Page 1

AB12/T-L TR12/S GR12/S TR12/C AB12/AT

TR12/TS AB22/AE TR22/C TR22/TE

MEAT MINCER AND GRATER

CONTENTS

1 GENERAL INFORMATION

Purpose of this manual………………….……….

Manufacturer and machine Identification……....

Machine description...………………….………...

Specifications………………………….………….

Overall dimensions……………………………….

Safety devices…………………………………….

Safety information………….………………….….

2 INSTALLATION

Packing and unpacking………..…………………

Installation area……….…………………………..

Electric connection…..…………………………...

4

4

5

6

6

7

7

8

8

8

3 OPERATION AND CLEANING

Control descriptions……………………………….

Using the grater……………………………….…..

Using the mincer…..………………………………

Dismantling the mincing set……………………...

Recommendations for use……………………….

End-day cleaning…...….………………………….

Long periods of inactivity……...………………….

4 TROUBLESHOOTING, RECYCLING

Foreword….………………………………………..

Troubles, causes and remedies..………………..

Disposal and recycling……………………………

ANNEXES

Unger mincing set assembly diagram

Spare parts catalogue

Electrical wiring diagram

9

9

10

10

10

11

11

12

12

12

Translation of the original instructions

370.223

A370.212 A370.350

Page 2

4

GENERAL

INFORMATION

1

Purpose of this manual

This manual has been written by the Manufacturer to make an integral part of the machine standard

equipment. During the design and construction phases, special care has been devoted to any aspects which

might endanger the safety and health of the people interacting with the machine. In addition to the applicable

safety legislation, all “good construction practice” rules have been adopted. The purpose of these information

notes is to make machine users aware that special care should be applied to prevent any risks. The biggest

asset to this end, however, is precaution. Safety is also the responsability of all the operators who interact

with the machine. Keep this manual in a suitable place, where it can be conveniently reached for

consultation. In order to highlight some parts of the text, the following symbols have been used:

DANGER – CAUTION: it indicates hazards likely to cause severe injury ; caution is

requested.

INFORMATION: technical indications of special interest.

This manual comes with the following annexes:

- a guarantee certificate containing the guarantee conditions prescribed by the Manufacturer.

- documents certifying compliance with the applicable safety and personal health legislation in force.

To request After-sales service, submit inquiries or dorder spare parts, contact your Authorised dealer.

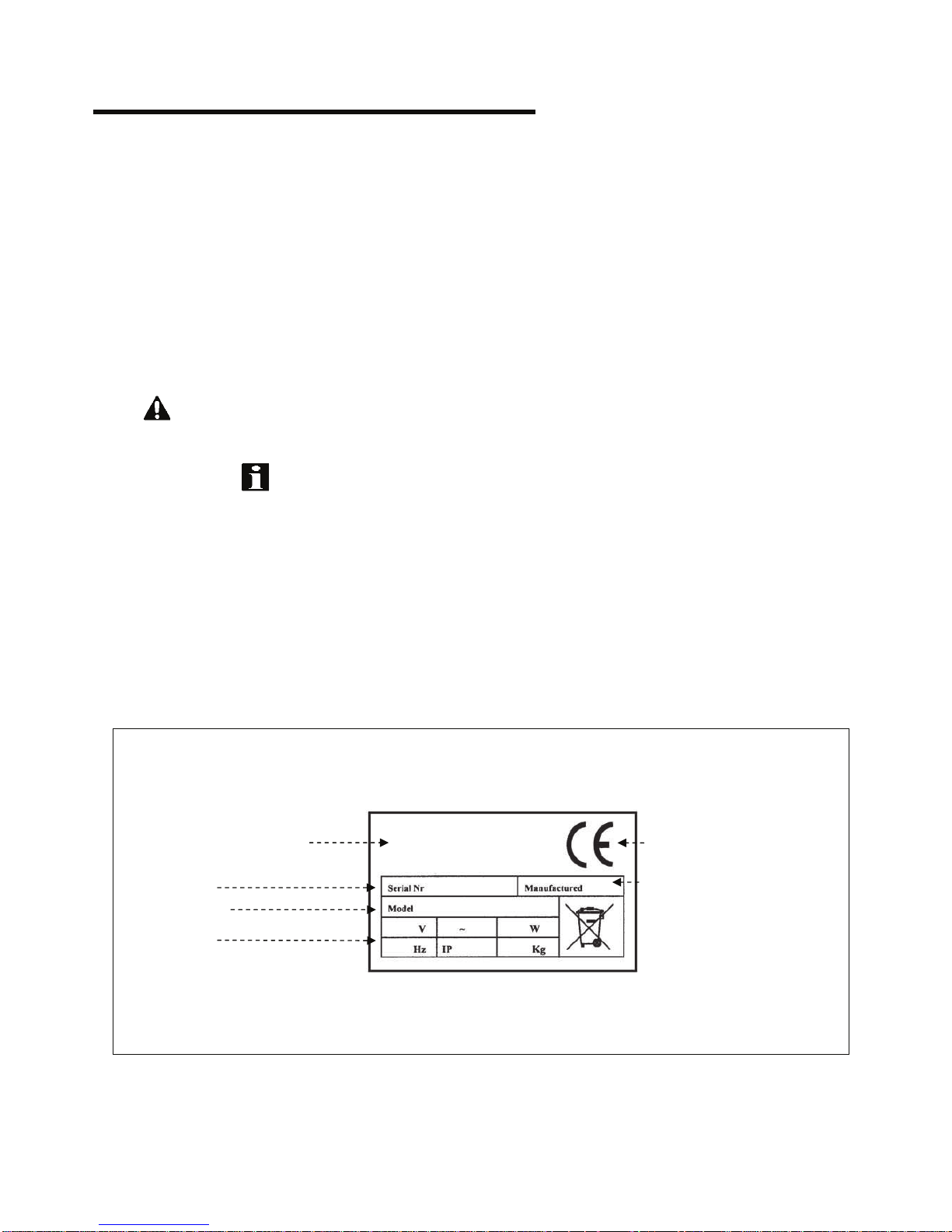

Manufacturer and machine Identification

Manufacturer Identification

Serial number

Machine model

Specifications

Mark of Compliance

Year of construction

Translation of the original instructions

Page 3

5

GENERAL

INFORMATION

1

Machine description

Combined mincer - grater:

The combined mincer-grater is a professional machine designed for processing meat and cheese for mass

catering purposes (restaurants, hotels, community centres, butcher’s shops, refectories, etc.). By using the

mincer with a series of different mincing plates, different kinds of minced meat can be obtained. The grater

can process products such as seasoned cheese, biscuits, dry bread, dried fruit, etc. The range includes 4

different models:

AB12/T (mod.12 basic version with round hopper)

AB12/L (mod.12 deluxe version with rectangular hopper and larger trays)

AB12/AT (mod.12 version with completely removable mincer set and round hopper)

AB22/AE (mod.22 version with completely removable mincer set and round hopper)

The machine has an easy-to-clean aluminium and stainless steel structure.

The machine’s safety devices conform to European Directives.

Mincer:

The mincer is a professional machine designed for processing meat for mass catering purposes (restaurants,

hotels, community centres, butchers, collective refectories). The application of different mincer plates makes

it possible to obtain various types of minced meat.

The range includes 5 models:

TR12/S (mod.12 basic version with round hopper)

TR12/TS (mod.12 version with completely removable mincer set and round hopper)

TR12/C (mod.12 version with completely removable mincer set and stainless steel housing)

TR22/TE (mod.22 version with completely removable mincer set and round hopper)

TR22/C (mod.22 version with completely removable mincer set and stainless steel housing)

The machine has an easy-to-clean aluminium and stainless steel structure.

The machine’s safety devices conform to European Directives.

Grater:

The grater is a professional machine designed for processing cheese for mass catering purposes

(restaurants, hotels, community centres, butchers, refectories, etc.). The grater can process products such

as: seasoned cheeses, biscuits, dry bread, dry fruit, etc.

The range is composed of 1 model:

GR12/S (mod.12 basic version with stainless steel roller)

The machine has an easy-to-clean aluminium and stainless steel structure.

The machine’s safety devices conform to European Directives.

MOD.AB12/T-L-12/AT-22/AE MOD.TR12/TS-12/S-12/C-

22/TE-22/C

MOD.GR12/S

Grater lever

Hopper

Handwheel

Control panel

Hopper

Handwheel

Control panel

Grater lever

Control panel

Translation of the original instructions

Page 4

6

GENERAL

INFORMATION

1

Specifications

Description Unit of measure AB12/T AB12/L AB12/AT AB22/AE

Electric power input V Hz Ph

230V 50Hz 1Ph

230/400V 50Hz 3Ph

Power kW (HP) 0.75 (1) 0.75 (1) 0.75 (1) 1.1 (1.5)

Mincer output kg 160 160 160 300

Grater output kg 40 40 40 40

Net weight kg 22 23 26 27

Packaged weight kg 26 27 30 31

Noise < 70 dB(A)

Installation On the table

Description Unit of measure TR12/S TR12/TS TR12/C TR22/TE TR22/C GR12/S

Electric power input V Hz Ph

230V 50Hz 1Ph

230/400V 50Hz 3Ph

Power kW (HP) 0.75 (1) 0.75 (1) 0.75 (1) 1.1 (1.5) 1.1 (1.5) 0.75 (1)

Mincer output kg 160 160 160 300 300 /

Grater output kg / / / / / 40

Net weight kg 20 20 22 24 26 17

Packaged weight kg 22 22 24 26 28 19

Noise < 70 dB(A)

Installation On the table

Overall dimensions

mm. A B C mm. A B C

AB12/T

AB12/L

AB12/AT

AB22/AE

TR12/S

TR12/TS

TR12/C

TR22/TE

TR22/C

GR12/S

290

290

290

290

290

290

290

290

290

290

740

740

740

740

460

460

460

460

460

460

460

460

460

460

460

460

460

460

460

460

AB12/T

AB12/L

AB12/AT

AB22/AE

670

750

580

630

300

320

350

350

460

400

470

480

mm. A B C mm. A B C

TR12/S

TR12/TS

TR12/C

TR22/TE

TR22/C

400

400

440

450

470

250

250

270

250

270

470

470

400

480

410

GR12/S

420 300 420

Translation of the original instructions

Page 5

7

GENERAL

INFORMATION

1

Safety devices

Microswitch: stops the machine

when the grater lever is lifted. When

the lever is lowered, restart the

machine by pressing the I button.

Remote control switch: can be used

to restart the machine when the

electricity supply is switched off

accidentally.

For Grater mod.GR12/S only, when

the machine stops, the electronic board

intervenes to block the roller using the

motor brake.

Safety information

It is of the greatest importance to carefully read this manual before carrying out installation and use

operations. Consistent compliance with the instructions contained in this manual will guarantee personal

and machine safety.

Do not tamper with the safety devices for any reason.

We recommend that industrial safety regulations issued nationally by the appointed organisms be strictly

respected.

The manufacturer declines all responsability for injures to persons or damages to property, resulting from

failure to comply with these safety rules.

Correct machine setting, lighting and workshop cleanness are pre-conditions for personal safety.

Do not expose the machine to atmospheric agents.

The machine connection and start-up should only be executed by skilled engineers.

Check that the plant mains ratings correspond to the specifications printed on the machine data plate.

Make sure that the machine is connected to a grounding system.

The work area around the machine should always be kept clean and dry.

Wear the work attire prescribed by the industrial accident-prevention regulations.

This machine should always be used for its recommended uses ; any other use is deemed improper and

therefore dangerous.

Check the suitability and weight of the products to work ; do not overload the machine to exceed its

capacity.

It is forbidden to introduce any objects, tools or hands in the dangerous parts.

Keep the machine out of children’ s reach.

Unplug the machine from the mains when not in use.

In the event of breakdowns and/or malfunctioning, do not carry out any repair yourselves, apply to your

Authorised dealer.

Order original spare parts only.

Before carrying out machine cleaning, unplug it from the power mains.

Do not clean with high-pressure water jets.

DANGER – CAUTION: Using plates with hole diameters over 8mm

and with total thickness under 5 mm is strictly prohibited.

Should wear cause plate thickness to drop under 5 mm, we recommend

you replace it. The manufacturer is not liable for any personal or property

damages due to failure to observe these instructions.

Translation of the original instructions

Page 6

8

INSTALLATION

2

Packing and unpacking

The machine will come packaged in a carton with foamed

polyester inserts to guarantee perfect safety during transport.

Handle the carton in compliance with the instructions.

Open the carton and make sure that all components are

intact. Keep the carton for any future machine removal.

Lift the machine according to the instructions and place it

in its selected setting for installation.

Installation area

The selected machine work setting must be sufficiently lit and have an electric power outlet. The worktop must be

sufficiently large, perfectly level and dry. The machine should be installed in non-explosive environments. In any

case, installation should be carried out by taking into account any applicable industrial safety regulations in force.

Environmental Condition Table

Descriptions Values

Working temperature 0÷35 °C (32÷95 °F)

Storage temperature -15 to +65 °C (from –6.8 to +149 °F)

Relative humidity

Maximum 80% at an ambient temperature of 20 °C

Maximum 50% at an ambient temperature of 20÷60 °C

Ambient dust Lower than 0.03 g/m³

Electric connection

DANGER – CAUTION: Electric connection to the power

mains should be executed by skilled engineers.

Single-phase Three-phase

connection connection

230V – 1Ph 230/400V – 3Ph

Check for the perfect effeciency of the plant grounding system. Make sure

that the line voltage (V) and frequency (Hz) correspond to the machine

ratings (refer to the machine identification plate and wiring diagram). The

machine comes equipped with an electric cable to which a multipolar plug

should be connected. Plug the machine into a main wall switch with

differential.

Three-phase connection

Start the machine for just a few seconds and check that the beater turns in

the right direction. If this is not the case, disconnect power and exchange

two of the three phase wires in the plug.

Translation of the original instructions

Page 7

9

OPERATION AND

CLEANING

3

Control descriptions

1) Start button “I”

Push the button to start up the machine. In the combined and grater

versions, start-up is only enabled when the grater lever is lowered.

2) Stop button “0”

Press the button to stop the machine.

3) Mincer filler knob (mod.AB12/T-L - TR12/S only)

Turn the knob to block (clockwise) or unblock (anti-clockwise) the mincer

filler. Do not start the machine until the mincer filler is blocked.

4) Mincer body blocking knobs (mod.AB12/AT – AB22/AE – TR12/TS

– TR12/C – TR22/TE – TR22/C only)

Screw down the knobs to block or screw off to unblock the mincer body.

5) Grater lever (mod.AB12/T-L-AT – AB22/AE – GR12/S only)

Press the lever down to grate the product to be processed.

6) Forward gear button (mod.AB22/AE – TR22/TE – TR22/C only)

Press the button to start the machine. In the combined versions, start-up is

only enabled when the grater lever is lowered.

7) Reverse gear button (mod.AB22/AE – TR22/TE – TR22/C only)

Press the button to invert the direction of machine rotation. In combined

versions, start-up is only enabled when the grater lever is lowered.

8) Stop button (mod.AB22/AE – TR22/TE – TR22/C only)

Press the button to stop the machine.

Using the grater

In combined mincer-grater models, remove the mincer set before using the grater.

Lift the grater lever and place the product to be processed inside the grater mouth.

Lower the grater lever and press the start button “I” (the machine will only start if the grater lever is

lowered).

Gradually press the lever until the product is finished.

At the end of processing lift the lever and introduce more product into the grater mouth; lower the lever

once more and press start button “I” (the machine will only start if the grater lever is lowered).

In order to stop the machine, press the stop button “0” or lift the grater lever.

At the end of the work cycle, grate a piece of hard bread or use the appropriate brush to clean the roller.

Translation of the original instructions

Page 8

10

OPERATION AND

CLEANING

3

Using the mincer

In combined grater-mincer versions, lower the grater lever.

Tighten the filler knob in the versions mod.AB12/T-L - TR12/S.

Tighten the mincer body-blocking knobs in versions mod.AB12/AT – AB22/AE – TR12/TS – TR12/C –

TR22/TE – TR22/C.

Tighten the handwheel on the output mouth of the mincer without blocking.

Start-up the machine by pressing start button “I” (in combined models start-up is only possible if the

grater lever is lowered).

Place the product inside the upper mincer mouth and press it down using the pestle supplied.

At the end of the work session press the stop button “0”.

At the end of the work cycle remove the mincer set and wash using suitable detergents in hot water or in

the dishwasher.

Dismantling the mincer set

Mod.AB12/T-L – TR12/S:

Remove the hopper from the upper mouth.

Rotate the handwheel anti-clockwise.

Extract:

- the mincing plate;

- the blade;

- and the volute, in sequence

Unscrew the filler knob by turning anti-clockwise

and extract the mincer filler.

Perform operations in reverse order to

reassemble the mincer group.

Mod.AB12/AT - AB22/AE – TR12/TS – TR12/C –

TR22/TE – TR22/C:

Remove the hopper from the upper mouth.

Turn the handwheel anti-clockwise.

Extract

- the mincing plate;

- the blade;

- and the volute in sequence

Unscrew the filler knobs and extract the mincer

filler .

Perform operations in reverse order to

reassemble mincer group.

INFORMATION: Prior to each work cycle ensure that the removable parts are properly fixed

to the machine.

Recommendations for use

The completely extractable mincing set on the versions AB12/AT-AB22/AE-TR12/TS-TR12/C-TR22/TETR22/C, permits the user to place it in refrigerators and other similar devices, even when it contains residual

product. This feature makes it possible to use the mincer at different times of the day without having to wash

and clean the various components after use, in conformity with hygiene laws currently in force.

Translation of the original instructions

Page 9

11

OPERATION AND

CLEANING

3

End-of-day cleaning

At the end of the working day remove the plug from the power socket.

Clean thoroughly using neutral products.

Wash the outer part of the machine using a damp sponge.

Do not use steel wool or abrasive pads.

Dismantle the mincer set and wash using suitable detergents in hot water or in the dishwasher.

Long periods of inactivity

If the machine is to be left idle for long periods of time, turn off the main wall switch, thoroughly clean the

machine and cover it with a sheet to protect it from dust.

Translation of the original instructions

Page 10

12

TROUBLESHOOTING

RECYCLING

4

Foreword

In the event of breakdowns or malfunctioning, turn off the main wall switch and contact your local Dealer’s

After-sales service. Do not disassemble any internal machine parts.

The Manufacturer declines all responsability for any tampering !

Troubles, causes and remedies

Trouble

Cause

Remedy

Main switch is off

Turn the main switch on to “I”

The machine will not start

No voltage input to power line

Apply to your local Dealer’s Aftersale service

Logic board protective fuse is blown

Apply to your local Dealer’s Aftersale service

Disposal and recycling

The markings illustrated here (barred garbage bin), on the utensil data plate, indicates that at the end of its

working life, the utensil must be disposed of and recycled according to European Directive. The Directive

provides for the separate collection of electric and electronic equipment by a collection system called RAEE.

Upon purchasing a new utensil, the user must not dispose of the utensil as urban waste but must return it, in

a one-to-one exchange, to the dealer or distributor. The dealer may dispose of the utensil following the

procedures set by the RAEE collection system. In the event the user disposes of the utensil without

purchasing a new one, in Italy contact the manufacturer who will provide suitable information on machine

disposal at the collection centre closest to the user. Users who do not reside in Italy must contact the Ministry

of the Environment in their countries who will provide information necessary for correct disposal. Failure to

observe the disposal procedure may cause harmful effects on the environment and people. Therefore, total

or partial illicit utensil disposal by users is punishable by local authorities.

Translation of the original instructions

Loading...

Loading...