Bartscher 2006301, 2006601 User Manual [ru]

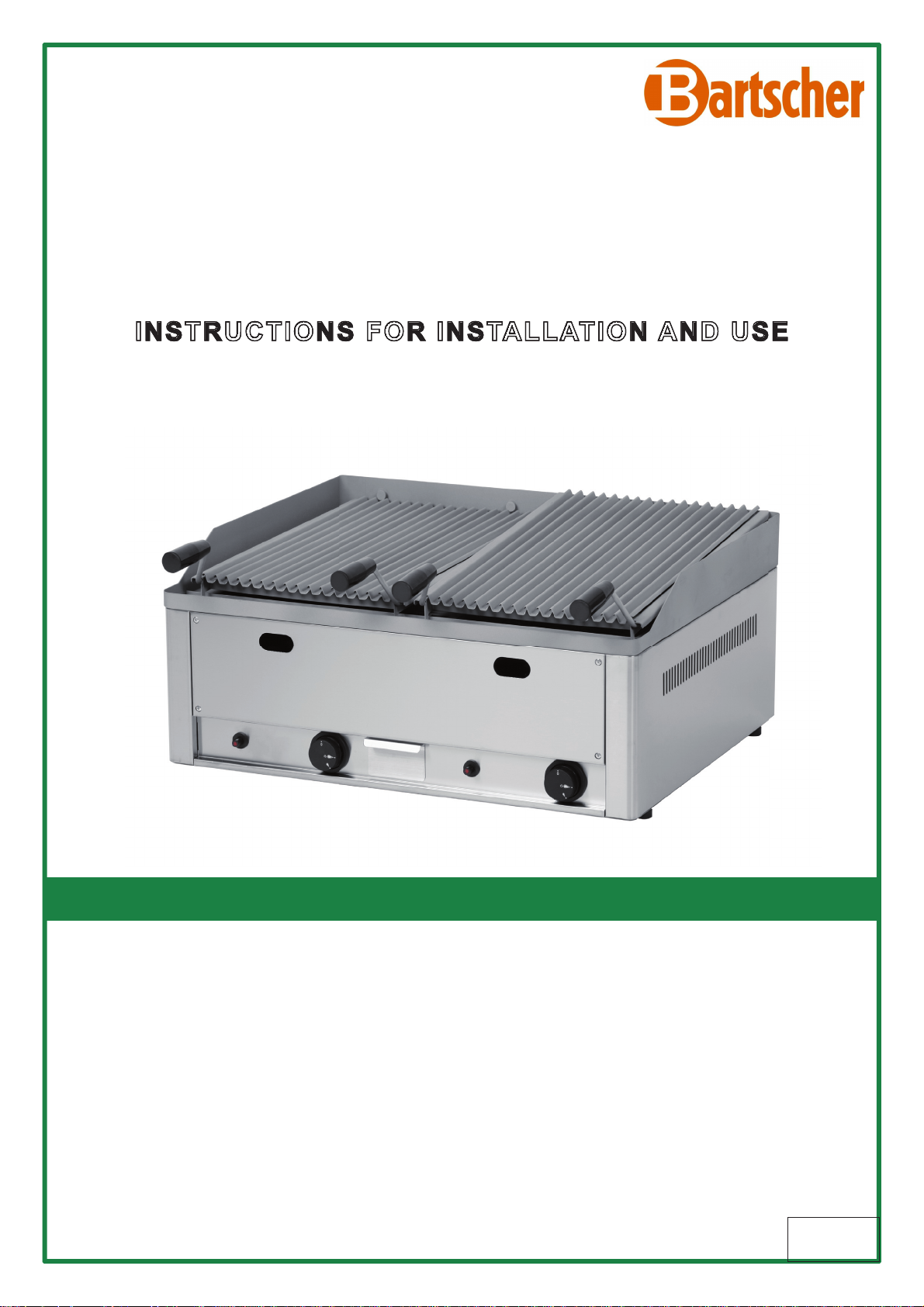

GAS LAVA STONE GRILLS

GGL - 30 G / GL - 60

2006301 / 2006601

Date:

08 / 2007

3

g

y

fi

.

ON

.

)

e

ff

g

C

j

fety

)

g

:

RMITYONFCO STANDARDSF A ON OLARATICDE

The producer confi rms that the devices agree with CEE 90/396 standards, rule nr. 22/1997 sb. and with relevant

overment orders. Instalation must be done with respect to valid standards. Attention, the producer refuses

an

responsibility in case of direct or indirect damages which are caused due to wrong instalation, incorrect

intervention or modi

resented by items in sale conditions. This appliance is set only for skilled use and must be operated by qualifi ed

ersons only. Parts set and secured by the producer or accredited person must not be rebuilt by user

cation, insuffi cient maintenance, incorrect use and also possibly caused by other reasons

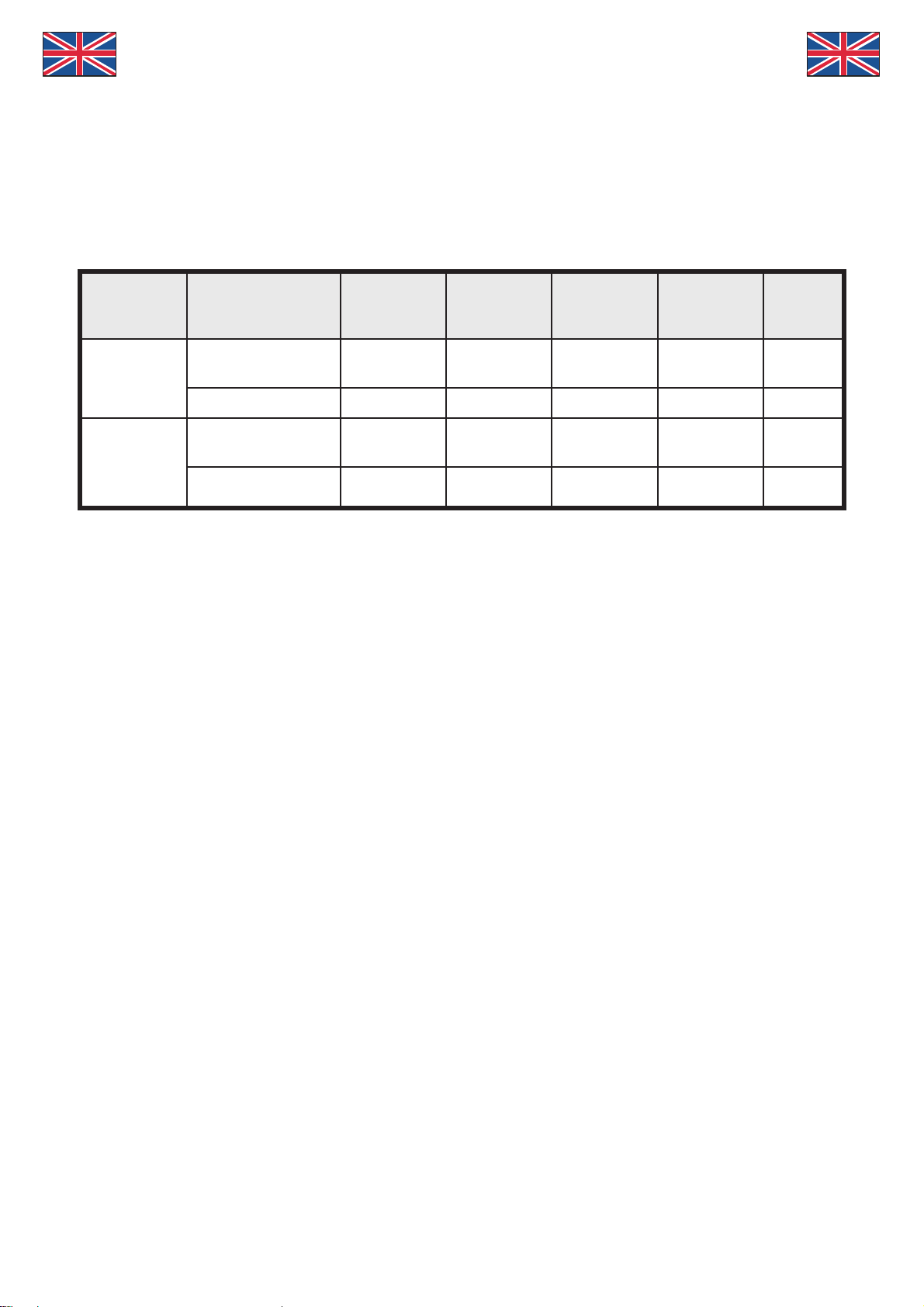

MODEL

BURNER

GL - 30 G

4,0 kW

GL - 60 G

2x 4,0 kW

12,8 kWh/kg

NOZZLE

NOZZLE OF BURNER

1/100 MM

CONSUPTION 0,546 kg/h 0,546 kg/h 0,5460 kg/h 0,74 m

NOZZLE OF BURNER

1/100 MM

CONSUPTION 1,092 kg/h 1,092 kg/h 1,092 kg/h 1,48 m

G 30/G 31

PROPAN / BUTAN

28 - 30 mbar

93 93 77 135 G 1/2“

2x 93 2x 93 2x 77 2x 135 G 1/2“

12,8 kWh/kg

G 31

PROPAN

37 mbar

12,8 kWh/kg

G 30/G 31

PROPAN / BUTAN

50 mbar

9,45 kWh/m3

G 20

NATURAL GAS

20 mbar

3

/h ---

3

/h ----

FEEDING

TUBE

GAS

EVICE INSTALATI

Instalation, setting, rebuilding for another gas type, putting into operation must be done by qualifi ed person who

is competent for this and according to the valid standards. The device can be instalated in good ventilated room

When it is possible place the device under the fumehood to suck off the products of combustion. Air needy to the

burning is 2m/3/h/kW ot the performance of the instaled device.

The device can be instalated separately or in a set with devices of our production. Min. distance 10 cm from other

subjects must be kept.It is also necessary to prevent our product from contact with combustible materials. In this

ase you must make corresponding changes to secure heat izolation of combustible parts (for example:place

between the device and combustible material azbestos plate

.

L. 12-2:Č008106N SČ TO

only adults can operate the devic

device must be safely used in common surroundings according to ČSN 332000-3. You must switch the gas

device o

or durin

stick linoleum, PV

before you start to instal the device you must get the licence for connection to the gas feeder from the

asworks

device must be placed so as to stand or hang on the noncombustible surface which is on each side 10 cm larger

than the device. No sub

is shorter than sa

in other directions

about the de

under the circumstances leading: to the danger of the temporary rise of the combustion gas or steam

works when there is a big possibilityof rise ot the temporary fi re danger or explosion (for example: to

etc.).

ects from combustible materials can be placed directly on the device or in distance which

distance (the shortestdistance is 50 cm in the direction of the heat emission and 10 cm

.- safety distances from various materials of different degree of combustion and information

ree of comb. of common building materials - see chart

GRDINCCON AOTICTEOF THE FIRE PROINT OTANDPSM THE O FRSRESUAFETY MEAS

hart

)

g

ily

ibl

kli

lih

e

C

g

ding

:

t

ds

n

y

h

h

ics

.

y

.

r

)

ue

e

ombustion degree of building materials classifi ed according to the combustion degree of materials and products

ČSN 730823

A noncombustible

uneas

1 hardly combustible leafy wood, plywood, sirkoklit, rare paper formica

2 middle combustible fi breboards, solodure, cork boards, rubber,fl oor-coverings

3 easily combustible wood-fi breboards, polystyrene,polyurethane,PV

evices must be instalated in a safe way and must be equipped by the regulation feet for compensation of

the hi

accor

ČSN 061008 fi re protection of local devices and sources of hea

ČSN 332000-3 surroundings for electric devices

ČSN EN 1775 Gas supplying - Gas fi ttings in the buildings - the highest operational pressure < 5 bar - operation

man

§ 10 law nr. 185/2001 Sb. about waste

combust

h and imbalances. When instaling you must respect corresponding project, safety and hygienic orders

to

e akumine, hera

ranit, sandstone, concretes,bricks, ceramic wallfacing tiles, plaster

te,

nos, itaver

Pipe for gas connectio

Gas must be connected by the pipe from zinc steel, copper or fl exible steel hose and that must be in confi rmit

with valid standards. Every device must have closable feeding tap. It enables you to stop the gas feeder easily.

aving instaled the device you must check all gas leaks.Never check the leaks by open fi re. You must use

aterials that do not cause corrosion. Use for example soap water. The devices were properly checked at

t

e producer. The data about gas type, pressure and the type ot the device are indicated on the label wit

racterist

.

Check the gas type the device is adjusted for

heck whether the device is set for the gas type you use. The gas type is indicated on the label of each device

Process of rebuilding the device for another gas type

The device is set and checked for liquefi ed gas (see the label). Rebuilding for another gas type must be done b

ualifi ed person. Nozzles are included in the packet with instructions for use.

xchange of the main burner´s nozzle: picture D

crew up and remove the bottom cover (21), screw up the nozzle (23a) and screw in the new one for required

as type - see technical chart. You need not to regulate air feeder.

mportant:

After having rebuilt the gas type, change the data on the label

ow to check the operation of the device:

check the gas leaks

check the ignition and fl ame of the main burne

check the ignition and fl ame of the main burner for min. performance (sporo

check whether the fl ame of the burner licks the thermoelement and whether it is bl

we recommend to the user when using the device to proceed according to the instructions for us

Loading...

Loading...