Bartscher 280021 User Manual [ru]

COD.90900110

INSTRUCTION MANUAL

FOR INSTALLATION,

AINTENANCE

M

AND USE

ELECTRIC KETTLES

INDIRECT

“PM8-9IE..A”

“PM1IE..A”

“PMRIE..A”

“PM9IE..GN”

280015

280016

280021

280022

280023

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

2

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

TABLE OF CONTENTS

1 GENERAL REMINDERS AND NOTES ............................................................................................... 3

1.1 General reminders ............................................................................................................................... 3

1.2 Construction ......................................................................................................................................... 3

1.2.1 Details only for pressure kettles ........................................................................................................... 4

1.3 Laws, technical prescriptions and directives ........................................................................................ 4

1.4 Special requirements for the installation site ........................................................................................ 4

1.5 Technical data PM8-9IE....................................................................................................................... 5

1.6 Technical data PM1IE.. ........................................................................................................................ 6

1.7 Technical data PMRIE ......................................................................................................................... 7

1.8 Technical data PM9IE..GN .................................................................................................................. 8

2 POSITIONING, INSTALLATION AND MAINTENANCE ..................................................................... 9

2.1 posItioning ........................................................................................................................................... 9

2.2 Installation............................................................................................................................................ 9

2.2.1 Electrical connections and equipotential bonding ................................................................................ 9

2.2.2 Connection to waterworks.................................................................................................................. 10

2.3 Commissioning and testing ................................................................................................................ 10

2.4 Maintenance of the appliance ............................................................................................................ 10

2.4.1 Possible failures and their elimination ................................................................................................ 11

3 USE AND CLEANING ....................................................................................................................... 12

3.1 Warnings and hints for user ............................................................................................................... 12

3.2 Instructions for use ............................................................................................................................ 12

3.2.1 Filling the jacket ................................................................................................................................. 12

3.2.2 Details regarding operation with pressure kettle ................................................................................ 13

3.2.3 Switching on, start cooking and switching off ..................................................................................... 13

3.3 Cleaning and care of the appliance ................................................................................................... 14

3.3.1 Daily cleaning .................................................................................................................................... 14

3.4 Special procedures in case of prolonged inactivity ............................................................................ 14

3.5 Special procedures in case of failures ............................................................................................... 14

3.6 How to proceed, if … ......................................................................................................................... 15

4 FIGURES AND DETAILS .................................................................................................................. 16

4.1 WIRING DIAGRAM OF CONTROL FUNCTIONS PM.IE . ................................................................ 16

4.2 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3N/PE AC 400V ............................................. 17

4.3 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 230V ................................................ 18

4.4 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 440V ................................................ 19

4.5 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 480V ................................................ 20

4.6 LAYOUT CONNECTIONS PMIE ...................................................................................................... 21

4.7 LAYOUT CONNECTIONS PMRIE .................................................................................................... 22

4.8 LAYOUT CONNECTIONS PM9IEGN ............................................................................................... 23

4.9 FIG. CONTROLS ............................................................................................................................... 24

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

3

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

Read the warnings contained in this manual carefully as they provide important information concerning

safety during the installation, use and maintenance of the appliance.

Keep these instructions carefully!

Only personnel trained for its specific use should use the equipment.

Keep the appliance under control during use.

The appliance should be used only for the purpose for which it has been specifically designed; other uses

are improper and hence dangerous.

During operation surfaces can become hot and require special operation.

Unplug the appliance in case of failures or improper operation.

Apply exclusively to a service centre for repairs or maintenance.

Any important information about the appliance required for technical service is contained in the technical

data plate (see figure “View of appliance”).

If technical assistance is required, the trouble must be described in as much detail as possible, so that a

service technician will be able to understand the nature of the problem.

Gloves should be worn to protect the hands during installation and maintenance operations.

Warning! : Follow the fire prevention regulations very carefully.

Main structure in AISI 430 with 4 adjustable height feet.

Panels in stainless steel AISI 304, thickness 10-12/10.

Cooking vat in stainless steel AISI 316, thickness 20/10.

Chrome-plated brass drainage tap.

Lid in stainless steel, hinged and spring balanced in all opening positions.

Jacket and lining in stainless steel AISI 304, thickness 15-20/10.

Heating system comprising shielded heating elements made from “Incoloy-800” alloy with boiler and steam

circulation.

Jacket pressure is controlled by a safety valve set at 0.5 bar; the appliance is equipped with an analogue

pressure gauge.

The cold / hot water connection is 10 mm (mod. 100/150 lt.).

The cold / hot water connection is ½" (mod. 200/300/500/170/270/370 lt.).

Safety thermostat to interrupt operation automatically in case of failures.

The appliance is equipped with a three-position selector with three heating functions:

position “0” Heating not activated

position “1” Reduced power 50%

position “2” Full power 100%

Operating thermostat for temperature adjustment inside the cooking vat.

1 GENERAL REMINDERS AND NOTES

1.1 GENERAL REMINDERS

1.2 CONSTRUCTION

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

4

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

Stainless steel lid with heat-resistant silicone gasket.

Hermetic closing of lid ensured by 4-6 screw clamps.

The relief valve for the pressure that develops inside the cooking vat is set at 0,05 bar.

On request, the appliance can be equipped with a pressure gauge indicating the pressure inside the

cooking vat.

When installing the appliance it is necessary to follow and comply with the following regulations:

current regulations on the matter;

any hygienic-sanitary regulations concerning cooking environments;

municipal and/or territorial building regulations and fire prevention prescriptions;

current accident prevention guidelines;

electricity board regulations concerning safety;

the regulations of the electrical power supply company or agency;

any other local prescriptions.

The room in which the appliance is to operate must be well ventilated.

In addition, it is good policy to locate the appliance under an extractor hood so that cooking vapours can

be removed rapidly and continuously.

Current regulations require the installation of a multiple pole switch between the appliance and the

electrical power supply; the switch must have a contact gap of least 3 mm on each pole.

This appliance requires two water connections: one for hot and one for cold water. Each line must be fitted

with an on-off valve.

Warning! : The electrical isolating switch and the water shutoff valves must both be located near

to the appliance, within easy reach for the user.

1.2.1 DETAILS ONLY FOR PRESSURE KETTLES

1.3 LAWS, TECHNICAL PRESCRIPTIONS AND DIRECTIVES

1.4 SPECIAL REQUIREMENTS FOR THE INSTALLATION SITE

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

5

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

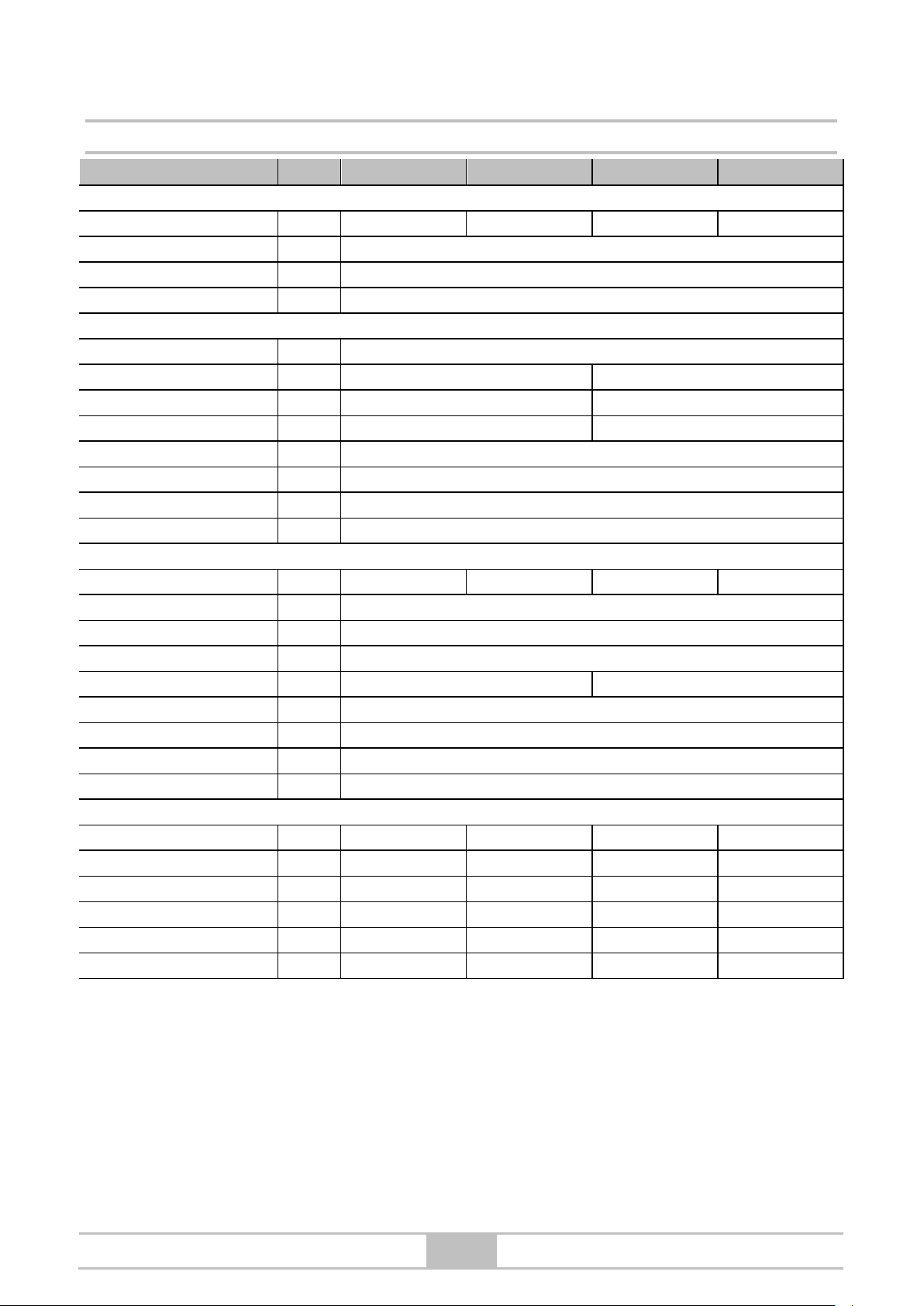

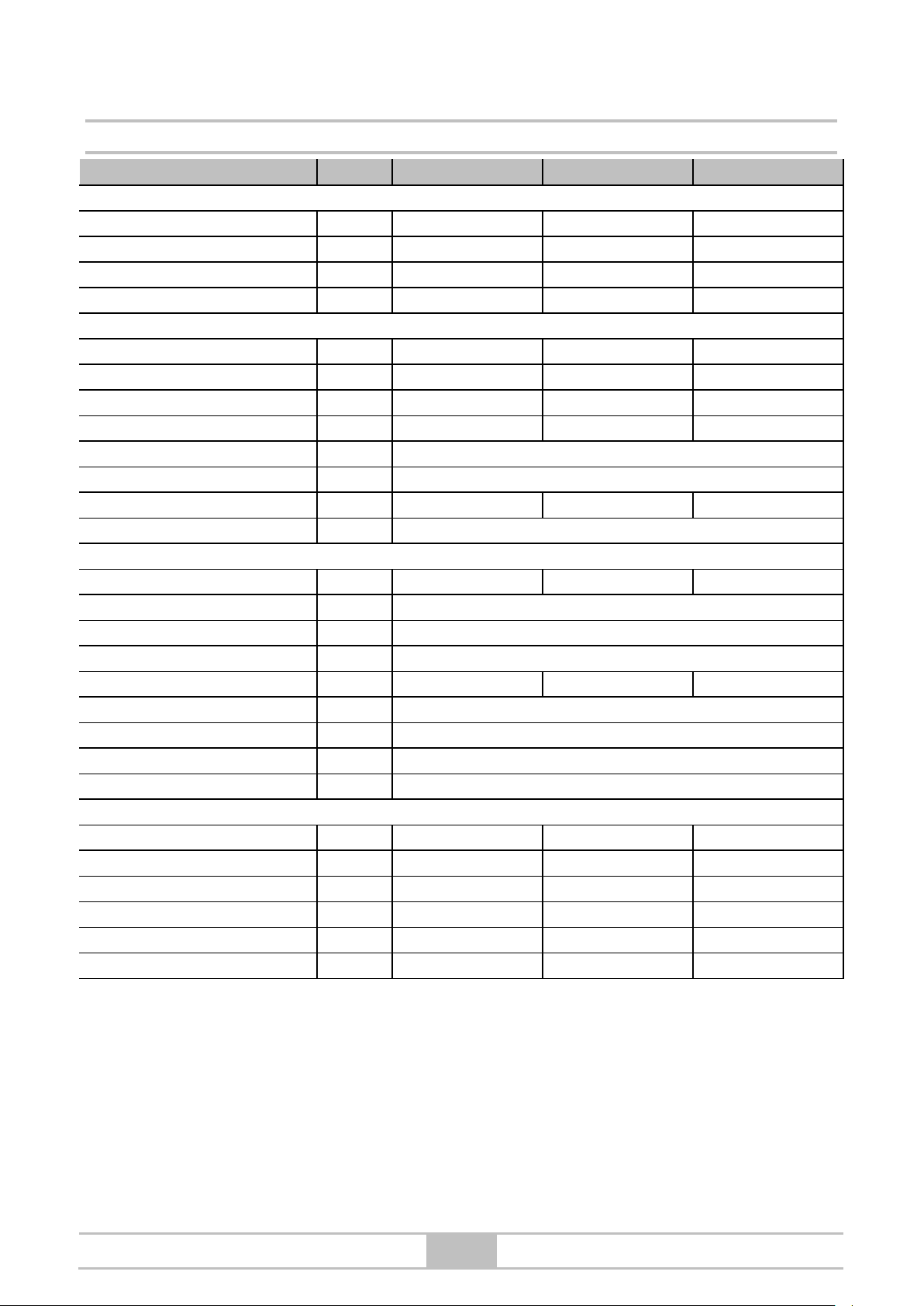

PM8IE100..A

PM9IE100..A

PM8IE150..A

PM9IE150..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A

mm

800

900

800

900

Equipment dim.B

mm

900

Equipment dim.H

mm

900

Equipment dim.H2

mm

1650

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter

mm

600

Pan dimension H

mm

415

540

Overvall volume

lt

113

150

Useful volume

lt

102

139

Pressure cooking (mod.A)

bar

0,05

Temperature

°C

20÷110

Jacket volume

lt

32

Pressure

bar

0,5

TECHNICAL DATA (INSTALLATION)

Electric power

kW

16

16

18

18

Voltage/Input (standard)**

V

3N/PE AC 400V

Frequency

Hz

50/60

IPX

IPX

4

Cable connection ***

mm²

5 X 6

5 X 6

Water pressure

kPa

50÷300

Hot water inlet

Ø"

Ø 10

Cold water inlet

Ø"

Ø 10

Sound level

dbA

< 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A

mm

1100

1100

1100

1100

Packaging dim.B

mm

870

970

870

970

Packaging dim.H

mm

1270

1270

1270

1270

Volume

m³

1,215

1,355

1,215

1,355

Net weight

kg

140

143

148

145

Gross weight

kg

165

173

173

175

**Verify on data plate - ***Cable for standard tension

1.5 TECHNICAL DATA PM8-9IE..

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

6

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

PM1IE200..A

PM1IE300..A

PM1IE500..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A

mm

1000

1150

1150

Equipment dim.B

mm

1150

1300

1300

Equipment dim.H

mm

900

900

1050

Equipment dim.H2

mm

1820

1970

2120

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter

mm

750

900

900

Pan dimension H

mm

520

520

780

Overvall volume

lt

220

325

480

Useful volume

lt

200

300

455

Pressure cooking (mod.A)

bar

0,05

Temperature

°C

20÷110

Jacket volume

lt

43

62

62

Pressure

bar

0,5

TECHNICAL DATA (INSTALLATION)

Electric power

kW

32

36

36

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency

Hz

50/60

IPX

IPX

4

Cable connection ***

mm²

5 X 10

5 X 16

5 X 16

Water pressure

kPa

50÷300

Hot water inlet

Ø"

1/2"

Cold water inlet

Ø"

1/2"

Sound level

dbA

< 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A

mm

1360

1500

1500

Packaging dim.B

mm

1100

1250

1250

Packaging dim.H

mm

1280

1280

1450

Volume

m³

1,92

2,4

2,72

Net weight

kg

235

280

300

Gross weight

kg

281

330

360

**Verify on data plate - ***Cable for standard tension

1.6 TECHNICAL DATA PM1IE..

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

7

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

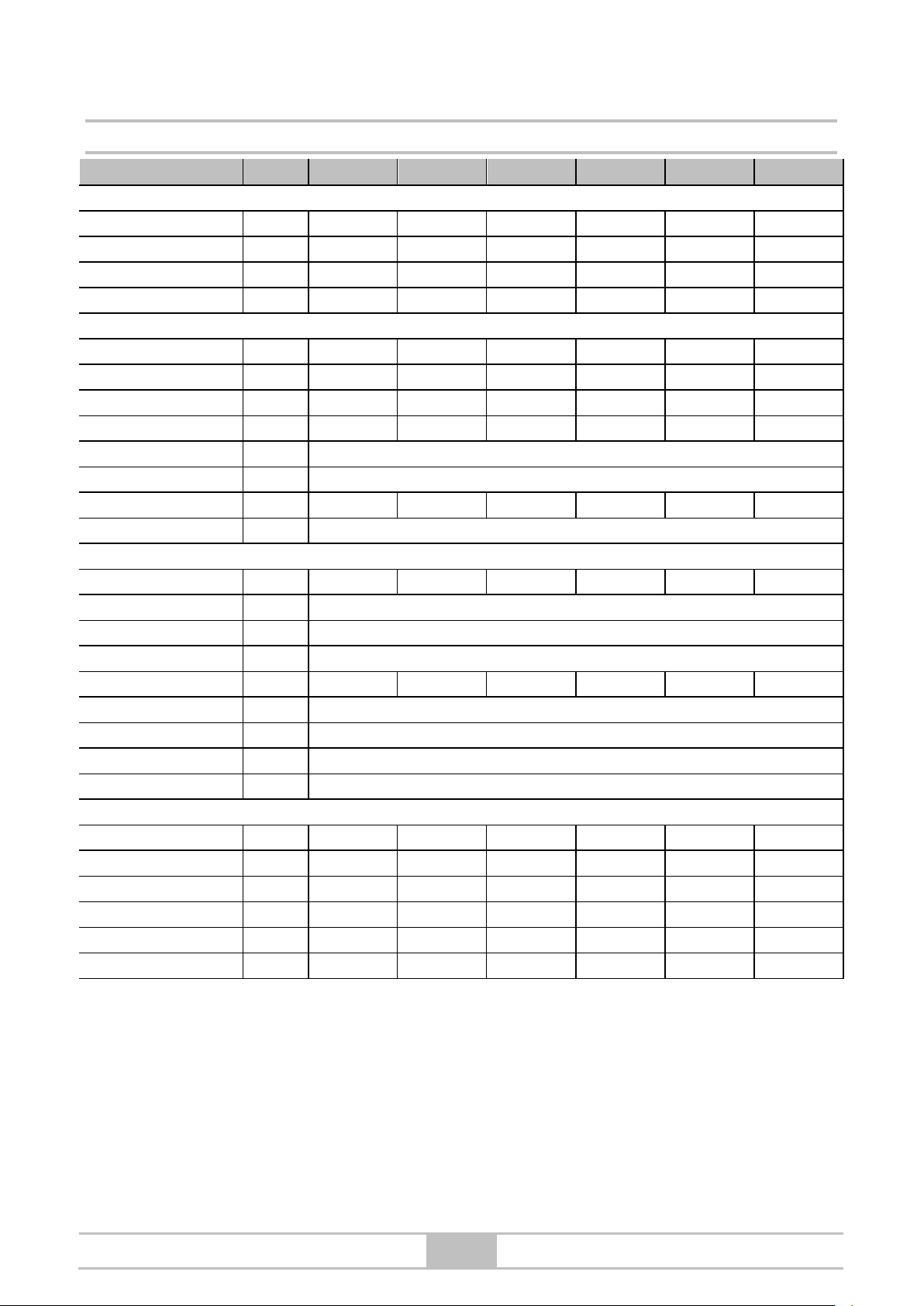

PMRIE

100..A

150..A

200..A

300..A

500..A

510..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A

mm

1025

1025

1175

1305

1305

1555

Equipment dim.B

mm

850

850

1000

1130

1130

1380

Equipment dim.H

mm

900

900

900

900

1050

920

Equipment dim.H2

mm

1650

1650

1820

1970

2120

2230

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter

mm

600

600

750

900

900

1100

Pan dimension H

mm

415

540

520

520

780

570

Overvall volume

lt

113

150

220

325

480

540

Useful volume

lt

102

139

200

300

455

500

Pressure cooking (mod.A)

bar

0,05

Temperature

°C

20÷110

Jacket volume

lt

32

32

43

62

62

95

Pressure

bar

0,5

TECHNICAL DATA (INSTALLATION)

Electric power

kW

16

18

32

36

36

36

Voltage/Input (standard)**

V

3N/PE AC 400V

Frequency

Hz

50/60

IPX

IPX

4

Cable connection ***

mm²

5 X 6

5 X 6

5 X 10

5 X 16

5 X 16

5 X 16

Water pressure

kPa

50÷300

Hot water inlet

Ø"

1/2"

Cold water inlet

Ø"

1/2"

Sound level

dbA

< 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A

mm

1360

1360

1500

1500

1500

1690

Packaging dim.B

mm

1100

1100

1250

1400

1400

1540

Packaging dim.H

mm

1280

1280

1280

1280

1450

1320

Volume

m³

1,92

1,92

2,4

2,7

3,05

3,44

Net weight

kg

140

150

207

250

270

355

Gross weight

kg

186

196

257

310

340

450

**Verify on data plate - ***Cable for standard tension

1.7 TECHNICAL DATA PMRIE

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE

Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

8

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

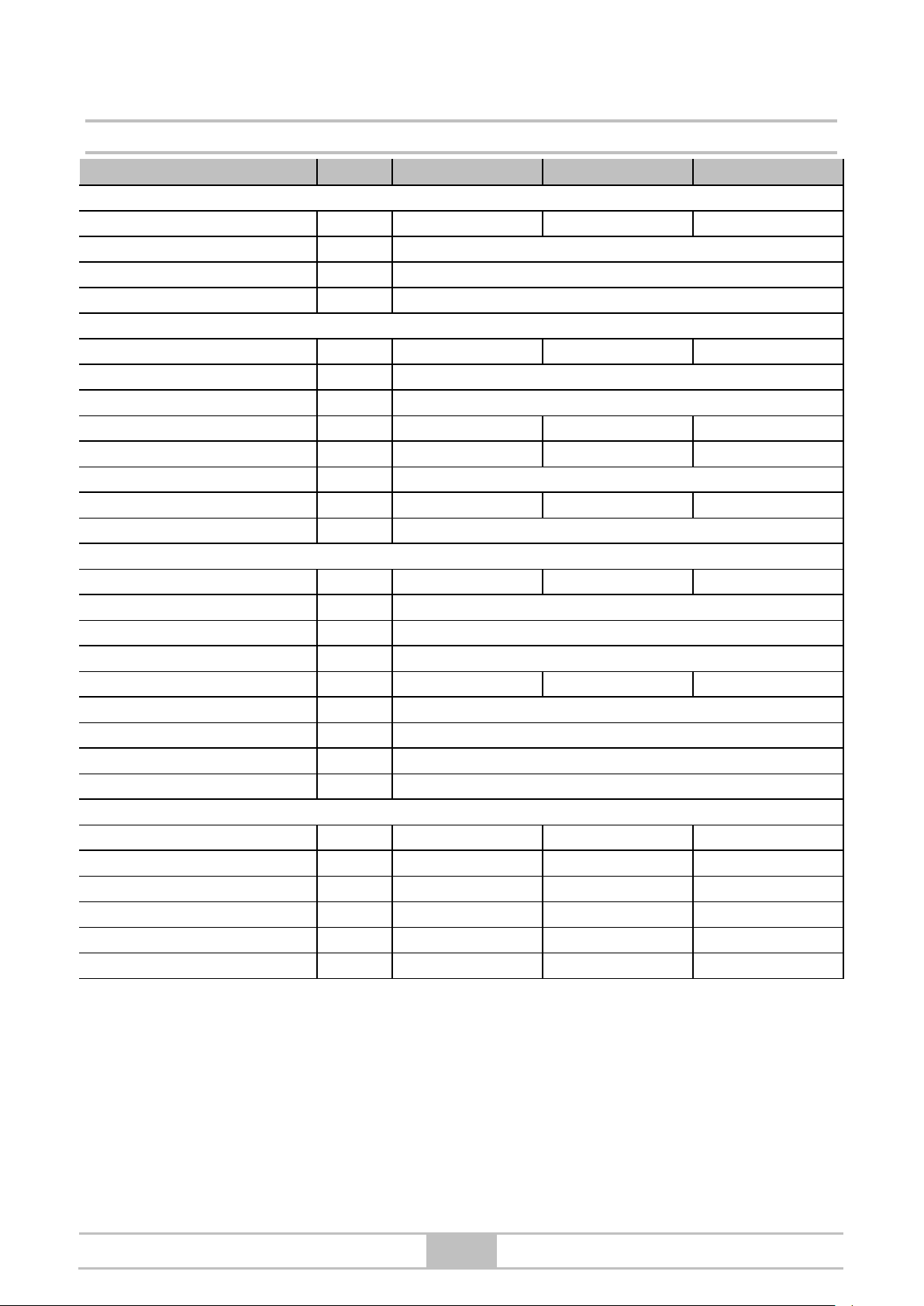

PM9IE170GN

PM9IE270GN

PM9IE370GN

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A

mm

1000

1400

1800

Equipment dim.B

mm

900

Equipment dim.H

mm

900

Equipment dim.H2

mm

1790

TECHNICAL DATA (FUNCTIONALITY)

Pan dimension A

mm

700

1100

1500

Pan dimension B

mm

550

Pan dimension H

mm

480

Overvall volume

lt

185

290

396

Useful volume

lt

170

270

370

Temperature

°C

20÷110

Jacket volume

lt

44

68

90

Pressure

bar

0,5

TECHNICAL DATA (INSTALLATION)

Electric power

kW

24

32

36

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency

Hz

50/60

IPX

IPX

4

Cable connection ***

mm²

5 X 10

5 X 16

5 X 16

Water pressure

kPa

50÷300

Hot water inlet

Ø"

1/2"

Cold water inlet

Ø"

1/2"

Sound level

dbA

< 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A

mm

1140

1540

2140

Packaging dim.B

mm

1140

1140

1140

Packaging dim.H

mm

1250

1250

1250

Volume

m³

1,63

2,2

3,1

Net weight

kg

240

290

330

Gross weight

kg

280

340

390

**Verify on data plate - ***Cable for standard tension

1.8 TECHNICAL DATA PM9IE..GN

Loading...

Loading...