędzy elemente m grzewcz ym a tacką na re sztki jedzenia it d.

• Setzen Sie den Schaltkasten mit Heizele ment vorsichtig auf den hinteren Rand d es Gerätes. Sworzeń w dolnej części skrzynki rozdzi elczej musi wchodzić w otwór w urządzeniu g łównym. W ta ki sposób skrzynka rozdzielcza jest pra widłowo usta wiona.

117910 27 / 68

Operating Instruction

EN

General Description of Appliances

Deck ovens must always be installed on a base. The bases offered by the

manufacturer must be ordered separately.

There are 4 deck ovens available:

Deck oven CL6040-1 with 1 baking chamber

Deck oven CL6080-1 with 1 baking chamber

Deck oven CL6080-2 with 2 baking chambers

Deck oven CL6080-3 with 3 baking chambers

Manual Baking

To achieve good baking results, certain conditions must be met: temperature,

humidity and time.

The manual baking mode is designed for fast baking in a single phase. This baking

mode can be used for simple baking or to manually test a recipe for later

programming.

Programmed Baking

The programmed baking mode is designed for baking in several phases. Up to 99

programmes can be set in the program mode.

The following settings can be configured for each program: program name, sound,

image.

In each cooking phase, you can set the time, temperature, steaming, position of the

vapour extraction flap or economic mode (ECO).

Functions and baking Characteristics

Heating Element

The air is heated by electric infrared tube heating elements in the bottom and ceiling

of the oven. The heating is controlled automatically by electronics and a

temperature sensor in the oven.

The temperature can be freely adjusted by the user in the range of 0–300°C, as

different products require different temperatures.

28 / 68 117910

Operating Instruction

EN

Steam

Steam is generated by a steam generator (external Steam-Box) located outside the

baking chamber, on the rear wall of the oven.

The steam generator has its own heating elements and water supply. When the

baking process begins, the generator pushes the steam into the baking chamber,

which evenly moistens the food inside without drawing energy from the baking

chamber.

The user can freely set the intensity of the steam. It is important to ensure that the

correct amount of moisture is supplied to the products so that they are evenly

moistened, as this affects the quality of the products.

Vapour Exhaust

During steaming, a positive pressure is created inside the oven and the excess

steam is discharged through the vapour extractor of the appliance. It is also

possible to ventilate the oven at any time during the baking process.

Baking Time

The countdown timer shows the time remaining in the baking process. The time can

be set according to the user's preference for particular products.

Automatic Oven Preparation Using the Timer

At the set time, the oven starts preparing the baking process to the set temperature

values. This function prepares the oven for immediate use. Automatic overnight

preparation starts at the time and to the temperature set in the settings.

Interior Lighting

LED lighting is installed on the left-hand side of the oven to illuminate the baking

chamber.

Economic Mode (ECO)

Activating the economic mode helps to save electricity by switching the steam

heating and baking chamber heating on and off.

117910 29 / 68

EN

Fig. 6

6.1 Operation

Control Panel

Operating Instruction

• Przed pierwszym użyciem wyczyścić urzą dzenie i wypos ażenie zgodnie z e wskazówka mi zawartymi w punkcie 6 „Czyszczenie” . Uważać, a by do instalacji elektrycznej i s krzynki rozdzielcz ej nie dostała si ę woda. Nast ępnie dokładnie os uszyć urządz enie i element y wyposażenia.

• Setzen Sie die Boden-Abdeckung in das Becken ein. Osł ona pełni fu nkcję rozpór ki pomiędzy elemente m grzewcz ym a tacką na reszt ki jedzenia it d.

• Setzen Sie den Schaltkasten mit Heizele ment vorsichtig auf den hintere n Rand des Ger ätes. Sworze ń w dolnej części i n the conn ection box mus t enter the hole in the main appliance. This way the connection box is properly mounted.

Preparation of the Appliance

1. Before starting-up, clean the appliance and its equipment inside and outside

observing instructions in section 'Cleaning'.

2. Connect the appliance to the power supply.

3. Switch the oven on by keeping the ON/OFF switch on the operating panel

pressed for a few seconds.

The digital display shows the operating hours and the hours remaining until the

required periodical maintenance.

30 / 68 117910

Operating Instruction

EN

Fig. 7

Fig. 8

After a few seconds, the screen switches to the main menu. The oven is now ready

for operation.

117910 31 / 68

Operating Instruction

EN

Fig. 9

• Prior to first operation, clean the appliance and its equipment, observing instructi ons in section 6 'Cleaning'. Make sur e no water enters electric installation and connection box. Then thoroughly dr y the appliance and the entire equipm ent.

• Insert the bottom cover into the appliance. The cover acts as a spacer between t he heating element and left-over food tray.

• Carefully insert the connection box with th e heating element at the back edge of th e appliance. A pin in the bottom part of the connection box must enter a hole in the main appliance. This way the co nnection box is properly mounted.

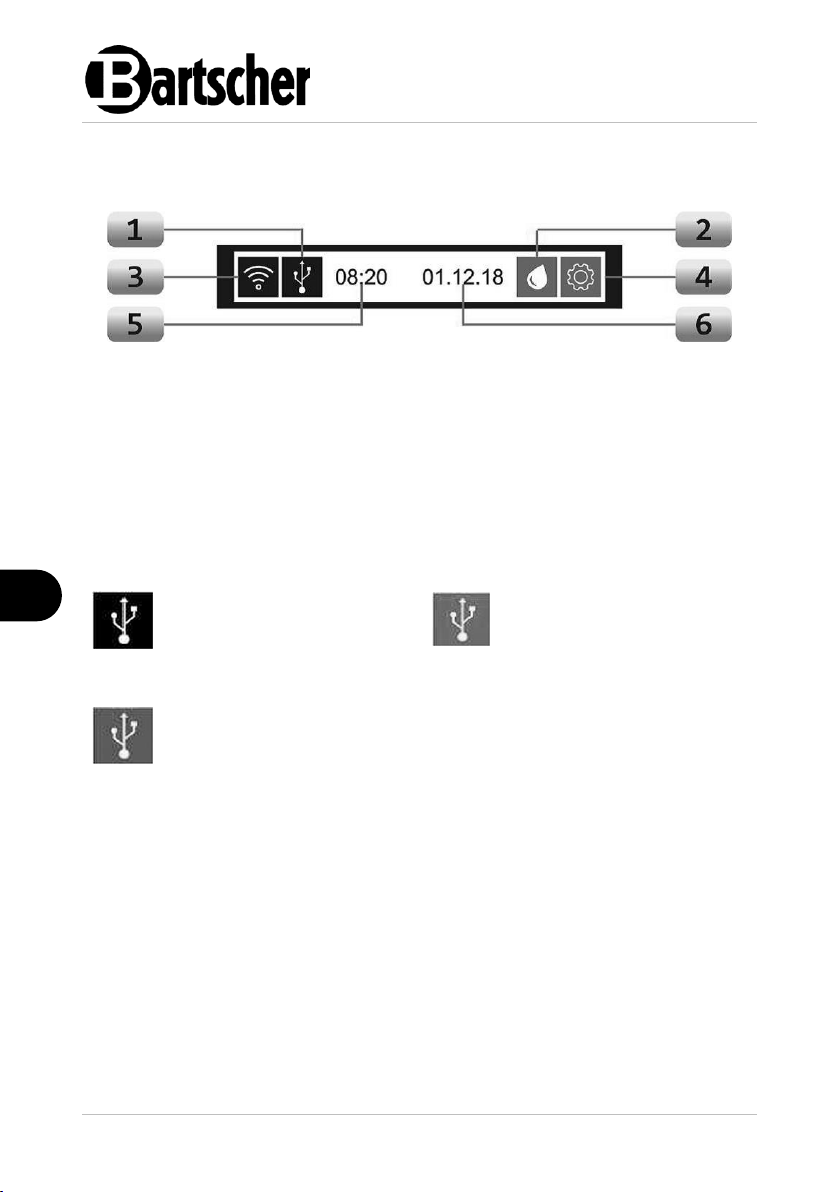

Main Menu Screen / Function Keys and Indicators

The main menu screen offers eight function and status icons, which are displayed in

the touch screen.

1. NAME OF CURRENT SCREEN

2. INFORMATION BAR

The name of the currently selected function is displayed in the information bar.

In the event of an error, the error message is also displayed in the information

bar.

3. MANUAL BAKING MODE

The manual baking mode is designed for fast baking in a single phase.

4. PROGRAMMED BAKING MODE

The programmed baking mode allows you to bake by selecting from a list one of

the pre-set baking programs.

32 / 68 117910

Operating Instruction

EN

function available

function selected

function locked

Fig. 10

5. BAKING PROGRAM EDIT MENU

This menu enables the user to activate or deactivate pre-set programs, create

new programs or edit the parameters of existing programs.

6. SETTINGS MENU

The settings menu gives access to several levels of parameters and information

7. OFF KEY

By pressing and holding this key for a few seconds, the user switches the oven

off.

8. STATUS BAR

The status bar shows certain information, e.g.: time, internet connection, USB

status, date, periodical maintenance status and water filter status.

• Prior to first operation, clean the appliance and its equipment, observing instructi ons in section 6 'Cleaning'. Make sur e no water enters electric installation and connection box. Then thoroughly dr y the appliance and the entire equipm ent.

• Insert the bottom cover into the appliance. The cover acts as a spacer between t he heating element and left-over food tray.

• Carefully insert the connection box with th e heating element at the back edge of th e appliance. A pin in the bottom part of the connection box must enter a hole in the main appliance. This way the co nnection box is properly mounted.

Navigation and Colour Messages

Navigation and icon selection may be executed directly by touching icons on the

screen.

The orange colour is used as an indicator of a current position on the screen.

Function and mode icons have the following features:

Different colours of icons in the main menu screen inform the user of the status of a

function. An example of different statuses of one icon is shown in Fig. 10.

The grey colour of an icon indicates that a function can be activated.

The orange colour of an icon indicates that a function is currently selected.

The dark grey colour of an icon indicates that a function is blocked and therefore

cannot be selected and that it is not available for the product.

117910 33 / 68

Operating Instruction

EN

Fig. 11

1. USB connection

2. Water filter

3. Internet connection

4. Periodical maintenance

5. Current time

6. Current date

Black USB indicator

Black colour of the icon

indicates no USB

communication.

Green USB indicator

Green colour of the icon

indicates that USB

communication is active and

working.

Red USB indicator

Red colour of the icon

indicates that USB

communication is active, but

due to an error is not working.

Status Bar

The status bar shows the following information:

USB Status Indicators

Information about the colour USB indicator icons:

34 / 68 117910

Operating Instruction

EN

Black Internet indicator

Black colour of the icon

indicates no Internet

communication.

Green Internet indicator

Green colour of the icon

indicates that Internet

communication is active and

working.

Red Internet indicator

Red colour of the icon

indicates that Internet

communication is active, but

due to an error is not working.

Green water filter indicator

Green colour indicates that

the water filter does not

require

maintenance/replacement.

Orange water filter indicator

The orange colour of the filter

icon indicates that the filter

should be replaced soon and

that service should be

informed so that replacement

can be scheduled in the right

time.

Red water filter indicator

Red colour of the filter icon

means that the water filter has

not been replaced in due time

and that it needs to be

replaced immediately.

Internet Status Indicators

Information about the colour Internet indicator icons:

Water Filter Status Indicator

Information about the colour water filter indicator icons.

117910 35 / 68

Operating Instruction

EN

NOTE!

As ovens can be installed in various

combinations, the water filter must be

checked manually by the user as it is used

to supply water to the entire appliance.

The filter icon is not an indicator of the

water filter status for the entire appliance.

Only the combination of information from

the filter icon and the manual inspection of

the water filter provides reliable

information on the status of the water filter.

Fig. 12: Water filter replacement required

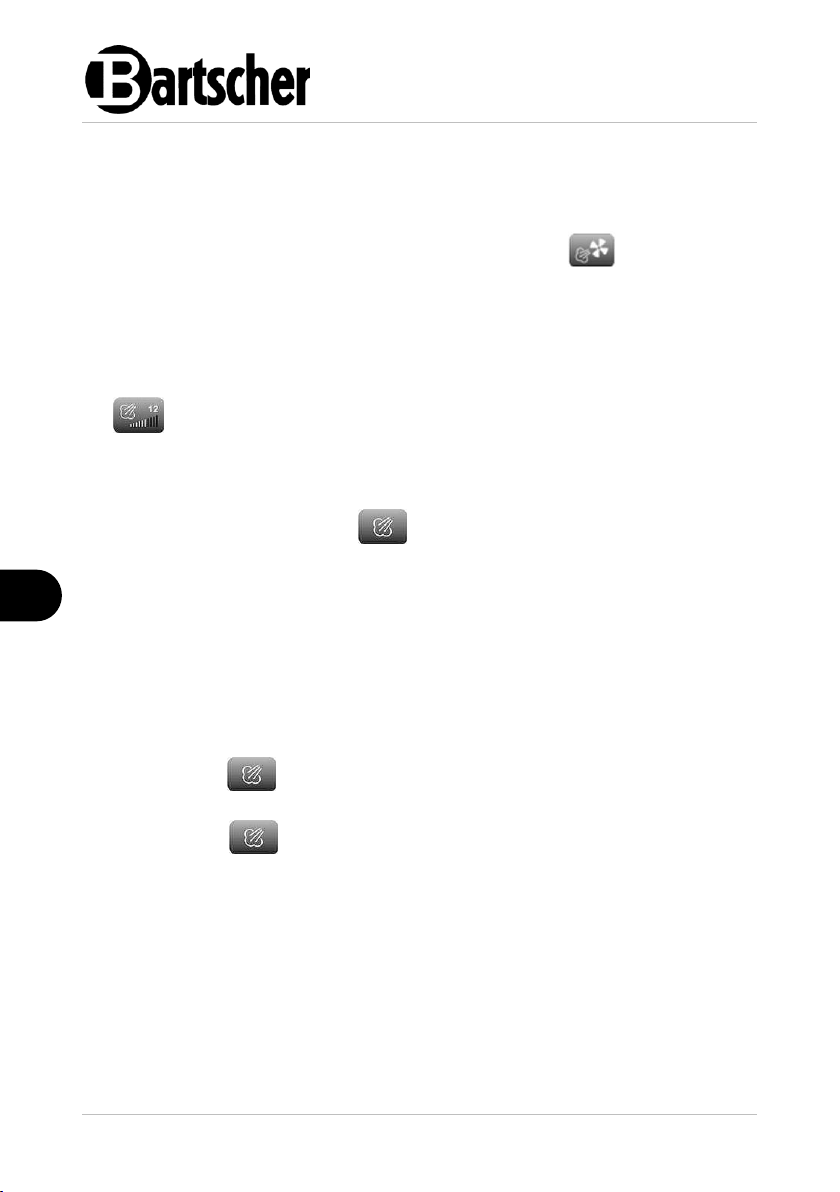

Green service indicator

The green colour of the icon

indicates that no maintenance

is required.

Orange service indicator

The orange colour of the

service icon indicates that an

annual service inspection will

soon be required and that the

service company should be

notified to schedule

maintenance in due course.

Red service indicator

The red colour of the service

icon indicates that the annual

service has not yet been

performed and that it must be

performed immediately!

Status Indicators for Periodical Service Inspection/Maintenance

Information about the colour service indicators.

36 / 68 117910

Operating Instruction

EN

NOTE!

As soon as the icons light up orange, an

extra precaution is automatically activated.

When the oven is switched on, the

'Periodical Maintenance' or 'Water Filter

Change Required' warning appears on the

main menu screen.

The warning is displayed and must be

acknowledged by pressing the

acknowledge key . The oven can then be

used. In some cases, for safety reasons,

the warning remains permanently active

until the inspection is completed. In the

meantime, the oven cannot be used.

Fig. 13: Periodical service inspection required

NOTE!

The service icon is only an indication for periodical maintenance. The

service icon is not an automatic error recognition system and does not

inform the user of errors that occur, as another system is responsible for

error recognition, error warning and error rectification.

117910 37 / 68

Operating Instruction

EN

Fig. 14

• Prior to first operation, clean the appliance and its equipment, observing instructi ons in section 6 'Cleaning'. Make sur e no water enters electric installation and connection box. Then thoroughly dr y the appliance and the entire equipmen t.

• Insert the bottom cover into the appliance. The cover acts as a spacer between t he heating element and left-over food tray.

• Carefully insert the connection box with th e heating element at the back edge of t he appliance. A pin in the bottom part of t he connection box must enter a hole in the main appliance. This way the co nnection box is properly mounted.

Manual Baking Mode

The manual baking mode is activated by pressing the 'Manual' key (Fig. 14) in the

main menu screen.

After activation, the MANUAL screen (Fig. 15) shows the functions and baking

parameters. Manual operation is always set with the parameters which were used

during the last baking. They can be changed each time manual operation is

activated.

The MANUAL indicator consists of the following icons: INFORMATION and

OPERATION (Fig. 15).

38 / 68 117910

Operating Instruction

EN

Fig. 15

1. Name of current screen

2. Information Bar

Information about the temperature

set for the pre-heating.

3. Pre-Set Baking Temperature, Top

Heating Element

Pre-set baking temperature indicator

for top heating element.

4. Actual Baking Temperature, Top

Heating Element

Actual baking temperature indicator

for top heating element.

5. Pre-Set Baking Temperature,

Bottom Heating Element

Pre-set baking temperature

indicator for bottom heating

element.

6. Actual Baking Temperature,

Bottom Heating Element

Actual baking temperature indicator

for bottom heating element.

117910 39 / 68

Operating Instruction

EN

7. Set Baking Time

Shows information about the set

time.

8. Remaining Baking Time

Shows the time remaining in the

baking process.

9. Vapour Extraction Flap Key

May be used to open or close the

vapour extraction flap.

10. Steam Generator Steaming Key

The steaming intensity is set in

intervals between 1 and 20. It can

only be set before baking.

It is not possible to use both

steaming systems at the same time,

therefore the icon for the steaming

system that is not selected is

blocked and dark grey.

11. Manual Steaming Key

Allows you to add steam manually.

12. Undo Key

With this key the user can return to

the previous indicator or to the main

menu.

13. STOP Key

Can be used to stop the pre-heating

or baking process (direct activation

icon).

14. ECONOMIC Key

By pressing this key, the economic

mode is activated.

40 / 68 117910

Operating Instruction

EN

Setting the Manual Baking Process Parameters

To start the single-phase fast baking process, set the following parameters (Fig.

15):

– baking temperature

– baking time

– vapour extraction flap position

– economic mode

– steam generator steaming .

The parameters can be set one by one. They can be edited by pressing the icon on

the control panel and setting the value.

Baking Temperature

1. Press the displayed temperature icon.

The icon lights up in orange.

2. Select the desired baking temperature by pressing the icon in the pop-up menu

that appears in the display.

The temperature may be set up to 300°C.

3. Press the selected icon to confirm the set temperature.

The set baking temperature is displayed at the right-hand side of the temperature

bar. The left-hand side shows the current temperature in the oven.

The oven pre-heating is communicated with the colour icon.

When the set temperature is reached, the icon changes colour to

grey.

Baking Time

1. Press the current baking time icon.

The icon lights up in orange.

2. Set the required baking time by pressing the icon, and using the keypad in the

displayed value setting screen.

3. Press the icon in the display to confirm the selected baking time.

117910 41 / 68

Operating Instruction

EN

Fig. 16: Baking process finished

The selected baking time is displayed on the right-hand side of the time bar.

4. To extend the baking time, during of after the baking process, select the 'Add

Time' icon.

The end of the baking process is communicated by an acoustic signal and the

'Baking Finished' message is displayed in the information bar.

42 / 68 117910

Operating Instruction

EN

Steaming

Due to the default settings, the manual steaming icon is dark grey, and the

steam generator icon is grey.

It is not possible to use both steaming system concurrently.

Therefore, the non-selected steaming system icon is locked and has a dark grey

background . When the baking process with generator steaming starts, the

manual steaming function may be used manually after the generator steaming is

finished.

Irrespective of steaming icons colour, you may select steam generator steaming

only.

1. In order to set the required number of steam intervals, press the steam

generator icon briefly.

2. Input the required number of parameters, using the keypad in the display pop-up

menu.

3. Press the confirmation icon in the display to confirm the number of

intervals.

When the steam generator is warm enough, the icon changes its colour from red

to white , which indicates that the steam generator is ready.

4. To add further steaming intervals during the baking process, select the manual

steaming icon.

Information about the Steam Generator System (Steam-Box)

• Steaming with the steam generator is an intermediate steaming system. Steam

is generated in an external steam generator (Steam-Box) and introduced into

the baking chamber when it is already hot.

• The main benefit of the steam generator is that it does not decrease the

temperature in the baking chamber. Therefore, baking results and oven

efficiency are improved.

• The default steaming is set to 0 intervals. To activate the process, set it

manually. You may set up to 20 intervals.

Information about the Steam Generator System

– The number of intervals can be set between 1 and 20.

117910 43 / 68

Operating Instruction

EN

– The information on the number of steaming intervals decreases

progressively during the baking process and shows the number of

remaining steaming intervals.

– During the baking process, further steaming intervals can only be added

via manual steaming by pressing the 'Add Steam' icon.

Steaming Intervals

• Intervals may be selected manually by changing the default steaming system.

• The number of intervals can be set between 1 and 20.

• Information about the number of selected intervals is displayed in the steam

icon.

• During the baking process the display shows the number of remaining steaming

intervals.

• During the baking process, subsequent steaming intervals may be added by

pressing the manual steaming icon.

• The colour of the steam generator icon indicates various system states: dark

grey colour of the icon means the function is locked. The grey colour of the icon

with a red steam cloud indicates that the steam generator is currently heating

up. The grey colour of the icon with a white steam cloud indicates that the steam

generator is ready for operation.

Adding Extra Steam During Baking Process

If an additional steaming interval is needed after the baking process has started and

the programmed steaming intervals have finished, it can be added by activating the

manual steaming icon.

By briefly pressing this icon once, the additional steaming interval is activated.

Holding down the icon activates the additional interval as long as the icon is

held down.

NOTE!

The steam may be added only when the programmed intervals have

elapsed and the steam generator is re-heated.

44 / 68 117910

Operating Instruction

EN

The colour of the steam generator icon shows the status of the function:

– the dark grey colour of the icon indicates that the function is blocked,

– the grey colour of the icon indicates that the function is available,

– red colour of the icon indicates that the function is active.

Economic Mode (ECO Mode)

1. Press the economic mode icon.

The icon is lit in orange and the economic mode is activated.

In the economic mode, the oven switches heating elements on and off to reach the

lowest power consumption possible.

Vapour Extraction Flap

The vapour extraction flap icon is used to open and close the flap in the

vapour extractor in order to evacuate excess steam from the baking chamber if

necessary.

1. Press the icon to select the position of the flap.

The colour of the icon indicates the vapour extraction flap position:

– grey colour of the icon with an image of a horizontal flap indicates

that the vapour extraction flap is closed.

– orange colour of the icon with image of a vertical flap indicates

that the vapour extraction flap is open.

Starting the Pre-Heating Process

The baking process can be started when the door is closed, there are no errors and

the status bar displays the message 'READY'.

1. Press the START key to start the pre-heating phase.

The 'PRE-HEAT' message is displayed in the information bar.

If the oven is cold, the first pre-heating phase lasts for approx. 30 minutes.

If the oven is already operating, the pre-heating for the new baking process lasts

up to 10 minutes.

If the steam generator system has been selected, the pre-heating phase

includes also pre-heating of the steam generator.

117910 45 / 68

Operating Instruction

EN

The end of the pre-heating phase is indicated by an acoustic signal and the status

of the information bar changes to 'INSERT PRODUCT'.

Start of Baking Process

WARNING! Risk of scalding!

When opening the appliance hot air and steam may escape.

Always open the appliance door with caution, using the door handle.

Always use oven mitts and protective gloves to operate the appliance.

Never put hands without oven mitts into the appliance!

Never slide baking sheets into the oven without oven mitts.

During operation, the housing and appliance door become very hot and

remain hot still for a while after switching the appliance off.

Never touch the inside or outside of the appliance door and housing without

oven mitts.

Baking sheets get very hot during operation.

Never touch the baking sheets without oven mitts.

• Open the appliance door carefully. When opening the appliance door, move as

far away from the oven as possible, as hot air and steam may escape.

• Place the sheets with the products carefully on the baking surface and slide the

sheets backwards into the baking chamber. This is important so that the inner

glass pane is not damaged!

• Each product on a baking sheet must have sufficient space so that the hot air

and humidity can circulate unhindered around each product.

• Always place the baking sheets on the fireclay brick.

• Always use baking sheets that fit the oven and comply with the standards set by

the manufacturer.

• Always insert the baking sheets into the oven only after pre-heating.

• Close the appliance door.

• Press the icon and the baking process starts. The 'BAKING' message is

displayed on the information bar.

Possible Actions and End of the Manual Baking Process

– The set temperature and baking time can be changed at any time.

46 / 68 117910

Operating Instruction

EN

– When the baking time is changed, the remaining baking time is adjusted

automatically.

– The appliance door can be opened at any time. The manufacturer

advises against opening the door during the baking process, as this

leads to a loss of energy, humidity and baking quality.

– Opening the appliance door interrupts the baking process and the baking

time continues to count down while the door is open.

– The end of the baking process is communicated by an acoustic signal

and a message on the information bar: 'BAKING ENDED'.

– The acoustic signal can be interrupted by touching anywhere on the

screen.

– Quickly, but carefully empty the oven and close the door of the oven as

soon as possible so that the oven does not cool down too much before

the next baking process.

– To exit the manual baking process, press the icon and the main

menu screen will appear on the control panel. The icon is locked

during the baking process.

At the end of a working day, always perform the following steps:

– Switch the oven off using the main ON/OFF switch. Do not disconnect

the main power supply.

– Clean and dry the baking chamber and the appliance door, as they must

be completely dry after use.

– Clean the seal in the appliance door with a damp cloth only (do not use

any cleaning agent).

117910 47 / 68

Operating Instruction

EN

Fig. 17: Program mode

1. Image

2. Selected program

3. Program number

4. Program name

5. Up

6. Down

7. Return to previous menu

• Setzen Sie den Schaltkasten mit Heizele ment vorsichtig auf den hintere n Rand des Ger ätes. Sworze ń w dolnej cz ęści skrzynki roz dzielczej musi wchodzić w otw ór w urządzeniu głównym. W ta ki sposób skrz ynka rozdzielcz a jest prawi dłowo ustawi ona.

Programmed Baking Mode

The programmed baking mode is activated by clicking the 'Programmed Baking

Mode' icon in the 'Main Menu' screen (Fig. 9). This opens the list of activated

programs.

The screen shows 6 programs per page (Fig. 17). Use the Up and Down icons to

browse through the list of available programs.

• Prior to first operation, clean the appliance and its equipment, observing instructi ons in section 6 'Cleaning'. Make sur e no water enters electric installation and connection box. Then thoroughly dr y the appliance and the entire equipm ent.

• Insert the bottom cover into the appliance. The cover acts as a spacer between t he heating element and left-over food tray.

• Carefully insert the connection box with th e heating element at the back edge of th e appliance. A pin in the bottom part of t he connection box must enter a hole in the main appliance. This way the co nnection box is properly mounted.

48 / 68 117910

Operating Instruction

EN

Fig. 18: Baking program

1. Program number

2. Program name

3. Screen change function key

4. Information bar

5. Program time

6. Top / bottom heating element

7. Steam setting

8. Add baking time

9. Vapour extraction flap position

10. Undo key

11. Start key

12. Economic mode key

117910 49 / 68

Operating Instruction

EN

Fig. 19

1. Image

2. Selected program

3. Program number

4. Program name

5. Up

6. Down

7. Undo key

Editing the Baking Program

You can access the 'Edit Program' list (Fig. 19) by pressing the 'Edit Program' icon

in the 'Main Menu' screen (Fig. 9). Ovens allow you to program and activate up to

99 baking programs. Each program may consist of 6 phases of the baking process.

Each program has a number, a name, a pictogram and an activation field.

The activation field shows whether or not a program is active and available in the

program mode list. If the program is not selected, it does not appear in the list of

programs active in program mode.

50 / 68 117910

Operating Instruction

EN

Fig. 20

1. Program number

The information bar shows the

program number, name and image.

2. Program name

The name of the program is

displayed.

Changing Program Parameters

The parameters of the first phase differ slightly from those of the other phases. The

menu contains the pre-heating temperature in the first line under the numerical

symbols. In the other phases, the total baking time is displayed in the first line.

117910 51 / 68

Operating Instruction

EN

3. Program phases

Each program may have up to 6

phases. The icons are numbered

from 1 to 6 and show the number of

available phases. White colour

indicates an active phase, dim

colour indicates that no phase is

available for the selected program,

orange colour indicates that the

display currently shows the

parameters in this list.

4. Pictogram

To change the pictogram, press the

pictogram icon in the upper right

corner of the screen. A new screen

with a list of pictograms will be

displayed. Select the desired

pictogram. After selecting the

desired pictogram, the display

automatically returns to the 'Edit

Program' message of the selected

program and displays the new

pictogram already.

5. Preparation function

In the first phase the pre-heating

time is displayed, while in the

other phases the total baking time

is displayed. When Preparation is

activated (ON), the oven prepares

itself to the set values of the

baking program.

6. Baking time

Shows the time of the selected

baking phase.

7. Top heating element temperature

Shows the set temperature for top

heating element. To change the

parameter, select the parameter by

pressing it. The keypad will appear.

Use the keypad to enter the desired

value and confirm the selected

temperature by pressing the

icon.

8. Baking temperature

Shows the set temperature for

bottom heating element. To change

the parameter, select the parameter

by pressing it. The keypad will

appear. Use the keypad to enter the

desired value and confirm the

selected temperature by pressing

the icon.

52 / 68 117910

Operating Instruction

EN

9. Steaming with steam generator

Shows the set steam intensity. The

steam intensity may be set in

intervals between 1 and 20.

10. Vapour extraction flap position

Shows the flap position set by

default during the baking phase.

The position may be set to

ON/OPEN or OFF/CLOSE.

11. ECONOMIC MODE (ECO) function

Shows the default setting for the

economic mode during the baking

phase. It may be switched on and

off with the ON or OFF options.

12. Undo key

Icon used to return to the 'Edit

Program' menu.

13. Deletion of the recently edited

baking phase

The last active baking phase in

the program can be deleted by

selecting the 'Delete Last Edited

Phase' icon. The action must be

confirmed by pressing the

icon in the pop-up menu that

appears in the display.

14. Adding a new baking phase

Adding a new baking phase to the

program is done by pressing the

'Add New Phase' icon. Confirm the

action by pressing the icon in

the pop-up menu that appears in the

display.

117910 53 / 68

Operating Instruction

EN

Fig. 21

1. Total time

Shows the total baking time of the

baking cycle.

2. Timer alarm

To set the timer alarm, select the

timer icon. A new screen appears

where you can use the keypad to

enter and confirm the desired value.

• Setzen Sie den Schaltkasten mit Heizele ment vorsichtig auf den hintere n Rand des Ger ätes. Sworze ń w dolnej części skrzynki roz dzielczej musi wchodzić w otw ór w urządze niu głównym. W taki sposób s krzynka rozdzielcz a jest prawidło wo ustawiona.

Adding timer alarms

Five different additional timer alarms may be set for various warnings during the

baking process. The timer alarms can be set independently of the main alarm,

which communicates the end of the baking process. Select any phase icon except

the first phase icon, as the first phase always shows the pre-heating temperature

and not the total time.

When the phase icon is selected, the screen with the total time information appears.

54 / 68 117910

Operating Instruction

EN

3. Adding a timer alarm

Adding a new timer alarm to the

program is done by selecting the

'Add New Timer Alarm' icon. The

action must be confirmed by

pressing the confirmation icon on

the pop-up menu that appears in the

display.

4. Deleting timer alarms

Delete the last alarm that was

added to the program by pressing

the 'Delete Last Timer Alarm' icon.

Confirm the action by pressing the

confirmation icon in the pop-up

menu that appears in the display.

Fig. 22

Fig. 23

1. LOG IN/OUT

This option is intended for

specialised personnel who have

access rights to locked options.

2. SCREEN BRIGHTNESS

Press the screen brightness icon to

set the screen brightness.

Settings Menu

The Settings menu can be activated by pressing the 'Settings' icon in the main

menu screen (Fig. 22). The settings mode includes 10 options (Fig. 23).

117910 55 / 68

Operating Instruction

EN

3. SOUND

Press the sound icon to set the

desired sound using the icons.

4. TIME

Here you can set the date (day,

month and year), time (hours,

minutes and seconds) and day of

the week (DOW).

5. GENERAL INFORMATION

Displays basic information about the

oven, such as oven type, serial

number, factory number,

manufacturer, year of manufacture,

installation date, etc.

6. LANGUAGE

Various languages may be selected.

Simply select the desired language

and return to the menu using the

Undo icon. The menu will be

displayed in the newly set language.

7. AUTO. PREHEATING

This option allows you to set an

automatic preparation process at a

specific time (e.g., in the morning

before the start of the working day).

Please read the following section

only about the preparation option.

8. PARAMETERS

Only qualified personnel may

access the parameters and set them

from scratch. Access is possible via

the Log In/Log Out option.

9. LICENCE PROLONGATION

Is an option only available to

maintenance and service personnel.

10. TRANSFER

Access is possible via the Log

In/Log Out option. Allows data to be

transferred to or from a USB drive.

56 / 68 117910

Operating Instruction

EN

Abb. 24

1. BASIC SETTINGS

Settings for temperature units,

display mode, locked and manual

programs, etc.

2. PASSWORD

Passwords for service use.

3. SOUND

Buzzer settings (on/off)

4. GENERAL SETTINGS

Condensation hood settings, door

lock, vapour hood flap, steam

settings.

5. TEMPERATURE

Setting of maximum and minimum

temperatures for steam generator

and baking chamber, etc.

6. STEAMING SETTINGS

Setting of steam interval time,

interval between steam intervals,

etc.

Parameter-Settings

117910 57 / 68

Operating Instruction

EN

7. FAN MOTOR

Option is not available for this

model.

8. POLARITIES

Setting of the standard vapour

extraction position.

9. VAPOUR EXTRACTION FLAP

Setting the time to open and close

the fume extraction flap.

10. CLEANING

Option is not available for this

model.

11. LIST OF ERRORS

Summary of all errors and their

significance.

12. INTERNET

Internet settings of server

addresses, DHCP, Ethernet

communication, etc.

13. STATISTICS

All data for man-hours, days to

service.

14. CONTROL SETUP

Contains the I/O menu for service.

Activating Timer for Automatic Pre-Heating

Pre-heating the oven is a function by which the appliance is pre-heated before

baking. This function reduces the total operating time. Namely, the steam generator

needs approximately 30 minutes (counting from a cold state) until it is ready for

operation. The settings for automatic pre-heating can be found in fig. down.

NOTE!

The oven pre-heating function can only be set one day in advance. The

settings must be repeated in advance for each subsequent day.

58 / 68 117910

Operating Instruction

EN

Fig. 25

1. ACTIVATION

Parameter 16.07 can be used to

enable or disable pre-heating. If the

oven has already been pre-heated,

the parameter automatically

switches to OFF.

2. START TIME

Parameter 16.08 can be used to set

the time by which the appliance

should be ready for operation.

3. START DAY

Parameter 16.09 shows the day on

which the pre-heating is activated.

4. PROGRAM NUMBER

Parameter 16.10 can be used to

select the number of baking

programs. (Only active programs

can be selected).

117910 59 / 68

Operating Instruction

EN

Fig. 26

1. DAY SELECTION

Indicator of the day for which

automatic pre-heating is activated.

2. TIME

Shows the time for which the

appliance is ready for operation.

3. PROGRAM NUMBER

Shows the number of the selected

program.

4. SETTINGS

Shortcut to the parameter settings

for automatic pre-heating.

5. CONFIRMATION

6. CANCEL

Pop-up menu before the oven is switched off:

60 / 68 117910

Operating Instruction

EN

Data Transfer

File transfer is carried out via the USB port.

A USB flash drive is required for file transfer. The volume can be up to 32 GB.

NOTE!

Ensure that the USB flash drive is empty before copying programs to it.