Bartscher 9PEN1, 9PEN2, 9PEN1A, 9PEN2A, 296910 Instruction Manual

...

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

11

INSTRUCTION MANUAL

FOR INSTALLATION,

MAINTENANCE

AND USE

ELECTRIC KETTLES

INDIRECT

SERIE 900

9PEN1 / 9PEN1A

9PEN2 / 9PEN2A

296910

296911

01.08.01 – GB

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

12

INDEX

Part 1: General reminders and notes

1.1. General reminders 13

1.2. Technical data 13

1.3. Construction 14

1.3.1. Details only for pressure kettles 14

1.4. Laws, technical prescriptions and directives 14

1.5. Special requirements for the installation site 15

Part 2: Positioning, installation and maintenance

2.1. Positioning 15

2.2. Installation 15

2.2.1. Electrical connections and equipotential bonding 16

2.2.2. Connection to waterworks 16

2.3. Commissioning and testing 16

2.4. Maintenance of the appliance 17

2.4.1.

Possible failures and their elimination

17

Part 3: Use and cleaning

3.1. Warnings and hints for user 17

3.2. Instructions for use 18

3.2.1. Filling the jacket 18

3.2.2. Details regarding the operation of the pressure kettles 18

3.2.3. Switch on, start of cooking and switch off 19

3.3. Cleaning and care of the appliance 19

3.3.1. Daily cleaning 19

3.4. Special procedures in case of long inactivity 20

3.5. Special procedures in case of failures 20

3.6. How to proceed, if … 20

Part 4: Figures and details

4.1. Wiring diagram Mod. 100-150 lt. 3N/PE AC 400V 52

4.1.1. Wiring diagram Mod. 100-150 lt. 3/PE AC 230V 54

4.1.2. Wiring diagram Mod. 100-150 lt. 3/PE AC440V 55

4.1.3. Wiring diagram Mod. 100-150 lt. 3/PE AC480V 56

4.2. View of appliance 57

4.3. Controls 58

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

13

1.1. GENERAL REMINDERS

− Read the warnings contained in this manual carefully as they provide important information concerning

safety during the installation, use and maintenance of the appliance.

− Keep these instructions carefully!

− Only personnel trained for its specific use should use the equipment.

− Keep the appliance under control during use.

− The appliance should be used only for the purpose for which it has been specifically designed; other uses

are improper and hence dangerous.

− During operation surfaces can become hot and require special operation.

− Unplug the appliance in case of failures or improper operation.

− Apply exclusively to a service centre for repairs or maintenance.

− Any important information about the appliance required for technical service is contained in the technical

data plate (see figure “View of appliance”).

− If technical assistance is required, the trouble must be described in as much detail as possible, so that a

service technician will be able to understand the nature of the problem.

− Gloves should be worn to protect the hands during installation and maintenance operations.

Warning! : Follow the fire prevention regulations very carefully.

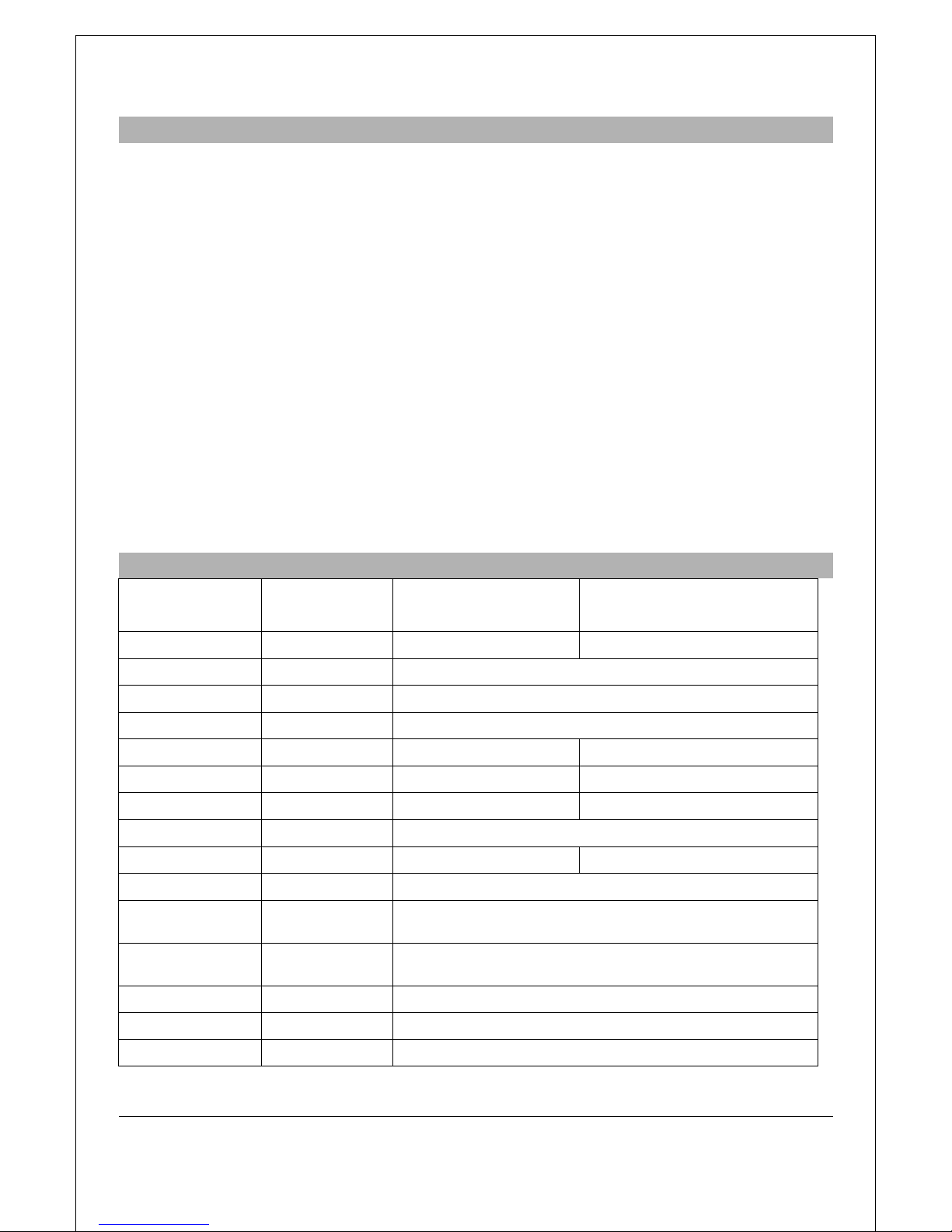

1.2. TECHNICAL DATA

Description Unit of

measurement

9PEN1

9PEN1A

9PEN2

9PEN2A

Width (A) mm

800 800

Depth (B) mm

900

Height (C) mm

900

Vat diameter mm

600

Vat height mm

415 540

Total volume l

110 145

Usable volume l

100 135

Voltage/Input

3 N AC 400V / 50 Hz

Power kW

16 18

Power cable mm²

Hot water

connection

mm

10

Cold water

connection

mm

10

Water pressure kPa

50 – 300

Jacket volume l

32

Jacket pressure bar

0,5

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

14

1.3. CONSTRUCTION

− Main structure in AISI 430 with 4 adjustable height feet.

− Panels in stainless steel AISI 304, thickness 10-12/10.

− Cooking vat in stainless steel AISI 316, thickness 20/10.

− Chrome-plated brass drainage tap.

− Lid in stainless steel, hinged and spring balanced in all opening positions.

− Jacket and lining in stainless steel AISI 304, thickness 15-20/10.

− Heating system comprising shielded heating elements made from “Incoloy-800” alloy with boiler and

steam circulation.

− Jacket pressure is controlled by a safety valve set at 0.5 bar; the appliance is equipped with an analogue

pressure gauge.

− The cold water connection is 10 mm.

− The hot water connection is 10 mm.

− Safety thermostat to interrupt operation automatically in case of failures.

− The appliance is equipped with a three-position selector with three heating functions:

− position “0” Heating not activated

− position “1” Reduced power 50%

− position “2” Full power 100%

− Operating thermostat for temperature adjustment inside the cooking vat.

1.3.1. DETAILS ONLY FOR PRESSURE KETTLES

− Stainless steel lid with heat-resistant silicone gasket.

− Hermetic closing of lid ensured by 4 screw clamps.

− The relief valve for the pressure that develops inside the cooking vat is set at 0,05 bar.

− On request, the appliance can be equipped with a pressure gauge indicating the pressure inside the

cooking vat.

1.4. LAWS, TECHNICAL PRESCRIPTIONS AND DIRECTIVES

− When installing the appliance it is necessary to follow and comply with the following regulations:

− current regulations on the matter;

− any hygienic-sanitary regulations concerning cooking environments;

− municipal and/or territorial building regulations and fire prevention prescriptions;

− current accident prevention guidelines;

− electricity board regulations concerning safety;

− the regulations of the electrical power supply company or agency;

− any other local prescriptions.

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

15

1.5. SPECIAL REQUIREMENTS FOR THE INSTALLATION SITE

− The room in which the appliance is to operate must be well ventilated.

− In addition, it is good policy to locate the appliance under an extractor hood so that cooking vapours can

be removed rapidly and continuously.

− Current regulations require the installation of a multiple pole switch between the appliance and the

electrical power supply; the switch must have a contact gap of least 3 mm on each pole.

− This appliance requires two water connections: one for hot and one for cold water. Each line must be

fitted with an on-off valve.

Warning! : The electrical isolating switch and the water shutoff valves must both be located near

to the appliance, within easy reach for the user.

2.1. POSTIONING

− Remove all the packaging and check that the appliance is in perfect conditions. In case of visible

damage, do not connect the appliance and notify the sales point immediately.

− Remove the PVC protection from the panels.

− Dispose of packaging according to regulations. Generally material is divided according to composition

and should be delivered to the waste disposal service.

− There are no special instructions regarding distances from other appliances or walls, however it is

advisable to maintain a sufficient distance to allow any servicing operations to be performed. In the event

the appliance should be installed in direct contact with inflammable walls, it is advisable to fit suitable heat

insulation.

− The appliance must stand level. Small differences in level can be eliminated by screwing or unscrewing

the adjustable feet: A significantly uneven or sloping stance can affect the operation of the appliance

adversely.

2.2. INSTALLATION

Warning! : Only qualified technicians must perform the installation, maintenance and test of the

appliance.

Warning! : Before connecting any parts of the appliance to supplies, make sure that the latter is

equivalent the requirements stated in the technical data plate, if the appliance has

been designed for these supplies.

Manuale d’istruzione per l’installazione, la manutenzione e l’uso

Pentole elettriche Indirette

01.08.01 - IT pagina

16

2.2.1. ELECTRICAL CONNECTIONS AND EQUIPOTENTIAL BONDING

Warning! : The appliance is supplied to operate according to the power supply indicated on the

data plate.

− As mentioned, the appliance must be connected to the power supply by way of a multiple pole main

isolating switch and protection device that must be proportioned to the power of the appliance (1 mA per

kW of rated power).

− The earthing system must be efficient.

− As this appliance is type X equipment (delivery without power cable and plug), the cable and other

hardware needed to make the connection to the electrical power supply must be provided by the installer.

− The power cable shall be of the kind described in the paragraph “Technical data" and shall be resistant to

oil.

− The power terminal board can be reached by removing the lower front panel (unloose the screws). The

cable fastener is on the lower right-hand side.

− The cable must be fed in from beneath the clamp. The individual wires are then fastened to the

corresponding terminals of the terminal board. The earth wire must be longer than the other wires, so that

in the event of the cable being jerked or the clamp broken, the live wires will disconnect first. Lock the

cord fastener.

− The appliance must incorporate an equipotential system.

− Connect the terminal on the lower right-hand side marked with the international symbol a connector with a nominal

cross section <10 mm2. All the appliances installed and the earth system of the building shall be connected like

this.

2.2.2. CONNECTION TO WATERWORKS

− Water inlet pressure must be between 50 and 300 kPa, otherwise install a pressure regulator on the line

before the appliance.

− Install a cut-off valve for each supply on the line before the appliance.

− Water connections to 10 mm are fitted in the lower part on the right-hand side of the appliance.

− Make connections according to regulations currently in force.

2.3. COMMISSIONING AND TESTING

− Once all the connections have been made, the appliance and the overall installation must be checked

following the directions given in this manual.

− Check in particular:

− that the protective film has been removed from the external surfaces;

− that the lower front panel removed for the electrical connection of the appliance has been fitted back

into position;

− that connections have been made in accordance with the requirements and directions indicated in

this manual;

− that all safety requirements in current standards, statutory regulations and directives have been met;

− that the water connections are leak-free;

− that the electrical connection has been performed according to standards.

− In addition, check that once the appliance has been installed, the power cord is neither subject to stretch

nor in contact with nor surfaces.

− Now proceed to light the appliance as directed in the instructions for use.

− While the appliance is in use, voltage should not differ from the nominal voltage more than +/- 10%.

− The test report must be completed in full and submitted to the customer who should then sign in

acceptance. With effect from this moment, the appliance is covered by the manufacturer’s warranty.

Loading...

Loading...