Page 1

INSTRUCTION MANUAL

FOR INSTALLATION,

MAINTENANCE

AND USE

ELECTRIC TILTING COOKER

“SERIE 900”

296676

296606

12.15.01 – EN

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

23

Page 2

INDEX

1.2.

Technical data

26

1.4.

Laws, technical prescriptions and directives

27

2.1.

Positioning

28

2.2.

Installation

28

2.2.1.

Electrical connections and equipotential bonding

28

2.2.2.

Connection to waterworks

29

2.3.

Commissioning and testing

29

2.4.

Maintenance of the appliance

29

3.1.

Warnings and hints for user

31

3.2.1.

Switch on, start of cooking and switch off

31

3.3.1.

Daily cleaning

32

3.5.

Special procedures in case of failures

32

4.1.1.

Size of appliance and position of connections Mod.

58

4.2.1.

Wiring diagram Mod. BRE92MF0/BRE92MD0 230V 3/PE AC

60

4.2.3.

Wiring diagram Mod. BRE93MF0/BRE93MD0 230V 3/PE AC

62

4.3.

Knob for water inlet

64

Part 1: General reminders and notes

1.1. General reminders 25

1.3. Construction 27

1.5. Special requirements for the installation site 27

Part 2: Positioning, installation and maintenance

2.4.1.

Possible failures and their elimination

30

Part 3: Use and cleaning

3.2. Instructions for use 31

3.3. Cleaning and care of the appliance 32

3.4. Special procedures in case of long inactivity 32

3.6. How to proceed, if … 33

Part 4: Figures and detail

4.1. Size of appliance and position of connections Mod. BRE92MF0/BRE92MD0 57

BRE93MF0/BRE93MD0

4.2. Wiring diagram Mod. BRE92MF0/BRE92MD0 400V 3/N/PE AC 59

4.2.2.

Wiring diagram Mod. BRE93MF0/BRE93MD0 400V 3/N/PE AC 61

4.2.4.

4.4. Control knob 65

Instruction manual for installation, maintenance and use

Wiring diagram Motor-version 63

Electric tilging cooker Serie 900

12.15.01 - EN

24

Page 3

1.1. GENERAL REMINDER

Read the warnings contained in this manual carefully as they provide important information concerning

The appliance should be used only for the purpose for which it has been specifically designed; other

e technical

In the event of technical assistance being required, the trouble must be described in as much detail as

−

safety during the installation, use and maintenance of the appliance.

− Keep these instructions carefully!

− Only personnel trained for its specific use should use the equipment.

− Keep the appliance under control during use.

−

uses are improper and hence dangerous.

− During operation surfaces can become hot and require special operation.

− Unplug the appliance in case of failures or improper operation.

− Apply exclusively to a service centre for repairs or maintenance.

−

All important information about the appliance required for technical service is contained in th

data plate (see figure 1).

−

possible, so that a service technician will be able to understand the nature of the problem.

− Gloves should be worn to protect the hands during installation and maintenance operations.

Warning! : Follow the fire prevention regulations very carefully.

WARNING! : NOT USED ABSOLUTLY AS FRYING MODE.

S

Instruction manual for installation, maintenance and use

Brasiere elettriche Serie 900 ILSA

12.15.01 - EN

25

Page 4

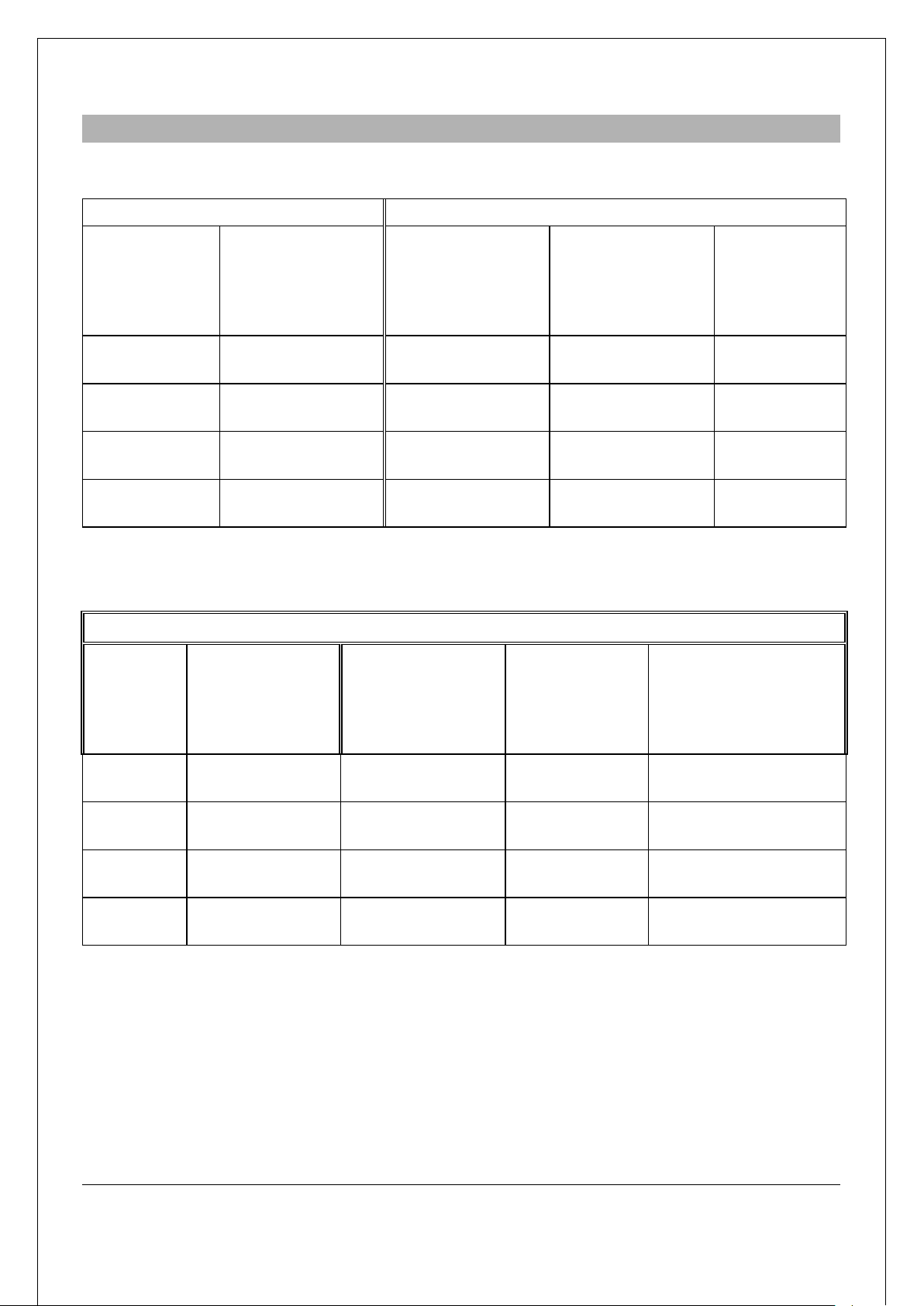

T

ABLA

1.2. TECNICAL DATA

1

Model

External dimensions

cm

Electrics

Electric cable

2

mm

Total power

kW

BRE92MF0 80 x 90 x 90 3/N/PE AC 400 V * 5 X 4 9,9

BRE92MD0 80 x 90 x 90 3/N/PE AC 400 V * 5 X 4 9,9

BRE93MF0 120 x 90 x 90 3/N/PE AC 400 V * 5 X 6 14,9

BRE93MD0 120 x 90 x 90 3/N/PE AC 400 V * 5 X 6 14,9

2

• * Convertible to 3/PE AC 230V with electric cable sez. 4 x 4 mm

.

TABLA

2

Cooking pans characteristics

Model

Dimensions

Pan capacity

(max. level)

Rotation angle

of the pan

Minimum widith

of the outlet

Cm

litres

cm

BRE92MF0 72 x 56 x 22,5 80 80° 12,5

BRE92MD0 72 x 56 x 22,5 80 80° 12,5

BRE93MF0 110 x 56 x 22,5 120 80° 18,5

BRE93MD0 110 x 56 x 22,5 120 80° 18,5

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

26

Page 5

1.3. CONSTRUCTION

In addition, it is good policy to locate the appliance under an extractor hood so that cooking vapours can

Current regulations require the installation of a multiple pole switch between the appliance and the

The electrical isolating switch and the water shutoff valves must both be located near

- Robust steel structure on 4 adjustable feet. Exterior and top finish entirely made of stainless steel 18/10.

-

Stainless steel pan with steel bpttpm in model BRE92MF0/BRE93MF0.

- Stainless steel vat lid, INOX (AISI 304) in model BRE92MD0/BRE93MD0.

-

Lid in stainless steel, hinged and spring balanced in all opening positions.

- Hand tilting of the pan.

- Heating of the pan by means of three heating elements (3400W 240V each), fitted to the bottom of the

pan.

- Temperature regulation is possible between 45° and 295°C by means of a thermostat fitted to the

switch.

- A safety thermostat cuts off power supply automatically in case of failure (eg. breaking of thermostat ).

- A green signal lamp lights when the appliance is on.

- An orange signal lamp lights when one of the heating elements is on.

- Filling of the pan by means of a tap placed on the front panel.

1.4. LAWS, TECHNICAL PRESCRIPTIONS AND DIRECTIVES

− When installing the appliance it is necessary to follow and comply with the following regulations:

−

current regulations on the matter;

− any hygienic-sanitary regulations concerning cooking environments;

−

municipal and/or territorial building regulations and fire prevention prescriptions;

−

current accident prevention guidelines;

− electricity board regulations concerning safety;

− the regulations of the electrical power supply company or agency;

− any other local prescriptions.

1.5. SPECIAL REQUIREMENTS FOR THE INSTALLATION SITE

− The room in which the appliance is to operate must be well ventilated.

−

be removed rapidly and continuously.

−

electrical power supply; the switch must have a contact gap of least 3 mm on each pole.

− This appliance requires one water connection. The line must be fitted with an on-off valve.

Warning! :

to the appliance, within easy reach for the user.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

27

Page 6

that the appliance is in perfect conditions. In case of visible

divided according to composition

There are no special instructions regarding distances from other appliances or walls, however it is

the appliance should be installed in direct contact with inflammable walls, it is advisable to fit a suitable

the adjustable feet: A significantly uneven or sloping stance can affect the operation of the appliance

Warning! : Only qualified technicians must perform the installation, maintenance and test of the

Before connecting any parts of the appliance to supplies, make sure that the latter is

equivalent the requirements stated in the technical data plate, if the appliance has

The appliance is supplied to operate according to the pow er supply indicated on the

As mentioned, the appliance must be connected to the power supply by way of a multiple pole main

rotection device, that must be proportioned to the power of the appliance (1 mA per

As this appliance is a type X equipment (delivery without power cable and plug), the cable and other

eeded to make the connection to the electrical power supply must be provided by the

and shall be resistant

amp. The individual wires are then fastened to the

corresponding terminals of the terminal board. The earth wire must be longer than the other wires, so

Lock

2.1. POSTIONING

− Remove all the packaging and check

damage, do not connect the appliance and notify the sales point immediately.

− Remove the PVC protection from the panels.

−

Dispose of packaging according to regulations. Generally material is

and should be delivered to the waste disposal service.

−

advisable to maintain a sufficient distance to allow any servicing operations to be performed. In the event

heat insulation.

− The appliance must stand level. Small differences in level can be eliminated by screwing or unscrewing

adversely.

2.2. INSTALLATION

appliance.

Warning! :

been designed for these supplies.

2.2.1. ELECTRICAL CONNECTIONS AND EQUIPOTENTIAL BONDING

Warning! :

data plate.

−

isolating switch and p

kW of rated power).

− The earthing system must be efficient.

−

hardware n

installer.

− The power cable shall be of the kind described in the paragraph “Technical data”

to oil.

− Proceed as follows to reach the power supply terminal board:

-

Disconnect the appliance using the switch placed before the appliance.

− Remove the fron panel, unloosing the two fixing screws.

− Remove the lid of the housing protecting the electrical components.

− The cable must be fed in from beneath the cl

that in the event of the cable being jerked or the clamp broken, the live wires will disconnect first.

the cord fastener.

− The appliance must incorporate an equipotential system.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

28

Page 7

Connect the terminal on the lower right-

hand side marked with the international symbol a connector with a

earth system of the building shall be

It’s strictly forbidden using the pending electric cable connected with terminal board,

Water inlet pressure must be between 50 and 300 kPa, otherwise install a pressure regulator on the line

the appliance and the overall installation must be checked

that connections have been made in accordance with the requirements and directions indicated in this

In addition, check that once the appliance has been installed, the power cord is neither subject to stretch

then sign in

All maintenance operations shall only be performed by a technically qualified service

only. Maintenance includes also to control the components and tear of pipes, feeding pipes, electrical

components during maintenance operations to avoid the need for other

−

nominal cross section <10 mm2. All the appliances installed and the

connected like this.

overhanging from the frame, to connect definitely the machine.

ATTENTION!

Cut the tension before to make the connection and/or maintenance .

2.2.2. CONNECTION TO WATERWORKS

before the appliance.

- Install a cut-off valve for each supply on the line before the appliance.

-

Make connections according to regulations currently in force.

-

Water connections to 12mm. are fitted in the lower part on the left-hand side of the appliance.

2.3. COMMISSIONING AND TESTING

- Once all the connections have been made,

following the directions given in this manual.

− Check in particular:

− that the protective film has been removed from the external surfaces;

that the terminal board housing, removed for electrical connections, has been reinstalled.

manual;

− that all safety requirements in current standards, statutory regulations and directives have been met;

− that the water connections are leak-free;

− that the electrical connection has been performed according to standards.

nor in contact with nor surfaces.

- Now proceed to light the appliance as directed in the instructions for use.

-

While the appliance is in use, voltage should not differ from the nominal voltage more than +/- 10%.

- The test report must be completed in full and submitted to the customer who should

acceptance. With effect from this moment, the appliance is covered by the manufacturer’s warranty.

Warning! :

centre!

- To ensure correct and safe operation, the appliance must be inspected and serviced at least once a year

components etc..

2.4. MAINTENANCE OF THE APPLIANCE

- It is advisable to replace worn

maintenance calls and unexpected failures.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

29

Page 8

It is also advisable to apply for a maintenance contract with the customer.

technically qualified service centres can perform the operations described

Before resetting the safety thermostat, it is always necessary to eliminate the problem

-

2.4.1. POSSIBLE FAILURES AND

Warning! : Only

below!

Warning! :

causing its activation!

Even a normal use of the appliance may cause operation inconveniences and failures.

The most common problems are the following:

P

AN DOES NOT REACH SET TEMPERATURE

Possible causes:

- Check connections to the switch.

- Check connection to the working thermostat.

- Check connection to electromagnetic switch.

- Heating elements are burned.

SIGNAL LAMPS DO NOT LIGHT UP

:

THEIR ELIMINATION

- Check the connection to the switch.

- Signal lamp is faulty.

THE BRATT PAN WORKS WITH DISCONNECTED THEMOSTAT

Electromagnetic switch contacts are cut off.

-

LOW EFFICIENTY OF THE PAN

Check t

-

he heating elements.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

30

Page 9

Tilting cookers are ideal for preparing cream and custards, delicate dishes and sauces as it ensures a

regulation (from 50 to 200 °C) and the operator can follow the cooking cycle without

Some improper operating conditions may even be caused by an improper use of the appliance,

Respect the periods required for maintenance. With this is mind, customers are recommended to sign a

The tilting of the pan is made by means of an handwheel placed on the RH side of the front panel. Turning

3.1. WARNINGS AND HIN

− This manual contains all the instructions required for a proper and safe use of our appliances.

Keep the manual in a safe place for future consultation!

- This appliance is for catering use, hence they must be used only by trained kitchen staff.

-

The appliance must always be kept under control during use.

specific temperature

difficulties.

Warning! : The manufacturer shall not be held responsible for injuries or damage due to the non-

compliance with safety rules or an improper use of the appliance by the operator.

therefore it is important to train personnel properly.

- All the installation and maintenance operations must be performed by fitters who are members of

an official register.

-

service agreement.

- In case of failures concerning the appliance, all outputs (electrical power supply and water) must be cut

off instantly.

- In case of recurrent failures contact a service technician.

TS FOR USER

3.2. INSTRUCTIONS FOR USE

- Before cooking with the appliance for the first time wash the interior of the cooking vat thoroughly.

Warning! : Fill the cooking vat up to a maximum of 40 mm under the overflow border, according

to the maximum level mark, including the food to be cooked.

3.2.1. SWITCH ON

− Activate the main switch, placed before the appliance.

− Starting from position “0” turn the thermostat knob to desired temperature between 45° and 295°C: the

signal lamps will light , the green one indicates that the appliance is on and the orange one indicates that

heating elements are on; when the desired temperature is reached this signal lamp will go out.

Emptying the cooking vat:

the handwheel anti-clockwise the pan goes up, turning it anti-clockwise the pan goes down.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

31

Page 10

o not use aggressive substances or abrasive detergents when cleaning the stainless steel

Avoid using metal pads of the steel parts as they may cause rust. For the same reason avoid contact

When cleaning the appliance never use direct jets of water to prevent infiltration of

External surfaces should be washed down using a sponge, and hot water with a suitable proprietary

dle for any length of time (e.g. holidays or seasonal closing) it must be

otected by applying a proprietary metal

ing use, turn it off immediately and close or cut off all

3.3. CLEANING AND CARE OF THE APP

- D

components.

with materials containing iron.

- Do not use sandpaper or abrasive paper for cleaning; in special cases use a powder pumice stone.

-

In case of particularly resistant dirt, it is advisable to use abrasive sponges (e.g. Scotch-Brite).

-

It is advisable to clean the appliance only once it has cooled down.

Warning! :

-

Clean the cooking vat with water and a detergent, rinse thoroughly and dry well with a soft cloth.

cleaner addend.

- Rinse always thoroughly and dry with a soft cloth.

3.3.1. DAILY CLEANING

the liquid and damage to components.

LIANCE

3.4. SPECIAL PROCEDURES IN CASE OF PROLONGED INACTIVITY

- If the appliance is to stand i

cleaned thoroughly, leaving not traces of food or dirt.

- Leave the lid open so that air can circulate inside the vat.

-

For added care after cleaning, the external surfaces can be pr

polish.

- Be absolutely certain to shut off all utilities (electrical power supply and water).

-

Air the room appropriately.

3.5. SPECIAL PROCEDURES IN CASE OF FAILURES

- If the appliance should not work properly dur

supplies (electrical power supply and water).

- Apply to a service centre for help.

The manufacturer shall not be held responsible nor has any warranty commitments

for damage caused by non-compliance with prescriptions or by installation not in

conformity with instructions.

The same applies in case of improper use or different application by the operator.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

32

Page 11

3.6. HOW TO PROCEED, IF

Maintenance operations and repairs must be performed only by specialists!

Disconnect the appliance. After having removed the control knob, remove the control panel, the handle of

water inlet tap and the handwheel for tilting of pan.

R

EPLACEMENT OF HEATING ELEMENTS

- Disconnect the electric cables to heating elements.

- Remove the front fixed panel and the steady pin of the tilting pan lever..

-

Rotate the pan in the max. opening.

-

Remove the insulation protection , unloosing the fixing screws to the pan.

- Remove the protection panel of heating elements.

- Remove the heating element support plate from damaged heating element.

-

Fit the new heating element operating in the opposite order.

REPLACEMENT OF SIGNAL LAMP

- Disconnect the power cables.

…

- Remove the signal lamp, unscrewing the fixed to the control pane .

-

Fit the new signal lamp in the reverse order of operation.

REPLACEMENT OF WORKING OR SAFETY THERMOSTAT

- Disconnect power cables, after having removed the front panel.

- Remove the insulation protection, unloosing the fixing screws to the pan.

-

Remove the protection panel of heating elements.

-

Remove the support plate of central heating element.

- Remove the central heating element and then the fixing bulb boss.

- Replacing the new thermostat be careful about tightening of the boss on the bulbs.

If the bulbs would be squeezed, this would cause the damage of thermostat.

EPLACEMENT OF THE SWITCH

R

- Disconnect the power cables, after having removed the front panel.

- Replace the switch uloosing the fixing screws to the support , after having taken off the coaxial working

thermostat.

- Fit the new switch in the reverse order of operation.

Instruction manual for installation, maintenance and use

Electric tilging cooker Serie 900

12.15.01 - EN

33

Page 12

Netzanschlußklemme - Conexion electrico

Empalme agua 12 mm

4.1. DIMENSIONI E POSIZIONE DEGLI ALLACCIAMENTI

DIMENSIONS DE L’APPAREIL ET POSITIONS DES ARRIVEES

SIZE OF APPLIANCE AND

ABMESSUNGEN DES GERÄ

DIMENSIONES DEL APARATO Y UBICACIÓN DE LAS CONEXIONES

LEGENDA – LEGENDE – LEGEND - LEYENDA:

E - Allacciamento elettrico – Raccordement

électrique – Electrical connection –

TS UND ANORDNUNG DER VERSORGUNGEN

MOD. BRE92MF0/BRE92MD0

POSITION OF CONNECTIONS

A - Attacco acqua 12 mm – Raccord eau 12 mm –

Water connection 12 mm – Wasseranschluß 12 mm -

57

12.15.01

Page 13

Netzanschlußklemme - Conexion electrico

Empalme agua 12 mm

4.1.1. DIMENSIONI E POSIZIONE DEGLI ALLACCIAMENTI

DIMENSIONS DE L’APPAREIL ET POSITIO

SIZE OF APPLIANCE AND

ABMESSUNGEN DES GERÄTS UND ANORDNUNG DER VERSORGUNGEN

DIMENSIONES DEL APARATO Y UBICACIÓN DE LAS CONEXIONES

MOD. BRE93MF0/BRE93MD0

LEGENDA – LEGENDE – LEGEND - LEYENDA:

E - Allacciamenti elettrico – Raccordement

électrique – Electrical connection –

NS DES ARRIVEES

POSITION OF CONNECTIONS

A - Attacco acqua 12 mm – Raccord eau 12 mm –

Water connection 12 mm – Wasseranschluß 12 mm -

12.15.01

58

Page 14

MA Morsettiera di arrivo linea – Bornier arrivée ligne –

llegada de línea

TL Termostato di lavoro – Thermostat de travail –

funcionamiento

SE Interruttore generale – Interrupteur général –

TS Termostato di sicurezza – Thermostat de sécurité –

seguridad

C1 Teleruttore – Télérupteur – Electromagnetic switch

– Fernschalter - Telerruptor

R1 Resistenza – Résistance – Heating element –

Heizelement - Resistencia

L1 Lampada spia verde – Témoin lumineux vert –

Green signal lamp – Grüne Signallampe - Luz testigo verde

M1 Microinterruttore – Microinterrupteur – Microswitch –

Mikroschalter - Microinterruptor

L2 Lampada spia arancione – Témoin lumineux

testigo anaranjada

F3 Fusibile – Fusible – Fuse – Schmelzsicherung F4 Fusibile – Fusible – Fuse – Schmelzsicherung -

Fusibile 25 A

3/N/PE AC 400 V

F4

mA

F3

N

L2 L1 L3

TS

R1

C1

3

1

5

SE

A1

4

2

6

A2

R1

P4

P2

1

P1

3

P3

2

4

M1

L1 L2

TL

SCHEMA ELETTRICO – SCHEMA ELECTRIQUE – WIRING DIAGRAM –

4.2.

ELEKTRISCHER SHALTPLAN - ESQU

MOD. BRE92MF0/BR

400V 3/N/PE AC

LEGENDA – LEGENDE – LEGEND - LEYENDA:

Junction block – Anschlußklemme - Tabl. de bornes de

General switch – Hauptschalter - Interruptor general

orange – Orange signal lamp – Orange Signallampe - Luz

EMA ELÉCTRICO

E92MD0

Thermostat – Betriebstemperaturregler - Termostato de

Safety thermostat – Temperaturbegrenzer - Termostato de

Fusibile 3,15 A

12.15.01

59

Page 15

MA Morsettiera di arrivo linea – Bornier arrivée

de

línea

TL Termostato di lavoro – Thermostat de travail –

SE Interruttore generale – Interrupteur général –

TS Termostato di sicurezza – Thermostat de

seguridad

C1 Teleruttore – Télérupteur – Electromagnetic

switch - Telerruptor

R1 Resistenza – Résistance – Heating element Resistencia

L1 Lampada spia verde – Témoin lumineux vert

– Green signal lamp - Luz testigo verde

M1 Microinterruttore – Microinterrupteur –

Microswitch - Microinterruptor

L2 Lampada spia arancione – Témoin lumineux

anaranjada

F3 Fusibile – Fusible – Fuse - Fusibile 3,15 A

F4 Fusibile – Fusible – Fuse - Fusibile 25 A

2

F4

L1

mA

F3

TS

1

230 V - 3/PE AC

L2 L3

C1

3 5

A1

P1

SE

1

4

6

A2

P4

3

P3

P2

2

L1

4

TL

M1

L2

R1

R1

4.2.1. SC

HEMA ELETTRICO – SCHEMA ELECTRIQUE – WIRING DIAGRAM - ESQUEMA ELÉCTRICO

MOD. BRE92MF0/BR

230V 3/PE AC

LEGENDA – LEGENDE – LEGEND - LEYENDA:

ligne – Junction block - Tabl. de bornes de llegada

General switch - Interruptor general

orange – Orange signal lamp - Luz testigo

E92MD0

Thermostat -Termostato de funcionamiento

sécurité – Safety thermostat - Termostato de

12.15.01

60

Page 16

4.2.2. SCH

MA Morsettiera di arrivo linea – Bornier arrivée

bornes de llegada de línea

TL Termostato di lavoro – Thermostat de travail –

de funcionamiento

SE Interruttore generale – Interrupteur général –

TS Termostato di sicurezza – Thermostat de

- Termostato de seguridad

C1 Teleruttore – Télérupteur – Electromagnetic

switch - Fernschalter - Telerruptor

R1 Resistenza – Résistance – Heating element –

Heizelement - Resistencia

L1 Lampada spia verde – Témoin lumineux vert

testigo verde

M1 Microinterruttore – Microinterrupteur –

L2 Lampada spia arancione – Témoin lumineux

- Luz testigo anaranjada

EMA ELETTRICO – SCHEMA ELECTRIQUE – WIRING DIAGRAM –

ELEKTRI

LEGENDA – LEGENDE – LEGEND - LEYENDA:

– Junction block – Anschlußklemme - Tabl. de

ligne

General switch – Hauptschalter - Interruptor general

– Green signal lamp – Grüne Signallampe - Luz

orange – Orange signal lamp – Orange Signallampe

SCHER SCHALPLAN - ESQUEMA ELÉCTRICO

MOD. BRE93MF0/BRE93MD0

400V 3/N/PE AC

Thermostat – Betr

sécurité – Safety thermostat – Temperaturbegrenzer

Microswitch – Mikroschalter - Microinterruptor

iebstemperaturregler - Termostato

12.15.01

61

Page 17

2.3. SCHEMA ELETTRICO – SCHEMA ELECTRIQUE –WIRING DIAGRAM –

MA M

orsettiera di arrivo linea

– Bornier arrivée

bornes de llegada de línea

TL Termostat

o di lavoro

– Thermostat de t

ravail

–

de funcionamiento

SE Interruttore generale – Interrupteur général –

TS Termostato di sicurezza – Thermostat de

Termostato de seguridad

C1 Teleruttore – Télérupteur – Electromagnetic

switch – Fernschalter - Telerruptor

R1 Resistenza – Résistance – Heating element –

Heizelement - Resistencia

L1 Lampada spia verde – Témoin lumineux vert

testigo verde

M1 Microinterruttore – Microinterrupteur –

L2 Lampada spia arancione – Témoin lumineux

-Luz testigo anaranjada

TL

SE

230 V - 3/PE AC

L1 L2 L3

P2

P1

P4

P3

C1

R1

C1

M1

2 1 4

3

TS

L2

R1

R1

L1

4.

ELEKTR

LEGENDA – LEGENDE – LEGEND - LEYENDA:

gne – Junction block –Anschlußklemme - Tabl. de

li

General switch – Hauptschalter - Interruptor general

– Green signal lamp – Grüne Signallampe - Luz

orange – Orange signal lamp – Orange Signallampe

ISCHER SHALTPLAN - ESQUEMA ELÉCTRICO

. BRE93MF0/BRE93MD0

MOD

230V 3

/PE AC

Thermostat –Bet

sécurité – Safety thermostat –Temperaturbegrenzer -

Microswitch – Mikroschalter - Microinterruptor

riebstemperaturregler - Termostato

mA

62

12.15.01

Page 18

. SCHEMA ELETTRICO VERSIONE MOTORIZZATA

MA M

orsettiera di arrivo linea

– Bornier arrivée l

igne

de llegada de línea

M2 Fi

necorsa salita

– Fi

n de course montée

–

Microinterruptor elevaciòn

F1 Fusibile generale neutro – Fusible général

Schmelzsicherung - Fusibile general neutro 3,15 A-T

RS Relè salita vasca – Relais montée cuve –

subida de la cuba 1P 30A

F2 Fusibile – Fusible – Fuse – Schmelzsicherung -

RD Relè discesa vasca – Relais descente cuve –

Pfanne - Relé bajada de la cuba 1P 30A

SE2 Selettore ribaltamento vasca – Sélecteur

Mm Motoriduttore monofase ribaltamento –

Kippung - Microinterruptor monofàsico inclinaciòn

M1 Finecorsa discesa – Fin de course descente –

Microinterruptor descenso

Co Condensatore – Condensateur – Capacitor –

TL Termostato di lavoro – Thermostat de travail –

funcionamiento

230V

N

L1

F1

S

D

NC

4.2.4

SCHEMA ELEC

LEGENDA – LEGENDE – LEGEND - LEYENDA:

Junction Block –Anschlußklemme - Tabl. de bornes

–

neutre – Fender-fuse for general-neutral –

Fusibile 16A

renversement cuve – Selector tilting of pan – Slektor Seletor vuelco cuba

Lowering limit switch – Mikroschalter Rückstellung -

Thermostat –Betriebstemperaturregler - Termostato de

TRIQUE VERSION MOTORISEE - WIRING DIAGRAM MOTOR-VERSION

LEKTRISCHER SCHALTPLAN MOTOR-VERSION

E

ESQUEMA EL

ÉCTRICO VERSION MOTORIZADO

ising limit switch – Mikroschalter Kippung -

R

Relay vat rising – Relais Kippung der Pfanne -Relé

Relay vat lowering – Relais Rückstellung der

Motoréducteur monophase renversement – Tilting

single-phase ratiomotor – Getriebemotor einphasig

Konsensator - Condensador

ONLY FOR ELECTRIC MOD

TL

SE2

NC

RD

mA

M1

Mn

M2

A1

RS

F2

F2

Co

12.15.01

63

Page 19

RUBINETTO DI CARICO DELL’ACQUA PER LA VASCA DI COTTURA

4.3.

MANETTE D’ALIMENTATIO

BEDIENNUNGSKNEBEL WASSERFÜLLUNG

BOTÓN PARA EL CARGO DE LA AGUA

N DE L’EAU – KNOB FOR WATER INLET

SENSO DI CARICO SENSO DI CHIUSURA

SENS DE CHARGEMENT SENS DE FERMETURE

WAY FOR WATER INLET STOP WATER INLET

DREHRICHTUNG FÜR WASSER FÜLLUNG SCHLIEß DREHRICHTUNG

ABIERTO CERRADO

12.15.01

64

Page 20

MANOPOLA DI COMANDO – POIGNEE DE COMMANDES -

A Manopola di comando – Poignée de commande

C Posizione di salita vasca – Position de

kippung des tiegels - Posición subida de la cuba

B Posizione di spento – Position de fermé – Off

apagado

D Posizione di discesa vasca – Position de

rückstellung des tiegels - Posición bajada de la cuba

A

B C

D

0

45

100

150

200

250

295

295

250

200

150

100

45

0

295

250

200

150

100

0

45

4.4.

CONTROL KNOB – BED

IENUNGSGRIFF - MANDOS

LEGENDA – LEGENDE – LEGEND - LEYENDA:

A. Manopola di comando – Poignée de commandes – Control knob – Bedienungsgriff - Botón de

mando

B. Posizione di spento – Position éteinte – Off position – Geschlossenstellung - Posición de

apagado

C. Posizione di minimo – Position minimum – Minimum position – Kleinstellung - Posición de

mínimo

D. Posizione di massimo – Position maximum – Mximum position – Großstellung - Posición de

máximo

RIBALTAMENTO VASCA MOTORIZZATO – RENVERSEMENT CUVE MOTORISEE – MOTOR TILTING

PAN – MOTOR KIPPVORRICHTUNG - VUELCO CUBA MOTORI ZADO

LEGENDA – LEGENDE – LEGEND - LEYENDA:

– Control knob - Bedieungsknebel - Botón de mando

position – Geschlossen-Stellung - Posición de

montée cuve – Position for vat tilting – Stellung für

descente cuve – Position for vat return – Stellung für

POSIZIONE “B” POSIZIONE “C” POSIZIONE “D”

12.15.01

65

Loading...

Loading...