Page 1

COD.90900110

INSTRUCTION MANUAL

FOR INSTALLATION,

MAINTENANCE

AND USE

ELECTRIC KETTLES

INDIRECT

“PM8-9IE..A”

“PM1IE..A”

“PMRIE..A”

“PM9IE..GN”

280.019

280.020

280.021

280.022

280.023

Page 2

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

2

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

TABLE OF CONTENTS

1 GENERAL REMINDERS AND NOTES...............................................................................................3

1.1 General reminders...............................................................................................................................3

1.2 Construction.........................................................................................................................................3

1.2.1 Details only for pressure kettles...........................................................................................................4

1.3 Laws, technical prescriptions and directives........................................................................................4

1.4 Special requirements for the installation site........................................................................................4

1.5 Technical data PM8-9IE.......................................................................................................................5

1.6 Technical data PM1IE..........................................................................................................................6

1.7 Technical data PMRIE .........................................................................................................................7

1.8 Technical data PM9IE..GN ..................................................................................................................8

2 POSITIONING, INSTALLATION AND MAINTENANCE.....................................................................9

2.1 posItioning ...........................................................................................................................................9

2.2 Installation............................................................................................................................................9

2.2.1 Electrical connections and equipotential bonding ................................................................................9

2.2.2 Connection to waterworks..................................................................................................................10

2.3 Commissioning and testing................................................................................................................10

2.4 Maintenance of the appliance............................................................................................................10

2.4.1 Possible failures and their elimination................................................................................................11

3 USE AND CLEANING.......................................................................................................................12

3.1 Warnings and hints for user...............................................................................................................12

3.2 Instructions for use ............................................................................................................................12

3.2.1 Filling the jacket.................................................................................................................................12

3.2.2 Details regarding operation with pressure kettle ................................................................................13

3.2.3 Switching on, start cooking and switching off.....................................................................................13

3.3 Cleaning and care of the appliance ...................................................................................................14

3.3.1 Daily cleaning ....................................................................................................................................14

3.4 Special procedures in case of prolonged inactivity ............................................................................14

3.5 Special procedures in case of failures ...............................................................................................14

3.6 How to proceed, if … .........................................................................................................................15

4 FIGURES AND DETAILS..................................................................................................................16

4.1 WIRING DIAGRAM OF CONTROL FUNCTIONS PM.IE .................................................................16

4.2 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3N/PE AC 400V.............................................17

4.3 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 230V................................................18

4.4 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 440V................................................19

4.5 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC 480V................................................20

4.6 LAYOUT CONNECTIONS PMIE ......................................................................................................21

4.7 LAYOUT CONNECTIONS PMRIE....................................................................................................22

4.8 LAYOUT CONNECTIONS PM9IEGN...............................................................................................23

4.9 FIG. CONTROLS...............................................................................................................................24

Page 3

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

3

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

1 GENERAL REMINDERS AND NOTES

1.1 GENERAL REMINDERS

−

− Read the warnings contained in this manual carefully as they provide important information concerning

safety during the installation, use and maintenance of the appliance.

− Keep these instructions carefully!

− Only personnel trained for its specific use should use the equipment.

− Keep the appliance under control during use.

− The appliance should be used only for the purpose for which it has been specifically designed; other uses

are improper and hence dangerous.

− During operation surfaces can become hot and require special operation.

− Unplug the appliance in case of failures or improper operation.

− Apply exclusively to a service centre for repairs or maintenance.

− Any important information about the appliance required for technical service is contained in the technical

data plate (see figure “View of appliance”).

− If technical assistance is required, the trouble must be described in as much detail as possible, so that a

service technician will be able to understand the nature of the problem.

− Gloves should be worn to protect the hands during installation and maintenance operations.

− Warning! : Follow the fire prevention regulations very carefully.

1.2 CONSTRUCTION

− Main structure in AISI 430 with 4 adjustable height feet.

− Panels in stainless steel AISI 304, thickness 10-12/10.

− Cooking vat in stainless steel AISI 316, thickness 20/10.

− Chrome-plated brass drainage tap.

− Lid in stainless steel, hinged and spring balanced in all opening positions.

− Jacket and lining in stainless steel AISI 304, thickness 15-20/10.

− Heating system comprising shielded heating elements made from “Incoloy-800” alloy with boiler and steam

circulation.

− Jacket pressure is controlled by a safety valve set at 0.5 bar; the appliance is equipped with an analogue

pressure gauge.

− The cold / hot water connection is 10 mm (mod. 100/150 lt.).

− The cold / hot water connection is ½" (mod. 200/300/500/170/270/370 lt.).

− Safety thermostat to interrupt operation automatically in case of failures.

− The appliance is equipped with a three-position selector with three heating functions:

− position “0” Heating not activated

− position “1” Reduced power 50%

− position “2” Full power 100%

− Operating thermostat for temperature adjustment inside the cooking vat.

Page 4

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

4

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

1.2.1 DETAILS ONLY FOR PRESSURE KETTLES

− Stainless steel lid with heat-resistant silicone gasket.

− Hermetic closing of lid ensured by 4-6 screw clamps.

− The relief valve for the pressure that develops inside the cooking vat is set at 0,05 bar.

− On request, the appliance can be equipped with a pressure gauge indicating the pressure inside the

cooking vat.

1.3 LAWS, TECHNICAL PRESCRIPTIONS AND DIRECTIVES

When installing the appliance it is necessary to follow and comply with the following regulations:

− current regulations on the matter;

− any hygienic-sanitary regulations concerning cooking environments;

− municipal and/or territorial building regulations and fire prevention prescriptions;

− current accident prevention guidelines;

− electricity board regulations concerning safety;

− the regulations of the electrical power supply company or agency;

− any other local prescriptions.

1.4 SPECIAL REQUIREMENTS FOR THE INSTALLATION SITE

− The room in which the appliance is to operate must be well ventilated.

− In addition, it is good policy to locate the appliance under an extractor hood so that cooking vapours can

be removed rapidly and continuously.

− Current regulations require the installation of a multiple pole switch between the appliance and the

electrical power supply; the switch must have a contact gap of least 3 mm on each pole.

− This appliance requires two water connections: one for hot and one for cold water. Each line must be fitted

with an on-off valve.

Warning! : The electrical isolating switch and the water shutoff valves must both be located near

to the appliance, within easy reach for the user.

Page 5

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

5

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

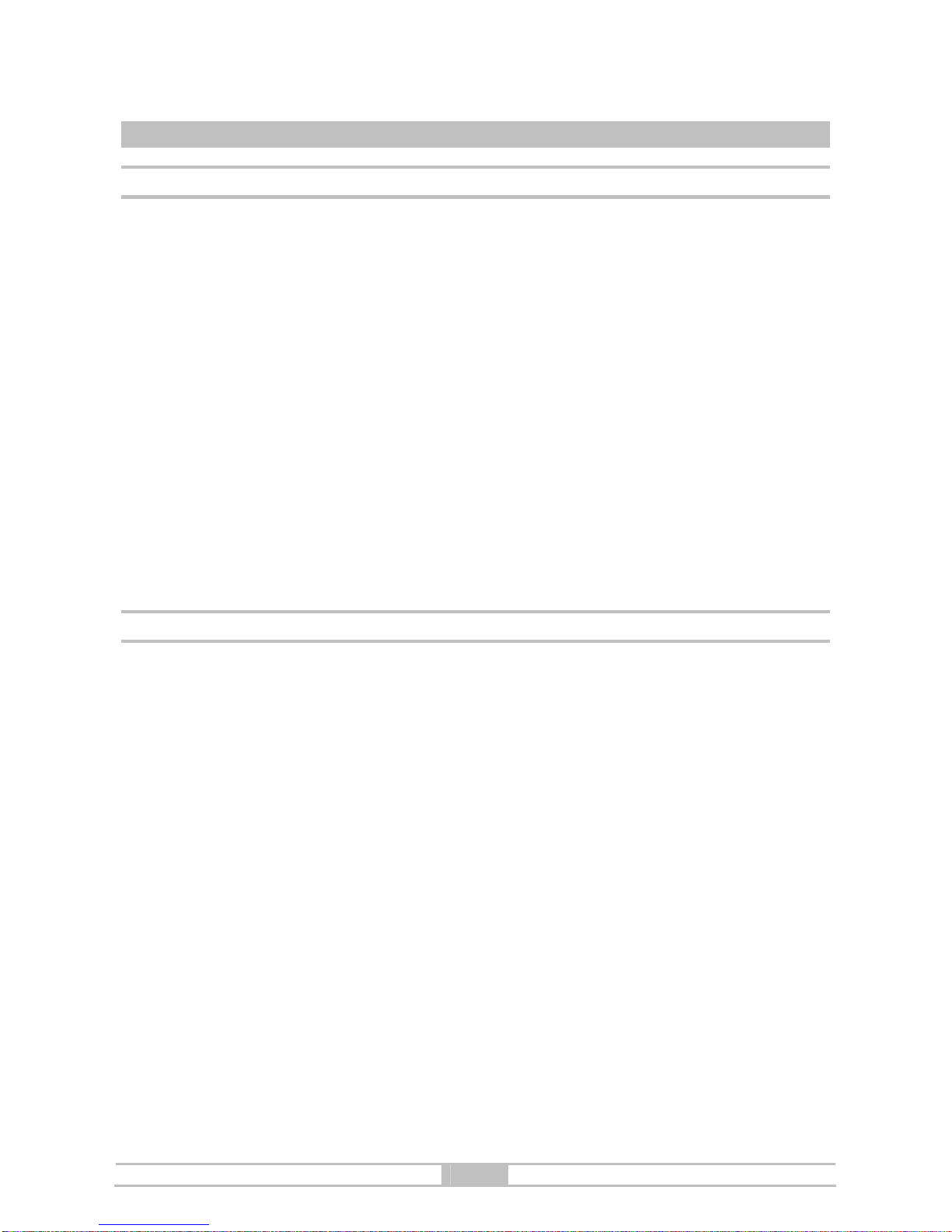

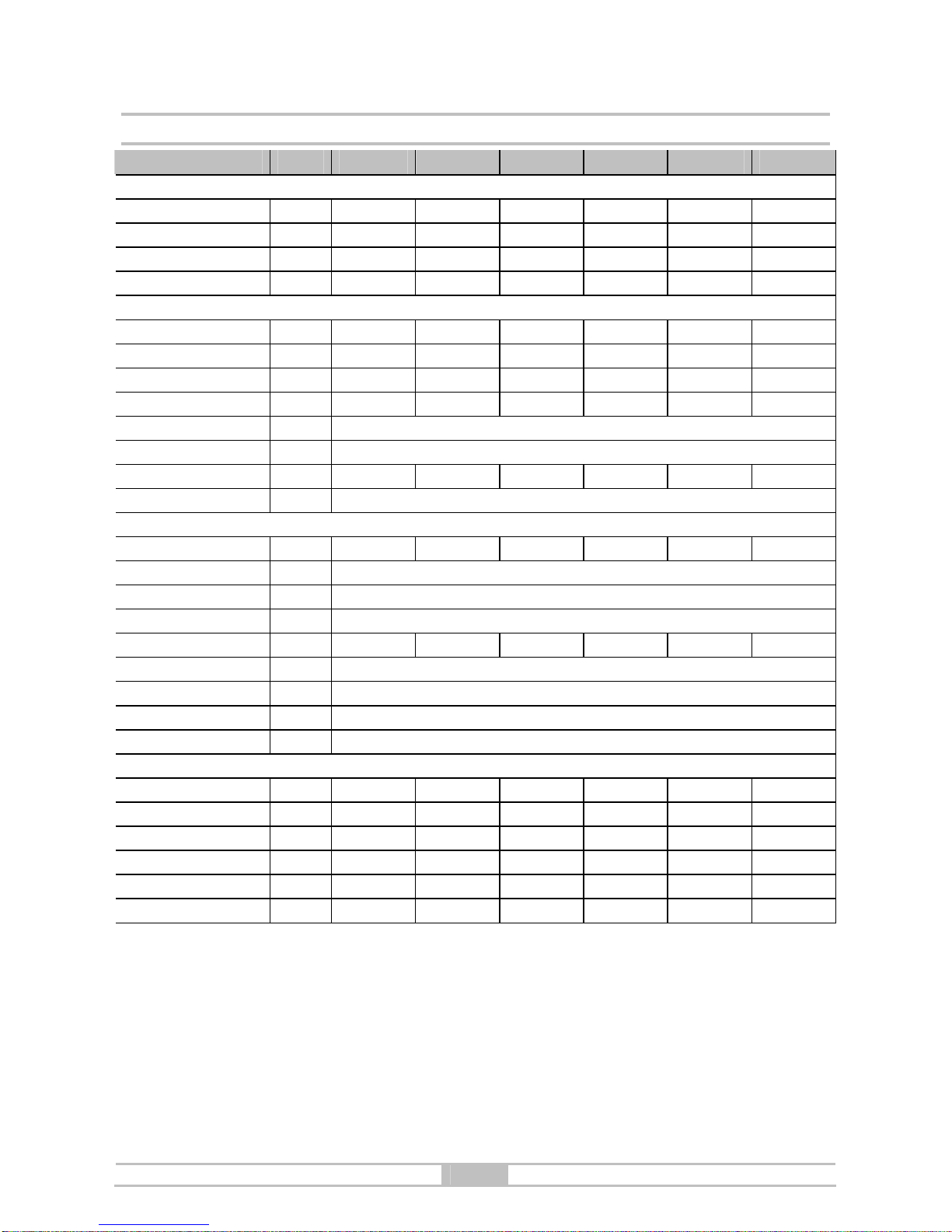

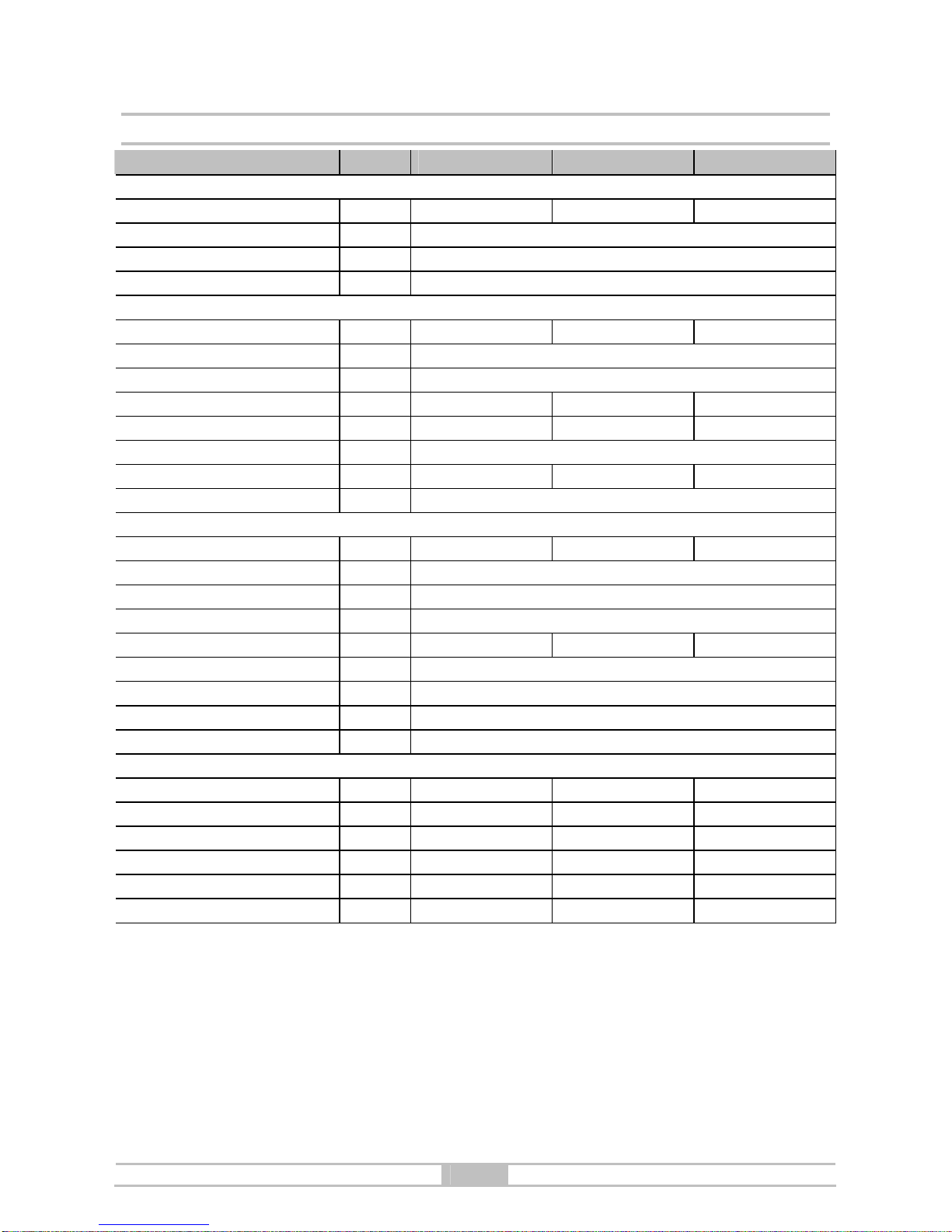

1.5 TECHNICAL DATA PM8-9IE..

PM8IE100..A PM9IE100..A PM8IE150..A PM9IE150..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A mm 800 900 800 900

Equipment dim.B mm 900

Equipment dim.H mm 900

Equipment dim.H2 mm 1650

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter mm 600

Pan dimension H mm 415 540

Overvall volume lt 113 150

Useful volume lt 102 139

Pressure cooking (mod.A) bar 0,05

Temperature °C 20÷110

Jacket volume lt 32

Pressure bar 0,5

TECHNICAL DATA (INSTALLATION)

Electric power kW 16

16

18

18

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency Hz 50/60

IPX IPX 4

Cable connection *** mm² 5 X 6 5 X 6

Water pressure kPa 50÷300

Hot water inlet Ø" Ø 10

Cold water inlet Ø" Ø 10

Sound level dbA < 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A mm 1100 1100 1100 1100

Packaging dim.B mm 870 970 870 970

Packaging dim.H mm 1270 1270 1270 1270

Volume m³ 1,215 1,355 1,215 1,355

Net weight kg 140 143 148 145

Gross weight kg 165 173 173 175

**Verify on data plate - ***Cable for standard tension

Page 6

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

6

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

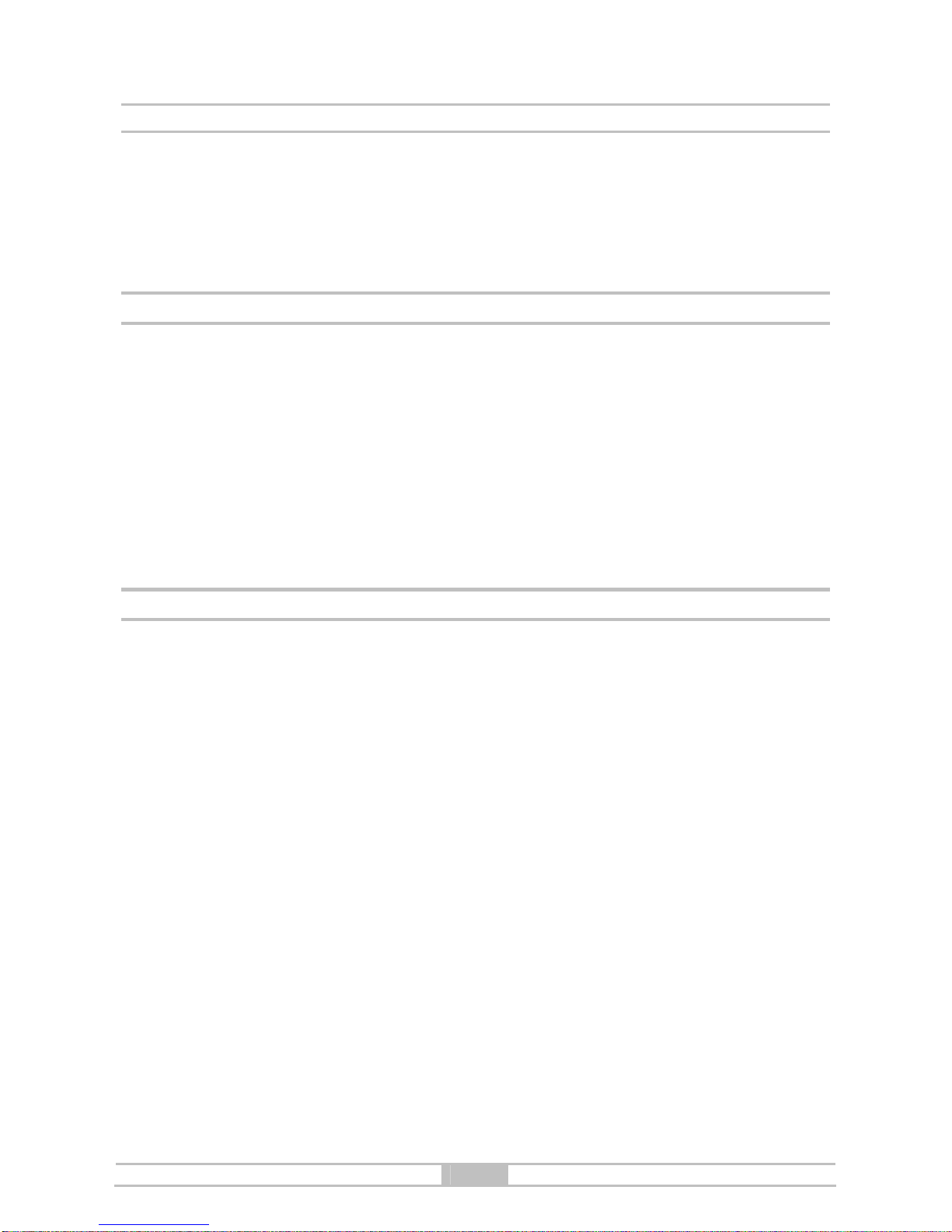

1.6 TECHNICAL DATA PM1IE..

PM1IE200..A PM1IE300..A PM1IE500..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A mm 1000 1150 1150

Equipment dim.B mm 1150 1300 1300

Equipment dim.H mm 900 900 1050

Equipment dim.H2 mm 1820 1970 2120

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter mm 750 900 900

Pan dimension H mm 520 520 780

Overvall volume lt 220 325 480

Useful volume lt 200 300 455

Pressure cooking (mod.A) bar 0,05

Temperature °C 20÷110

Jacket volume lt 43 62 62

Pressure bar 0,5

TECHNICAL DATA (INSTALLATION)

Electric power kW 32 36 36

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency Hz 50/60

IPX IPX 4

Cable connection *** mm² 5 X 10 5 X 16 5 X 16

Water pressure kPa 50÷300

Hot water inlet Ø" 1/2"

Cold water inlet Ø" 1/2"

Sound level dbA < 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A mm 1360 1500 1500

Packaging dim.B mm 1100 1250 1250

Packaging dim.H mm 1280 1280 1450

Volume m³ 1,92 2,4 2,72

Net weight kg 235 280 300

Gross weight kg 281 330 360

**Verify on data plate - ***Cable for standard tension

Page 7

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

7

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

1.7 TECHNICAL DATA PMRIE

PMRIE 100..A 150..A 200..A 300..A 500..A 510..A

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A mm 1025 1025 1175 1305 1305 1555

Equipment dim.B mm 850 850 1000 1130 1130 1380

Equipment dim.H mm 900 900 900 900 1050 920

Equipment dim.H2 mm 1650 1650 1820 1970 2120 2230

TECHNICAL DATA (FUNCTIONALITY)

Kettle diameter mm 600

600

750

900

900 1100

Pan dimension H mm 415

540

520

520

780

570

Overvall volume lt 113

150

220

325

480

540

Useful volume lt 102

139

200

300

455

500

Pressure cooking (mod.A) bar 0,05

Temperature °C 20÷110

Jacket volume lt 32 32 43 62 62 95

Pressure bar 0,5

TECHNICAL DATA (INSTALLATION)

Electric power kW 16

18

32

36

36

36

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency Hz 50/60

IPX IPX 4

Cable connection *** mm² 5 X 6 5 X 6 5 X 10 5 X 16 5 X 16 5 X 16

Water pressure kPa 50÷300

Hot water inlet Ø" 1/2"

Cold water inlet Ø" 1/2"

Sound level dbA < 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A mm 1360 1360 1500 1500 1500 1690

Packaging dim.B mm 1100 1100 1250 1400 1400 1540

Packaging dim.H mm 1280 1280 1280 1280 1450 1320

Volume m³ 1,92 1,92 2,4 2,7 3,05 3,44

Net weight kg 140 150 207 250 270 355

Gross weight kg 186 196 257 310 340 450

**Verify on data plate - ***Cable for standard tension

Page 8

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

8

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

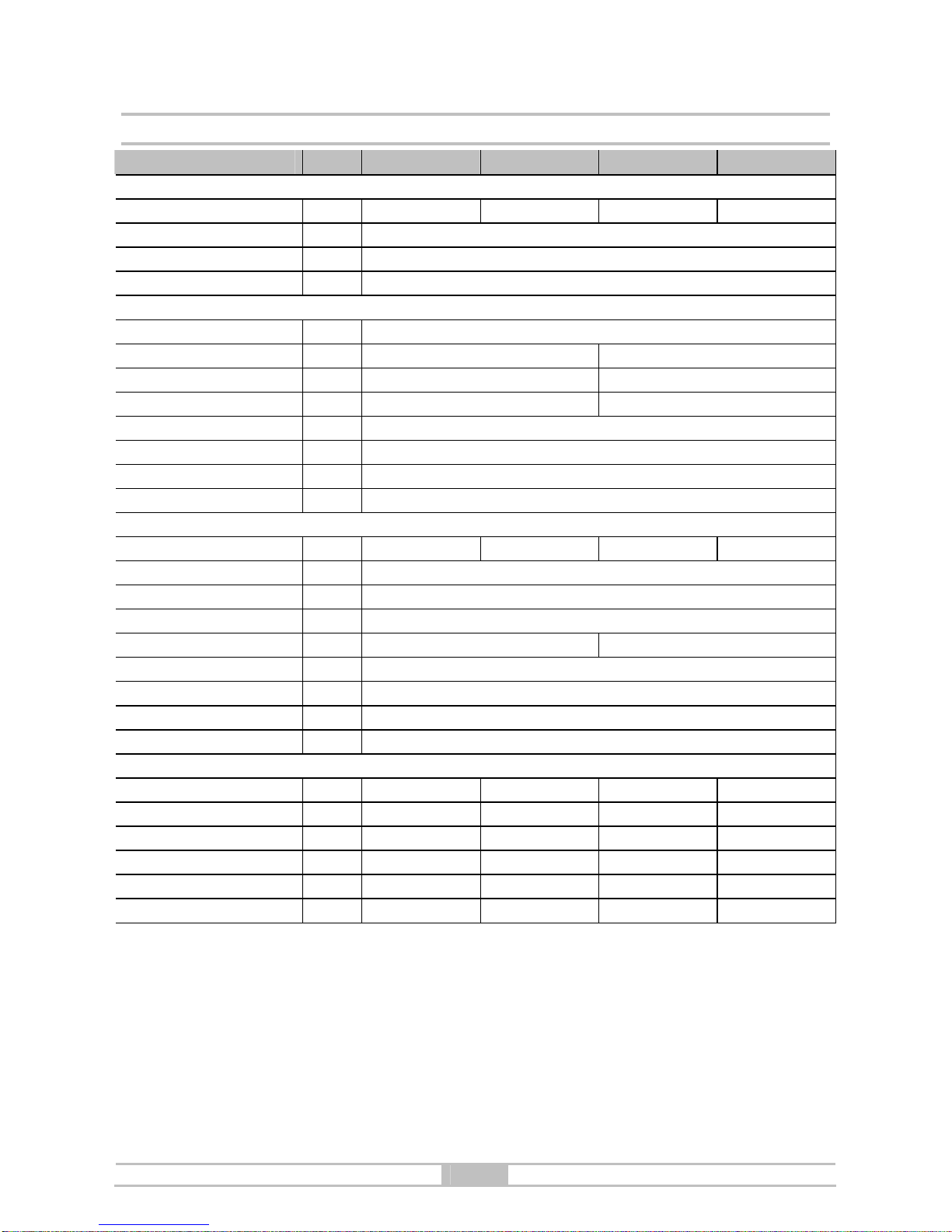

1.8 TECHNICAL DATA PM9IE..GN

PM9IE170GN PM9IE270GN PM9IE370GN

TECHNICAL DATA (DIMEMSIONS)

Equipment dim.A mm 1000 1400 1800

Equipment dim.B mm 900

Equipment dim.H mm 900

Equipment dim.H2 mm 1790

TECHNICAL DATA (FUNCTIONALITY)

Pan dimension A mm 700 1100 1500

Pan dimension B mm 550

Pan dimension H mm 480

Overvall volume lt 185 290 396

Useful volume lt 170 270 370

Temperature °C 20÷110

Jacket volume lt 44 68 90

Pressure bar 0,5

TECHNICAL DATA (INSTALLATION)

Electric power kW 24 32 36

Voltage/Input (standard)** V 3N/PE AC 400V

Frequency Hz 50/60

IPX IPX 4

Cable connection *** mm² 5 X 10 5 X 16 5 X 16

Water pressure kPa 50÷300

Hot water inlet Ø" 1/2"

Cold water inlet Ø" 1/2"

Sound level dbA < 70

TECHNICAL DATA (STORAGE/MOVEMENT)

Packaging dim.A mm 1140 1540 2140

Packaging dim.B mm 1140 1140 1140

Packaging dim.H mm 1250 1250 1250

Volume m³ 1,63 2,2 3,1

Net weight kg 240 290 330

Gross weight kg 280 340 390

**Verify on data plate - ***Cable for standard tension

Page 9

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

9

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

2 POSITIONING, INSTALLATION AND MAINTENANCE

2.1 POSITIONING

− Remove all the packaging and check that the appliance is in perfect conditions. In case of visible damage,

do not connect the appliance and notify the sales point immediately.

− Remove the PVC protection from the panels.

− Dispose of packaging according to regulations. Generally material is divided according to composition and

should be delivered to the waste disposal service.

− There are no special instructions regarding distances from other appliances or walls, however it is

advisable to maintain a sufficient distance to allow any servicing operations to be performed. In the event

the appliance should be installed in direct contact with inflammable walls, it is advisable to fit suitable heat

insulation.

− The appliance must stand level. Small differences in level can be eliminated by screwing or unscrewing

the adjustable feet: A significantly uneven or sloping stance can affect the operation of the appliance

adversely.

2.2 INSTALLATION

Warning! : Only qualified technicians must perform the installation, maintenance and test of the

appliance.

Warning! : Before connecting any parts of the appliance to supplies, make sure that the latter is

equivalent the requirements stated in the technical data plate, if the appliance has been designed for

these supplies.

2.2.1 ELECTRICAL CONNECTIONS AND EQUIPOTENTIAL BONDING

Warning! : The appliance is supplied to operate according to the power supply indicated on the

data plate.

− As mentioned, the appliance must be connected to the power supply by way of a multiple pole main

isolating switch and protection device that must be proportioned to the power of the appliance (1 mA per

kW of rated power).

− The earthing system must be efficient.

− As this appliance is type X equipment (delivery without power cable and plug), the cable and other

hardware needed to make the connection to the electrical power supply must be provided by the installer.

− The power cable shall be of the kind described in the paragraph “Technical data" and shall be resistant to

oil.

− The power terminal board can be reached by removing the lower front panel (unloose the screws). The

cable fastener is on the lower right-hand side.

− The cable must be fed in from beneath the clamp. The individual wires are then fastened to the

corresponding terminals of the terminal board. The earth wire must be longer than the other wires, so that

in the event of the cable being jerked or the clamp broken, the live wires will disconnect first. Lock the cord

fastener.

− The appliance must incorporate an equipotential system.

Page 10

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

10

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

− Connect the terminal on the lower right-hand side marked with the international symbol a connector with a

nominal cross section <10 mm2. All the appliances installed and the earth system of the building shall be

connected like this.

2.2.2 CONNECTION TO WATERWORKS

Water inlet pressure must be between 50 and 300 kPa, otherwise install a pressure regulator on the line

before the appliance.

Install a cut-off valve for each supply on the line before the appliance.

Water connections are fitted in the lower part on the right-hand side of the appliance.

Make connections according to regulations currently in force.

2.3 COMMISSIONING AND TESTING

− Once all the connections have been made, the appliance and the overall installation must be checked

following the directions given in this manual.

− Check in particular:

− that the protective film has been removed from the external surfaces;

− that the lower front panel removed for the electrical connection of the appliance has been fitted back into

position;

− that connections have been made in accordance with the requirements and directions indicated in this

manual;

− that all safety requirements in current standards, statutory regulations and directives have been met;

− that the water connections are leak-free;

− that the electrical connection has been performed according to standards.

− In addition, check that once the appliance has been installed, the power cord is neither subject to stretch

nor in contact with nor surfaces.

− Now proceed to light the appliance as directed in the instructions for use.

− While the appliance is in use, voltage should not differ from the nominal voltage more than +/- 10%.

− The test report must be completed in full and submitted to the customer who should then sign in

acceptance. With effect from this moment, the appliance is covered by the manufacturer’s warranty.

2.4 MAINTENANCE OF THE APPLIANCE

Warning! : All maintenance operations shall only be performed by a technically qualified service

centre!

− To ensure correct and safe operation, the appliance must be inspected and serviced at least once a year

only. Maintenance includes also controlling the components and tear of pipes, feeding pipes, electrical

components etc.

− It is advisable to replace worn components during maintenance operations to avoid the need for other

maintenance calls and unexpected failures.

− It is also advisable to apply for a maintenance contract with the customer.

Page 11

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

11

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

2.4.1 POSSIBLE FAILURES AND THEIR ELIMINATION

Warning! : Only technically qualified service centres can perform the operations described below!

Warning! : Before resetting the safety thermostat, it is always necessary to eliminate the problem

causing its activation!

Problem and possible cause Access to components and operation

− The content of the vat does not heat

up:

− the safety thermostat has been

activated;

− the heating elements have a failure;

− selector/switch failure.

− Operating thermostat failure.

− Safety thermostat

The safety thermostat can be reached once the lower front

panel has been removed.

Heating elements

The heating elements can be reached once the lower front

panel has been removed.

Selector/switch - Operatingthermostat

To reach remove the vat drainage tap and then the upper front

panel.

Page 12

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

12

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

3 USE AND CLEANING

3.1 WARNINGS AND HINTS FOR USER

− This manual contains all the instructions required for a proper and safe use of our appliances.

− Keep the manual in a safe place for future consultation!

− This appliance is for catering use, hence they must be used only by trained kitchen staff.

− The appliance must always be kept under control during use.

− Warning! : The manufacturer shall not be held responsible for injuries or damage due to the non-

compliance with safety rules or an improper use of the appliance by the operator.

− Some improper operating conditions may even be caused by an improper use of the appliance, therefore it

is important to train personnel properly.

− All the installation and maintenance operations must be performed by fitters who are members of

an official register.

− Respect the periods required for maintenance. With this is mind, customers are recommended to sign a

service agreement.

− In case of failures concerning the appliance, all outputs (electrical power supply and water) must be cut off

instantly.

− In case of recurrent failures, contact a service technician.

3.2 INSTRUCTIONS FOR USE

− Before cooking with the appliance for the first time, wash the interior of the cooking vat

thoroughly.

Warning! : Fill the cooking vat up to a maximum of 40 mm under the overflow border, according to

the maximum level mark, including the food to be cooked.

Warning! : Before filling the vat, always check that the drainage tap is closed.

3.2.1 FILLING THE JACKET

MOD. 100-150 lt

Warning! : The water level in the jacket must be checked each time before lighting.

Warning! : It is advisable to use softened water to fill the jacket!

− Open the level tap on the front of the appliance.

− Unscrew the filling cap on the safety valve unit. The latter is on the right of the appliance surface (see

figure “Size of appliance and position of connections ”).

− Fill with softened water (the capacity of the jacket is stated in the paragraph “Technical data”).

− When water flows out of the level tap, close it and screw back on the safety unit cap.

Mod. PM1IE200/300/500 – PMRIE100/150/200/300/500/510 – PM9IE170/270/370GN

Warning! : The water level in the jacket must be checked each time before lighting.

Warning! : It is advisable to use softened water to fill the jacket!

− Open the level tap on the front of the appliance.

Page 13

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

13

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

− Unscrew the filling cap on the safety valve unit. The latter is on the right of

the appliance surface (see figure “Size of appliance and position of

connections ”).

−

− Reposition the tap (an external hole is available) on the external pin of the

relief valve.

− This operation is required to prevent water bubbles from forming in the

jacket during water loading. Water bubbles would not make it possible to

reach a correct water level in the jacket.

− Fill with softened water (the capacity of the jacket is stated in the paragraph “Technical data”).

− When water flows out of the level tap, close it and screw back on the safety unit cap.

3.2.2 DETAILS REGARDING OPERATION WITH PRESSURE KETTLE

− Before turning the appliance on, close the lid firmly and lock the 4 screw clamps.

− Check that the valve is in a resting position.

− Start cooking at full power. When steam starts to come out of the valve, reduce heating power. The steam

coming out of the valve must be constant and light.

− The pressure inside the cooking vat can reach a maximum of 0.05 bar. On request, the appliance can be

equipped with a pressure gauge that shows the pressure inside the cooking vat.

− Turn off the appliance after cooking.

− Before opening the lid, release all the pressure from the cooking vat by lifting the relief valve lever (see

figure “Controls”).

− Check that the valve lever is still "On" and unscrew the screw clamps.

3.2.3 SWITCHING ON, START COOKING AND SWITCHING OFF

− Fill the vat with hot or cold water, according to need, using the tap that the appliance is equipped with.

− The appliance has a three-position selector to start cooking functions (see figure “Controls").

− Here is a list of the procedures for a safe and correct use of the appliance.

− Energising the unit:

− Connect the appliance by turning on the main switch installed before it.

− Start of cooking:

− Turn the selector from position “0” to one of the heating positions according to cooking requirements.

− The green light turns on automatically.

− Generally cooking is started with the selector in position “2”; once the vat has reached cooking

temperature, turn the selector to “1” to maintain it.

− Set the operating thermostat knob on the desired temperature between 40 and 100°C.

− Heating will start and the orange light will turn on automatically.

− The orange light will turn off as soon as the set temperature has been reached.

− To make water boil quickly, turn the knob over the temperaure of 100°C.

− Heating elements operate continuously.

− By turning the selector from position “2” to “1”, it is possible to keep the water boiling and use less power.

Page 14

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

14

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

3.3 CLEANING AND CARE OF THE APPLIANCE

− Do not use aggressive substances or abrasive detergents when cleaning the stainless steel components.

− Avoid using metal pads of the steel parts as they may cause rust. For the same reason, avoid contact with

materials containing iron.

− Do not use sandpaper or abrasive paper for cleaning; in special cases use a powder pumice stone.

− In case of particularly resistant dirt, it is advisable to use abrasive sponges (e.g. Scotch-Brite).

− It is advisable to clean the appliance only once it has cooled down.

3.3.1 DAILY CLEANING

Warning! : When cleaning the appliance never use direct jets of water to prevent infiltration of the

liquid and damage to components.

− Clean the cooking vat with water and a detergent, rinse thoroughly and dry well with a soft cloth.

− External surfaces should be washed down using a sponge, and hot water with a suitable proprietary

cleaner addend.

− Rinse always thoroughly and dry with a soft cloth.

− Notes regarding the pressure kettles:

− Do not use detergents containing high percentages of ammonia and sodium to clean the lid gasket, as it

could be damaged and its tightness quickly affected.

3.4 SPECIAL PROCEDURES IN CASE OF PROLONGED

INACTIVITY

− If the appliance is to stand idle for any length of time (e.g. holidays or seasonal closing), it must be

cleaned thoroughly, leaving not traces of food or dirt.

− Leave the lid open so that air can circulate inside the vat.

− For added care after cleaning, the external surfaces can be protected by applying a proprietary metal

polish.

− Be absolutely sure to shut off all utilities (electrical power supply and water).

− Air the room appropriately.

3.5 SPECIAL PROCEDURES IN CASE OF FAILURES

− If the appliance should not work properly during use, turn it off immediately and close or cut off all supplies

(electrical power supply and water).

− Apply to a service centre for help.

The manufacturer shall not be held responsible nor has any warranty commitments for damage

caused by non-compliance with prescriptions or by installation not in conformity with instructions.

The same applies in case of improper use or different application by the operator.

Page 15

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

15

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

3.6 HOW TO PROCEED, IF …

WARNING! :

Problems and failures may occur even when the appliance is used properly. Here is a list of the mist

probably situations and controls that the operator should perform to avoid applying to a service centre

unnecessarily.

If the problem is not solved after the necessary controls, turn off the appliance immediately, unplug it,

cut off any supplies and apply to a service centre.

− … the vat contents do not

heat up:

− check that the power ON/OFF switch installed before the appliance

is on;

− otherwise turn off the appliance and apply to a service centre, as

the safety thermostat may have been activated due to an excess of

temperature in the cooking vat. This occurs especially when the

appliance is turned on and the vat and/or the jacket is/are empty

Page 16

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

16

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4 FIGURES AND DETAILS

4.1 WIRING DIAGRAM OF CONTROL FUNCTIONS PM.IE .

LEGEND:

F1 Fuse 3,15 A-T S1 Jacket filling solenoid valve (OPTIONAL)

SE Selector TS Safety thermostat

L1 Green warning light TL Operating thermostat

L2 Heating on signal-lamp C1 Electromagnetic switch min.

LR Orange lamp warning light failing water in the jacket C2 Electromagnetic switch max

LA Red lamp warning light in the jacket C3 Electromagnetic switch security

SL Level control device

Page 17

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

17

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.2 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3N/PE AC

400V

LEGEND:

mA End line terminal board C3 Electromagnetic switch security

C1 Electromagnetic switch min. R1 Heating element (230V)

C2 Electromagnetic switch max B Sensor for safety thermostat

Page 18

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

18

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.3 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC

230V

LEGEND:

mA End line terminal board C3 Electromagnetic switch security

C1 Electromagnetic switch min. R1 Heating element (230V)

C2 Electromagnetic switch max B Sensor for safety thermostat

Page 19

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

19

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.4 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC

440V

LEGEND:

mA End line terminal board TR Transformer 440-480/230V

C1 Electromagnetic switch min. R1. Heating element (254V)

C2 Electromagnetic switch max B Sensor for safety thermostat

C3 Electromagnetic switch security

Page 20

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

20

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.5 WIRING DIAGRAM ( HEATING ELEMENTS PM.IE ) 3/PE AC

480V

LEGEND:

mA End line terminal board TR Transformer 440-480/230V

C1 Electromagnetic switch min. R1.. Heating element (277V)

C2 Electromagnetic switch max B Sensor for safety thermostat

C3 Electromagnetic switch security

Page 21

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

21

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

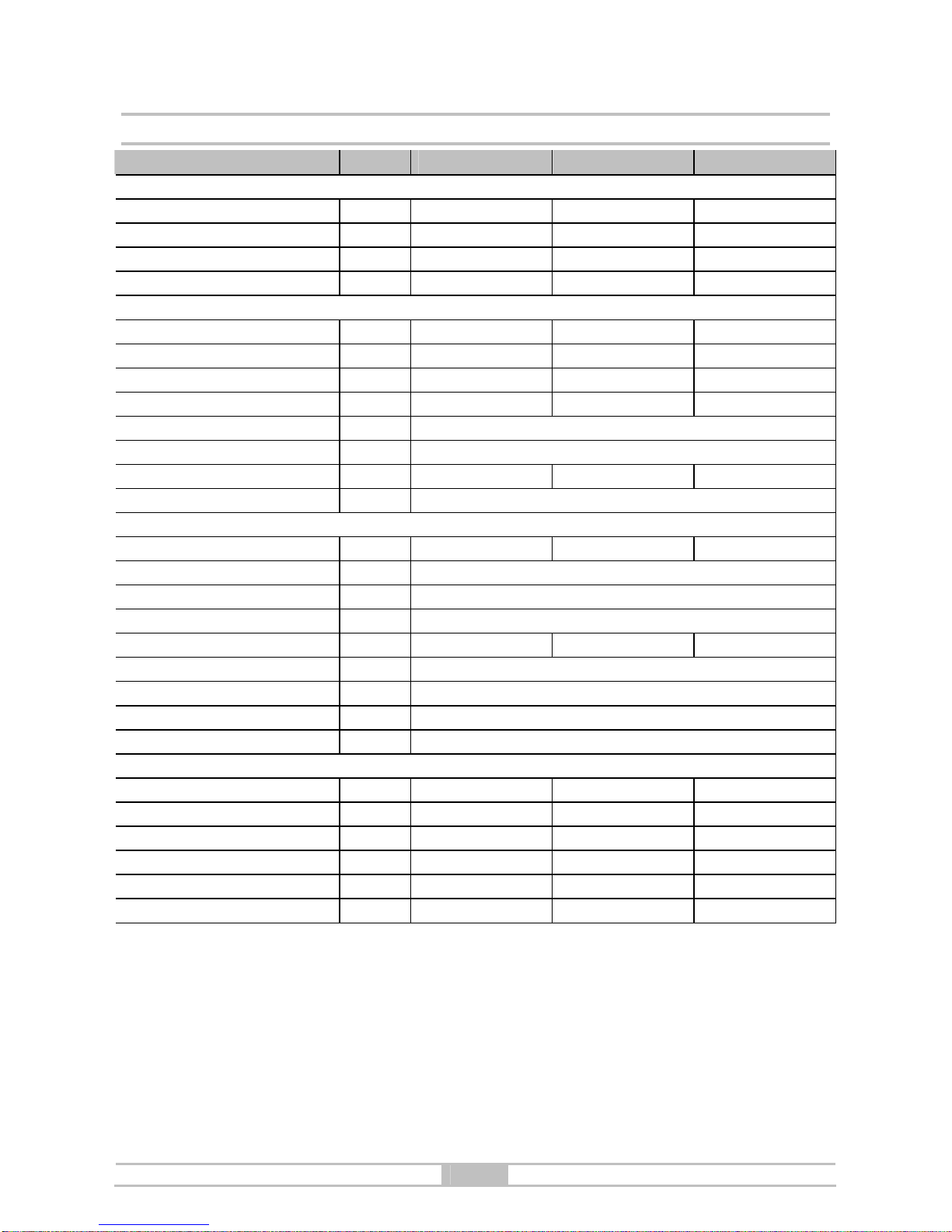

4.6 LAYOUT CONNECTIONS PMIE

LEGEND:

E Electrical connection 1 Cooking vat drainage tap

Q Equipotential clamp 2 Vat water feed tap

A Hot water connection 3 Jacket level tap

B Cold water connection OPTIONAL

C Autom,jacket water-charge

Page 22

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

22

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.7 LAYOUT CONNECTIONS PMRIE

LEGEND:

E Electrical connection 1 Cooking vat drainage tap

Q Equipotential clamp 2 Vat water feed tap

A Hot water connection 3 Jacket level tap

B Cold water connection OPTIONAL

C Autom,jacket water-charge

Page 23

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

23

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.8 LAYOUT CONNECTIONS PM9IEGN

LEGEND:

E Electrical connection 1 Cooking vat drainage tap

Q Equipotential clamp 2 Vat water feed tap

A Hot water connection 3 Jacket level tap

B Cold water connection OPTIONAL

C Autom,jacket water-charge

Page 24

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

24

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

4.9 FIG. CONTROLS

LEGEND:

1 Selector 4 Operating thermostat

2 Green warning light 5 Orange lamp warning light failing water in the jacket

3 Heating on signal-lamp 6 Red lamp warning light in the jacket

SELECTOR

Position “0” = Off Position “1” = 50 % power Position “2” = 50 % power

Page 25

INSTRUCTION MANUAL FOR INSTALLATION, MAINTENANCE AND USE Rev-09

PM.IE 8-9-1-R-GN-DU-GB-09

25

ELECTRIC KETTLES INDIRECT

“PM8-9IE..A” “PM1IE..A” “PMRIE..A” “PM9IE..GN”

OPERATING THERMOSTAT

ONLY FOR PRESSURE KETTLES

Valve and position of relief valve

Open valve Closed valve

Loading...

Loading...